Pressure Induced Densification and Compression in a Reprocessed Borosilicate Glass

Abstract

:1. Introduction

2. Results

2.1. Reprocessed Borosilicate Glass Sample

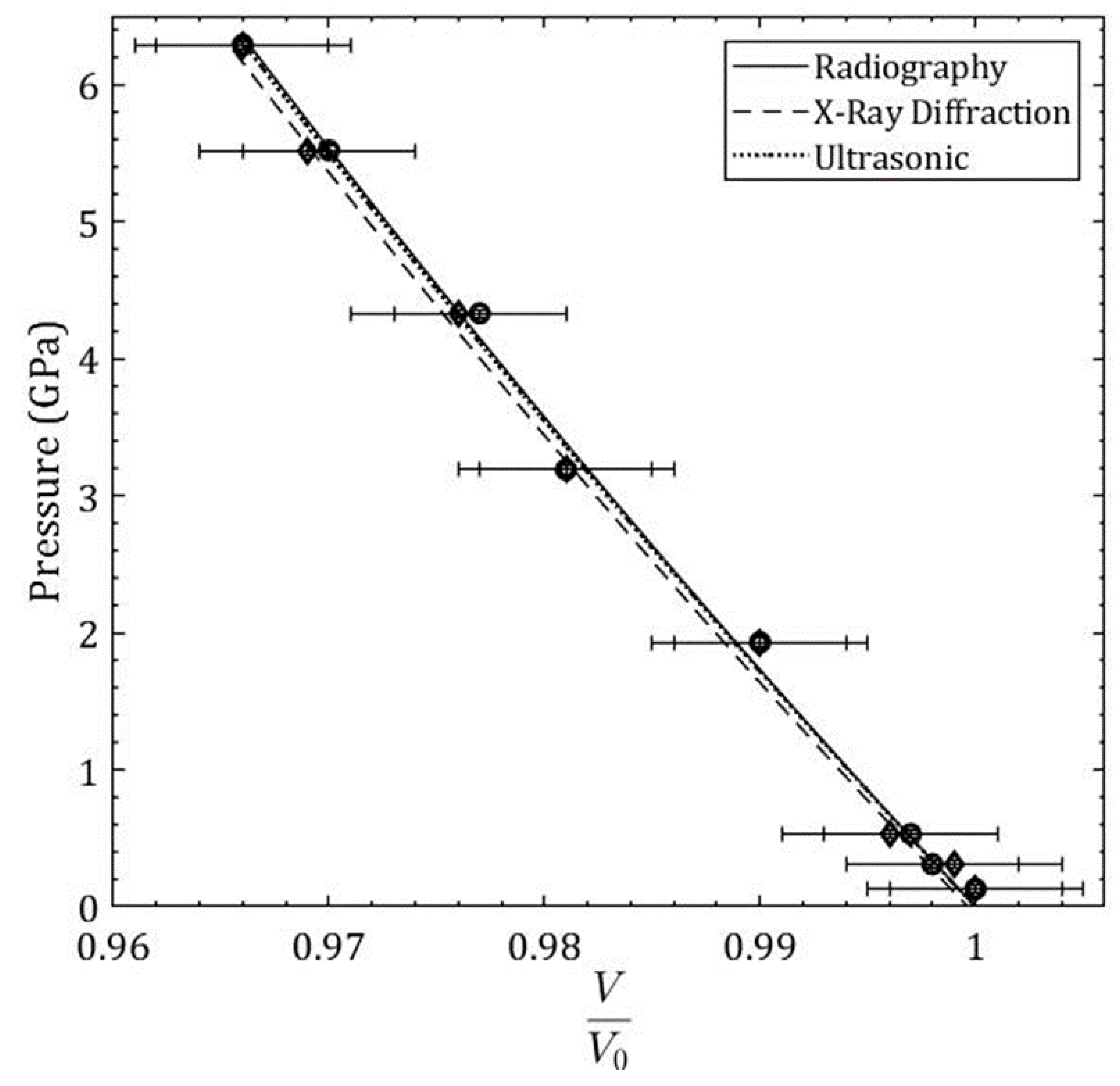

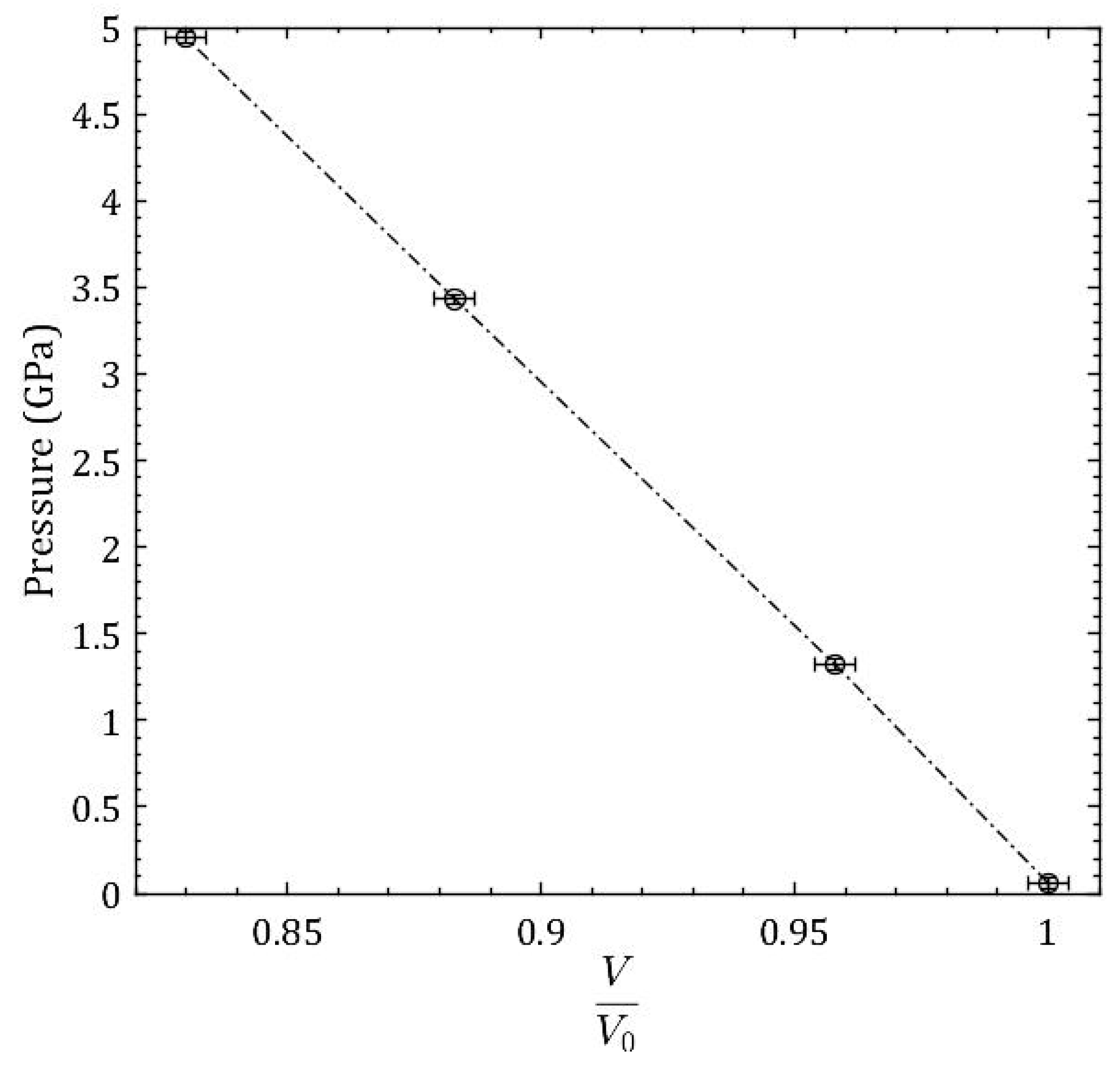

2.2. Density Measurements

3. Discussion

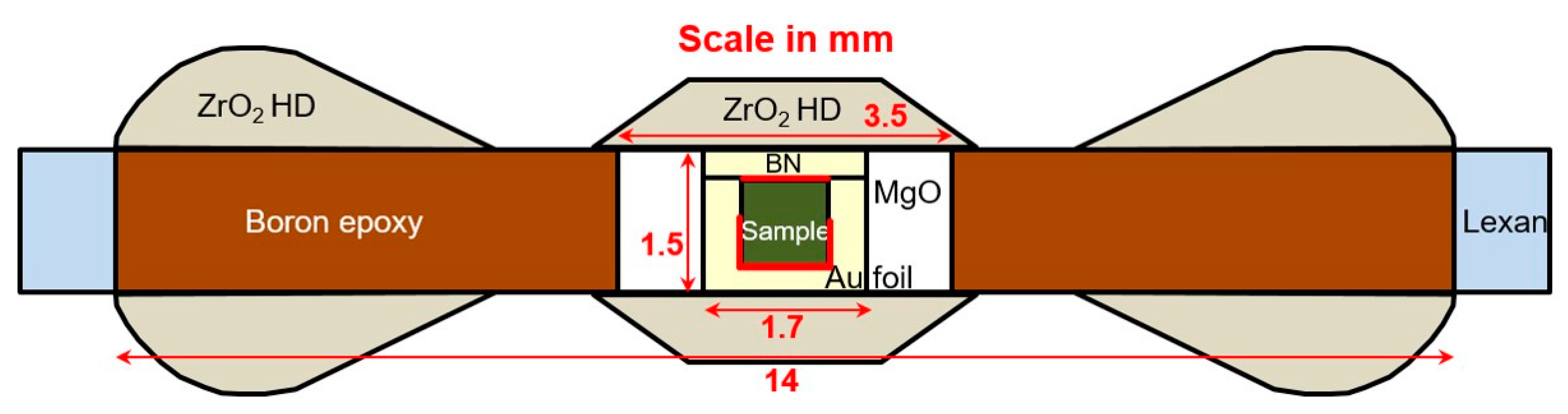

4. Materials and Methods

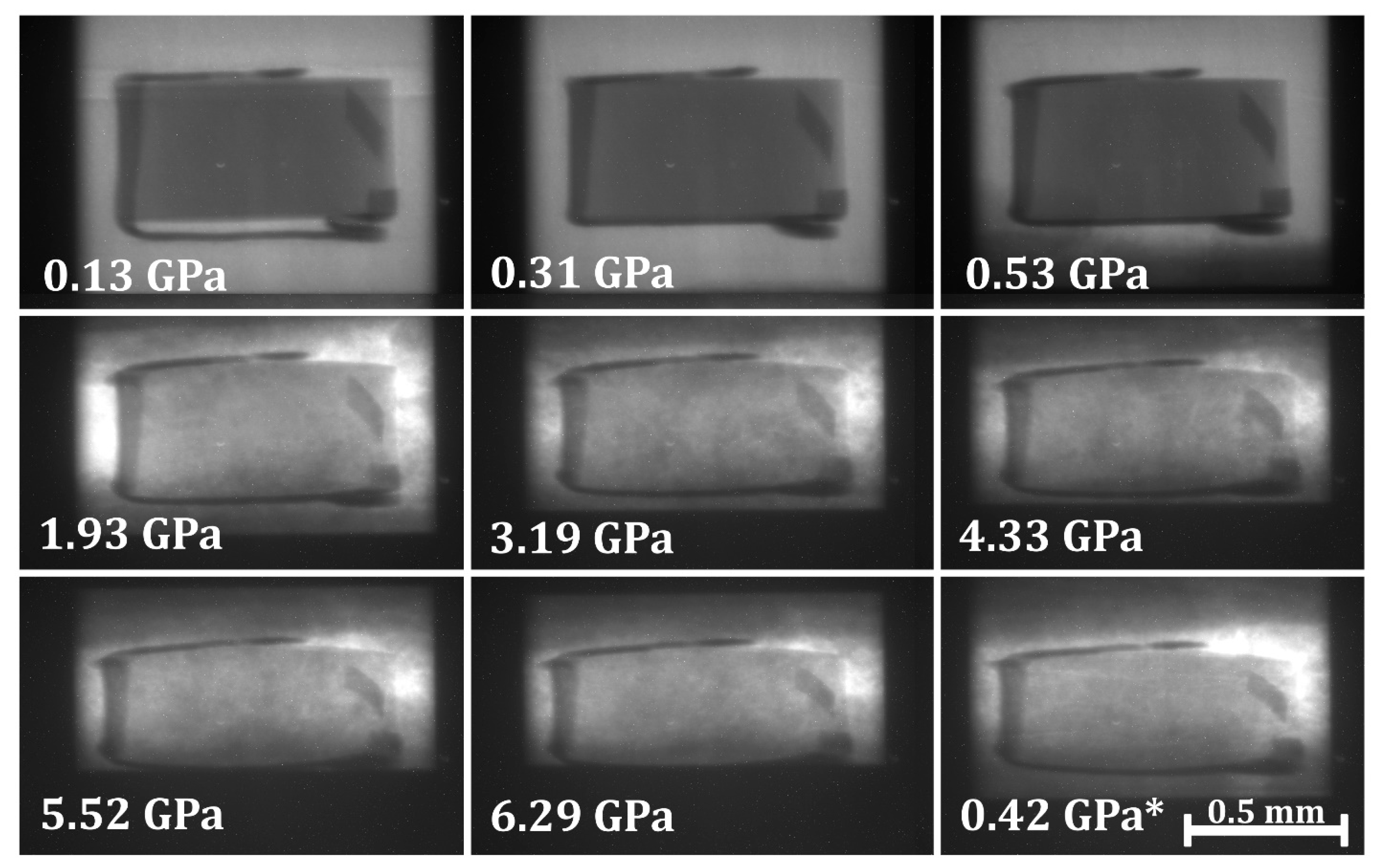

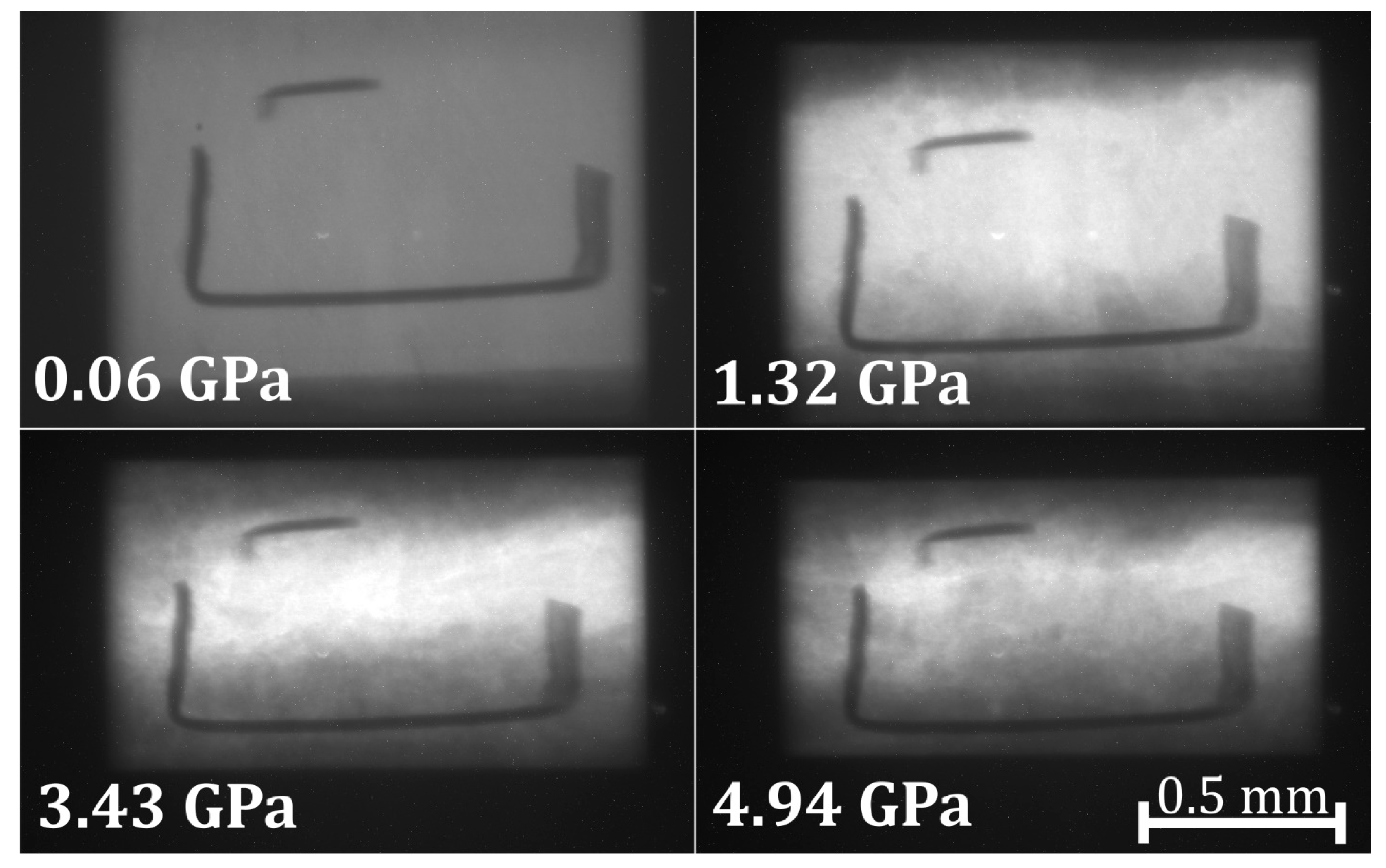

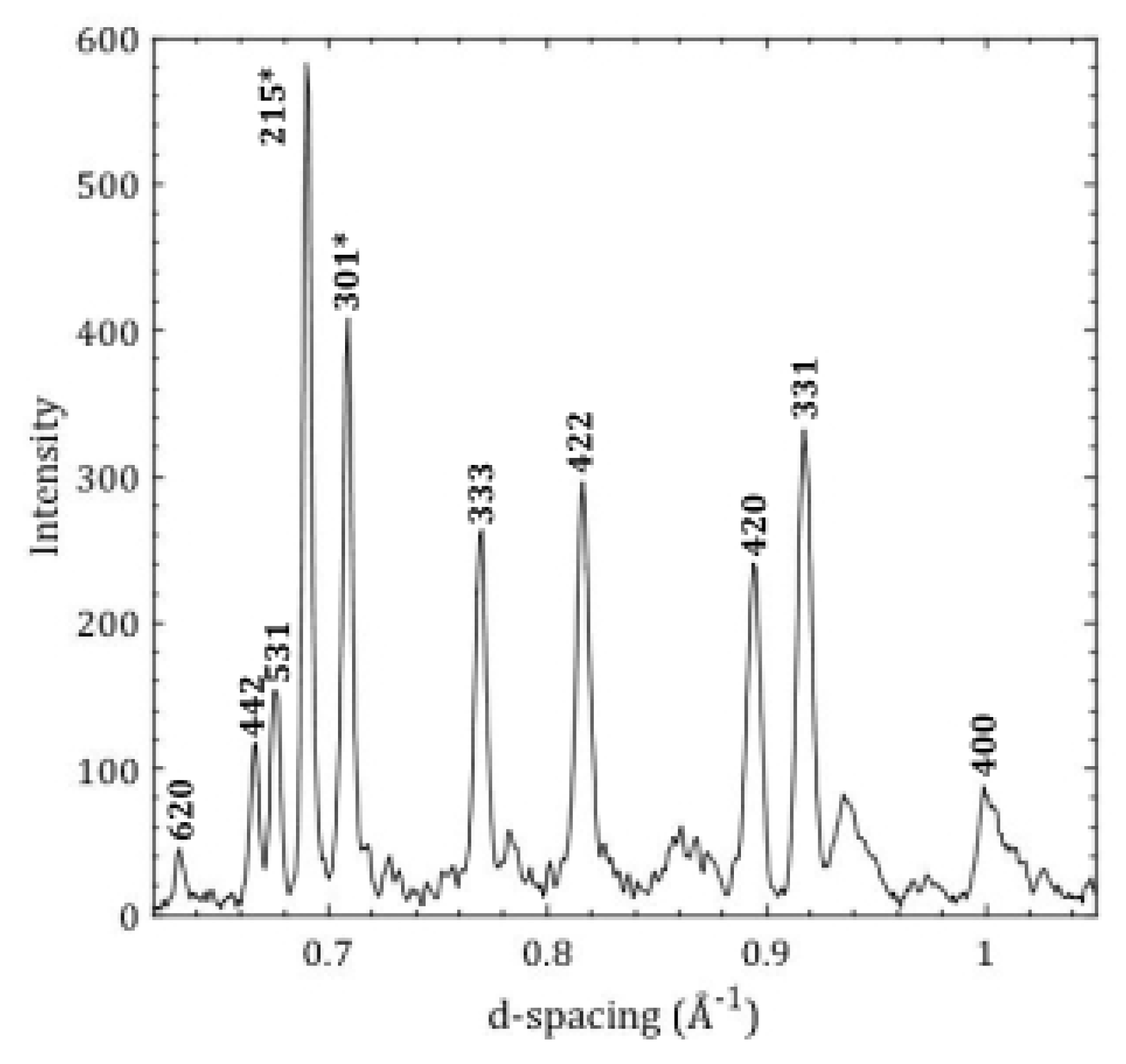

White-Beam X-ray Radiography

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Birch, F. Finite elastic strain of cubic crystals. Phys. Rev. 1947, 71, 809–824. [Google Scholar] [CrossRef]

- Fei, Y.; Li, J.; Hirose, K.; Minarik, W.G.; Van Orman, J.A.; Sanloup, C.; Westrenen, W.; van Komabayashi, T.; Funakoshi, K. A critical evaluation of pressure scales at high temperatures by in situ X-ray diffraction measurements. Phys. Earth Planet. Inter. 2004, 143–144, 515–526. [Google Scholar] [CrossRef]

- Amin, S.A.; Rissi, E.N.; McKiernan, K.; Yarger, J.L. Determining the equation of state of amorphous solids at high pressure using optical microscopy. Rev. Sci. Instrum. 2012, 83. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, L.; Xiao, X.; De Carlo, F.; Feng, J.; Mao, H.; Hemley, R.H. Anomalous high-pressure behavior of amorphous selenium from synchrotron X-ray diffraction and microtomography. Proc. Natl. Acad. Sci. USA 2008, 105, 13229–13234. [Google Scholar] [CrossRef] [PubMed]

- Kono, Y.; Yamada, A.; Wang, Y.; Yu, T.; Inoue, T. Combined ultrasonic elastic wave velocity and microtomography measurements at high pressures. Rev. Sci. Instrum. 2011, 82. [Google Scholar] [CrossRef] [PubMed]

- Li, L.L.; Weidner, D.; Raterron, P.; Chen, J.H.; Vaughan, M.; Me, S.H.; Durham, B. Deformation of olivine at mantle pressure using the D-DIA. Eur. J. Mineral. 2006, 18, 7–19. [Google Scholar] [CrossRef]

- Ham, K.J.; Vohra, Y.K.; Kono, Y.; Wereszczak, A.; Patel, P. White-beam X-ray diffraction and radiography studies on high-boron-containing borosilicate glass at high pressures. High Press. Res. 2017, 37, 233–243. [Google Scholar] [CrossRef]

- Guinan, M.W.; Beshers, D.N. Pressure derivatives of the elastic constants of α-iron to 10 kbs. J. Phys. Chem. Solids 1968, 29, 541–549. [Google Scholar] [CrossRef]

- Wereszczak, A.A.; Anderson, C.E. Borofloat and starphire float glasses: A comparison. Int. J. Appl. Glass Sci. 2015, 5, 334–344. [Google Scholar] [CrossRef]

- SCHOTT Technical Glass Solutions GmbH. Schott Borofloat R 33; SCHOTT Technical Glass Solutions GmbH: Jena, Germany, 2018. [Google Scholar]

| EOS Parameters | X-ray Radiography | X-ray Diffraction | Ultrasonic [8] |

|---|---|---|---|

| (GPa) | 167.6 | 164.4 | 166.4 |

| 5.29 (fixed) | 5.29 (fixed) | 5.29 |

| Heating Rate (°C Per Minute) | Ending Temperature (°C) | Time * (h) |

|---|---|---|

| 5.25 | 1540 | 17.0 |

| 0.9 | 1090 | 4.5 |

| 0.7 | 935 | 3.5 |

| 0.5 | 820 | 3.5 |

| 0.3 | 590 | 14.0 |

| 0.2 | 535 | 8.5 |

| 0.2 | 450 | 5.5 |

| 0.2 | 25 | End |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ham, K.J.; Kono, Y.; Patel, P.J.; Kilczewski, S.M.; Vohra, Y.K. Pressure Induced Densification and Compression in a Reprocessed Borosilicate Glass. Materials 2018, 11, 114. https://doi.org/10.3390/ma11010114

Ham KJ, Kono Y, Patel PJ, Kilczewski SM, Vohra YK. Pressure Induced Densification and Compression in a Reprocessed Borosilicate Glass. Materials. 2018; 11(1):114. https://doi.org/10.3390/ma11010114

Chicago/Turabian StyleHam, Kathryn J., Yoshio Kono, Parimal J. Patel, Steven M. Kilczewski, and Yogesh K. Vohra. 2018. "Pressure Induced Densification and Compression in a Reprocessed Borosilicate Glass" Materials 11, no. 1: 114. https://doi.org/10.3390/ma11010114