Investigations on Structural, Optical and X-Radiation Responsive Properties of a-Se Thin Films Fabricated by Thermal Evaporation Method at Low Vacuum Degree

Abstract

:1. Introduction

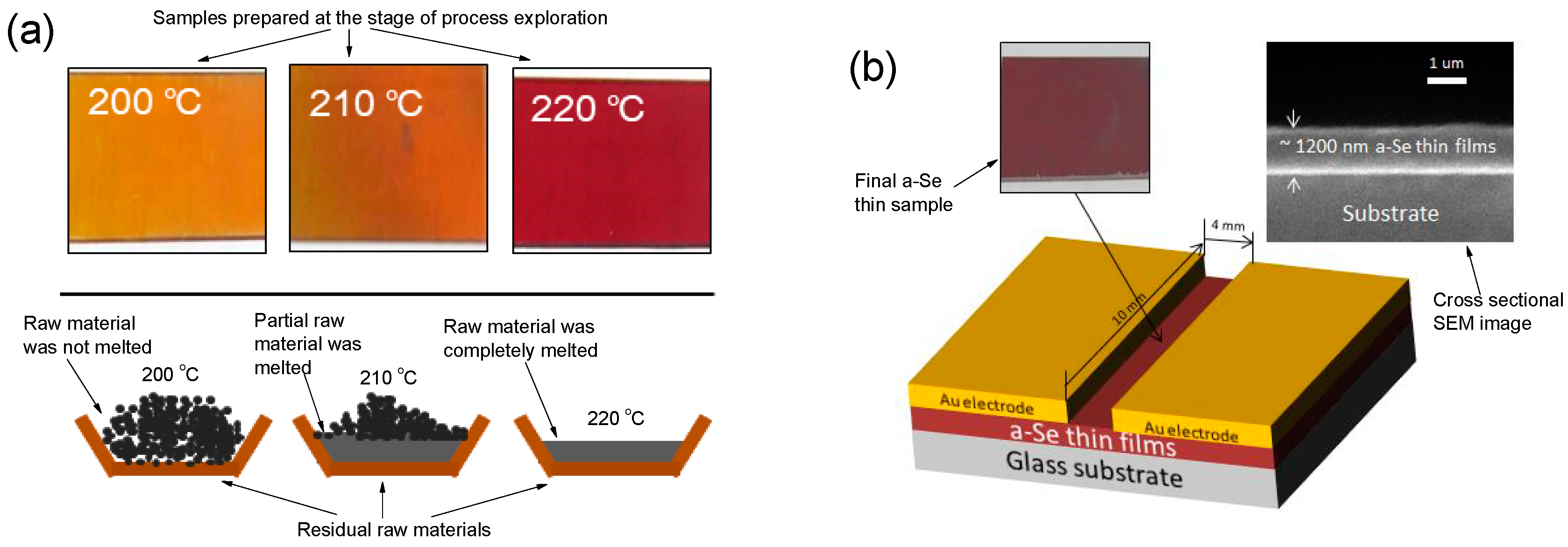

2. Material and Methods

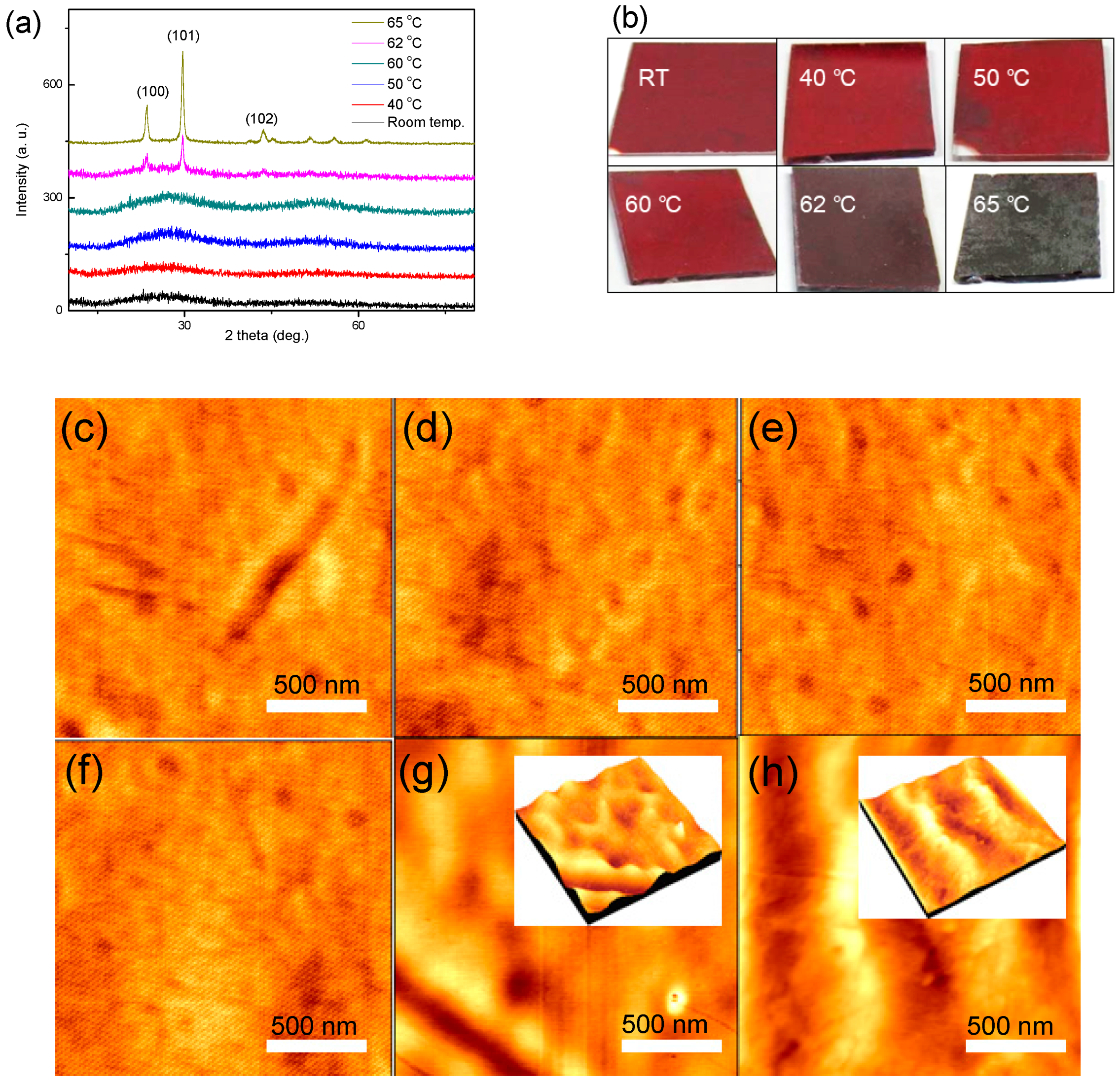

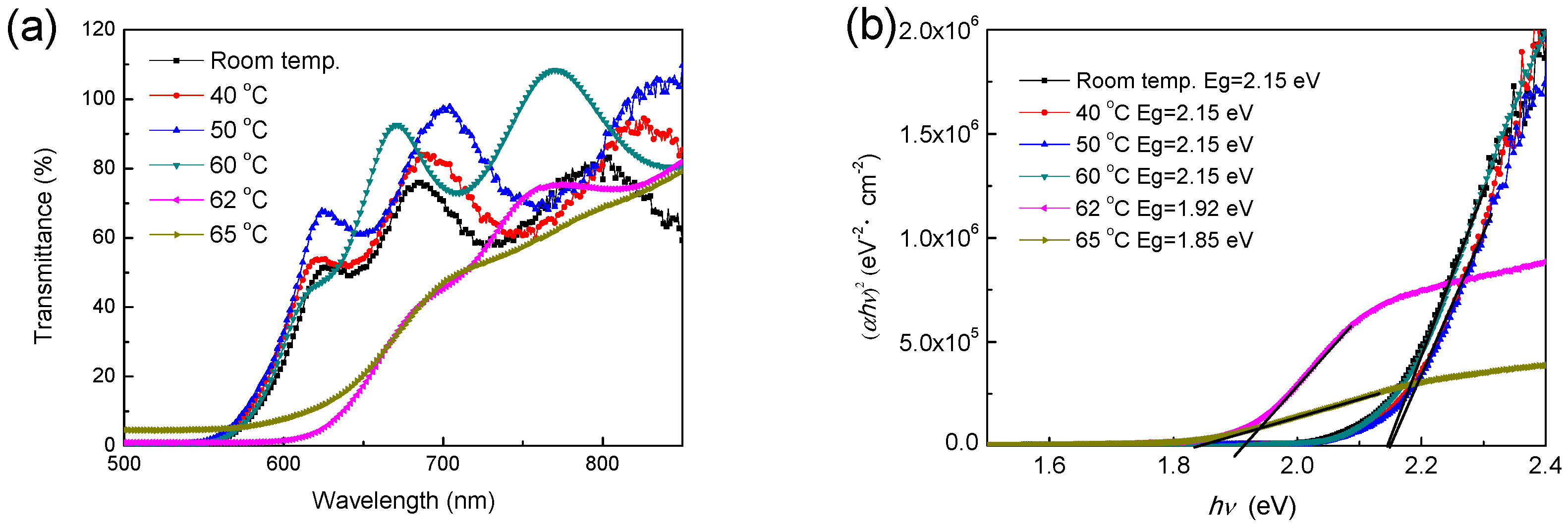

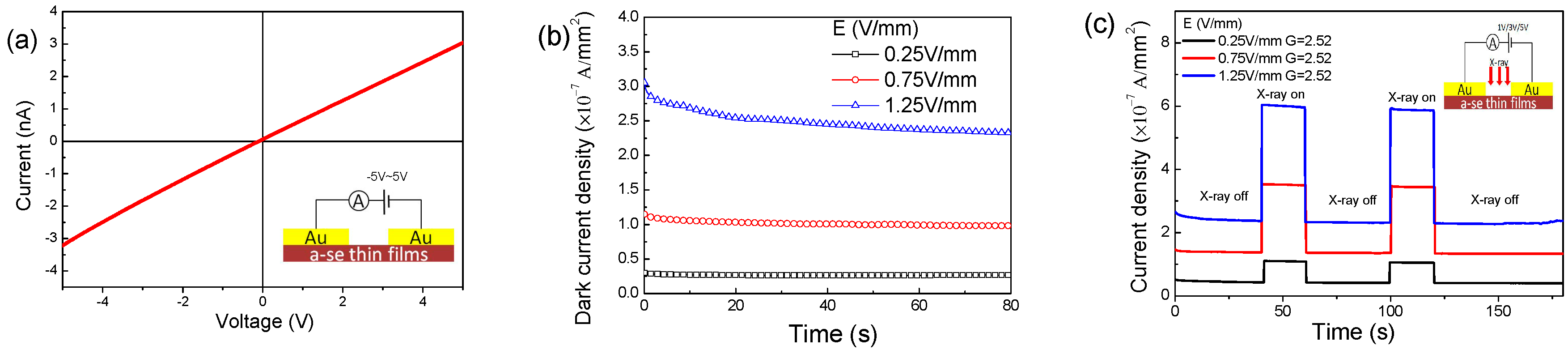

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hijazi, N.; Panneerselvam, D.; Kabir, M.Z. Electron-hole pair creation energy in amorphous selenium for high energy photon excitation. J. Mater. Sci. Mater. Electron. 2018, 29, 486–490. [Google Scholar] [CrossRef]

- Tomoaki, M.; Shingo, K.; Masanori, O.; Richika, K.; Ichitaro, S.; Takatoshi, Y.; Angel, T.; Koh, T.; Daniel, H.; Chua, C.; et al. Conditions for a carrier multiplication in amorphous-selenium based photodetector. Appl. Phys. Lett. 2013, 102, 073506. [Google Scholar] [CrossRef]

- Kolobov, A.V.; Fons, P. Insights into the physics and chemistry of chalcogenides obtained from X-ray absorption spectroscopy. Semicond. Sci. Technol. 2017, 32, 123003. [Google Scholar] [CrossRef]

- Gayathri, S.; Sridevi, S.; Asokan, S. Investigations on photo-mechanical and photo-thermo-mechanical strain variations in amorphous selenium using fiber Bragg grating sensor. J. Non-Cryst. Solids 2017, 477, 7–11. [Google Scholar] [CrossRef]

- Shiva, A.; Alireza, T.; William, S.W.; Karim, S.K. Enhanced Dark Current Suppression of Amorphous Selenium Detector with Use of IGZO Hole Blocking Layer. IEEE Trans. Electron Dev. 2014, 61, 3355–3357. [Google Scholar]

- Benkhedir, M.L.; Aida, M.S.; Adriaenssens, G.J. Defect levels in the band gap of amorphous selenium. J. Non-Cryst. Solids 2004, 344, 193–198. [Google Scholar] [CrossRef]

- Kotkata, M.F.; Abdel-Wahab, F.A.; Al-Kotb, M.S. Effect of In-content on the optical properties of a-Se films. Appl. Surf. Sci. 2009, 255, 9071–9077. [Google Scholar] [CrossRef]

- Chen, Z.; Dong, M.; Li, C.; Shao, S.; Hu, S.; Kang, D. Improved thermal stability of antimony-doped amorphous selenium film for X-ray flat-panel detectors. Phys. Status Solidi A 2013, 210, 580–584. [Google Scholar] [CrossRef]

- Cosmas, M.M.; Julius, M.M.; Sathiaraj, T.S.; James, G.K. Optical properties of amorphous Se90-XIn10SbX thin film alloys. J. Alloys Compd. 2016, 689, 432–438. [Google Scholar]

- Chen, F.; Wang, K.; Fang, Y.; Allec, N.; Belev, G.; Kasap, S.; Karim, K.S. Direct-Conversion X-Ray Detector Using Lateral Amorphous Selenium Structure. IEEE Sens. J. 2010, 11, 505–509. [Google Scholar] [CrossRef]

- Yu, T.Y.; Pan, F.M.; Chang, C.Y.; Lin, J.S.; Huang, W.H. Thermal stability and photoconductive properties of photosensors with an alternating multilayer structure of amorphous Se and AsxSe1−x. J. Appl. Phys. 2015, 118, 044509. [Google Scholar] [CrossRef]

- Tonchev, D.; Mani, H.; Belev, G.; Kostova, I.; Kasap, S. X-ray sensing materials stability: Influence of ambient storage temperature on essential thermal properties of undoped vitreous selenium. J. Phys. Conf. Ser. 2014, 558, 012007. [Google Scholar] [CrossRef]

- Imura, S.; Kikuchi, K.; Miyakawa, K.; Ohtake, H.; Kubota, M.; Okino, T.; Hirose, Y.; Kato, Y.; Teranishi, N. High-Sensitivity Image Sensors Overlaid With Thin-Film Gallium Oxide/Crystalline Selenium Heterojunction Photodiodes. IEEE Trans. Electron Dev. 2015, 63, 86–91. [Google Scholar] [CrossRef]

- Nyakotyo, H.; Sathiaraj, T.S.; Muchuweni, E. Effect of annealing on the optical properties of amorphous Se79Te10Sb4Bi7 thin films. Opt. Laser Technol. 2017, 92, 182–188. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, X.; Yang, D.; Wangyang, P.; Gao, X.; Tian, H. An economical method for amorphous selenium thick films preparation: E-beam evaporation. Mater. Lett. 2016, 183, 94–96. [Google Scholar] [CrossRef]

- Sharma, R.; Kumar, D.; Srinivasan, V.; Jain, H.; Adarsh, K.V. Engineering the optical response of a-Se thin films by employing morphological disorder. Opt. Express 2015, 23, 14085–14094. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, D.; Zhu, X.; Sun, H.; Gao, X.; Wangyang, P.; Tian, H. Structural and optical properties of nano-crystalline ZnO thin films synthesized by sol-gel method. J. Sol-Gel Sci. Technol. 2017, 82, 563–568. [Google Scholar] [CrossRef]

- Li, J.; Yang, D.; Zhu, X.; Sun, H.; Gao, X.; Wangyang, P. Enhanced Structural and Photoelectric Properties of CdCl2 Coated CdS Thin Films Deposited by Magnetron Sputtering. Nanosci. Nanotechnol. Lett. 2017, 9, 1363–1367. [Google Scholar] [CrossRef]

- Frey, J.B.; Belev, G.; Tousignant, O.; Mani, H.; Kasap, S.O. Dark current in multilayer stabilized amorphous selenium based photoconductive X-ray detectors. J. Appl. Phys. 2012, 112, 014502. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhu, X.; Yang, D.; Gu, P.; Wu, H. Investigations on Structural, Optical and X-Radiation Responsive Properties of a-Se Thin Films Fabricated by Thermal Evaporation Method at Low Vacuum Degree. Materials 2018, 11, 368. https://doi.org/10.3390/ma11030368

Li J, Zhu X, Yang D, Gu P, Wu H. Investigations on Structural, Optical and X-Radiation Responsive Properties of a-Se Thin Films Fabricated by Thermal Evaporation Method at Low Vacuum Degree. Materials. 2018; 11(3):368. https://doi.org/10.3390/ma11030368

Chicago/Turabian StyleLi, Jitao, Xinghua Zhu, Dingyu Yang, Peng Gu, and Haihua Wu. 2018. "Investigations on Structural, Optical and X-Radiation Responsive Properties of a-Se Thin Films Fabricated by Thermal Evaporation Method at Low Vacuum Degree" Materials 11, no. 3: 368. https://doi.org/10.3390/ma11030368