Tribological Behaviors of Graphene and Graphene Oxide as Water-Based Lubricant Additives for Magnesium Alloy/Steel Contacts

Abstract

:1. Introduction

2. Experimental

2.1. Materials

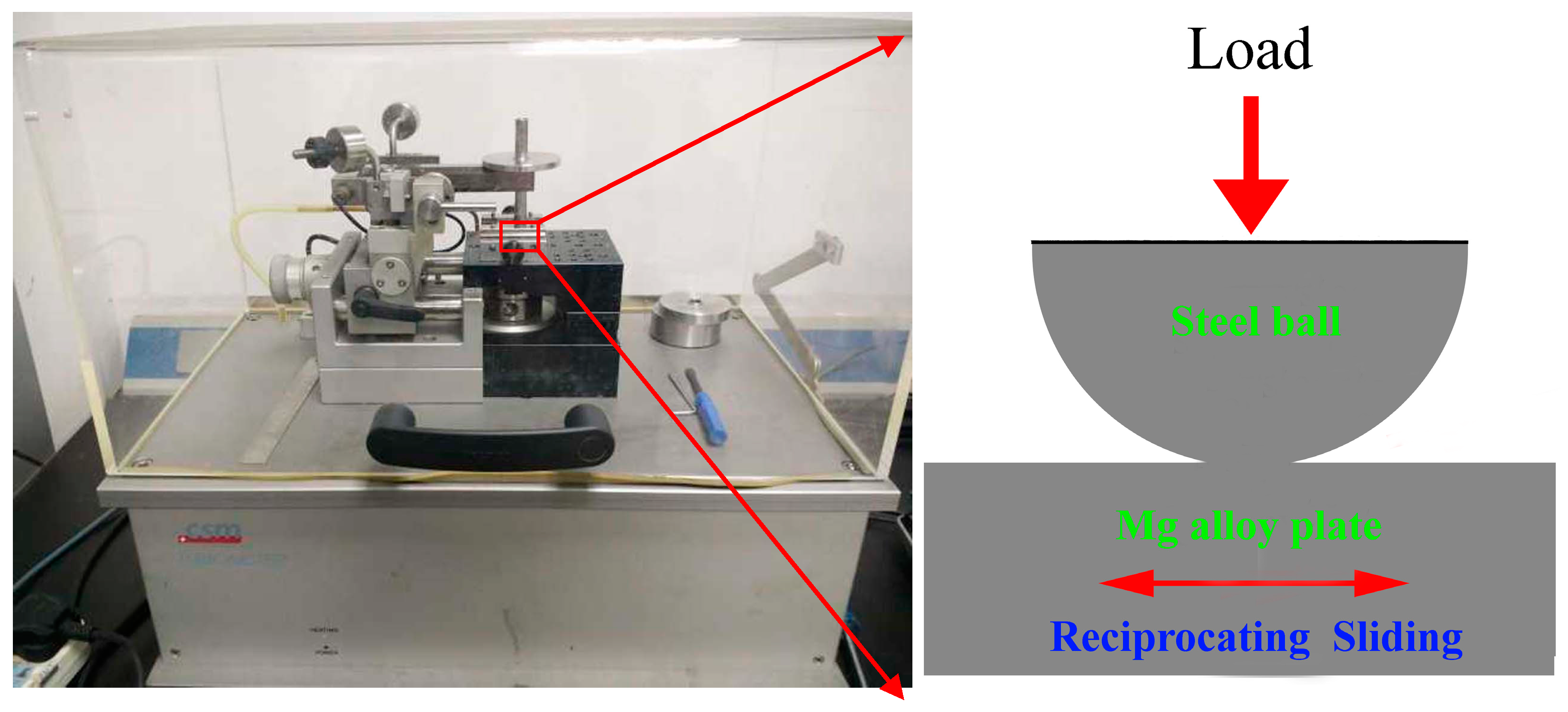

2.2. Tribological Tests

2.3. Surface Characterization

3. Results and Discussion

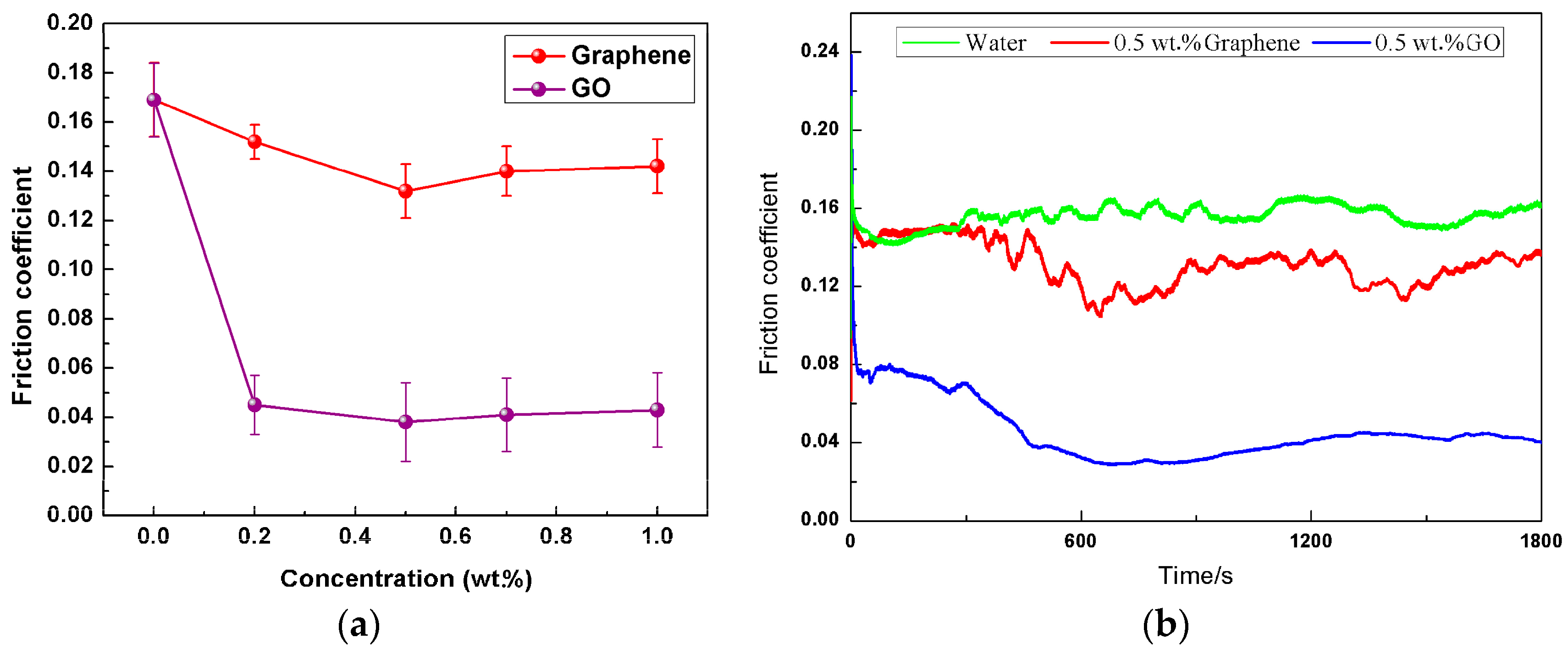

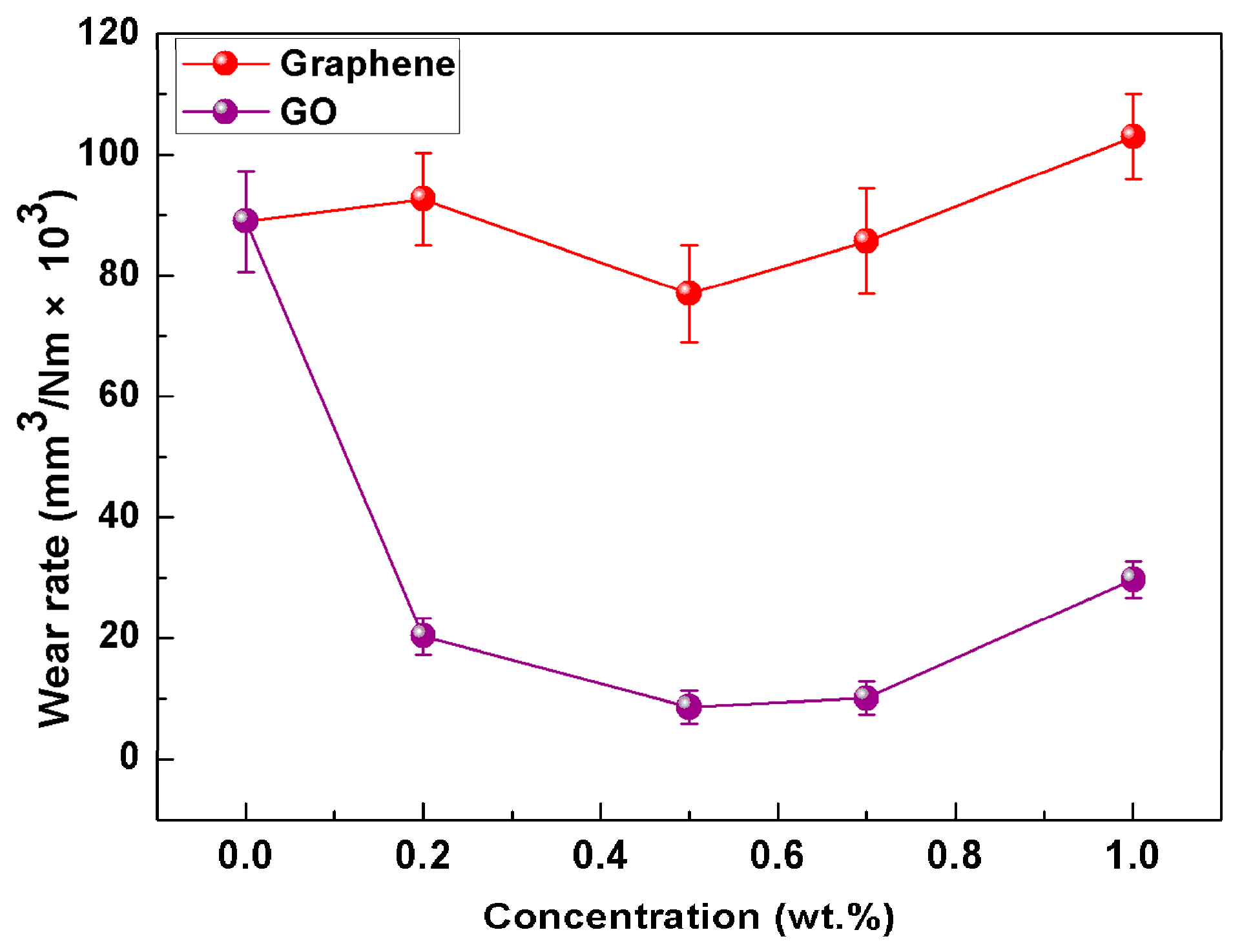

3.1. Influence of Nanoparticle Concentration on Lubrication Performance

3.2. Influence of Normal Load on Lubrication Performance

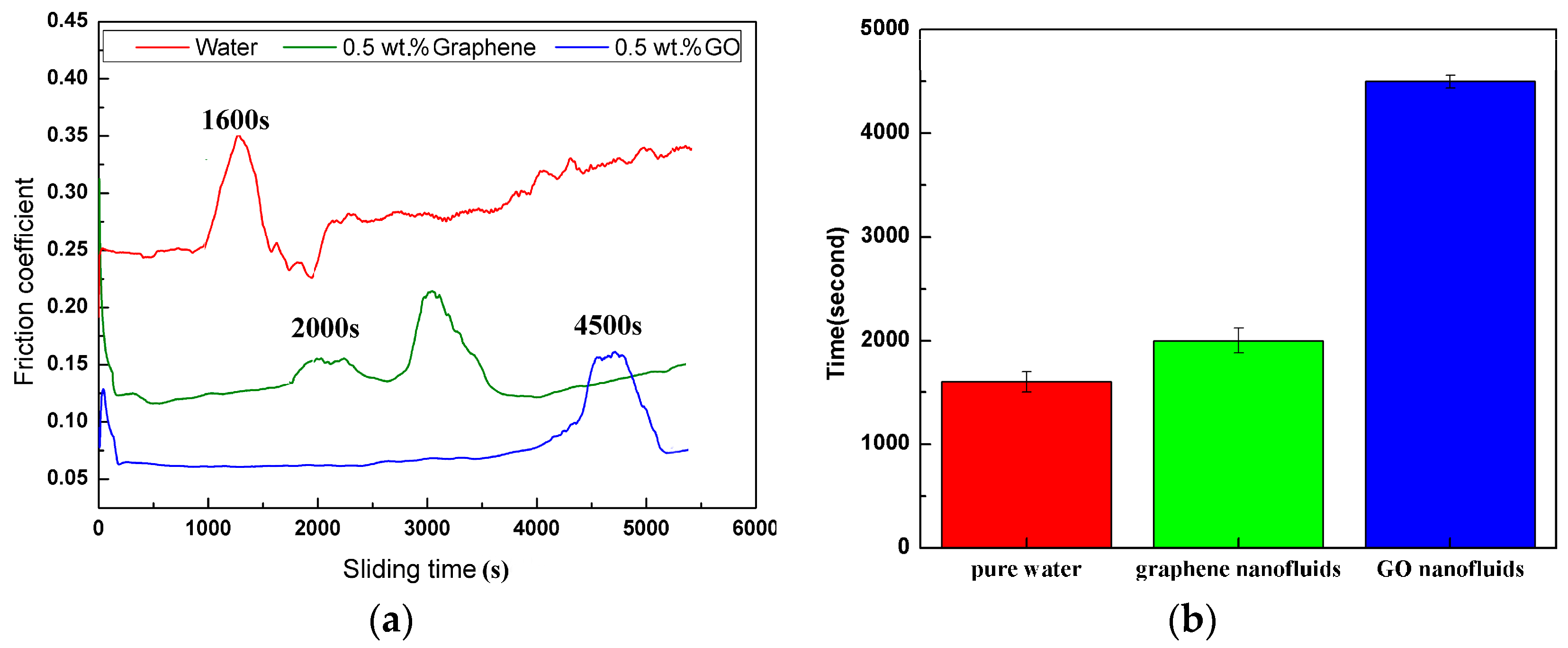

3.3. The Endurance of Lubrication Film

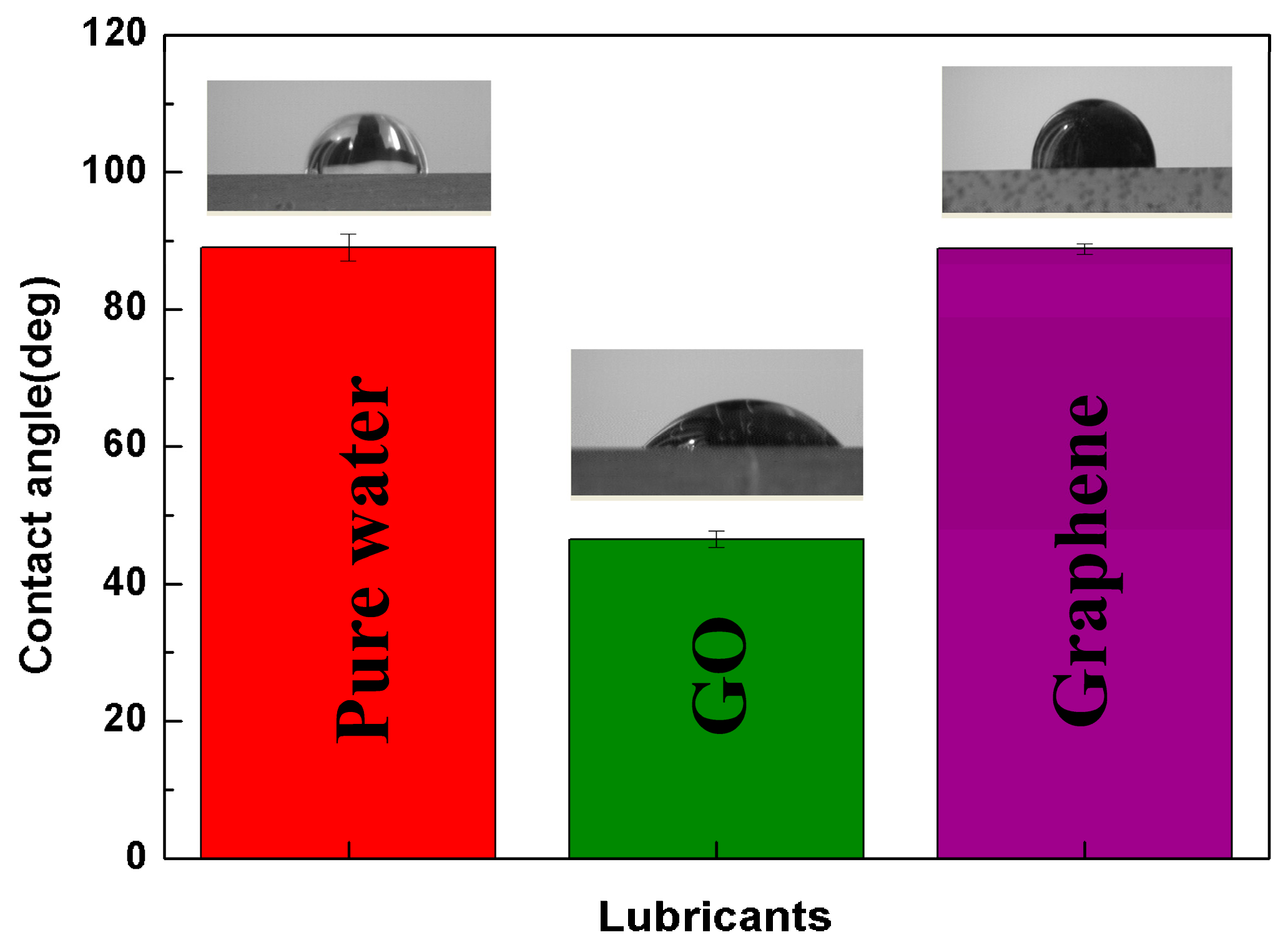

3.4. Surface Wettability Test

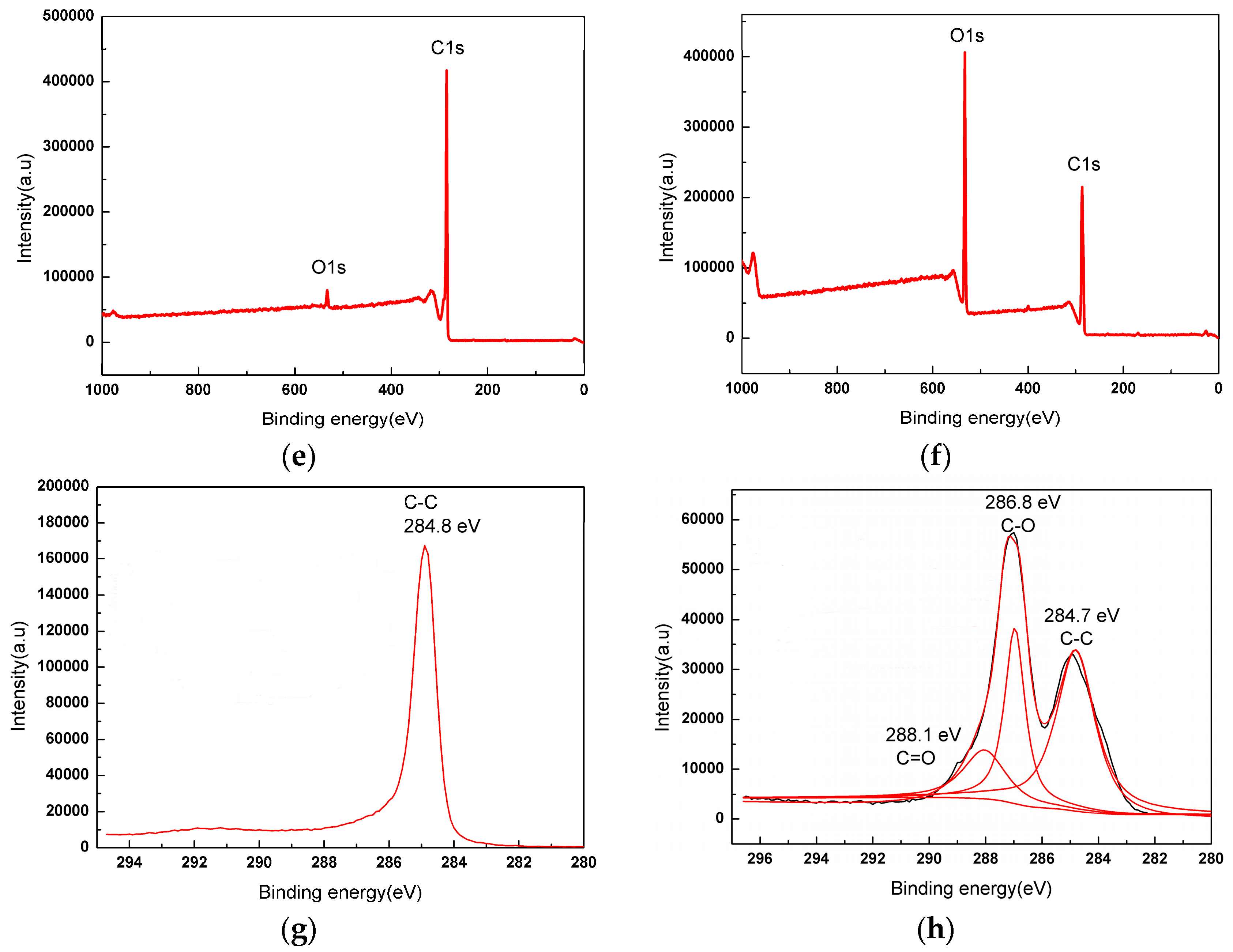

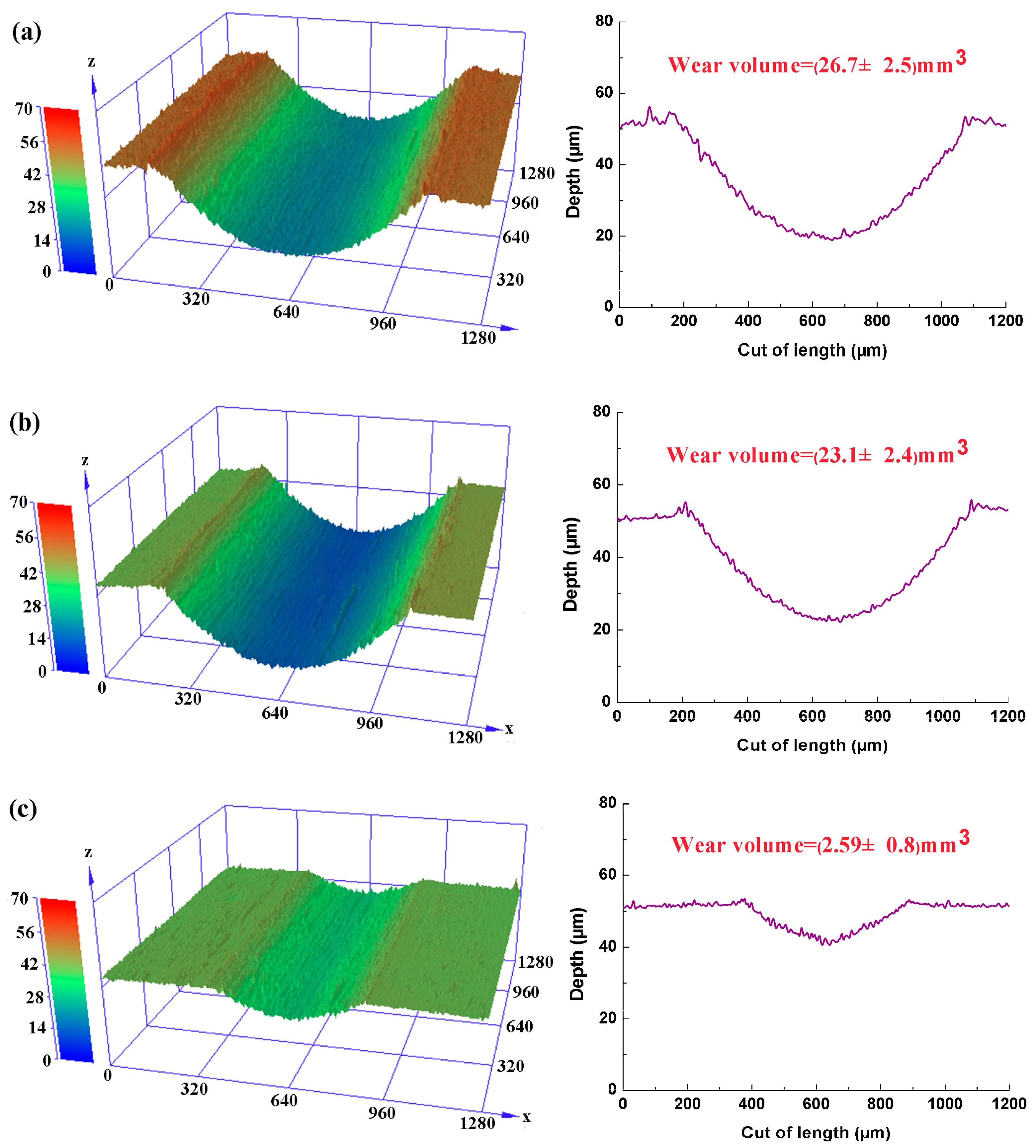

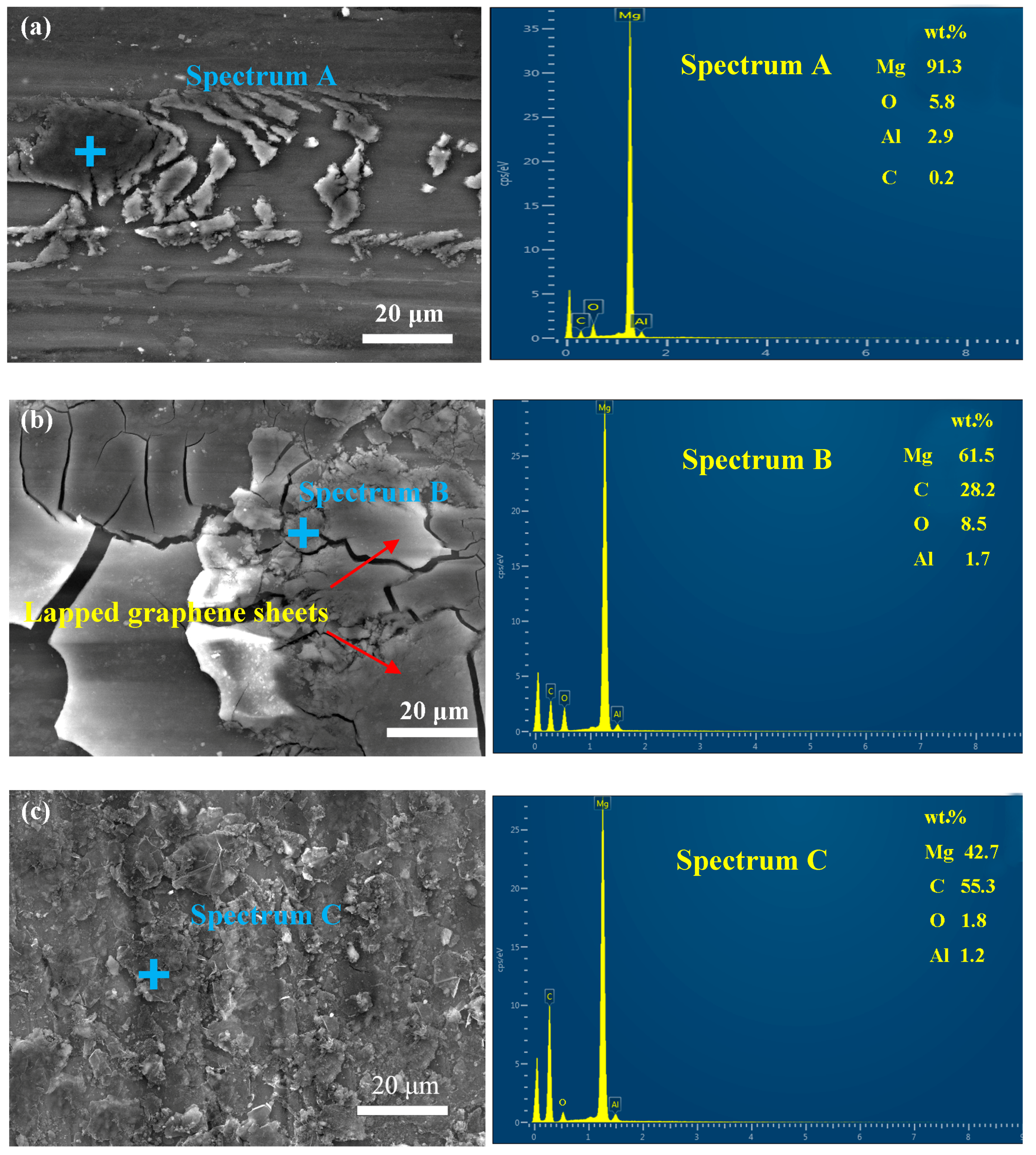

3.5. The Worn Surface Analysis

3.6. Related Tribological Mechanism of Nanofluids

4. Conclusions

- (1)

- Graphene and GO as water-based lubricant additives improved the friction-reducing and anti-wear abilities. The best tribological response of the magnesium alloy/steel pairs evaluated was obtained when graphene or GO at a concentration of 0.5 wt.% was added to water.

- (2)

- Graphene and GO exhibited different friction-reducing and anti-wear efficiencies, and the tribological performances of GO are superior to that of graphene. Meanwhile, the positive effect of the GOnanofluids was also more pronounced in terms of the load-carrying capacity and the lubrication film endurance.

- (3)

- The prominent lubricant performance of GO nanofluids can be attributed to the strong affinity between GO sheets and magnesium alloy surface, superior dispersion in the water and excellent wetting of the GO nanofluids on the magnesium alloy surface.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Aatthisugan, I.; Rose, A.R.; Jebadurai, D.S. Mechanical and wear behaviour of AZ91D magnesium matrix hybrid composite reinforced with boron carbide and graphite. J. Magnes. Alloys 2017, 5, 20–25. [Google Scholar] [CrossRef]

- Li, Q.; Huang, G.J.; Huang, X.D.; Pan, S.W.; Tan, C.L.; Liu, Q. On the texture evolution of Mg–Zn–Ca alloy with different hot rolling paths. J. Magnes. Alloys 2017, 5, 166–172. [Google Scholar] [CrossRef]

- Griffiths, D. Explaining texture weakening and improved formability in magnesium rare earth alloys. Mater. Sci. Technol. 2014, 31, 10–24. [Google Scholar] [CrossRef]

- Selvam, B.; Marimuthu, P.; Narayanasamy, R.; Senthilkumar, V.; Tun, K.S.; Gupta, M. Effect of temperature and strain rate on compressive response of extruded magnesium nano-composite. J. Magnes. Alloys 2015, 3, 224–230. [Google Scholar] [CrossRef]

- Podgornik, B.; Kosec, T.; Kocijan, A.; Donik, Č. Tribological behaviour and lubrication performance of hexagonal boron nitride (h-BN) as a replacement for graphite in aluminium forming. Tribol. Int. 2015, 81, 267–275. [Google Scholar] [CrossRef]

- Brostow, W.; Lobland, H.E.H. Materials: Introduction and Applications; John Wiley & Sons: New York, NY, USA, 2017. [Google Scholar]

- St. Dennis, J.E.; Jin, K.; John, V.T.; Pesika, N.S. Carbon Microspheres as Ball Bearings in Aqueous-Based Lubrication. ACS Appl. Mater. Interfaces 2011, 3, 2215–2218. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Jiang, B.; Wang, Q.; Xia, X.; Pan, F. Effects of combined additions of SiO2 and MoS2 nanoparticles as lubricant additive on the tribological properties of AZ31 magnesium alloy. Sci. China Technol. Sci. 2016, 59, 689–698. [Google Scholar] [CrossRef]

- Huang, W.; Du, C.; Li, Z.; Liu, M.; Liu, W. Tribological characteristics of magnesium alloy using N-containing compounds as lubricating additives during sliding. Wear 2006, 260, 140–148. [Google Scholar] [CrossRef]

- Huang, W.; Fu, Y.; Wang, J. Effect of chemical structure of borates on the tribological characteristics of magnesium alloy during sliding. Tribol. Int. 2005, 38, 775–780. [Google Scholar] [CrossRef]

- Xia, Y.Q.; Jia, Z.F.; Jia, J.H. Advanced Tribology; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Yan, L.; Yue, W.; Wang, C.; Wei, D.; Xu, B. Comparing tribological behaviors of sulfur- and phosphorus-free organomolybdenum additive with ZDDP and MoDTC. Tribol. Int. 2012, 53, 150–158. [Google Scholar] [CrossRef]

- Li, Z.; Li, X.; Zhang, Y.; Ren, T.; Zhao, Y.; Zeng, X.; van der Heide, E. Tribological study of a highly hydrolytically stable phenylboronic acid ester containing benzothiazolyl in mineral oil. Appl. Surf. Sci. 2014, 308, 91–99. [Google Scholar] [CrossRef]

- Cai, M.; Liang, Y.; Zhou, F.; Liu, W. Tribological properties of novel imidazolium ionic liquids bearing benzotriazole group as the antiwear/anticorrosion additive in poly(ethylene glycol) and polyurea grease for steel/steel contacts. ACS Appl. Mater. Interfaces 2011, 3, 4580–4592. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xu, H.; Wang, J.; Ye, X.; Lei, W.; Xue, M.; Tang, H.; Li, C. Synthesis of Ultrathin WS2 Nanosheets and Their Tribological Properties as Lubricant Additives. Nanoscale Res. Lett. 2016, 11, 442–451. [Google Scholar] [CrossRef] [PubMed]

- Yi, M.; Zhang, C. The synthesis of MoS2 particles with different morphologies for tribological applications. Tribol. Int. 2017, 116, 285–294. [Google Scholar] [CrossRef]

- Podgornik, B.; Kafexhiu, F.; Kosec, T.; Jerina, J.; Kalin, M. Friction and anti-galling properties of hexagonal boron nitride (h-BN) in aluminium forming. Wear 2017, 388–389, 2–8. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; Liu, B.; Wang, Q.; Xu, J.; Pan, F. An Investigation on the Tribological Performances of the SiO2/MoS2 Hybrid Nanofluids for Magnesium Alloy-Steel Contacts. Nanoscale Res. Lett. 2016, 11, 329–346. [Google Scholar] [CrossRef] [PubMed]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Li, P.F.; Zhou, H.; Cheng, X. Investigation of a hydrothermal reduced graphene oxide nano coating on Ti substrate and its nano-tribological behavior. Surf. Coat. Technol. 2014, 254, 298–304. [Google Scholar] [CrossRef]

- Min, C.; Nie, P.; Song, H.-J.; Zhang, Z.; Zhao, K. Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition. Tribol. Int. 2014, 80, 131–140. [Google Scholar] [CrossRef]

- Lahiri, D.; Hec, F.; Thiesse, M.; Durygin, A.; Zhang, C.; Agarwal, A. Nanotribological behavior of graphene nanoplatelet reinforced ultra high molecular weight polyethylene composites. Tribol. Int. 2014, 70, 165–169. [Google Scholar] [CrossRef]

- Shah, R.; Datashvili, T.; Cai, T.; Wahrmund, J.; Menard, B.; Menard, K.P.; Brostow, W.; Perez, J. Effects of functionalised reduced graphene oxide on frictional and wear properties of epoxy resin. Mater. Res. Innov. 2014, 19, 97–106. [Google Scholar] [CrossRef]

- Mungse, H.P.; Khatri, O.P. Chemically Functionalized Reduced Graphene Oxide as a Novel Material for Reduction of Friction and Wear. J. Phys. Chem. C 2014, 118, 14394–14402. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, X.; Ren, T.; de Vries, E.; van der Heide, E. The emulsifying and tribological properties of modified graphene oxide in oil-in-water emulsion. Tribol. Int. 2017, 105, 304–316. [Google Scholar] [CrossRef]

- Fan, X.; Xia, Y.; Wang, L.; Li, W. Multilayer Graphene as a Lubricating Additive in Bentone Grease. Tribol. Lett. 2014, 55, 455–464. [Google Scholar] [CrossRef]

- Zhao, J.; He, Y.; Wang, Y.; Wang, W.; Yan, L.; Luo, J. An investigation on the tribological properties of multilayer graphene and MoS2 nanosheets as additives used in hydraulic applications. Tribol. Int. 2016, 97, 14–20. [Google Scholar] [CrossRef]

- Liang, S.; Shen, Z.; Yi, M.; Liu, L.; Zhang, X.; Ma, S. In situ exfoliated graphene for high-performance water-based lubricants. Carbon 2016, 96, 1181–1190. [Google Scholar] [CrossRef]

- Brostow, W.; Kovačević, V.; Vrsaljko, D.; Whitworth, J. Tribology of polymers and polymer-based composites. J. Mater. Educ. 2010, 32, 273–290. [Google Scholar]

- Song, H.; Wang, Z.; Yang, J. Tribological properties of graphene oxide and carbon spheres as lubricating additives. Appl. Phys. A 2016, 122, 933–941. [Google Scholar] [CrossRef]

- Zin, V.; Barison, S.; Agresti, F.; Colla, L.; Paguraa, C.; Fabrizioa, M. Improved tribological and thermal properties of lubricants by graphene-based nano-additives. RSC Adv. 2016, 6, 59477–59486. [Google Scholar] [CrossRef]

- Jaiswal, V.; Kalyani; Umrao, S.; Rastogi, R.B.; Kumar, R.; Srivastava, A. Synthesis, Characterization, and Tribological Evaluation of TiO2-Reinforced Boron and Nitrogen co-Doped Reduced Graphene Oxide Based Hybrid Nanomaterials as Efficient Antiwear Lubricant Additives. ACS Appl. Mater. Interfaces 2016, 8, 11698–11710. [Google Scholar] [PubMed]

- Meng, Y.; Su, F.; Chen, Y. Au/Graphene Oxide Nanocomposite Synthesized in Supercritical CO2 Fluid as Energy Efficient Lubricant Additive. ACS Appl. Mater. Interfaces 2017, 9, 39549–39559. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, K.; Gyawali, G.; Lee, S.W. Graphene Coating via Chemical Vapor Deposition for Improving Friction and Wear of Gray Cast Iron at Interfaces. ACS Appl. Mater. Interfaces 2017, 9, 32336–32351. [Google Scholar] [CrossRef] [PubMed]

- Ismail, N.A.; Bagheri, S. Highly oil-dispersed functionalized reduced graphene oxide nanosheets as lube oil friction modifier. Mater. Sci. Eng. B 2017, 222, 34–42. [Google Scholar] [CrossRef]

- Zheng, D.; Cai, Z.-B.; Shen, M.-X.; Li, Z.-Y.; Zhu, M.-H. Investigation of the tribology behaviour of the graphene nanosheets as oil additives on textured alloy cast iron surface. Appl. Surf. Sci. 2016, 387, 66–75. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts: Part III—Fully Flooded Results. J. Lubr. Technol. 1977, 99, 264–302. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Ball Bearing Lubrication: The Elastohydrodynamics of Elliptical Contacts; John Wiley & Sons: Hoboken, NJ, USA, 1981. [Google Scholar]

- Qu, J.; Wang, J.; Liu, S.; Mu, B.; Ren, J.; Wang, H.; Yang, S. Tribology Study of Reduced Graphene Oxide Sheets on Silicon Substrate Synthesized via Covalent Assembly. Langmuir 2010, 26, 15830–15836. [Google Scholar]

- He, A.; Huang, S.; Yun, J.-H.; Wu, H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. Tribological Performance and Lubrication Mechanism of Alumina Nanoparticle Water-Based Suspensions in Ball-on-Three-Plate Testing. Tribol. Lett. 2017, 65, 40–45. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L.; et al. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, X.; Wang, Z.; Liu, Y.; You, T. Preparation of water-soluble nanographite and its application in water-based cutting fluid. Nanoscale Res. Lett. 2013, 8, 52–60. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Jiang, D. Molecular dynamics simulation of mechanical performance of graphene/graphene oxide paper-based polymer composites. Carbon 2014, 67, 784–791. [Google Scholar] [CrossRef]

- Kim, H.J.; Kim, D.E. Water Lubrication of Stainless Steel using Reduced Graphene Oxide Coating. Sci. Rep. 2015, 5, 17034–17047. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, A.K.; Khalid, M.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Graphene-based nanofluids and nanolubricants—Review of recent developments. Renew. Sustain. Energy Rev. 2016, 63, 346–362. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S. 2D nanomaterials as lubricant additive: A review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

| Material | 0.2% YS/MPa | UTS/MPa | Elongation/% | HV0.01 |

|---|---|---|---|---|

| Extruded AZ31 | 142.1 | 305 | 18.5 | 66.7 |

| Test | Load (N) | Contact Pressure (MPa) | Sliding Speed (m/s) | Sliding Time (h) | Lubricants |

|---|---|---|---|---|---|

| The effect of concentration | 3 | 312 | 0.08 | 0.5 h | Water Graphene nanofluids with different concentration GO nanofluids with different concentration |

| Carrying capacity | 1 | 223 | 0.08 | 0.5 h | Water 0.5 wt.% Graphene nanofluids 0.5 wt.% GO nanofluids |

| 3 | 312 | ||||

| 5 | 381 | ||||

| 8 | 446 | ||||

| Endurance of lubrication film | 8 | 446 | 0.03 | 1.5 h | Water 0.5 wt.% Graphene nanofluids 0.5 wt.% GO nanofluids |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Jiang, B.; Dai, J.; Peng, C.; Li, C.; Li, Q.; Pan, F. Tribological Behaviors of Graphene and Graphene Oxide as Water-Based Lubricant Additives for Magnesium Alloy/Steel Contacts. Materials 2018, 11, 206. https://doi.org/10.3390/ma11020206

Xie H, Jiang B, Dai J, Peng C, Li C, Li Q, Pan F. Tribological Behaviors of Graphene and Graphene Oxide as Water-Based Lubricant Additives for Magnesium Alloy/Steel Contacts. Materials. 2018; 11(2):206. https://doi.org/10.3390/ma11020206

Chicago/Turabian StyleXie, Hongmei, Bin Jiang, Jiahong Dai, Cheng Peng, Chunxia Li, Quan Li, and Fusheng Pan. 2018. "Tribological Behaviors of Graphene and Graphene Oxide as Water-Based Lubricant Additives for Magnesium Alloy/Steel Contacts" Materials 11, no. 2: 206. https://doi.org/10.3390/ma11020206