Interface Tailoring Effect for Heusler Based CPP-GMR with an L12-Type Ag3Mg Spacer

Abstract

:1. Introduction

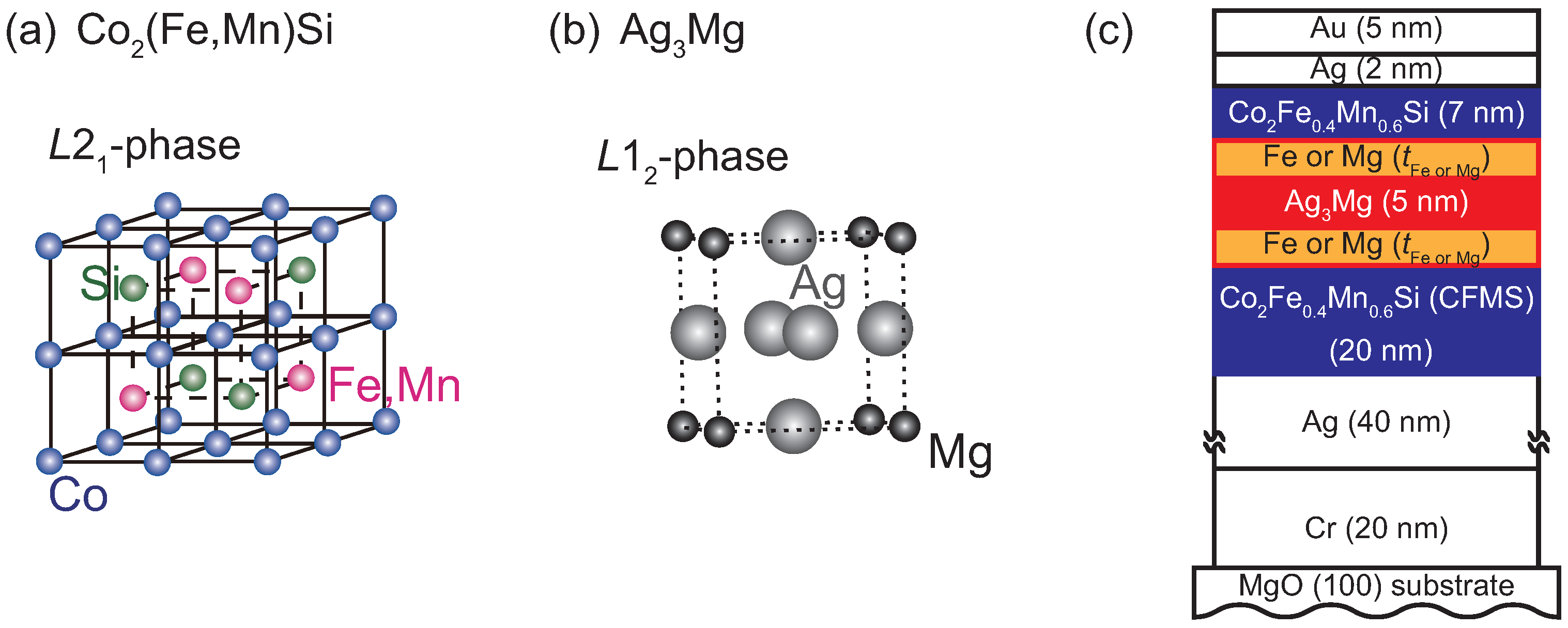

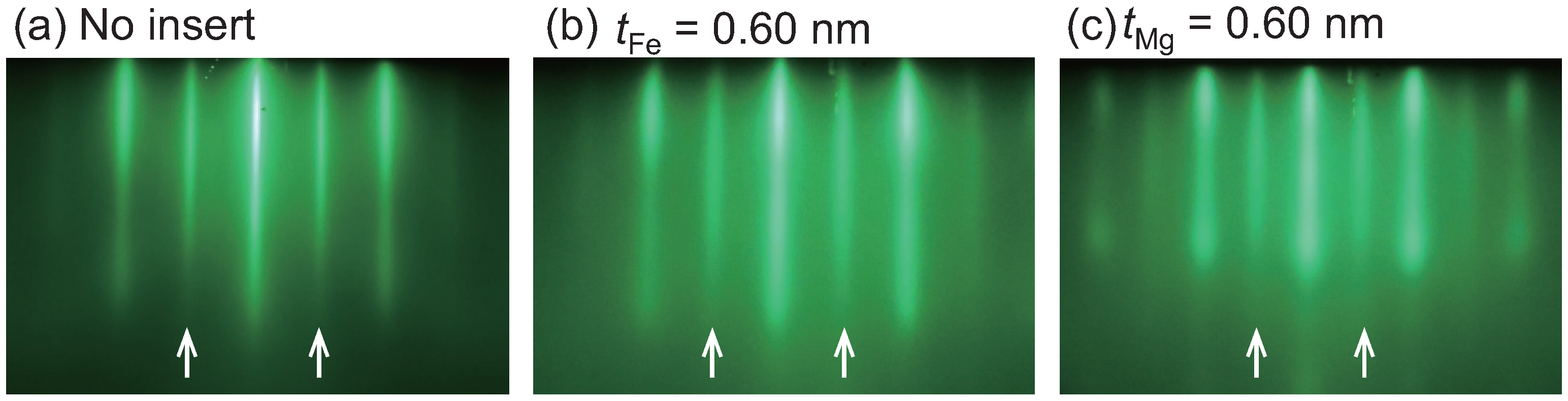

2. Materials and Methods

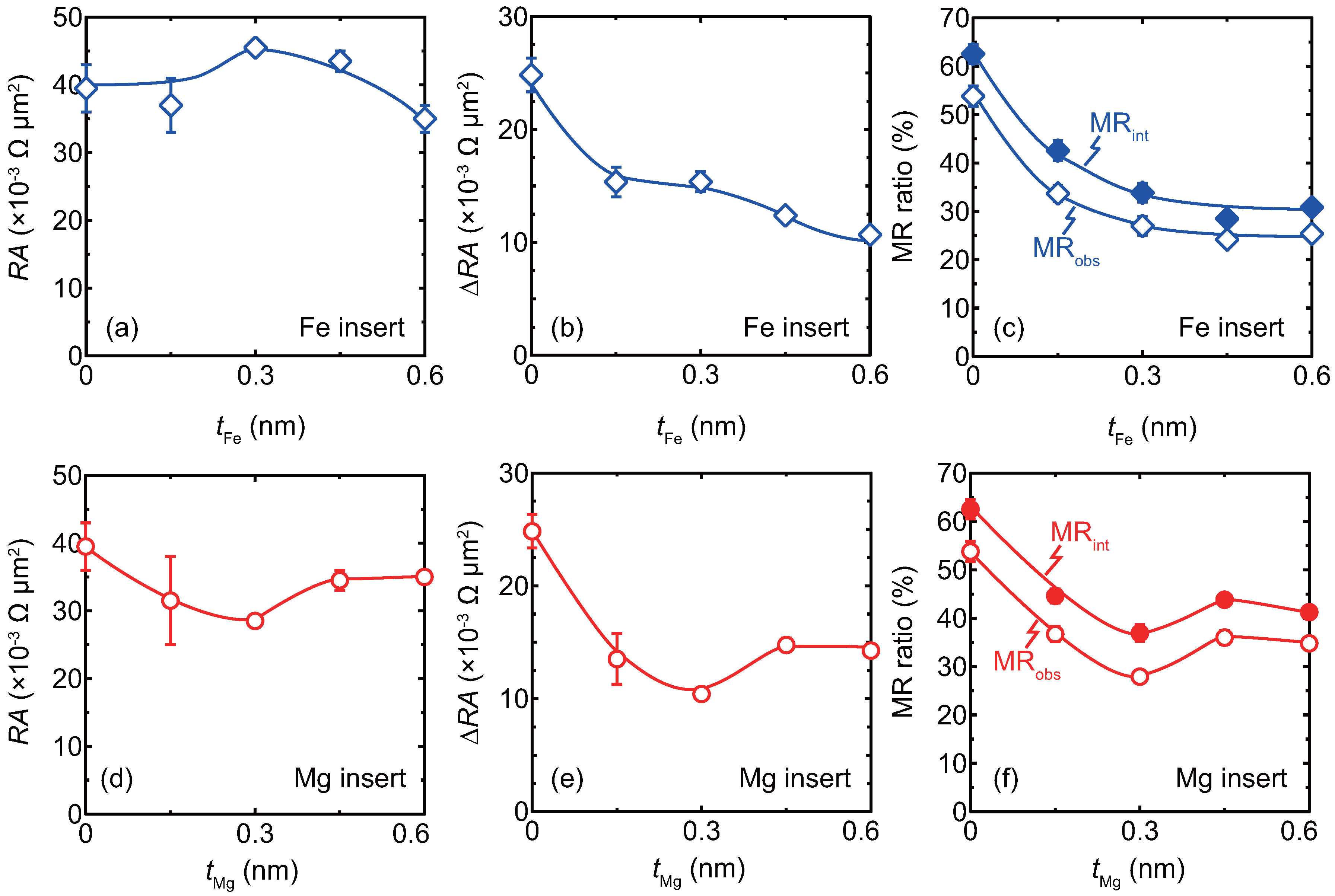

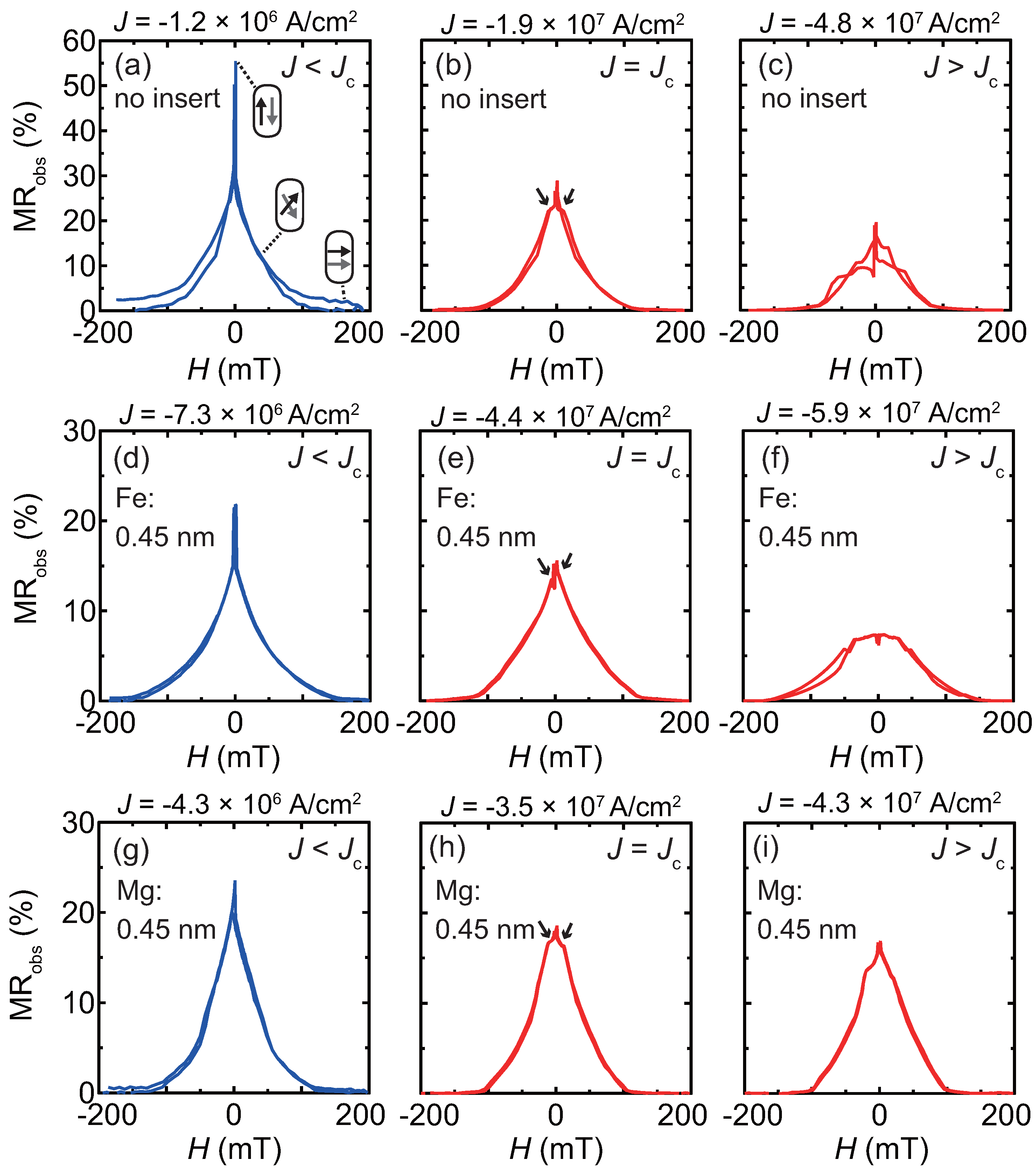

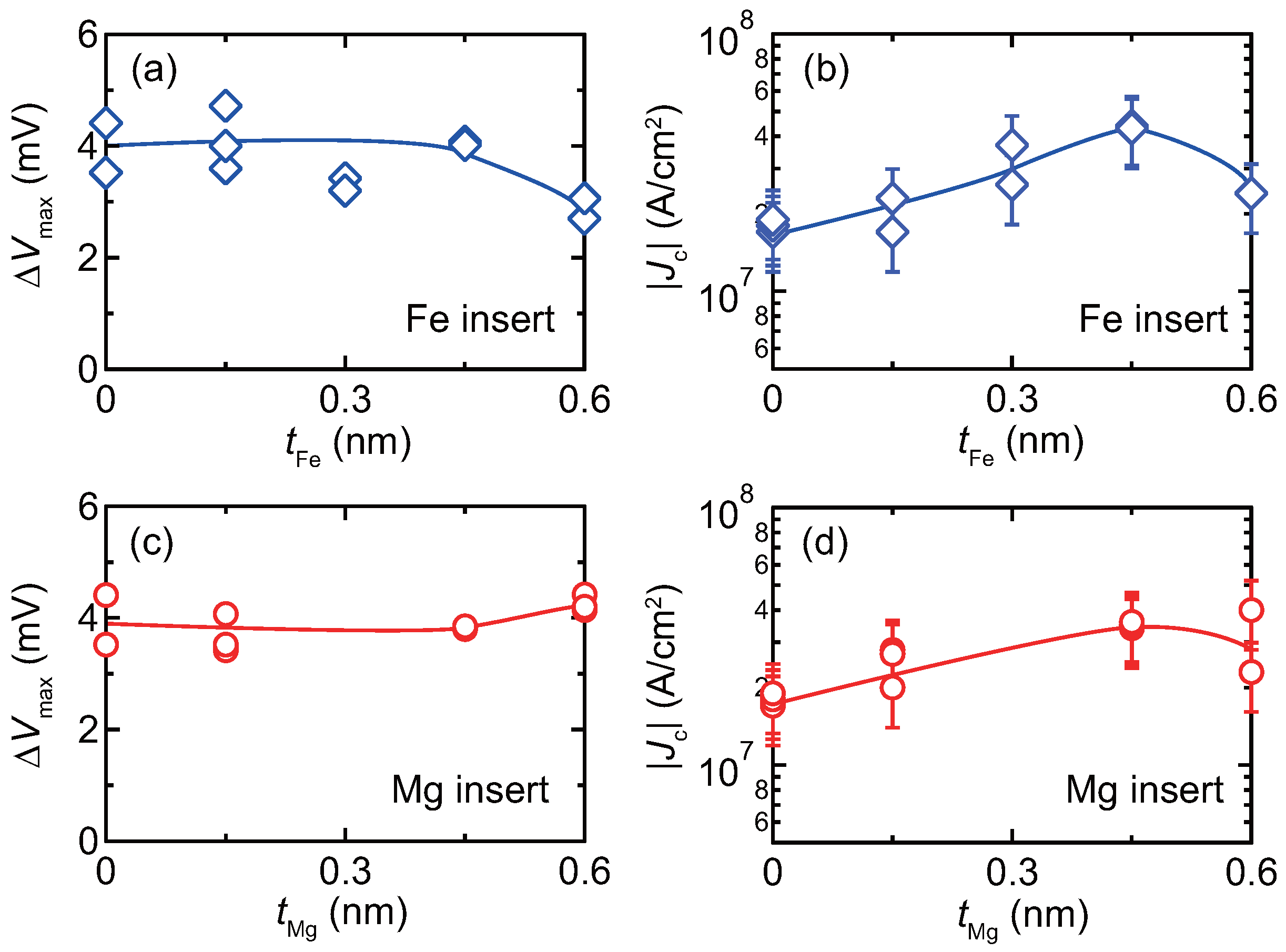

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Takagishi, M.; Koi, K.; Yoshikawa, M.; Funayama, T.; Iwasaki, H.; Sahashi, M. The applicability of CPP-GMR heads for magnetic recording. IEEE Trans. Magn. 2002, 38, 2277–2282. [Google Scholar] [CrossRef]

- Childress, J.R.; Carey, M.J.; Maat, S.; Smith, N.; Fontana, R.E.; Druist, D.; Carey, K.; Katine, J.A.; Robertson, N.; Boone, T.D.; et al. All-Metal Current-Perpendicular-to-Plane Giant Magnetoresistance Sensors for Narrow-Track Magnetic Recording. IEEE Trans. Magn. 2008, 44, 90–94. [Google Scholar] [CrossRef]

- Takagishi, M.; Yamada, K.; Iwasaki, H.; Fuke, H.N.; Hashimoto, S. Magnetoresistance Ratio and Resistance Area Design of CPP-MR Film for 2–5 Tb/in2 Read Sensors. IEEE Trans. Magn. 2010, 46, 2086–2089. [Google Scholar] [CrossRef]

- Hirohata, A.; Sukegawa, H.; Yanagihara, H.; Zutic, I.; Seki, T.; Mizukami, S.; Swaminathan, R. Roadmap for Emerging Materials for Spintronic Device Applications. IEEE Trans. Magn. 2015, 51, 1–11. [Google Scholar] [CrossRef]

- Nagamine, Y.; Maehara, H.; Tsunekawa, K.; Djayaprawira, D.D.; Watanabe, N.; Yuasa, S.; Ando, K. Ultralow resistance-area product of 0.4 Ωμm2 and high magnetoresistance above 50% in CoFeB/MgO/CoFeB magnetic tunnel junctions. Appl. Phys. Lett. 2006, 89, 162507. [Google Scholar] [CrossRef]

- Maehara, H.; Nishimura, K.; Nagamine, Y.; Tsunekawa, K.; Seki, T.; Kubota, H.; Fukushima, A.; Yakushiji, K.; Ando, K.; Yuasa, S. Tunnel Magnetoresistance above 170% and Resistance–Area Product of 1 Ω(μm)2 Attained by In situ Annealing of Ultra-Thin MgO Tunnel Barrier. Appl. Phys. Express 2011, 4, 033002. [Google Scholar] [CrossRef]

- Butler, W.H.; Zhang, X.G.; Schulthess, T.C.; MacLaren, J.M. Spin-dependent tunneling conductance of Fe|MgO|Fe sandwiches. Phys. Rev. B 2001, 63, 054416. [Google Scholar] [CrossRef]

- Mathon, J.; Umerski, A. Theory of tunneling magnetoresistance of an epitaxial Fe/MgO/Fe(001) junction. Phys. Rev. B 2001, 63, 220403. [Google Scholar] [CrossRef]

- Valet, T.; Fert, A. Theory of the perpendicular magnetoresistance in magnetic multilayers. Phys. Rev. B 1993, 48, 7099–7113. [Google Scholar] [CrossRef]

- Felser, C.; Fecher, G.; Balke, B. Spintronics: A Challenge for Materials Science and Solid-State Chemistry. Angew. Chem. Int. Ed. 2007, 46, 668–699. [Google Scholar] [CrossRef] [PubMed]

- Yakushiji, K.; Saito, K.; Mitani, S.; Takanashi, K.; Takahashi, Y.K.; Hono, K. Current-perpendicular-to-plane magnetoresistance in epitaxial Co2MnSiCrCo2MnSi trilayers. Appl. Phys. Lett. 2006, 88, 222504. [Google Scholar] [CrossRef]

- Iwase, T.; Sakuraba, Y.; Bosu, S.; Saito, K.; Mitani, S.; Takanashi, K. Large Interface Spin-Asymmetry and Magnetoresistance in Fully Epitaxial Co2MnSi/Ag/Co2MnSi Current-Perpendicular-to-Plane Magnetoresistive Devices. Appl. Phys. Express 2009, 2, 063003. [Google Scholar] [CrossRef]

- Furubayashi, T.; Kodama, K.; Sukegawa, H.; Takahashi, Y.K.; Inomata, K.; Hono, K. Current-perpendicular-to-plane giant magnetoresistance in spin-valve structures using epitaxial Co2FeAl0.5Si0.5/Ag/Co2FeAl0.5Si0.5 trilayers. Appl. Phys. Lett. 2008, 93, 122507. [Google Scholar] [CrossRef]

- Nakatani, T.M.; Furubayashi, T.; Kasai, S.; Sukegawa, H.; Takahashi, Y.K.; Mitani, S.; Hono, K. Bulk and interfacial scatterings in current-perpendicular-to-plane giant magnetoresistance with Co2Fe(Al0.5Si0.5) Heusler alloy layers and Ag spacer. Appl. Phys. Lett. 2010, 96, 212501. [Google Scholar] [CrossRef]

- Maat, S.; Carey, M.J.; Childress, J.R. Current perpendicular to the plane spin-valves with CoFeGe magnetic layers. Appl. Phys. Lett. 2008, 93, 143505. [Google Scholar] [CrossRef]

- Carey, M.J.; Maat, S.; Chandrashekariaih, S.; Katine, J.A.; Chen, W.; York, B.; Childress, J.R. Co2MnGe-based current-perpendicular-to-the-plane giant-magnetoresistance spin-valve sensors for recording head applications. J. Appl. Phys. 2011, 109, 093912. [Google Scholar]

- Sato, J.; Oogane, M.; Naganuma, H.; Ando, Y. Large Magnetoresistance Effect in Epitaxial Co2Fe0.4Mn0.6Si/ Ag/Co2Fe0.4Mn0.6Si Devices. Appl. Phys. Express 2011, 4, 113005. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Ueda, M.; Miura, Y.; Sato, K.; Bosu, S.; Saito, K.; Shirai, M.; Konno, T.J.; Takanashi, K. Extensive study of giant magnetoresistance properties in half-metallic Co2(Fe,Mn)Si-based devices. Appl. Phys. Lett. 2012, 101, 252408. [Google Scholar] [CrossRef]

- Li, S.; Takahashi, Y.K.; Furubayashi, T.; Hono, K. Enhancement of giant magnetoresistance by L21 ordering in Co2Fe(Ge0.5Ga0.5) Heusler alloy current-perpendicular-to-plane pseudo spin valves. Appl. Phys. Lett. 2013, 103, 042405. [Google Scholar] [CrossRef]

- Nikolaev, K.; Kolbo, P.; Pokhil, T.; Peng, X.; Chen, Y.; Ambrose, T.; Mryasov, O. “All-Heusler alloy” current-perpendicular-to-plane giant magnetoresistance. Appl. Phys. Lett. 2009, 94, 222501. [Google Scholar] [CrossRef]

- Ko, V.; Han, G.; Qiu, J.; Feng, Y.P. The band structure-matched and highly spin-polarized Co2CrZ/Cu2CrAl Heusler alloys interface. Appl. Phys. Lett. 2009, 95, 202502. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Izumi, K.; Iwase, T.; Bosu, S.; Saito, K.; Takanashi, K.; Miura, Y.; Futatsukawa, K.; Abe, K.; Shirai, M. Mechanism of large magnetoresistance in Co2MnSi/Ag/Co2MnSi devices with current perpendicular to the plane. Phys. Rev. B 2010, 82, 09444. [Google Scholar] [CrossRef]

- Miura, Y.; Futatsukawa, K.; Nakajima, S.; Abe, K.; Shirai, M. First-principles study of ballistic transport properties in Co2MnSi/X/Co2MnSi(001) (X = Ag, Au, Al, V, Cr) trilayers. Phys. Rev. B 2011, 84, 134432. [Google Scholar] [CrossRef]

- Kubota, T.; Oogane, M.; Mizukami, S.; Naganuma, H.; Ando, Y.; Miyazaki, T. Magnetoresistance Effect in Co2MnSi/semimetallic-Fe2VAl/CoFe Junctions. J. Phys. Conf. Ser. 2011, 266, 012096. [Google Scholar] [CrossRef]

- Li, S.; Takahashi, Y.K.; Sakuraba, Y.; Chen, J.; Furubayashi, T.; Mryasov, O.; Faleev, S.; Hono, K. Current-perpendicular-to-plane giant magnetoresistive properties in Co2Mn(Ge0.75Ga0.25)/Cu2TiAl/Co2Mn (Ge0.75Ga0.25) all-Heusler alloy pseudo spin valve. J. Appl. Phys. 2016, 119, 093911. [Google Scholar]

- Hase, N.; Nakatani, T.; Kasai, S.; Takahashi, Y.; Furubayashi, T.; Hono, K. Effect of NiAl underlayer and spacer on magnetoresistance of current-perpendicular-to-plane spin valves using Co2Mn(Ga0.5Sn0.5) Heusler alloy. J. Magn. Magn. Mater. 2012, 324, 440–444. [Google Scholar] [CrossRef]

- Furubayashi, T.; Takahashi, Y.K.; Sasaki, T.T.; Hono, K. Enhancement of current-perpendicular-to-plane giant magnetoresistance in Heusler-alloy based pseudo spin valves by using a CuZn spacer layer. J. Appl. Phys. 2015, 118, 163901. [Google Scholar] [CrossRef]

- Li, S.; Nakatani, T.; Masuda, K.; Sakuraba, Y.; Xu, X.; Sasaki, T.; Tajiri, H.; Miura, Y.; Furubayashi, T.; Hono, K. Enhancement of current-perpendicular-to-plane giant magnetoresistive outputs by improving B2-order in polycrystalline Co2(Mn0.6Fe0.4)Ge Heusler alloy films with the insertion of amorphous CoFeBTa underlayer. Acta Mater. 2018, 142, 49–57. [Google Scholar] [CrossRef]

- Nakatani, T.; Mihajlović, G.; Read, J.C.; Suk Choi, Y.; Childress, J.R. High signal output in current-perpendicular- to-the-plane giant magnetoresistance sensors using In-Zn-O-based spacer layers. Appl. Phys. Express 2015, 8, 093003. [Google Scholar]

- Balke, B.; Fecher, G.H.; Kandpal, H.C.; Felser, C.; Kobayashi, K.; Ikenaga, E.; Kim, J.J.; Ueda, S. Properties of the quaternary half-metal-type Heusler alloy Co2Mn1-xFexSi. Phys. Rev. B 2006, 74, 104405. [Google Scholar] [CrossRef]

- Kubota, T.; Tsunegi, S.; Oogane, M.; Mizukami, S.; Miyazaki, T.; Naganuma, H.; Ando, Y. Half-metallicity and Gilbert damping constant in Co2FexMn1-xSi Heusler alloys depending on the film composition. Appl. Phys. Lett. 2009, 94, 122504. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Ueda, M.; Bosu, S.; Saito, K.; Takanashi, K. CPP-GMR study of half-metallic full-Heusler compound Co2(Fe,Mn)Si. J. Magn. Soc. Jpn. 2014, 38, 45–49. [Google Scholar] [CrossRef]

- Yako, H.; Sakuraba, Y.; Amemiya, K.; Sakamaki, M.; Kubota, T.; Sasaki, T.; Miura, Y.; Hono, K.; Takanashi, K. Investigation of the exchange stiffness at Co2MnSi/Ag and Co2FeSi/Ag interfaces using the depth-resolved X-ray magnetic circular dichroism. In Proceedings of the 59th Annual Conference on Magnetism and Magnetic Materials, Honolulu, HI, USA, 3–7 November 2014; p. EP–13. [Google Scholar]

- Kubota, T.; Ina, Y.; Tsujikawa, M.; Morikawa, S.; Narisawa, H.; Wen, Z.; Shirai, M.; Takanashi, K. Current perpendicular-to-plane giant magnetoresistance devices using half-metallic Co2Fe0.4Mn0.6Si electrodes and a Ag-Mg spacer. J. Phys. D Appl. Phys. 2016, 50, 014004. [Google Scholar] [CrossRef]

- Narisawa, H.; Kubota, T.; Takanashi, K. Current perpendicular to film plane type giant magnetoresistance effect using a Ag-Mg spacer and Co2Fe0.4Mn0.6Si Heusler alloy electrodes. Appl. Phys. Express 2015, 8, 063008. [Google Scholar] [CrossRef]

- Kubota, T.; Ina, Y.; Wen, Z.; Narisawa, H.; Takanashi, K. Current perpendicular-to-plane giant magnetoresistance using an L12 Ag3Mg spacer and Co2Fe0.4Mn0.6Si Heusler alloy electrodes: Spacer thickness and annealing temperature dependence. Phys. Rev. Mater. 2017, 1, 044402. [Google Scholar] [CrossRef]

- Jung, J.W.; Sakuraba, Y.; Sasaki, T.T.; Miura, Y.; Hono, K. Enhancement of magnetoresistance by inserting thin NiAl layers at the interfaces in Co2FeGa0.5Ge0.5/Ag/Co2FeGa0.5Ge0.5 current-perpendicular-to-plane pseudo spin valves. Appl. Phys. Lett. 2016, 108, 102408. [Google Scholar] [CrossRef]

- Jung, J.W.; Sakuraba, Y.; Bosu, S.; Li, S.; Hono, K. Enhancement of Interfacial Spin-Dependent Scattering of Co2Fe(Ga0.5Ge0.5)/Ag/Co2Fe(Ga0.5Ge0.5) Current-Perpendicular-to-Plane Giant Magnetoresistive Pseudo-Spin Valves. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Aballe, L.; Rogero, C.; Horn, K. Quantum-size effects in ultrathin Mg films: Electronic structure and collective excitations. Surf. Sci. 2002, 518, 141–154. [Google Scholar] [CrossRef]

- Narisawa, H.; Kubota, T.; Takanashi, K. Reply to “Comment on ‘Current perpendicular to film plane type giant magnetoresistance effect using a Ag-Mg spacer and Co2Fe0.4Mn0.6Si Heusler alloy electrodes”. Appl. Phys. Express 2015, 8, 119102. [Google Scholar] [CrossRef]

- Nakatani, T.M.; Mitani, S.; Furubayashi, T.; Hono, K. Oscillatory antiferromagnetic interlayer exchange coupling in Co2Fe(Al0.5Si0.5)/Ag/Co2Fe(Al0.5Si0.5) films and its application to trilayer magnetoresistive sensor. Appl. Phys. Lett. 2011, 99, 182505. [Google Scholar] [CrossRef]

- Oogane, M.; Kubota, T.; Kota, Y.; Mizukami, S.; Naganuma, H.; Sakuma, A.; Ando, Y. Gilbert magnetic damping constant of epitaxially grown Co-based Heusler alloy thin films. Appl. Phys. Lett. 2010, 96, 252501. [Google Scholar] [CrossRef]

- Oogane, M.; Wakitani, T.; Yakata, S.; Yilgin, R.; Ando, Y.; Sakuma, A.; Miyazaki, T. Magnetic Damping in Ferromagnetic Thin Films. Jpn. J. Appl. Phys. 2006, 45, 3889–3891. [Google Scholar] [CrossRef]

- Slonczewski, J. Current-driven excitation of magnetic multilayers. J. Magn. Magn. Mater. 1996, 159, L1–L7. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubota, T.; Ina, Y.; Wen, Z.; Takanashi, K. Interface Tailoring Effect for Heusler Based CPP-GMR with an L12-Type Ag3Mg Spacer. Materials 2018, 11, 219. https://doi.org/10.3390/ma11020219

Kubota T, Ina Y, Wen Z, Takanashi K. Interface Tailoring Effect for Heusler Based CPP-GMR with an L12-Type Ag3Mg Spacer. Materials. 2018; 11(2):219. https://doi.org/10.3390/ma11020219

Chicago/Turabian StyleKubota, Takahide, Yusuke Ina, Zhenchao Wen, and Koki Takanashi. 2018. "Interface Tailoring Effect for Heusler Based CPP-GMR with an L12-Type Ag3Mg Spacer" Materials 11, no. 2: 219. https://doi.org/10.3390/ma11020219