Magnetoelectric Force Microscopy on Antiferromagnetic 180∘ Domains in Cr2O3

Abstract

:1. Introduction

Antiferromagnetic CrO and the Linear Magnetoelectric Effect

2. Research Method and Materials

2.1. CrO Samples

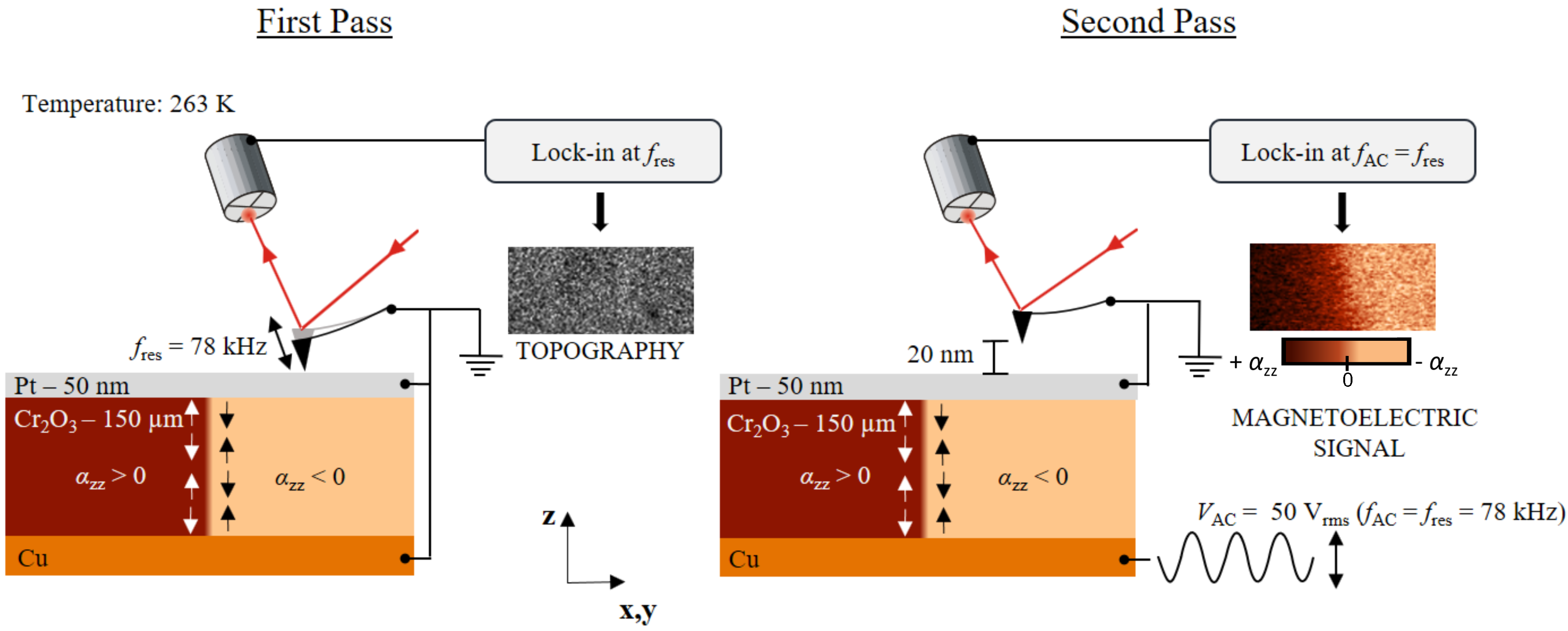

2.2. Magnetoelectric Force Microscopy

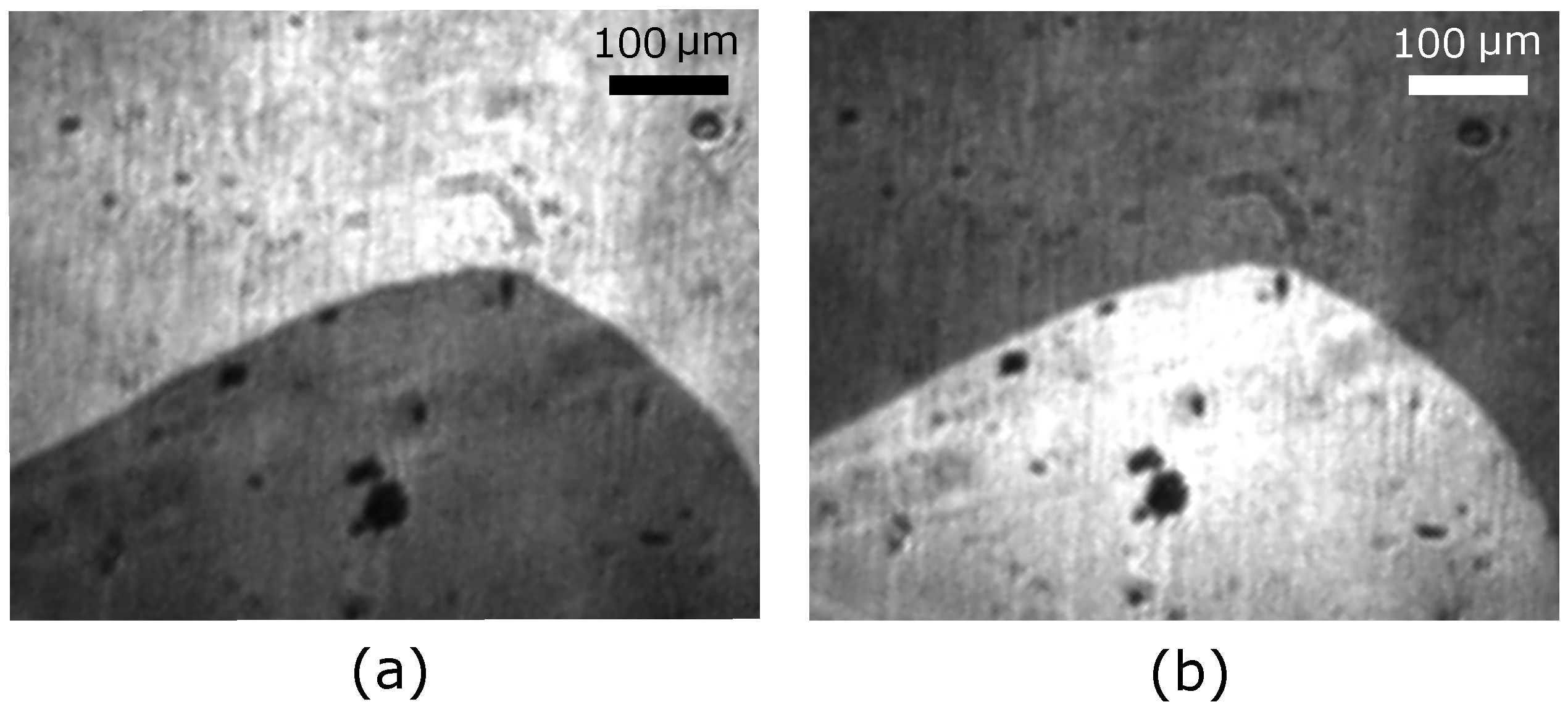

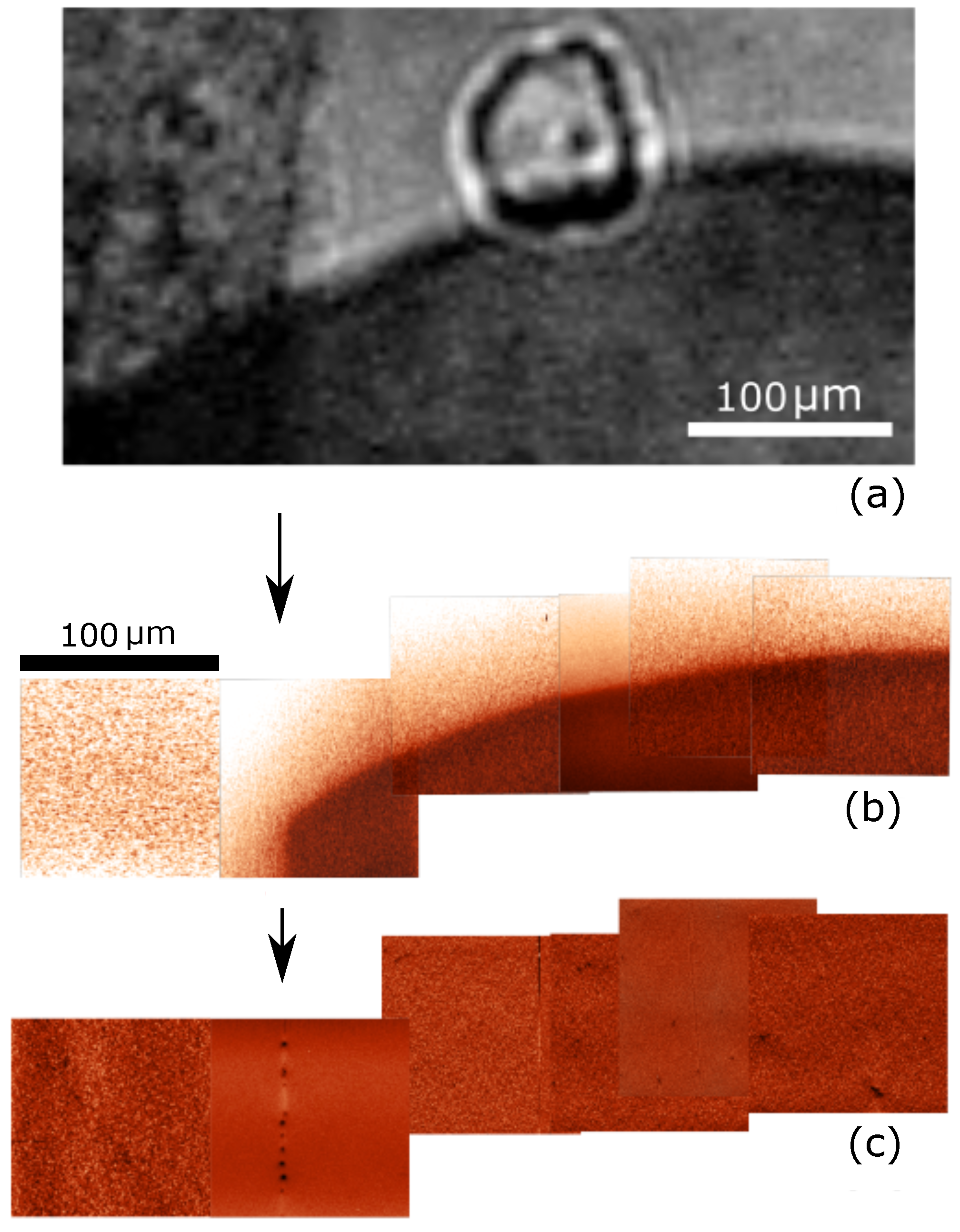

2.3. Second Harmonic Generation

3. Results and Discussion

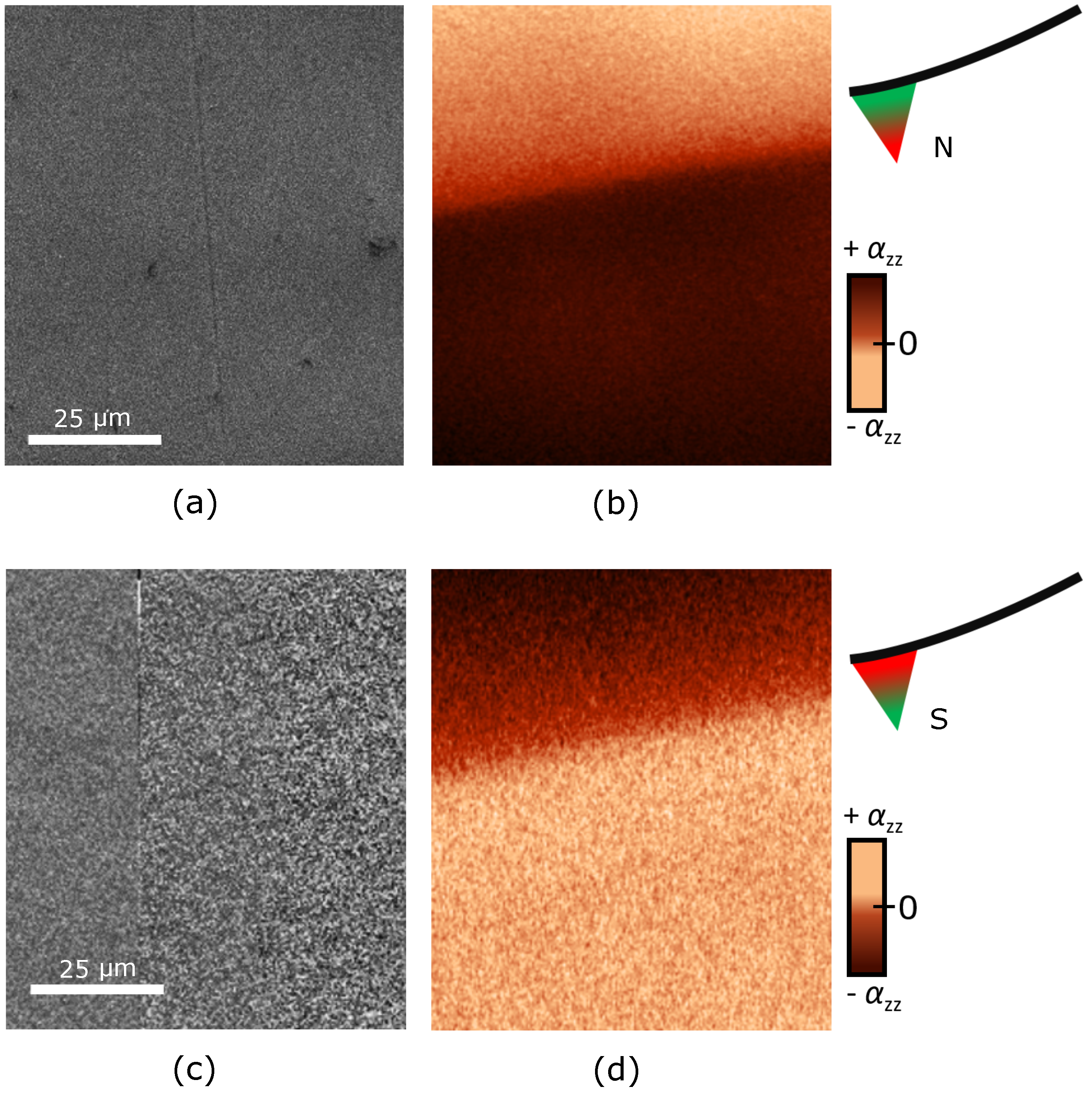

3.1. Detection of Antiferromagnetic 180 Domains

3.2. Verification of the Magnetoelectric Detection

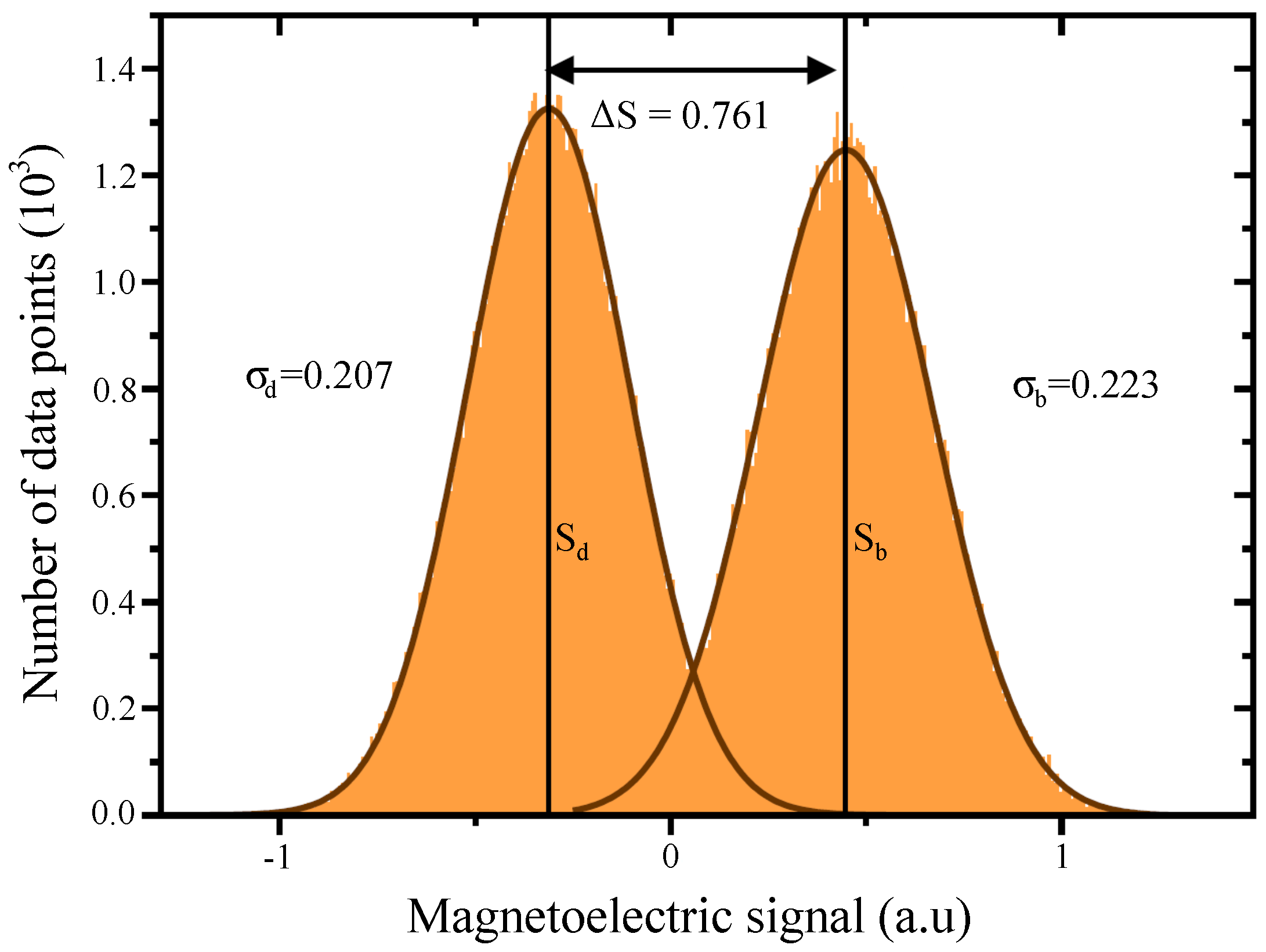

3.3. Sensitivity

3.4. Possible Improvements

3.5. Superior Aspects of Magnetoelectric Force Microscopy

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Deshpande, A.; Bao, W.; Zhao, Z.; Lau, C.N.; LeRoy, B.J. Mapping the Dirac point in gated bilayer graphene. Appl. Phys. Lett. 2009, 95, 243502. [Google Scholar] [CrossRef]

- Guillaume, S.-O.; Zheng, B.; Charlier, J.-C.; Henrard, L. Electronic properties and STM images of doped bilayer graphene. Phys. Rev. B 2012, 85, 035444. [Google Scholar] [CrossRef]

- Norregaard, K.; Metzler, R.; Ritter, C.M.; Berg-Sørensen, K.; Oddershede, L.B. Manipulation and motion of organelles and single molecules in living cells. Chem. Rev. 2017, 117, 4342–4375. [Google Scholar] [CrossRef] [PubMed]

- Müller, D.J.; Helenius, J.; Alsteens, D.; Dufrene, Y.F. Force probing surfaces of living cells to molecular resolution. Nat. Chem. Biol. 2009, 5, 383–390. [Google Scholar] [CrossRef] [PubMed]

- Hirt, L.; Ihle, S.; Pan, Z.; Dorwling-Carter, L.; Reiser, A.; Wheeler, J.M.; Spolenak, R.; Vörös, J.; Zambelli, T. Template-Free 3D microprinting of metals using a force-controlled nanopipette for layer-by-layer electrodeposition. Adv. Mater. 2016, 28, 2311–2315. [Google Scholar] [CrossRef] [PubMed]

- Kalinin, S.; Gruverman, A. Scanning Probe Microscopy: Electrical and Electromechanical Phenomena at the Nanoscale; Springer: New York, NY, USA, 2007. [Google Scholar]

- Owens, F.J. Physics of Magnetic Nanostructures; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Kholkin, A.L.; Kalinin, S.V.; Roelofs, A.; Gruverman, A. Review of ferroelectric domain imaging by Piezoresponse force microscopy. In Scanning Probe Microscopy: Electrical and Electromechanical Phenomena at the Nanoscale; Kalinin, S., Gruverman, A., Eds.; Springer: New York, NY, USA, 2007; Volume 1, pp. 173–214. [Google Scholar]

- Trassin, M. Low energy consumption spintronics using multiferroic heterostructures. J. Phys. Condens. Matter 2016, 28, 033001. [Google Scholar] [CrossRef] [PubMed]

- Seidel, J.; Martin, L.W.; He, Q.; Zhan, Q.; Chu, Y.-H.; Rother, A.; Hawkridge, M.E.; Maksymovych, P.; Yu, P.; Gajek, M.; et al. Conduction at domain walls in oxide multiferroics. Nat. Mater. 2009, 8, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Meier, D. Functional domain walls in multiferroics. J. Phys. Condens. Matter 2015, 27, 463003. [Google Scholar] [CrossRef] [PubMed]

- Bhalla, A.S.; Raina, G.; Sharma, S.K. Ferroelastic domain study by atomic force microscope (AFM). Mater. Lett. 1998, 35, 28–32. [Google Scholar] [CrossRef]

- Spaldin, N.A.; Fiebig, M.; Mostovoy, M. The toroidal moment in condensed-matter physics and its relation to the magnetoelectric effect. J. Phys. Condens. Matter 2008, 20, 434203. [Google Scholar] [CrossRef]

- Park, B.G.; Wunderlich, J.; Martí, X.; Holý, V.; Kurosaki, Y.; Yamada, M.; Yamamoto, H.; Nishide, A.; Hayakaw, J.; Takahashi, H.; et al. A spin-valve-like magnetoresistance of an antiferromagnet-based tunnel junction. Nat. Mater. 2011, 10, 347–351. [Google Scholar] [CrossRef] [PubMed]

- Kimel, A.V.; Kirilyuk, A.; Tsvetkov, A.; Pisarev, R.V.; Rasing, T. Laser-induced ultrafast spin reorientation in the antiferromagnet TmFeO3. Nature 2004, 429, 850–853. [Google Scholar] [CrossRef] [PubMed]

- Gong, G.-Q.; Canedy, C.; Xiao, G.; Sun, J.Z.; Gupta, A.; Gallagher, W.J. Colossal magnetoresistance of 1000000-fold magnitude achieved in the antiferromagnetic phase of La1-xCaxMnO3. Appl. Phys. Lett. 1995, 67, 1783. [Google Scholar] [CrossRef]

- Sachdev, S. Entangling Superconductivity and Antiferromagnetism. Science 2012, 336, 1510–1511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Löhneysen, H.V.; Rosch, A.; Vojta, M.; Wölfle, P. Fermi-liquid instabilities at magnetic quantum phase transitions. Rev. Mod. Phys. 2007, 79, 1015–1075. [Google Scholar] [CrossRef]

- Fiebig, M.; Lottermoser, T.; Meier, D.; Trassin, M. The evolution of multiferroics. Nat. Rev. Mater. 2016, 1, 16046. [Google Scholar] [CrossRef]

- Heron, J.T.; Trassin, M.; Ashraf, K.; Gajek, M.; He, Q.; Yang, S.Y.; Nikonov, D.E.; Chu, Y.H.; Salahuddin, S.; Ramesh, R. Electric-field-induced magnetization reversal in a ferromagnet-multiferroic heterostructure. Phys. Rev. Lett. 2011, 107, 217202. [Google Scholar] [CrossRef] [PubMed]

- Heron, J.T.; Bosse, J.L.; He, Q.; Gao, Y.; Trassin, M.; Ye, L.; Clarkson, J.D.; Wang, C.; Liu, J.; Salahuddin, S.; et al. Deterministic switching of ferromagnetism at room temperature using an electric field. Nature 2014, 516, 370–373. [Google Scholar] [CrossRef] [PubMed]

- Jungwirth, T.; Marti, X.; Wadley, P.; Wunderlich, J. Antiferromagnetic spintronics. Nat. Nanotechnol. 2016, 11, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Marti, X.; Fina, I.; Frontera, C.; Liu, J.; Wadley, P.; He, Q.; Paull, R.J.; Clarkson, J.D.; Kudrnovský, J.; Turek, I.; et al. Room-temperature antiferromagnetic memory resistor. Nature 2014, 13, 367–374. [Google Scholar] [CrossRef]

- Wadley, P.; Howells, B.; Železný, J.; Andrews, C.; Hills, V.; Campion, R.P.; Novák, V.; Olejník, K.; Maccherozzi, F.; Dhesi, S.S.; et al. Electrical switching of an antiferromagnet. Science 2016, 351, 587–590. [Google Scholar] [CrossRef] [PubMed]

- Kosub, T.; Kopte, M.; Hühne, R.; Appel, P.; Shields, B.; Maletinsky, P.; Hübner, R.; Liedke, M.O.; Fassbender, J.; Schmidt, O.G.; et al. Purely antiferromagnetic magnetoelectric random access memory. Nat. Commun. 2017, 8, 13985. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Das, H.; Wysocki, A.L.; Wang, X.; Cheong, S.-W.; Mostovoy, M.; Fennie, C.J.; Wu, W. Direct visualization of magnetoelectric domains. Nat. Mater. 2013, 13, 163–167. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Wu, W. Magnetoelectric force microscopy based on magnetic force microscopy with modulated electric field. Rev. Sci. Instrum. 2014, 85, 053901. [Google Scholar] [CrossRef] [PubMed]

- Das, H.; Wysocki, L.A.; Geng, Y.; Wu, W.; Fennie, J.C. Bulk magnetoelectricity in the hexagonal manganites and ferrites. Nat. Commun. 2014, 5, 2998. [Google Scholar] [CrossRef] [PubMed]

- O’Dell, T.H. The Electrodynamics of Magneto-Electric Media; North-Holland Publishing Company: Amsterdam, The Netherlands, 1970. [Google Scholar]

- Rado, G.T. Observation and possible mechanisms of magnetoelectric effects in a ferromagnet. Phys. Rev. Lett. 1964, 13, 335–337. [Google Scholar] [CrossRef]

- Rado, G.T.; Ferrari, J.M.; Maisc, W.G. Magnetoelectric susceptibility and magnetic symmetry of magnetoelectrically annealed TbPO4. Phys. Rev. B 1984, 29, 4041–4048. [Google Scholar] [CrossRef]

- Hornreich, R.; Shtrikman, S. Statistical mechanics and origin of the magnetoelectric effect in Cr2O3. Phys. Rev. 1967, 161, 506–512. [Google Scholar] [CrossRef]

- Tanner, B.K. Antiferromagnetic domains. Contemp. Phys. 1979, 20, 187–210. [Google Scholar] [CrossRef]

- Schlenker, M.; Baruchel, J. Neutron techniques for the observation of ferro- and antiferromagnetic domains. J. Appl. Phys. 1978, 49, 1996–2001. [Google Scholar] [CrossRef]

- Baruchel, J.; Schlenker, M.; Barbara, B. 180∘ antiferromagnetic domains in MnF2 by neutron topography. J. Magn. Magn. Mater. 1980, 15–18, 1510–1512. [Google Scholar] [CrossRef]

- Fiebig, M.; Fröhlich, D.; Krichevtsov, B.B.; Pisarev, R.V. Second harmonic generation and magnetic-dipole-electric-dipole interference in antiferromagnetic Cr2O3. Phys. Rev. Lett. 1994, 73, 2127–2130. [Google Scholar] [CrossRef] [PubMed]

- Fiebig, M.; Fröhlich, D.; Sluyterman v. L., G.; Pisarev, R.V. Domain topography of antiferromagnetic Cr2O3 by second harmonic generation. Appl. Phys. Lett. 1995, 66, 2906–2908. [Google Scholar] [CrossRef]

- Eremenko, V.V.; Kharchenko, N.F.; Beliy, L.I. Visualization of the 180-degree antiferromagnetic domains by means of new magnetooptical effect. J. Appl. Phys. 1979, 50, 7751–7753. [Google Scholar] [CrossRef]

- Krichevtsov, B.B.; Pavlov, V.V.; Pisarev, R.V.; Gridnev, V.N. Spontaneous non-reciprocal reflection of light from antiferromagnetic Cr2O3. J. Phys. Condens. Matter 1993, 5, 8233–8244. [Google Scholar] [CrossRef]

- Baruchel, J.; Boller, E.; Espeso, J.I.; Klein, H.; Medrano, C.; Nogues, J.; Pernot, E.; Schlenker, M. Bragg-diffraction imaging of magnetic crystals with third generation synchrotron radiation. J. Magn. Magn. Matter 2001, 233, 38–47. [Google Scholar] [CrossRef]

- Curie, P. Sur la symétrie dans les phénomènes physiques, symétrie d’un champ électrique et d’un champ magnétique. J. Phys. Theor. Appl. 1894, 3, 393–415. [Google Scholar] [CrossRef]

- Fiebig, M. Revival of the magnetoelectric effect. J. Phys. D Appl. Phys. 2005, 38, R123–R152. [Google Scholar] [CrossRef]

- Gehring, G.A. On the microscopic theory of the magnetoelectric effect. Ferroelectrics 1994, 161, 275–285. [Google Scholar] [CrossRef]

- Fiebig, M.; Fröhlich, D.; Thiele, H.-J. Determination of spin direction in the spin-flop phase of Cr2O3. Phys. Rev. B 1996, 54, 681–684. [Google Scholar] [CrossRef]

- Dzyaloshinskii, I.E. On the magneto-electrical effect in antiferromagnets. Sov. Phys. JETP 1960, 10, 628–629. [Google Scholar]

- Astrov, D.N. The magnetoelectric effect in antiferromagnetics. Sov. Phys. JETP 1960, 11, 708–709. [Google Scholar]

- Rado, G.T.; Folen, V.J. Observation of the magnetically induced magnetoelectric effect and evidence for antiferromagnetic doamins. Phys. Rev. Lett. 1961, 7, 310–311. [Google Scholar] [CrossRef]

- Wiegelmann, H.; Jansen, A.G.M.; Wyder, P.; Rivera, J.-P.; Schmid, H. Magnetoelectric effect of Cr2O3 in strong static magnetic fields. Ferroelectrics 1994, 162, 141–146. [Google Scholar] [CrossRef]

- Rivera, J.-P. A short review of the magnetoelectric effect and related experimental techniques on single phase (multi-) ferroics. Eur. Phys. J. B 2009, 71, 299–313. [Google Scholar] [CrossRef]

- Dussaux, A.; Schoenherr, P.; Koumpouras, K.; Chico, J.; Chang, K.; Lorenzelli, L.; Kanazawa, N.; Tokura, Y.; Garst, M.; Bergman, A.; et al. Local dynamics of topological magnetic defects in the itinerant helimagnet FeGe. Nat. Commun. 2016, 22, 96–118. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.R. The Principles of Nonlinear Optics; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Fiebig, M.; Pavlov, V.V.; Pisarev, R.V. Second-harmonic generation as a tool for studying electronic and magnetic structures of crystals: Review. J. Opt. Soc. Am. B 2005, 22, 96–118. [Google Scholar] [CrossRef]

- Rivera, J.-P. The linear magnetoelectric effect in LiCoPO4. Ferroelectrics 1994, 161, 147–164. [Google Scholar] [CrossRef]

- Lilienblum, M.; Hoffmann, Á.; Soergel, E.; Becker, P.; Bohatý, L.; Fiebig, M. Piezoresponse force microscopy at sub-room temperatures. Rev. Sci. Instrum. 2013, 84, 043703. [Google Scholar] [CrossRef] [PubMed]

- Aoki, T.; Hiroshima, M.; Kitamura, K.; Tokunaga, M.; Yanagida, T. Non-contact scanning probe microscopy with sub-piconewton force sensitivity. Ultramicroscopy 1997, 70, 45–55. [Google Scholar] [CrossRef]

- Cappella, B.; Dietler, G. Force-distance curves by atomic force microscopy. Surf. Sci. Rep. 1999, 34, 1–104. [Google Scholar] [CrossRef]

- Futamoto, M.; Hagami, T.; Ishihara, S.; Soneta, K.; Ohtake, M. Improvement of Magnetic Force Microscope Resolution and Application to High-Density Recording Media. IEEE Trans. Magn. 2013, 49, 2748–2754. [Google Scholar] [CrossRef]

- Precner, M.; Fedor, J.; Tóbik, J.; Šoltýs, J.; Cambel, V. High resolution tips for switching magnetization MFM. Acta Phys. Pol. A 2014, 124, 2748–2754. [Google Scholar] [CrossRef]

Sample Availability: CrO samples are available from Manfred Fiebig. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schoenherr, P.; Giraldo, L.M.; Lilienblum, M.; Trassin, M.; Meier, D.; Fiebig, M. Magnetoelectric Force Microscopy on Antiferromagnetic 180∘ Domains in Cr2O3. Materials 2017, 10, 1051. https://doi.org/10.3390/ma10091051

Schoenherr P, Giraldo LM, Lilienblum M, Trassin M, Meier D, Fiebig M. Magnetoelectric Force Microscopy on Antiferromagnetic 180∘ Domains in Cr2O3. Materials. 2017; 10(9):1051. https://doi.org/10.3390/ma10091051

Chicago/Turabian StyleSchoenherr, Peggy, L. Marcela Giraldo, Martin Lilienblum, Morgan Trassin, Dennis Meier, and Manfred Fiebig. 2017. "Magnetoelectric Force Microscopy on Antiferromagnetic 180∘ Domains in Cr2O3" Materials 10, no. 9: 1051. https://doi.org/10.3390/ma10091051