Mechanical and Microstructural Evaluations of Lightweight Aggregate Geopolymer Concrete before and after Exposed to Elevated Temperatures

Abstract

:1. Introduction

2. Results and Discussion

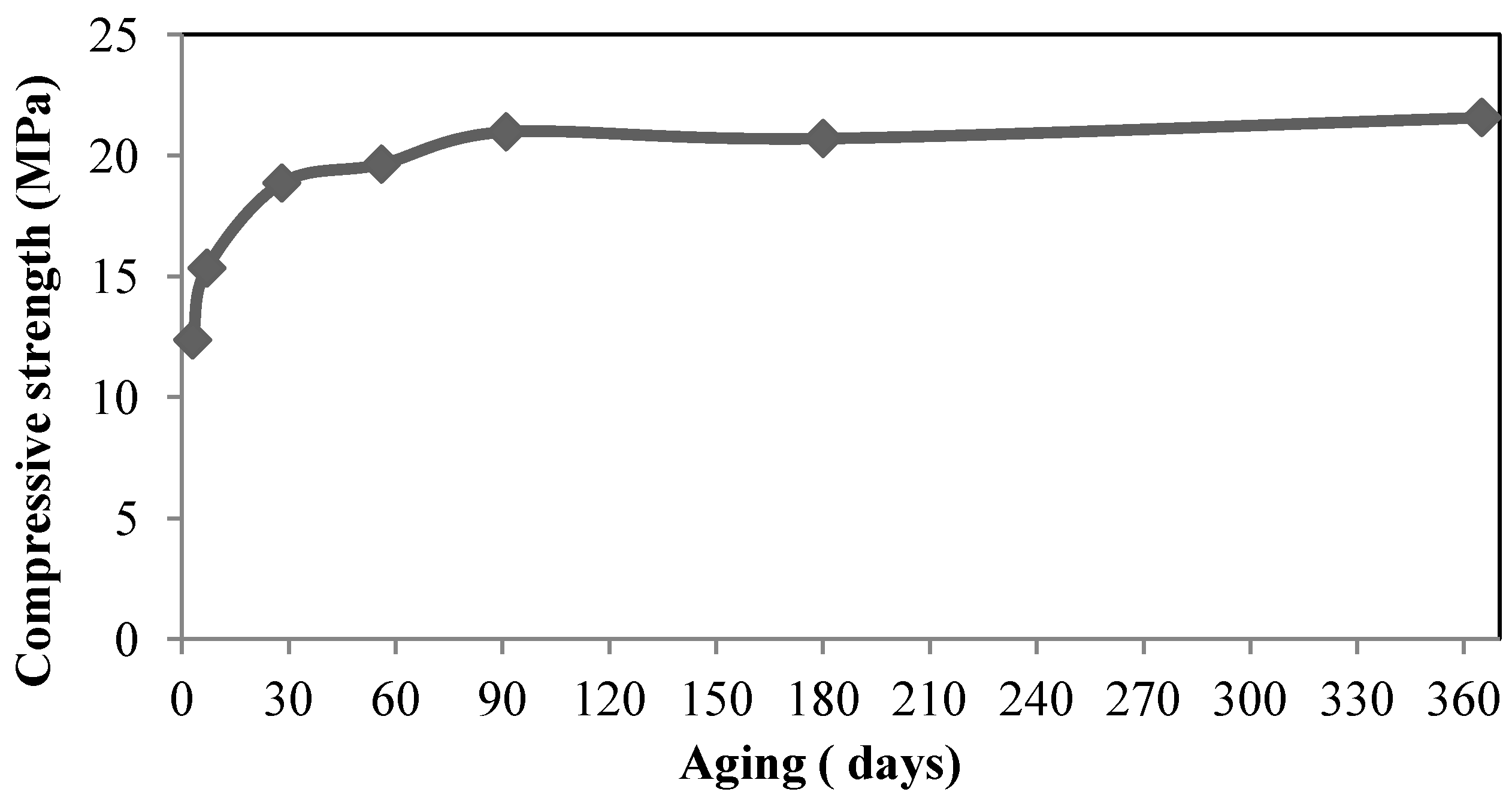

2.1. Mechanical and Physical Properties of the Unexposed LWAGC

| Property | LWAGC |

|---|---|

| Compressive (MPa) | 18.86 |

| OD-Density (kg/m3) | 1438.7 |

| Water absorption (%) | 10.7 |

| Fresh Slump (mm) | 95 |

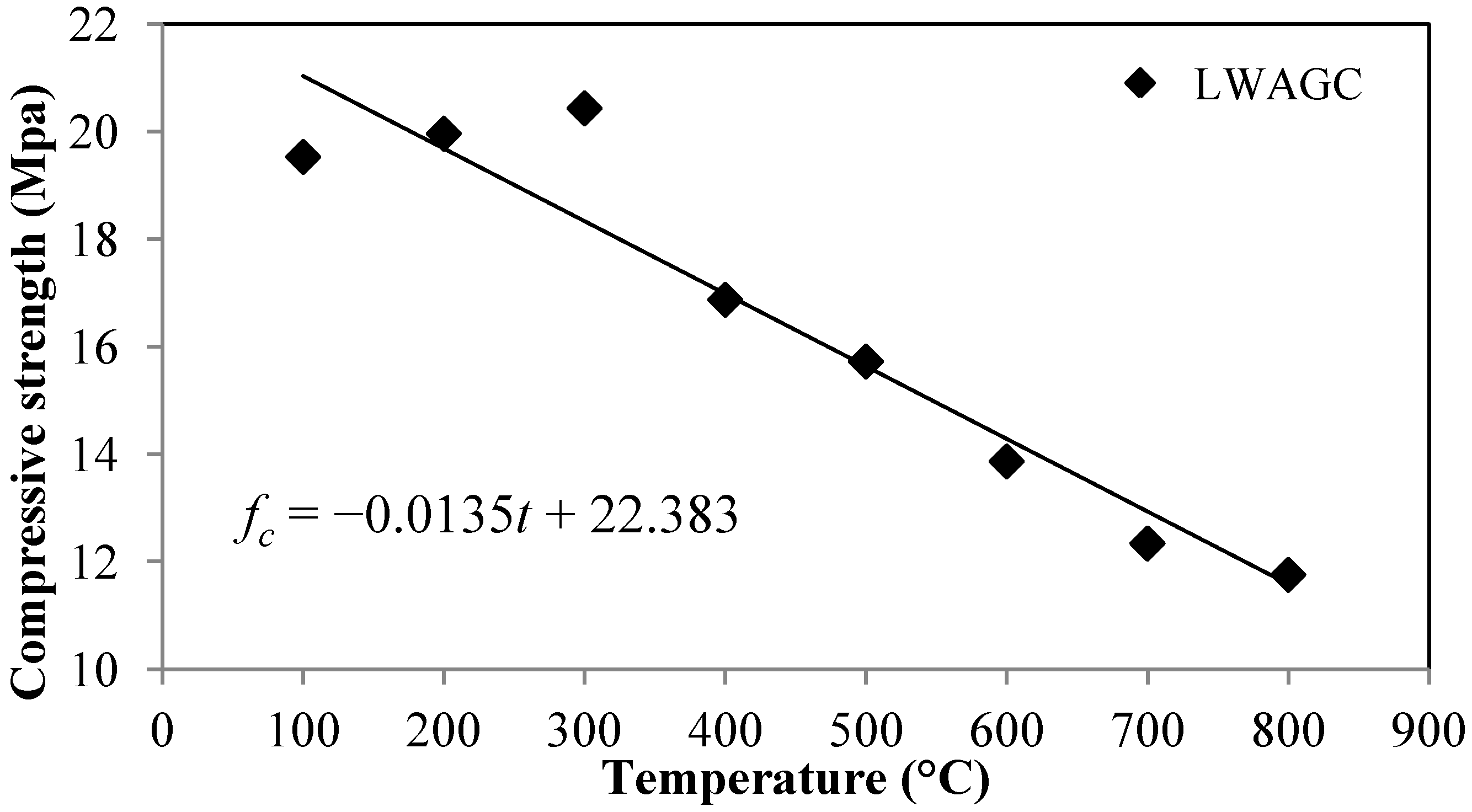

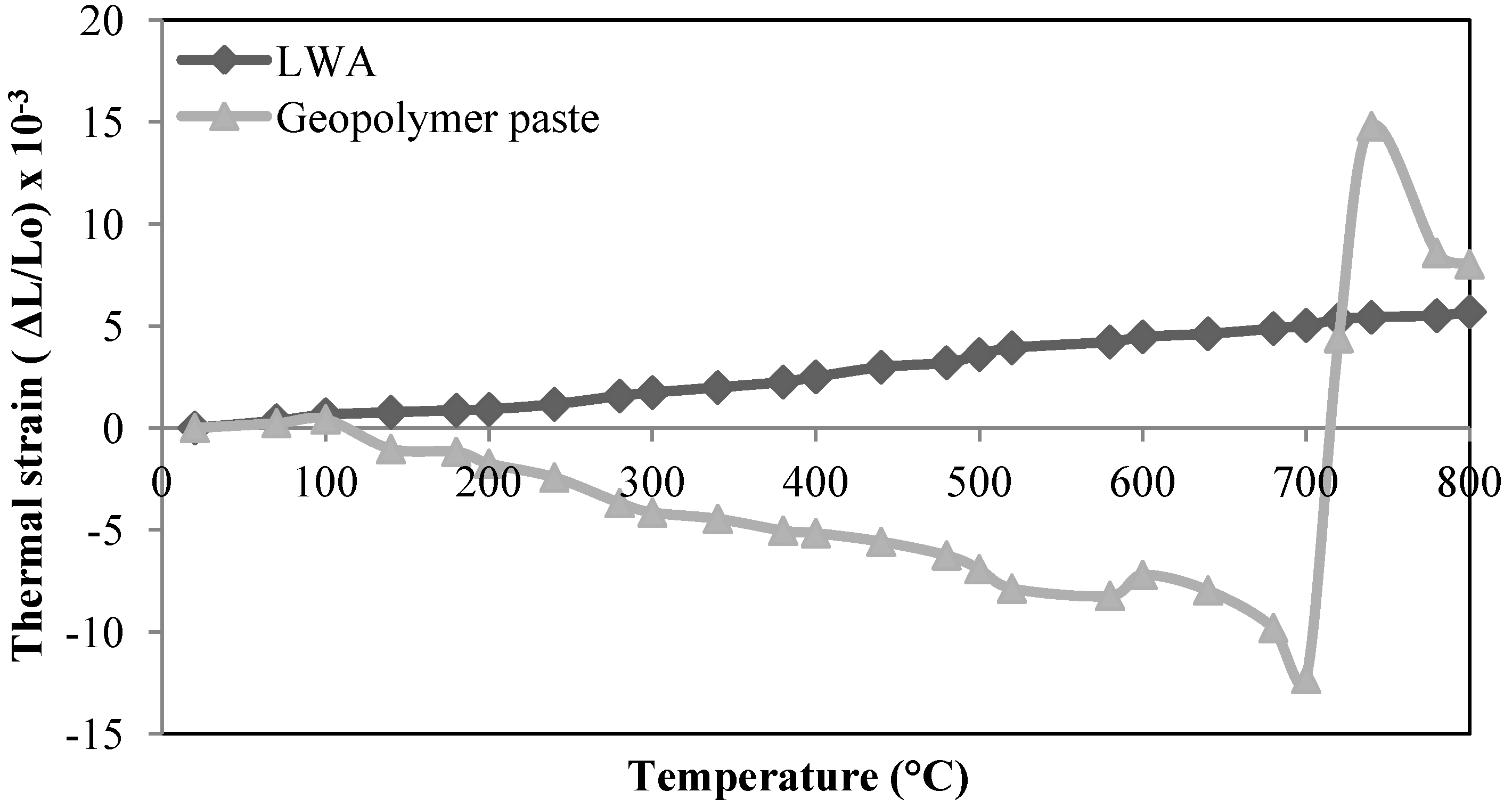

2.2. Properties of LWAGC Exposed to Elevated Temperatures

2.2.1. Residual Compressive Strength

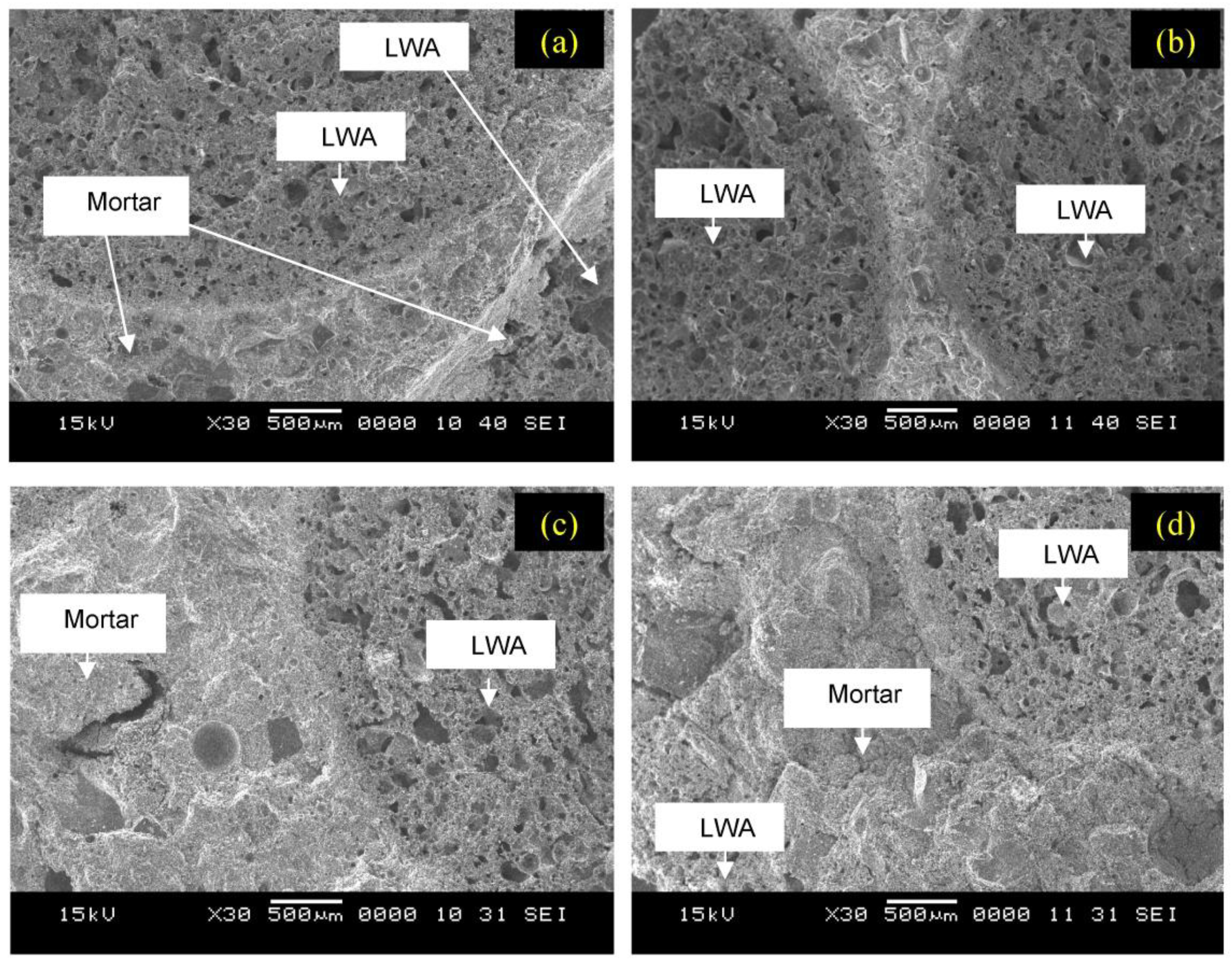

2.2.2. Microstructure of the Exposed LWAGC

3. Experimental Procedure

3.1. Source Materials

| Chemical | wt % |

|---|---|

| SiO2 | 26.4 |

| Al2O3 | 9.25 |

| Fe2O3 | 30.13 |

| TiO2 | 3.07 |

| CaO | 21.6 |

| MnO | 0.27 |

| CuO | 0.14 |

| K2O | 2.58 |

| P2O5 | 0.67 |

| SO3 | 1.3 |

| SrO | 1.57 |

| LOI | 3.02 |

| Sieve (mm) | Passing (%) Sand | Passing (%) LWA |

|---|---|---|

| 9.5 | – | 100 |

| 6.3 | – | 60 |

| 4.75 | 100 | 25 |

| 2.38 | 98.75 | 0 |

| 1.19 | 95 | – |

| 0.59 | 70 | – |

| 0.30 | 40 | – |

| 0.15 | 10 | – |

| Property | Value |

|---|---|

| Specific gravity (OD) | 0.9 |

| Specific gravity (SSD) | 1.05 |

| Apparent Specific gravity | 1.07 |

| Density (OD) | 897.75 (kg/m3) |

| Density (SSD) | 1047.37 (kg/m3) |

| Apparent Density | 1067 (kg/m3) |

| Water absorption (%) | 17.2 |

3.2. LWAGC Preparation

| Constituents | LWAGC |

|---|---|

| FA | 341.89 |

| Na2SiO3 | 100.86 |

| NaOH | 100.86 |

| Activator/FA mass ratio | 0.59 |

| LWA | 484 |

| Sand | 823.39 |

| Extra H2O | 91.47 |

3.3. Curing Regime

3.4. Elevated Temperatures Exposure Method

3.5. Dilatometry Analysis

3.6. Microstructural Investigation

4. Conclusion

Acknowledgments

Conflicts of Interest

References

- Swamy, R.N.; Jiang, E.D. Pore structure and carbonation of lightweight concrete after 10 years’ exposure. ACI Spec. Publ. 1993, 136, 377–395. [Google Scholar]

- Swamy, R.N.; Lambert, G.H. Mix design and properties of concrete made from PFA coarse aggregates and sand. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 263–275. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. The microstructure of Lytag aggregate. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 273–282. [Google Scholar] [CrossRef]

- Mouli, M.; Khelafi, H. Performance characteristics of lightweight aggregate concrete containing natural pozzolan. Build. Environ. 2008, 43, 31–36. [Google Scholar] [CrossRef]

- Davidovits, J. Chemistry of Geopolymeric Systems, Terminology. In Proceedings of Second International Conference on Geopolymers, Saint-Quentin, France, 28–29 June 1999; pp. 9–40.

- Yang, K.; Song, J.; Lee, J. Properties of alkali-activated mortar and concrete using lightweight aggregates. Mater. Struct. 2010, 43, 403–416. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Z.; Zhang, Y. Development of Sustainable Cementitious Materials. In Proceedings of International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 20–21.

- Wallah, S.E.; Rangan, B.V. Low-Calcium Fly Ash Based Geopolymer Concrete: Long-Term Properties. In Research Report GC2; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- Gourley, J.; Johnson, G. Developments in Geopolymer Precast Concrete. In Proceedings of Fourth World Congress Geopolymer, Saint- Quentin, France, 1 July 2005; pp. 133–137.

- Abdullah, M.M.A.B.; Jamaludin, L.; Hussin, K.; Bnhussain, M.; Ghazali, C.M.R.; Ahmad, M.I. Fly ash porous material using geopolymerization process for high temperature exposure. Int. J. Mol. Sci. 2012, 13, 4388–4395. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Yahya, Z.; Razak, R.A. Fly ash-based geopolymer lightweight concrete using foaming agent. Int. J. Mol. Sci. 2012, 13, 7186–7198. [Google Scholar] [CrossRef] [PubMed]

- Abdulkareem, O.A.; Bakri, A.M.M.A.; Kamarudin, H.; Nizar, I.K. A study on the synthesis of fly ash-based lightweight aggregate geopolymer concrete. Adv. Sci. Lett. 2013, 19, 282–285. [Google Scholar] [CrossRef]

- American Concrete Institute Committee. Guide for Structural Lightweight Aggregate Concrete; American Concrete Institute Committee: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete. In Research Report GC1; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2005. [Google Scholar]

- Collins, F.; Sanjayan, J.G. Strength and shrinkage properties of alkali-activated slag concrete containing porous coarse aggregate. Cem. Concr. Res. 1999, 29, 607–610. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Rashad, A.M.; Zeedan, S.R. The effect of activator concentration on the residual strength of alkali-activated fly ash pastes subjected to thermal load. Contsr. Build. Mater. 2011, 25, 3098–3107. [Google Scholar] [CrossRef]

- Hu, S.G.; Wu, J.; Yang, W.; He, Y.J.; Wang, F.Z.; Ding, Q.J. Preparation and properties of geopolymer-lightweight aggregate refractory concrete. J. Cent. South Univ. Technol. 2009, 16, 914–918. [Google Scholar] [CrossRef]

- Rickard, W.D.; Temuujin, J.; van Riessen, A. Thermal analysis of geopolymer pastes synthesised from five fly ashes of variable composition. J. Non Cryst. Solids 2012, 358, 1830–1839. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Bakri, A.M.M.A.; Kamarudin, H.; Nizar, I.K. Alternation in the microstructure of fly ash geopolymers upon exposure to elevated temperatures. Adv. Mater. Res. 2013, 795, 201–205. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, C.Z.; Duxson, P.; van Deventer, J.S.J. Correlating mechanical and thermal properties of sodium silicate-fly ash geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2009, 336, 57–63. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Topçu, I.B. Thermal expansion of self-consolidating normal and lightweight aggregate concrete at elevated temperature. Contsr. Build. Mater. 2009, 23, 3063–3069. [Google Scholar]

- Andiç-Çakır, Ö.; Hizal, S. Influence of elevated temperatures on the mechanical properties and microstructure of self-consolidating lightweight aggregate concrete. Contsr. Build. Mater. 2012, 34, 575–583. [Google Scholar]

- Saad, M.; Abo-El-Enein, S.A.; Hanna, G.B.; Kotkata, M.F. Effect of temperature on physical and mechanical properties of concrete containing silica fume. Cem. Concr. Res. 1996, 26, 669–675. [Google Scholar] [CrossRef]

- Ke, Y.; Ortola, S.; Beaucour, A.L.; Dumontet, H. Identification of microstructural characteristics in lightweight aggregate concretes by micromechanical modeling including the interfacial transition zone (ITZ). Cem. Concr. Res. 2010, 40, 1590–1600. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Uygunoğlu, T. Properties of autoclaved lightweight aggregate concrete. Build. Environ. 2007, 42, 4108–4116. [Google Scholar] [CrossRef]

- ASTM (American Society for Testing and Materials). Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete (C618-08); ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- American Concrete Institute Committee. Standard Practice for Selecting Proportions for Structural Lightweight Concrete; American Concrete Institute Committee: Farmington Hills, MI, USA, 1998. [Google Scholar]

- ASTM (American Society for Testing and Materials). Standard Test Method for Sampling and Testing Concrete Masonry Units and Related Units (C 140-01); ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Eurpoean Committee for Standardization. Testing Hardened Concrete—Part 3: Compressive Strength of Testing Specimens; Eurpoean Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- ASTM (American Society for Testing and Materials). Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis (E 831-03); ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Abdulkareem, O.A.; Abdullah, M.M.A.B.; Hussin, K.; Ismail, K.N.; Binhussain, M. Mechanical and Microstructural Evaluations of Lightweight Aggregate Geopolymer Concrete before and after Exposed to Elevated Temperatures. Materials 2013, 6, 4450-4461. https://doi.org/10.3390/ma6104450

Abdulkareem OA, Abdullah MMAB, Hussin K, Ismail KN, Binhussain M. Mechanical and Microstructural Evaluations of Lightweight Aggregate Geopolymer Concrete before and after Exposed to Elevated Temperatures. Materials. 2013; 6(10):4450-4461. https://doi.org/10.3390/ma6104450

Chicago/Turabian StyleAbdulkareem, Omar A., Mohd Mustafa Al Bakri Abdullah, Kamarudin Hussin, Khairul Nizar Ismail, and Mohammed Binhussain. 2013. "Mechanical and Microstructural Evaluations of Lightweight Aggregate Geopolymer Concrete before and after Exposed to Elevated Temperatures" Materials 6, no. 10: 4450-4461. https://doi.org/10.3390/ma6104450