Trifunctional Epoxy Resin Composites Modified by Soluble Electrospun Veils: Effect on the Viscoelastic and Morphological Properties

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Electrospun Veil Preparation

2.3. Neat Resin Preparation

2.4. Composite Laminate Production

3. Characterization

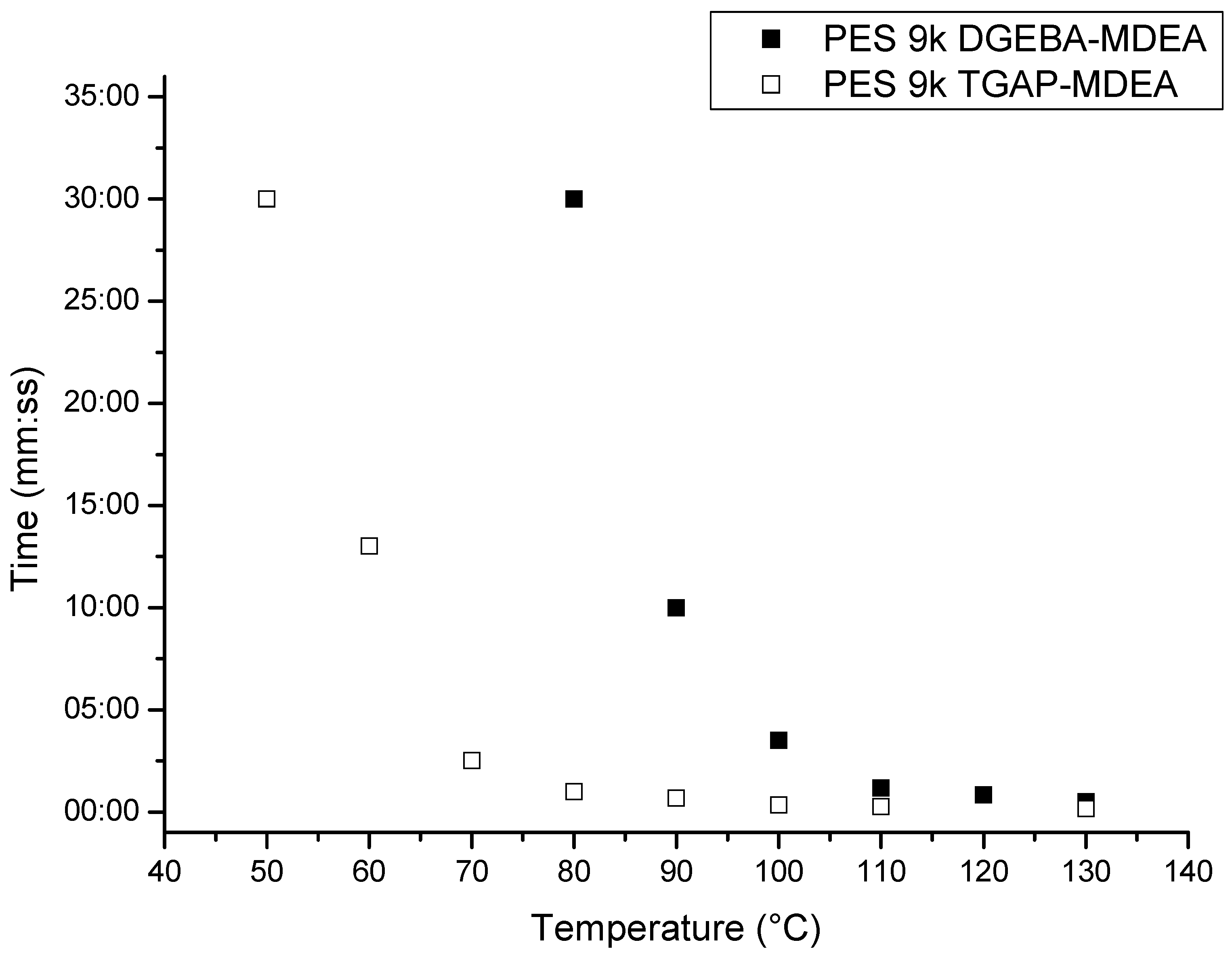

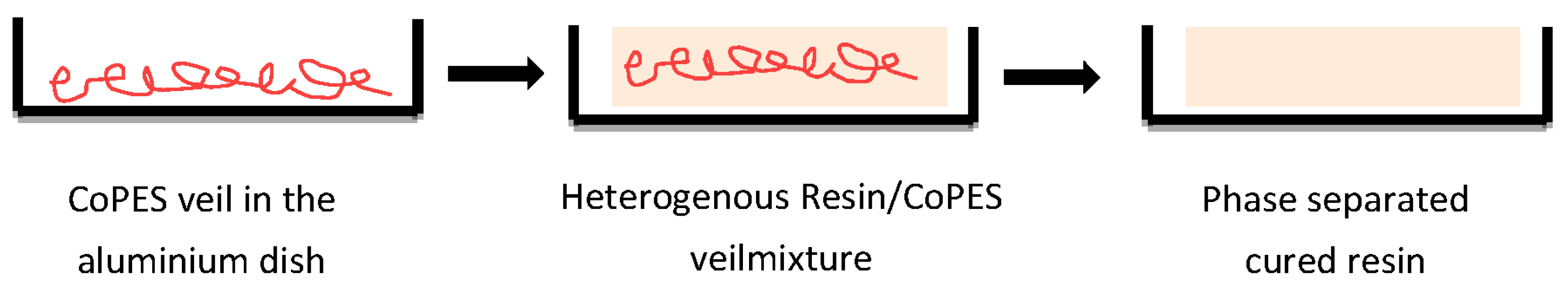

3.1. Hot-Stage Microscopy

3.2. Dynamic Mechanical Analysis (DMA)

3.3. Scanning Electron Microscopy (SEM)

4. Results and Discussion

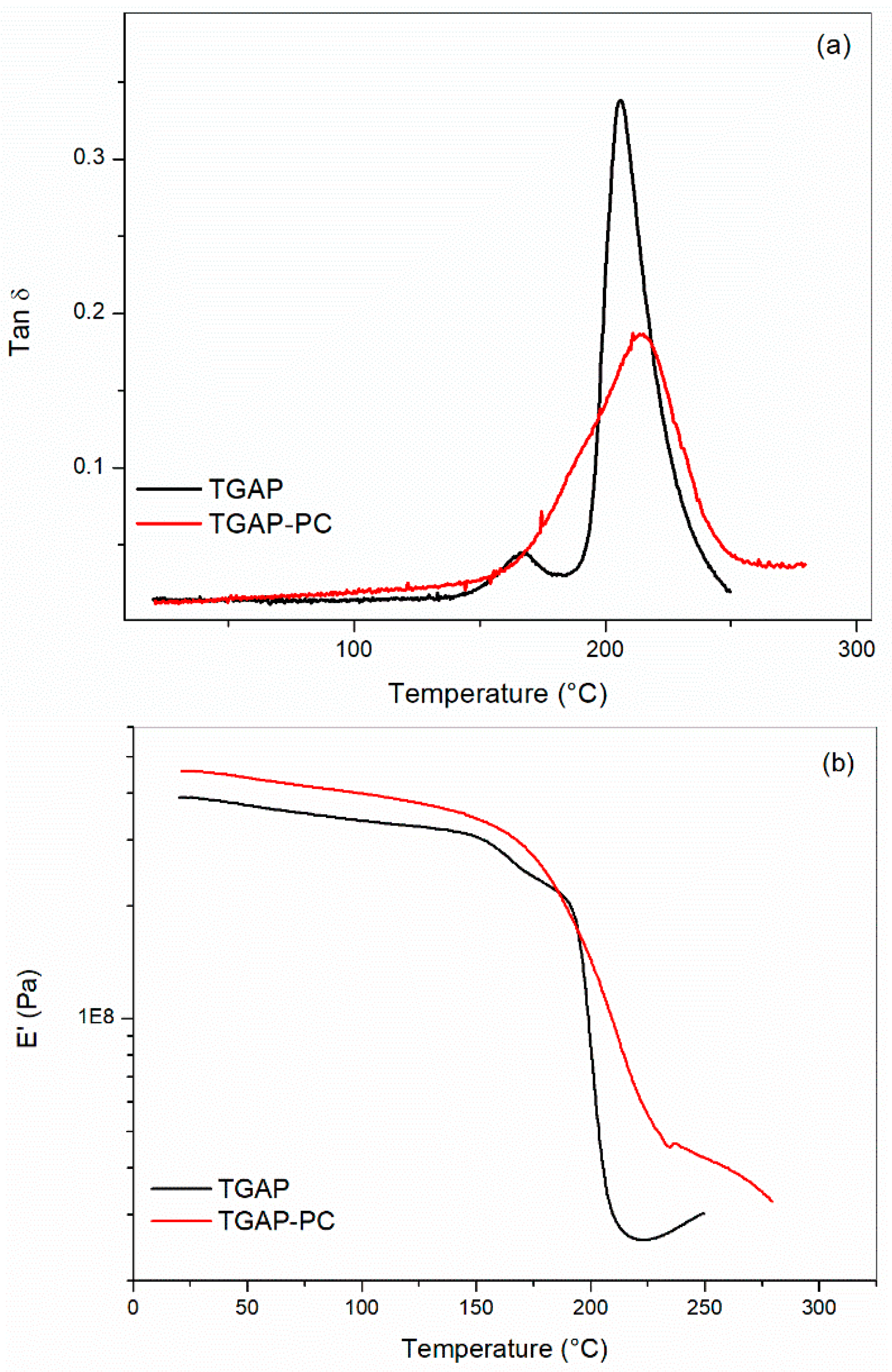

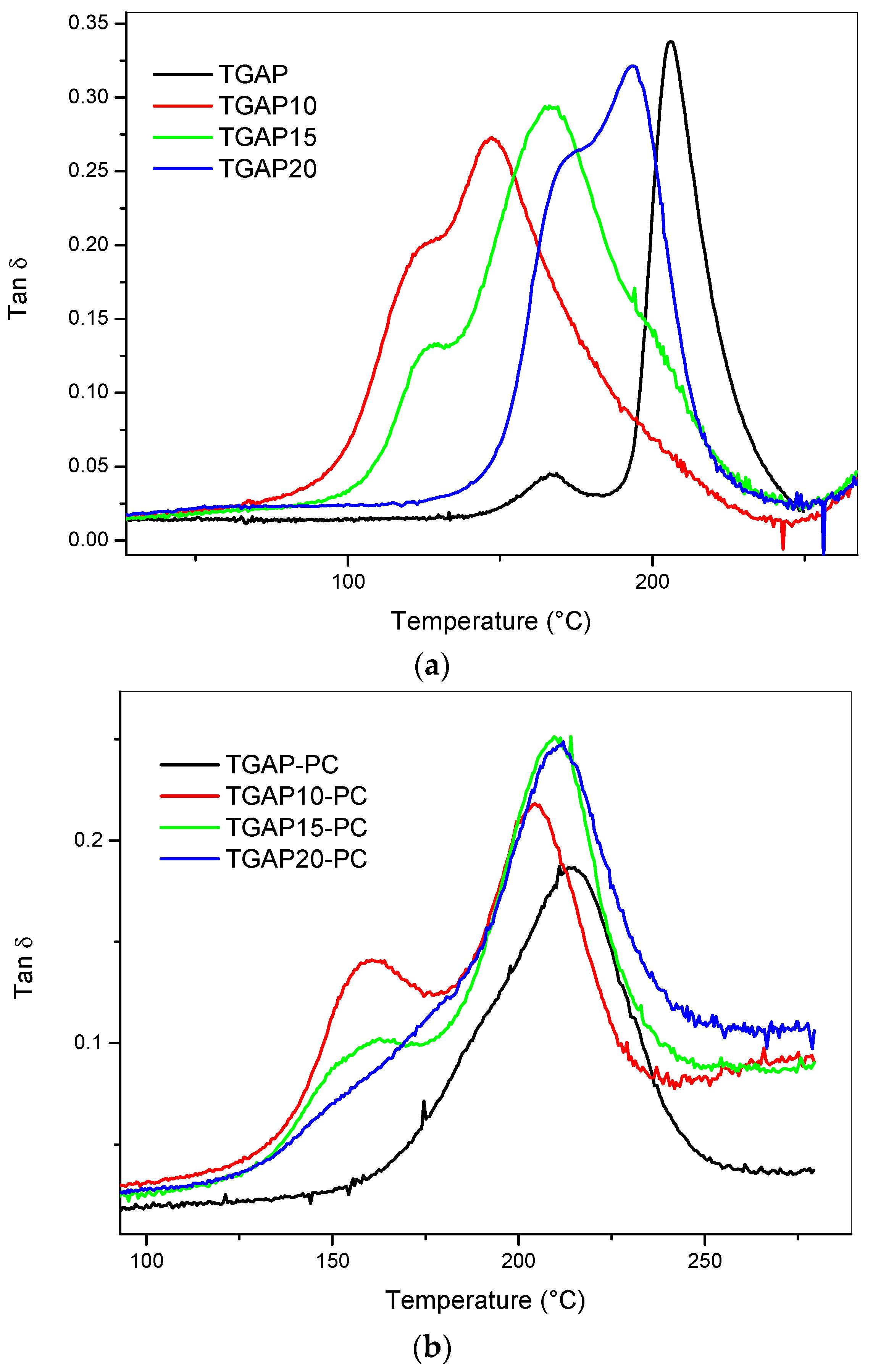

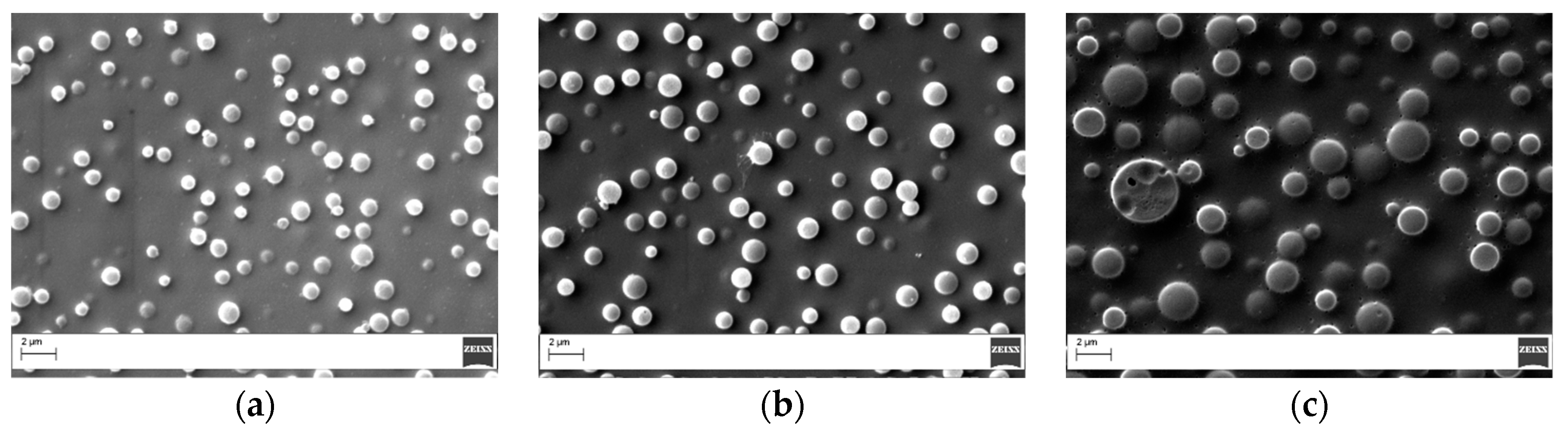

4.1. Neat Resin Samples

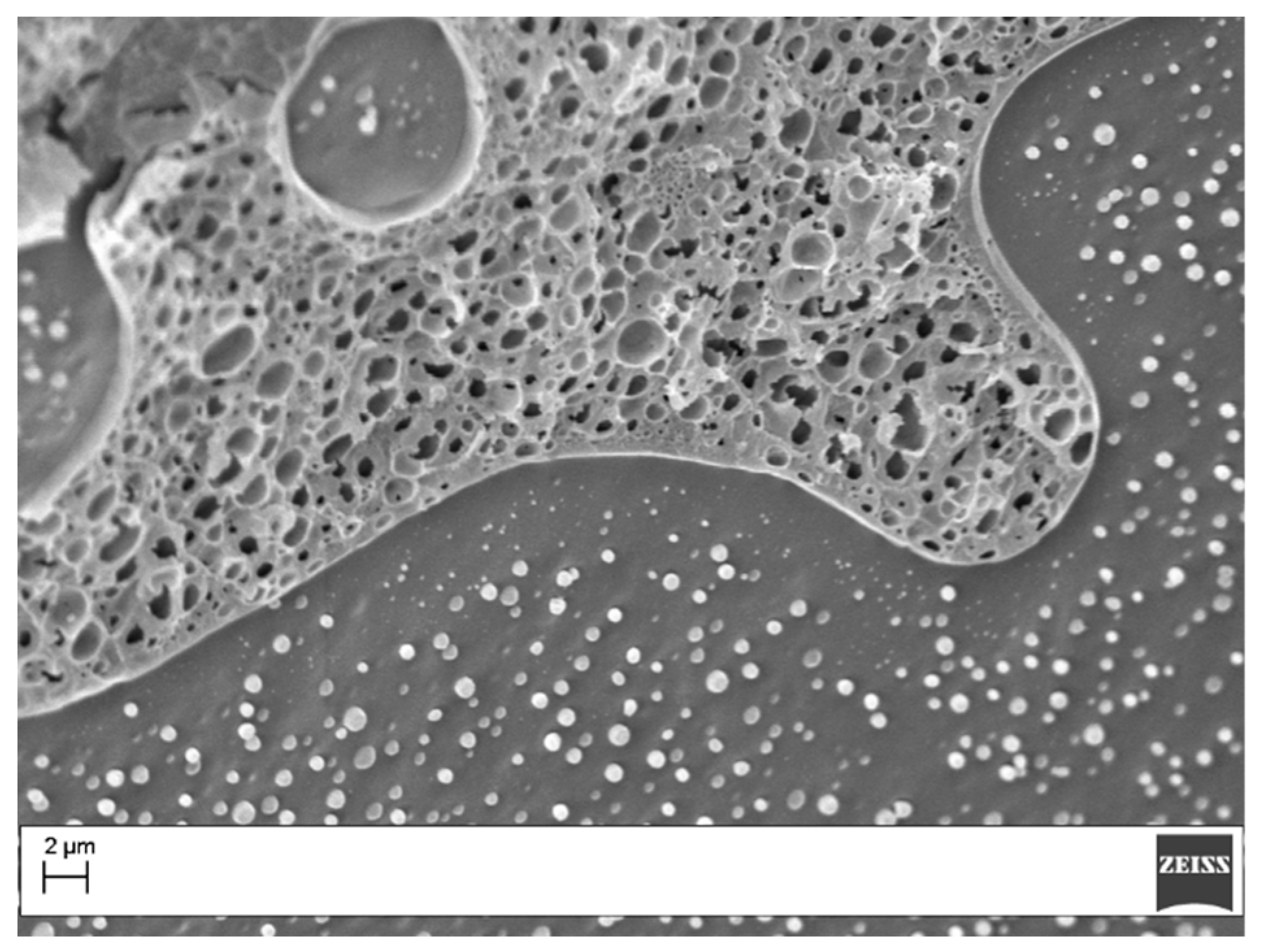

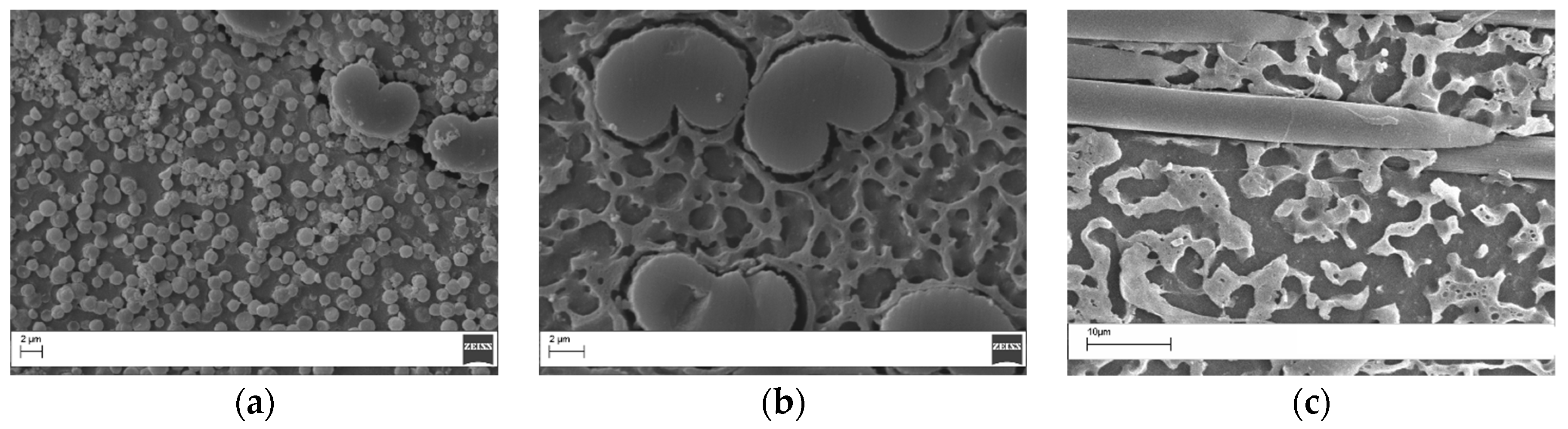

4.2. Composite Laminate Samples

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ellis, B. Chemistry and Technology of Epoxy Resins; Blackie Academic & Professional: Glasgow, UK, 1993. [Google Scholar]

- Bilyeu, B.; Brostow, W.; Menard, K.P. Epoxy thermosets and their applications I: Chemical structures and applications. J. Mater. Educ. 1999, 21, 281–286. [Google Scholar]

- Bilyeu, B.; Brostow, W.; Menard, K.P. Epoxy thermosets and their applications. II. Thermal analysis. J. Mater. Educ. 2000, 22, 107–130. [Google Scholar]

- Bilyeu, B.; Brostow, W.; Menard, K.P. Epoxy thermosets and their applications. III. Kinetic equations and models. J. Mater. Educ. 2001, 23, 189–204. [Google Scholar]

- Bilyeu, B.; Brostow, W.; Menard, K.P. Separation of gelation from vitrification in curing of a fiber-reinforced epoxy composite. Polym. Compos. 2002, 23, 1111–1119. [Google Scholar] [CrossRef]

- Pederson, C.; Lo Faro, C.; Aldridge, M.; Maskell, R. Epoxy-soluble thermoplastic fibers: Enabling technology for manufacturing high toughness structures by liquid resin infusion. SAMPE J. 2003, 39, 22–28. [Google Scholar]

- Li, G.; Li, P.; Zhang, C.; Yu, Y.; Liu, H.; Zhang, S.; Ji, X.; Yang, X.; Xue, Z.; Ryu, S. Inhomogeneous toughening of carbon fiber/epoxy composite using electrospunpolysulfone nanofibrous membranes by in situ phase separation. Compos. Sci. Technol. 2008, 68, 987–994. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Wang, X. Electrospun nanofibre toughened carbon/epoxy composites: Effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness. Compos. Sci. Technol. 2010, 70, 1660–1666. [Google Scholar] [CrossRef]

- Magniez, K.; Chaffraix, T.; Fox, B. Toughening of a carbon-fibre composite using electrospun poly (hydroxyether of bisphenol a) nanofibrous membranes through inverse phase separation and inter-domain etherification. Materials 2011, 4, 1967–1984. [Google Scholar] [CrossRef] [PubMed]

- Molnar, K.; Kostakova, E.; Meszaros, L. The effect of needleless electrospun nanofibrous interleaves on mechanical properties of carbon fabrics/epoxy laminates. Express Polym. Lett. 2014, 8, 62–72. [Google Scholar] [CrossRef] [Green Version]

- Cicala, G.; Mannino, S.; Latteri, A.; Ognibene, G.; Saccullo, G. Effects of mixing di-and tri-functional epoxy monomers on epoxy/thermoplastic blends. Adv. Polym. Technol. 2017, 1–10. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.R. Roles of difunctional epoxy in the tetrafunctional epoxy matrix system. J. Mater. Sci. Lett. 2001, 20, 773–775. [Google Scholar] [CrossRef]

- Yi, J.W.; Um, M.K.; Byun, J.H.; Lee, S.B.; Lee, S.K. Development of high Tg epoxy resin and mechanical properties of its fiber-reinforced composites. J. Appl. Polym. Sci. 2013, 127, 4328–4333. [Google Scholar] [CrossRef]

- Shang, J.; Guo, Q.; Fox, B.L. Study on thermoplastic-modified multifunctional epoxies: Influence of heating rate on cure behaviour and phase separation. Compos. Sci. Technol. 2009, 69, 1172–1179. [Google Scholar]

- Hourston, D.J.; Lane, J.M.; Zhang, H.X. Toughening of epoxy resins with thermoplastics: 3. An investigation into the effects of composition on the properties of epoxy resin blends. Polym. Int. 1997, 42, 349–355. [Google Scholar] [CrossRef]

- Bonnaud, L.; Pascault, J.P.; Sautereau, H. Kinetic of a thermoplastic-modified epoxy-aromatic diamine formulation: Modeling and influence of a trifunctional epoxy prepolymer. Eur. Polym. J. 2000, 36, 1313–1321. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Mannino, S.; Ognibene, G.; Blanco, I. Influence of Soluble Electrospun Co-Polyethersulfone Veils on Dynamic Mechanical and Morphological Properties of Epoxy Composites: Effect of Polymer Molar Mass. Adv. Polym. Technol. 2016. [Google Scholar] [CrossRef]

- Puglisi, C.; Samperi, F.; Cicala, G.; Recca, A.; Restuccia, C.L. Combined MALDI–TOF MS and NMR characterization of copoly (arylen ether sulphone)s. Polymer 2006, 47, 1861–1874. [Google Scholar] [CrossRef]

- Kim, B.S.; Inou, T. Dynamic mechanical and Fourier-transform infra-red analyses on the very late stage of the cure process in thermoset/thermoplastic blends: Trifunctional epoxy/poly (ether sulfone). Polymer 1995, 36, 1985–1989. [Google Scholar] [CrossRef]

- Varley, R.J.; Hodkin, J.H.; Hawthorne, D.G.; Simon, G.P. Toughening of a trifunctional epoxy system: IV. Dynamic mechanical relaxational study of the thermoplastic-modified cure process. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 153–163. [Google Scholar] [CrossRef]

- van Overbeke, E.; Carlier, V.; Devaux, J.; Carter, J.T.; McGrail, P.T.; Legras, R. The use of Raman spectroscopy to study the reaction between an amine-terminated thermoplastic and epoxy resins. Polymer 2000, 41, 8241–8245. [Google Scholar] [CrossRef]

- Cicala, G.; La Spina, R.; Sturiale, S.; Recca, A. Influence of copolymer’s end groups and molecular weights on the rheological and thermomechanical properties of blends of novel thermoplastic copolymers and epoxy resins. J. Appl. Polym. Sci. 2006, 101, 250–257. [Google Scholar] [CrossRef]

- Bonnaud, L.; Bonnet, A.; Pascault, J.P.; Sautereau, H.; Riccardi, C.C. Different parameters controlling the initial solubility of two thermoplastics in epoxy reactive solvents. J. Appl. Polym. Sci. 2002, 83, 1385–1396. [Google Scholar] [CrossRef]

- Varley, R.J.; Hodgkin, J.H. Effect of reinforcing fibres on the morphology of a toughened epoxy/amine system. Polymer 1997, 38, 1005–1009. [Google Scholar] [CrossRef]

- Olmos, D.; Gonzalez-Benito, J. Visualization of the morphology at the interphase of glass fibre reinforced epoxy-thermoplastic polymer composites. Eur. Polym. J. 2007, 43, 1487–1500. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ognibene, G.; Mannino, S.; Fragalà, M.E.; Cicala, G. Trifunctional Epoxy Resin Composites Modified by Soluble Electrospun Veils: Effect on the Viscoelastic and Morphological Properties. Materials 2018, 11, 405. https://doi.org/10.3390/ma11030405

Ognibene G, Mannino S, Fragalà ME, Cicala G. Trifunctional Epoxy Resin Composites Modified by Soluble Electrospun Veils: Effect on the Viscoelastic and Morphological Properties. Materials. 2018; 11(3):405. https://doi.org/10.3390/ma11030405

Chicago/Turabian StyleOgnibene, Giulia, Salvatore Mannino, Maria Elena Fragalà, and Gianluca Cicala. 2018. "Trifunctional Epoxy Resin Composites Modified by Soluble Electrospun Veils: Effect on the Viscoelastic and Morphological Properties" Materials 11, no. 3: 405. https://doi.org/10.3390/ma11030405