Improving Mechanical Properties of PVPPA Welded Joints of 7075 Aluminum Alloy by PWHT

Abstract

:1. Introduction

2. Experimental

3. Results

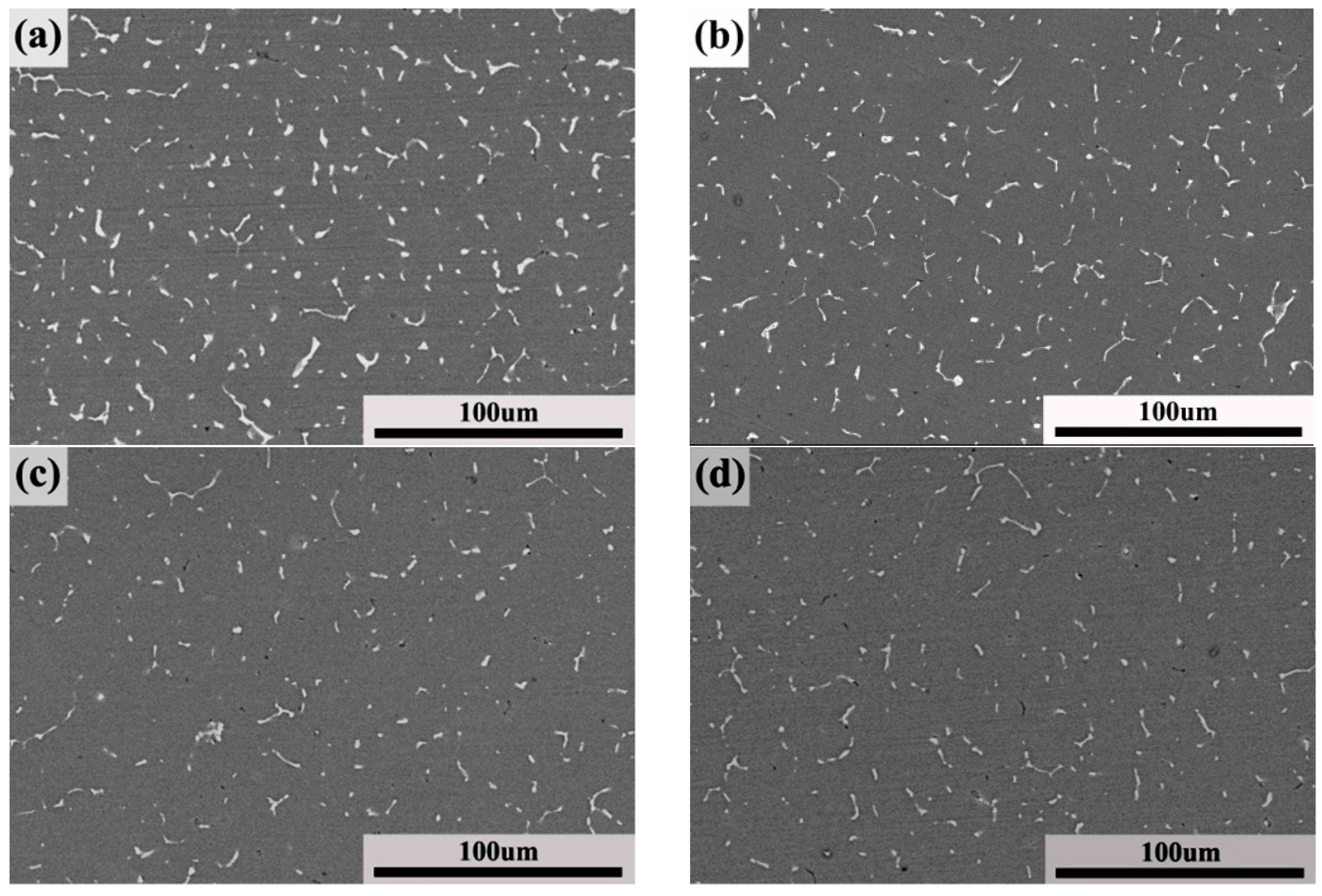

3.1. Microstructure

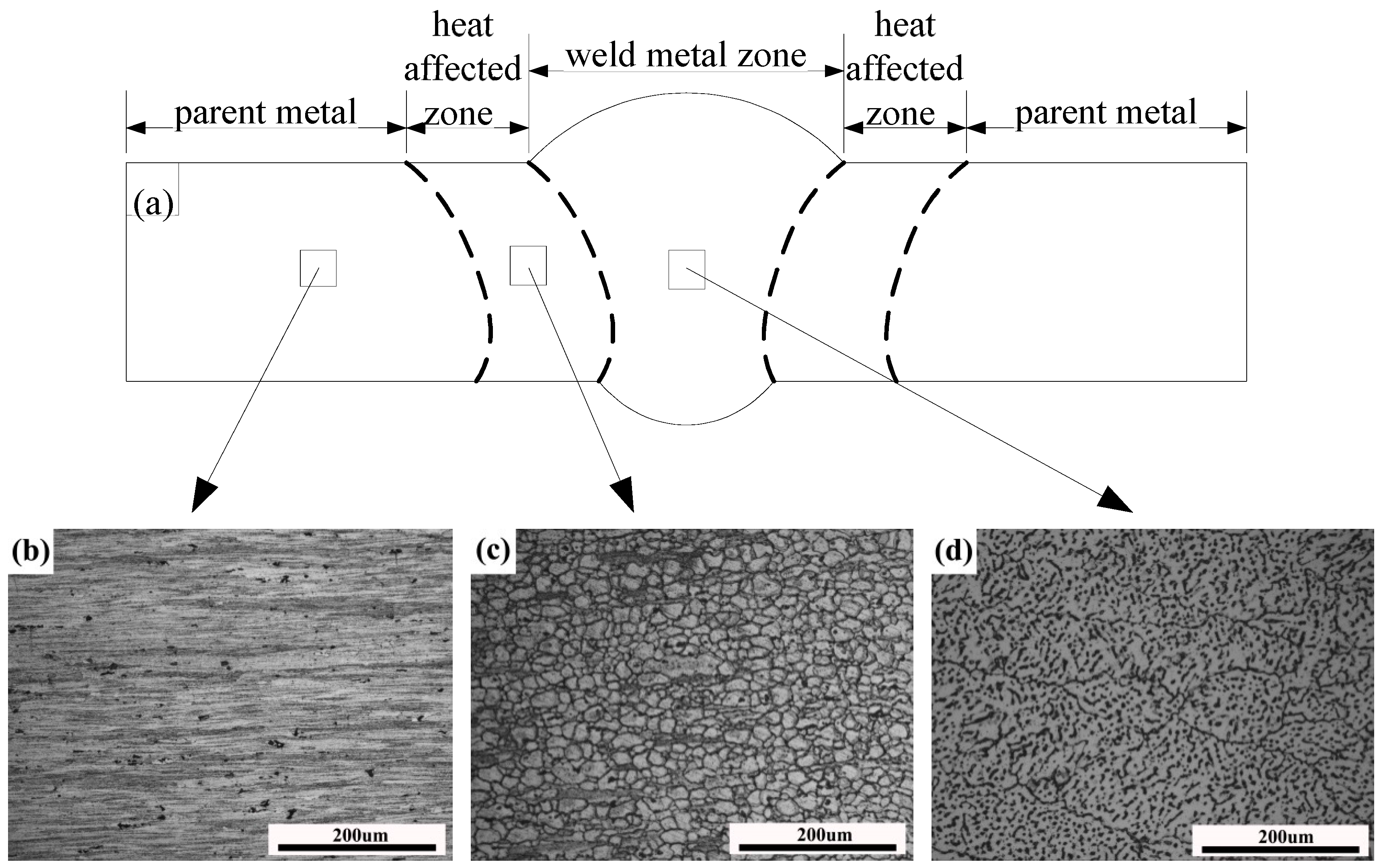

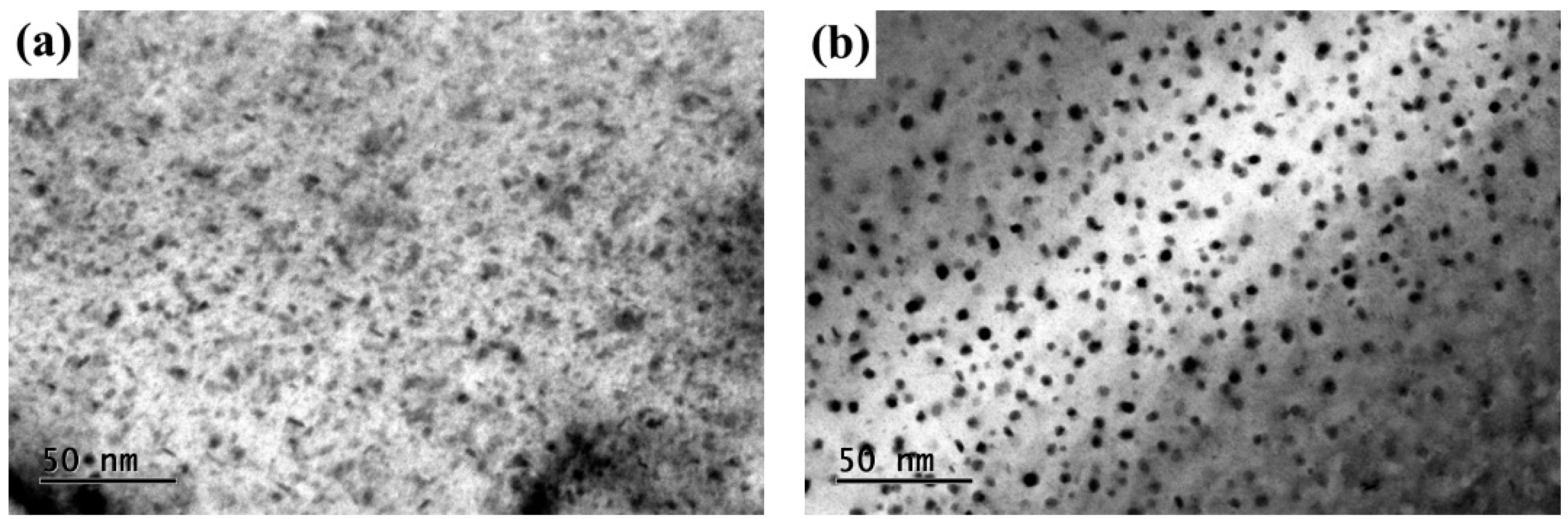

3.1.1. As-Welded

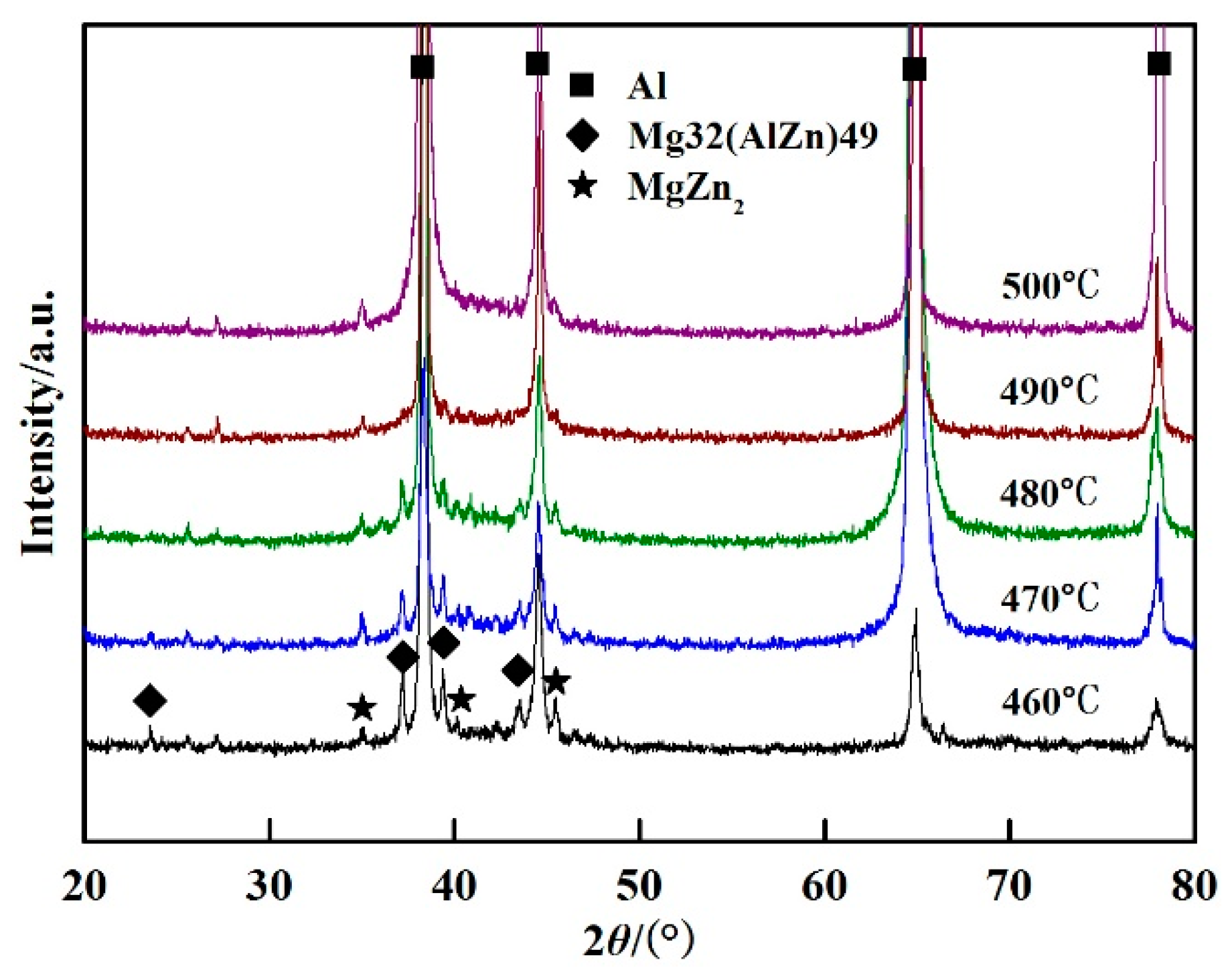

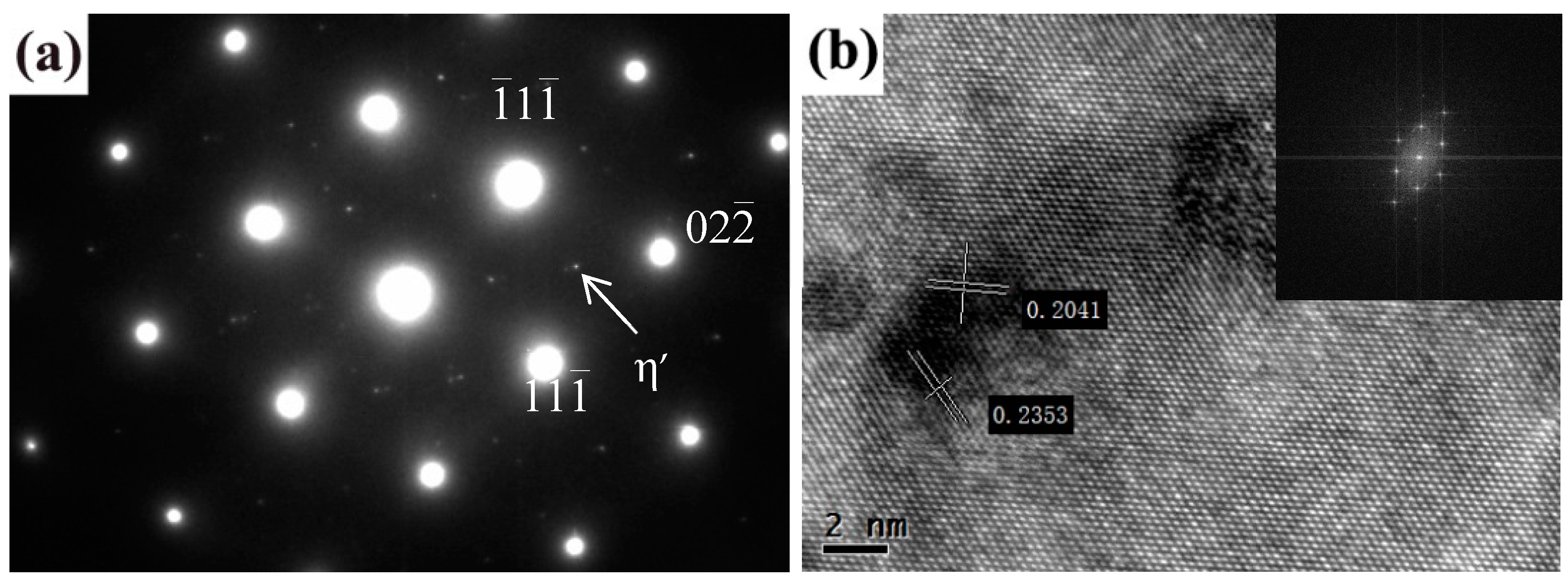

3.1.2. Effect of Solution Temperature

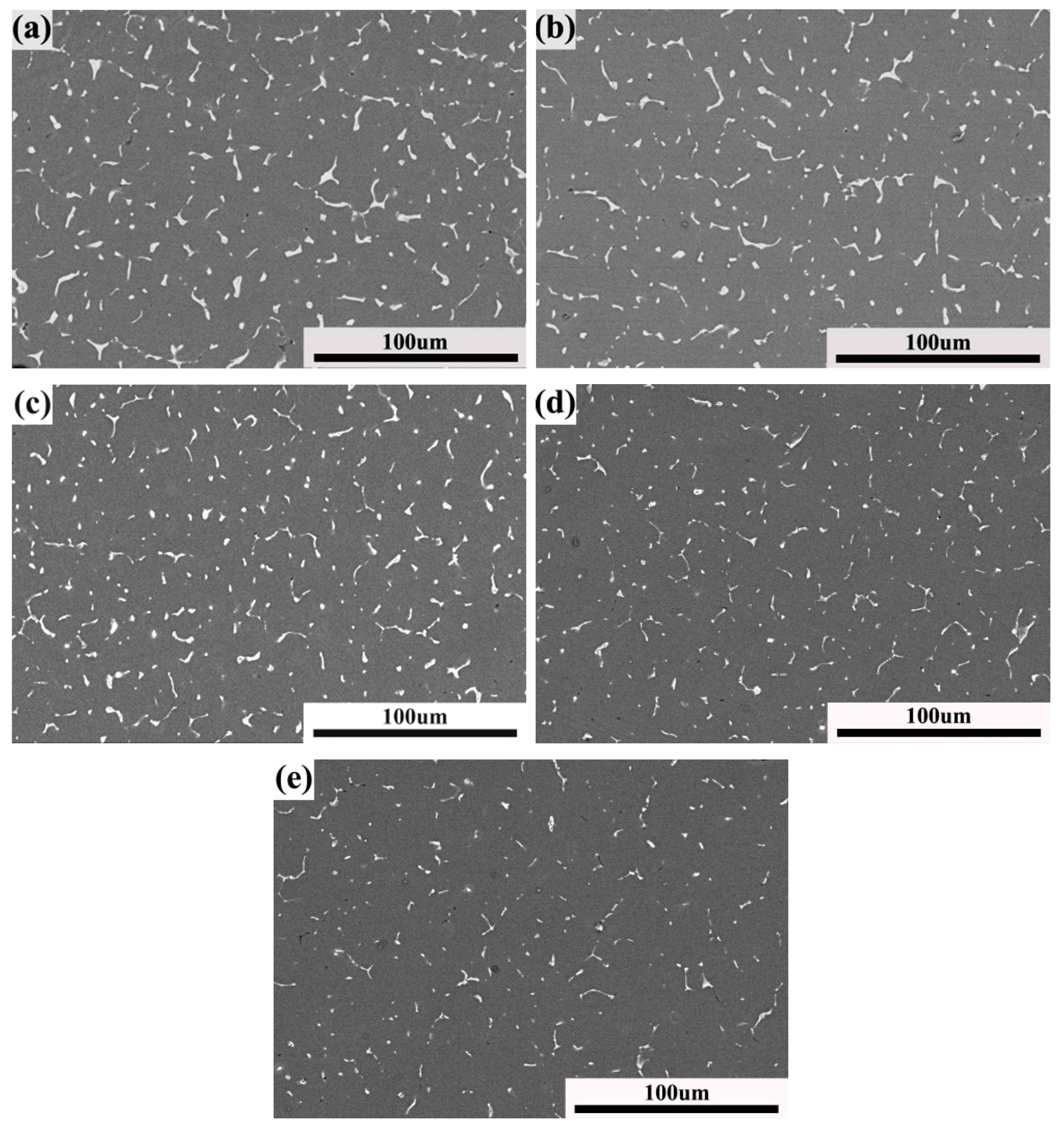

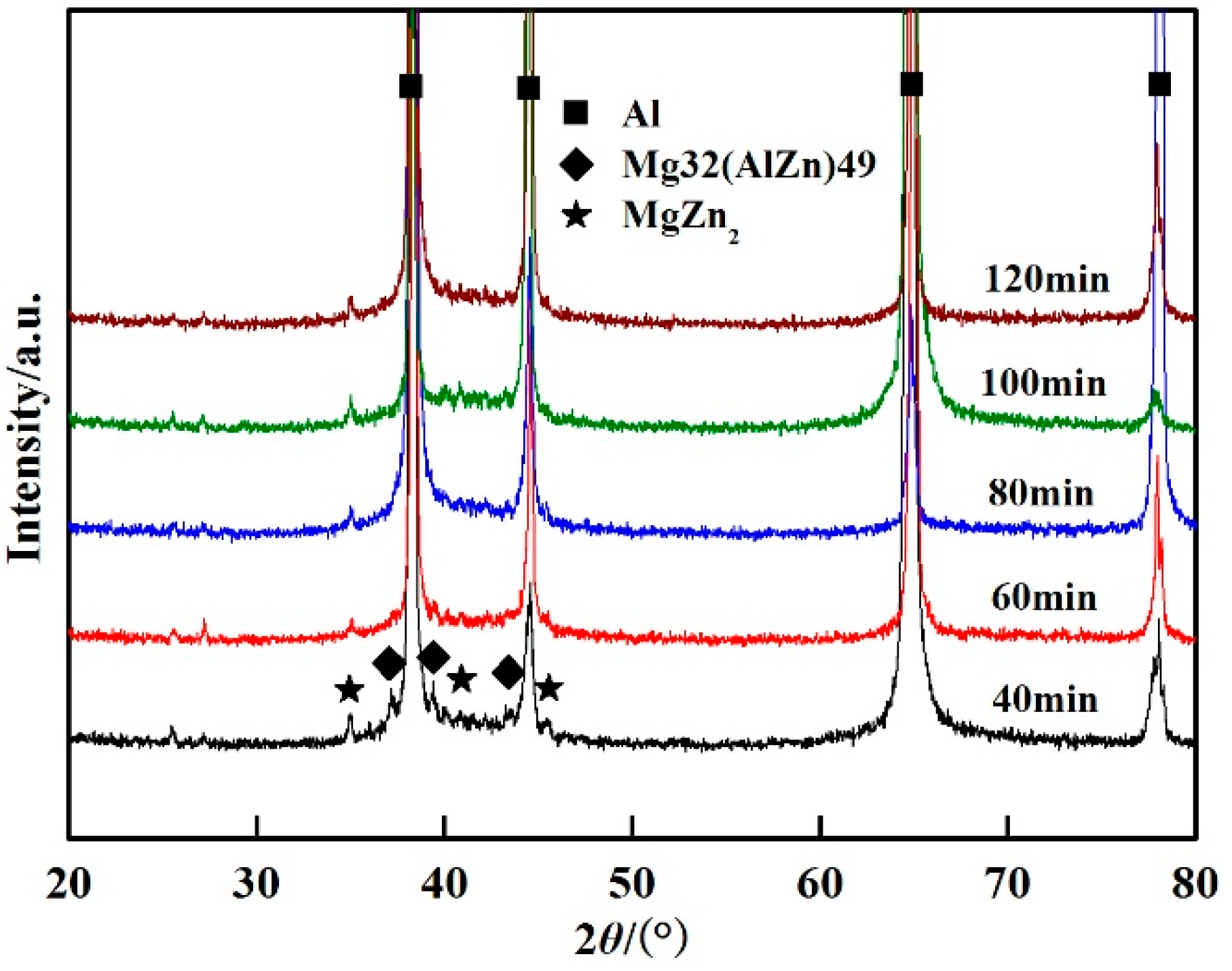

3.1.3. Effect of Solution Time

3.2. Mechanical Properties

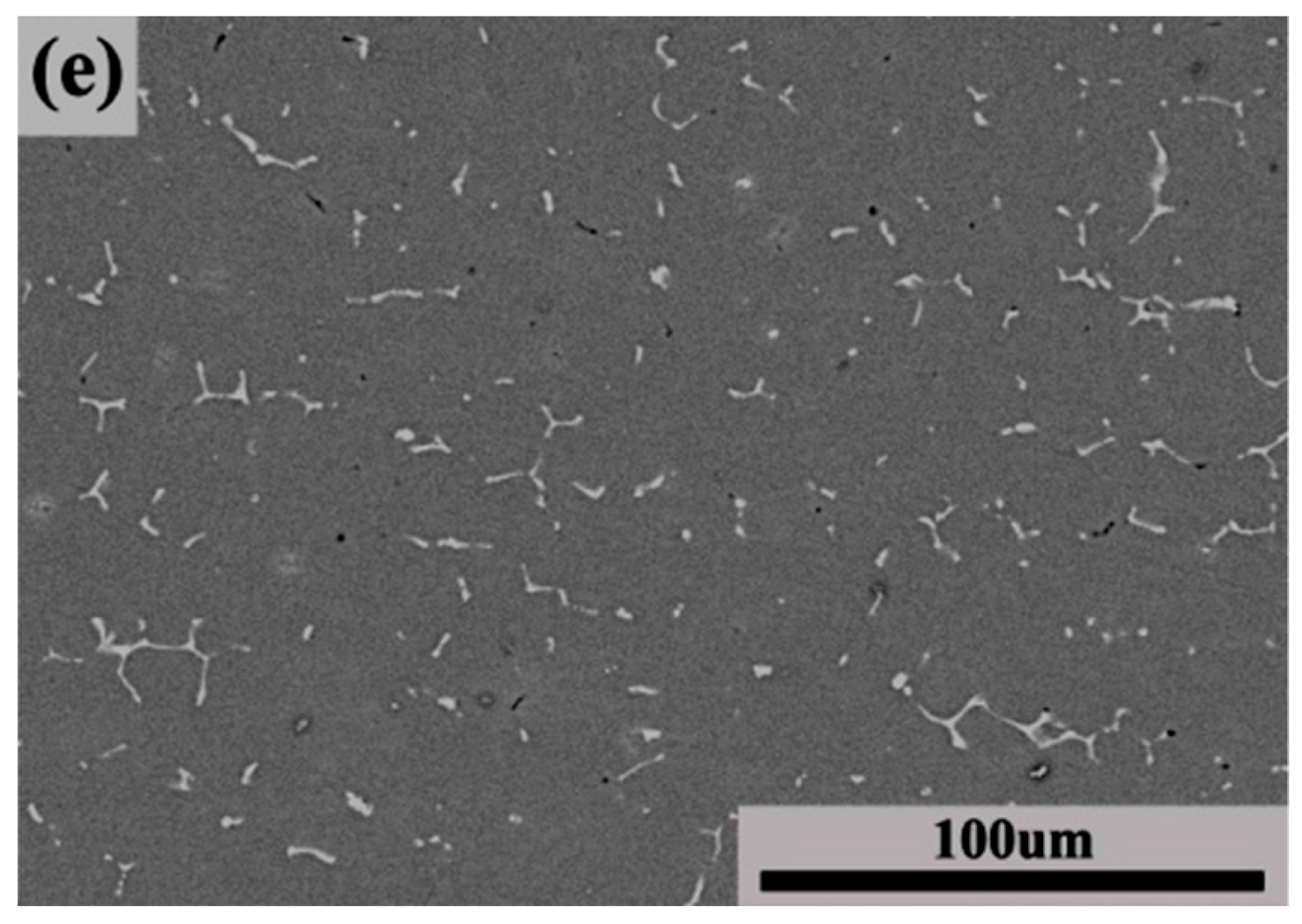

3.2.1. Effect of Solution Temperature

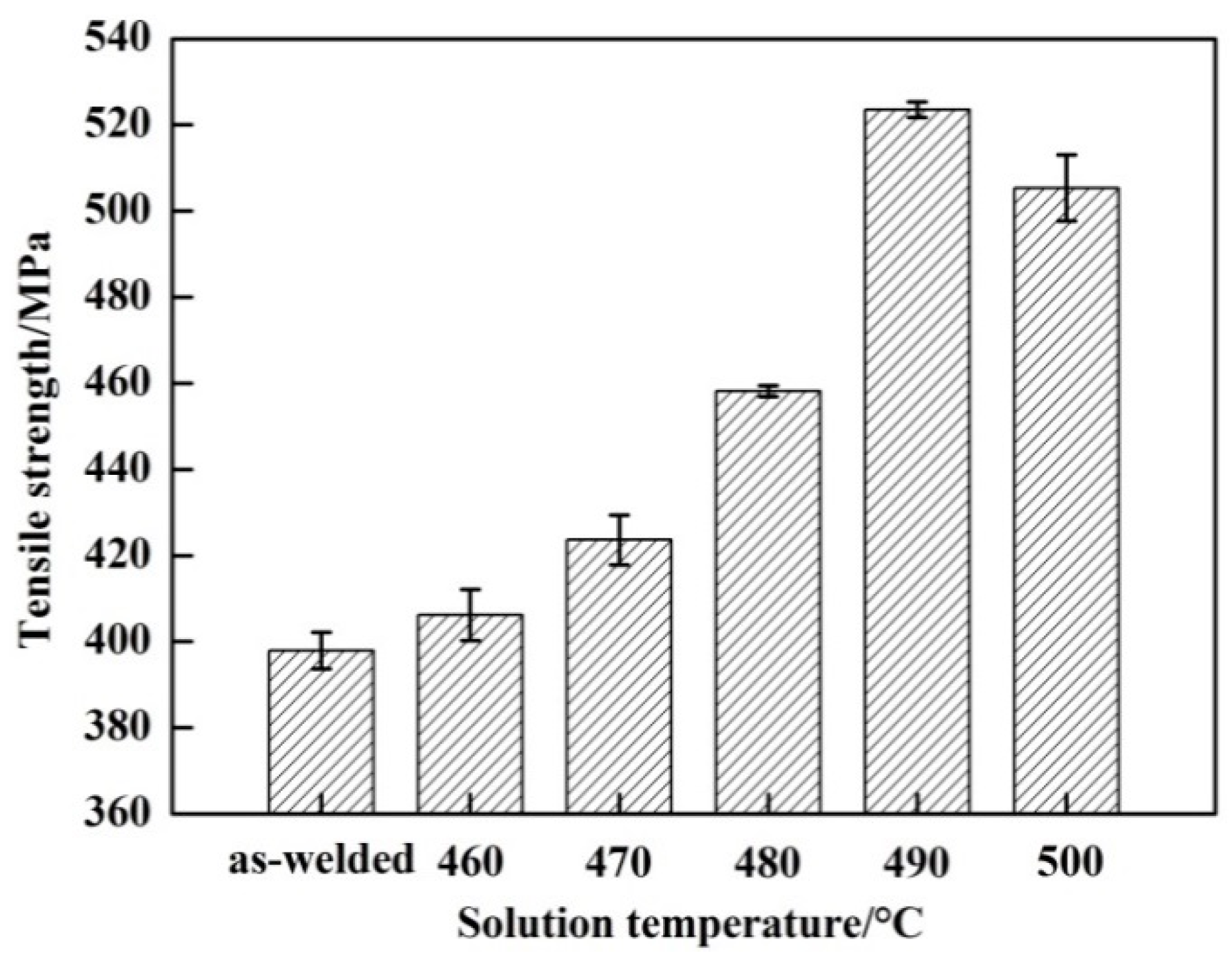

3.2.2. Effect of Solution Time

4. Discussion

5. Conclusions

- (1)

- 7075 aluminum alloy with a thickness of 10 mm can be successfully welded with no obvious defects by PVPPA welding. The tensile strength of the welded joint using PVPPA welding reached 67.5% of the parent metal.

- (2)

- The solution temperature and time have an important effect on the mechanical properties of the welded joint. During PWHT, the tensile strength and microhardness first increased and then decreased slightly with the increase of the solution temperature and solution time. The change of the mechanical properties was due to the dissolution of the T phase and the precipitation of η′ phase during PWHT.

- (3)

- The mechanical properties of the welded joint using PVPPA welding can be improved by the PWHT. The highest tensile strength of 537.5 MPa was obtained when the solution was treated at 490 °C for 80 min followed by aging at 120 °C for 24 h, which is about 91.2% of the parent metal. The maximum microhardness (143.7 HV) at the center of welded joints was also obtained under this heat treatment.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Squillace, A.; Fenzo, A.D.; Giorleo, G.; Bellucci, F. A Comparison between FSW and TIG welding techniques: Modifications of microstructure and pitting corrosion resistance in AA 2024-T3 butt joints. J. Mater. Process. Technol. 2004, 152, 97–105. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, H.J.; Wang, Q.L.; Kovacevic, R. Control for weld penetration in VPPAW of aluminum alloys using the front weld pool image signal. Weld. J. 2000, 12, 363–371. [Google Scholar]

- Nunes, A.C.; Bayless, E.O.; Jones, C.S.; Munafo, P.M.; Biddle, A.P.; Wilson, W.A. Variable polarity plasma arc welding on space shuttle external tank. Weld. J. 1984, 63, 27–35. [Google Scholar]

- Torres, M.R.; McClure, J.C.; Nunes, A.C.; Gurevitch, A.C. Gas contamination effects in variable polarity plasma arc welded aluminum. Weld. J. 1992, 71, 123–130. [Google Scholar]

- Li, G.W.; Chen, F.R.; Han, Y.Q.; Liang, Y.H. Microstructure and mechanical properties of pulse VPPA welded high-strength aluminum alloy joints. Trans. Chin. Weld. Inst. 2016, 37, 27–30. [Google Scholar]

- Tao, B.H.; Li, Q.; Zhang, Y.H.; Zhang, T.C.; Liu, Y. Effects of post-weld heat treatment on fracture toughness of linear friction welded joint for dissimilar titanium alloys. Mater. Sci. Eng. A 2015, 634, 141–146. [Google Scholar] [CrossRef]

- Yu, K.; Jiang, Z.G.; Leng, B.; Li, C.W.; Chen, S.J.; Tao, W.; Zhou, X.T.; Li, Z.J. Effects of post-weld heat treatment on microstructure and mechanical properties of laser welds in GH3535 superalloy. Opt. Laser Technol. 2016, 81, 18–25. [Google Scholar] [CrossRef]

- Wang, S.G.; Huang, Y.; Zhao, L. Effects of different aging treatments on microstructures and mechanical properties of Al-Cu-Li alloy joints welded by electron beam welding. Chin. J. Aeronaut. 2017. [Google Scholar] [CrossRef]

- Fadaeifard, F.; Matori, K.A.; Garavi, F.; Falahi, M.A.; Sarrigani, G.V. Effect of post weld heat treatment on microstructure and mechanical properties of gas tungsten arc welded AA6061-T6 alloy. Trans. Nonferrous Met. Soc. Chin. 2016, 26, 3102–3114. [Google Scholar] [CrossRef]

- Lin, Y.T.; Wang, M.C.; Zhang, Y.; He, Y.Z.; Wang, D.P. Investigation of microstructure evolution after post-weld heat treatment and cryogenic fracture toughness of the weld metal of AA2219 VPTIG joints. Mater. Des. 2017, 113, 54–59. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Ravisankar, V.; Reddy, G.M. Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int. J. Adv. Manuf. Technol. 2008, 29, 492–500. [Google Scholar] [CrossRef]

- Ahmad, R.; Bakar, M.A. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AA6061 joints welded by the gas metal arc welding cold metal transfer method. Mater. Des. 2011, 32, 5120–5126. [Google Scholar] [CrossRef]

- Priya, R.; Sarma, V.S.; Rao, K.P. Effect of post weld heat treatment on the microstructure and tensile properties of dissimilar friction stir welded AA 2219 and AA 6061 alloys. Trans. Indian Inst. Met. 2009, 62, 11–19. [Google Scholar] [CrossRef]

- Sullivan, A.; Robson, J.D. Microstructural properties of friction stir welded and post-weld heat-treated 7449 aluminum alloy thick plate. Mater. Sci. Eng. A 2008, 478, 351–360. [Google Scholar] [CrossRef]

- Aoba, T.; Kobayashi, M.; Miura, H. Effects of aging on mechanical properties and microstructure of multidirectionally forged 7075 aluminum alloy. Mater. Sci. Eng. A 2017, 700, 220–225. [Google Scholar] [CrossRef]

- Zou, X.L.; Yan, H.; Chen, X.H. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment. Trans. Nonferrous Met. Soc. Chin. 2017, 27, 2146–2155. [Google Scholar] [CrossRef]

- Mahathaninwonga, N.; Plookphola, T.; Wannasina, J.; Wisutmethangoonb, S. T6 heat treatment of rheocasting 7075 Al alloy. Mater. Sci. Eng. A 2012, 532, 91–99. [Google Scholar] [CrossRef]

- Sun, C.; Dong, L.X.; Liu, L.L. Effect of solution treatment on microstructure and mechanical properties of 7075 Al alloy. Hot Work. Technol. 2010, 39, 249–251, 256. [Google Scholar]

| Elements | Zn | Mg | Cu | Cr | Mn | Ti | Fe | Si | Impurity | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | |||||||||||

| 7075 | 5.1∼6.1 | 2.1∼2.9 | 1.2∼2.0 | 0.18∼0.28 | 0.3 | 0.2 | 0.5 | 0.4 | 0.15 | Bal. | |

| 5183 | 0.25 | 4.3∼5.2 | 0.1 | 0.05∼0.25 | 0.5∼1.0 | 0.15 | 0.4 | 0.4 | 0.15 | Bal. | |

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| 7075 | 589.2 | 535.3 | 12 | 150 |

| Welding Parameters | Positive Polarity Current (A) | Reversed Polarity Current (A) | Welding Speed (mm·min−1) | Wire Feeding Speed (mm·min−1) | Plasma Gas Flow Rate (L·min−1) |

| value | 240∼260 | 280∼300 | 150 | 220 | 2.0 |

| Welding Parameters | Protection Gas Flow Rate (L·min−1) | Tungsten Electrode Neck-In (mm) | Time Ratio (ms) | High Frequency (Hz) | Low Frequency (Hz) |

| value | 15 | 3 | 21:4 | 50 | 1 |

| Number | Solution Temperature (°C) | Solution Time (min) |

|---|---|---|

| 1 | 460 | 60 |

| 2 | 470 | |

| 3 | 480 | |

| 4 | 490 | |

| 5 | 500 | |

| 6 | 490 | 40 |

| 7 | 60 | |

| 8 | 80 | |

| 9 | 100 | |

| 10 | 120 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Chen, F.; Han, Y.; Liang, Y. Improving Mechanical Properties of PVPPA Welded Joints of 7075 Aluminum Alloy by PWHT. Materials 2018, 11, 379. https://doi.org/10.3390/ma11030379

Li G, Chen F, Han Y, Liang Y. Improving Mechanical Properties of PVPPA Welded Joints of 7075 Aluminum Alloy by PWHT. Materials. 2018; 11(3):379. https://doi.org/10.3390/ma11030379

Chicago/Turabian StyleLi, Guowei, Furong Chen, Yongquan Han, and Yahong Liang. 2018. "Improving Mechanical Properties of PVPPA Welded Joints of 7075 Aluminum Alloy by PWHT" Materials 11, no. 3: 379. https://doi.org/10.3390/ma11030379