Helicity Distributions of Single-Walled Carbon Nanotubes and Its Implication on the Growth Mechanism

Abstract

:1. Introduction

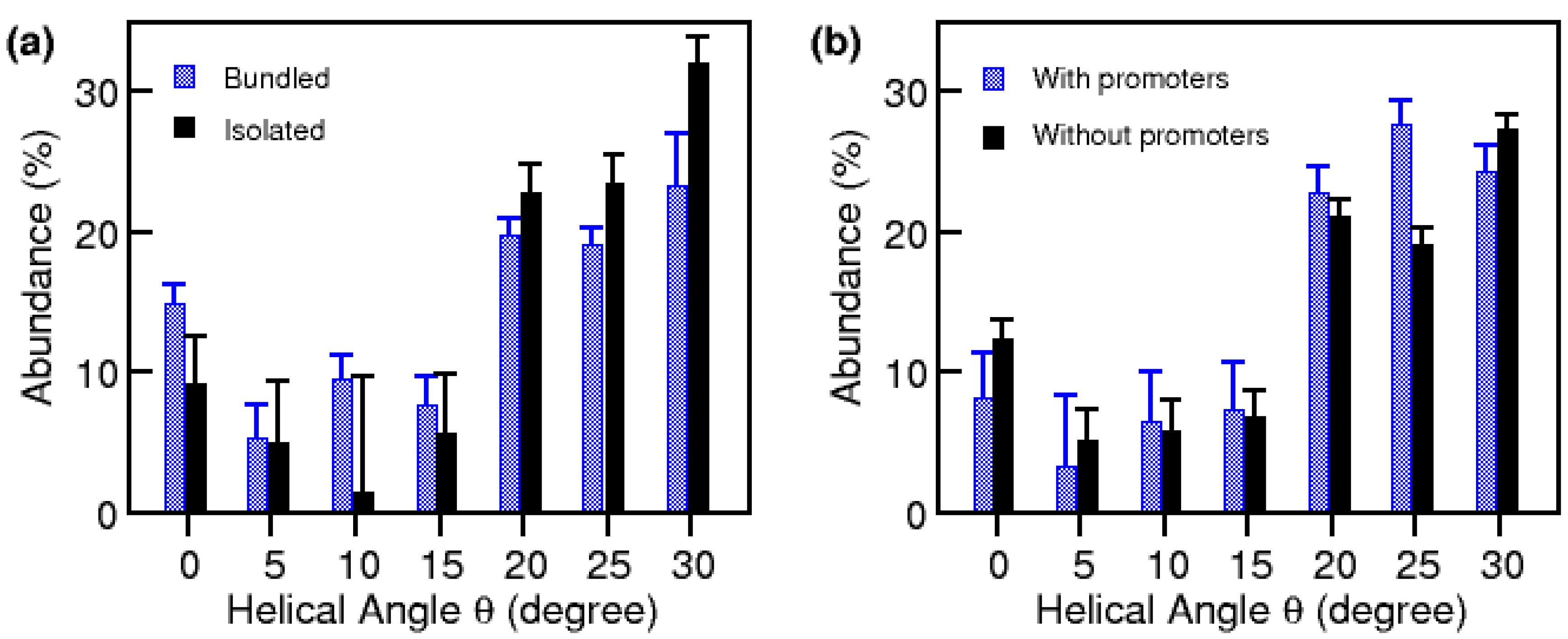

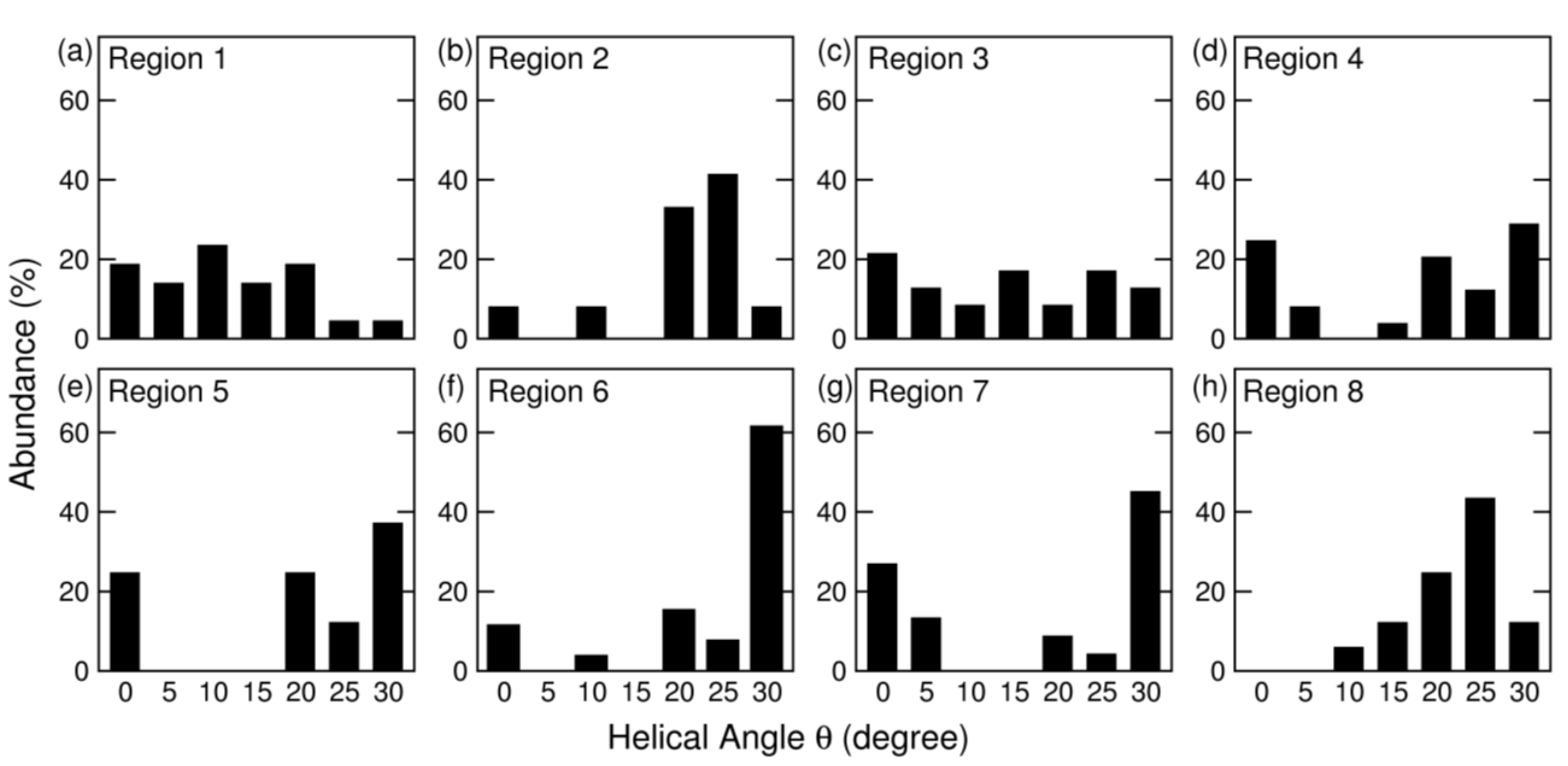

2. Results and Discussion

3. Experimental Section

4. Conclusion

Acknowledgements

References and Notes

- Bethune, D.S.; Kiang, C.-H.; de Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalyzed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar]

- Iijima, S.; Ichihashi, T. Single-shell nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar]

- Saito, R.; Dresselhaus, G.; Dresselhaus, M.S. Physical Properties of Carbon Nanotubes; Imperial College Press: London, UK, 1998. [Google Scholar]

- Appenzeller, J.; Knoch, J.; Derycke, V.; Martel, R.; Wind, S.; Avouris, Ph. Field-modulated carrier transport in carbon nanotube transistors. Phys. Rev. Lett. 2002, 89, 126801. [Google Scholar]

- Ajayan, P.M.; Zhou, O. Applications of Carbon Nanotubes; Dresselhaus, M.S., Dresselhaus, G., Avouris, P., Eds.; Springer: Heidelberg, Germany, 2001; pp. 391–425. [Google Scholar]

- Yoon, M.; Han, S.W.; Kim, G.; Lee, S.B.; Berber, S.; Osawa, E.; Ihm, J.; Terrones, M.; Banhart, F.; Charlier, J.C.; Grobert, N.; Terrones, H.; Ajayan, P.M.; Tománek, D. Zipper mechanism of nanotube fusion: Theory and experiment. Phys. Rev. Lett. 2004, 92, 075504. [Google Scholar]

- Mintmire, J.W.; Dunlap, B.I.; White, C.T. Are fullerene tubules metallic? Phys. Rev. Lett. 1992, 68, 631–634. [Google Scholar]

- Baughman, R.H.; Zakhidov, A.A.; de Heer, W.A. Carbon nanotubes--the route toward applications. Science 2002, 297, 787–792. [Google Scholar]

- Cao, Q.; Kim, H.-S.; Pimparkar, N.; Kulkarni, J.P.; Wang, C.; Shim, M.; Roy, K.; Alam, M.A.; Rogers, J.A. Medium-scale carbon nanotube thin-film integrated circuits on flexible plastic substrates. Nature 2008, 454, 495–500. [Google Scholar]

- Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J.; Xu, C.; Lee, Y.H.; Kim, S.G.; Rinzler, A.G.; Colbert, D.T.; Scuseria, G.E.; Tománek, D.; Fisher, J.; Smalley, R.E. Crystalline ropes of metallic carbon nanotubes. Science 1996, 273, 483–487. [Google Scholar]

- Cowley, J.M.; Nikolaev, P.; Thess, A.; Smalley, R.E. Electron nano-diffraction study of carbon single-walled nanotube ropes. Chem. Phys. Lett. 1997, 265, 379–384. [Google Scholar]

- Odom, T.W.; Huang, J.-L.; Kim, P.; Lieber, C.M. Atomic structure and electronic properties of single-walled carbon nanotubes. Nature 1998, 391, 62–64. [Google Scholar]

- Qin, L.C.; Iijima, S.; Kataura, H.; Maniwa, Y.; Suzuki, S.; Achiba, Y. Determination and mapping of diameter and helicity for single-walled carbon nanotubes using nanobeam electron diffraction. Chem. Phys. Lett. 1997, 268, 101–106. [Google Scholar]

- Gao, M.; Zuo, J.M.; Twesten, R.D.; Petrov, I. Structure determination of individual single-wall carbon nanotubes by nanoarea electron diffraction. Appl. Phys. Lett. 2003, 82, 2703–2705. [Google Scholar]

- Zheng, M.; Jagota, A.; Strano, M.S.; Santos, A.P.; Barone, P.; Chou, S.G.; Diner, B.A.; Dresselhaus, M.S.; Mclean, R.S.; Onoa, G.B.; Samsonidze, G.C.; Semke, E.D.; Usrey, M.; Walls, D.J. Structure-based carbon nanotube sorting by sequence-dependent DNA assembly. Science 2003, 302, 1545–1548. [Google Scholar]

- Chattopadhyay, D.; Galeska, I.; Papadimitrakopoulos, F. A route for bulk separation of semiconducting from metallic single-wall carbon nanotubes. J. Am. Chem. Soc. 2003, 125, 3370–3375. [Google Scholar]

- Gigliotti, B.; Sakizzie, B.; Bethune, D.S.; Shelby, R.M.; Cha, J.N. Sequence-independent helical wrapping of single-walled carbon nanotubes by long genomic DNA. Nano Lett. 2006, 6, 159–164. [Google Scholar]

- Martel, R.; Derycke, V.; Lavoie, C.; Appenzeller, J.; Chan, K.K.; Tersoff, J.; Avouris, Ph. Ambipolar electrical transport in semiconducting single-wall carbon nanotubes. Phys. Rev. Lett. 2001, 87, 256805. [Google Scholar]

- Triozon, F.; Roche, S.; Rubio, A.; Mayou, D. Electrical transport in carbon nanotubes: Role of disorder and helical symmetries. Phys. Rev. B 2004, 69, 121410. [Google Scholar]

- Avouris, Ph.; Chen, Z.; Perebeinos, V. Phonon populations and electrical power dissipation in carbon nanotube transistors. Nat. Nanotechnol. 2007, 2, 605. [Google Scholar]

- Charlier, J.C.; Blase, X.; Roche, S. Electronic and transport properties of nanotubes. Rev. Mod. Phys. 2007, 79, 677–732. [Google Scholar]

- Kanungo, M.; Lu, H.; Malliaras, G.G.; Blanchet, G.B. Suppression of metallic conductivity of single-walled carbon nanotubes by cycloaddition reactions. Science 2009, 323, 234–237. [Google Scholar]

- Purewal, M.; Hong, B.H.; Ravi, A.; Chandra, B.; Hone, J.; Kim, P. Scaling of Resistance and Electron Mean Free Path of Single-Walled Carbon Nanotubes. Phys. Rev. Lett. 2007, 98, 186808. [Google Scholar]

- Wu, D.S.; Cheng, W.D.; Zhang, H.; Li, X.D.; Lan, Y.Z.; Chen, D.G.; Gong, Y.J.; Zhang, Y.C. Chirality-dependent absorption and third-order polarizability spectra in open single-wall carbon nanotubes. Phys. Rev. B 2003, 68, 125402. [Google Scholar]

- Kane, C.L.; Mele, E.J. Ratio problem in single carbon nanotube fluorescence spectroscopy. Phys. Rev. Lett. 2003, 90, 207401. [Google Scholar]

- Miyauchi, Y.; Chiashi, S.; Murakami, Y.; Hayashida, Y.; Maruyama, S. Fluorescence spectroscopy of single-walled carbon nanotubes synthesized from alcohol. Chem. Phys. Lett. 2004, 387, 198–203. [Google Scholar]

- Hauge, R.H.; Bachilo, S.M.; Smattey, R.E.; Strano, M.S.; Weisman, R.B.; Kittrell, C. Structure-assigned optical spectra of single-walled carbon nanotubes. Science 2002, 298, 2361–2366. [Google Scholar]

- Gabor, N.M.; Zhong, Z.; Bosnick, K.; Park, J.; McEuen, P.L. Extremely efficient multiple electron-hole pair generation in carbon nanotube photodiodes. Science 2009, 325, 1367–1371. [Google Scholar]

- Heller, D.A.; Jin, H.; Martinez, B.M.; Miller, B.M.; Patel, D.; Yeung, T.K.; Jena, P.V.; Hobartner, C.; Ha, T.J.; Silverman, S.K.; Strano, M.S. Multi-modal optical sensing and analyte specificity via single-walled carbon nanotubes. Nat. Nanotechnol. 2009, 4, 114–120. [Google Scholar]

- Kiang, C.-H.; Goddard III, W.A.; Beyers, R.; Salem, J.R.; Bethune, D.S. Catalytic synthesis of single-layer carbon nanotubes with a wide range of diameters. J. Phys. Chem. 1994, 98, 6612–6618. [Google Scholar]

- Kiang, C.-H.; Goddard III, W.A.; Beyers, R.; Bethune, D.S. Catalytic effects of heavy metals on the growth of single-layer carbon nanotubes and nanoparticles. J. Phys. Chem. Solids 1996, 57, 35–39. [Google Scholar]

- Kiang, C.-H.; Dresselhaus, M.S.; Beyers, R.; Bethune, D.S. Vapor-phase self-assembly of carbon nanomaterials. Chem. Phys. Lett. 1996, 259, 41–47. [Google Scholar]

- Cowley, J.M. Electron nanodiffraction: Progress and prospects. J. Electron Microsc. 1996, 45, 3–10. [Google Scholar]

- Meyer, J.C.; Paillet, M.; Duesberg, G.S.; Roth, S. Electron diffraction analysis of individual single-walled carbon nanotubes. Ultramicroscopy 2006, 106, 176–190. [Google Scholar]

- Cowley, J. M.; Sundell, F. Nanodiffraction and dark-field STEM characterization of single-walled carbon nanotube ropes. Ultramicroscopy 1997, 68, 1–12. [Google Scholar]

- Kiang, C.-H. Growth of large diameter single-walled carbon nanotubes. J. Phys. Chem. A 2000, 104, 2454–2456. [Google Scholar]

- Ding, F.; Harutyunyan, A.R.; Yakobson, B.L. Dislocation theory of chirality-controlled nanotube growth. Proc. Natl. Acad. Sci. USA 2009, 106, 2506–2509. [Google Scholar]

- Gómez-Gualdrón, D.A.; Balbuena, P.B. The role of cap chirality in the mechanism of growth of single-wall carbon nanotubes. Nanotechnology 2008, 19, 485604. [Google Scholar]

- Reich, S.; Li, L.; Robertson, J. Structure and formation energy of carbon nanotube caps. J. Phys. Rev. B 2005, 72, 165423. [Google Scholar]

- Robertson, D.H.; Brenner, D.W.; Mintmire, J.W. Energetics of nanoscale graphitic tubules. Phys. Rev. B 1992, 45, 12592–12595. [Google Scholar]

- Hirahara, K.; Kociak, M.; Bandow, S.; Nakahira, T.; Itoh, K.; Saito, Y.; Iijima, S. Chirality correlation in double-wall carbon nanotubes as studied by electron diffraction. Phys. Rev. B 2006, 73, 195420. [Google Scholar]

- Liu, Z.; Zhang, Q.; Qin, L.C. Determination and mapping of diameter and helicity for single-walled carbon nanotubes using nanobeam electron diffraction. Phys. Rev. B 2005, 71, 245413. [Google Scholar]

- Wildöer, J.W.G.; Venema, L.C.; Rinzler, A.G.; Smalley, R.E.; Dekker, C. Electronic structure of atomically resolved carbon. Nature 1998, 391, 59–62. [Google Scholar]

- Dresselhaus, M.S. Nanotubes: Burn and interrogate. Science 2001, 292, 650–651. [Google Scholar]

- Krupke, R.; Hennrich, F.; Löhneysen, H.V.; Kappes, M.M. Separation of metallic from semiconducting single-walled carbon nanotubes. Science 2003, 301, 344–347. [Google Scholar]

- Kiang, C.-H. Carbon rings and cages in the growth of single-walled carbon nanotubes. J. Chem. Phys. 2000, 113, 4763–4776. [Google Scholar]

- Kiang, C.-H.; Goddard, W. Polyyne ring nucleus growth model for single-layer carbon nanotubes. Phys. Rev. Lett. 1996, 76, 2515–2518. [Google Scholar]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wijeratne, S.S.; Harris, N.C.; Kiang, C.-H. Helicity Distributions of Single-Walled Carbon Nanotubes and Its Implication on the Growth Mechanism. Materials 2010, 3, 2725-2734. https://doi.org/10.3390/ma3042725

Wijeratne SS, Harris NC, Kiang C-H. Helicity Distributions of Single-Walled Carbon Nanotubes and Its Implication on the Growth Mechanism. Materials. 2010; 3(4):2725-2734. https://doi.org/10.3390/ma3042725

Chicago/Turabian StyleWijeratne, Sithara S., Nolan C. Harris, and Ching-Hwa Kiang. 2010. "Helicity Distributions of Single-Walled Carbon Nanotubes and Its Implication on the Growth Mechanism" Materials 3, no. 4: 2725-2734. https://doi.org/10.3390/ma3042725