Modal Identification in an Automotive Multi-Component System Using HS 3D-DIC

Abstract

:1. Introduction

2. Materials and Method

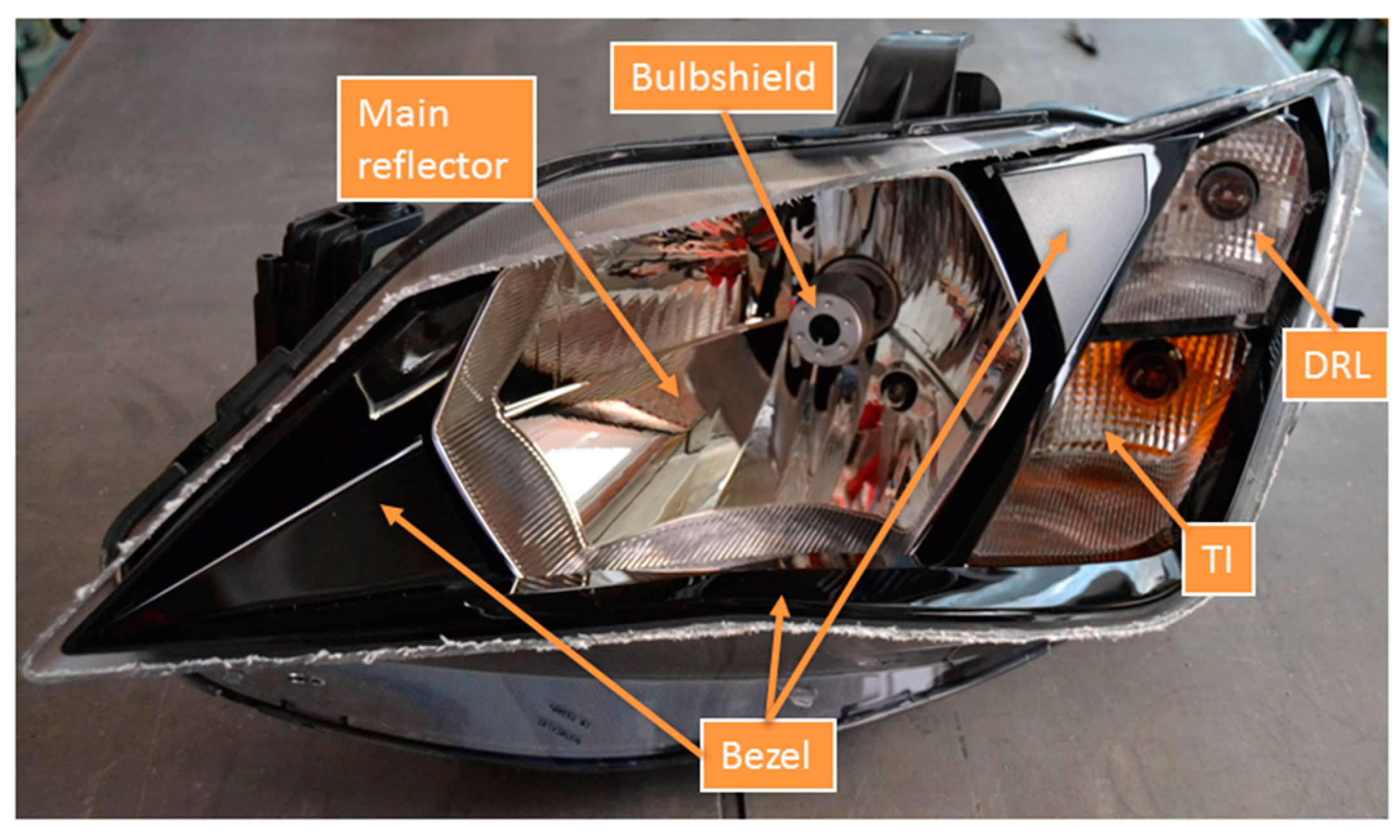

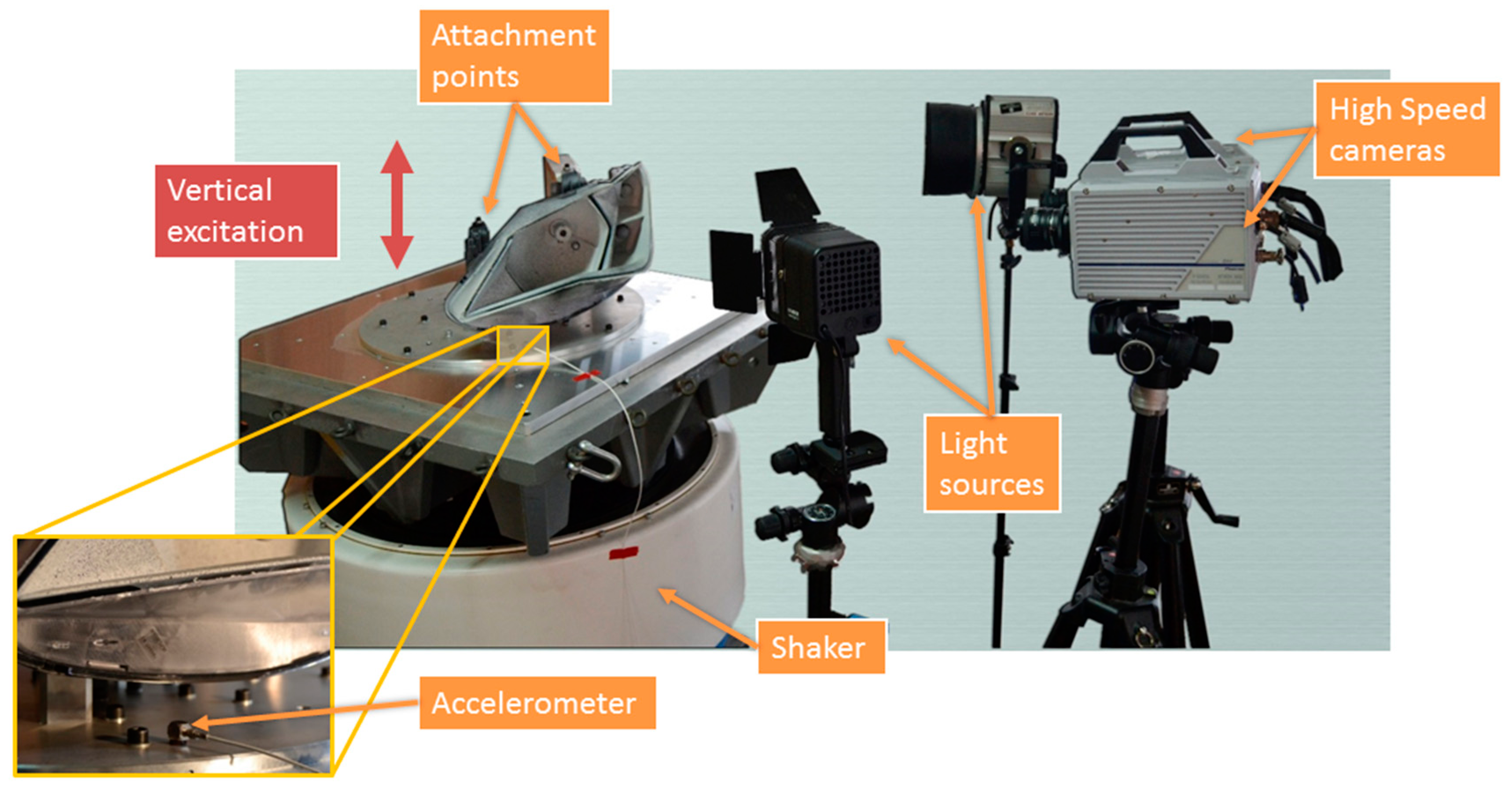

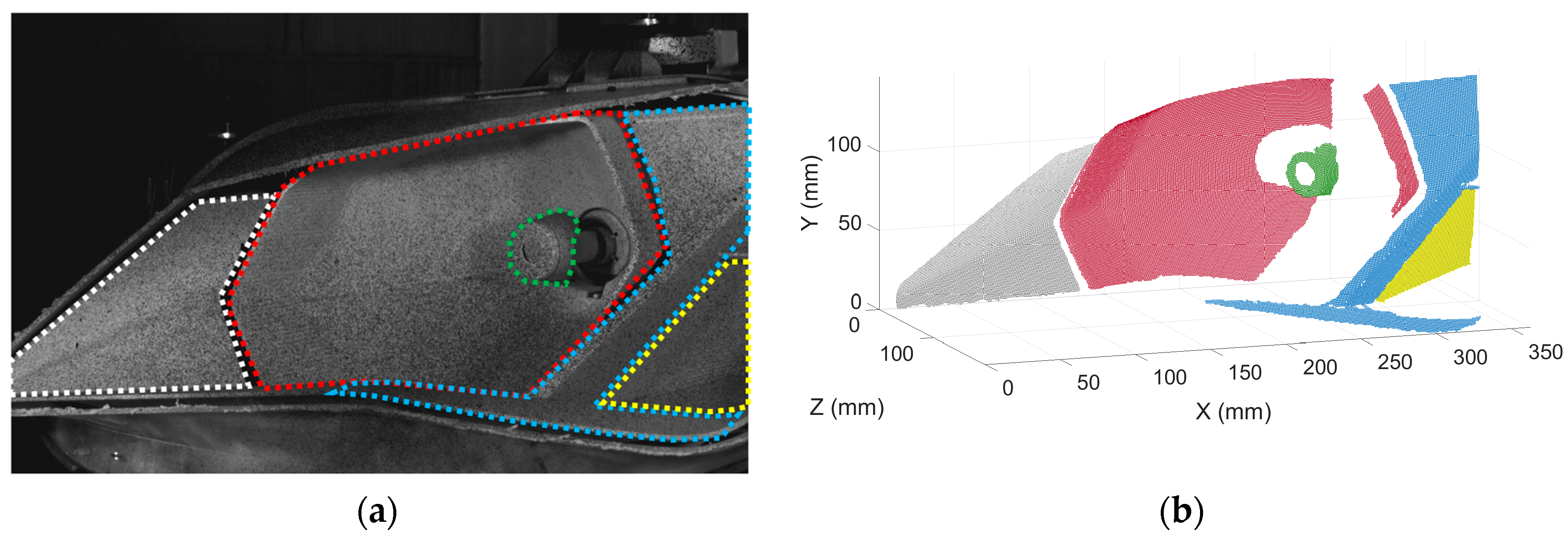

2.1. Experimental Set-Up

2.2. Transmissibility Functions Using HS 3D-DIC

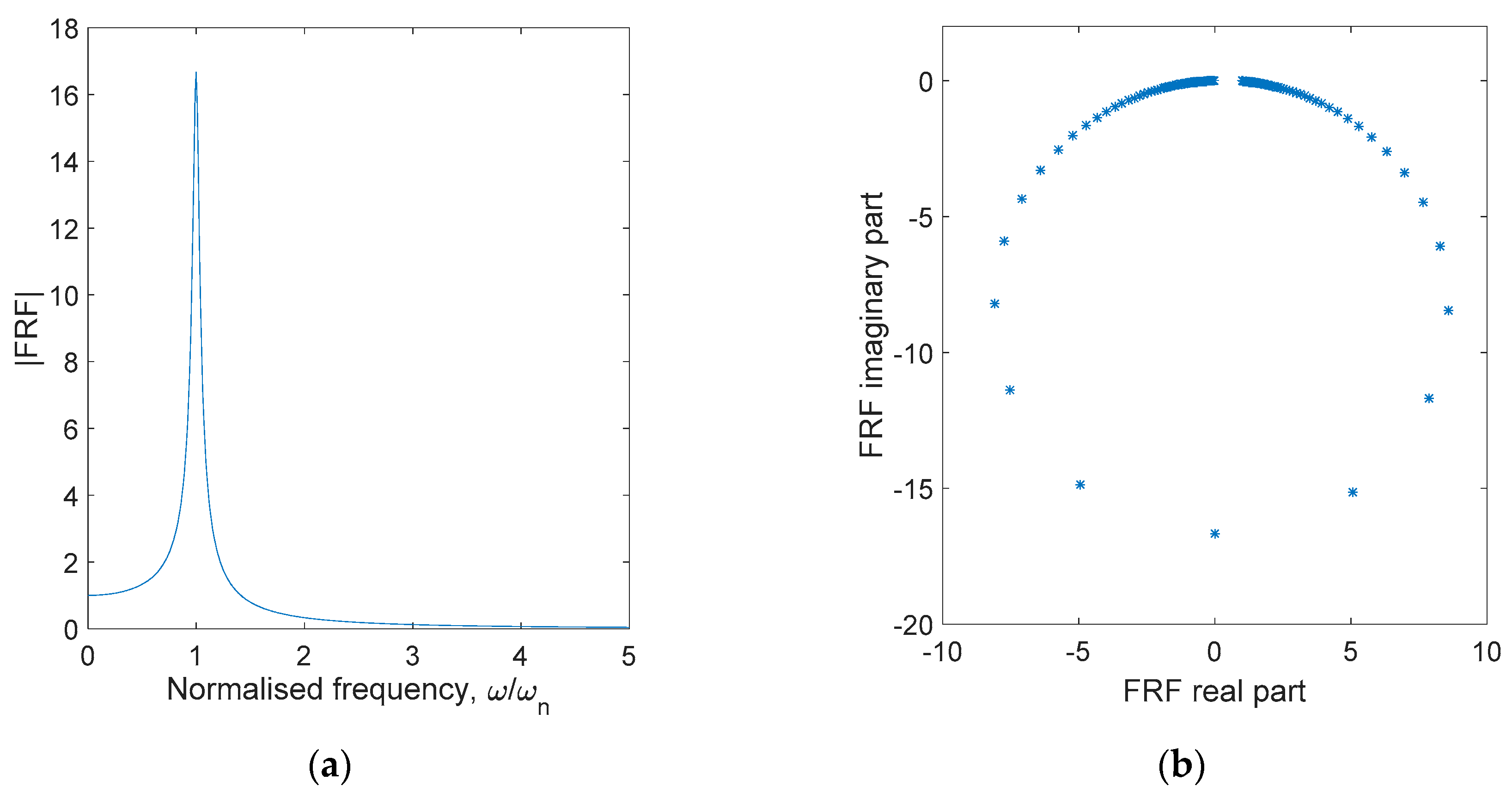

2.3. Procedure for Modal Identification in Base Motion Tests Using the Circle-Fit Approach

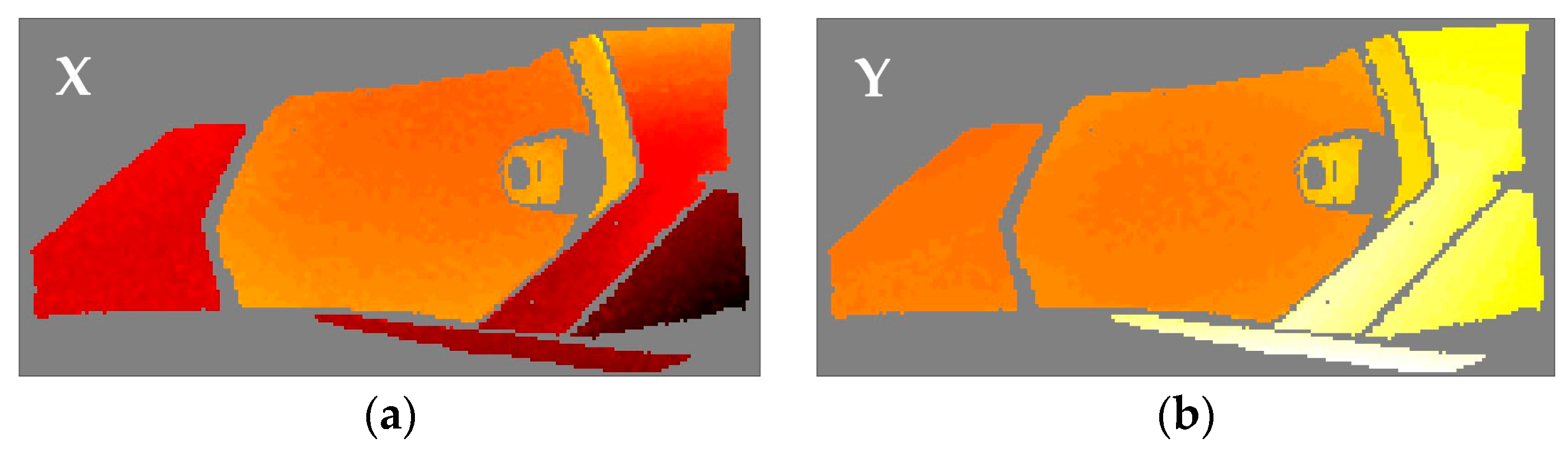

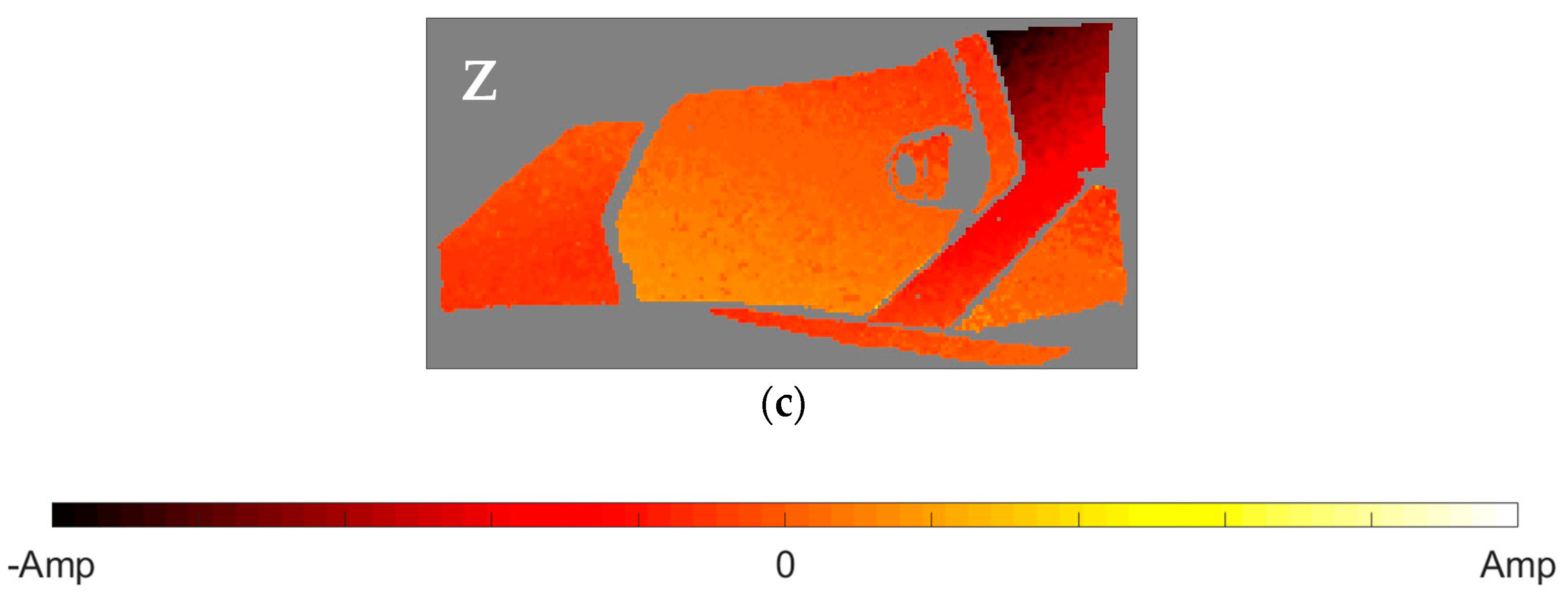

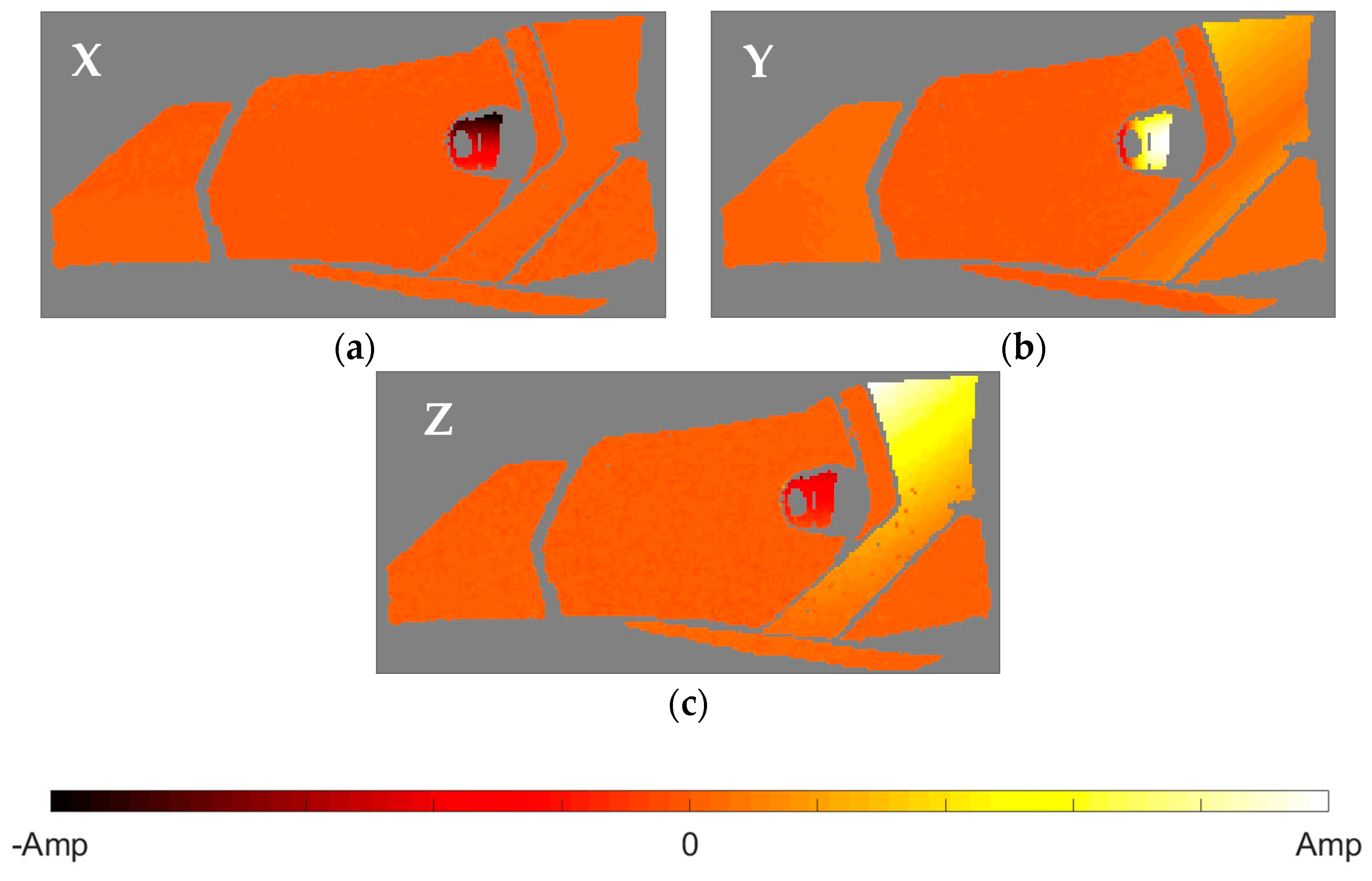

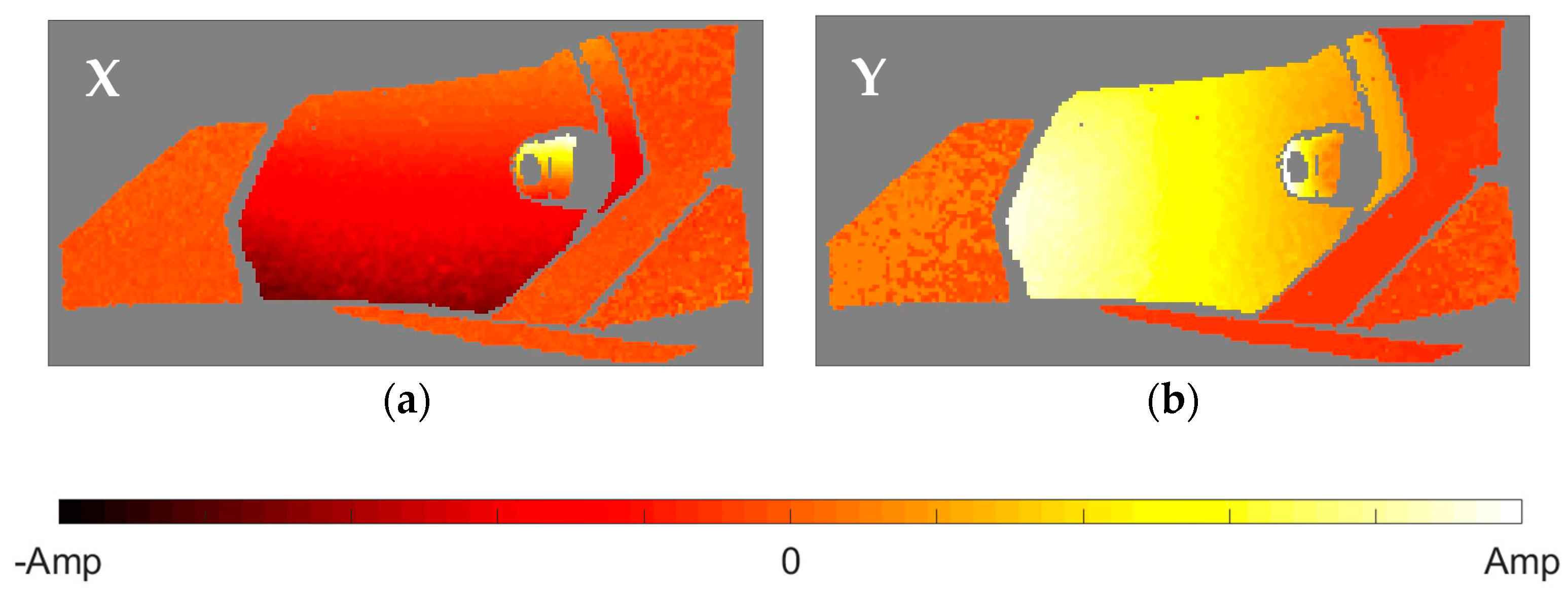

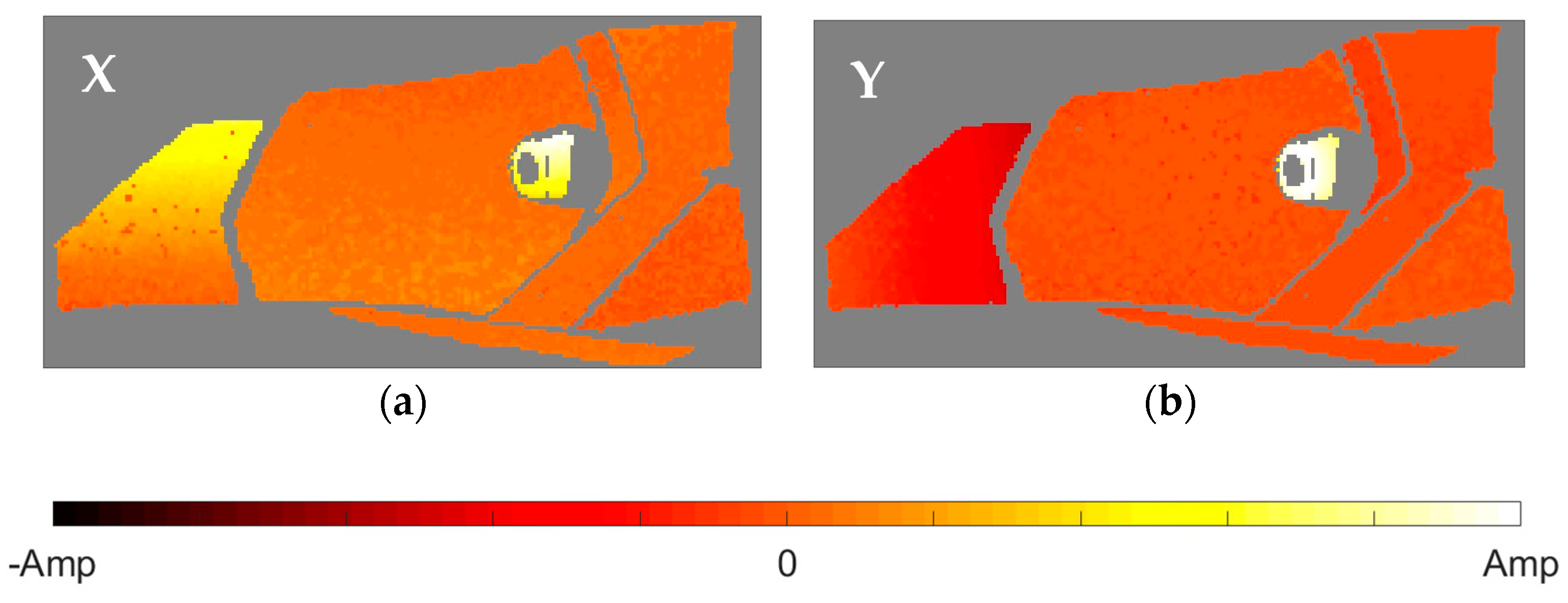

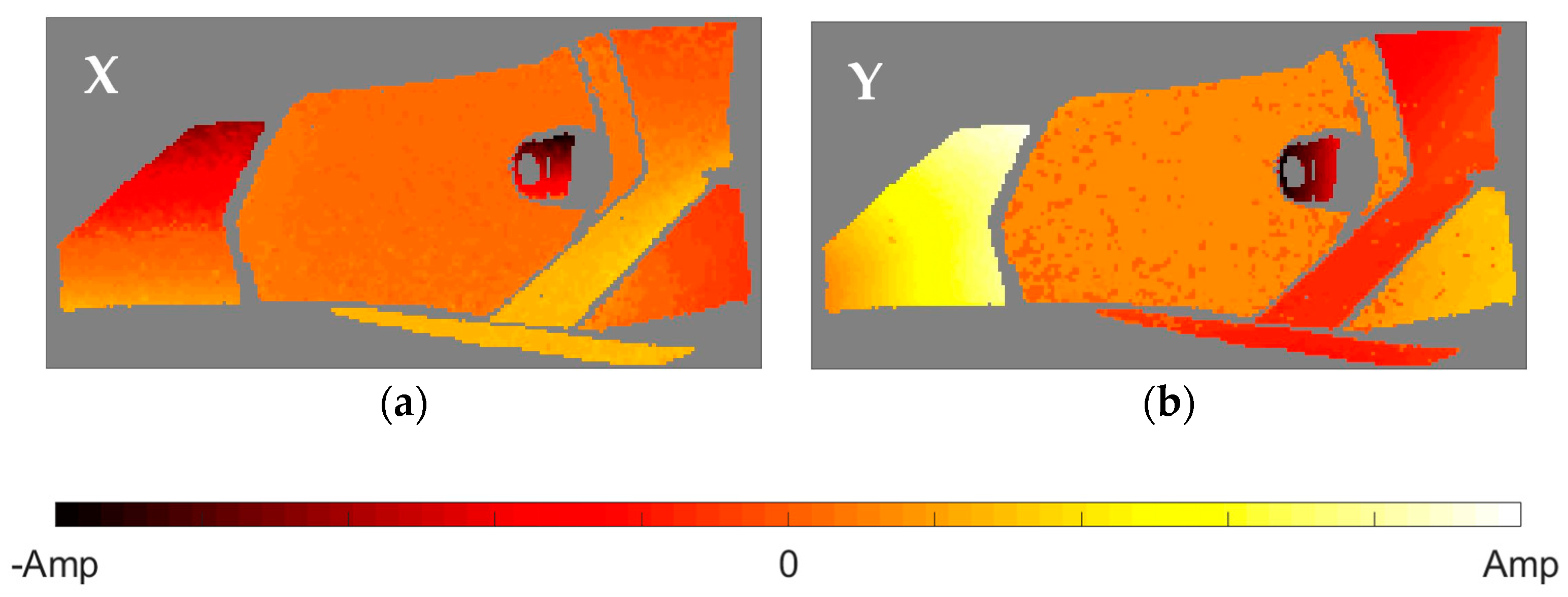

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

References

- Ewins, D.J. Modal Testing: Theory, Practice, and Application, 2nd ed.; Roberts, J.B., Ed.; Research Studies Press Ltd.: Baldock, UK, 2000; ISBN 978-0863802188. [Google Scholar]

- Sharpe, W.N. Springer Handbook of Experimental Solid Mechanics; Sharpe, W.N., Ed.; Springer US: Boston, MA, USA, 2008; ISBN 978-0-387-26883-5. [Google Scholar]

- Stanbridge, A.B.; Ewins, D.J. Modal testing using a scanning laser doppler vibrometer. Mech. Syst. Signal Process. 1999, 13, 255–270. [Google Scholar] [CrossRef]

- Stanbridge, A.B.; Martarelli, M.; Ewins, D.J. Measuring area vibration mode shapes with a continuous-scan LDV. Meas. J. Int. Meas. Confed. 2004, 35, 181–189. [Google Scholar] [CrossRef]

- Helfrick, M.N.; Niezrecki, C.; Avitabile, P.; Schmidt, T. 3D digital image correlation methods for full-field vibration measurement. Mech. Syst. Signal Process. 2010, 25, 917–927. [Google Scholar] [CrossRef]

- Warren, C.; Niezrecki, C.; Avitabile, P.; Pingle, P. Comparison of FRF measurements and mode shapes determined using optically image based, laser, and accelerometer measurements. Mech. Syst. Signal Process. 2011, 25, 2191–2202. [Google Scholar] [CrossRef]

- Reu, P.L.; Rohe, D.P.; Jacobs, L.D. Comparison of DIC and LDV for practical vibration and modal measurements. Mech. Syst. Signal Process. 2017, 86, 2–16. [Google Scholar] [CrossRef]

- Ha, N.S.; Jin, T.; Goo, N.S. Modal analysis of an artificial wing mimicking an Allomyrina dichotoma beetle’s hind wing for flapping-wing micro air vehicles by noncontact measurement techniques. Opt. Lasers Eng. 2013, 51, 560–570. [Google Scholar] [CrossRef]

- Baqersad, J.; Carr, J.; Lundstrom, T.; Niezrecki, C.; Avitabile, P.; Slattery, M. Dynamic characteristics of a wind turbine blade using 3D digital image correlation. In Proceedings of SPIE; Kundu, T., Ed.; SPIE: Bellingham, WA, USA, 2012; Volume 8348, p. 83482I. [Google Scholar]

- Siebert, T.; Becker, T.; Spiltthof, K.; Neumann, I.; Krupka, R. High-speed digital image correlation: Error estimations and applications. Opt. Eng. 2007, 46, 51004. [Google Scholar] [CrossRef]

- Wang, W.; Mottershead, J.E.; Ihle, A.; Siebert, T.; Reinhard Schubach, H. Finite element model updating from full-field vibration measurement using digital image correlation. J. Sound Vib. 2011, 330, 1599–1620. [Google Scholar] [CrossRef]

- Siebert, T.; Wood, R.; Splitthof, K. High speed image correlation for vibration analysis. J. Phys. Conf. Ser. 2009, 181, 12064. [Google Scholar] [CrossRef]

- Ehrhardt, D.A.; Allen, M.S.; Yang, S.; Beberniss, T.J. Full-field linear and nonlinear measurements using Continuous-Scan Laser Doppler Vibrometry and high speed Three-Dimensional Digital Image Correlation. Mech. Syst. Signal Process. 2017, 86, 82–97. [Google Scholar] [CrossRef]

- Molina-Viedma, A.J.; Felipe-Sesé, L.; López-Alba, E.; Díaz, F. High frequency mode shapes characterisation using Digital Image Correlation and phase-based motion magnification. Mech. Syst. Signal Process. 2018, 102, 245–261. [Google Scholar] [CrossRef]

- Felipe-Sesé, L.; Díaz, F.A. Damage methodology approach on a composite panel based on a combination of Fringe Projection and 2D Digital Image Correlation. Mech. Syst. Signal Process. 2018, 101, 467–479. [Google Scholar] [CrossRef]

- Berke, R.B.; Sebastian, C.M.; Chona, R.; Patterson, E.A.; Lambros, J. High temperature vibratory response of Hastelloy-X: Stereo-DIC measurements and image decomposition analysis. Exp. Mech. 2015, 231–243. [Google Scholar] [CrossRef]

- Trebuňa, F.; Hagara, M. Experimental modal analysis performed by high-speed digital image correlation system. Measurement 2014, 50, 78–85. [Google Scholar] [CrossRef]

- Wang, W.; Mottershead, J.E.; Siebert, T.; Pipino, A. Frequency response functions of shape features from full-field vibration measurements using digital image correlation. Mech. Syst. Signal Process. 2012, 28, 333–347. [Google Scholar] [CrossRef]

- Beberniss, T.J.; Ehrhardt, D.A. High-speed 3D digital image correlation vibration measurement: Recent advancements and noted limitations. Mech. Syst. Signal Process. 2017, 86, 35–48. [Google Scholar] [CrossRef]

- Huňady, R.; Hagara, M. A new procedure of modal parameter estimation for high-speed digital image correlation. Mech. Syst. Signal Process. 2017, 93, 66–79. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Single-camera high-speed stereo-digital image correlation for full-field vibration measurement. Mech. Syst. Signal Process. 2017, 94, 374–383. [Google Scholar] [CrossRef]

- Ha, N.S.; Vang, H.M.; Goo, N.S. Modal analysis using Digital Image Correlation Technique: An application to artificial wing Mimicking Beetle’s Hind Wing. Exp. Mech. 2015, 989–998. [Google Scholar] [CrossRef]

- Molina-Viedma, Á.J.; López-Alba, E.; Felipe-Sesé, L.; Díaz, F.A. Full-field modal analysis during base motion excitation using high-speed 3D digital image correlation. Meas. Sci. Technol. 2017, 28, 105402. [Google Scholar] [CrossRef]

- Kouroussis, G.; Fekih, L.B.; Conti, C.; Verlinden, O. Easymod: A Matlab / Scilab Toolbox for teaching modal analysis. In Proceedings of the 19th International Congress on Sound and Vibration, Vilnius, Lithuania, 8–12 July 2012. [Google Scholar]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Boston, MA, USA, 2009; ISBN 978-0-387-78746-6. [Google Scholar]

- Lecompte, D.; Smits, A.; Bossuyt, S.; Sol, H.; Vantomme, J.; Van Hemelrijck, D.; Habraken, A.M. Quality assessment of speckle patterns for digital image correlation. Opt. Lasers Eng. 2006, 44, 1132–1145. [Google Scholar] [CrossRef]

- Correlated Solutions. Available online: http://correlatedsolutions.com/ (accessed on 15 December 2017).

- Lazan, B.J. Damping of Materials and Members in Structural Mechanics; Pergamon Press: Oxford, UK, 1968. [Google Scholar]

- Orban, F. Damping of materials and members in structures. J. Phys. Conf. Ser. 2011, 268, 12022. [Google Scholar] [CrossRef]

| Element | Material |

|---|---|

| Bezel | Polycarbonate |

| Main reflector | Thermoset BMC |

| TI reflector | Polycarbonate |

| Bulbshield | Sheet metal steel |

| Mode | Natural Frequency (Hz) | Structural Damping (%) | ||||

|---|---|---|---|---|---|---|

| Bezel’s Right Area | Bezel’s left Area | TI Reflector | Main Reflector | Bulbshield | ||

| 1 | 43.92 | 8.17 | 6.68 | 8.38 | 7.68 | 7.87 |

| 2 | 60.56 | 6.24 | - | - | 6.61 | 1.14 |

| 3 | 73.45 | - | - | - | 7.97 | 8.18 |

| 4 | 83.42 | - | 3.72 | - | 6.88 | 3.42 |

| 5 | 93.68 | 5.98 | 6.24 | 4.99 | 4.76 | 7.95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina-Viedma, Á.J.; López-Alba, E.; Felipe-Sesé, L.; Díaz, F.A. Modal Identification in an Automotive Multi-Component System Using HS 3D-DIC. Materials 2018, 11, 241. https://doi.org/10.3390/ma11020241

Molina-Viedma ÁJ, López-Alba E, Felipe-Sesé L, Díaz FA. Modal Identification in an Automotive Multi-Component System Using HS 3D-DIC. Materials. 2018; 11(2):241. https://doi.org/10.3390/ma11020241

Chicago/Turabian StyleMolina-Viedma, Ángel Jesús, Elías López-Alba, Luis Felipe-Sesé, and Francisco A. Díaz. 2018. "Modal Identification in an Automotive Multi-Component System Using HS 3D-DIC" Materials 11, no. 2: 241. https://doi.org/10.3390/ma11020241