Scanning Electron Microscopy with Samples in an Electric Field

Abstract

:1. Historical Introduction

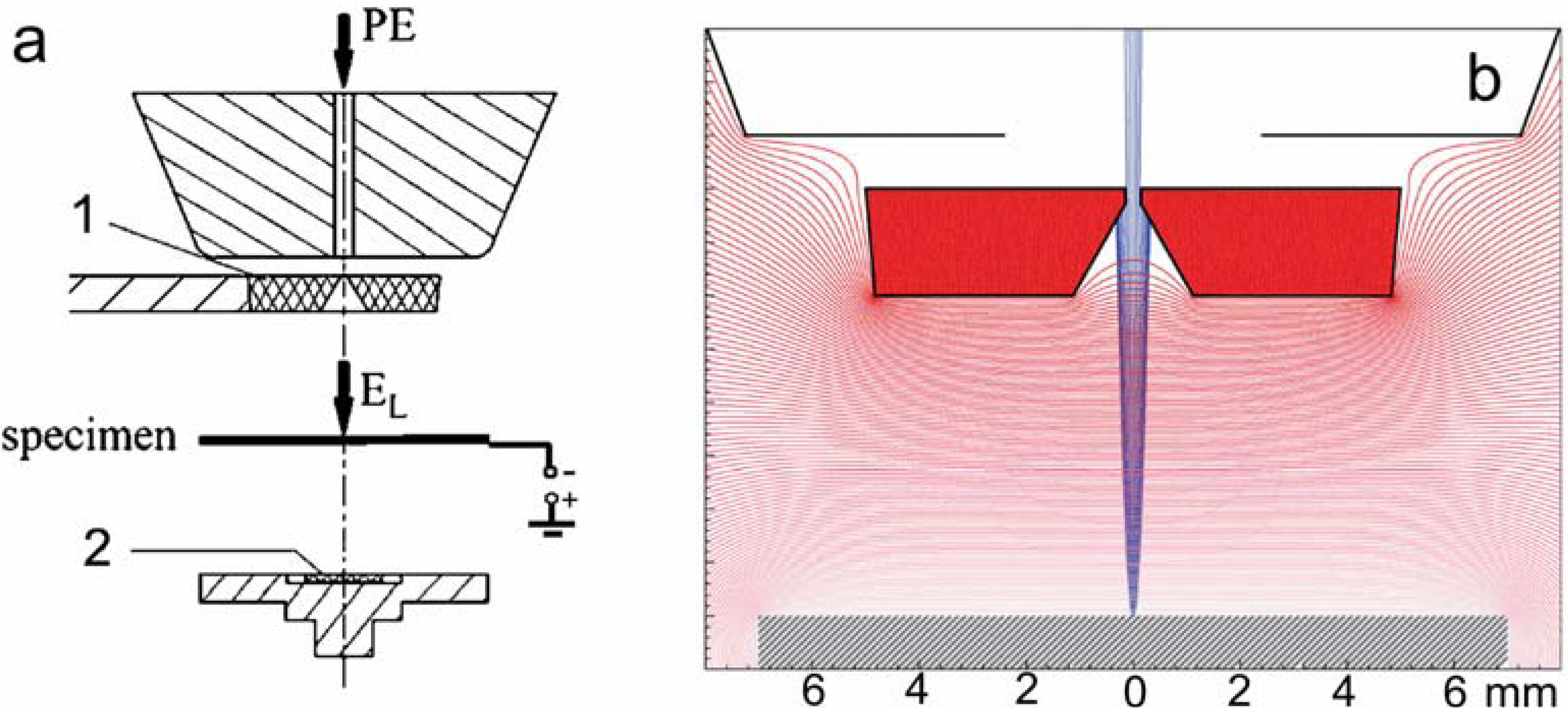

2. Motivation

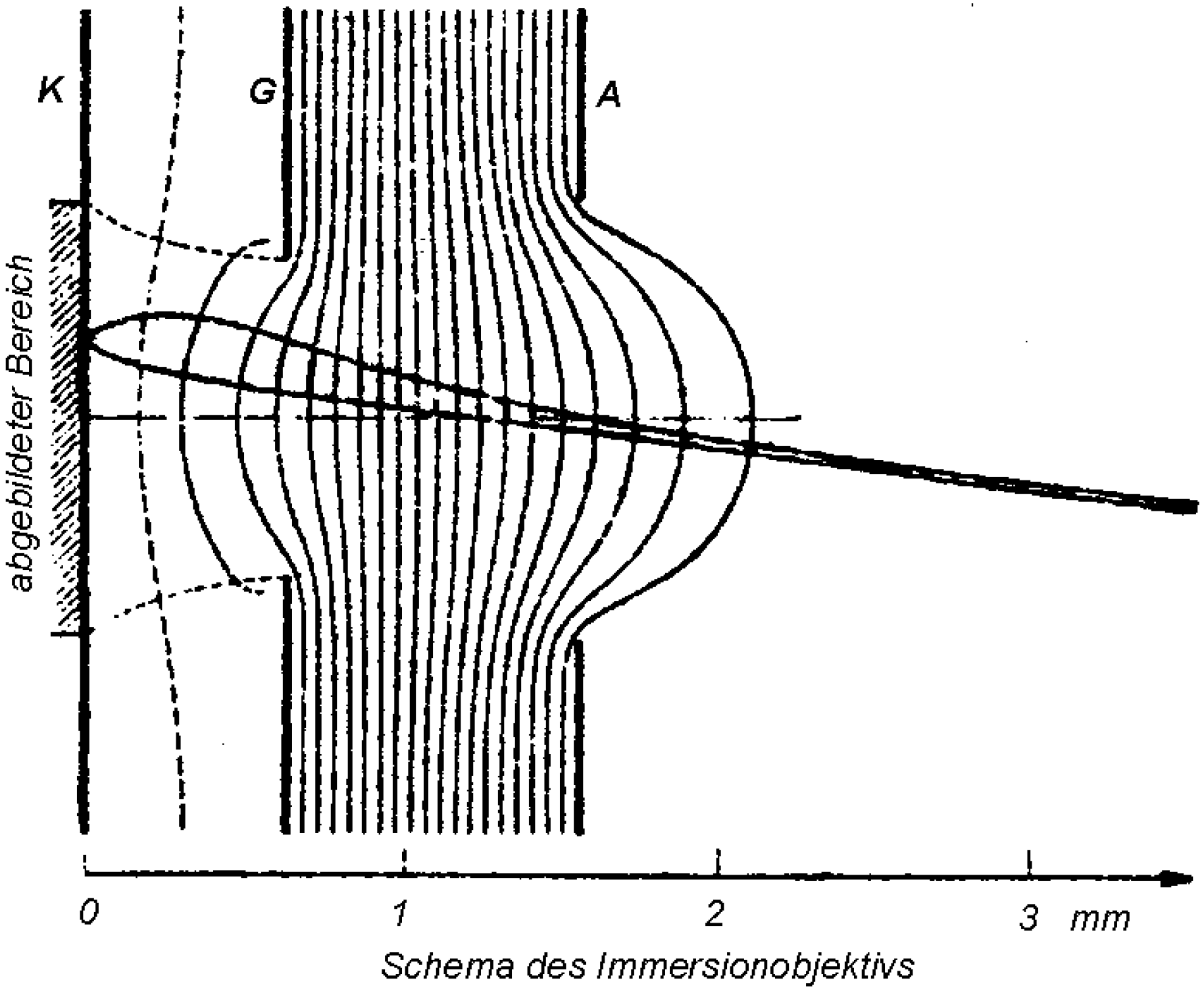

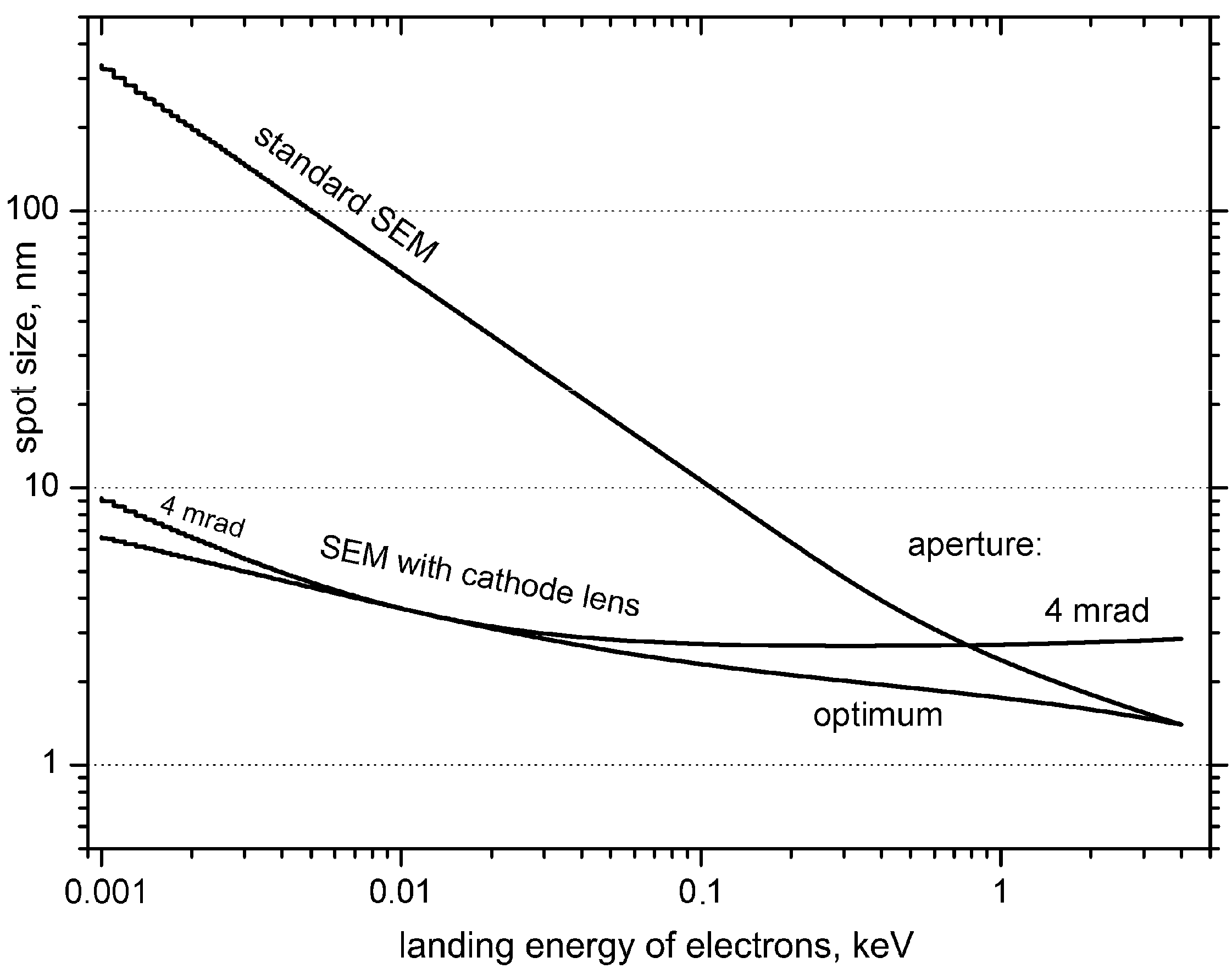

3. Electron Optical Aspects

4. Experimental Conditions

5. Experimental Results

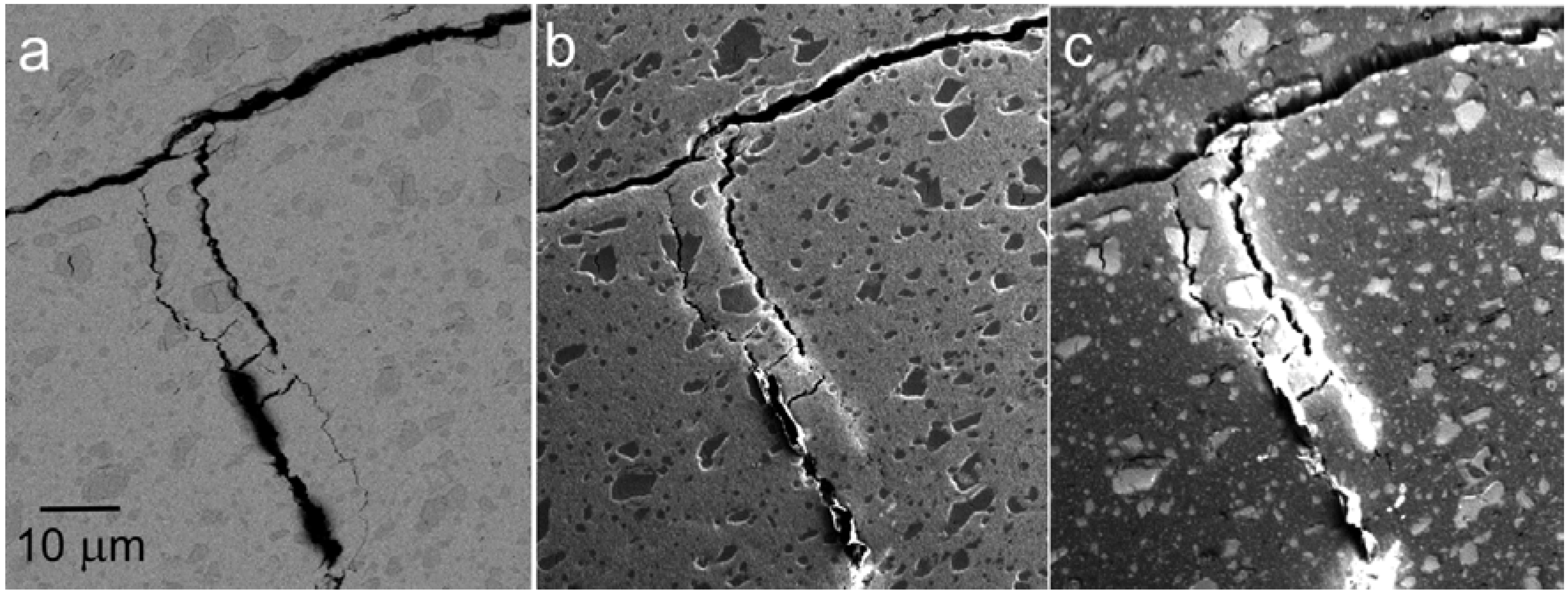

5.1. Traditional SEM Contrasts

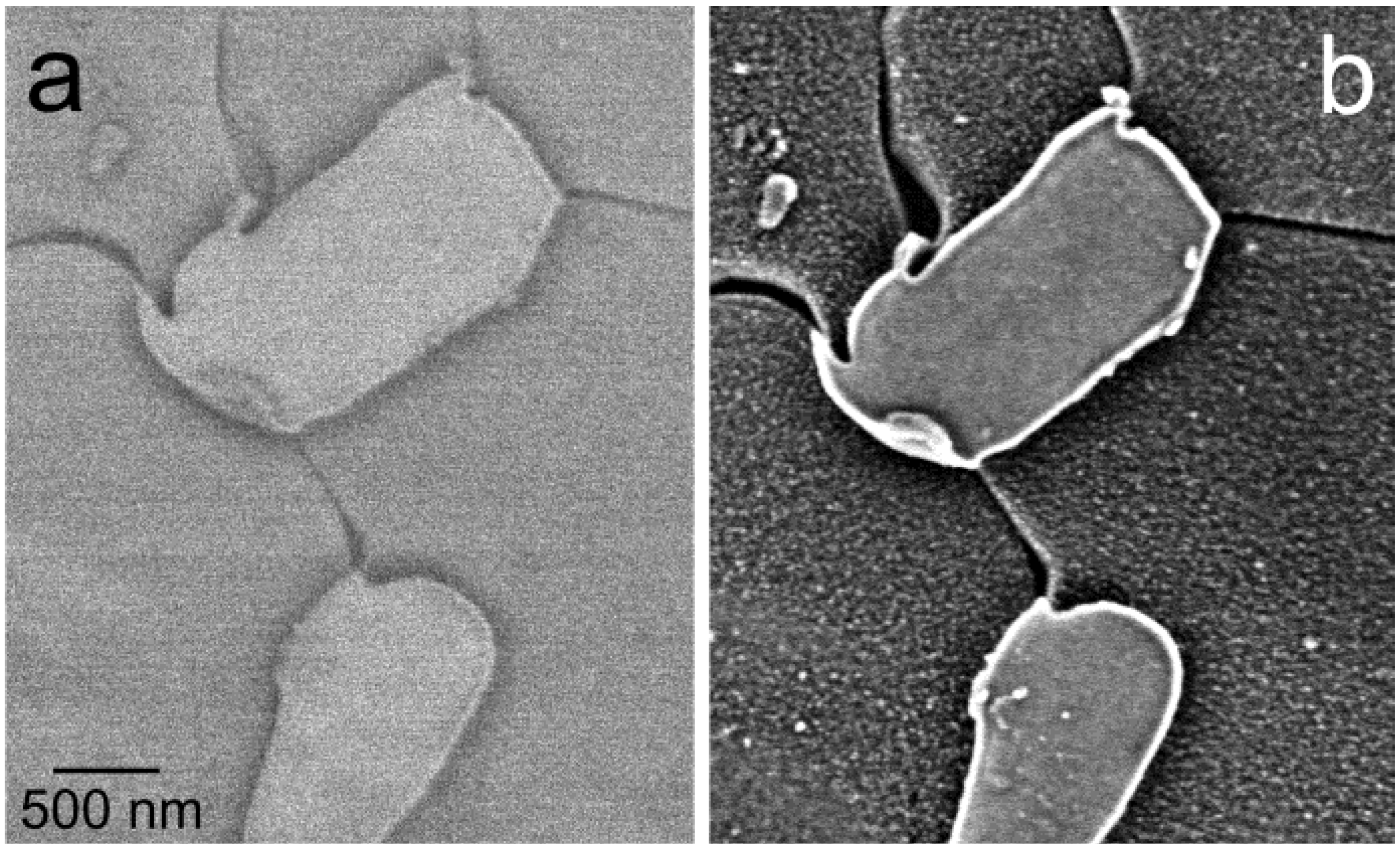

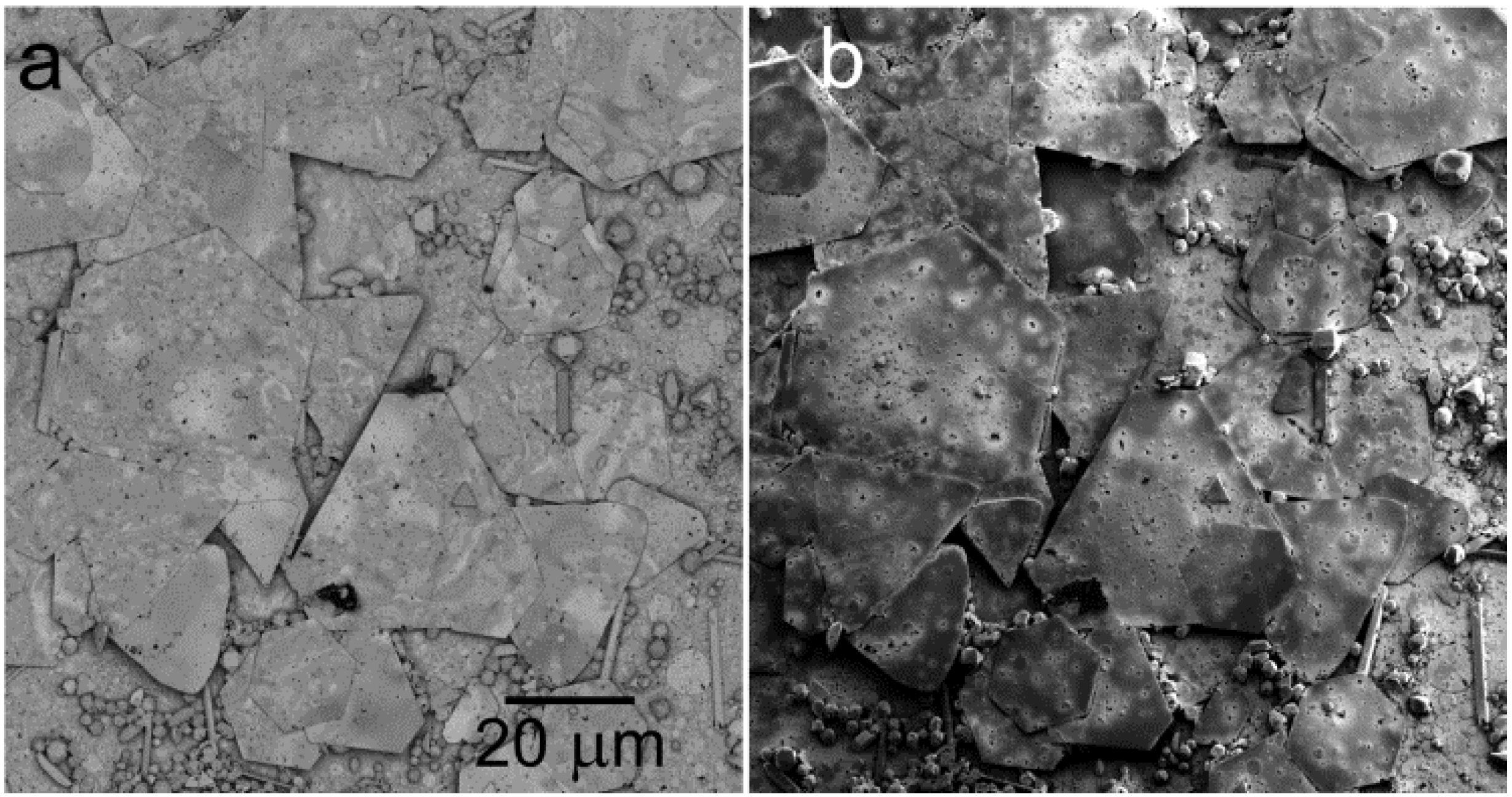

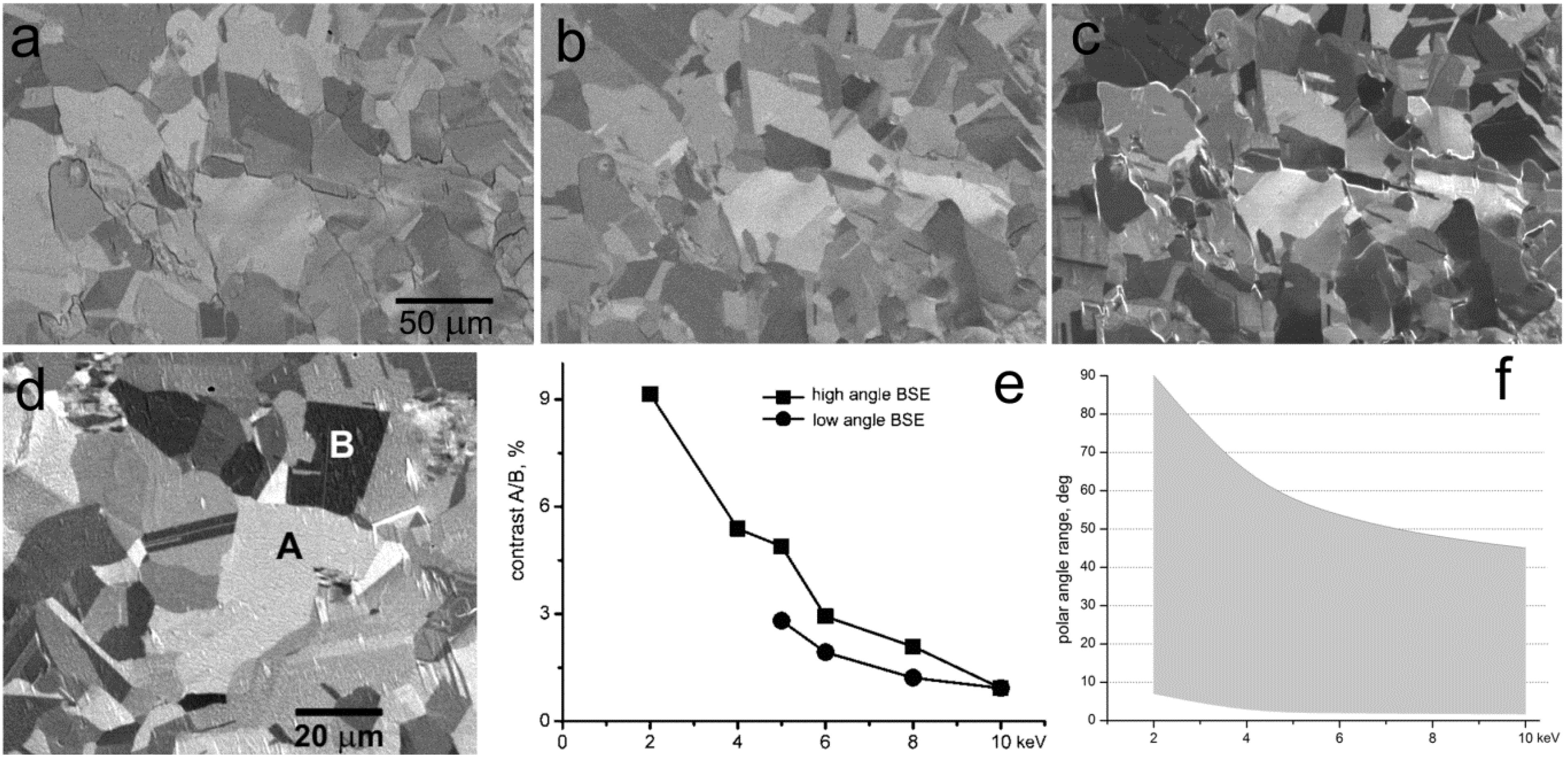

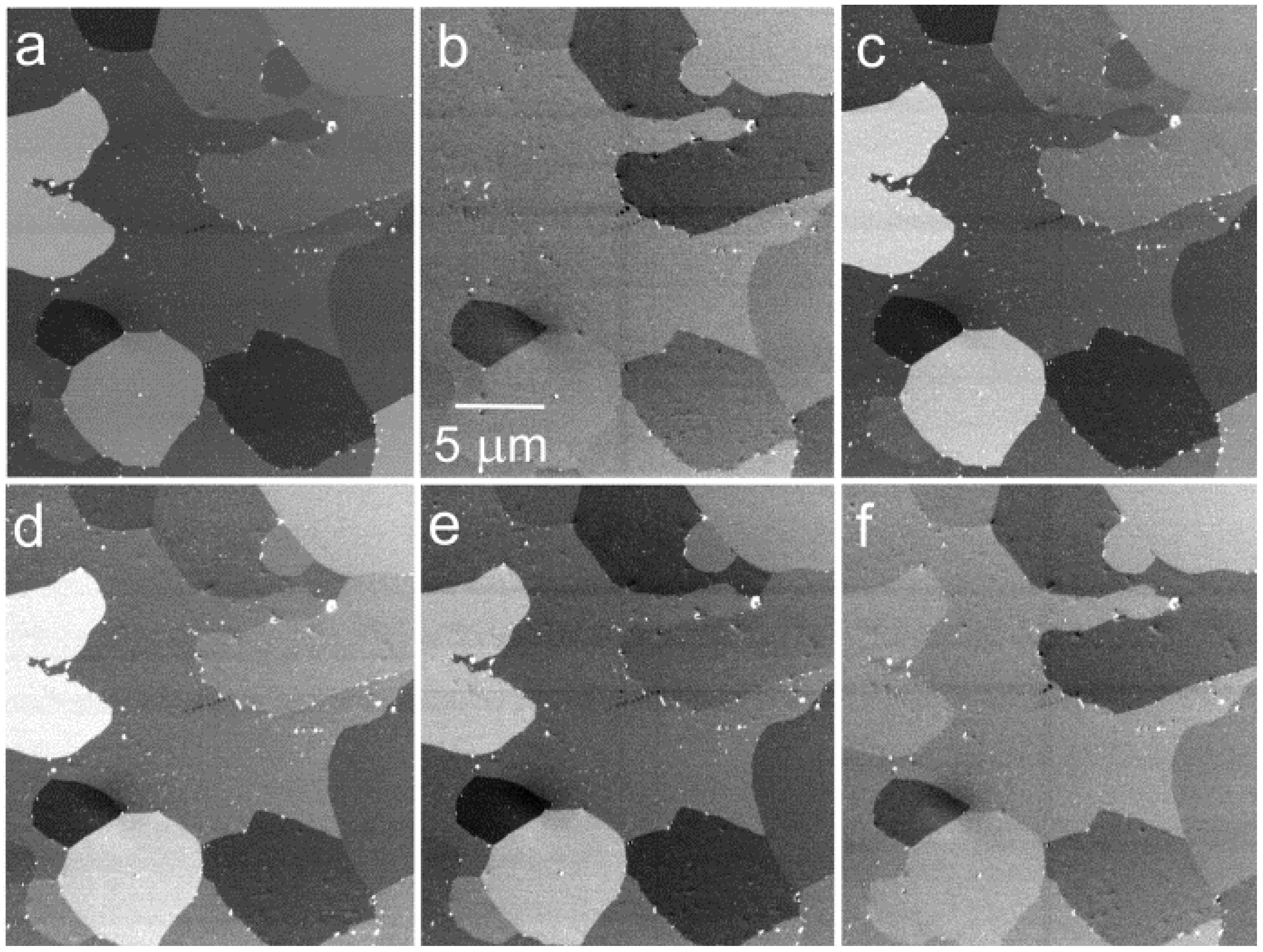

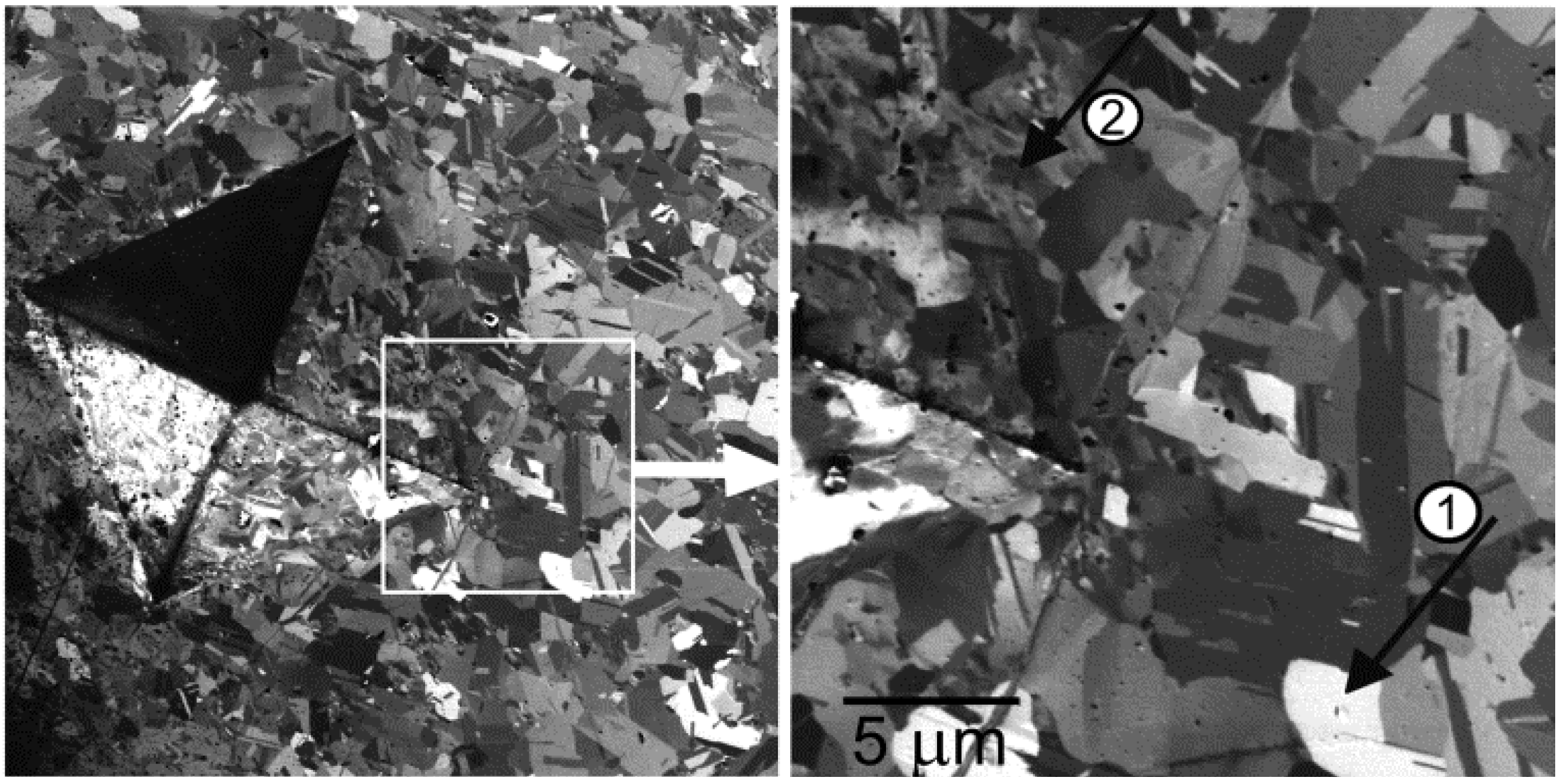

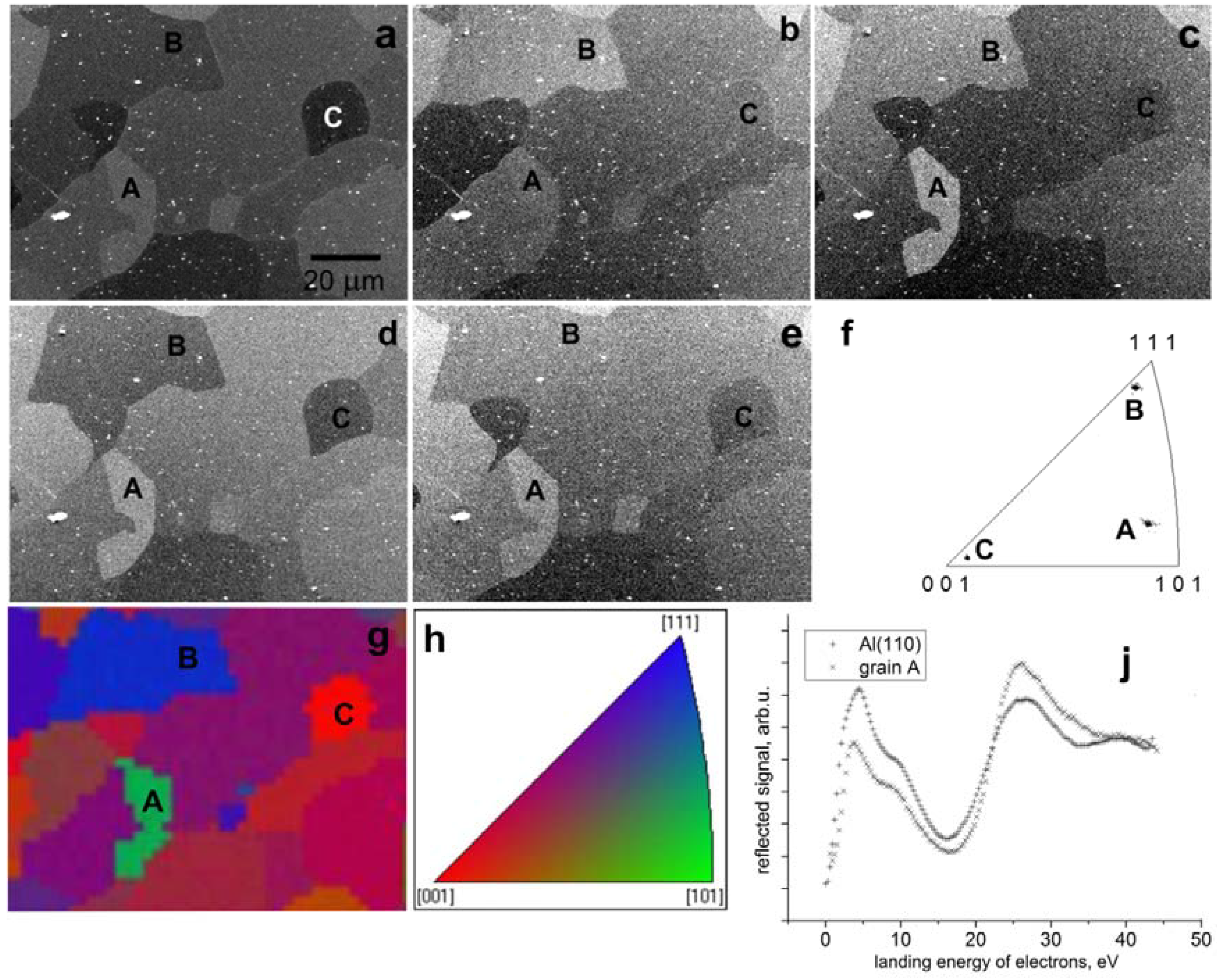

5.2. Grain Contrast

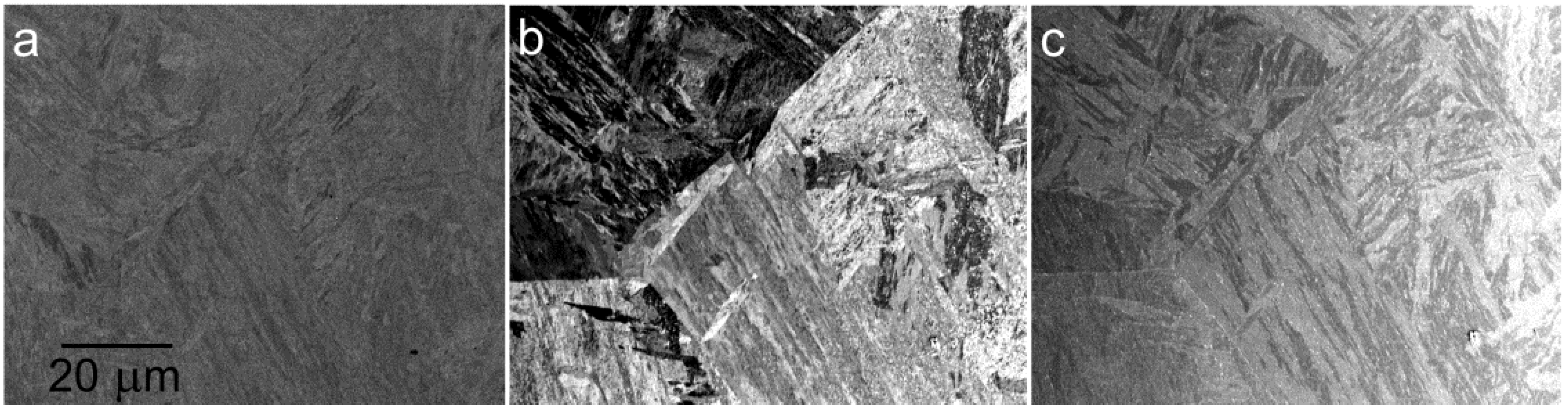

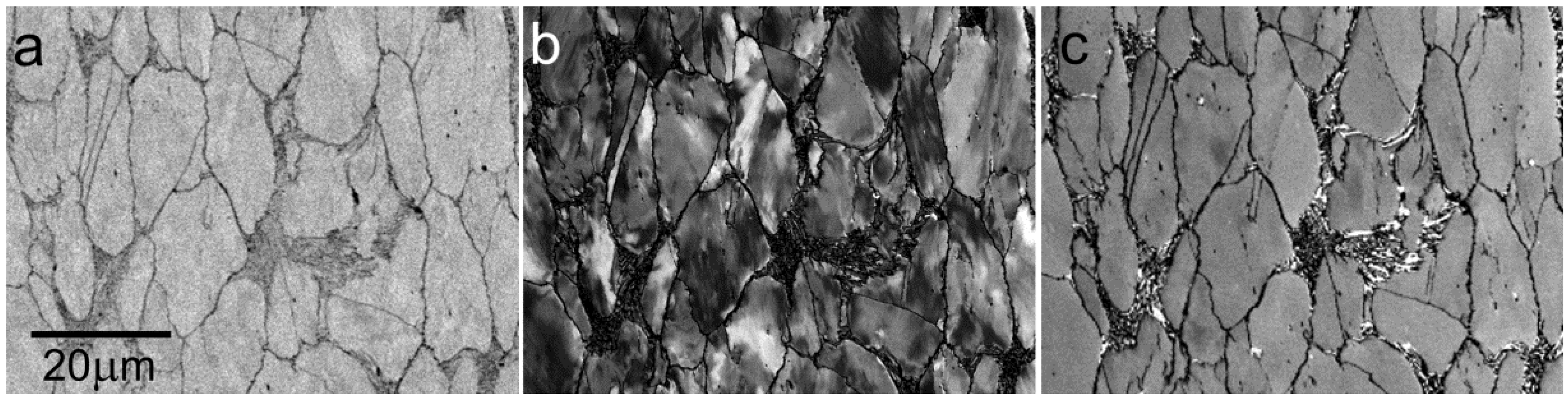

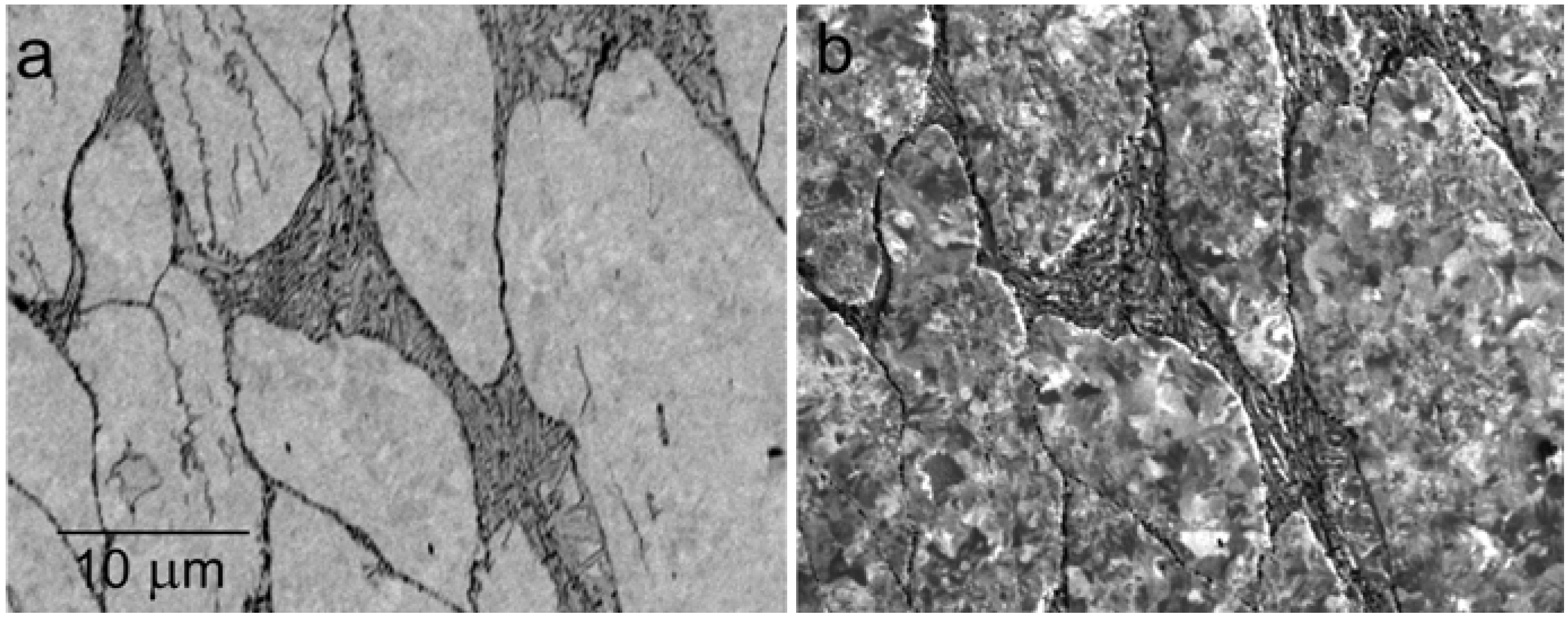

5.3. Mapping of Residual Strains

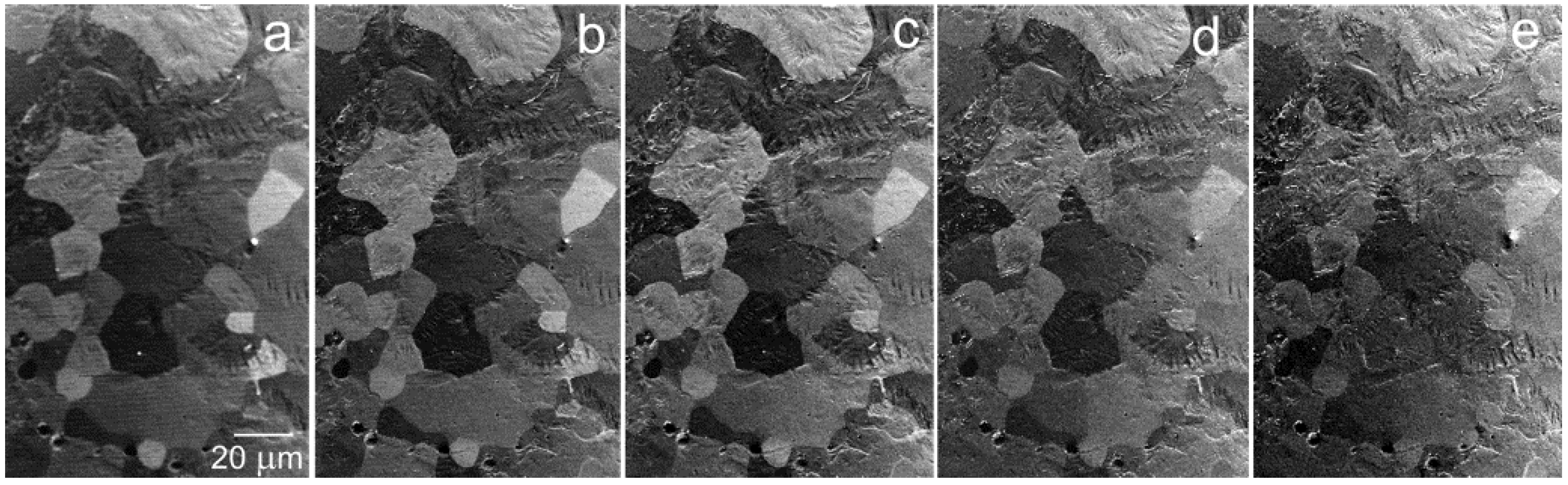

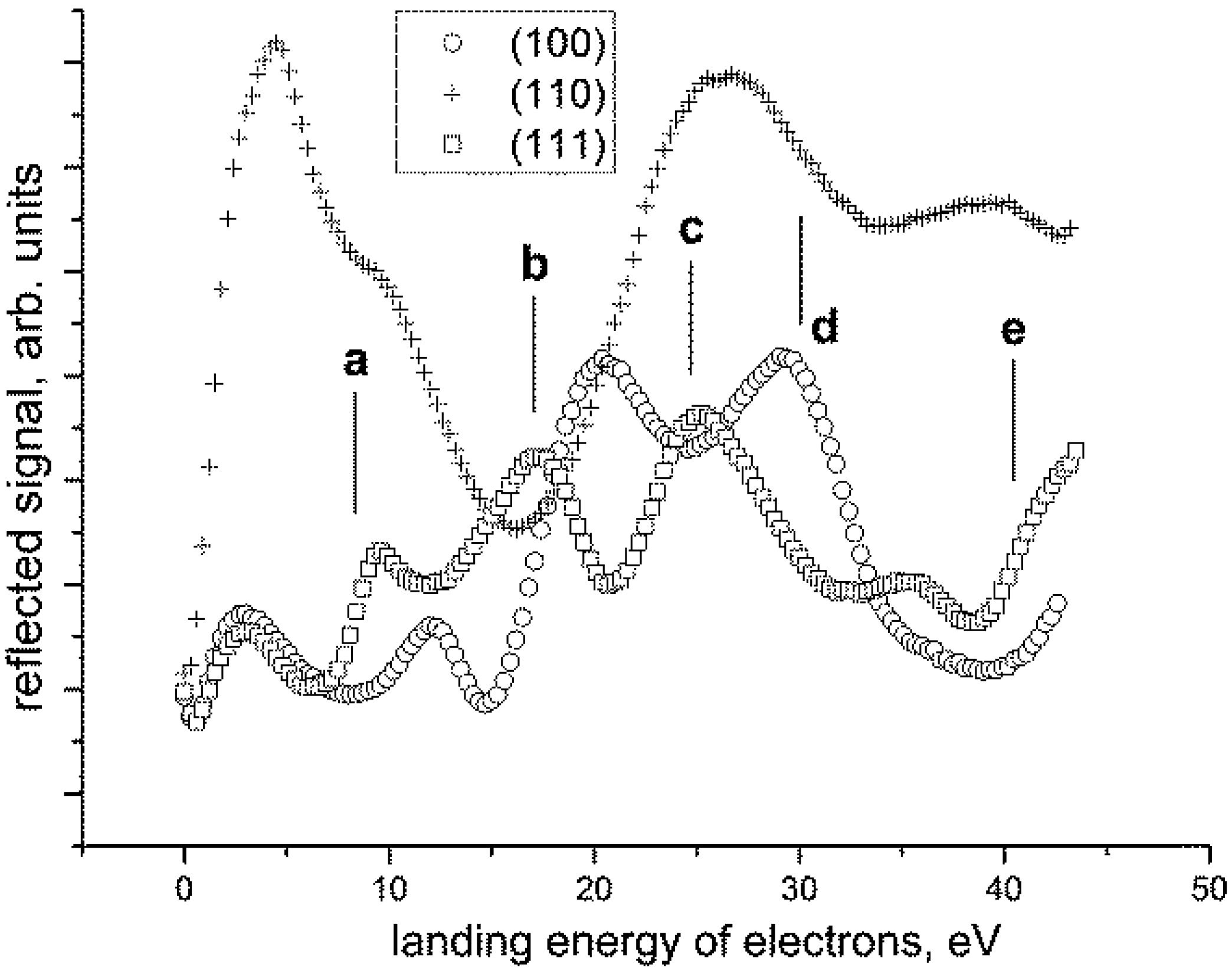

5.4. Very Low Energy Reflectance

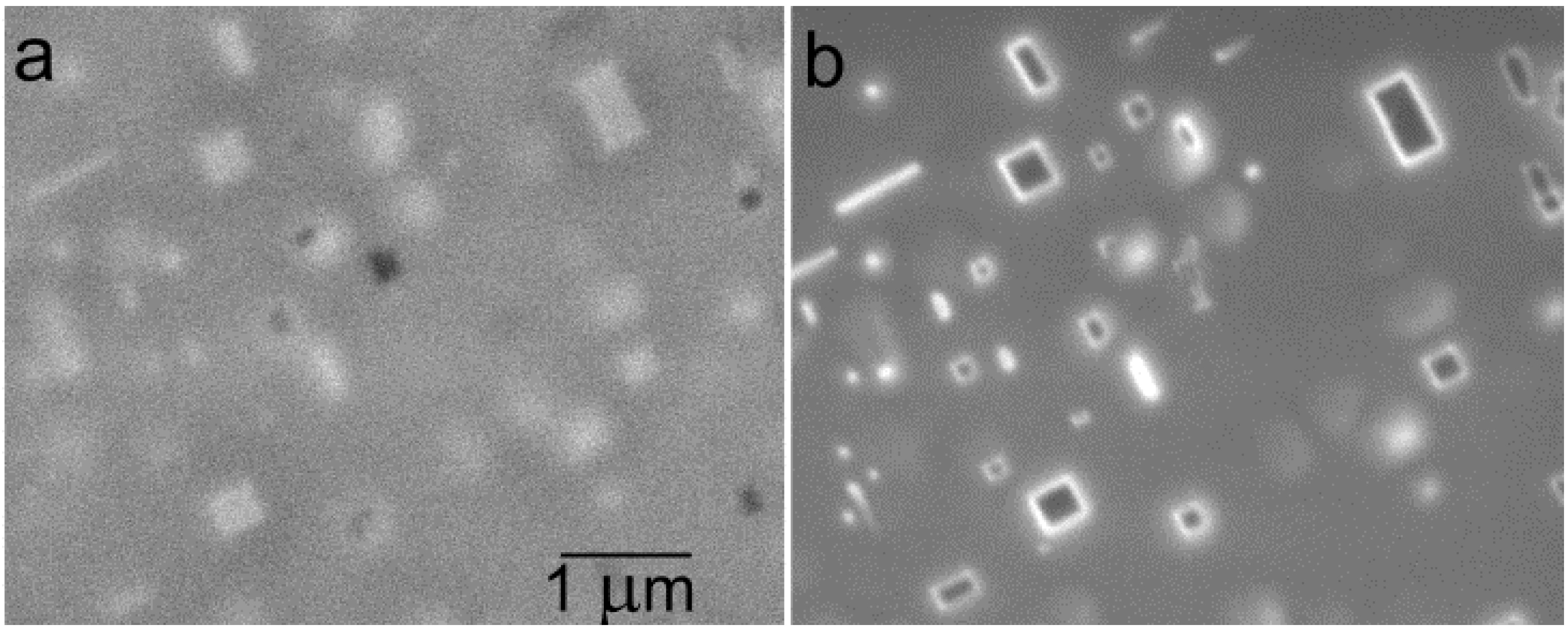

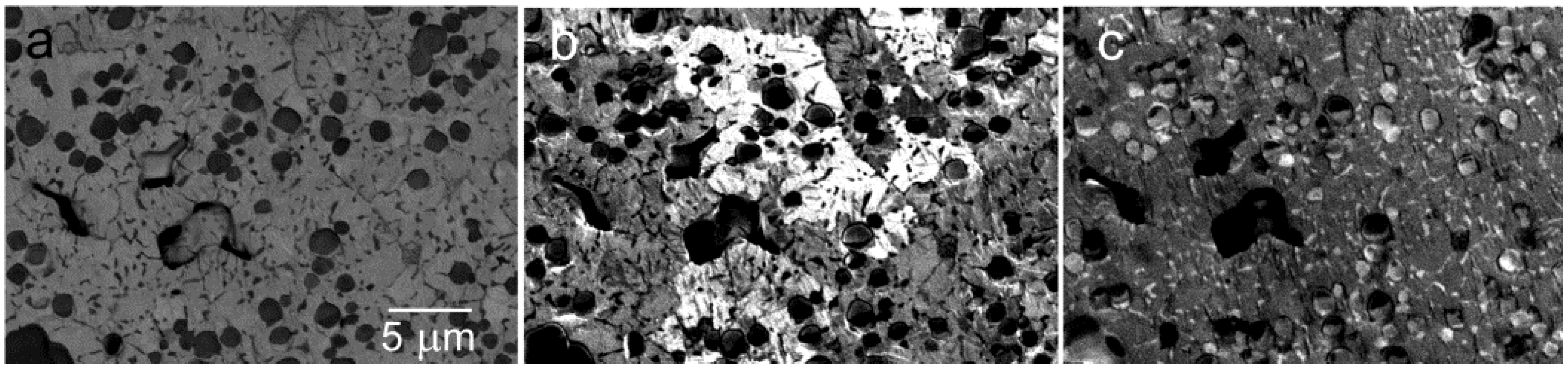

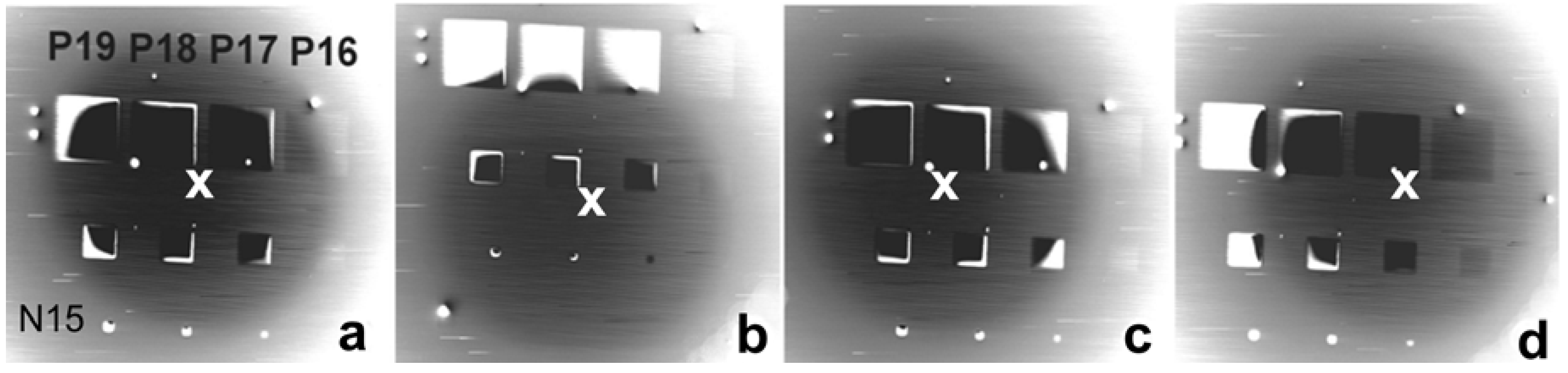

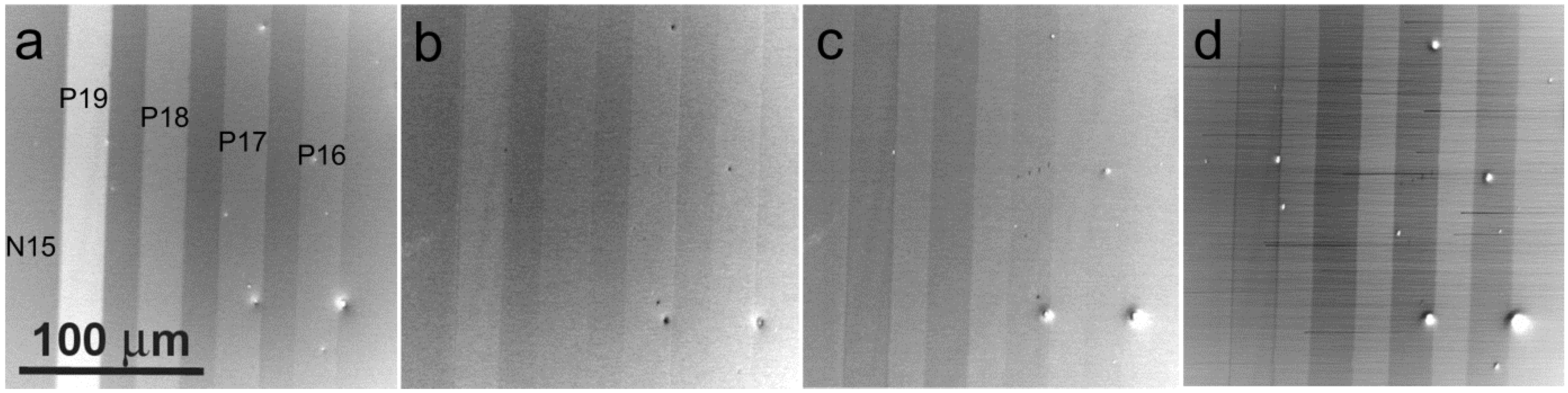

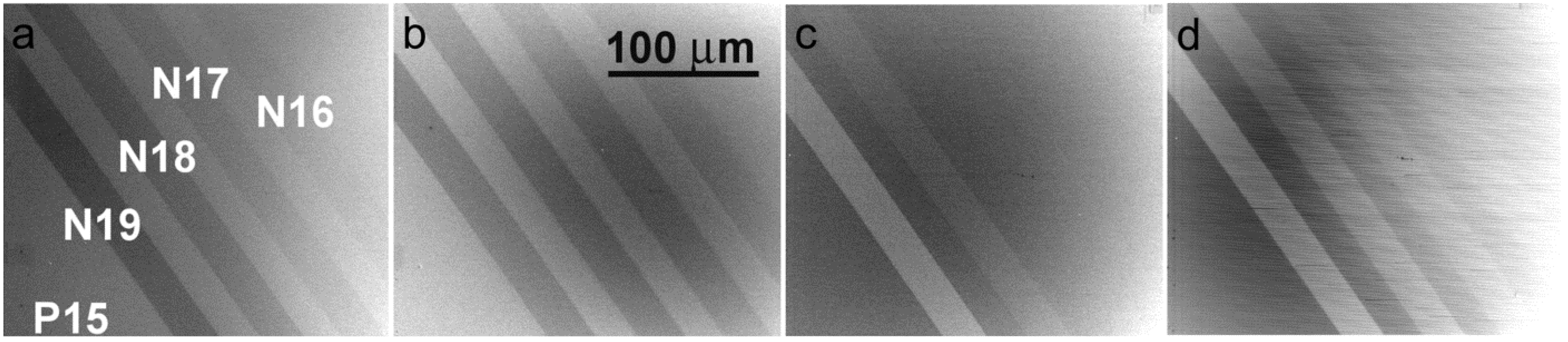

5.5. Dopant Contrast

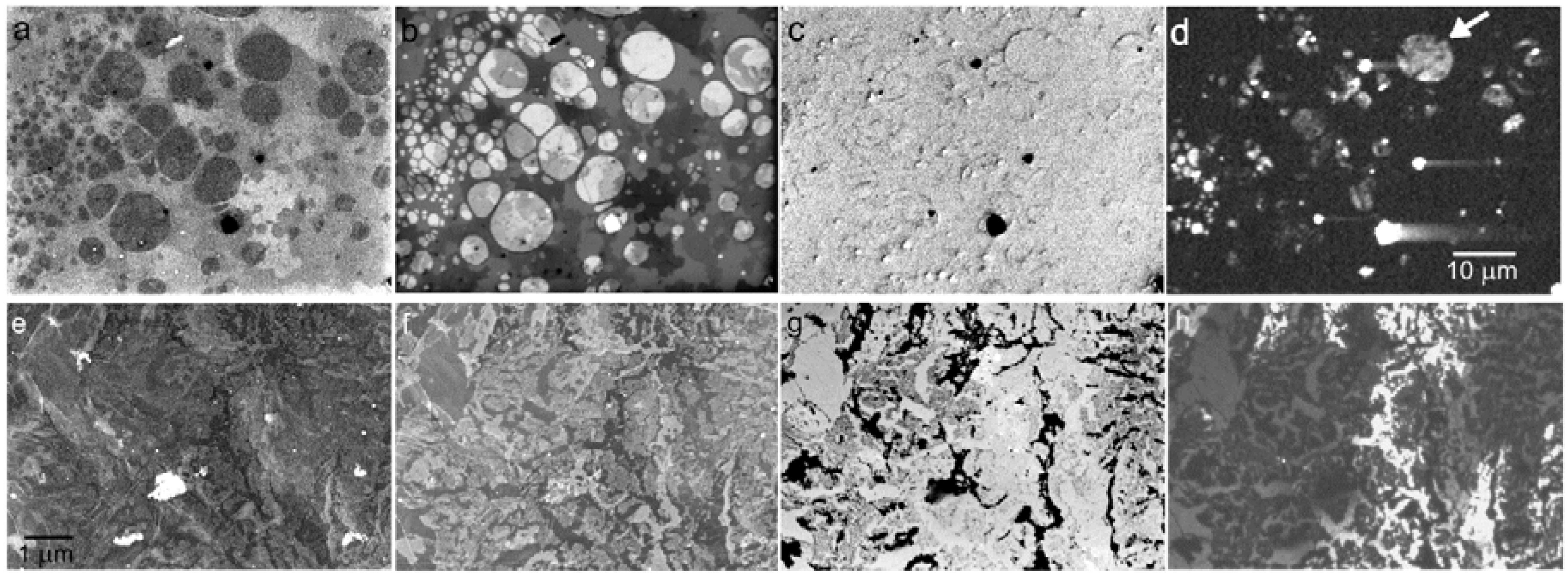

5.6. Transmission Mode

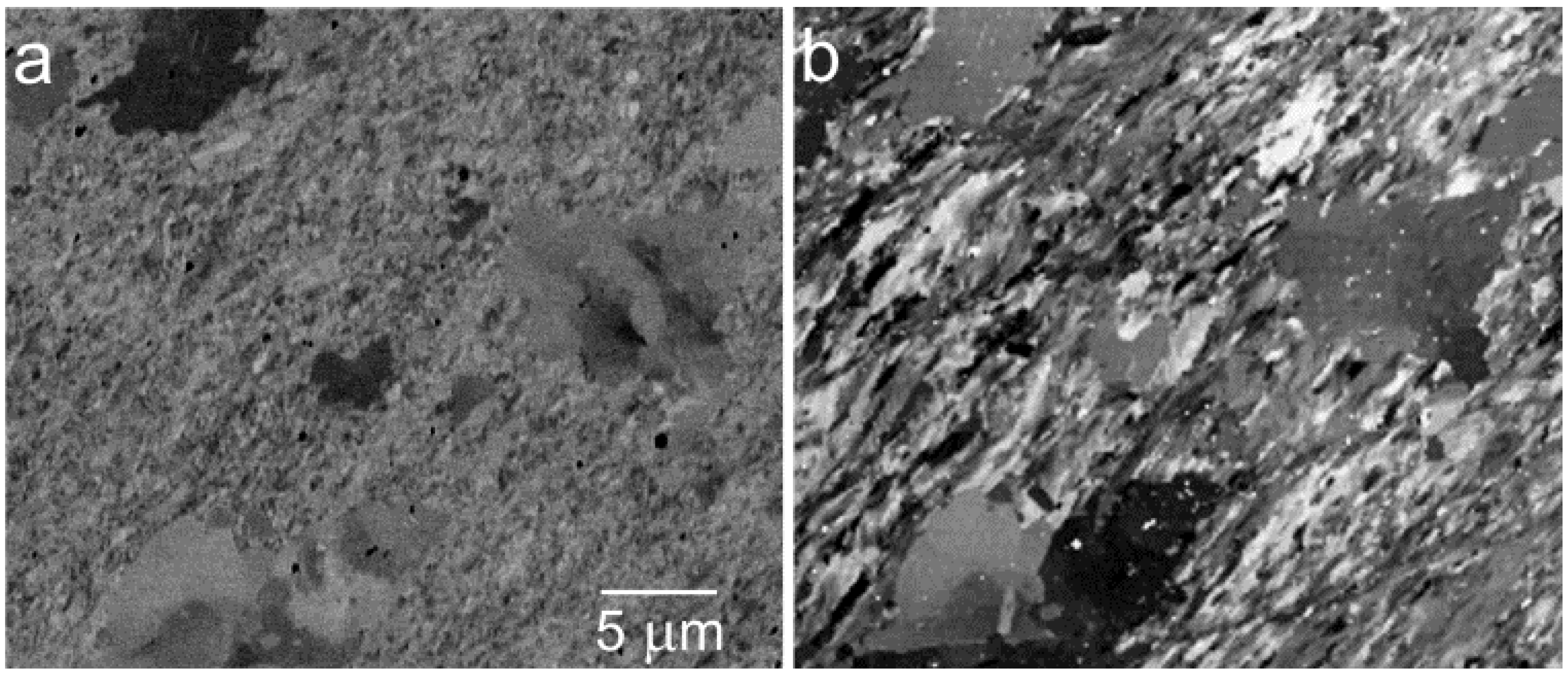

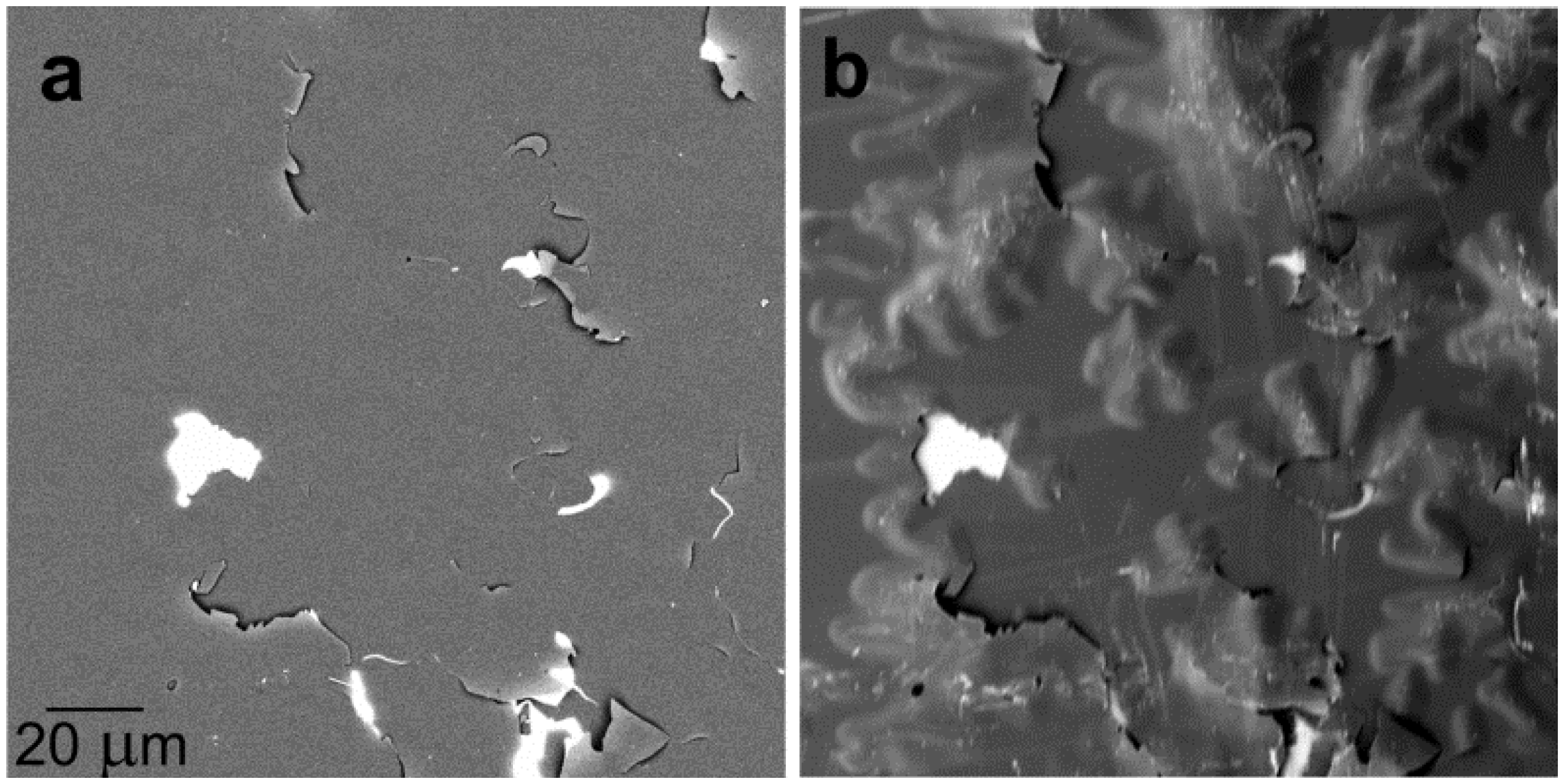

5.7. Thin Surface Coatings

6. Conclusions

Acknowledgments

References

- Brüche, E.; Johannson, H. Elektronenoptik und Elektronenmikroskop. Die Nat. 1932, 21, 353–358. [Google Scholar] [CrossRef]

- Recknagel, A. Theorie des elektrischen Elektronenmikroskops für Selbststrahler. Z. Phys. 1941, 117, 689–708. [Google Scholar] [CrossRef]

- Agar, A.W. Emission microscopes. In The Growth of Electron Microscopy; Mulvey, T., Ed.; Academic Press: San Diego, CA, USA, 1996; Volume 96, pp. 486–489. [Google Scholar]

- Zworykin, V.A.; Hillier, J.; Snyder, R.L. A scanning electron microscope. ASTM Bull. 1942, 117, 15–23. [Google Scholar]

- Bauer, E. Low energy electron reflection microscopy. In Proceedings of the Fifth International Congress on Electron Microscopy, Philadelphia, USA, 29 August–5 September 1962; Bresse, S.S., Jr., Ed.; Academic Press: New York, USA, 1962; Volume 1, pp. 11–12. [Google Scholar]

- Bauer, E. Low energy electron microscopy. Rep. Prog. Phys. 1994, 57, 895–938. [Google Scholar] [CrossRef]

- Müllerová, I.; Lenc, M. Some approaches to low-voltage scanning electron microscopy. Ultramicroscopy 1992, 41, 399–410. [Google Scholar] [CrossRef]

- Paden, R.S.; Nixon, W.C. Retarding field scanning electron microscopy. J. Phys. E Sci. Instrum. 1968, 1, 1073–1080. [Google Scholar] [CrossRef]

- Lenc, M.; Müllerová, I. Optical properties and axial aberration coefficients of the cathode lens in combination with a focusing lens. Ultramicroscopy 1992, 45, 159–162. [Google Scholar] [CrossRef]

- Müllerová, I.; Frank, L. Very low energy microscopy in commercial SEMs. Scanning 1993, 15, 193–201. [Google Scholar] [CrossRef]

- Müllerová, I.; Frank, L. Scanning low energy electron microscopy. Adv. Imaging Electron Phys. 2003, 128, 309–443. [Google Scholar]

- Frank, L.; Hovorka, M.; Konvalina, I.; Mikmeková, Š.; Müllerová, I. Very low energy scanning electron microscopy. Nucl. Instrum. Methods Phys. Res. A 2011, 645, 46–54. [Google Scholar] [CrossRef]

- Müllerová, I.; Hovorka, M.; Mika, F.; Mikmeková, E.; Mikmeková, Š.; Pokorná, Z.; Frank, L. Very low energy scanning electron microscopy in nanotechnology. Int. J. Nanotechnol. 2012, 9, 695–716. [Google Scholar] [CrossRef]

- Seiler, H. Secondary electron emission in the scanning electron microscope. J. Appl. Phys. 1983, 54, R1–R18. [Google Scholar] [CrossRef]

- Frank, L.; Müllerová, I.; Faulian, K.; Bauer, E. The scanning low-energy electron microscope: First attainment of diffraction contrast in the scanning electron microscope. Scanning 1999, 21, 1–13. [Google Scholar] [CrossRef]

- Spence, J.C.H. Electron diffraction and microdiffraction. In Microscopy, 2nd ed.; Rossiter, B.W., Hamilton, J.F., Eds.; Wiley: New York, NY, USA, 1991; pp. 153–201. [Google Scholar]

- Barth, J.E.; Kruit, P. Addition of different contributions to the charged particle probe size. Optik 1996, 101, 101–109. [Google Scholar]

- Frank, L.; Müllerová, I. Strategies for low- and very-low-energy SEM. J. Electron Microsc. 1999, 48, 205–219. [Google Scholar] [CrossRef]

- Káňová, J.; Zobač, M.; Oral, M.; Müllerová, I.; Frank, L. Corrections of magnification and focusing in a cathode lens-equipped scanning electron microscope. Scanning 2006, 28, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Müllerová, I.; Frank, L. Use of cathode lens in scanning electron microscope for low voltage applications. Mikrochim. Acta 1994, 114–115, 389–396. [Google Scholar] [CrossRef]

- Frank, L.; Steklý, R.; Zadražil, M.; El-Gomati, M.M.; Müllerová, I. Electron backscattering from real and in-situ treated surfaces. Mikrochim. Acta 2000, 132, 179–188. [Google Scholar] [CrossRef]

- Frank, L. Real image resolution of SEM and low-energy SEM and its optimization. Ultramicroscopy 1996, 62, 261–269. [Google Scholar] [CrossRef] [PubMed]

- Reimer, L. Emission of backscattered and secondary electrons. In Scanning Electron Microscopy: Physics of Image Formation and Microanalysis, 2nd ed.; Springer: Berlin, Germany, 1998; pp. 135–170. [Google Scholar]

- Pejchl, D.; Müllerová, I.; Frank, L. Unconventional imaging of surface relief. Czechoslov. J. Phys. 1993, 43, 983–992. [Google Scholar] [CrossRef]

- Reimer, L. Electron scattering and diffusion. In Scanning Electron Microscopy: Physics of Image Formation and Microanalysis, 2nd ed.; Springer: Berlin, Germany, 1998; pp. 57–134. [Google Scholar]

- Frank, L.; Zadražil, M.; Müllerová, I. Scanning electron microscopy of nonconductive specimens at critical energies in a cathode lens system. Scanning 2001, 23, 36–50. [Google Scholar] [CrossRef] [PubMed]

- Zobačová, J.; Frank, L. Specimen charging and detection of signal from non-conductors in a cathode lens-equipped scanning electron microscope. Scanning 2003, 25, 150–156. [Google Scholar] [CrossRef] [PubMed]

- El Gomati, M.M.; Walker, C.G.H.; Assa’d, A.M.D.; Zadražil, M. Theory experiment comparison of the electron backscattering factor from solids at low electron energy (250–5000 eV). Scanning 2008, 30, 2–15. [Google Scholar] [CrossRef] [PubMed]

- Müllerová, I.; Konvalina, I.; Frank, L. Acquisition of the angular distribution of backscattered electrons at low energies. Mater. Trans. 2007, 48, 940–943. [Google Scholar] [CrossRef]

- Mikmeková, Š.; Hovorka, M.; Müllerová, I.; Man, O.; Pantělejev, L.; Frank, L. Grain contrast imaging in UHV SLEEM. Mater. Trans. 2010, 51, 292–296. [Google Scholar] [CrossRef]

- Fitting, H.-J.; Schreiber, E.; Kuhr, J.-Ch.; von Czarnowski, A. Attenuation and escape depths of low-energy electron emission. J. Electron Spectrosc. Relat. Phenom. 2001, 119, 35–47. [Google Scholar] [CrossRef]

- Dingley, D.J.; Wilkinson, A.J.; Meaden, G.; Karamched, P.S. Elastic strain tensor measurement using electron backscatter diffraction in the SEM. J. Electron Micros. 2010, 59, S155–S163. [Google Scholar] [CrossRef]

- Bartoš, I. Electronic structure of crystals via VLEED. Prog. Surf. Sci. 1998, 59, 197–206. [Google Scholar] [CrossRef]

- Jaklevic, R.C.; Davis, L.C. Band signatures in the low-energy-electron reflectance spectra of fcc metals. Phys. Rev. B 1982, 26, 5391–5397. [Google Scholar] [CrossRef]

- Pokorná, Z.; Frank, L. Mapping of the local density of states by very low energy scanning electron microscope. Mater. Trans. 2010, 51, 214–218. [Google Scholar] [CrossRef]

- Bartoš, I.; Van Hove, M.A.; Altman, M.S. Cu(111) electron band structure and channeling by VLEED. Surf. Sci. 1996, 352–354, 660–664. [Google Scholar]

- Pokorná, Z.; Mikmeková, Š.; Müllerová, I.; Frank, L. Characterization of the local crystallinity via reflectance of very slow electrons. Appl. Phys. Lett. 2012, 100, 261602:1–261602:4. [Google Scholar] [CrossRef]

- Chang, T.H.P.; Nixon, W.C. Electron beam induced potential contrast on unbiased planar transistors. Solid State Electron. 1967, 10, 701–704. [Google Scholar] [CrossRef]

- Perovic, D.D.; Castell, M.R.; Howie, A.; Lavoie, C.; Tiedje, T.; Cole, J.S.W. Field-emission SEM imaging of compositional and doping layer semiconductor superlattices. Ultramicroscopy 1995, 58, 104–113. [Google Scholar] [CrossRef]

- Turan, R.; Perovic, D.D.; Houghton, D.C. Mapping electrically active dopant profiles by field-emission scanning electron microscopy. Appl. Phys. Lett. 1996, 69, 1593–1595. [Google Scholar] [CrossRef]

- Sealy, C.P.; Castell, M.R.; Wilshaw, P.R. Mechanism for secondary electron dopant contrast in the SEM. J. Electron Micros. 2000, 49, 311–321. [Google Scholar] [CrossRef]

- Kazemian, P.; Mentink, S.A.M.; Rodenburg, C.; Humphreys, C.J. Quantitative secondary electron energy filtering in a scanning electron microscope and its applications. Ultramicroscopy 2007, 107, 140–150. [Google Scholar] [CrossRef] [PubMed]

- El-Gomati, M.M.; Wells, T.C.R. Very-low-energy electron microscopy of doped semiconductors. Appl. Phys. Lett. 2001, 79, 2931–2933. [Google Scholar] [CrossRef]

- Müllerová, I.; El-Gomati, M.M.; Frank, L. Imaging of the boron doping in silicon using low energy SEM. Ultramicroscopy 2002, 93, 223–243. [Google Scholar] [CrossRef] [PubMed]

- El-Gomati, M.M.; Wells, T.C.R.; Müllerová, I.; Frank, L.; Jayakody, H. Why is it that differently doped regions in semiconductors are visible in low voltage SEM? IEEE Trans. Electron Devices 2004, 51, 288–291. [Google Scholar] [CrossRef]

- Mika, F.; Frank, L. Two-dimensional dopant profiling with low energy SEM. J. Micros. 2008, 230, 76–83. [Google Scholar] [CrossRef]

- El Gomati, M.M.; Zaggout, F.; Jayacody, H.; Tear, S.; Wilson, K. Why is it possible to detect doped regions of semiconductors in low voltage SEM: A review and update. Surf. Interface Anal. 2005, 37, 901–911. [Google Scholar] [CrossRef]

- Frank, L.; Müllerová, I.; Valdaitsev, D.; Gloskovskii, A.; Nepijko, S.; Elmers, H.; Schönhense, G. The origin of contrast in the imaging of doped areas in silicon by slow electrons. J. Appl. Phys. 2006, 100, 093712:1–093712:5. [Google Scholar] [CrossRef]

- Hovorka, M.; Mika, F.; Mikulík, P.; Frank, L. Profiling n-type dopants in silicon. Mater. Trans. 2010, 51, 237–242. [Google Scholar] [CrossRef]

- Frank, L.; Müllerová, I. The injected-charge contrast mechanism in scanned imaging of doped semiconductors by very slow electrons. Ultramicroscopy 2005, 106, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Drummy, L.F.; Yang, J.; Martin, D.C. Low-voltage electron microscopy of polymer and organic molecular thin films. Ultramicroscopy 2004, 99, 247–256. [Google Scholar] [CrossRef] [PubMed]

- Dellby, N.; Krivanek, O.L.; Nellist, P.D.; Batson, P.E.; Lupini, A.R. Progress in aberration-corrected scanning transmission electron microscopy. J. Electron Micros. 2001, 50, 177–185. [Google Scholar]

- Dellby, N.; Bacon, N.J.; Hrncirik, P.; Murfitt, M.F.; Skone, G.S.; Szilagyi, Z.S.; Krivanek, O.L. Dedicated STEM for 200 to 40 keV operation. Eur. Phys. J. Appl. Phys. 2011, 54. [Google Scholar] [CrossRef]

- Müllerová, I.; Hovorka, M.; Hanzlíková, R.; Frank, L. Very low energy scanning electron microscopy of free-standing ultrathin films. Mater. Trans. 2010, 51, 265–270. [Google Scholar] [CrossRef]

- Müllerová, I.; Hovorka, M.; Konvalina, I.; Unčovský, M.; Frank, L. Scanning transmission low-energy electron microscopy. IBM J. Res. Dev. 2011, 55, 2:1–2:6. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Frank, L.; Hovorka, M.; Mikmeková, Š.; Mikmeková, E.; Müllerová, I.; Pokorná, Z. Scanning Electron Microscopy with Samples in an Electric Field. Materials 2012, 5, 2731-2756. https://doi.org/10.3390/ma5122731

Frank L, Hovorka M, Mikmeková Š, Mikmeková E, Müllerová I, Pokorná Z. Scanning Electron Microscopy with Samples in an Electric Field. Materials. 2012; 5(12):2731-2756. https://doi.org/10.3390/ma5122731

Chicago/Turabian StyleFrank, Ludĕk, Miloš Hovorka, Šárka Mikmeková, Eliška Mikmeková, Ilona Müllerová, and Zuzana Pokorná. 2012. "Scanning Electron Microscopy with Samples in an Electric Field" Materials 5, no. 12: 2731-2756. https://doi.org/10.3390/ma5122731