7.1. Application of the finite strain Gurson’s coupled elastoplastic-damage model

Gurson’s coupled elastoplastic-damage two-dimensional model that was previously presented corresponds to the modeling of the effective behavior of a porous material in which the long cylindrical pores are oriented in the 1-direction. Consequently, it should be interesting to compare the predictions of the Gurson’s model with the corresponding ones obtained from HFGMC micromechanical analysis. To this end, the doubly periodic HFGMC in which one of the phases has zero stiffness is considered. the volume fraction of this phase is taken to be equal to the porosity

D in Equation

8. We start our investigation by comparing the initial yield surfaces as predicted by the Gurson’s and HFGMC models.

For the Gurson’s model the initial yielding is determined from Equation

8 which provides

The von Mises yielding criterion is obtained from this equation by setting

. Suppose that in the Gurson’s model the initial yield surface

against

is requested, where

being the first Piola-Kirchhoff stress tensor. Here all components

are equal to zero except

and

that may take any combination. Hence let us represent these components in the form

where

A is the radial distance of a point located on the initial yield surface envelope

-

and

θ is the corresponding polar angle. The substitution of these values in Equation

73, shows that for a given angle

θ, the radial distance of

of this point is given by root of the transcendental equation

where in Equation

73,

and

have been substituted. Since in typical metallic materials yielding takes place at very small strains (in aluminum, for example, yielding in simple tension accrues at a strain of about 0.4 percent), it can be practically assumed that

. Other types of initial yield surfaces can be generated in the same manner.

The initial yield surfaces that are predicted by the HFGMC model, on the other hand, can be generated by establishing the instantaneous stress concentration tensor

which relates the rate of the local Piola-Kirchhoff stress tensor

to the externally applied stress rate

, namely

From Equations

66–

68 this tensor can be shown to be given by

Corresponding to the above discussion, suppose that the initial yield envelope

against

is requested. Here too all the average (composite) Piola-Kirchhoff stress components

are equal to zero except

and

which can be represented by Equation

74. The initial yielding of any ductile phase of the HFGMC model is given by the von Mises criterion namely, it is given by Equation

73 in which

is substituted. In addition, for initial yielding at very small strains, Equation

76 can be reduced to

. Hence the initial yielding of a point whose polar angle is

θ as predicted by the HFGMC is given by

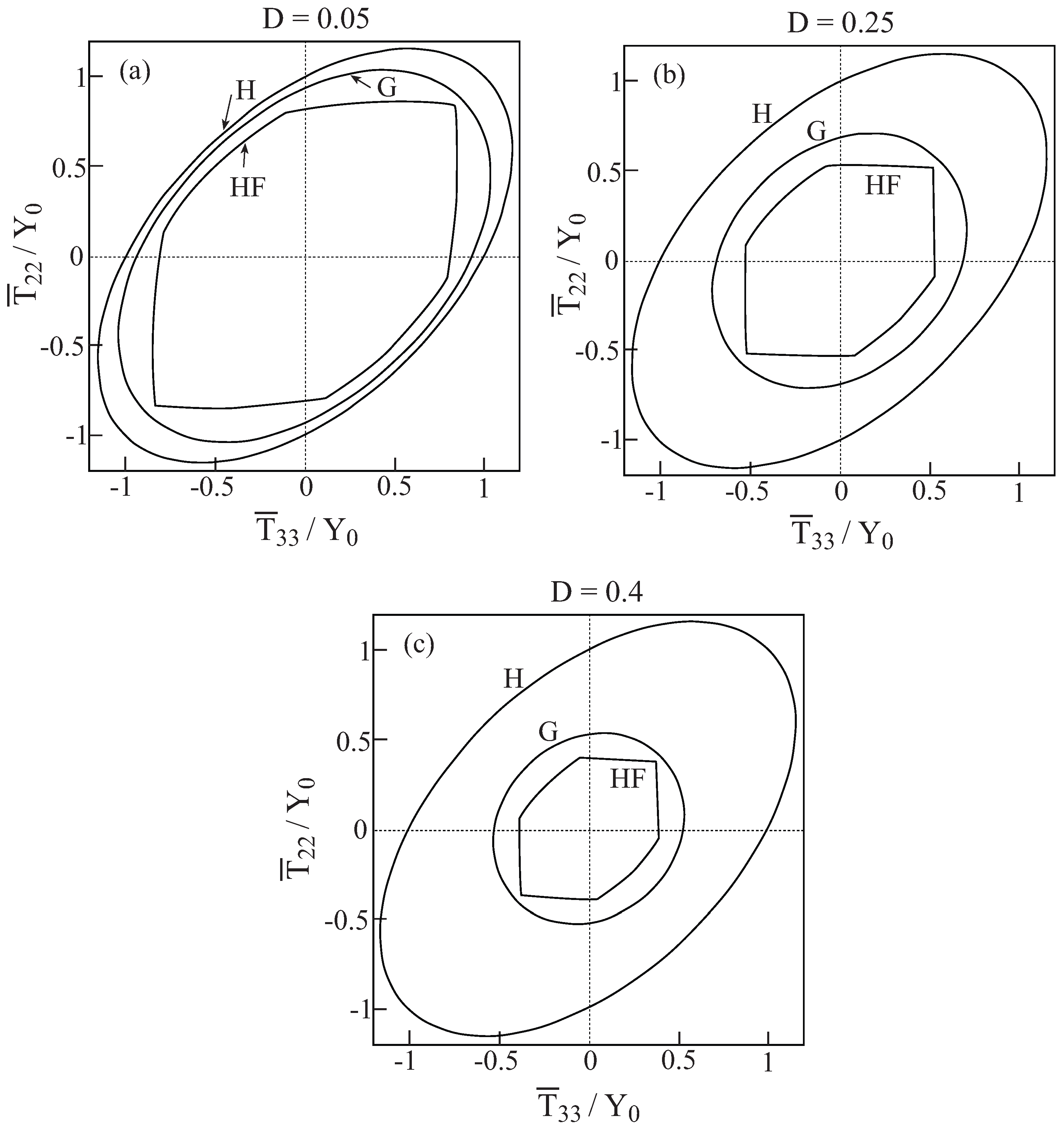

In

Figure 1, comparisons between the initial yield surfaces

against

as predicted by the Gurson’s and HFGMC models are shown for three values of damage (porosity) values:

and

. Also shown as a reference is the simple von Mises criterion of a homogeneous elastoplastic material namely:

. It can be clearly observed that a fair correspondence between the two models exist. Next,

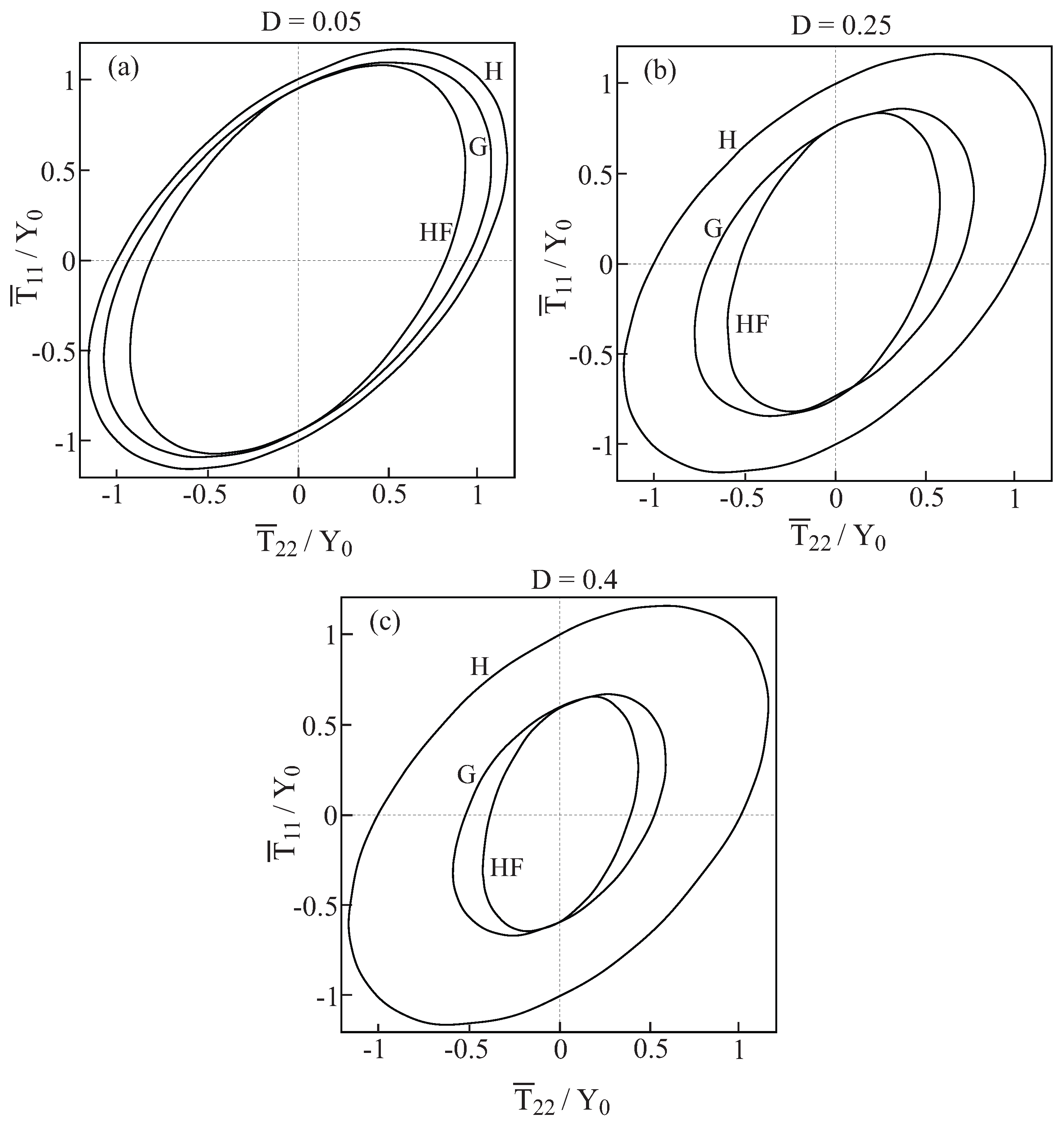

Figure 2 shows the initial yield surfaces in the

-

plane. Since the voids in the Gurson and HFGMC models are oriented in the 1-direction, the symmetry which can be observed in

Figure 1 in the 2 and 3-directions does not exist anymore in the 1 and 2-direction in

Figure 2. Here too, fair agreement between the two models can be observed. Finally, let us examine the initial yield envelopes for the loading

and

. The resulting envelopes are shown in

Figure 3 for the above three values of porosity. It should be noted that the simple von Mises criterion (for yielding of homogeneous ductile materials) reduces in this case to two parallel straight lines

the first one of which passes the points:

and

, whereas the second one passes through the points:

and

, with the expected result that yielding will not occur for stress values between these two lines. Here too, the correspondence between the two models is quite good. In conclusion, these three figures show that the simple Gurson’s model is quite reliable for the prediction of initial yield surfaces of porous materials.

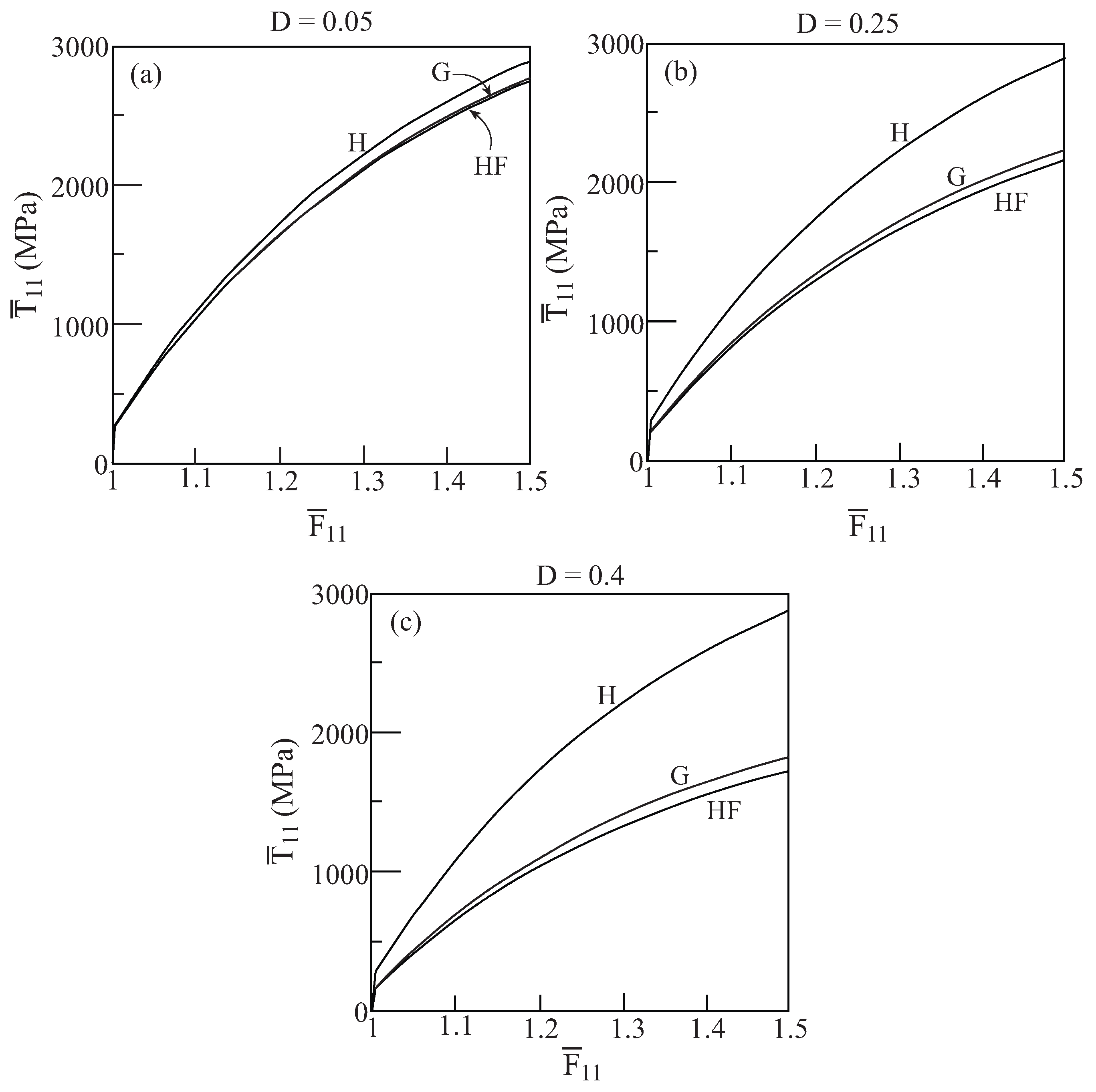

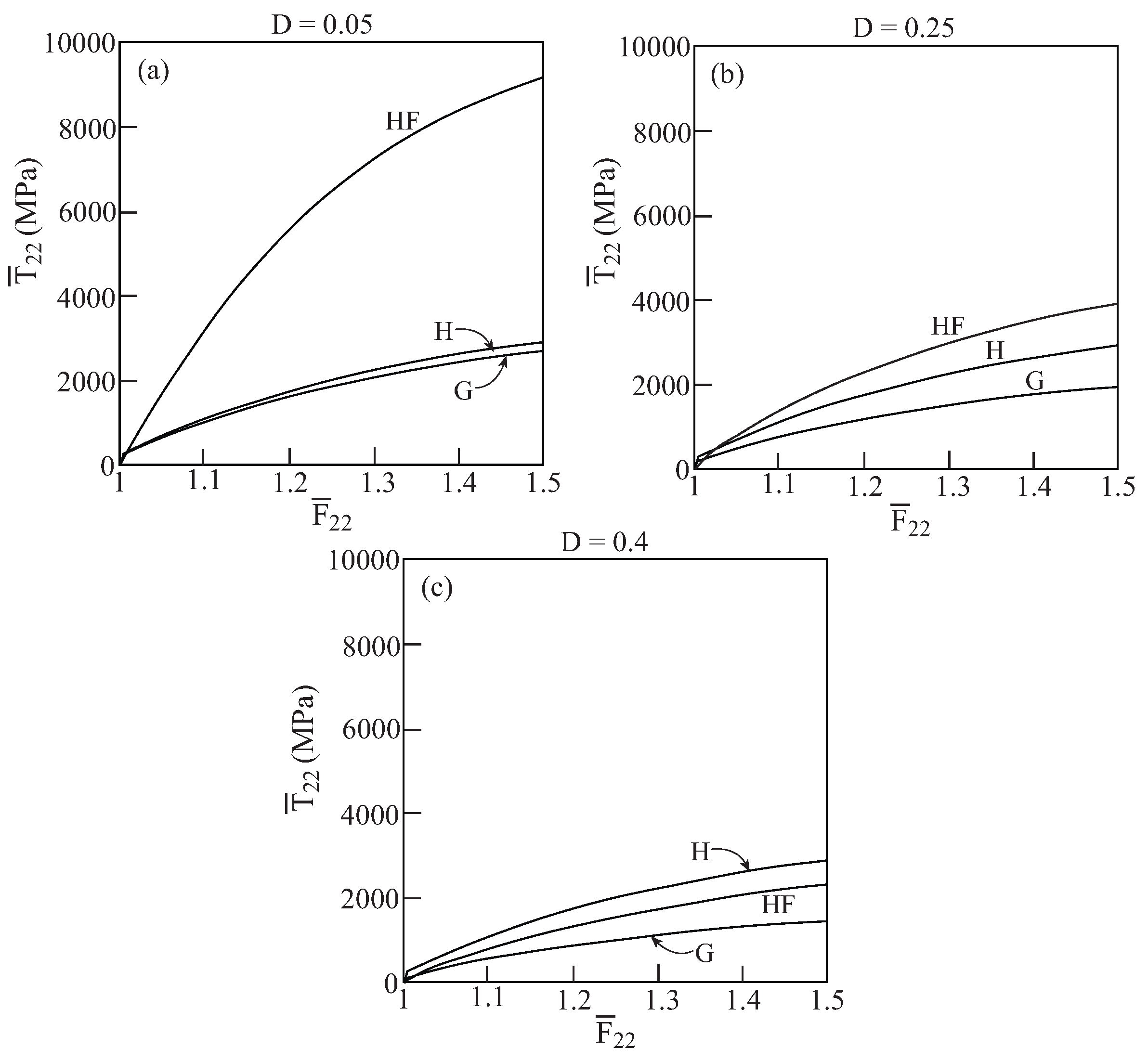

Thus far the initial yield envelopes that are predicted by the two models have been investigated. The next investigation is concerned with the responses of porous materials that are obtained by the Gurson and HFGMC model. To this end, let us consider the ductile material that is characterized by

Table 1. The response of this material with three values of porosity:

,

and

, is shown in

Figure 4. This figure shows the average uniaxial stress responses

to loading in the 1-direction (

i.e., in the direction of which the pores are oriented) as predicted by the Gurson and HFGMC model. Also shown for reference is the uniaxial stress response of the bulk material (

i.e., with zero porosity

). The graphs show that good agreement between the predictions of Gurson and HFGMC model exists. The effect of porosity (damage) is clearly exhibited by comparison with the homogeneous material behavior.

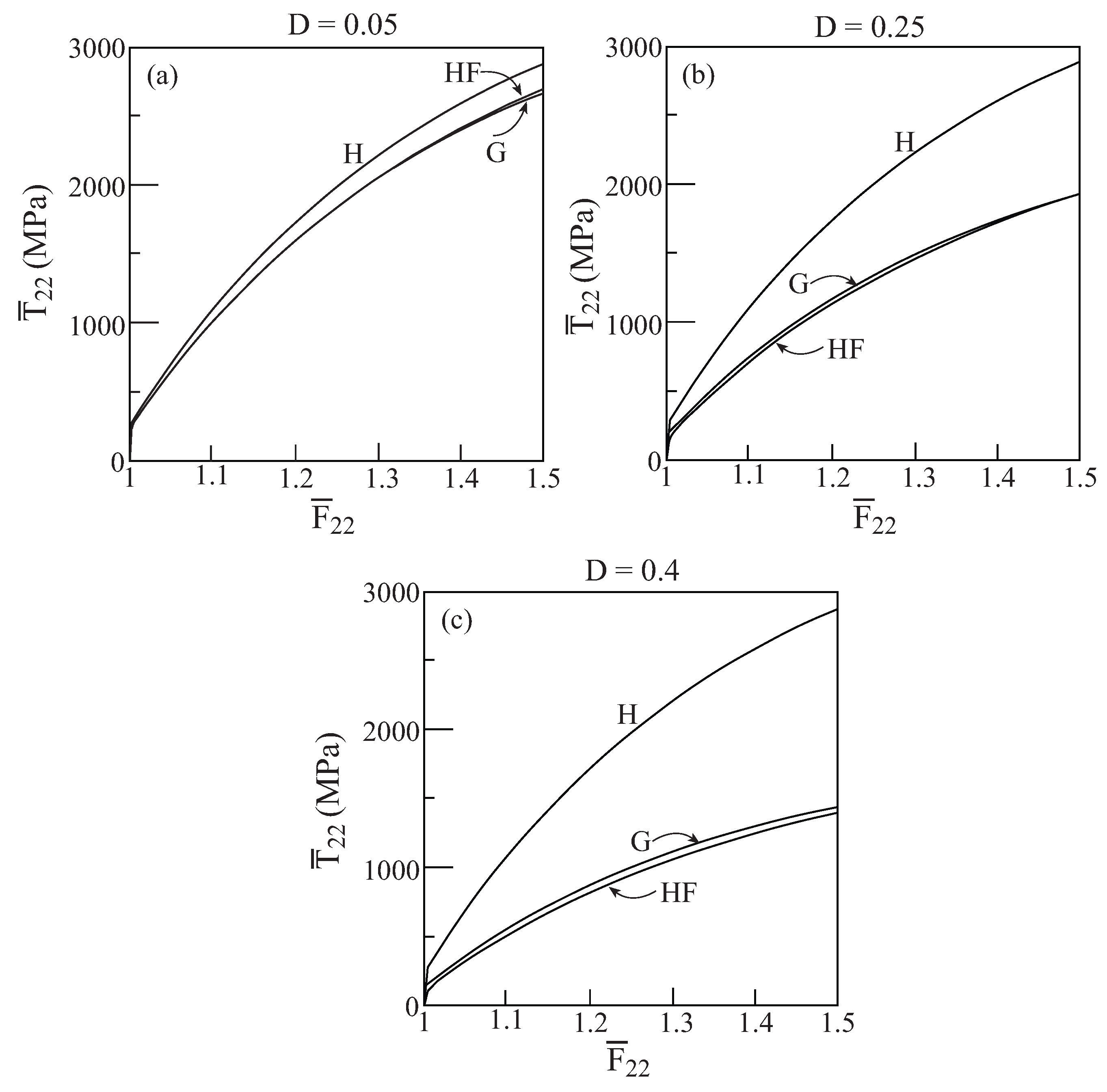

The responses

as predicted by the two models to a uniaxial stress loading of the porous material in the transverse 2-direction are shown in

Figure 5 for three values of porosity (the response of the homogeneous material is included for comparison). Here too, very good agreement between the Gurson and HFGMC model can be clearly observed. It should be noted that a careful comparison between the flow stress levels of

Figure 4 and

Figure 5 reveals that the axial 1-direction along which the pore extends is relatively stronger (exhibiting higher stresses) than the transverse 2-direction. This observation is consistent with

Figure 2 which shows that the porous material yields earlier when loaded in the transverse direction as compared to a loading in the axial direction.

Figure 1.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. Also shown, as a reference, is the simple von Mises envelope in a homogeneous elastoplastic material (H). (a) , (b) , (c) .

Figure 1.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. Also shown, as a reference, is the simple von Mises envelope in a homogeneous elastoplastic material (H). (a) , (b) , (c) .

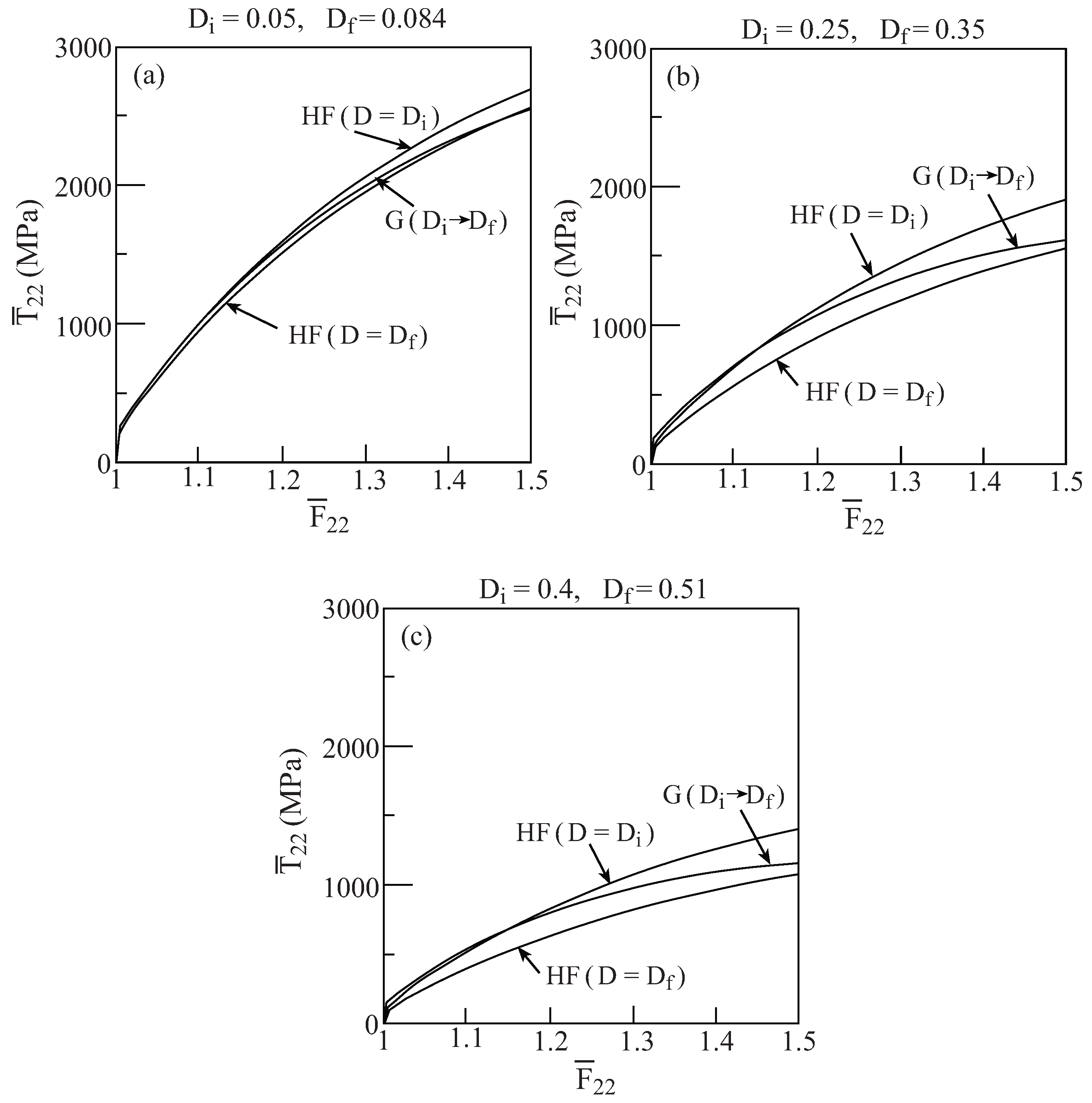

In

Figure 4 and

Figure 5, the porous material behavior was shown in various cases at every one of which the prescribed value of porosity

D was held constant. In the framework of Gurson’s model the porosity (damage) can evolve as the plasticity develops, see Equation

13. Hence, it should be interesting to allow the damage, in the framework of Gurson’s model, to evolve from a certain initial value

to a final value

which is determined by the model when the loading is terminated. The resulting response can be compared with HFGMC prediction in which the volume fraction of the pores is equal to

and

.

Figure 6 presents the uniaxial stress response

to a transverse loading of the porous material as predicted by Gurson’s and HFGMC model. In the Gurson model, initial porosity of

and

evolve with loading to the final values:

and

, respectively at which the applied deformation is terminated at

. The corresponding HFGMC predictions are shown in this figure for these values of

and

. It can be readily observed that Gurson’s predictions extend between HFGMC prediction for

and

.

Figure 2.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. Also shown, as a reference, is the simple von Mises envelope in a homogeneous elastoplastic material (H). (a) , (b) , (c) .

Figure 2.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. Also shown, as a reference, is the simple von Mises envelope in a homogeneous elastoplastic material (H). (a) , (b) , (c) .

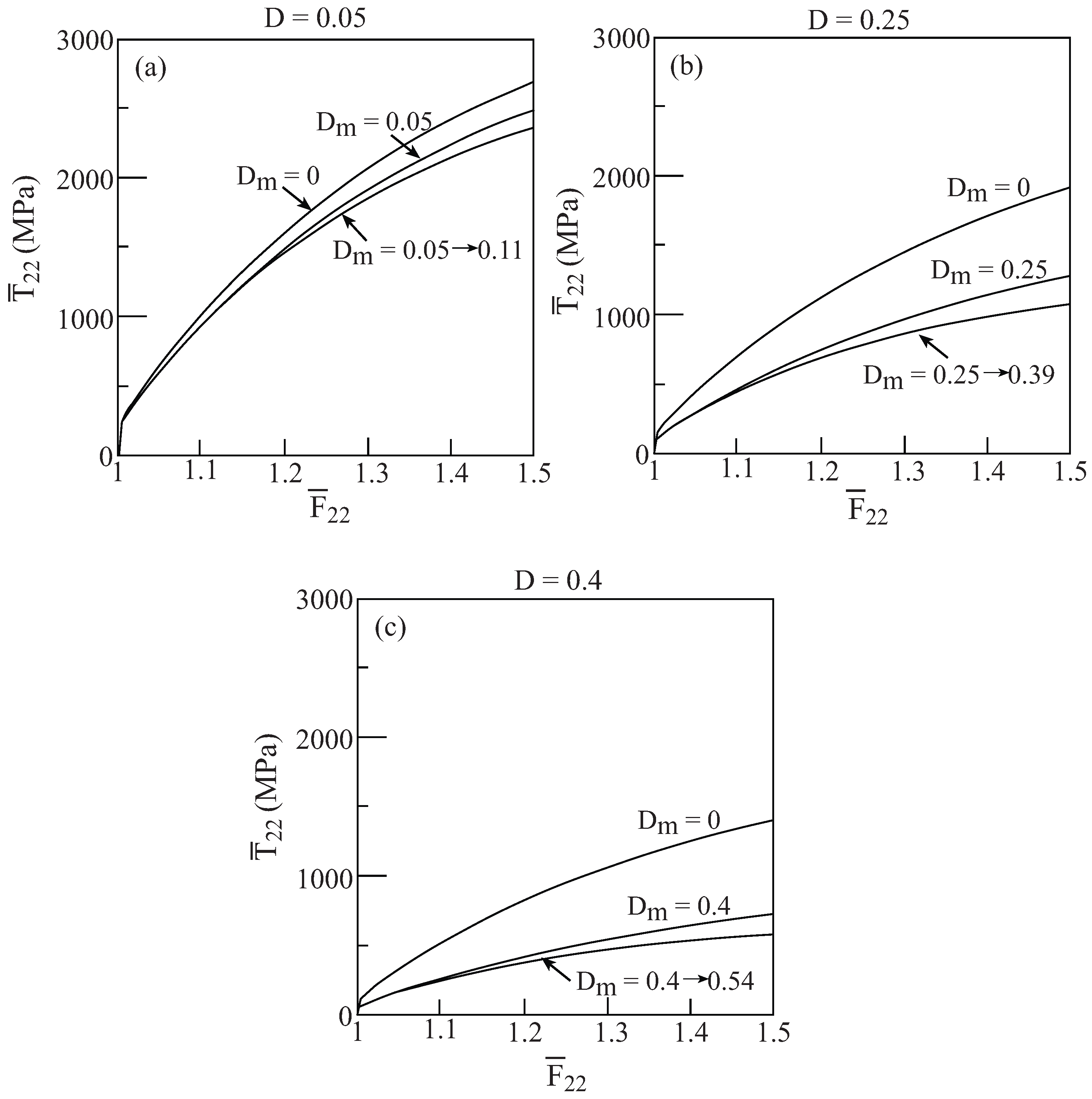

As a final investigation of the effect of evolving damage in the Gurson’s model, we consider again, in the framework of the HFGMC, a composite material whose matrix is characterized by

Table 1 while the second phase is a pore. Let

D, as before, denotes the amount of porosity of this composite. As the loading of the composite (porous) material increases, damage evolves in the ductile matrix the amount of which is denoted by

.

Figure 7 shows the uniaxial stress response

to a transverse loading of the composite whose porosity is

D when: (1)

(

i.e., no damage takes place in the matrix), (2)

(

i.e., the damage in the matrix is kept equal to

D) and, (3)

evolves from

to the final value

when the loading reaches

. In this last case and as indicated in

Figure 7, for

,

reaching the final value of

; for

,

reaching the final value of

; and for

,

reaching the final value of

. This figure well exhibits the effect of zero, constant and evolving damage in the ductile matrix of a porous material (composite) in which the amount of porosity is prescribed..

Figure 3.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. (a) , (b) , (c) .

Figure 3.

Comparisons between the initial yield surfaces as predicted by the Gurson’s (G) and HFGMC (HF) models. (a) , (b) , (c) .

7.2. Application of the finite strain Lemaitre’s coupled elastoplastic-damage model

In the present subsection, a unidirectional composite that consists of a rubber-like hyperelastic matrix reinforced by ductile fibers whose properties are given in

Table 1 is considered.

The metallic fibers are modeled by Lemaitre’s coupled elastoplastic-damage representation that was discussed in

subsection 2.2 , where the values of the parameters

r and

s are:

,

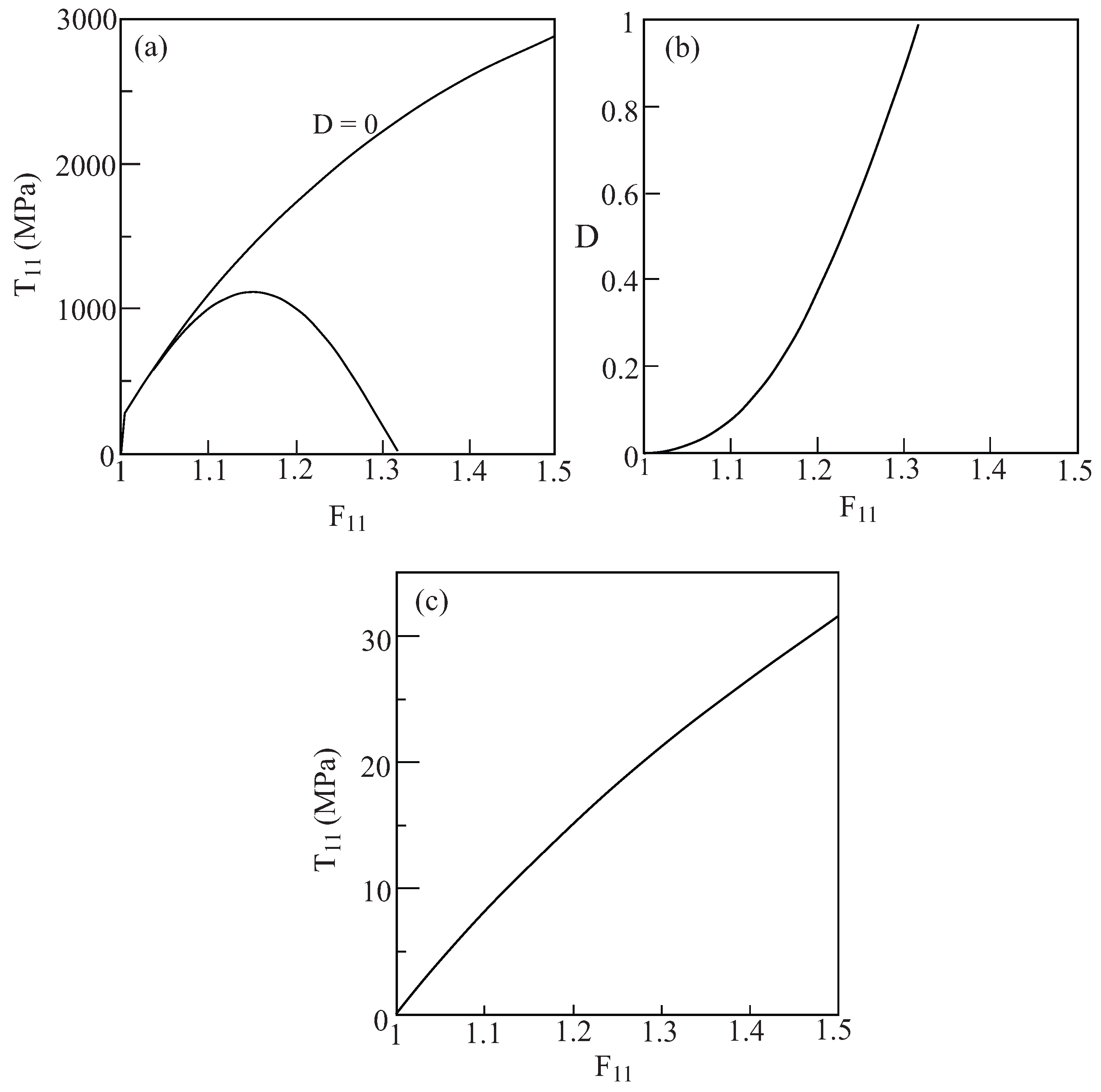

.

Figure 8(a) shows the uniaxial stress response response of the monolithic ductile material in the absence of any damage (

i.e.,

) and the corresponding case in which the damage evolves from

according to Equation

24. The response in the latter case is terminated when the damage approaches its final value

. The evolution of the damage is exhibited in

Figure 8(b) which shows its gradual increase with the applied loading.

Figure 4.

Comparisons between the uniaxial stress response to loading in the axial 1-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous elastoplastic material (H). (a)

, (b)

, (c)

.

Figure 4.

Comparisons between the uniaxial stress response to loading in the axial 1-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous elastoplastic material (H). (a)

, (b)

, (c)

.

The rubber-like matrix is modeled as a hyperelastic compressible neo-Hookean material whose strain energy function is given by (Bonet and Wood [

26])

where

is the first invariant of the right Cauchy-Green deformation tensor

,

and

λ and

μ are material constants. The second Piola-kirchhoff stress tensor

is obtained from

and the constitutive relations of this material can be established in the form given by Equation

15, where the instantaneous first tangent tensor

of the material is given by

Figure 8(c) shows the uniaxial stress behavior of the monolithic hyperelastic material characterized by:

and

.

Figure 5.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the elastoplastic homogeneous material (H). (a)

, (b)

, (c)

.

Figure 5.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the elastoplastic homogeneous material (H). (a)

, (b)

, (c)

.

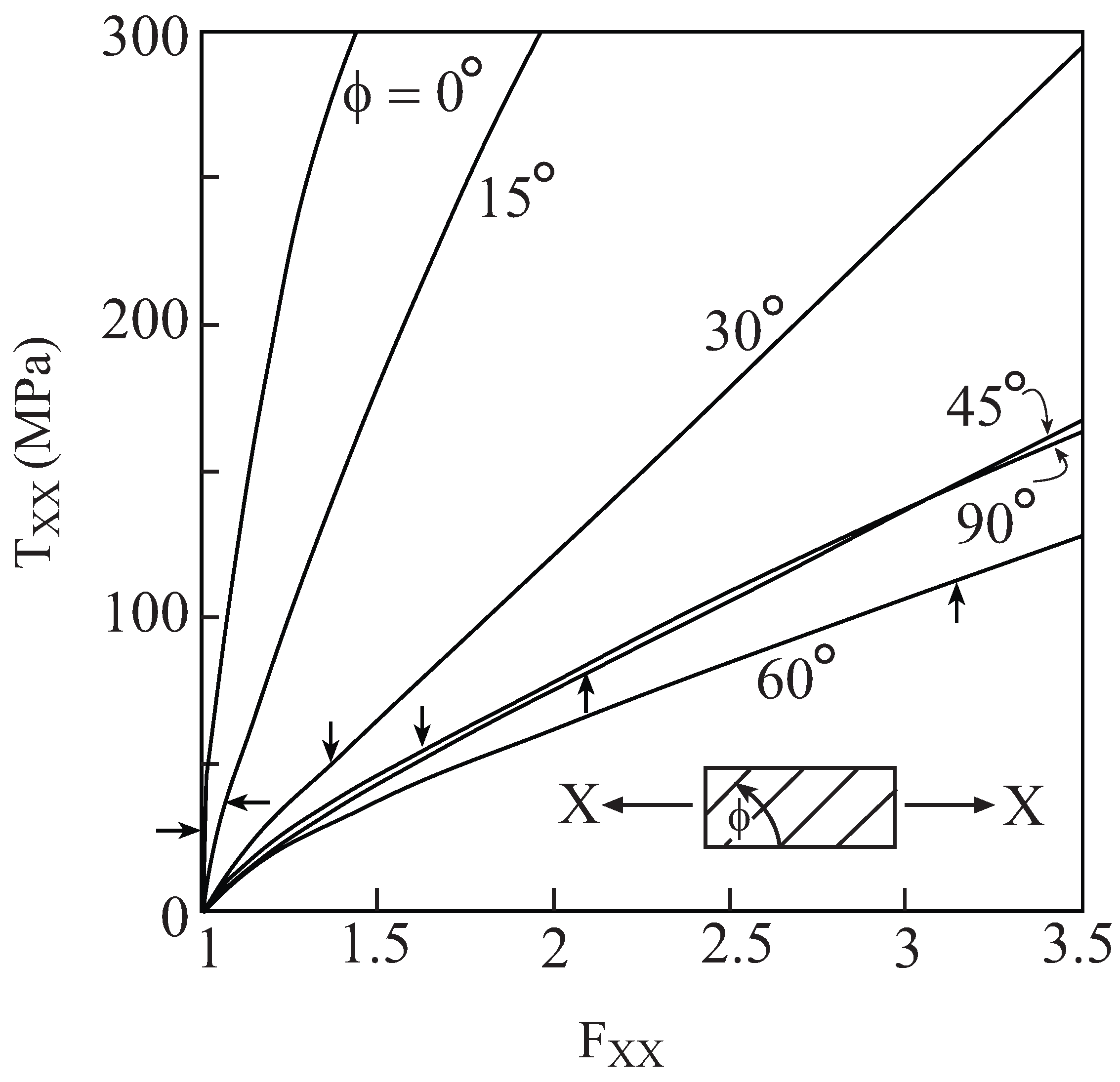

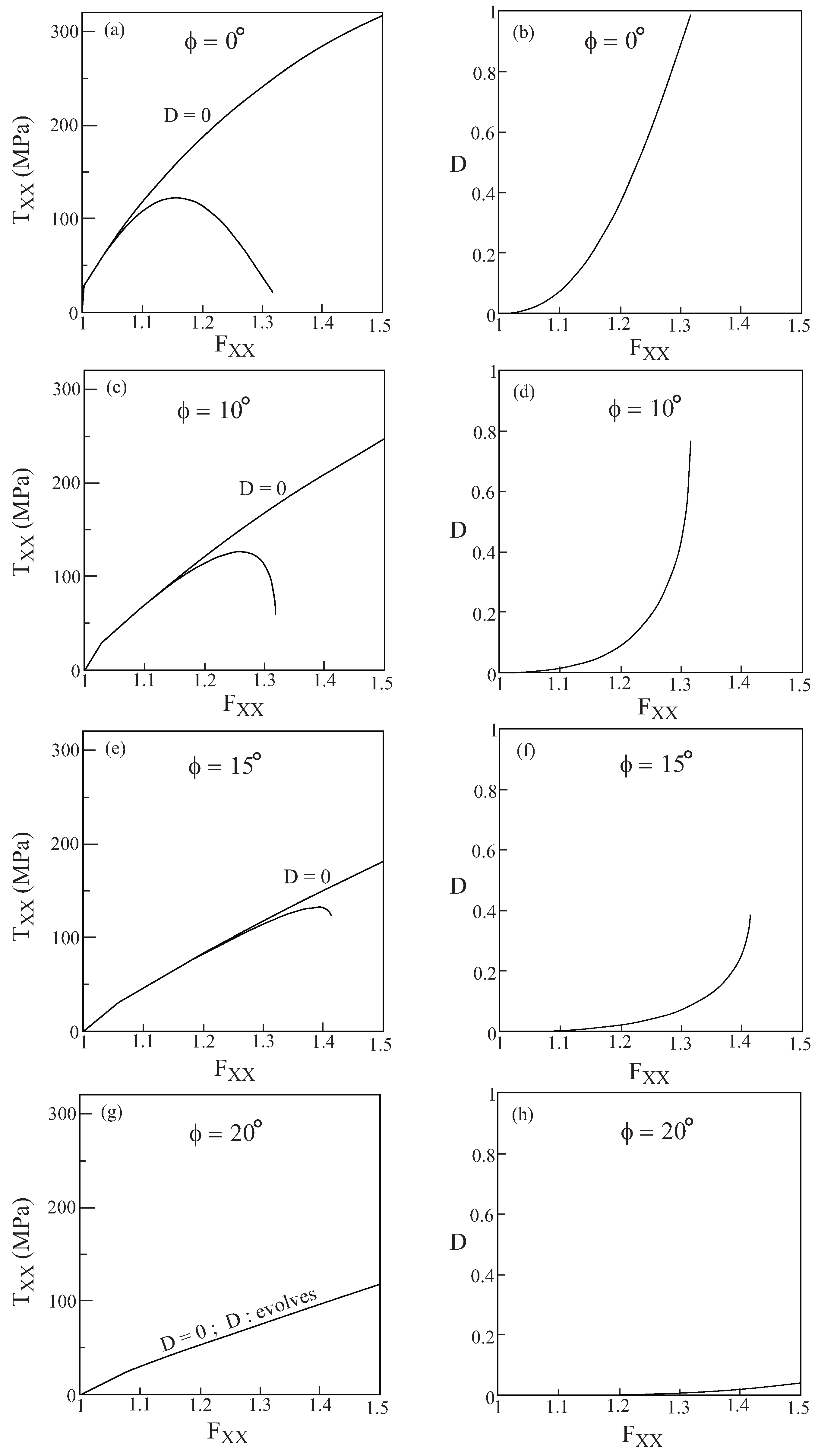

Consider this metal/rubber-like composite in which the continuous metallic fibers are oriented in the axial 1-direction. The volume fraction of the fibers is . Let the composite be subjected to an off-axis uniaxial stress loading. Here, the fibers which are oriented in the 1-direction, are rotated around the 3-direction by an angle ϕ. As a result, a new system of coordinates is obtained such that . The uniaxial stress loading is applied in the X-direction which is at angle ϕ with respect to the fibers direction. Referring to this new system of coordinates, the composite is loaded by the application of the deformation gradient , and all components of the first Piola-Kirchhoff stress tensor , referred to the new coordinate system, are equal to zero except . In particular, and correspond to longitudinal and transverse uniaxial stress loading, respectively.

The locations of the initial yielding of this composite can be determined by generating its uniaxial stress response at various off-axis angles

ϕ and detecting the stress at which yielding of the metallic fibers takes place.

Figure 9 shows the off-axis stress-displacement gradient response of the composite in the absence of damage in the fiber phase (

). The locations of yielding points are indicated by the arrows. It should be noted that the earliest yielding is obtained when the composite is loaded in the axial direction (

), whereas loading in the transverse direction (

) caused yielding at a later stage. Among the six off-axis angles at which the response of the composite is generated in the range of

, the highest yield stress is obtained at

.

Figure 6.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson and HFGMC models. In the Gurson’s elastoplastic model, the initial porosity (damage) is

which subsequently evolves to the final value

when

. The corresponding responses that are predicted by the HFGMC model are given for

and

. (a)

,

; (b)

,

; (c)

,

.

Figure 6.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile elastoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson and HFGMC models. In the Gurson’s elastoplastic model, the initial porosity (damage) is

which subsequently evolves to the final value

when

. The corresponding responses that are predicted by the HFGMC model are given for

and

. (a)

,

; (b)

,

; (c)

,

.

Figure 10 presents that the metallic/rubber-like composite’s response to uniaxial stress loading at various off-axis angles. Here, both cases in which the damage in the fiber phase is absent

as well as when it is evolving from zero are shown. In the latter case, the dependence of damage evolutions on the applied deformation gradient are also shown. For loading in the axial direction

, the damage variable increases with applied loading until it reaches its final value of

. For the off-axis angle

, on the other hand, the amount of evolving damage in the fiber phase is very small, as a result of which the difference between the responses in the absence and presence of damage is indistinguishable. It should be noted that the for

,

and

, the computations were terminated when the damage variables reached a certain value after which it jumped in the next step of computations to

.

Figure 7.

The response of a porous elastoplastic material modeled by Gurson’s equations (

D is the amount of porosity) to a uniaxial stress loading applied in the transverse 2-direction. The properties of the matrix are given by

Table 1. With

denoting the amount of damage in the matrix, the response is given in the following three cases. (1)

, (2)

, and (3)

evolving to the final value

when

. (a)

, (b)

, (c)

.

Figure 7.

The response of a porous elastoplastic material modeled by Gurson’s equations (

D is the amount of porosity) to a uniaxial stress loading applied in the transverse 2-direction. The properties of the matrix are given by

Table 1. With

denoting the amount of damage in the matrix, the response is given in the following three cases. (1)

, (2)

, and (3)

evolving to the final value

when

. (a)

, (b)

, (c)

.

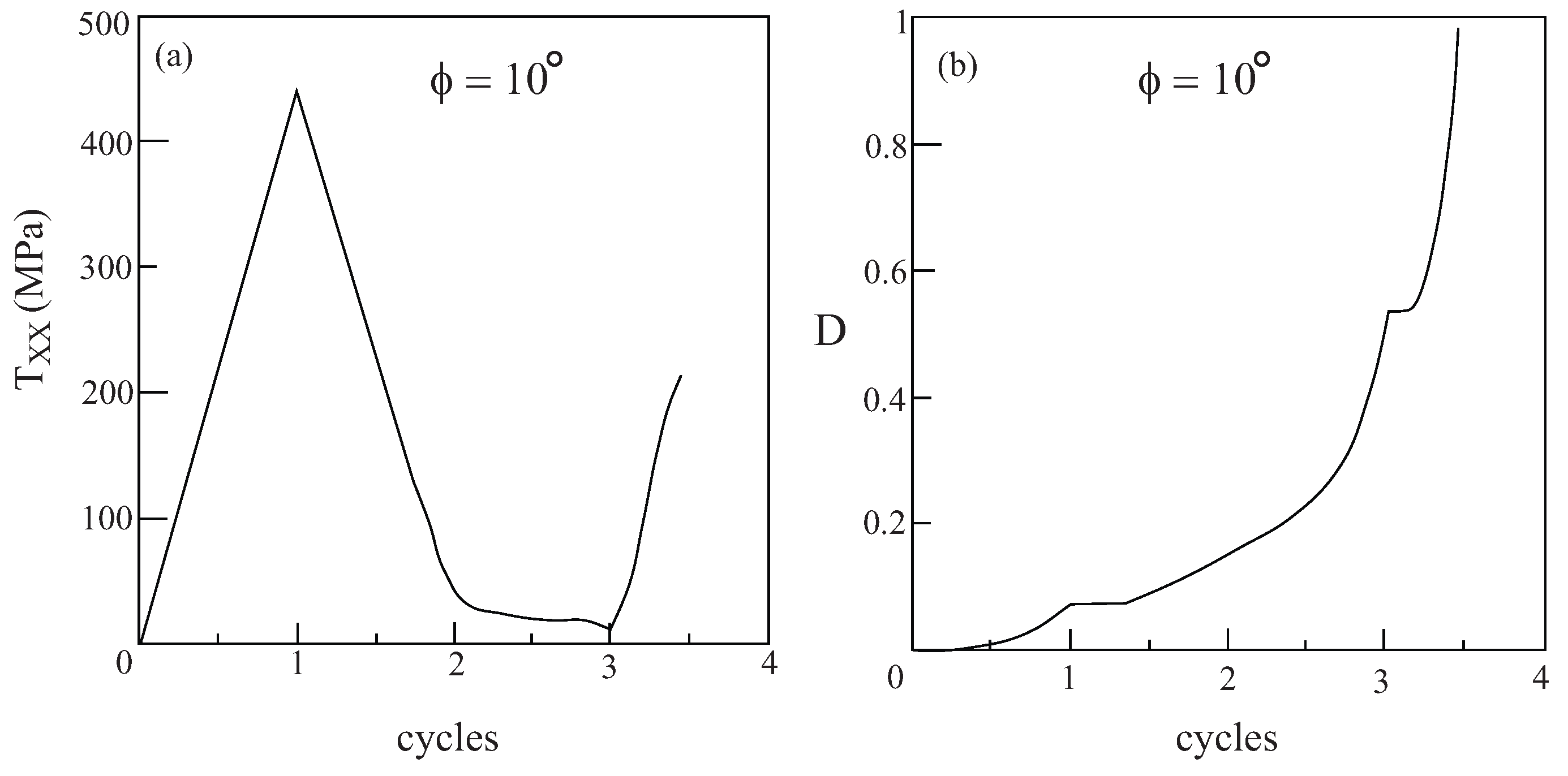

It is possible of course to increase the amplitude of applied loading in

Figure 10 above the value of

to get appreciable values of damage in the fiber constituent for the off-axis loading case

. It is interesting however to observe the response and damage evolution when the metallic/rubber-like composite is subjected to a cyclic loading such that

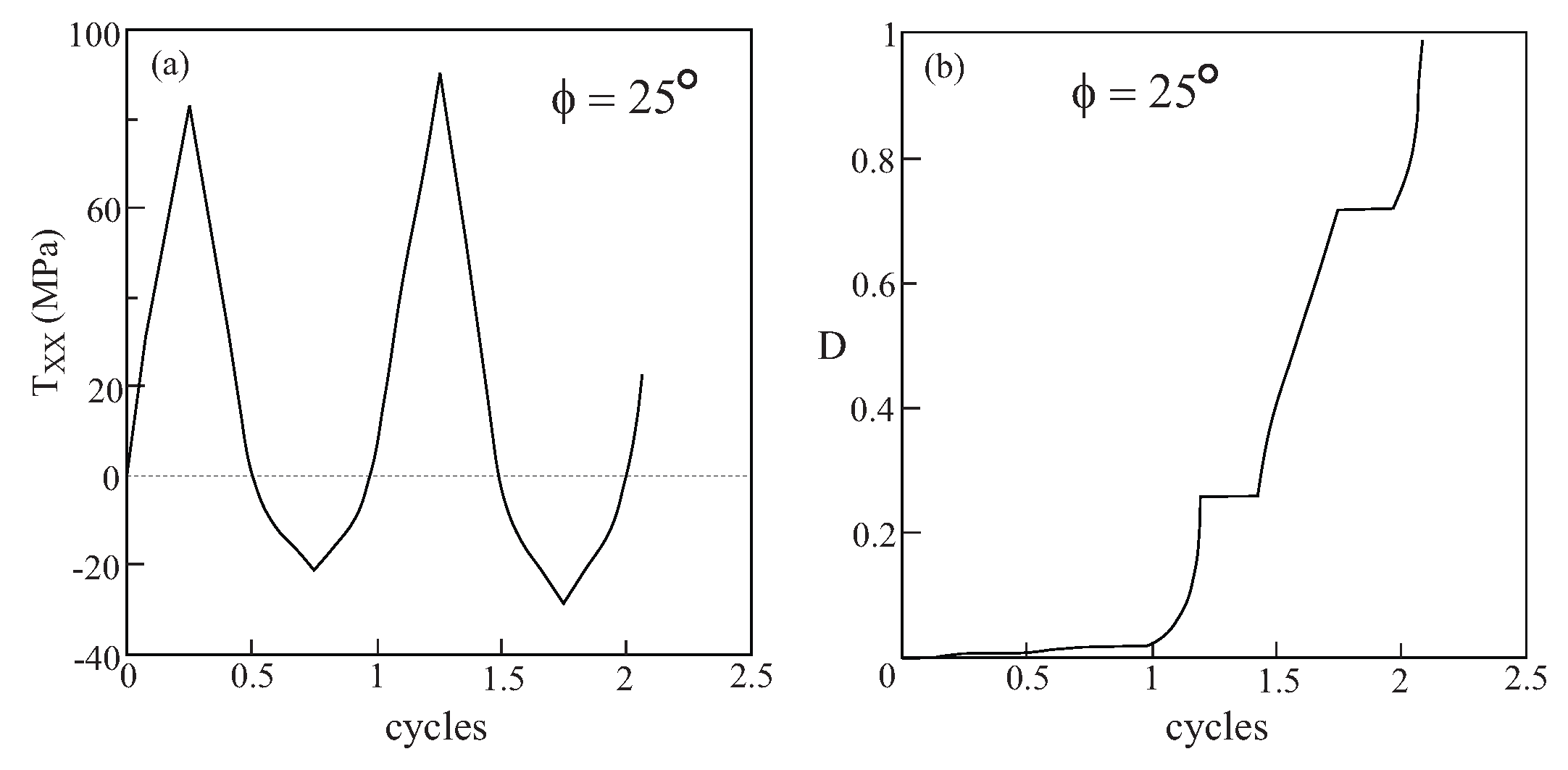

.

Figure 11 presents the response of the composite and damage evolution in the fiber phase for a uniaxial stress cyclic loading for an off-axis angle of

. The figure clearly shows that the macroscopic stress

exhibits a cyclic behavior but the damage in the fiber constituent continue to increase while during unloading it retains its value. The figure indicates that the computations were terminated as the damage variable approached 1 after two cycles.

Figure 8.

(a) The uniaxial stress response of the monolithic metallic material whose properties are given by

Table 1. Its constitutive relations are given by the Lemaitre elastoplastic model. The response is shown in the absence (

) and evolving damage and, (b) the form of the damage evolution with the applied displacement gradient. (c) The uniaxial stress response of the monolithic hyperelastic matrix whose strain energy is given by Equation

79.

Figure 8.

(a) The uniaxial stress response of the monolithic metallic material whose properties are given by

Table 1. Its constitutive relations are given by the Lemaitre elastoplastic model. The response is shown in the absence (

) and evolving damage and, (b) the form of the damage evolution with the applied displacement gradient. (c) The uniaxial stress response of the monolithic hyperelastic matrix whose strain energy is given by Equation

79.

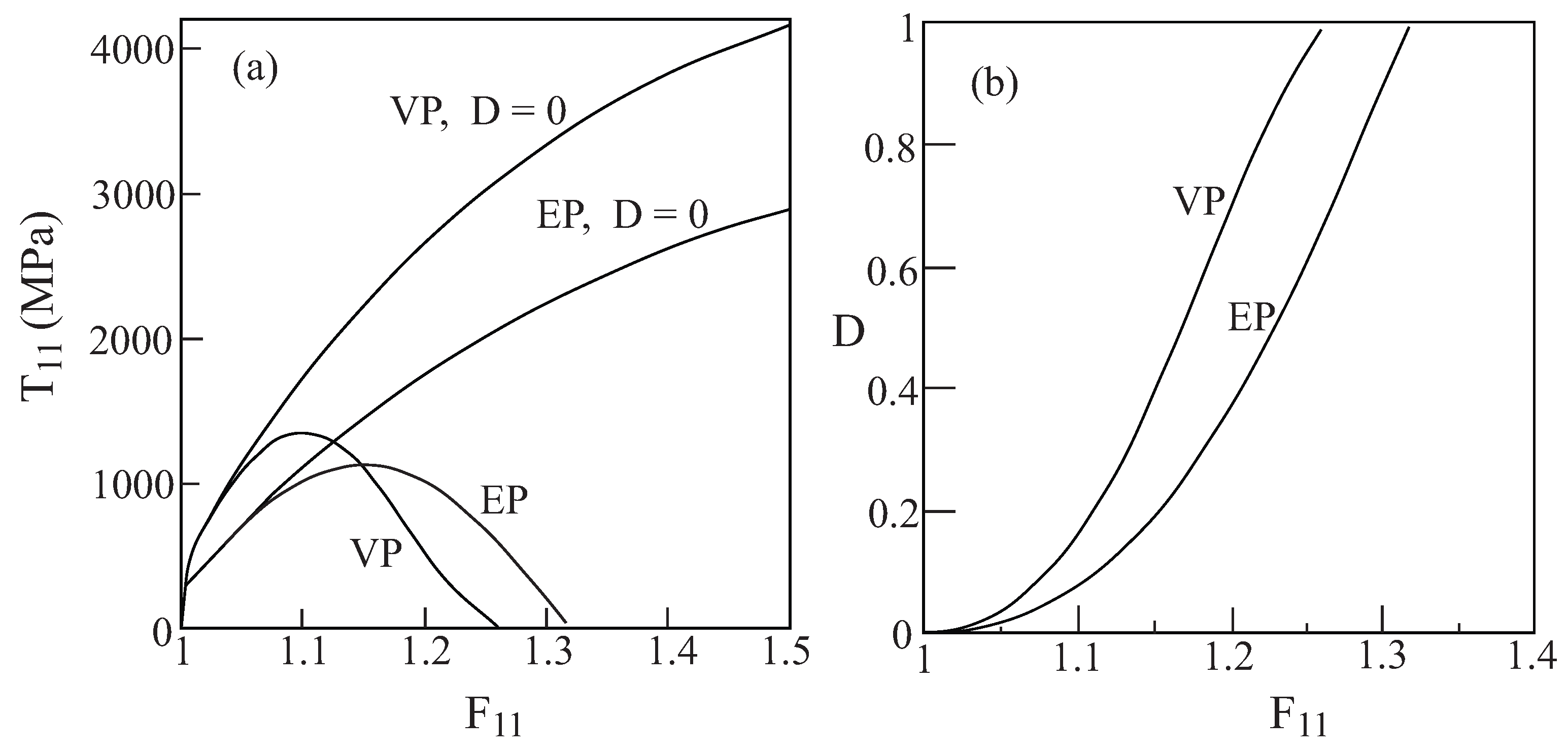

7.4. Application of the finite strain Lemaitre’s coupled viscoplastic-damage model

Consider the ductile material whose properties are given by

Table 1. This material is represented by the Lemaitre’s coupled viscoplastic-damage model, see Equation

26, in which the viscosity and rate sensitivity parameters are:

and

, respectively. In all cases shown herein the loading was applied at a rate of

, and

,

.

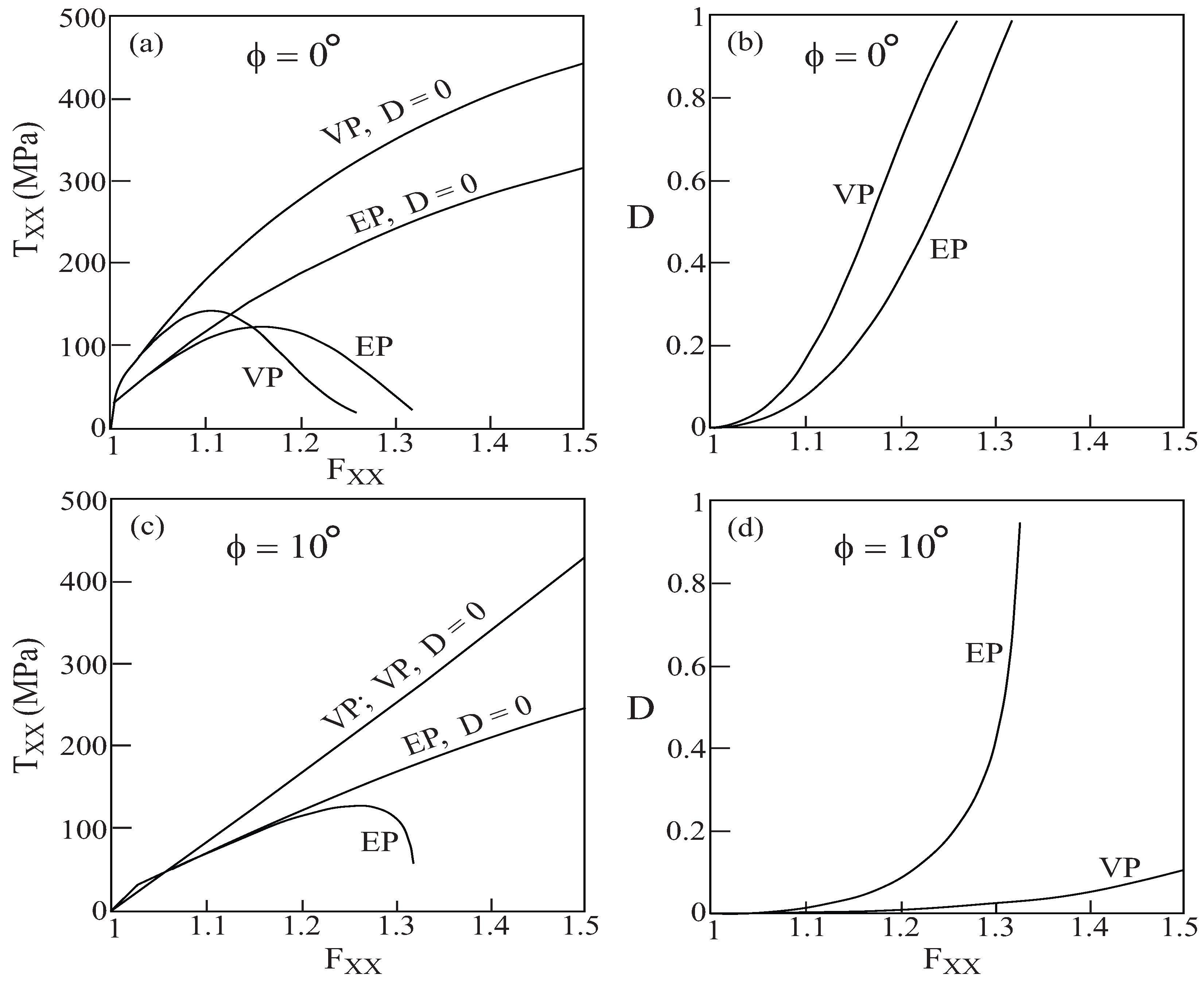

Figure 14 shows a comparison between the response of the homogeneous ductile material when it is represented by Lemaitre’s viscoplastic and elastoplastic coupled with damage models. The computations were terminated when the damage

D approaches unity. This figure shows also the special case in which no damage takes place (

i.e.,

). As it is expected, the elastoplastic case exhibits lower stress values as compared to the viscoplastic behavior, but the evolution of damage is more rapid in the viscoplastic case.

Figure 10.

The response to uniaxial stress loading at various off-axis angles ϕ of a unidirectional metal/rubber-like composite in the absence () and presence of evolving damage in the fiber phase which is modeled by Lemaitre elastoplastic equations. Also shown in each case is the form of the damage evolution with applied deformation gradient. (a)-(b) , (c)-(d) , (e)-(f) , (g)-(h) .

Figure 10.

The response to uniaxial stress loading at various off-axis angles ϕ of a unidirectional metal/rubber-like composite in the absence () and presence of evolving damage in the fiber phase which is modeled by Lemaitre elastoplastic equations. Also shown in each case is the form of the damage evolution with applied deformation gradient. (a)-(b) , (c)-(d) , (e)-(f) , (g)-(h) .

Figure 11.

The response to uniaxial stress cyclic loading () at off-axis angle of a unidirectional metal/rubber-like composite in which the fibers are modeled by Lemaitre elastoplastic equations. (a) Variation of the stress with the cycles, (b) the evolution of damage in the fiber phase.

Figure 11.

The response to uniaxial stress cyclic loading () at off-axis angle of a unidirectional metal/rubber-like composite in which the fibers are modeled by Lemaitre elastoplastic equations. (a) Variation of the stress with the cycles, (b) the evolution of damage in the fiber phase.

Figure 12.

Comparisons between the uniaxial stress response to loading in the axial 1-direction of the porous viscoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous viscoplastic material (H). (a)

, (b)

, (c)

.

Figure 12.

Comparisons between the uniaxial stress response to loading in the axial 1-direction of the porous viscoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous viscoplastic material (H). (a)

, (b)

, (c)

.

The behavior of a unidirectional metal/rubber-like composite (with fiber volume fraction

) is shown in

Figure 15 in which the metallic fibers (whose properties are given by

Table 1) are represented by Lemaitre’s viscoplastic and elastoplastic coupled with damage models, whereas the rubber-like matrix behavior is given by Equation

79. The responses shown in this figure are caused by the application of uniaxial stress loadings

applied at off-axis angles

and

with respect to the fibers. The figure shows also the damage evolution in the metallic phase and the response in the special case in which the damage in the fibers is ignored. For the axial loading case (

) the elastoplastic and viscoplastic response and damage evolution are quite similar. The graphs show however that in contradistinction to the elastoplastic case (

Figure 10c,d), damage evolution in the viscoplastic case when

is relatively small as compared to the elastoplastic prediction in which the damage approaches unity. As a result, the stress-deformation curve in the viscoplastic case is indistinguishable from the corresponding one in which the damage is ignored.

Figure 13.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile viscoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous viscoplastic material (H). (a)

, (b)

, (c)

.

Figure 13.

Comparisons between the uniaxial stress response to loading in the transverse 2-direction of the porous ductile viscoplastic material whose matrix properties are given in

Table 1 as predicted by the Gurson (G) and HFGMC (HF) models. Also shown for a reference is the uniaxial stress response of the homogeneous viscoplastic material (H). (a)

, (b)

, (c)

.

Figure 14.

A comparison between the response and damage evolution of the monolithic ductile material, whose properties were specified by

Table 1, when it is modeled by Lemaitre viscoplastic (VP) and elastoplastic (EP) equations. Also shown are the corresponding special cases when the damage is ignored (

). (a) Stress-deformation response and, (b) damage evolution.

Figure 14.

A comparison between the response and damage evolution of the monolithic ductile material, whose properties were specified by

Table 1, when it is modeled by Lemaitre viscoplastic (VP) and elastoplastic (EP) equations. Also shown are the corresponding special cases when the damage is ignored (

). (a) Stress-deformation response and, (b) damage evolution.

Figure 15.

The response to uniaxial stress loading at two off-axis angles of a unidirectional metal/rubber-like composite in the absence () and presence of evolving damage in the fiber phase which is modeled by Lemaitre viscoplastic (VP) and elastoplastic (EP) equations. Also shown in each case is the form of the damage evolution with applied deformation gradient. (a)-(b) , (c)-(d)

Figure 15.

The response to uniaxial stress loading at two off-axis angles of a unidirectional metal/rubber-like composite in the absence () and presence of evolving damage in the fiber phase which is modeled by Lemaitre viscoplastic (VP) and elastoplastic (EP) equations. Also shown in each case is the form of the damage evolution with applied deformation gradient. (a)-(b) , (c)-(d)

As shown in

Figure 15d, the evolution of damage in the metallic phase in the viscoplastic case is quite weak. Consequently, let the unidirectional metal/rubber-like composite be subjected to a uniaxial stress cyclic loading

at the off-axis angle

. The resulting response of the composite and the damage evolution in the fiber phase are shown in

Figure 16. The graph shows that the damage increases rapidly and total failure of the fiber occurs after less than

cycles.

7.5. Application of the finite strain coupled viscoelastic-damage model

Let us consider a composite material that consists of a finite viscoelastic matrix whose free energy is given by Equation

44, which represents a single Maxwell element with the parameters given by

Table 2. The damage parameters in Equation

53 are:

and

. The viscoelastic matrix is reinforced by continuous linearly elastic isotropic nylon fibers oriented in the 1-direction, whose Young’s modulus and Poisson’s ratio are

and

, respectively. The volume fraction of the fibers is denoted by

.

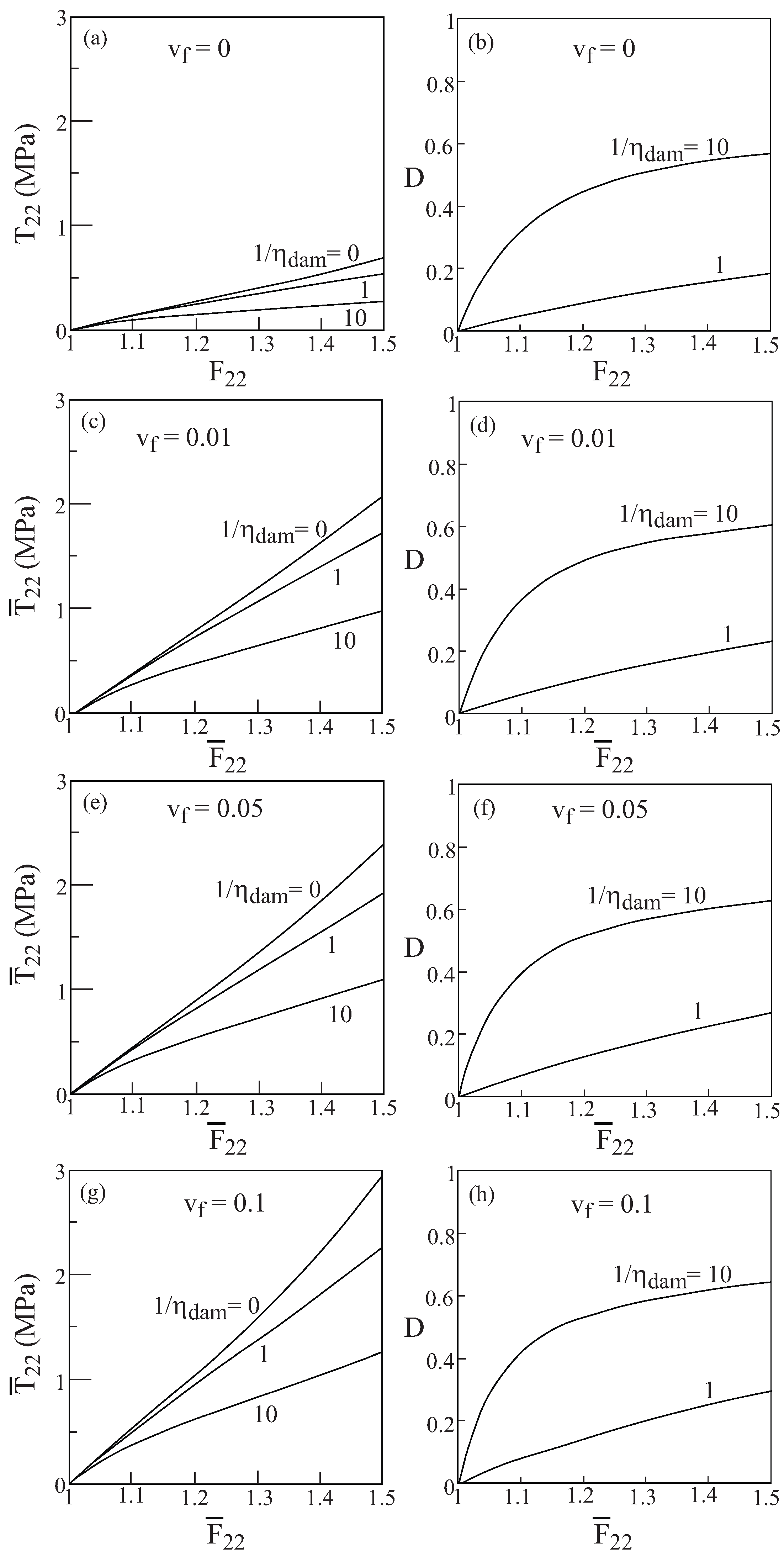

Figure 17a shows the response of the monolithic finite viscoelastic material that is subjected to a uniaxial stress loading applied at a rate of

for three values the damage parameter

.

Figure 17b exhibits the corresponding damage evolutions in these cases. Referring to Equation

51, the value of

corresponds to the case in which no damage takes place namely,

. The other parts of

Figure 17 shows the response of the unidirectional composite and the corresponding damage evolution in the matrix phase for various amounts of fiber volume ratio and the above three values of damage parameter

. Changing the values of the latter parameters illustrates the effect of damage on the resulting behavior of the matrix and the overall response of the composite. The uniaxial stress loading is applied perpendicular to the fiber direction namely, in the transverse 2-direction. It should be noted that due to the large contrast between the moduli of the fiber and matrix, loading in the fiber direction would not exhibit the viscoelastic effects since in such a case the effect of the elastic fiber is dominant.

Figure 16.

The response to uniaxial stress cyclic loading () at off-axis angle of a unidirectional metal/rubber-like composite in which the fibers are modeled by Lemaitre viscoplastic equations. (a) Variation of the stress with the cycles, (b) the evolution of damage in the fiber phase.

Figure 16.

The response to uniaxial stress cyclic loading () at off-axis angle of a unidirectional metal/rubber-like composite in which the fibers are modeled by Lemaitre viscoplastic equations. (a) Variation of the stress with the cycles, (b) the evolution of damage in the fiber phase.

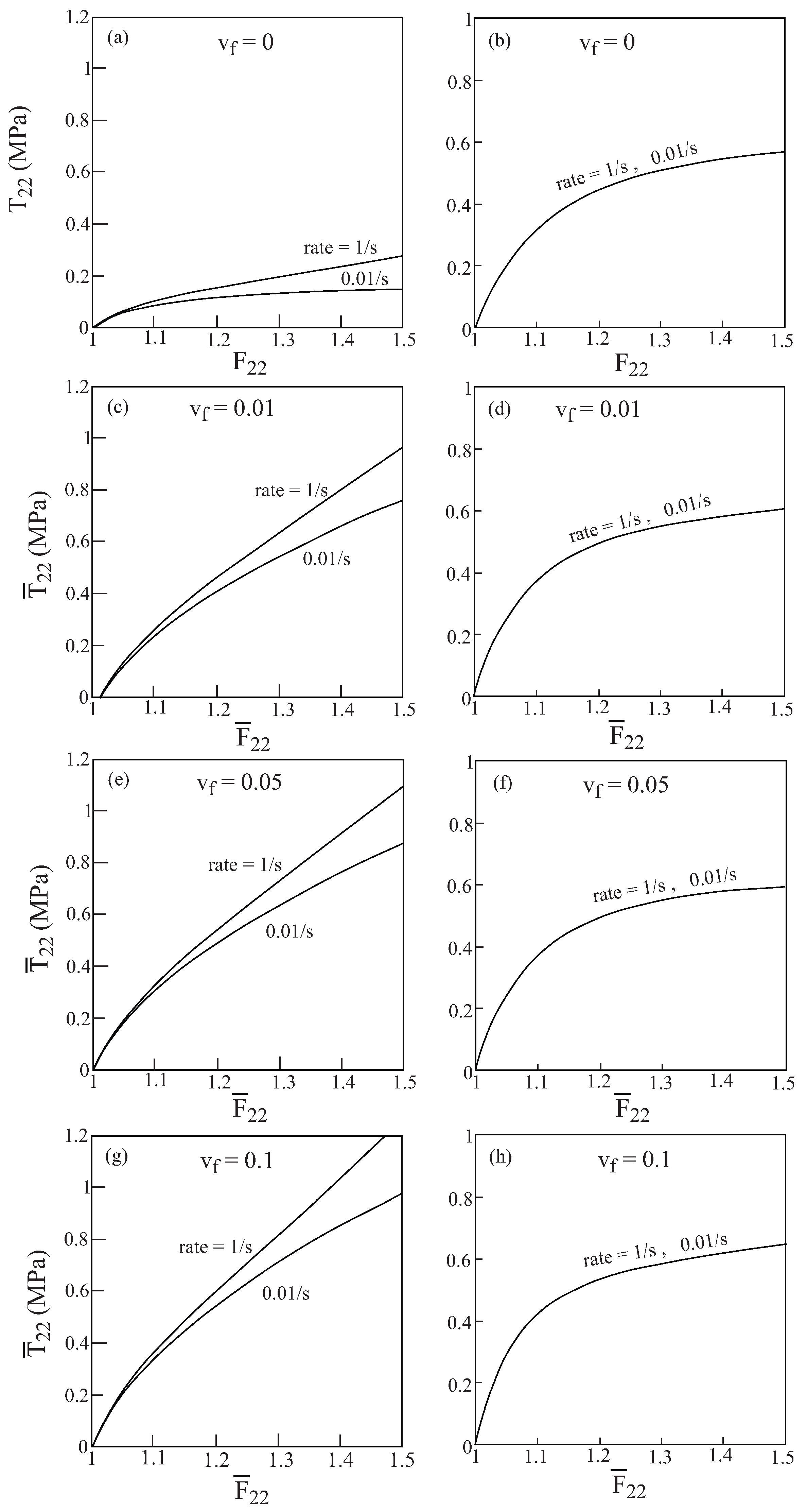

The responses and damage evolutions in

Figure 17 were caused by uniaxial transverse stress loading applied at a rate of

.

Figure 18 exhibits the effect of applying the transverse loading at two different rates:

and

which is caused by the presence of the viscoelastic mechanism. In all cases shown in this figure, the damage parameter

is kept constant.

Figure 18a,b show the response of the unreinforced finite viscoelastic matrix and the resulting damage evolution at these two rates, whereas the other portions of this figure exhibit the behavior of the nylon reinforced matrix with various fiber volume ratios. It is interesting to observe that whereas the stress responses are sensitive to the rate of applied loading, the damage evolution in the matrix is not sensitive in the sense that up to the scale of the plot the behaviors caused by these two rates are indistinguishable.

Figure 17.

The response to transverse uniaxial stress loading applied at a rate of of a composite that consists of a finite viscoelastic matrix reinforced by nylon elastic fibers oriented in the axial 1-direction. The figure shows the stress response and the resulting damage evolution in the matrix for various values of fiber volume ratio and damage parameter . (a)-(b) Stress and damage evolution in the (unreinforced) matrix, (c)-(d), (e)-(f) and (g)-(h) stress and damage evolution for composites with fiber volume fraction and , respectively.

Figure 17.

The response to transverse uniaxial stress loading applied at a rate of of a composite that consists of a finite viscoelastic matrix reinforced by nylon elastic fibers oriented in the axial 1-direction. The figure shows the stress response and the resulting damage evolution in the matrix for various values of fiber volume ratio and damage parameter . (a)-(b) Stress and damage evolution in the (unreinforced) matrix, (c)-(d), (e)-(f) and (g)-(h) stress and damage evolution for composites with fiber volume fraction and , respectively.

Figure 18.

The response to transverse uniaxial stress loading applied at two rates of and of a composite that consists of a finite viscoelastic matrix reinforced by nylon elastic fibers oriented in the axial 1-direction. The figure shows the stress response and the resulting damage evolution in the matrix in which the damage parameter is held constant for various values of fiber volume ratio . (a)-(b) Stress and damage evolution in the (unreinforced) matrix, (c)-(d), (e)-(f) and (g)-(h) stress and damage evolution for composites with fiber volume fraction and , respectively.

Figure 18.

The response to transverse uniaxial stress loading applied at two rates of and of a composite that consists of a finite viscoelastic matrix reinforced by nylon elastic fibers oriented in the axial 1-direction. The figure shows the stress response and the resulting damage evolution in the matrix in which the damage parameter is held constant for various values of fiber volume ratio . (a)-(b) Stress and damage evolution in the (unreinforced) matrix, (c)-(d), (e)-(f) and (g)-(h) stress and damage evolution for composites with fiber volume fraction and , respectively.