Exploring the Effects of Argon Plasma Treatment on Plasmon Frequency and the Chemiresistive Properties of Polymer-Carbon Nanotube Metacomposite

Abstract

:1. Introduction

2. Experimental Details

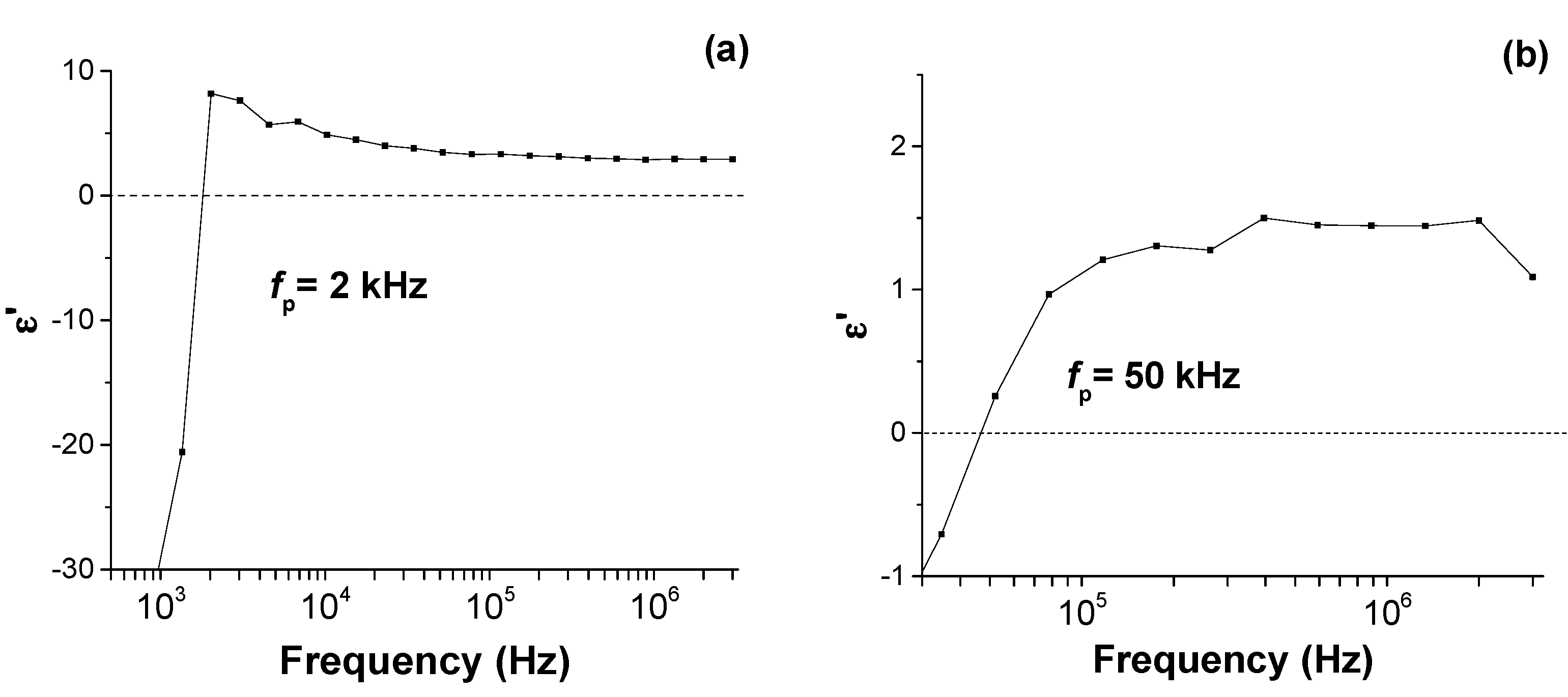

3. Findings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gu, H.; Guo, J.; Wei, S.; Guo, Z. Polyaniline nanocomposites with negative permittivity. J. Appl. Polym. Sci. 2013, 130, 2238–2244. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Qi, S.; Tian, G.; Wu, D. Permittivity transition from highly positive to negative: Polyimide/carbon nanotube composite’s dielectric behavior around percolation threshold. Appl. Phys. Lett. 2015, 107, 012905. [Google Scholar] [CrossRef]

- Pendry, J.; Holden, A.; Stewart, W.; Youngs, I. Extremely low frequency plasmons in metallic mesostructures. Phys. Rev. Lett. 1996, 76, 4773–4776. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, C.H.; Lee, A.H.; Liu, C.D.; Han, J.L.; Hsieh, K.H.; Lee, S.N. Polyaniline nano-composites with large negative dielectric permittivity. AIP Adv. 2012, 2, 012127. [Google Scholar] [CrossRef]

- Li, B.; Sui, G.; Zhong, W.H. Single negative metamaterials in unstructured polymer nanocomposites toward selectable and controllable negative permittivity. Adv. Mater. 2009, 21, 4176–4180. [Google Scholar] [CrossRef]

- Sayago, I.; Terrado, E.; Lafuente, E.; Horrillo, M.C.; Maser, W.K.; Benito, A.M.; Navarro, R.; Urriolabeitia, E.P.; Martinez, M.T.; Gutierrez, J. Hydrogen sensors based on carbon nanotubes thin films. Synth. Met. 2005, 148, 15–19. [Google Scholar] [CrossRef]

- Lobotka, P.; Kunzo, P. Processing, performance and application Volume B: Carbon nanotube based polymer composites. In Handbook of Polymer Nanocomposites; Kar, K.K., Pandey, J.K., Rana, S., Eds.; Springer: Berlin, Germany, 2015; pp. 577–601. [Google Scholar]

- Dabhade, R.V.; Bodas, D.S.; Gangal, S.A. Plasma-treated polymer as humidity sensing material—A feasibility study. Sens. Actuators B Chem. 2004, 98, 37–40. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Gu, H.; Guo, J.; He, Q.; Jiang, Y.; Huang, Y.; Haldolaarachige, N.; Luo, Z.; Young, D.P.; Wei, S.; Guo, Z. Magnetoresistive polyaniline/multi-walled carbon nanotube nanocomposites with negative permittivity. Nanoscale 2014, 6, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Cazzanelli, E.; Caputi, L.; Castriota, M.; Cupolillo, A.; Giallombardo, C.; Papagno, L. Carbon linear chains inside multiwalled nanotubes. Surf. Sci. 2007, 601, 3926–3932. [Google Scholar] [CrossRef]

- Fantini, C.; Cruz, E.; Jorio, A.; Terrones, M.; Terrones, H.; Van Lier, G.; Charlier, J.C.; Dresselhaus, M.S.; Saito, R.; Kim, Y.A.; et al. Resonance Raman study of linear carbon chains formed by the heat treatment of double-wall carbon nanotubes. Phys. Rev. B 2006, 73, 193408. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cancado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1291. [Google Scholar] [CrossRef] [PubMed]

- Antunes, E.F.; Lobo, A.O.; Corat, E.J.; Trava-Airoldi, V.J.; Martin, A.A.; Veríssimo, C. Comparative study of first- and second-order Raman spectra of MWCNT at visible and infrared laser excitation. Carbon 2006, 44, 2202–2211. [Google Scholar] [CrossRef]

- Chaun, Y.; Wang, T.K.; Donnet, J.B. Stability and existence of carbyne with carbon chains. New Carbon Mater. 2005, 20, 83–92. [Google Scholar]

- Costa, S.; Borowiak-Palen, E. Raman Study on Doped Multiwalled Carbon Nanotubes. Acta Phys. Pol. A 2009, 116, 32–35. [Google Scholar] [CrossRef]

- Zhou, W.; Vavro, J.; Nemes, N.M.; Fischer, J.E.; Borondics, F.; Kamarás, K.; Tanner, D.B. Publisher’s Note: Charge transfer and Fermi level shift in p-doped single-walled carbon nanotubes. Phys. Rev. B 2005, 71, 205423. [Google Scholar] [CrossRef]

- Dhall, S.; Jaggi, N.; Nathawat, R. Functionalized multiwalled carbon nanotubes based hydrogen gas sensor. Sens. Actuators A Phys. 2013, 201, 321–327. [Google Scholar] [CrossRef]

- Sekral, M.; Legrand, P. A spectroscopic investigation of the carrageenans and agar in the 1500–100 cm−1 spectral range. Spectrochim. Acta Mol. Spectrosc. 1993, 49, 209–221. [Google Scholar]

- Aldalbahi, A.; Chu, J.; Feng, P.; In Het Panhuis, M. Conducting composite materials from the biopolymer kappa-carrageenan and carbon nanotubes. Beilstein J. Nanotechnol. 2012, 3, 415–427. [Google Scholar] [CrossRef] [PubMed]

- France, R.M.; Short, R.D. Effects of energy transfer from an argon plasma on the surface chemistry of poly(styrene), low density poly(ethylene), poly(propylene) and poly(ethylene terephthalate). J. Chem. Soc. Faraday Trans. 1997, 93, 3173–3178. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Leys, C.; Gengembre, L.; Payen, E. Treatment of polymer films with a dielectric barrier discharge in air, helium and argon at medium pressure. Surf. Coat. Technol. 2007, 201, 7066–7075. [Google Scholar] [CrossRef]

- Lehocky’, M.; Drnovska’, H.; Lapcíková, B.; Barros-Timmons, A.M.; Trindade, T.; Zembala, M.; Lapcík, L., Jr. Plasma surface modification of polyethylene. Colloids Surf. A Physicochem. Eng. Asp. 2003, 222, 125–131. [Google Scholar] [CrossRef]

- Pisal, S.H.; Harale, N.S.; Bhat, T.S.; Deshmukh, H.P.; Patil, P.S. Functionalized multi-walled carbon nanotubes for nitrogen sensor. IOSR J. Appl. Chem. 2014, 7, 49–52. [Google Scholar] [CrossRef]

- Riccardi, R.; Barni, R.; Selli, E.; Mazzone, G.; Massafra, M.R.; Marcandalli, B.; Poletti, G. Surface modification of poly(ethylene terephthalate) fibers induced by radio frequency air plasma treatment. Appl. Surf. Sci. 2003, 211, 386–397. [Google Scholar] [CrossRef]

- Gheorghiu, M.; Arefi, F.; Amouroux, J.; Placinta, G.; Popa, G.; Tatoulian, M. Surface cross linking and functionalization of poly(ethylene terephthalate) in a helium discharge. Plasma Sources Sci. Technol. 1997, 6, 8–19. [Google Scholar] [CrossRef]

- Maio, A.; Botta, L.; Tito, A.C.; Pellegrino, L.; Daghetta, M.; Scaffaro, R. Statistical Study of the Influence of CNTs Purification and Plasma Functionalization on the Properties of Polycarbonate-CNTs Nanocomposites. Plasma Process. Polym. 2014, 11, 664–677. [Google Scholar] [CrossRef]

- Martıínez-Rubí, Y.; Guan, J.; Lin, S.; Scriver, C.; Sturgeon, R.E.; Simard, B. Rapid and controllable covalent functionalization of single-walled carbon nanotubes at room temperature. Chem. Commun. 2007, 48, 5146–5148. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Yan, K.; Fan, R.; Qian, L.; Zhang, Z.; Sun, K.; Chen, M. Negative permittivity behavior in the carbon/silicon nitride composites prepared by impregnation-carbonization approach. Carbon 2016, 96, 678–684. [Google Scholar] [CrossRef]

- Shi, Z.C.; Mao, F.; Wang, J.; Fan, R.; Wang, X. Percolative silver/alumina composites with radio frequency dielectric resonance-induced negative permittivity. RSC Adv. 2015, 5, 107307–107312. [Google Scholar] [CrossRef]

- Qian, L.; Lu, L.; Fan, R. Tunable negative permittivity based on phenolic resin and multi-walled carbon nanotubes. RSC Adv. 2015, 5, 16618–16621. [Google Scholar] [CrossRef]

- Zhu, J.; Gu, H.; Luo, Z.; Haldolaarachige, N.; Young, D.P.; Wei, S.; Guo, Z. Carbon Nanostructure-Derived Polyaniline Metacomposites: Electrical, Dielectric, and Giant Magnetoresistive Properties. Langmuir 2012, 28, 10246–10255. [Google Scholar] [CrossRef] [PubMed]

- Kunzo, P.; Lobotka, P.; Micusik, M.; Kovacova, E. Palladium-free hydrogen sensor based on oxygen-plasma-treated polyaniline thin film. Sens. Actuators B 2012, 171–172, 838–845. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera, M.; Rahaman, M.; Aldalbahi, A.; Velázquez, R.; Zhou, A.F.; Feng, P.X. Exploring the Effects of Argon Plasma Treatment on Plasmon Frequency and the Chemiresistive Properties of Polymer-Carbon Nanotube Metacomposite. Materials 2017, 10, 986. https://doi.org/10.3390/ma10090986

Rivera M, Rahaman M, Aldalbahi A, Velázquez R, Zhou AF, Feng PX. Exploring the Effects of Argon Plasma Treatment on Plasmon Frequency and the Chemiresistive Properties of Polymer-Carbon Nanotube Metacomposite. Materials. 2017; 10(9):986. https://doi.org/10.3390/ma10090986

Chicago/Turabian StyleRivera, Manuel, Mostafizur Rahaman, Ali Aldalbahi, Rafael Velázquez, Andrew F. Zhou, and Peter X. Feng. 2017. "Exploring the Effects of Argon Plasma Treatment on Plasmon Frequency and the Chemiresistive Properties of Polymer-Carbon Nanotube Metacomposite" Materials 10, no. 9: 986. https://doi.org/10.3390/ma10090986