Ratcheting Strain and Microstructure Evolution of AZ31B Magnesium Alloy under a Tensile-Tensile Cyclic Loading

Abstract

:1. Introduction

2. Experiments

3. Results and Discussion

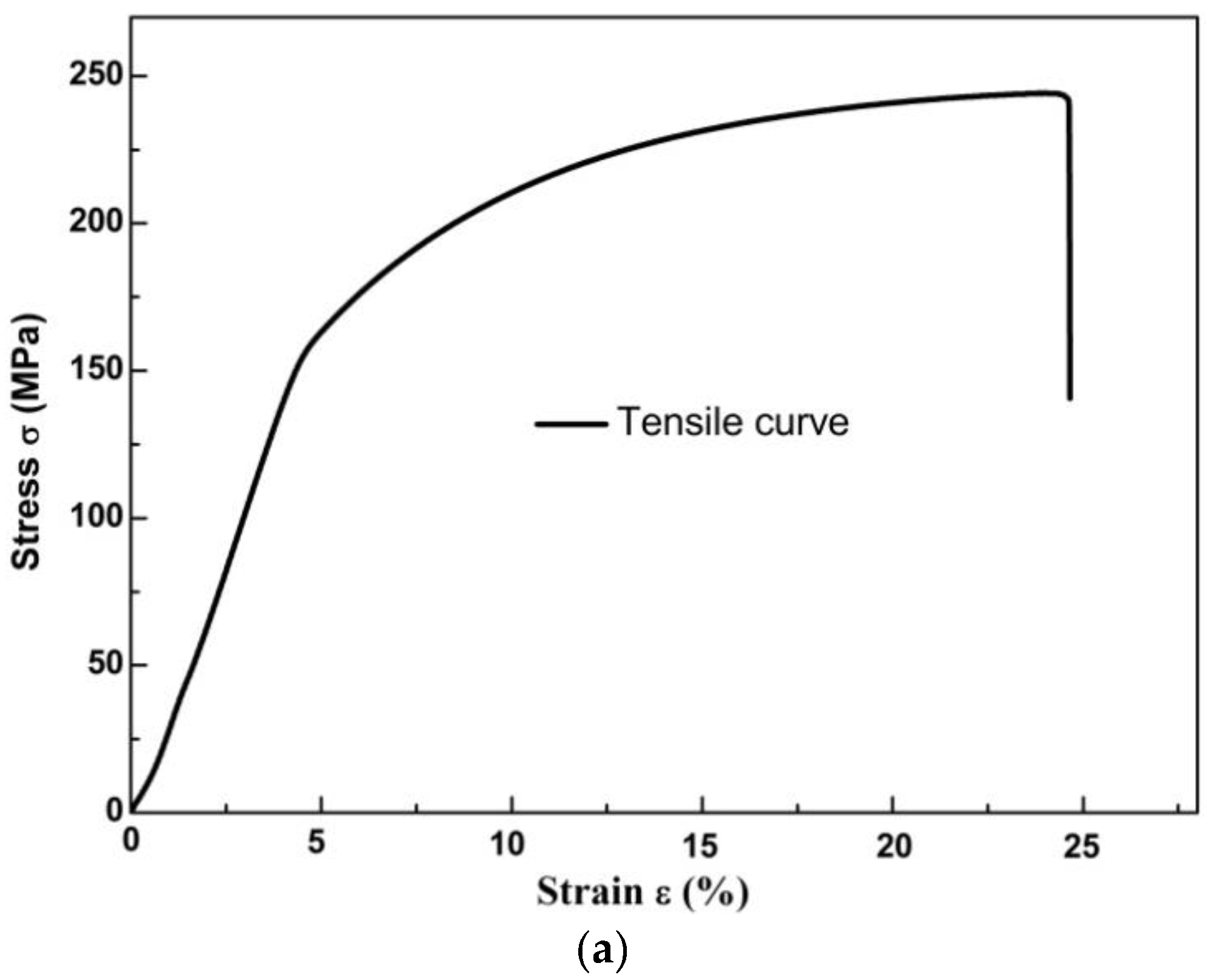

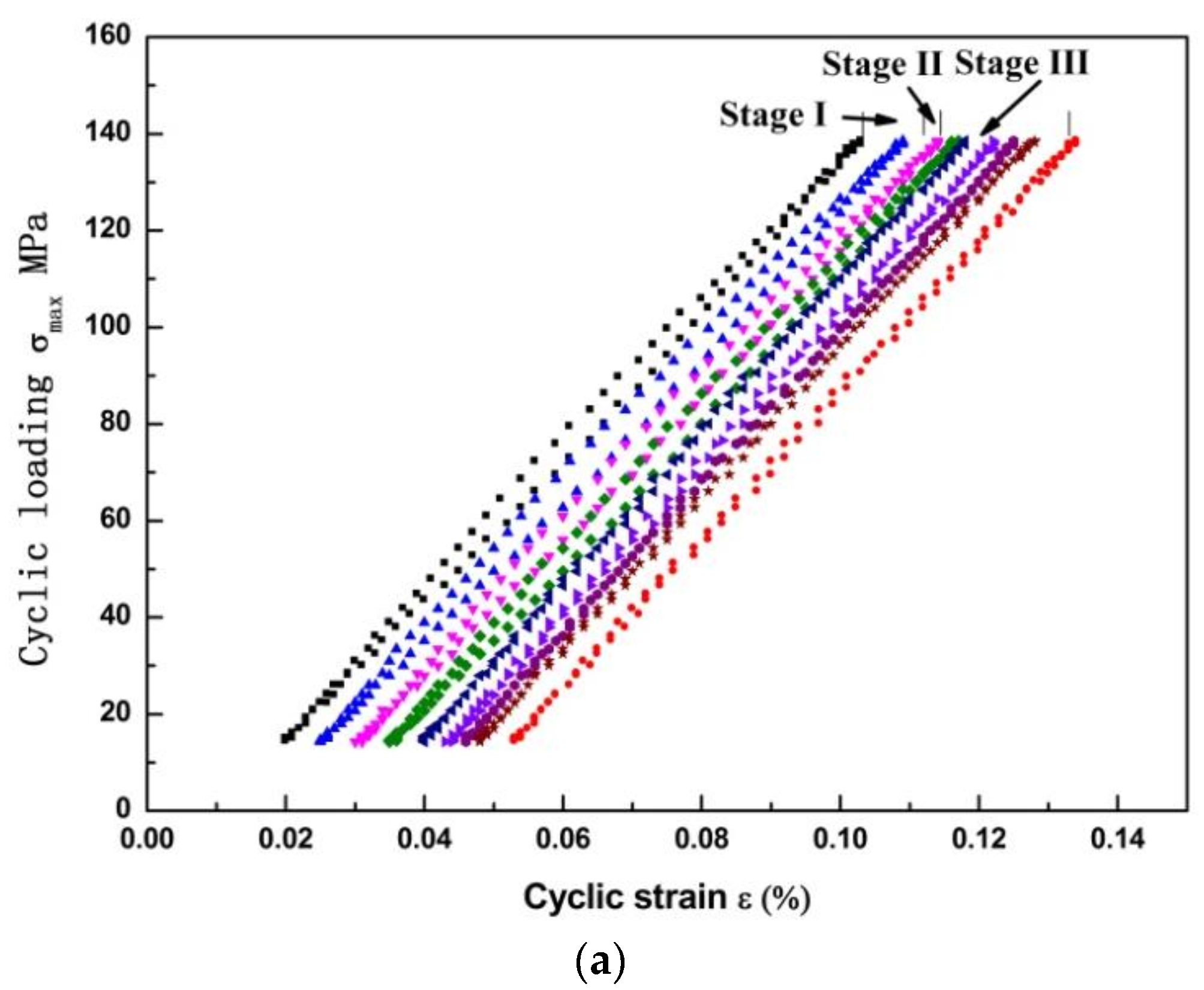

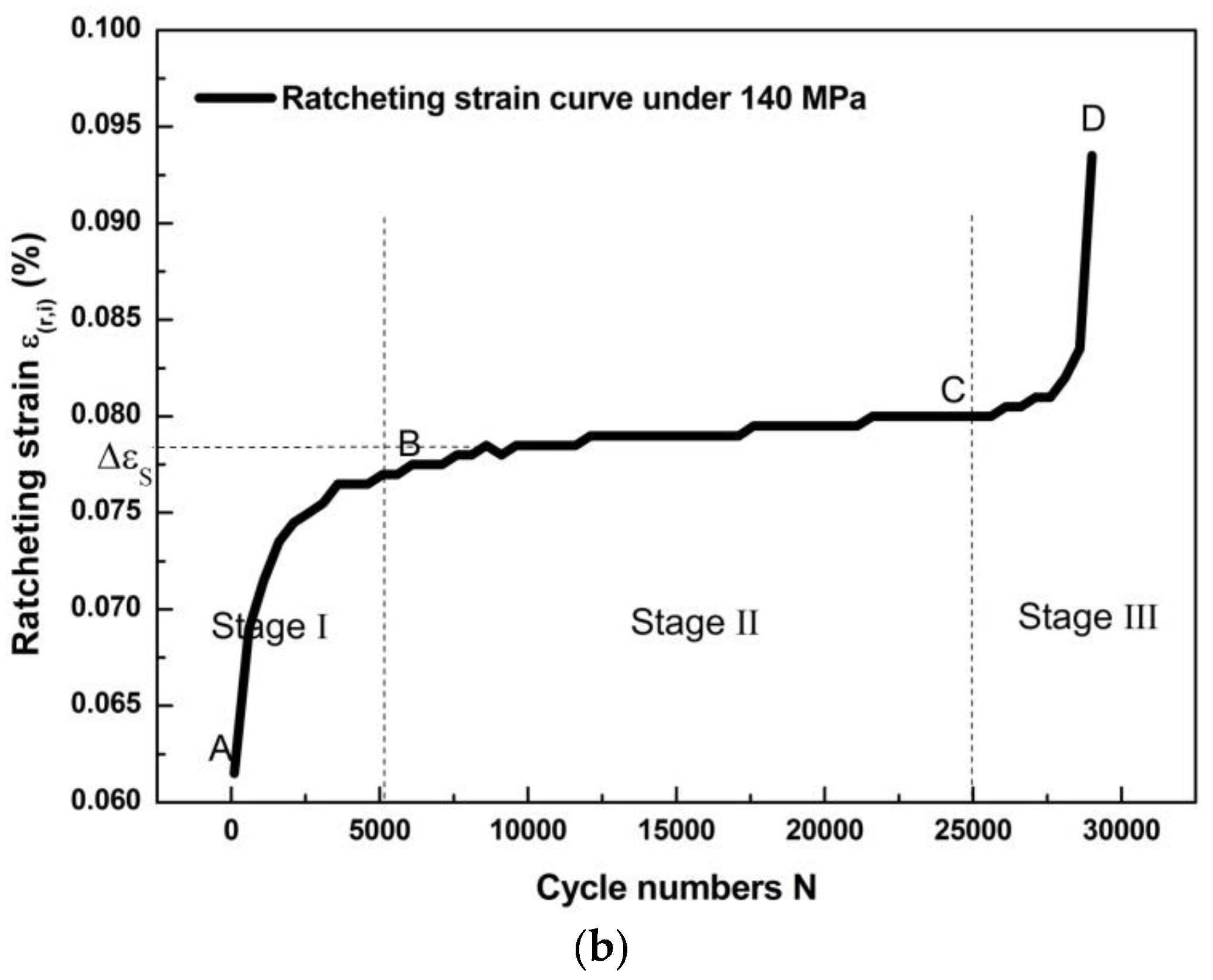

3.1. Deformation Curves of the AZ31B Alloy under cyclic loading

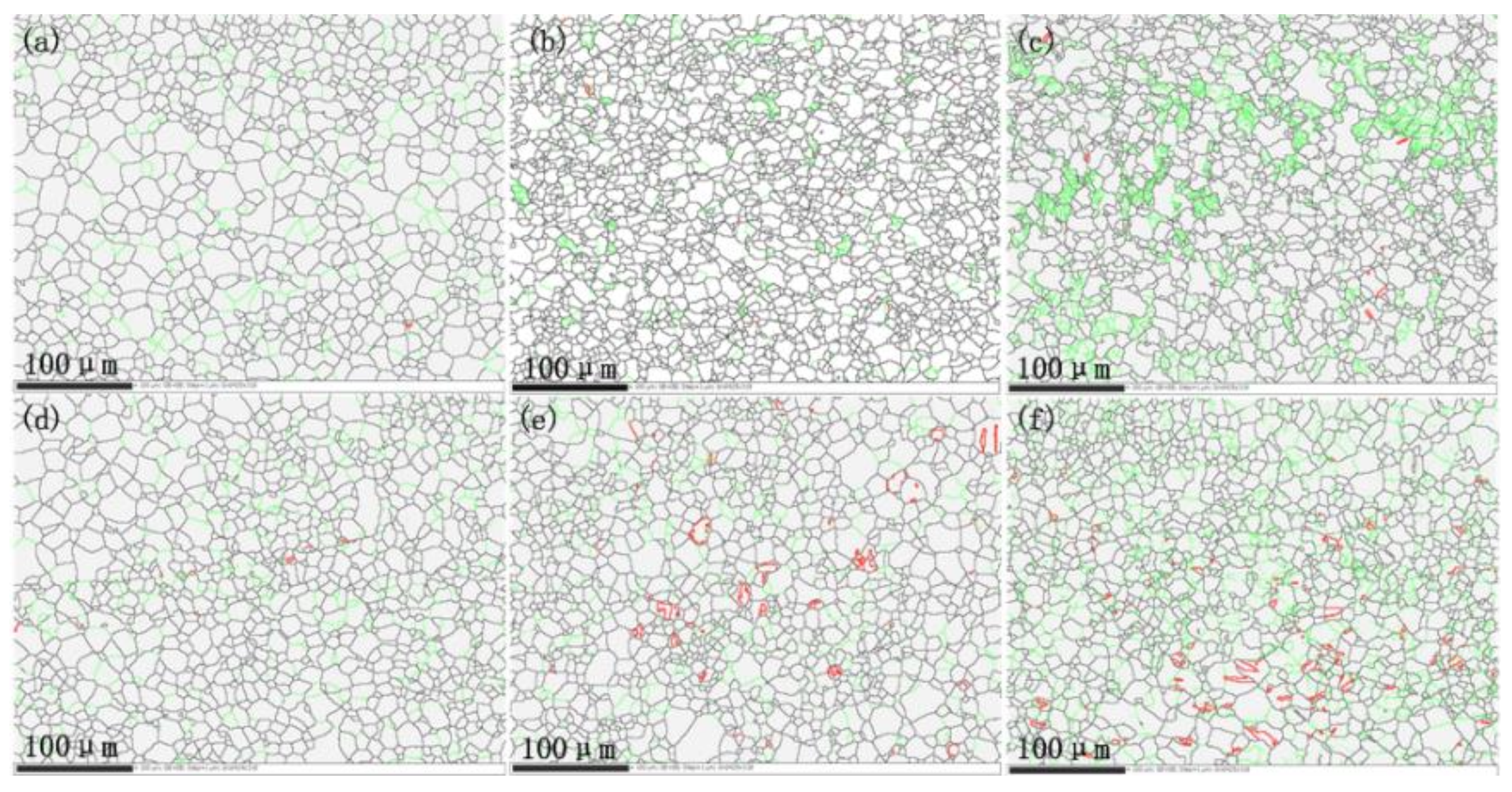

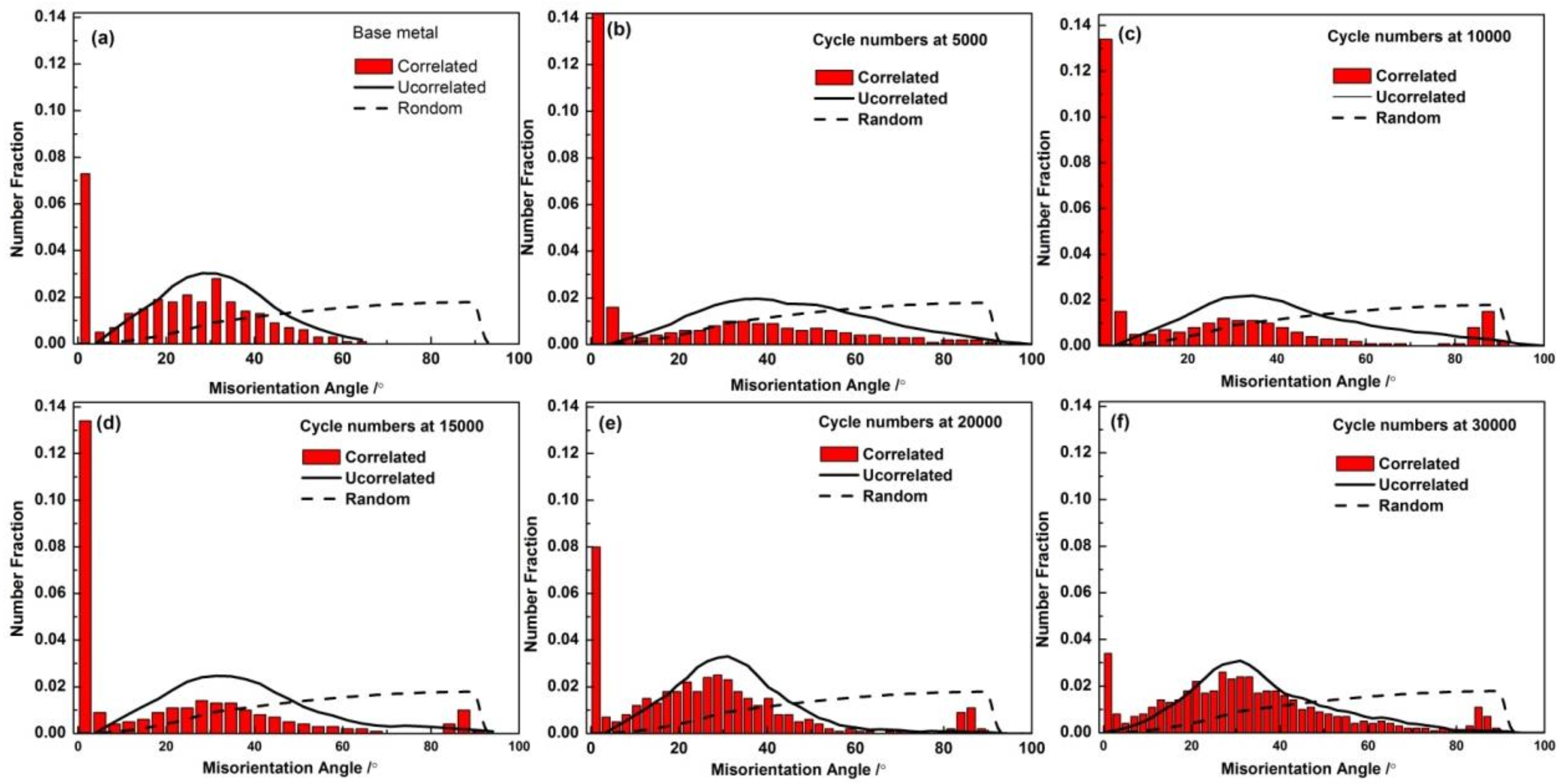

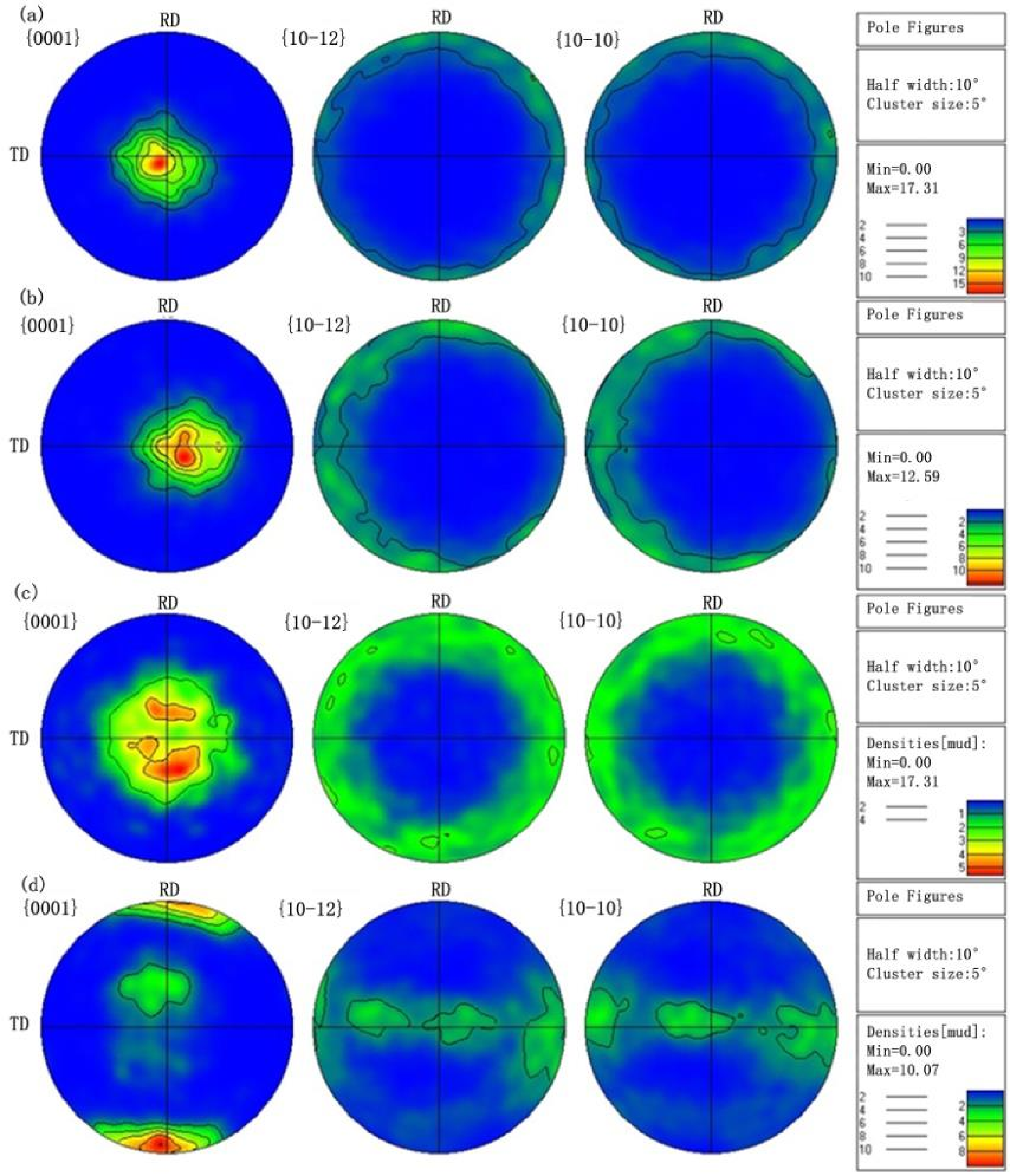

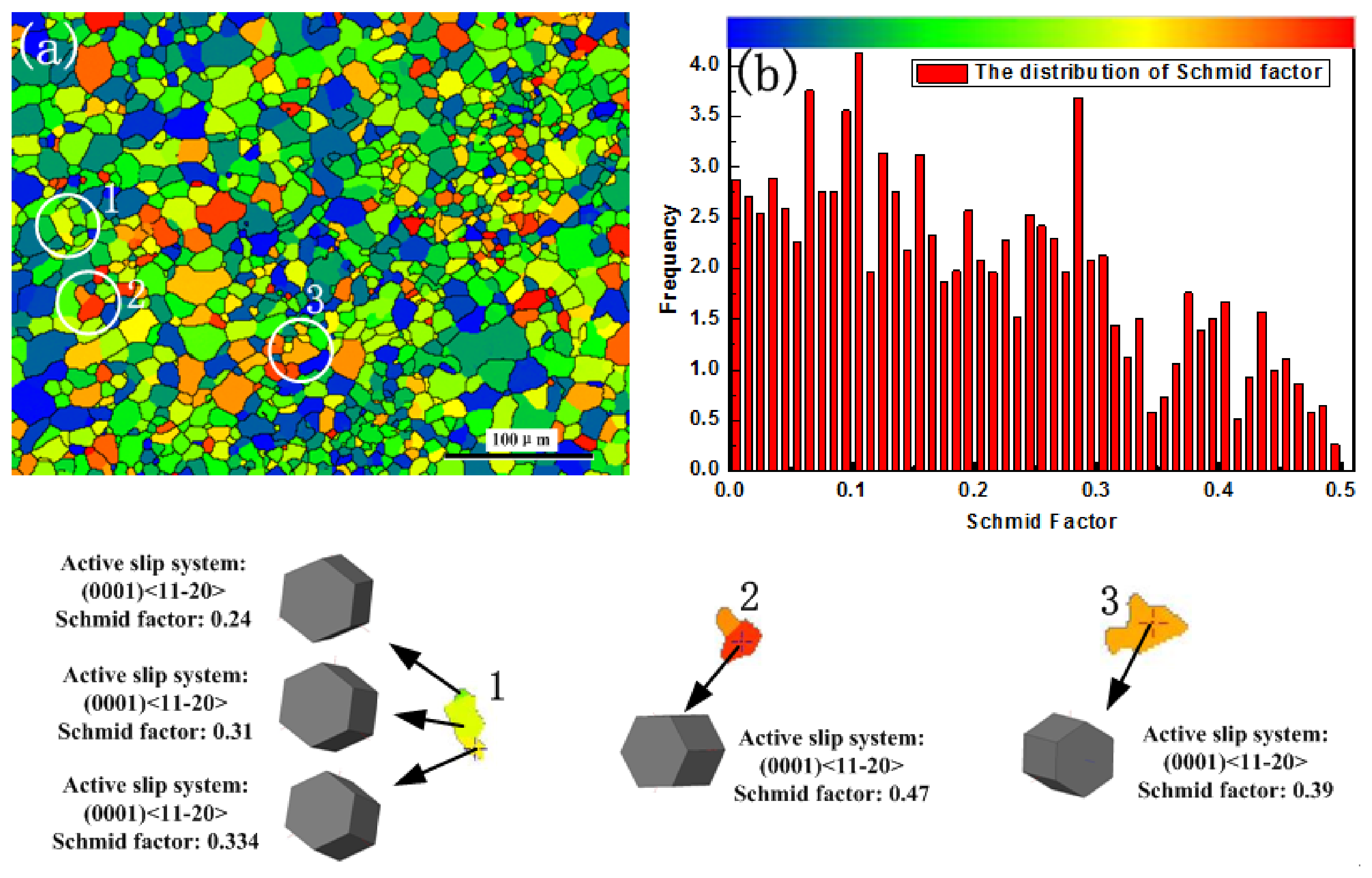

3.2. Microstructure Evolution

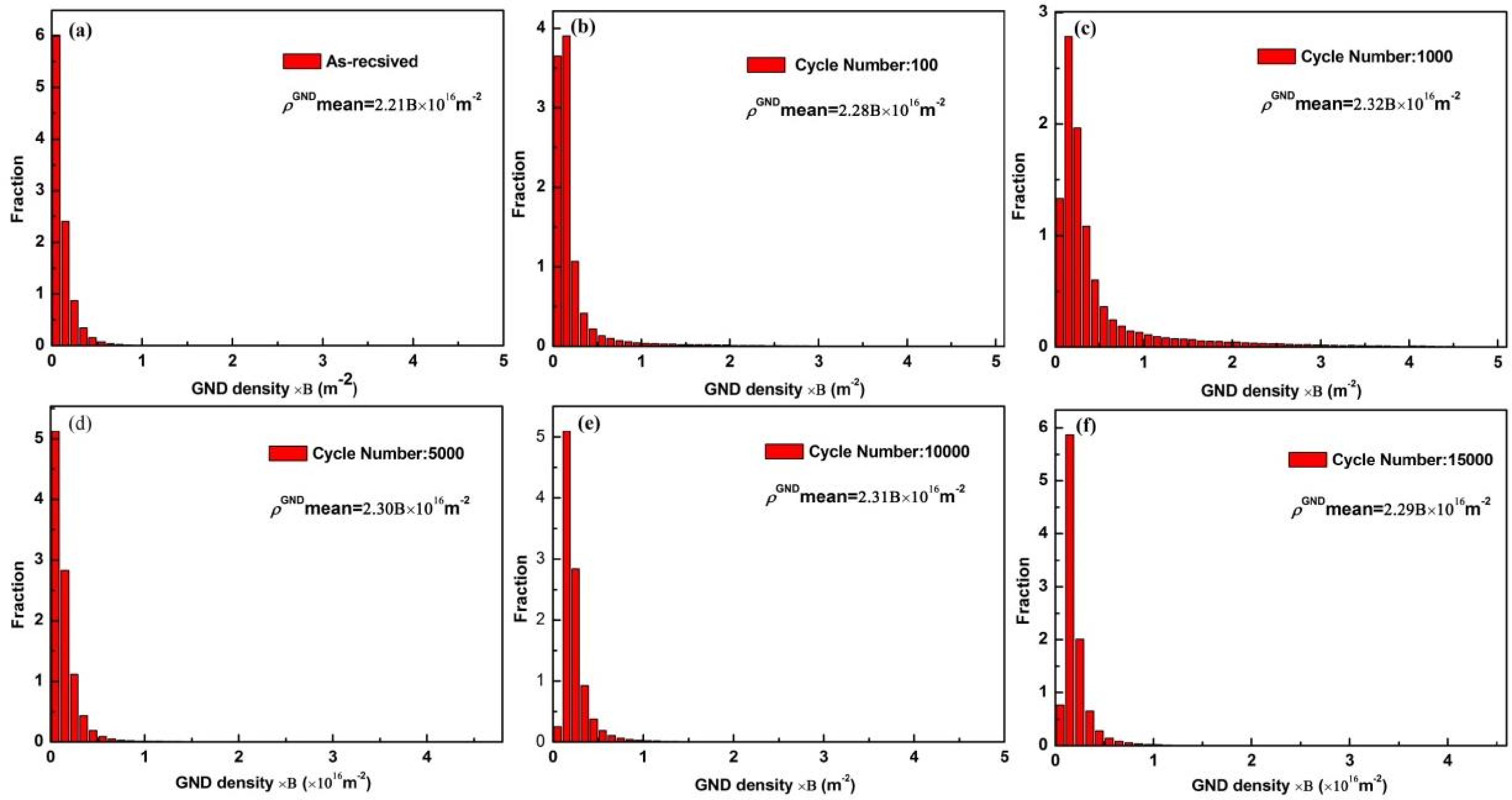

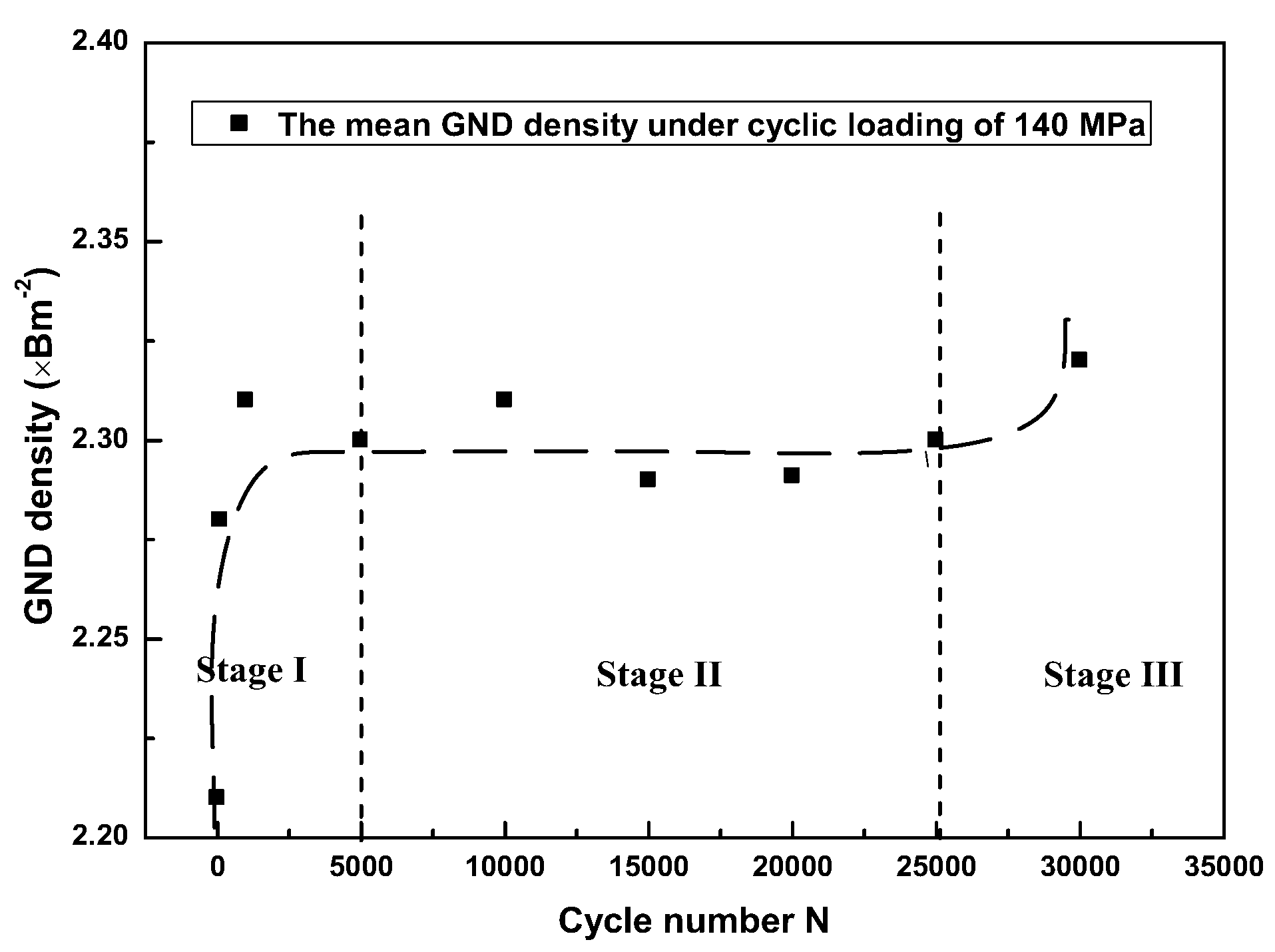

3.3. Geometrically Necessary Dislocation (GND) Density Change with the Cycle Increase

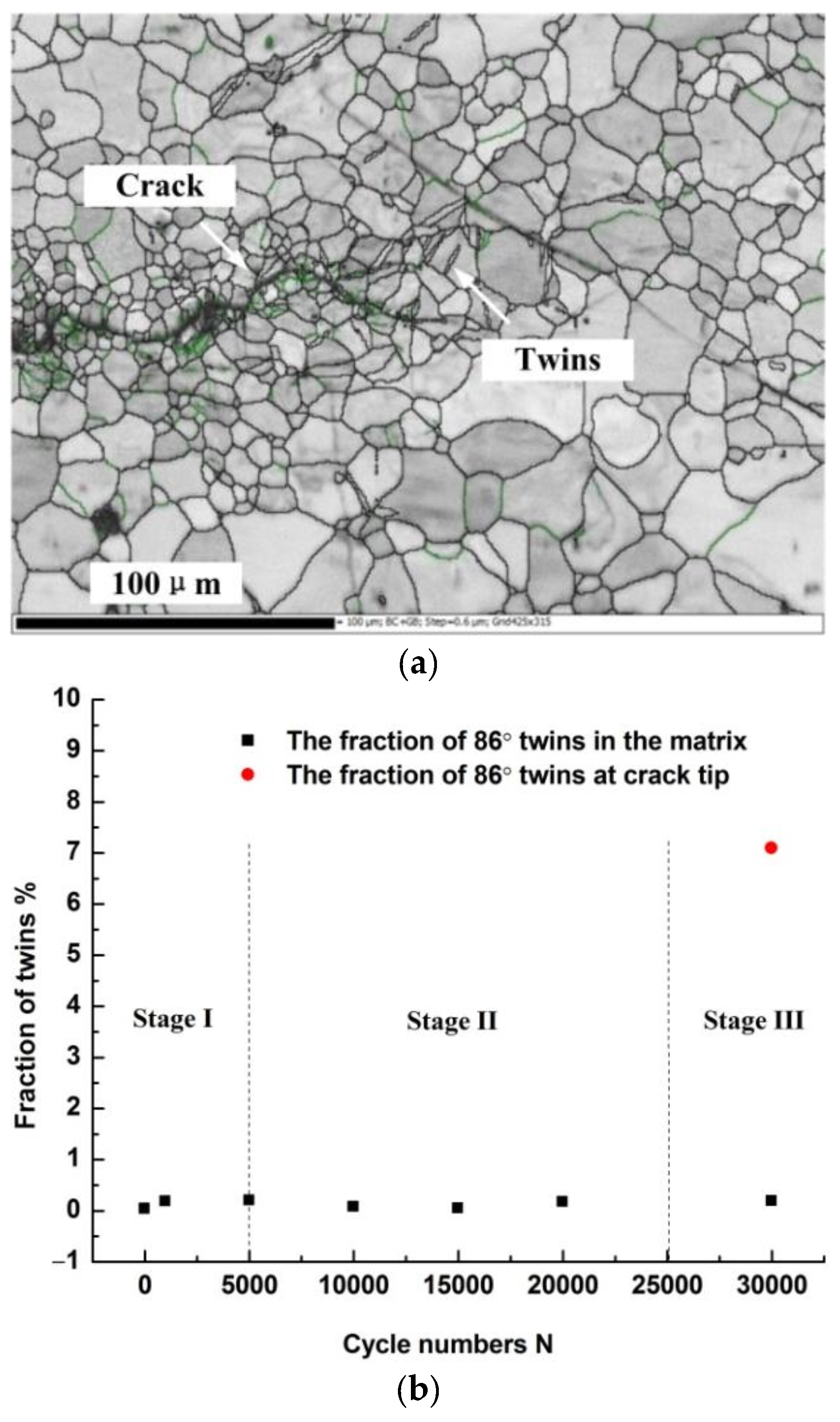

3.4. The Microstructure at the Crack Tip Area

3.5. The Fatigue Fracture Mechanism

4. Conclusions

- (1)

- There is the ratcheting effect for the alloy under a cyclic loading of 140 MPa. The development of the ratcheting strain includes three stages: rapid increase stage (Stage I); steady stage (Stage II); and final abrupt increase stage (Stage III). The change of Extra Geometrically Necessary Dislocations (GNDs) was found to have the same evolutionary tendency as that of the ratcheting strain.

- (2)

- Two deformation mechanisms, basal slip and {10−12} tensile twinning, are found to be dominant during a cyclic loading, which is stress-controlled. The {0001} basal slip dominates plastic deformation during the crack initiation (Stage I and II) and the 86° {10−12} tensile twinning is dominant in Stage III.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Morita, S.; Ohno, N.; Tamai, F.; Kawakami, Y. Fatigue properties of rolled AZ31B magnesium alloy plate. Trans. Nonferr. Met. Soc. China 2010, 20, 523–526. [Google Scholar] [CrossRef]

- Ishihara, S.; McEvily, A.J.; Sato, M.; Taniguchi, K.; Goshima, T. The effect of load ratio on fatigue life and crack propagation behavior of an extruded magnesium alloy. Int. J. Fatigue 2009, 31, 1788–1794. [Google Scholar] [CrossRef]

- Li, Z.M.; Wang, Q.G.; Luo, A.A.; Peng, L.M.; Zhang, P. Fatigue behavior and life prediction of cast magnesium alloys. Mater. Sci. Eng. A 2015, 647, 113–126. [Google Scholar] [CrossRef]

- Dallmeier, J.; Huber, O.; Saage, H.; Eigenfield, K. Uniaxial cyclic deformation and fatigue behavior of AM50 magnesium alloy sheet metals under symmetric and asymmetric loadings. Mater. Des. 2015, 70, 10–30. [Google Scholar] [CrossRef]

- Castro, F.; Jiang, Y.Y. Fatigue of extruded AZ31B magnesium alloy under stress-and strain-controlled conditions including step loading. Mech. Mater. 2017, 108, 77–86. [Google Scholar] [CrossRef]

- Xiong, Y.; Jiang, Y.Y. Fatigue of ZK60 magnesium alloy under uniaxial loading. Int. J. Fatigue 2014, 64, 74–83. [Google Scholar] [CrossRef]

- Shahzad, M.; Chaussumier, M.; Chieragatti, R.; Mabru, C.; Rezai-Aria, F. Surface characterization and influence of anodizing process on fatigue life of Al 7050 alloy. Mater. Des. 2011, 32, 3328–3335. [Google Scholar] [CrossRef] [Green Version]

- Hudson, C.M.; Seward, S.K. A literature review and inventory of the effects of environment on the fatigue behavior of metals. Eng. Fract. Mech. 1976, 8, 315–329. [Google Scholar] [CrossRef]

- Zhang, X.P.; Castagne, S.; Luo, X.F.; Gu, C.F. Effects of extrusion ratio on the ratcheting behavior of extruded AZ31B magnesium alloy under asymmetrical uniaxial cyclic loading. Mater. Sci. Eng. A 2011, 528, 838–845. [Google Scholar] [CrossRef]

- Chen, G.; Lu, L.T.; Cui, Y.; Xing, R.S.; Gao, H.; Chen, X. Ratcheting and low-cycle fatigue characterizations of extruded AZ31B Mg alloy with and without corrosive environment. Int. J. Fatigue 2015, 80, 364–371. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Chen, J. Low-cycle fatigue behaviors of hot-rolled AZ91 magnesium alloy under asymmetrical stress-controlled cyclic loadings. J. Alloys Compd. 2013, 579, 540–548. [Google Scholar] [CrossRef]

- Xiong, Y.; Jiang, Y.Y. Cyclic deformation and fatigue of rolled AZ80 magnesium alloy along different material orientations. Mater. Sci. Eng. A 2016, 677, 58–67. [Google Scholar] [CrossRef]

- Wen, B.K.; Wang, F.H.; Jin, L.; Dong, J. Fatigue damage development in extruded Mg-3Al-Zn magnesium alloy. Mater. Sci. Eng. A 2016, 667, 171–178. [Google Scholar] [CrossRef]

- Yu, D.L.; Zhang, D.F.; Luo, Y.X.; Sun, J.; Xu, J.Y.; Pan, F.S. Microstructure evolution during high cycle fatigue in Mg-6Zn-1Mn alloy. Mater. Sci. Eng. A 2016, 658, 99–108. [Google Scholar] [CrossRef]

- Huang, G.S.; Li, J.H.; Han, T.Z.; Zhang, H.; Pan, F.S. Improving low-cycle fatigue properties of rolled AZ31 magnesium alloy by pre-compression deformation. Mater. Des. 2014, 58, 439–444. [Google Scholar] [CrossRef]

- Xiong, Y.; Yu, Q.; Jiang, Y. An experimental study of cyclic plastic deformation of extruded ZK60 magnesium alloy under uniaxial loading at room temperature. Int. J. Fatigue 2014, 53, 107–124. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, D.X.; Ma, S.J.; Gu, C.F.; Chen, S.; Zhang, X.P. Effects of percent reduction and specimen orientation on the ratcheting behavior of hot-rolled AZ31B magnesium alloy. Mater. Sci. Eng. A 2013, 575, 223–230. [Google Scholar] [CrossRef]

- Azar, A.S.; Svensson, L.E.; Nyhus, B. Effect of crystal orientation and texture on fatigue crack evolution in high strength steel welds. Int. J. Fatigue 2015, 77, 95–104. [Google Scholar] [CrossRef]

- Higuera-Cobos, O.F.; Berríos-Ortiz, J.A.; Cabrera, J.M. Texture and fatigue behavior of ultrafine grained copper produced by ECAP. Mater. Sci. Eng. A 2014, 609, 273–282. [Google Scholar] [CrossRef]

- Hazeli, K.; Askari, H.; Cuadra, J.; Streller, F.; Carpick, R.W.; Zbib, H.M.; Kontsos, A. Microstructuresensitive investigation of magnesium alloy fatigue. Int. J. Plast. 2015, 68, 55–76. [Google Scholar] [CrossRef]

- Razavi, S.M.; Foley, D.C.; Karaman, I.; Hartwig, K.T.; Duygulu, O.; Kecskes, L.J.; Hammond, V.H. Effect of grain size on prismatic slip in Mg-3Al-1Zn alloy. Scr. Mater. 2012, 67, 439–442. [Google Scholar] [CrossRef]

- GB/T 3075-2008 Metallic Materials Fatigue Testing Axial Force Controlled Method; China Standards Press: Beijing, China. (In Chinese)

- Lin, Y.C.; Liu, Z.H.; Chen, X.M.; Chen, J. Uniaxial ratcheting and fatigue failure behaviors of hot-rolledAZ31B magnesium alloy under asymmetrical cyclic stress-controlled loadings. Mater. Sci. Eng. A 2013, 573, 234–244. [Google Scholar] [CrossRef]

- Yan, Z.F.; Zhang, H.X.; Wang, W.X.; He, X.L.; Liu, X.Q.; Wu, G.H. Temperature evolution mechanism of AZ31B magnesium alloy during high-cycle fatigue process. Theor. Appl. Fract. Mech. 2014, 70, 30–38. [Google Scholar] [CrossRef]

- Kang, G.; Yu, C.; Liu, Y.; Quan, G. Uniaxial ratchetting of extruded AZ31 magnesium alloy: Effect of mean stress. Mater. Sci. Eng. A 2014, 607, 318–327. [Google Scholar] [CrossRef]

- Dong, S.; Yu, Q.; Jiang, Y.; Dong, J.; Wang, F.; Jin, L.; Ding, W. Characteristic cyclic plastic deformation in ZK60 magnesium alloy. Int. J. Plast. 2017, 91, 25–47. [Google Scholar] [CrossRef]

- Guo, S.; Zhou, Y.; Zhang, H.; Yan, Z.; Wang, W.; Sun, K.; Li, Y. Thermographic analysis of the fatigue heating process for AZ31B magnesium alloy. Mater. Des. 2015, 65, 1172–1180. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, Y.; Niezgoda, S.R. Microstructural and micromechanical evolution during dynamic recrystallization. Int. J. Plast. 2018, 100, 52–68. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.J.; Xiong, L.G.; Liu, T.Y.; He, L.J. High temperature tensile deformation behavior and microstructure evolution of Ti55 Titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Yang, P.; Hu, Y.; Cui, F. Texture investigation on the deformation mechanisms in magnesium alloy AZ31 deformed at high temperatures. Chin. J. Mater. Res. 2004, 18, 25–59. [Google Scholar]

- Tan, L.; Zhang, X.Y.; Sun, Q.; Yu, J.P.; Huang, G.J.; Liu, Q. Pyramidal slips in high cycle fatigue deformation of a rolled Mg-3Al-1Zn magnesium alloy. Mater. Sci. Eng. A 2017, 699, 247–253. [Google Scholar] [CrossRef]

- Calcagnottok, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Ma, X.L.; Huang, C.X.; Moering, J.; Ruppert, M.; Höppil, H.W.; Göken, M.; Narayan, J.; Zhu, Y.T. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y.; Nix, W.D.; Hutchinson, J.W. Mechanism based strain gradient plasticity I. Theory. J. Mech. Phys. Solids 1999, 47, 1239–1263. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Z.; Wang, D.; Wang, W.; Zhou, J.; He, X.; Dong, P.; Zhang, H.; Sun, L. Ratcheting Strain and Microstructure Evolution of AZ31B Magnesium Alloy under a Tensile-Tensile Cyclic Loading. Materials 2018, 11, 513. https://doi.org/10.3390/ma11040513

Yan Z, Wang D, Wang W, Zhou J, He X, Dong P, Zhang H, Sun L. Ratcheting Strain and Microstructure Evolution of AZ31B Magnesium Alloy under a Tensile-Tensile Cyclic Loading. Materials. 2018; 11(4):513. https://doi.org/10.3390/ma11040513

Chicago/Turabian StyleYan, Zhifeng, Denghui Wang, Wenxian Wang, Jun Zhou, Xiuli He, Peng Dong, Hongxia Zhang, and Liyong Sun. 2018. "Ratcheting Strain and Microstructure Evolution of AZ31B Magnesium Alloy under a Tensile-Tensile Cyclic Loading" Materials 11, no. 4: 513. https://doi.org/10.3390/ma11040513