Nanoporous Gold: Fabrication, Characterization, and Applications

Abstract

:1. Introduction

2. Research Fronts

2.1. Sensor Applications

2.2. Surface- and Porosity-Related Phenomenon

2.3. Catalysis

3. Fabrication and Synthesis Methods

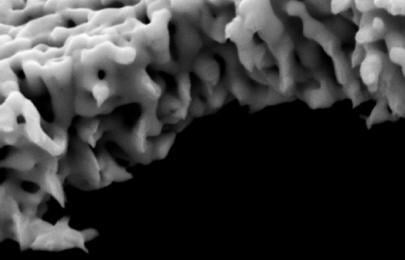

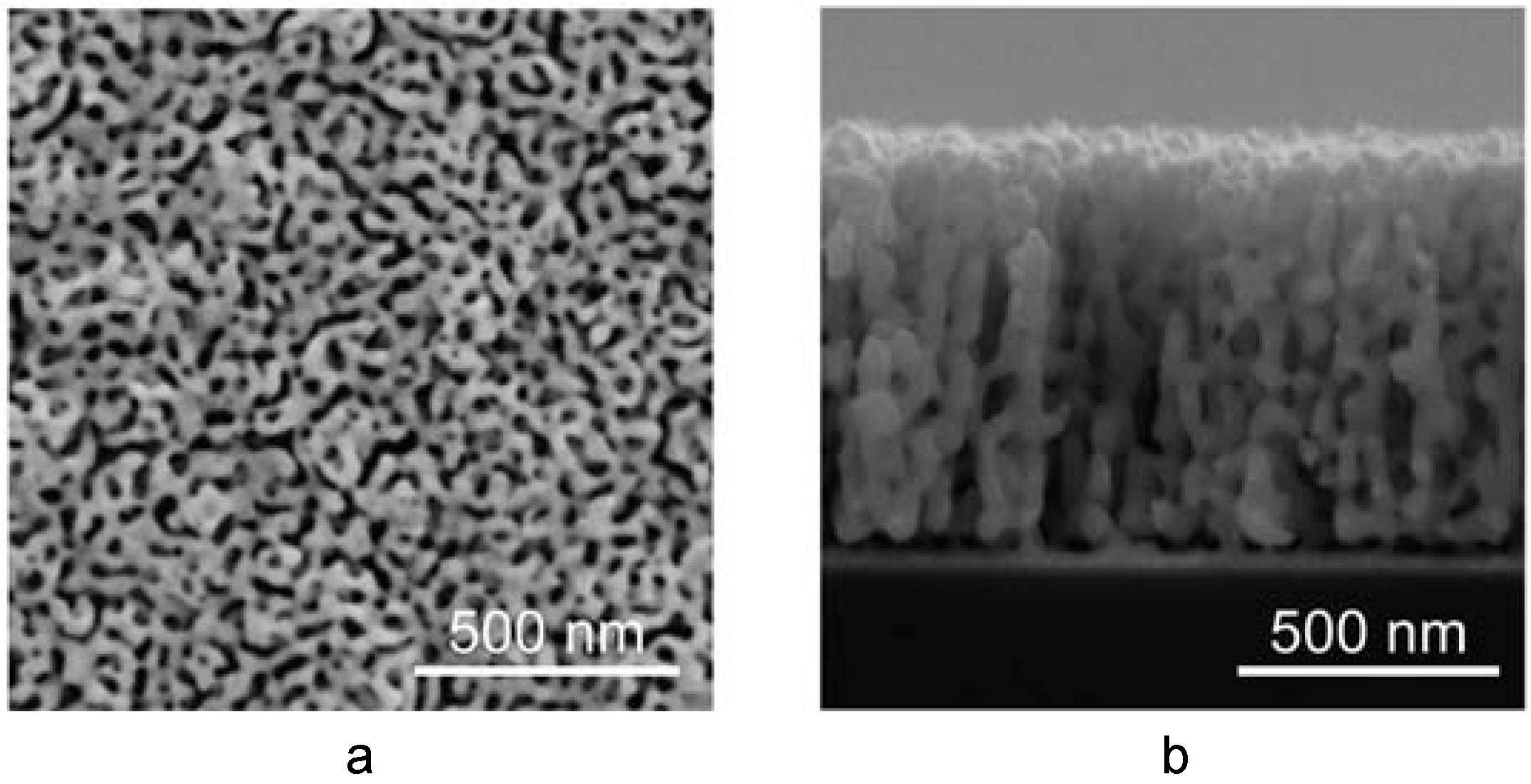

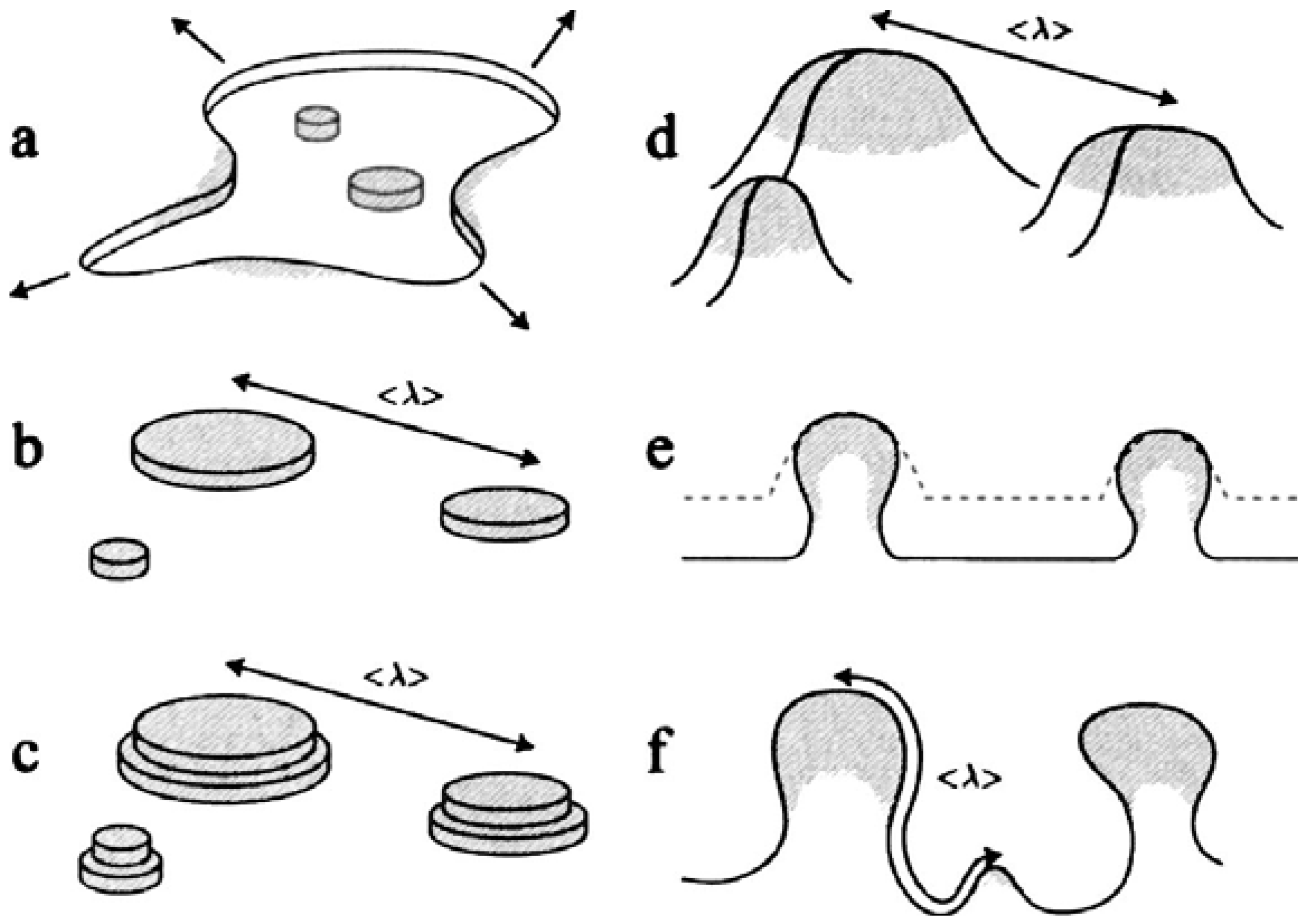

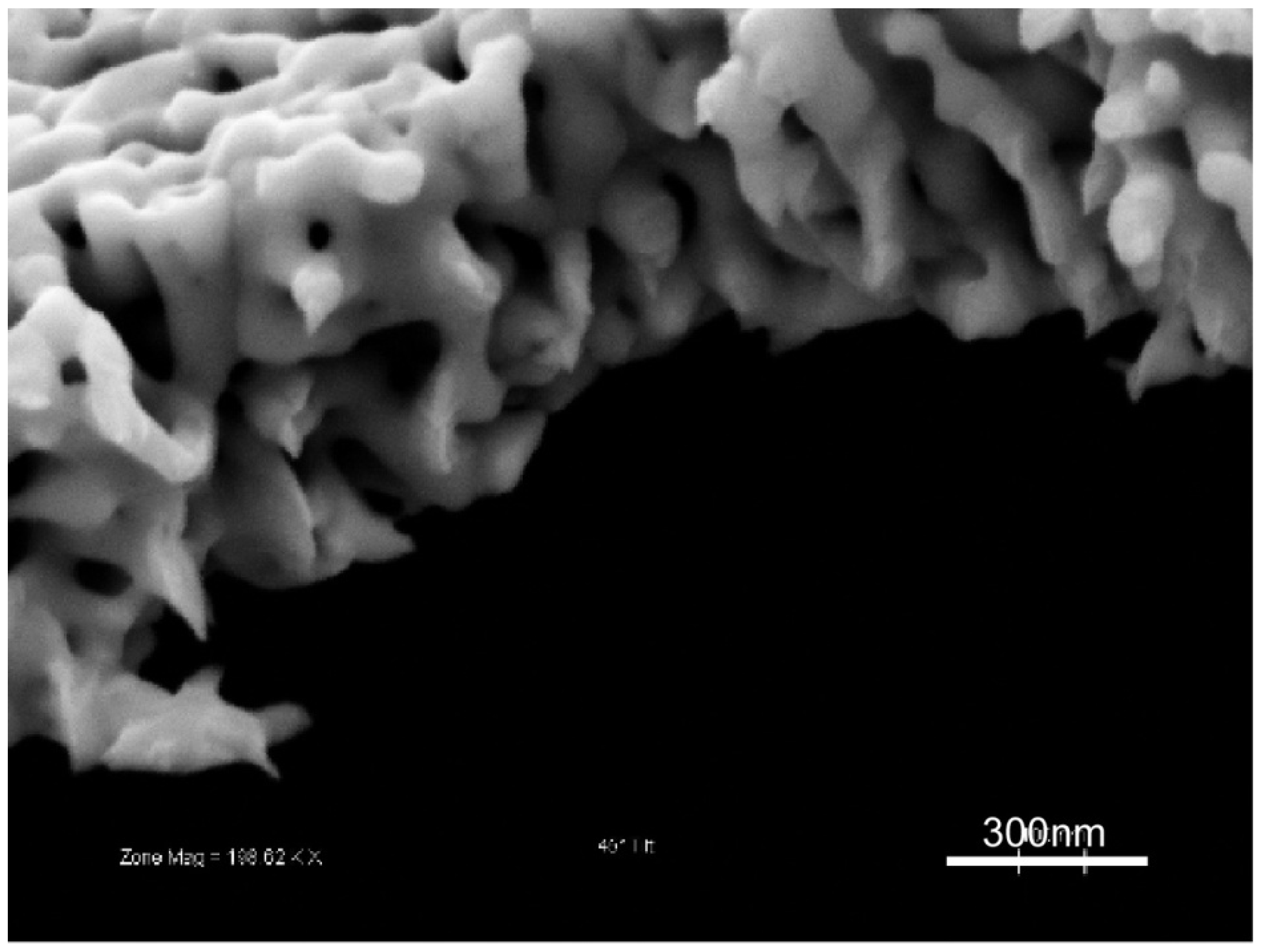

3.1. Porosity Formation

3.2. Alloy Preparation

3.3. Dissolution Methods

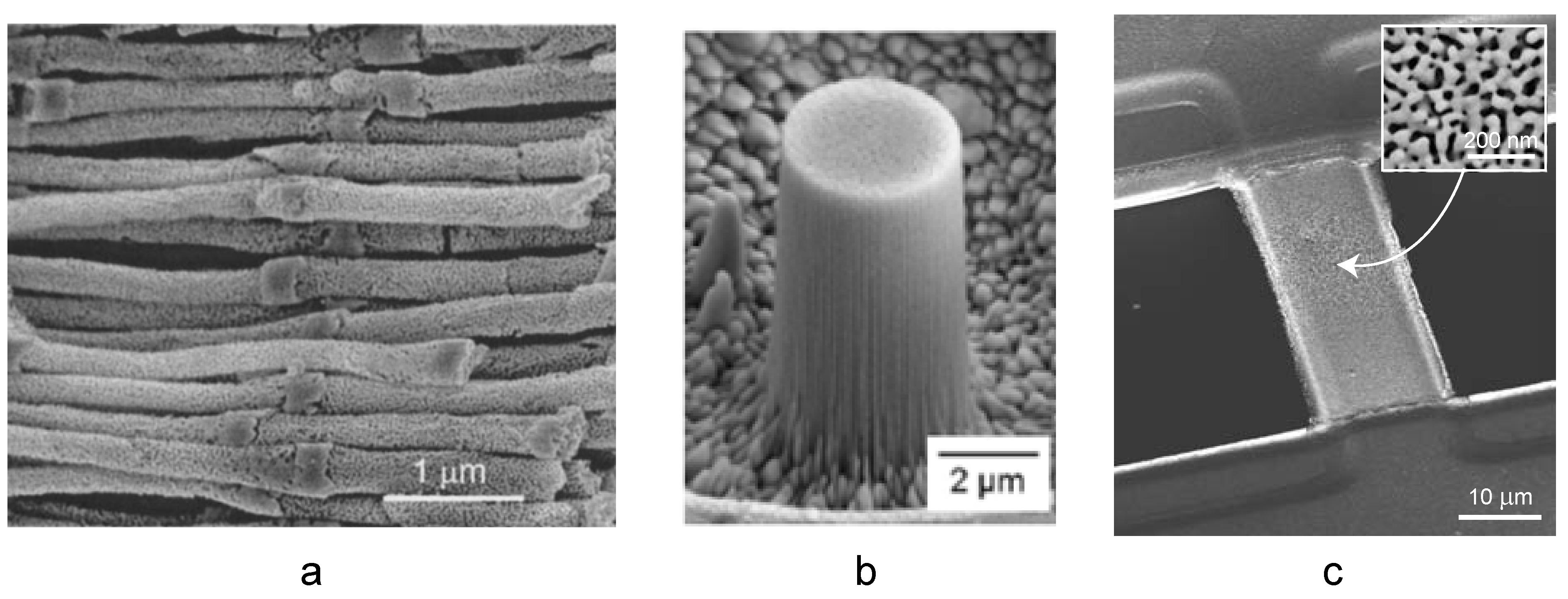

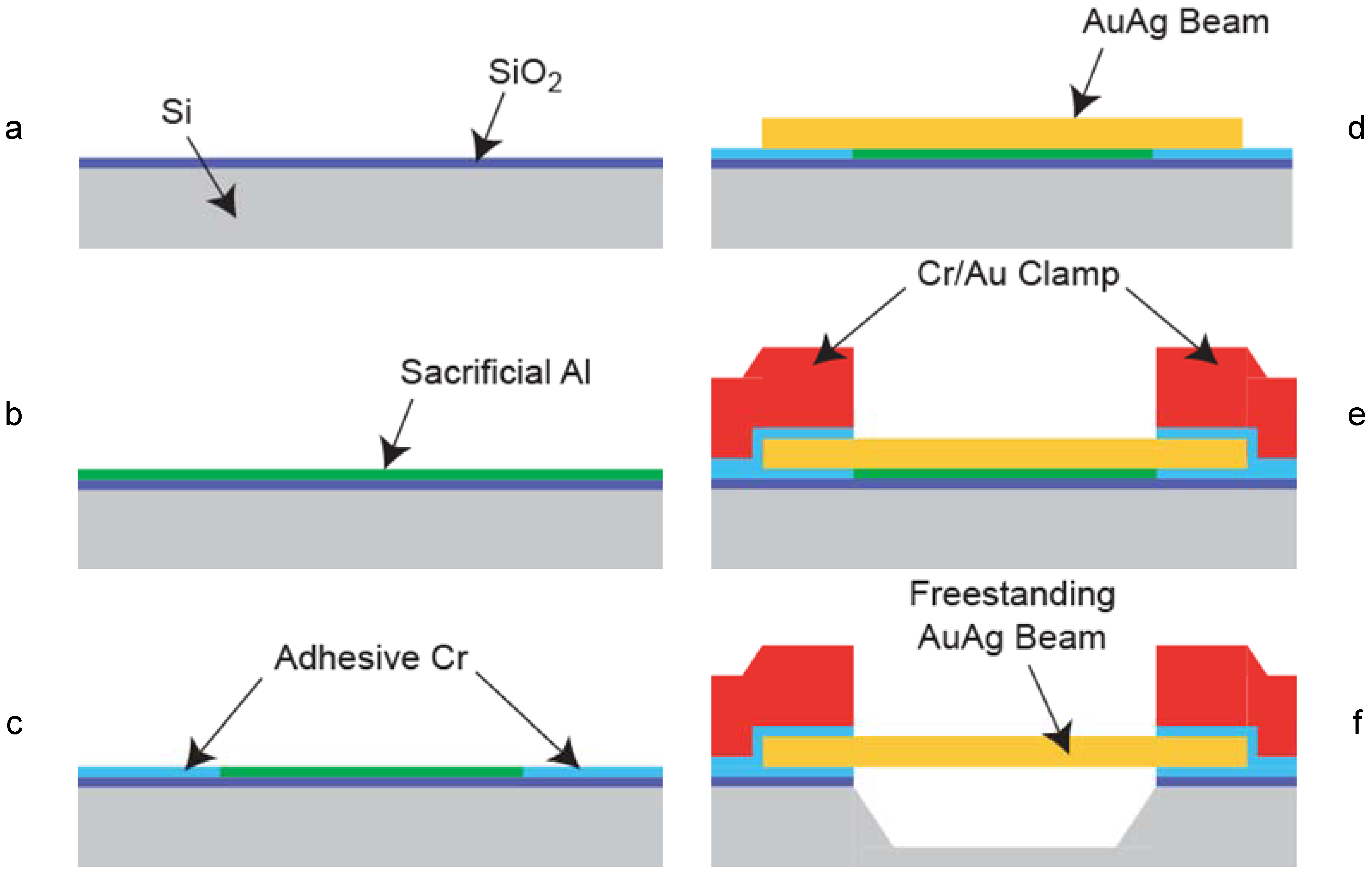

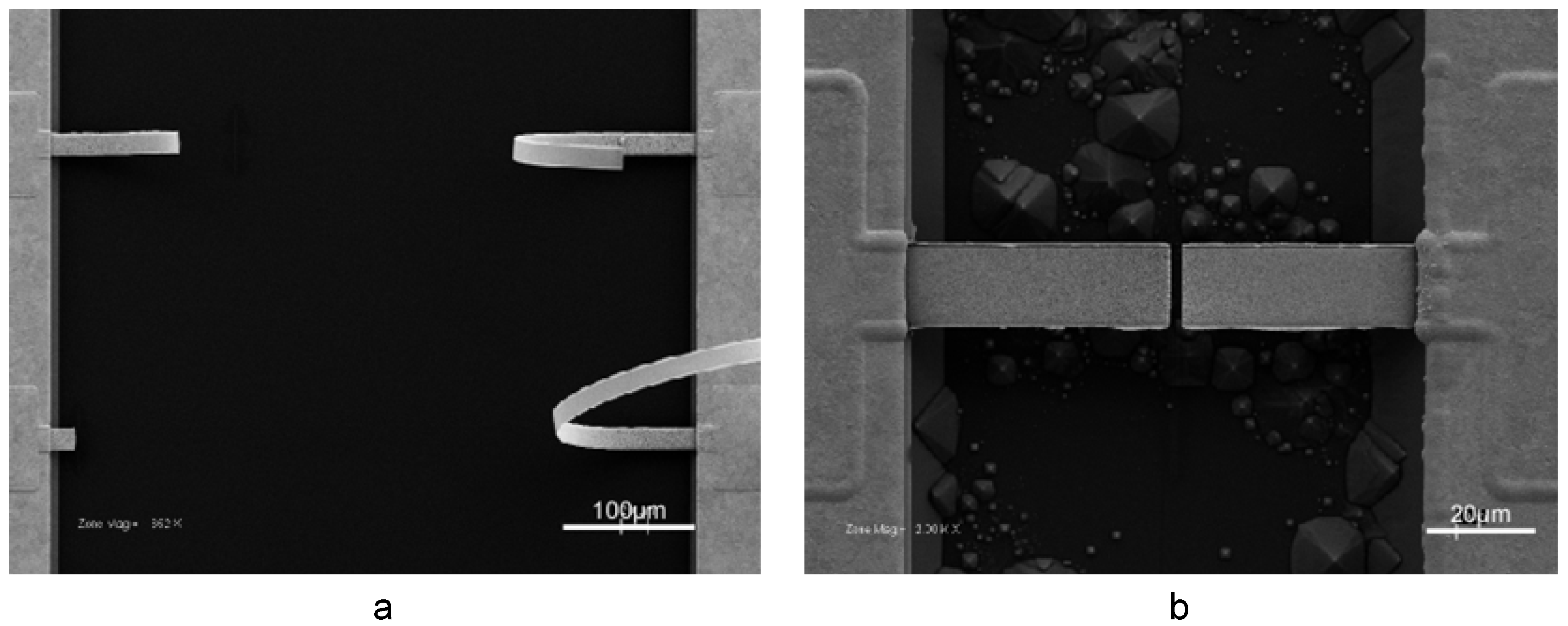

3.4. Micropatterning Techniques

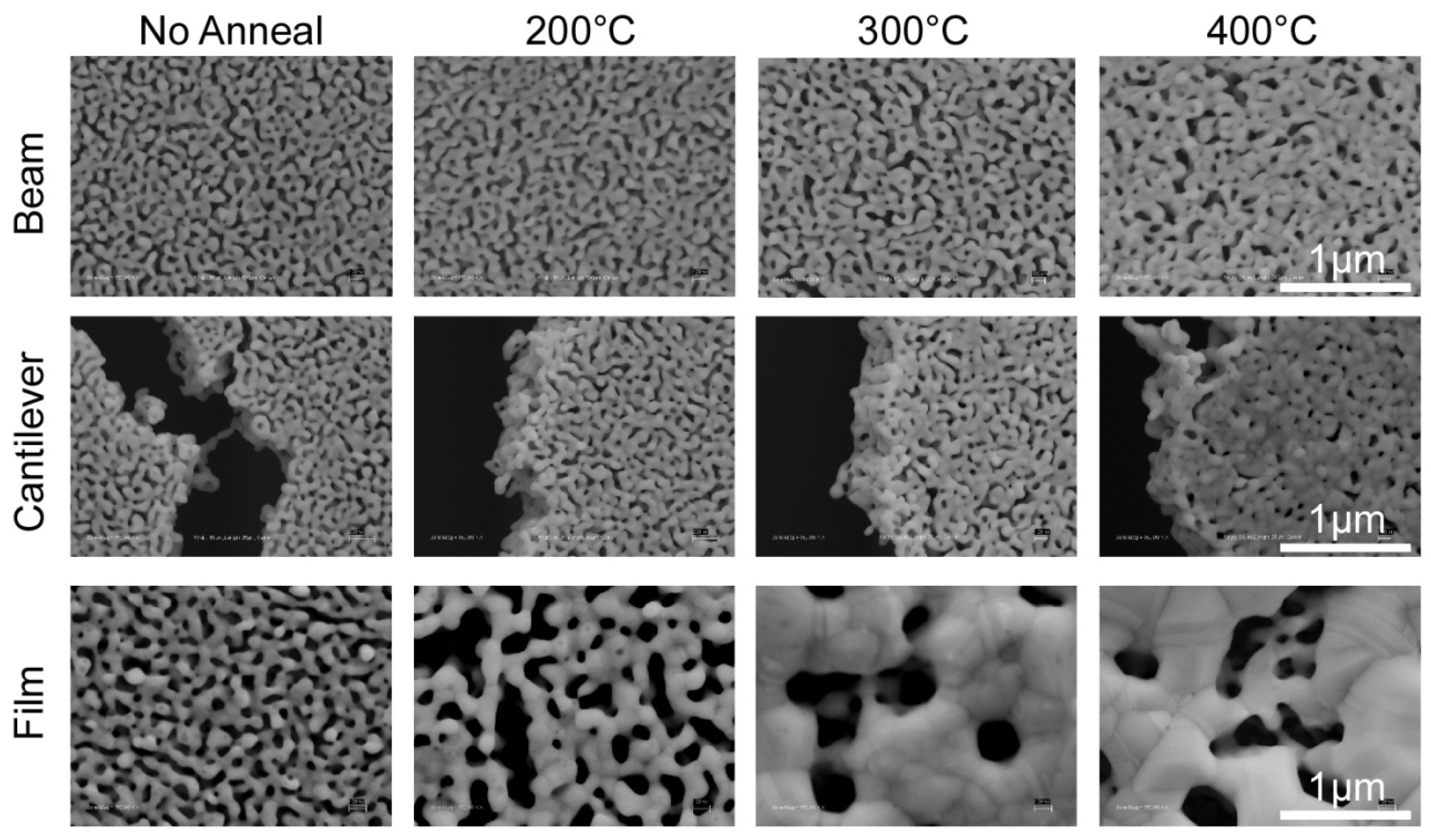

3.5. Morphology Modification

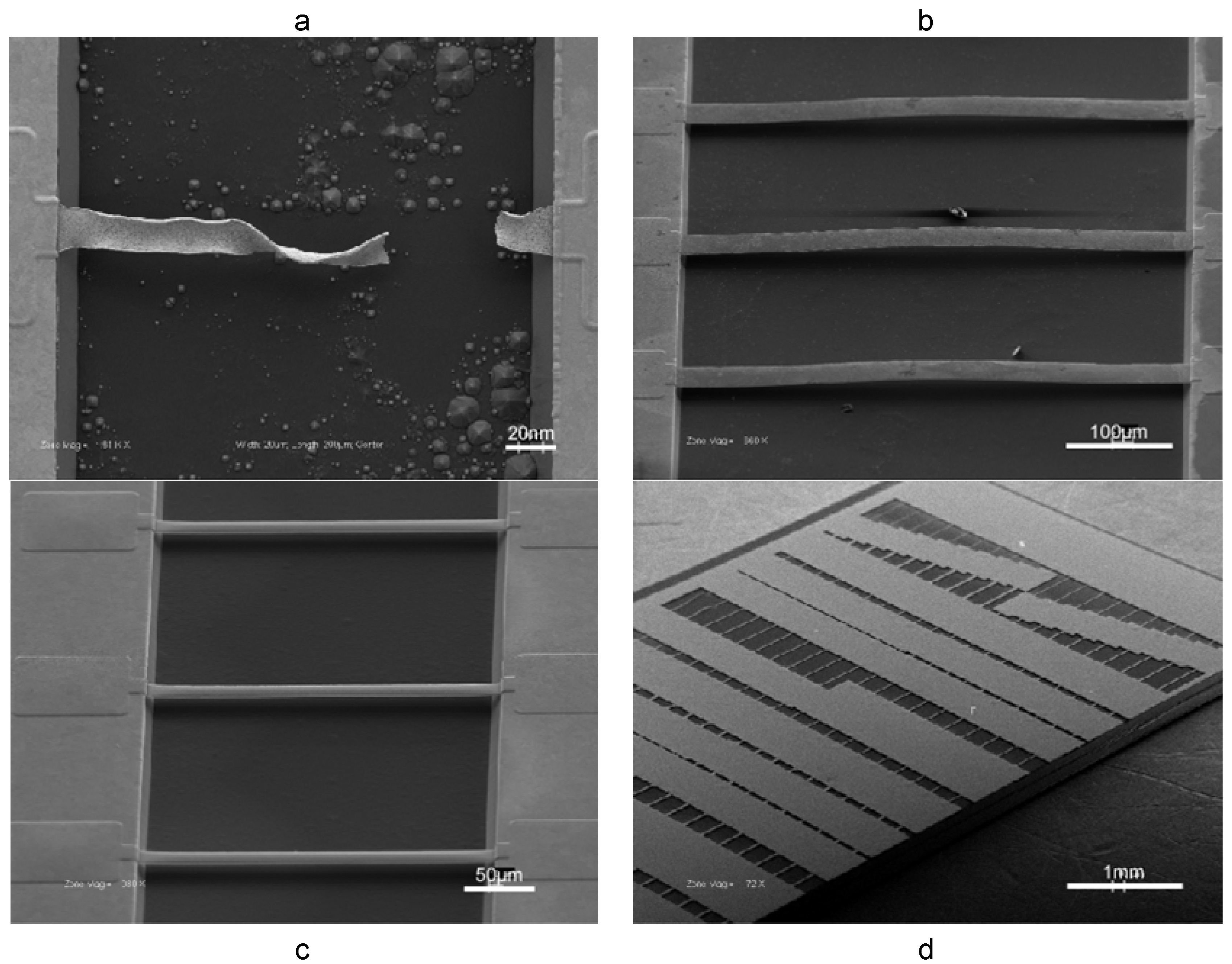

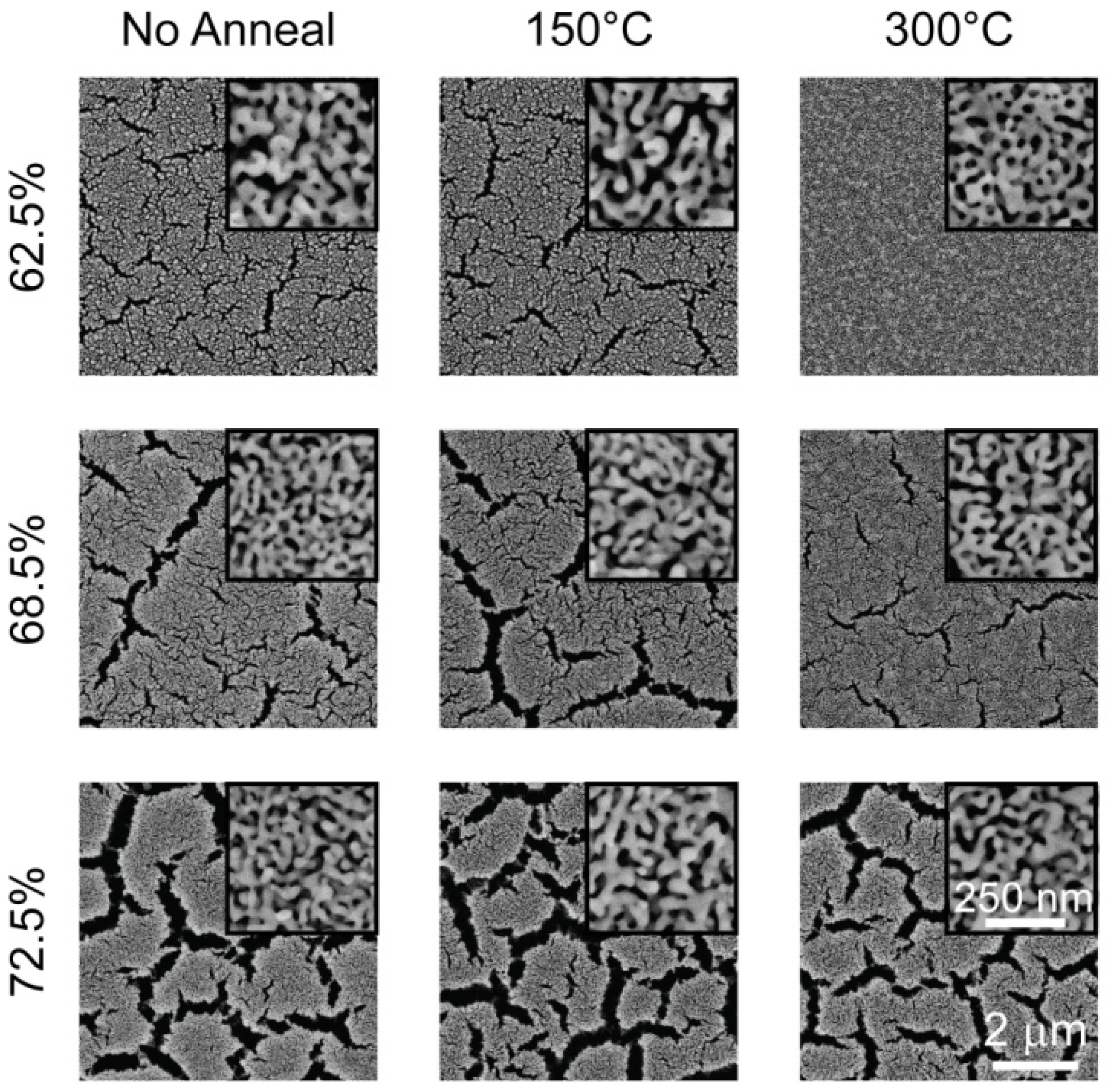

3.6. Fracture and Remedy

4. Characterization

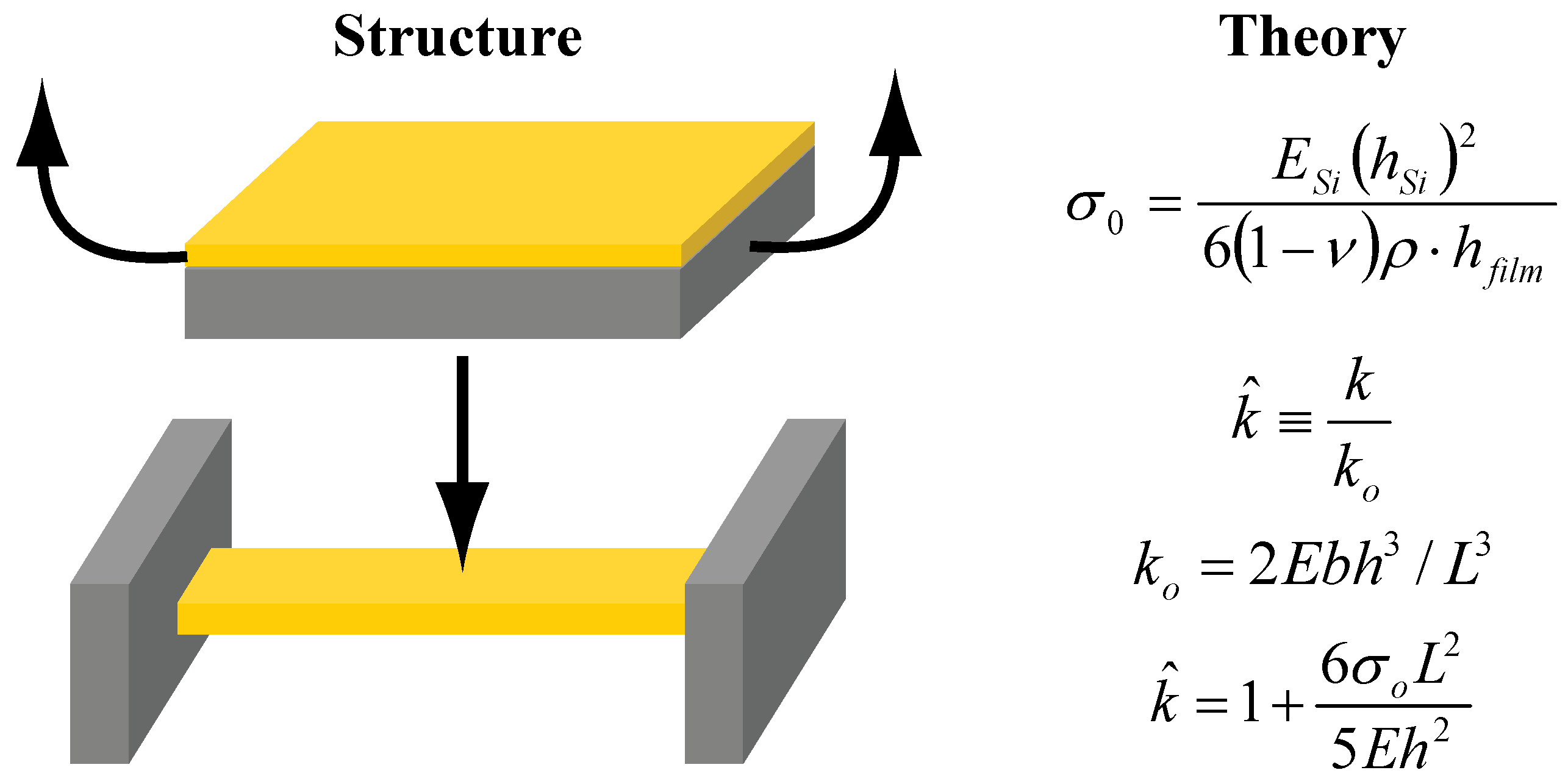

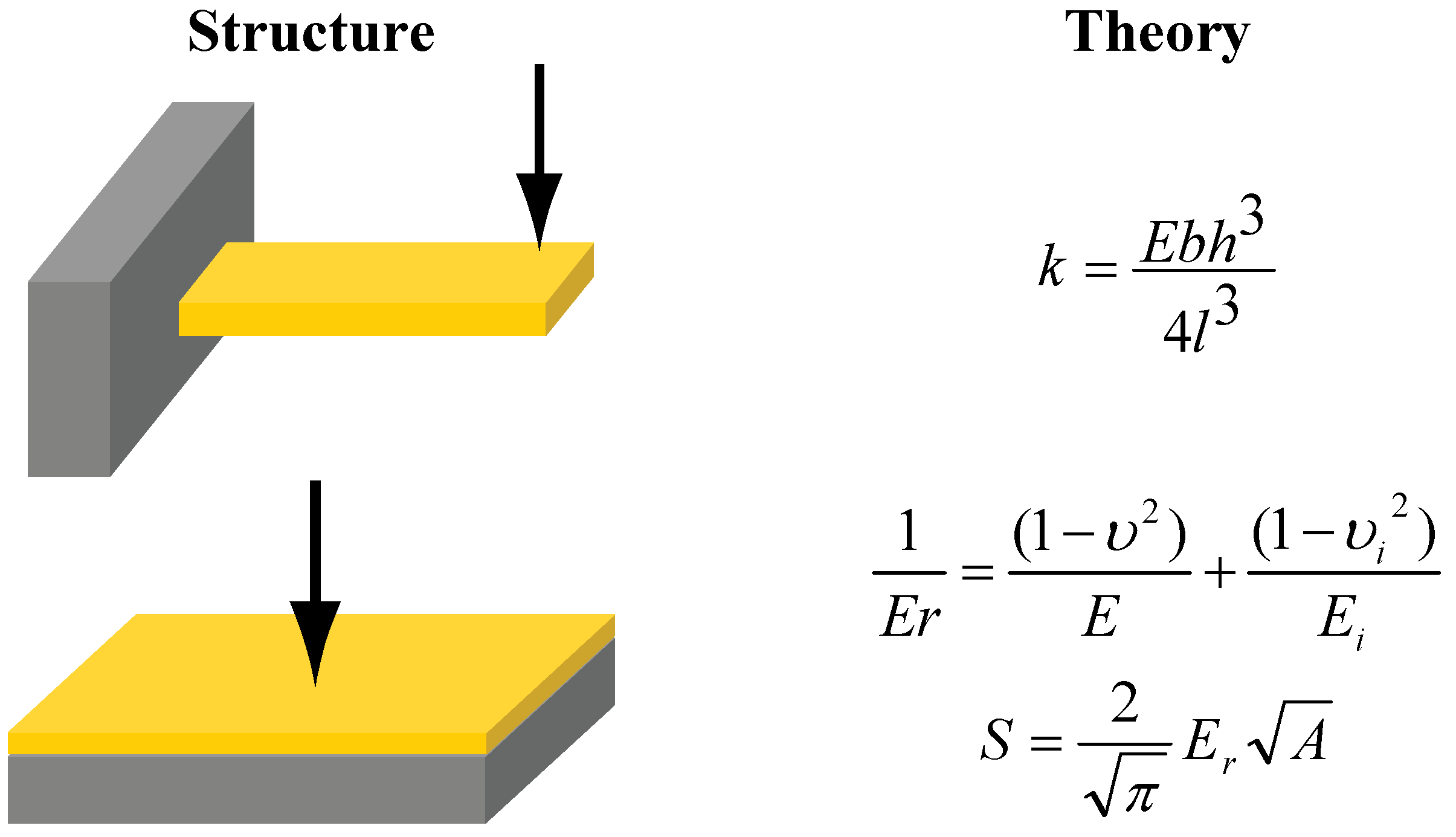

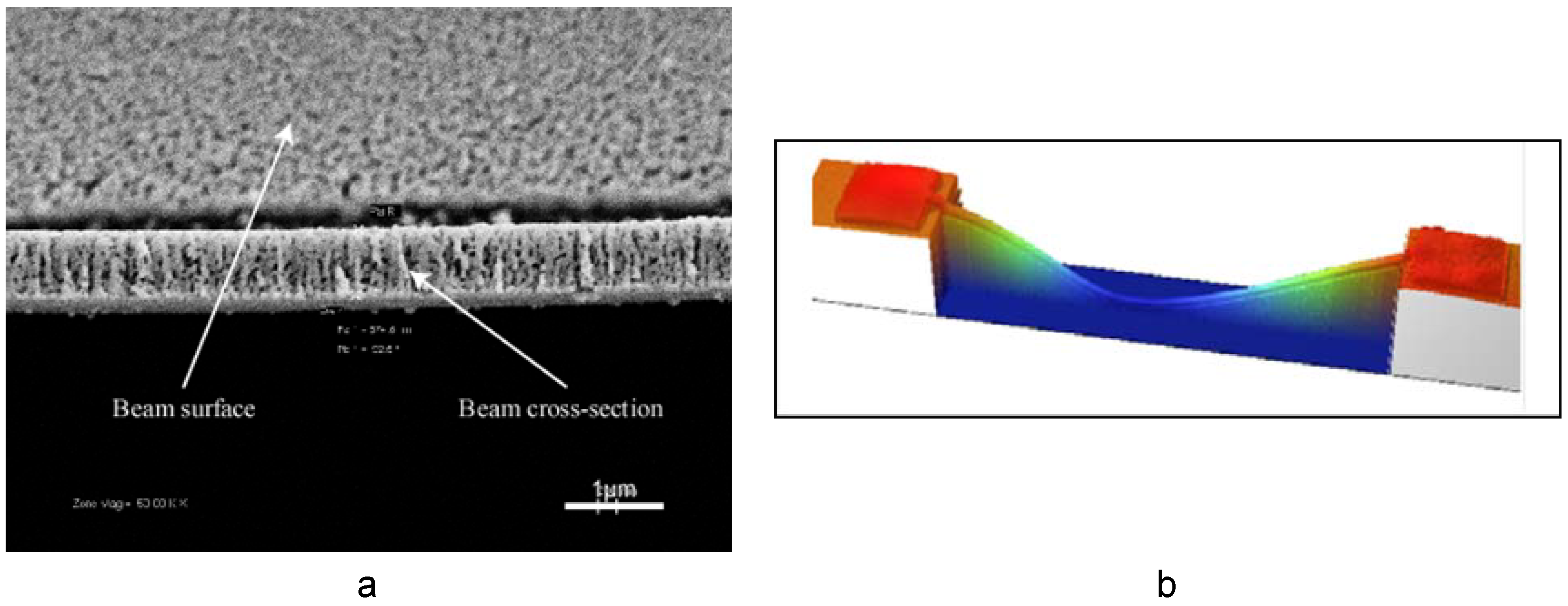

4.1. Mechanical Characterization

4.2. Geometric and Spectroscopic Measurements

4.3. Material Analysis

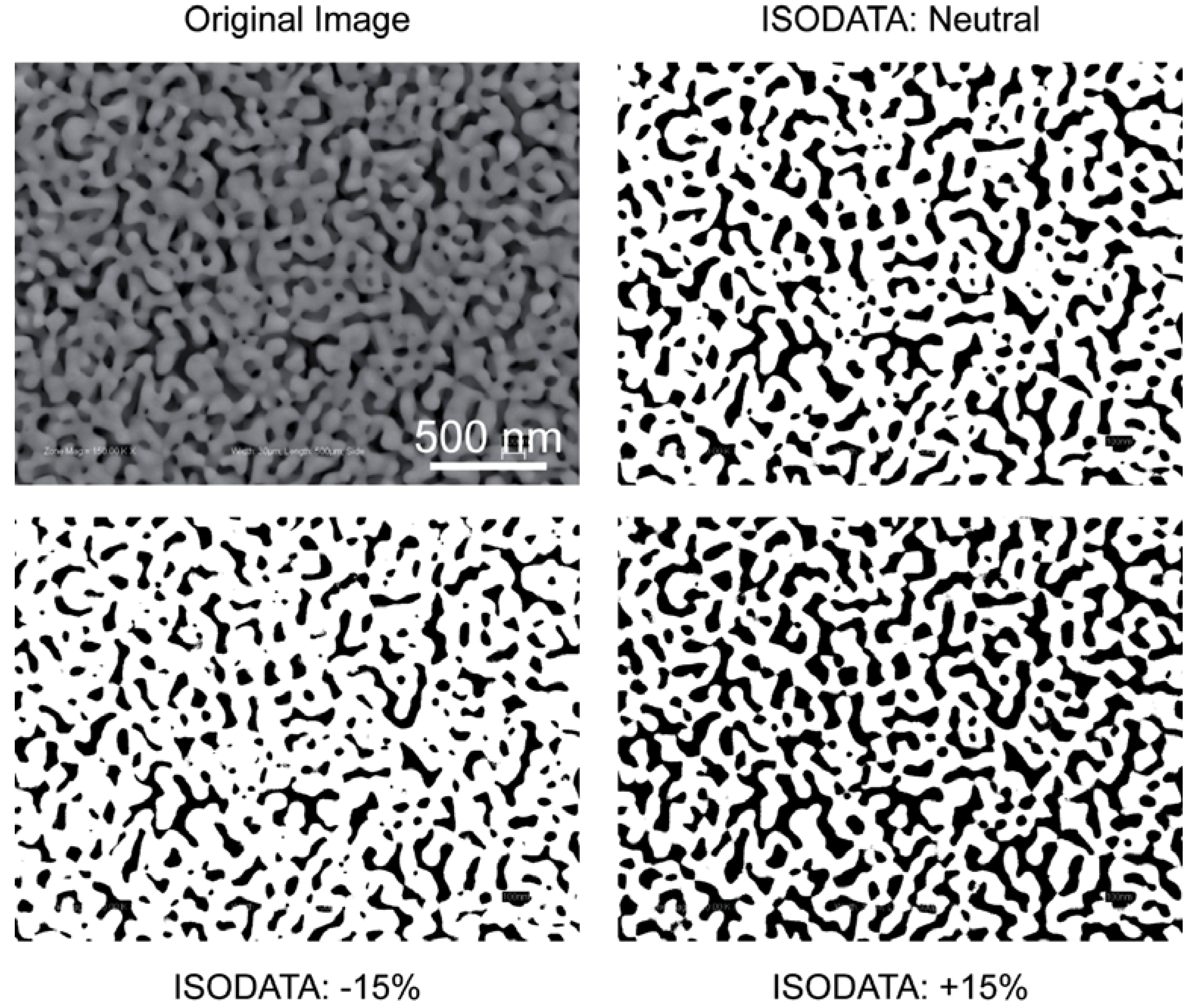

4.4. Morphology Analysis

5. Conclusions and Future Studies

- Although now a general understanding of porosity evolution exists, it is necessary to study the effects of stress generation during dealloying in structures under different mechanical constraints and the effects of multiple alloy constituents in pore morphology.

- Identifying the relationship between alloys constituents and resulting morphologies, particularly for alloy systems with multiple constituents, can assist in expanding the repertoire of nanoporous gold with distinct pore structures and enable a multitude of applications.

- The coarsening effect of thermal treatment on porosity evolution is well known, but the dynamics of the process are probed mostly theoretically. An interesting experiment may involve real-time observation of porosity evolution under thermo-mechanical stress using a scanning electron microscope with a heated stage to provide insight into routes of coarsening.

- Film delamination and cracking limit the successful integration of np-Au as functional coating. Most delamination problems during dealloying are a result of the absence of the adhesive layers between the np-Au layer and the substrate, compounded by residual stress accumulation due to volume contraction. Characterization of the interface strength and optimization of fabrication variables may mitigate such issues, thereby enabling synthesis of intact np-Au structures.

- Volume contraction during dealloying is widely observed and there are several methods to blunt its scale; however, it should be more systematically studied with particular attention to the effects of key parameters, such as electrolyte type, temperature, sample dimensions, and dealloying potential.

- Flow-through np-Au catalysts and molecular sieves are promising applications; however, the pressure-flow relationships as well membrane strength with respect to membrane architecture need to be established in order to implement this structure in such applications.

Acknowledgements

References

- Weissmüller, J.; Newman, R.; Jin, H.; Hodge, A.; Kysar, J. Theme article—Nanoporous metals by alloy corrosion: Formation and mechanical propertieS. Mater. Res. Soc. Bull. 2009, 34, 577–586. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, M. Theme article—Nanoporous metals for catalytic and optical applications. Mater. Res. Soc. Bull. 2009, 24, 569–576. [Google Scholar] [CrossRef]

- Hieda, M.; Garcia, R.; Dixon, M.; Daniel, T.; Allara, D.; Chan, M. Ultrasensitive quartz crystal microbalance with porous gold electrodes. Appl. Phys. Lett. 2004, 84, 628–630. [Google Scholar] [CrossRef]

- Lavrik, N.; Tipple, C.; Sepaniak, M.; Datskos, P. Gold nano-structures for transduction of biomolecular interactions into micrometer scale movements. Biomed. Microdevices 2001, 3, 35–44. [Google Scholar] [CrossRef]

- Liu, Z.; Searson, P. Single nanoporous gold nanowire sensors. J. Phys. Chem. B 2006, 110, 4318–4322. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Lan, D.; Li, X.; Zhang, S. Electrochemical DNA biosensor based on nanoporous gold electrode and multifunctional encoded DNA Au bio bar codes. Anal. Chem. 2008, 80, 9124–9130. [Google Scholar] [CrossRef] [PubMed]

- Shulga, O.; Zhou, D.; Demchenko, A.; Stine, K. Detection of free prostate specific antigen (fPSA) on a nanoporous gold platform. The Analyst 2008, 133, 319–322. [Google Scholar] [CrossRef] [PubMed]

- Mortari, A.; Maaroof, A.; Martin, D.; Cortie, M. Mesoporous gold electrodes for sensors based on electrochemical double layer capacitance. Sensor. Actuator. B Chem. 2007, 123, 262–268. [Google Scholar] [CrossRef]

- Yang, Q.; Liang, Y.; Zhou, T.; Shi, G.; Jin, L. Electrochemical investigation of platinum-coated gold nanoporous film and its application for Escherichia coli rapid measurement. Electrochem. Commun. 2009, 11, 893–896. [Google Scholar] [CrossRef]

- Liu, Z.; Du, J.; Qiu, C.; Huang, L.; Ma, H.; Shen, D.; Ding, Y. Electrochemical sensor for detection of p-nitrophenol based on nanoporous gold. Electrochem. Commun. 2009, 11, 1365–1368. [Google Scholar] [CrossRef]

- Zhu, A.; Tian, Y.; Liu, H.; Luo, Y. Nanoporous gold film encapsulating cytochrome c for the fabrication of a H2O2 biosensor. Biomaterials 2009, 30, 3183–3188. [Google Scholar] [CrossRef] [PubMed]

- Seker, E.; Berdichevsky, Y.; Begley, M.; Reed, M.; Staley, K.; Yarmush, M. Fabrication of low-impedance nanoporous gold multiple electrode arrays for neural electrophysiology studies. Nanotechnology 2009. submitted. [Google Scholar]

- Biener, J.; Wittstock, A.; Zepeda-Ruiz, L.; Biener, M.; Zielasek, V.; Kramer, D.; Viswanath, R.; Weissmüller, J.; Bäumer, M.; Hamza, A. Surface-chemistry-driven actuation in nanoporous gold. Nature Materials 2009, 8, 47–51. [Google Scholar] [CrossRef] [PubMed]

- Kramer, D.; Viswanath, R.; Weissmuller, J. Surface-stress induced macroscopic bending of nanoporous gold cantilevers. Nano Lett. 2004, 4, 793–796. [Google Scholar] [CrossRef]

- Jin, H.; Parida, S.; Kramer, D.; Weissmüller, J. Sign-inverted surface stress-charge response in nanoporous gold. Surf. Sci. 2008, 602, 3588–3594. [Google Scholar] [CrossRef]

- Kucheyev, S.; Hayes, J.; Biener, J.; Huser, T.; Talley, C.; Hamza, A. Surface-enhanced Raman scattering on nanoporous Au. Appl. Phys. Lett. 2006, 89, 053102–053104. [Google Scholar] [CrossRef]

- Qian, L.; Yan, X.; Fujita, T.; Inoue, A.; Chen, M. Surface enhanced Raman scattering of nanoporous gold: Smaller pore sizes stronger enhancements. Appl. Phys. Lett. 2007, 90, 153120. [Google Scholar] [CrossRef]

- Huang, L.; Seker, E.; Begley, M.; Utz, M.; Landers, J. Quantitative end-grafting of DNA onto flat and nanoporous gold surfaces. In Proceedings of the 12th International Conference on Miniaturized Systems for Chemistry and Life Sciences; MicroTAS: San Diego, CA, USA, 2008; Vol. 2, pp. 1567–1569. [Google Scholar]

- Seker, E.; Begley, M.; Reed, M.; Utz, M. Kinetics of capillary wetting in nanoporous films in the presence of surface evaporation. Appl. Phys. Lett. 2008, 92, 013128. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, P.; Ma, H.; Ding, Y. Nanostructured porous gold for methanol electro-oxidation. J. Phys. Chem. C 2007, 111, 10382–10388. [Google Scholar] [CrossRef]

- Xu, C.; Su, J.; Xu, X.; Liu, P.; Zhao, H.; Tian, F.; Ding, Y. Low temperature CO oxidation over unsupported nanoporous gold. J. Am. Chem. Soc 2007, 129, 42–43. [Google Scholar] [CrossRef] [PubMed]

- Zeis, R.; Mathur, A.; Fritz, G.; Lee, J.; Erlebacher, J. Platinum-plated nanoporous gold: An efficient, low Pt loading electrocatalyst for PEM fuel cells. J. Power Sources 2007, 165, 65–72. [Google Scholar] [CrossRef]

- Masing, G. Zur Theorie der Resistenzgrenzen in Mischkristallen. Z. Anorg. Allg. Chem. 1921, 118, 293–308. [Google Scholar] [CrossRef]

- Erlebacher, J. An atomistic description of dealloying. J. Electrochem. Soc. 2004, 151, C614–C626. [Google Scholar] [CrossRef]

- Erlebacher, J.; Aziz, M.; Karma, A.; Dimitrov, N.; Sieradzki, K. Evolution of nanoporosity in dealloying. Nature 2001, 410, 450–453. [Google Scholar] [CrossRef] [PubMed]

- Crowson, D.; Farkas, D.; Corcoran, S. Geometric relaxation of nanoporous metals: The role of surface relaxation. Scripta Mater. 2007, 56, 919–922. [Google Scholar] [CrossRef]

- Policastro, S.; Carnahan, J.; Zangari, G.; Bart-Smith, H.; Begley, M.; Seker, E.; Reed, M.; Reynolds, P.; Kelly, R. Metal and electrolyte roles in selective dissolution I: Surface diffusion and dissolution kinetics at the electrolyte-metal interface. J. Electrochem. Soc. 2009, submitted. [Google Scholar]

- Huang, J.; Sun, I. Fabrication and surface functionalization of nanoporous gold by electrochemical alloying/dealloying of Au-Zn in an ionic liquid, and the self-assembly of L-cysteine monolayers. Adv. Funct. Mater. 2005, 15, 989–994. [Google Scholar] [CrossRef]

- Rouya, E.; Reed, M.; Kelly, R.; Bart-Smith, H.; Begley, M.; Zangari, G. Synthesis of nanoporous gold structures via dealloying of electroplated Au-Ni alloy films. In 211th Electrochemical Society Transactions, Chicago, IL, May 6–10, 2007; Vol. 6, pp. 41–50.

- Zhang, Q.; Wang, X.; Qi, Z.; Wang, Y.; Zhang, Z. A benign route to fabricate nanoporous gold through electrochemical dealloying of Al–Au alloys in a neutral solution. Electrochim. Acta 2009, 54, 6190–6198. [Google Scholar] [CrossRef]

- Snyder, J.; Asanithi, P.; Dalton, A.; Erlebacher, J. Stabilized nanoporous metals by dealloying ternary alloy precursors. Adv. Mater. 2008, 20, 4883–4886. [Google Scholar] [CrossRef]

- Barnes, A.; Senior, N.; Newman, R. Film-induced cleavage of Ag-Au alloys. Met. Trans. A Phys. Met. Mater. Sci. 2009, 40, 58–68. [Google Scholar] [CrossRef]

- Senior, N.; Newman, R. Synthesis of tough nanoporous metals by controlled electrolytic dealloying. Nanotechnology 2006, 17, 2311–2316. [Google Scholar] [CrossRef]

- Biener, J.; Hodge, A.; Hamza, A.; Hsiung, L.; Satcher Jr, J. Nanoporous Au: A high yield strength material. J. Appl. Phys. 2005, 97, 024301. [Google Scholar] [CrossRef]

- Volkert, C.; Lilleodden, E.; Kramer, D.; Weissmüller, J. Approaching the theoretical strength in nanoporous Au. Appl. Phys. Lett. 2006, 89, 061920. [Google Scholar] [CrossRef]

- Hakamada, M.; Mabuchi, M. Mechanical strength of nanoporous gold fabricated by dealloying. Scripta Mater. 2007, 56, 1003–1006. [Google Scholar] [CrossRef]

- Ding, Y.; Kim, Y.; Erlebacher, J. Nanoporous gold leaf: "Ancient technology"/advanced material. Adv. Mater. 2004, 16, 1897–1900. [Google Scholar] [CrossRef]

- Lee, D.; Wei, X.; Chen, X.; Zhao, M.; Jun, S.; Hone, J.; Herbert, E.; Oliver, W.; Kysar, J. Microfabrication and mechanical properties of nanoporous gold at the nanoscale. Scripta Mater. 2007, 56, 437–440. [Google Scholar] [CrossRef]

- Mathur, A.; Erlebacher, J. Size dependence of effective Young’s modulus of nanoporous gold. Appl. Phys. Lett. 2007, 90, 061910. [Google Scholar] [CrossRef]

- Seker, E.; Reed, M.; Utz, M.; Begley, M. Flexible and conductive bilayer membranes of nanoporous gold and silicone: Synthesis and characterization. Appl. Phys. Lett. 2008, 92, 154101. [Google Scholar] [CrossRef]

- Ji, C.; Searson, P. Synthesis and characterization of nanoporous gold nanowires. J. Phys. Chem. B 2003, 107, 4494–4499. [Google Scholar] [CrossRef]

- Seker, E.; Gaskins, J.; Bart-Smith, H.; Zhu, J.; Reed, M.; Zangari, G.; Kelly, R.; Begley, M. The effects of post-fabrication annealing on the mechanical properties of freestanding nanoporous gold structures. Acta Mater. 2007, 55, 4593–4602. [Google Scholar] [CrossRef]

- Seker, E.; Gaskins, J.; Bart-Smith, H.; Zhu, J.; Reed, M.; Zangari, G.; Kelly, R.; Begley, M. The effects of annealing prior to dealloying on the mechanical properties of nanoporous gold microbeams. Acta Mater. 2007, 56, 324–332. [Google Scholar] [CrossRef]

- Seker, E.; Reed, M.; Begley, M. A thermal treatment approach to reduce microscale void formation in blanket nanoporous gold films. Scripta Mater. 2009, 60, 435–438. [Google Scholar] [CrossRef]

- Sun, Y.; Kucera, K.; Burger, S.; John Balk, T. Microstructure, stability and thermomechanical behavior of crack-free thin films of nanoporous gold. Scripta Mater. 2008, 58, 1018–1021. [Google Scholar] [CrossRef]

- Dursun, A.; Pugh, D.; Corcoran, S. A Steady-state method for determining the dealloying critical potential. Electrochem. Solid-State Lett. 2003, 6, B32–B34. [Google Scholar] [CrossRef]

- Dursun, A.; Pugh, D.; Corcoran, S. Dealloying of Ag-Au alloys in halide-containing electrolytes. J. Electrochem. Soc. 2003, 150, B355–B360. [Google Scholar] [CrossRef]

- Dursun, A.; Pugh, D.; Corcoran, S. Probing the dealloying critical potential. J. Electrochem. Soc. 2005, 152, B65–B72. [Google Scholar] [CrossRef]

- Snyder, J.; Livi, K.; Erlebacher, J. Dealloying silver/gold alloys in neutral silver nitrate solution: Porosity evolution, surface composition, and surface oxides. J. Electrochem. Soc. 2008, 155, C464. [Google Scholar] [CrossRef]

- Ji, C.; Searson, P. Fabrication of nanoporous gold nanowires. Appl. Phys. Lett. 2002, 81, 4437–4439. [Google Scholar] [CrossRef]

- Seker, E.; Zhu, J.; Bart-Smith, H.; Begley, M.; Kelly, R.; Zangari, G.; Reed, M. Thermo-mechanical and size-dependent behavior of freestanding Au-Ag and nanoporous-Au beams. In Materials Research Society Symposium Proceedings; MRS: Boston, MA, USA, 2007; Vol. 976, pp. 13–18. [Google Scholar]

- Liu, L.; Lee, W.; Huang, Z.; Scholz, R.; Gosele, U. Fabrication and characterization of a flow-through nanoporous gold nanowire/AAO composite membrane. Nanotechnology 2008, 19, 335604. [Google Scholar] [CrossRef] [PubMed]

- Shim, S.; Bei, H.; Miller, M.; Pharr, G.; George, E. Effects of focused ion beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 2009, 57, 503–510. [Google Scholar] [CrossRef]

- Zhu, J.; Seker, E.; Bart-Smith, H.; Begley, M.; Kelly, R.; Zangari, G.; Lye, W.; Reed, M. Mitigation of tensile failure in released nanoporous metal microstructures via thermal treatment. Appl. Phys. Lett. 2006, 89, 133104. [Google Scholar] [CrossRef]

- Lee, D.; Wei, X.; Zhao, M.; Chen, X.; Jun, S.; Hone, J.; Kysar, J. Plastic deformation in nanoscale gold single crystals and open-celled nanoporous gold. Modell. Simul. Mater. Sci. Eng. 2007, 15, S181–S192. [Google Scholar] [CrossRef]

- Hakamada, M.; Mabuchi, M. Microstructural evolution in nanoporous gold by thermal and acid treatments. Mater. Lett. 2008, 62, 483–486. [Google Scholar] [CrossRef]

- Hakamada, M.; Mabuchi, M. Thermal coarsening of nanoporous gold: Melting or recrystallization. J. Mater. Res. 2009, 24, 301–304. [Google Scholar] [CrossRef]

- Li, R.; Sieradzki, K. Ductile-brittle transition in random porous Au. Phys. Rev. Lett. 1992, 68, 1168–1171. [Google Scholar] [CrossRef] [PubMed]

- Hodge, A.; Biener, J.; Hayes, J.; Bythrow, P.; Volkert, C.; Hamza, A. Scaling equation for yield strength of nanoporous open-cell foams. Acta Mater. 2007, 55, 1343–1349. [Google Scholar] [CrossRef]

- Lu, X.; Bischoff, E.; Spolenak, R.; Balk, T. Investigation of dealloying in Au–Ag thin films by quantitative electron probe microanalysis. Scripta Mater. 2007, 56, 557–560. [Google Scholar] [CrossRef]

- Ding, Y.; Erlebacher, J. Nanoporous metals with controlled multimodal pore size distribution. J. Am. Chem. Soc 2003, 125, 7772–7773. [Google Scholar] [CrossRef] [PubMed]

- Parida, S.; Kramer, D.; Volkert, C.; Rösner, H.; Erlebacher, J.; Weissmüller, J. Volume change during the formation of nanoporous gold by dealloying. Phys. Rev. Lett. 2006, 97, 35504–35506. [Google Scholar] [CrossRef]

- Qian, L.; Chen, M. Ultrafine nanoporous gold by low-temperature dealloying and kinetics of nanopore formation. Appl. Phys. Lett. 2007, 91, 083105. [Google Scholar] [CrossRef]

- Sun, Y.; Balk, T. A multi-step dealloying method to produce nanoporous gold with no volume change and minimal cracking. Scripta Mater. 2008, 58, 727–730. [Google Scholar] [CrossRef]

- Freund, L.; Suresh, S. Thin Film Materials; Cambridge University Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Begley, M.; Barker, S. Analysis and design of kinked (bent) beam sensors. J. Micromechanic. Microengineer. 2007, 17, 350–357. [Google Scholar] [CrossRef]

- Maner, K.; Begley, M.; Oliver, W. Nanomechanical testing of circular freestanding polymer films with sub-micron thickness. Acta Mater. 2004, 52, 5451–5460. [Google Scholar] [CrossRef]

- Klug, H.; Alexander, L. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials; Wiley-Interscience: New York, NY, USA, 1974; Vol. 200. [Google Scholar]

- Begley, M. The impact of materials selection and geometry on multi-functional bilayer micro-sensors and actuators. J. Micromechanic. Microengineer. 2005, 15, 2379–2388. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Biener, J.; Hodge, A.; Hamza, A. Microscopic failure behavior of nanoporous gold. Appl. Phys. Lett. 2005, 87, 121908. [Google Scholar] [CrossRef]

- Gibson, L.; Ashby, M. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, MA, USA, 1999. [Google Scholar]

- Greer, J.; Oliver, W.; Nix, W. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 2005, 53, 1821–1830. [Google Scholar] [CrossRef]

- Biener, J.; Hodge, A.; Hayes, J.; Volkert, C.; Zepeda-Ruiz, L.; Hamza, A.; Abraham, F. Size effects on the mechanical behavior of nanoporous Au. Nano Lett. 2006, 6, 2379–2382. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Kurmanaeva, L.; Schmauch, J.; Rösner, H.; Ivanisenko, Y.; Weissmüller, J. Deforming nanoporous metal: Role of lattice coherency. Acta Mater. 2009, 57, 2665–2672. [Google Scholar] [CrossRef]

- Petegem, S.; Brandstetter, S.; Maass, R.; Hodge, A.; El-Dasher, B.; Biener, J.; Schmitt, B.; Borca, C.; Swygenhoven, H. On the microstructure of nanoporous gold: An X-ray diffraction study. Nano Lett. 2009, 9, 1158–1163. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Ye, J.; Minor, A.; Balk, T. In situ indentation of nanoporous gold thin films in the transmission electron microscope. Microsc. Res. Tech. 2009, 72, 232–241. [Google Scholar] [CrossRef] [PubMed]

- Gregg, S.; Sing, K. Adsorption, Surface Area, and Porosity; Academic Press: London/New York, UK/USA, 1983. [Google Scholar]

- Ahn, S.; Lee, J.; Kim, H.; Kim, J. A study on the quantitative determination of through-coating porosity in PVD-grown coatings. Appl. Surf. Sci. 2004, 233, 105–114. [Google Scholar] [CrossRef]

- Kelly, R.; Young, A.; Newman, R. The Characterization of the Coarsening of Dealloyed Layers by EIS and Its Correlation with Stress-Corrosion Cracking: Electrochemical Impedance: Analysis and Interpretation; ASTM STP: Fredericksburg, VA, USA, 1993; pp. 94–112. [Google Scholar]

- Rouya, E.; Cattarin, S.; Reed, M.; Kelly, R.; Zangari, G. Surface characterization of nanoporous gold using Cu UPD, AuO/Au Redox, and EIS methods. unpublished work.

- Newman, R.; Corcoran, S.; Erlebacher, J.; Aziz, M.; Sieradzki, K. Alloy corrosion. MRS Bull. Mater. Res. Soc. 1999, 24, 24–28. [Google Scholar]

- Rosner, H.; Parida, S.; Kramer, D.; Volkert, C.; Weissmuller, J. Reconstructing a nanoporous metal in three dimensions: An electron tomography study of dealloyed gold leaf. Adv. Eng. Mater. 2007, 9, 535–541. [Google Scholar] [CrossRef]

- Fujita, T.; Qian, L.; Inoke, K.; Erlebacher, J.; Chen, M. Three-dimensional morphology of nanoporous gold. Appl. Phys. Lett. 2008, 92, 251902. [Google Scholar] [CrossRef]

- Li, Z.; Zhuo, S.; Li, H.; Si, W.; Ding, Y. Determination of ligament size distribution of nanoporous gold by scanning electron microscopy and image analysis. J. Nanosci. Nanotechnol. 2009, 9, 1651. [Google Scholar] [CrossRef] [PubMed]

- Velasco, F. Thresholding using the ISODATA clustering algorithm. IEEE Trans. Systems Man Cybernetics 1980, 10, 771–774. [Google Scholar] [CrossRef]

- Sezgin, M.; Sankur, B. Survey over image thresholding techniques and quantitative performance evaluation. J. Electr. Imag. 2004, 13, 146–168. [Google Scholar] [CrossRef]

- Vincent, L.; Soille, P. Watersheds in digital spaces: An efficient algorithm based onimmersion simulations. IEEE Trans. Pattern Analysis Machine Intelligence 1991, 13, 583–598. [Google Scholar] [CrossRef]

- Reed, M.; Lye, W. Microsystems for drug and gene delivery. Proc. IEEE 2004, 92, 56–75. [Google Scholar] [CrossRef]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Seker, E.; Reed, M.L.; Begley, M.R. Nanoporous Gold: Fabrication, Characterization, and Applications. Materials 2009, 2, 2188-2215. https://doi.org/10.3390/ma2042188

Seker E, Reed ML, Begley MR. Nanoporous Gold: Fabrication, Characterization, and Applications. Materials. 2009; 2(4):2188-2215. https://doi.org/10.3390/ma2042188

Chicago/Turabian StyleSeker, Erkin, Michael L. Reed, and Matthew R. Begley. 2009. "Nanoporous Gold: Fabrication, Characterization, and Applications" Materials 2, no. 4: 2188-2215. https://doi.org/10.3390/ma2042188