Radiation Resistance of the U(Al, Si)3 Alloy: Ion-Induced Disordering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Experimental Results

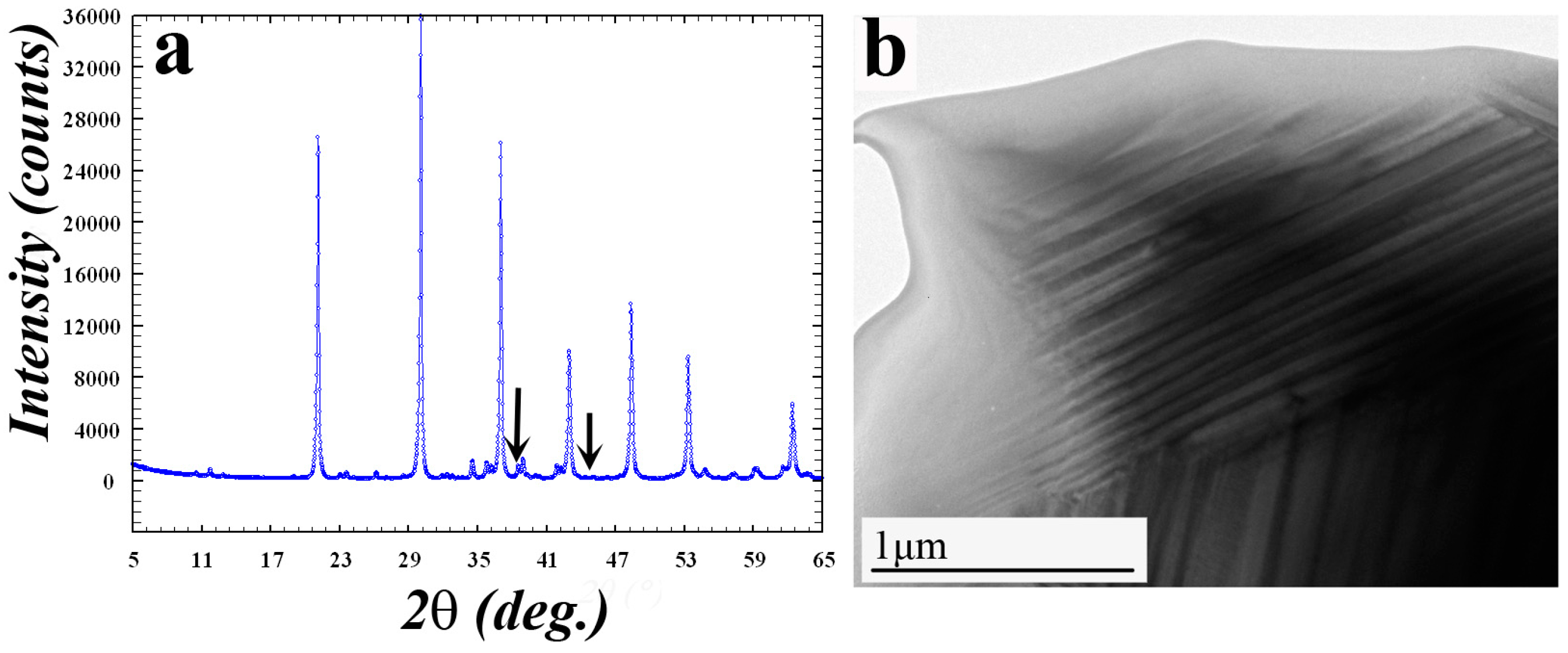

3.1.1. Initial Characterization of the Alloy

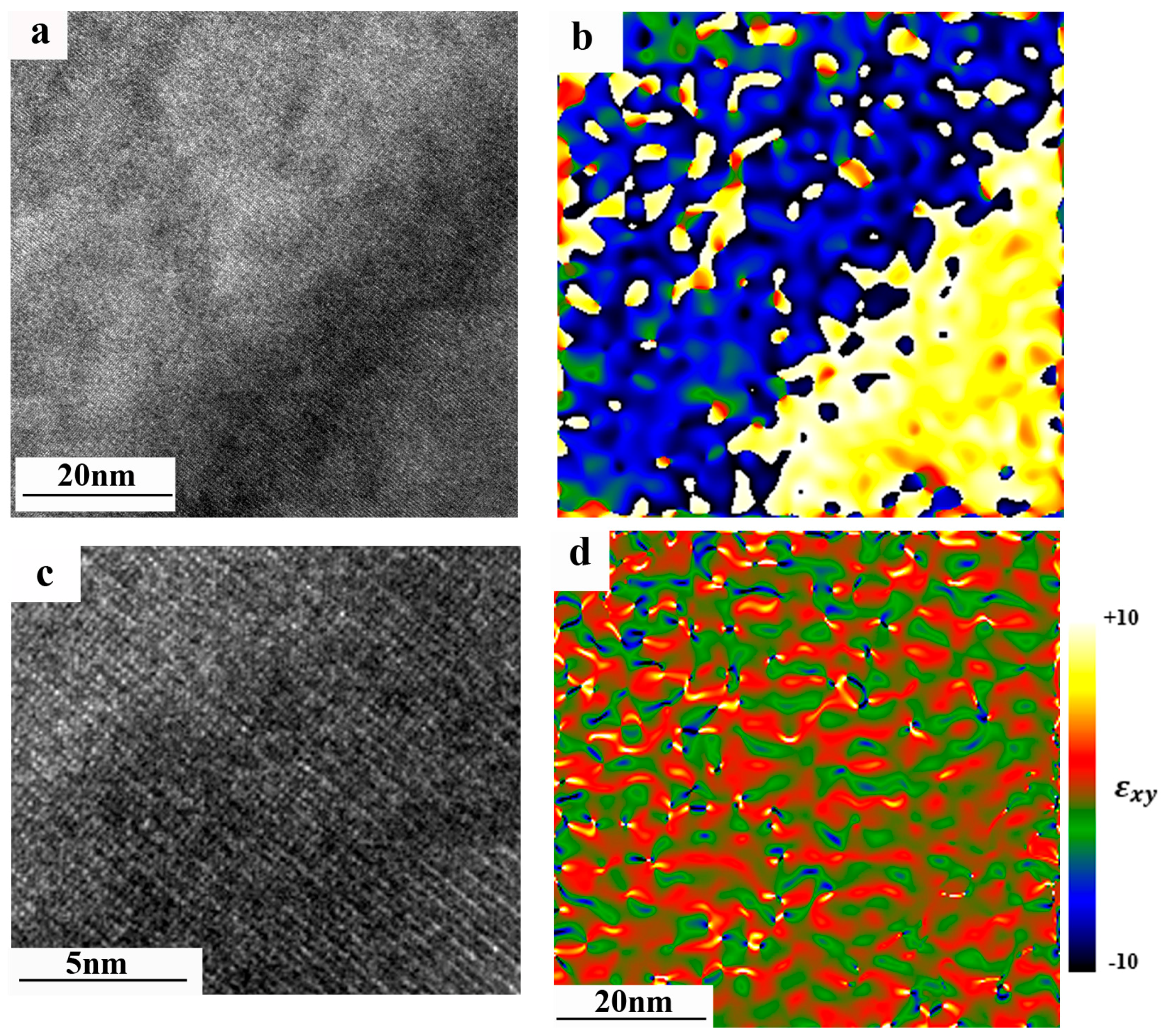

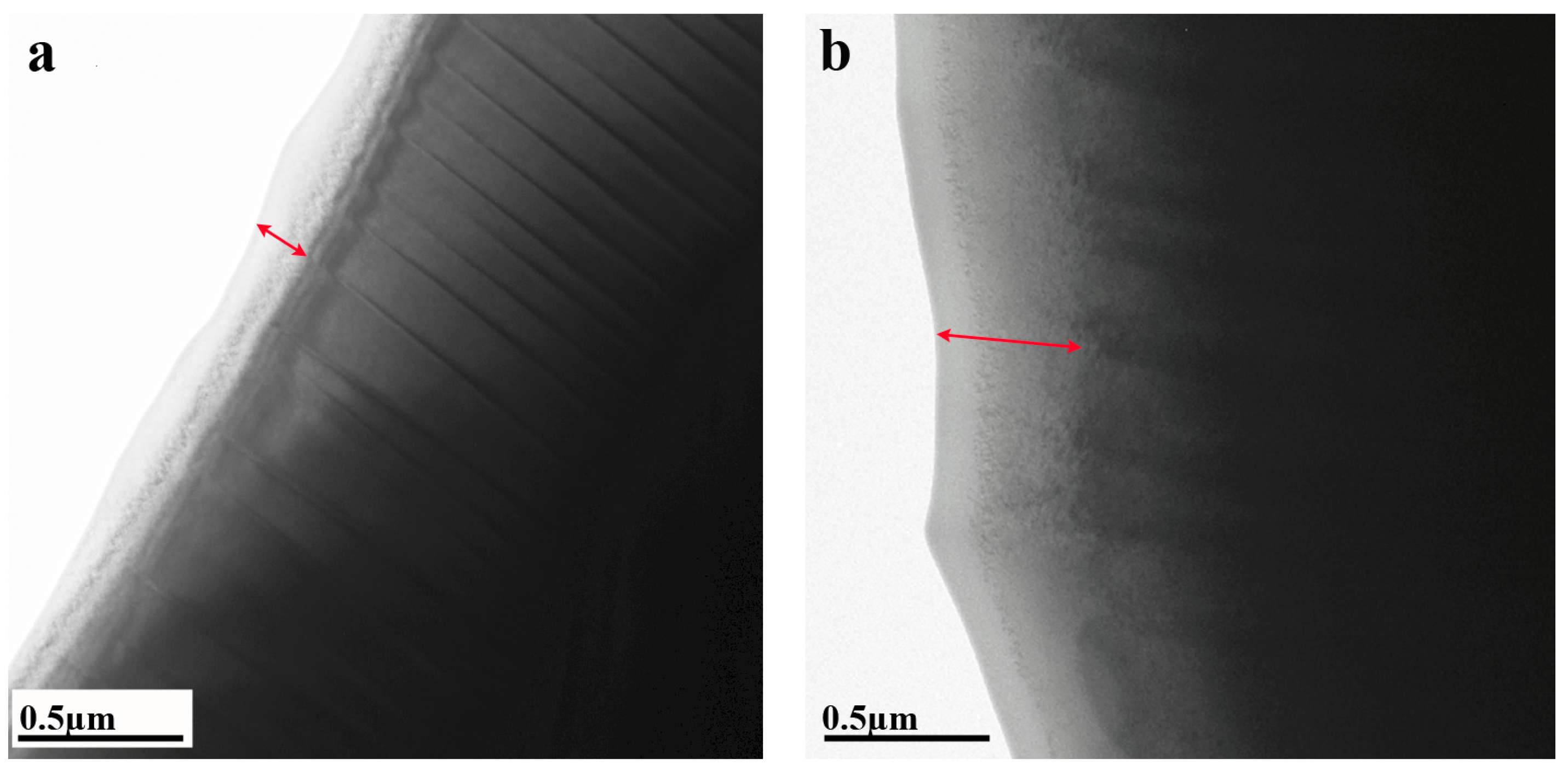

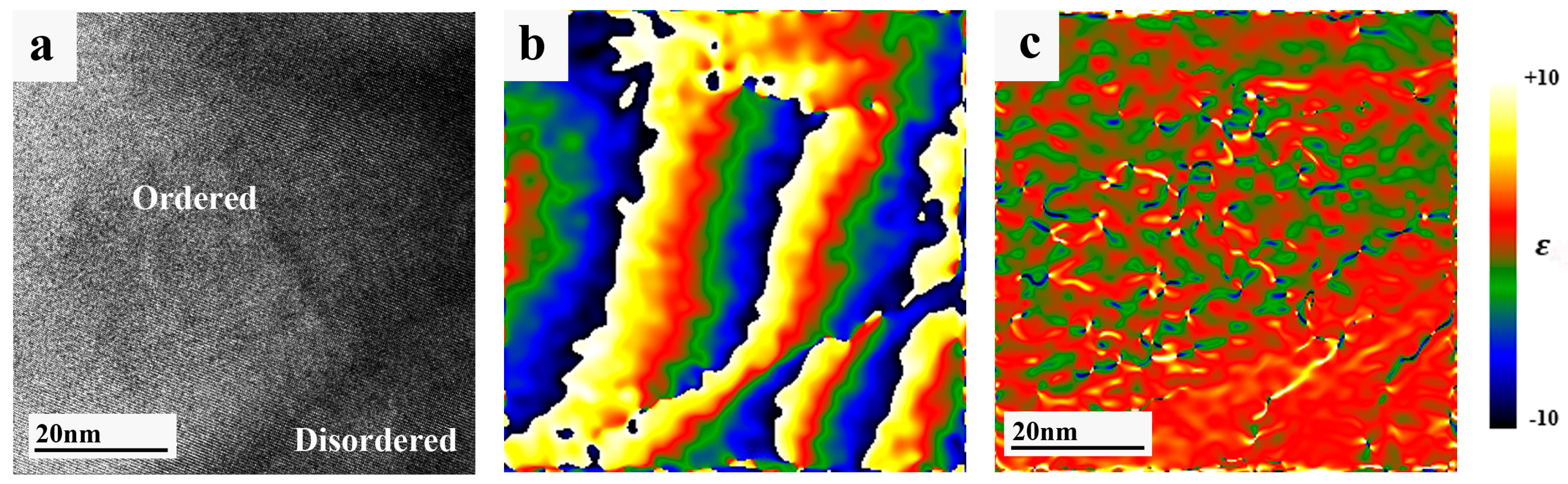

3.1.2. Samples after the Irradiation

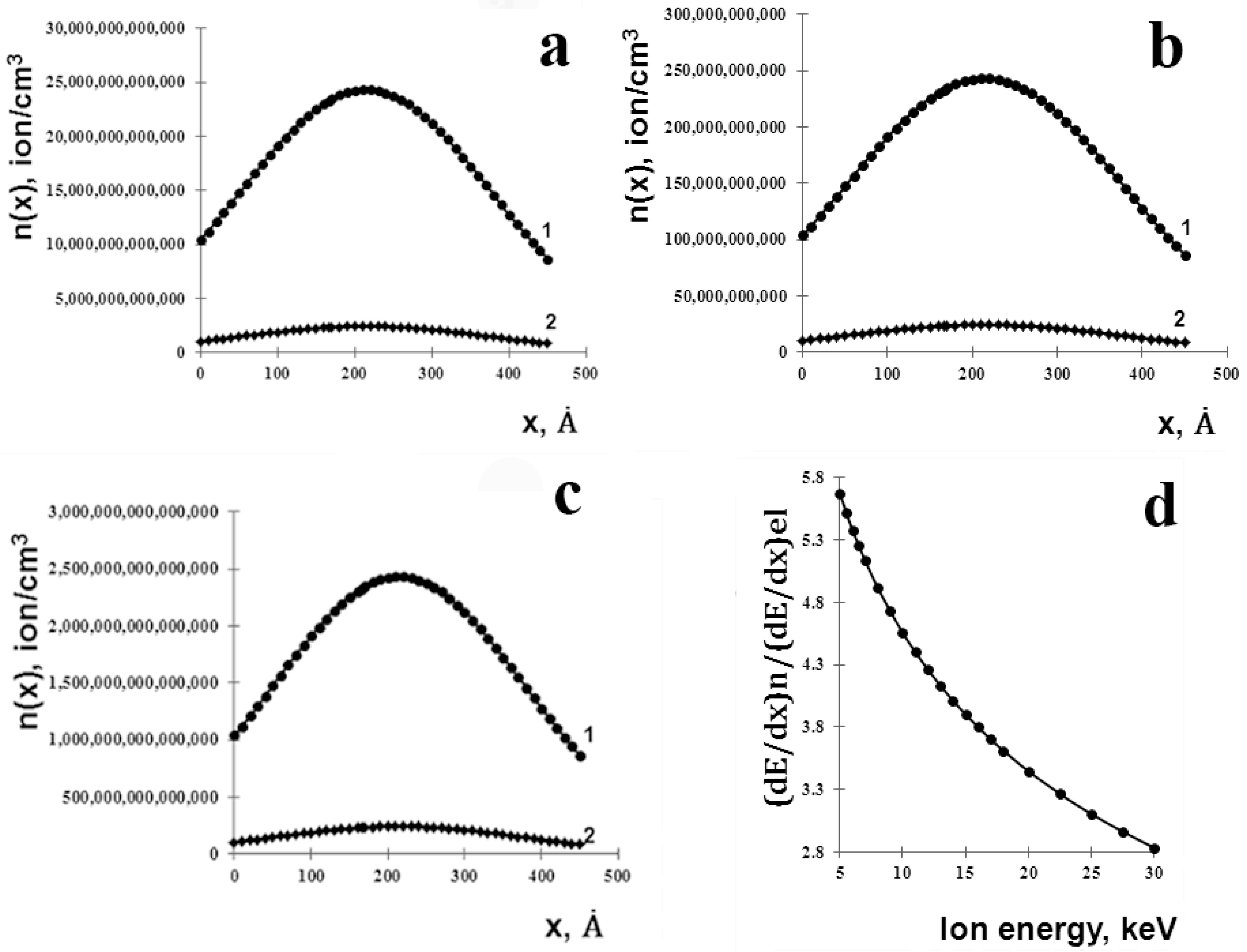

3.2. Interpretation of the Results

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ryu, H.J.; Kim, Y.S.; Park, J.M.; Chae, H.T.; Kim, C.K. Performance evaluation of U-Mo/Al dispersion fuel by considering a fuel-matrix interaction. Nucl. Eng. Technol. 2008, 40, 409–418. [Google Scholar] [CrossRef]

- Kim, Y.S. Uranium Intermetallic Fuels (U–Al, U–Si, U–Mo). In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 391–422. [Google Scholar]

- Finlay, M.R.; Wachs, D.M.; Robinson, A.B.; Hofman, G.L. Post irradiation examination of monolithic mini-fuel plates from RERTR–6 & 7. In Proceedings of the 11th International Topical Meeting on Research Reactor Fuel Management, Lyon, France, 11–15 March 2007. [Google Scholar]

- Birtcher, R.C.; Richardson, J.W.; Mueller, M.H. Amorphization of U3Si2 by ion or neutron irradiation. J. Nucl. Mater. 1996, 230, 158–163. [Google Scholar] [CrossRef]

- Chiang, H.Y.; Zweifel, T.; Palancher, H.; Bonnin, A.; Beck, L.; Weiser, P.; Döblinger, M.; Sabathier, C.; Jungwirth, R.; Petry, W. Evidence of amorphous interdiffusion layer in heavy ion irradiated U-8 wt % Mo/Al interfaces. J. Nucl. Mater. 2013, 440, 117–123. [Google Scholar] [CrossRef]

- Gan, J.; Keiser, D.D.; Miller, B.D.; Wachs, D.M.; Allen, T.R.; Kirk, M.; Rest, J. Microstructure of RERTR DU-alloys irradiated with krypton ions up to 100 dpa. J. Nucl. Mater. 2011, 411, 174–180. [Google Scholar] [CrossRef]

- Rabin, D.; Shneck, R.Z.; Rafailov, G.; Dahan, I.; Meshi, L.; Brosh, E. Thermodynamic modeling of Al–U–X (X = Si, Zr). J. Nucl. Mater. 2015, 464, 170–184. [Google Scholar] [CrossRef]

- Dwight, A.E. A Study of the Uranium–Aluminum–Silicon System; ANL-82-14; Argonne National Library: Argonne, IL, USA, 1982.

- Weitzer, F.; Noël, H.; Rogl, P. Phase relations and magnetism in the ternary system U–Al–Si. In Proceedings of the 22iemes Journées des Actinides, Meribel, France; 1992; pp. 35–36. [Google Scholar]

- Nazare, S. New low enrichment dispersion fuels for research reactors prepared by PM-techniques. Powder Metall. Int. 1986, 18, 150–158. [Google Scholar]

- Alonso, P.R.; Gargano, P.H.; Rubiolo, G.H. First principles calculation of the Al3U–Si3U pseudobinary FCC phase equilibrium diagram. Calphad 2012, 38, 117–121. [Google Scholar] [CrossRef]

- Chebotarev, N.T.; Konovalov, L.I.; Zhmak, V.A. Investigation on the crystal structure and phase transformation of alloys of the USi2–UAl2 section of the ternary system uranium–aluminum–silicon. Quest. At. Sci. Tech. Ser. Mater. Sci. New Mater. 1990, 3, 11–13. [Google Scholar]

- Zenou, V.Y.; Rafailov, G.; Dahan, I.; Kiv, A.; Meshi, L.; Fuks, D. Ordered U(Al, Si)3 phase: Structure and bonding. J. Alloys Compd. 2017, 690, 884–889. [Google Scholar] [CrossRef]

- Rafailov, G.; Dahan, I.; Meshi, L. New ordered phase in the quasi-binary UAl3–USi3 system. Acta Crystallogr. B 2014, 70, 580–585. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Jin, K.; Beland, L.K.; Zhang, F.; Yang, T.; Qiao, L.; Zhang, Y.; Bei, H.; Christen, H.M.; Stoller, R.E.; et al. Direct observation of defect range and evolution in ion-irradiated single crystalline Ni and Ni binary alloys. Sci. Rep. 2016, 6, 19994. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, J.F. Ion Implantation Science and Technology, 2nd ed.; Academic Press: London, UK, 2012. [Google Scholar]

- Zeigler, J.F. SRIM-2000, Code and Manuals. 2013. Available online: http://www.srim.org/ (accessed on 1 January 2016).

- Hytch, M.; Snoeck, E.; Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 1998, 74, 131–146. [Google Scholar] [CrossRef]

- Linden, Y.; Pinkas, M.; Munitz, A.; Meshi, L. Long-period antiphase domains and short-range order in a B2 matrix of the AlCoCrFeNi high-entropy alloy. Scr. Mater. 2017, 139, 49–52. [Google Scholar] [CrossRef]

- Stadelman, P.A. EMS—A software package for electron diffraction analysis and HREM image simulation in materials science. Ultramicroscopy 1987, 21, 131–145. [Google Scholar] [CrossRef]

- Fu, E.G.; Wang, Y.O.; Nastasi, M. Mechanisms for ion-irradiation induced relaxation of stress in mosaic structured Cu thin films. J. Phys. D Appl. Phys. 2012, 45, 495303. [Google Scholar] [CrossRef]

- Kiv, A.; Mykytenko, N.; Fuks, D.; Dahan, I.; Meshi, L. Molecular dynamics probing of the energy spectrum of particles in radiation stimulated processes. Int. J. Adv. Comput. Technol. 2016, 4, 81–86. [Google Scholar]

- Was, G.S. Fundamentals of Radiation Materials Science, 2nd ed.; Springer: New York, NY, USA, 2017. [Google Scholar]

- Tilinin, I.S. Elastic energy losses of ions and atoms in atomic collisions. Nucl. Instrum. Methods Phys. Res. B 1995, 98, 380–384. [Google Scholar] [CrossRef]

- Chu, P.K. Microelectronic materials and processing. In Ion Implantation; City University of Hong Kong: Hong Kong, China, 2011; Chapter 9. [Google Scholar]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Match, M.P.; Naundorf, V. Diffusion coefficients of Nickel and Silicon in ion irradiated Fe-20Cr-20Ni. In Radiation Induced Changes in Microstructure; Garner, F.A., Packan, N.H., Kumar, A.S., Eds.; 13th International Symposium (Part 1); ASTM International: Philadelphia, PA, USA, 1987; pp. 5–13. [Google Scholar]

- Averback, R.S.; De La Rubia, T.D. Displacement damage in irradiated metals and semiconductors. In Solid State Physics; Ehrenfest, H., Spaepen, F., Eds.; Academic Press: New York, NY, USA, 1998; Volume 51, pp. 281–402. [Google Scholar]

- Nastasi, M.; Mayer, J.; Hirvonen, J. Ion-Solid Interactions—Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

| Dose | 1016 | 1015 | 1014 | 1013 |

| Width (nm) | 600 | 400 | 220 | 150 |

| Dose | 1018 | 1017 | 1016 | 1015 | 1014 | 1013 |

| F1 | 1.5 × 1015 | 1.5 × 1014 | 1.5 × 1013 | 1.5 × 1012 | 1.5 × 1011 | 1.5 × 1010 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meshi, L.; Yaniv, G.; Horak, P.; Vacik, J.; Mykytenko, N.; Rafailov, G.; Dahan, I.; Fuks, D.; Kiv, A. Radiation Resistance of the U(Al, Si)3 Alloy: Ion-Induced Disordering. Materials 2018, 11, 228. https://doi.org/10.3390/ma11020228

Meshi L, Yaniv G, Horak P, Vacik J, Mykytenko N, Rafailov G, Dahan I, Fuks D, Kiv A. Radiation Resistance of the U(Al, Si)3 Alloy: Ion-Induced Disordering. Materials. 2018; 11(2):228. https://doi.org/10.3390/ma11020228

Chicago/Turabian StyleMeshi, Louisa, Gili Yaniv, Pavel Horak, Jiri Vacik, Natalia Mykytenko, Gennady Rafailov, Itzchak Dahan, David Fuks, and Arik Kiv. 2018. "Radiation Resistance of the U(Al, Si)3 Alloy: Ion-Induced Disordering" Materials 11, no. 2: 228. https://doi.org/10.3390/ma11020228