3.1. Low Energy Electron Diffraction

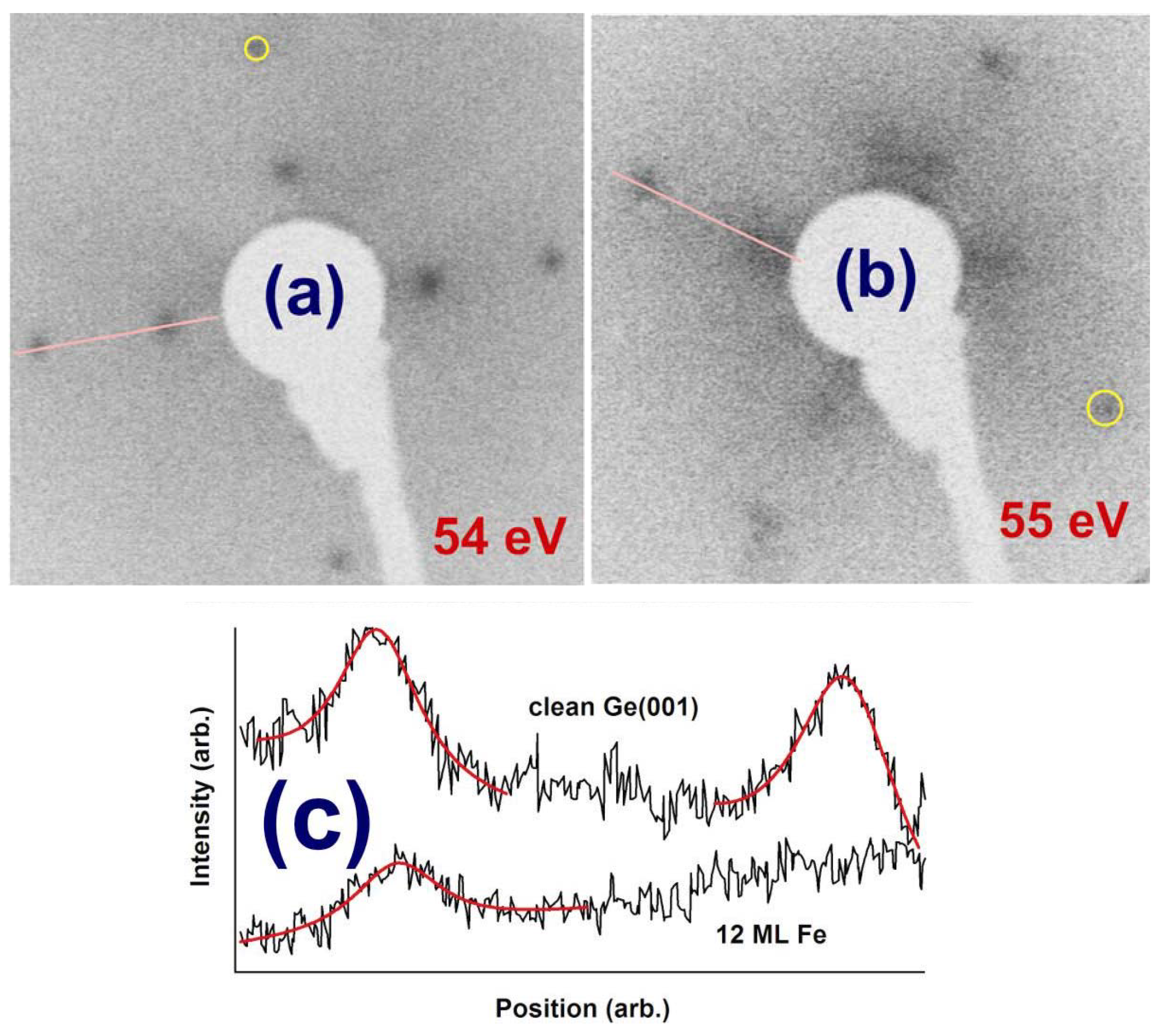

Figure 1 presents LEED images obtained at 54–55 eV electron energies on the clean Ge(001) sample and on 12 ML Fe deposited on Ge(001). Visible LEED patterns were obtained on the sample with 12 ML Fe also at energies of 47, 68 and 88 eV, but no patterns were visible at higher electron energies, whereas the clean Ge(001) exhibits a rich LEED structure up to about 200 eV with the present setup. Therefore, the surface is disordered by Fe deposition. The (1 × 2) − (2 × 1) reconstruction practically disappears and in fact the only relevant (1 × 1) LEED pattern is the one represented in

Figure 2b. Note also that 1 ML Fe/Ge(001) exhibited a clear LEED pattern, with (1 × 2) − (2 × 1) spots; starting with 3 ML the LEED spots became barely visible, then the (1 × 1) spots appear again for the thickest layer investigated in this series, 12 ML.

Figure 1.

Low energy electron diffraction (LEED) patterns of clean Ge(001) (2 × 1) − (1 × 2) (a) and of 12 ML Fe/Ge(001) deposited at 500 °C (b). In order to enhance the clarity, negatives of the original photographs are used. The energy used is represented on each pattern. Each pattern has one spot highlighted by a yellow circle, to estimate its approximate broadening; (c) LEED spot profile analysis of both images along the designated pink curves in (a) and (b). Black lines are intensity profiles, red curves are fits using Voigt profiles.

Figure 1.

Low energy electron diffraction (LEED) patterns of clean Ge(001) (2 × 1) − (1 × 2) (a) and of 12 ML Fe/Ge(001) deposited at 500 °C (b). In order to enhance the clarity, negatives of the original photographs are used. The energy used is represented on each pattern. Each pattern has one spot highlighted by a yellow circle, to estimate its approximate broadening; (c) LEED spot profile analysis of both images along the designated pink curves in (a) and (b). Black lines are intensity profiles, red curves are fits using Voigt profiles.

However, this is an encouraging result pointing on the survival of the long range crystalline order on the FeGe(001) surface. Generally, few LEED patterns are obtained for metals deposited on semiconductors. In [

10], Fe/Si(001) exhibited a LEED pattern only up to about 0.8 nm of Fe deposited, whereas in [

26,

27] Sm/Si(001) deposited at 300 °C showed a very diffuse LEED pattern for 3.2 nm of Sm deposited. Here, we obtained clear LEED patterns for the equivalent of 1.7 nm Fe deposited. (All thicknesses are referenced to the crystal structure of the metal deposited.)

Moreover, although from a first inspection of

Figure 1a,b it seems that the spots are broader on the FeGe(001) surface, in fact, a spot profile analysis, represented in

Figure 1c yielded results not far away from that of the clean Ge(001) surface. More specifically, the profiles were fit with a Voigt profile [

28], which is a convolution between Lorentz and Gauss profiles. The Gauss profile accounts for the spatial distribution of the electron spot and for thermal broadening, whereas the Lorentz profile is connected to the coherence length, as usual in diffraction. The Gaussian broadening was similar in both cases (by about 2% lower for the FeGe(001) film, which may be attributed to a better focusing of the electron beam in the latter case). The Lorentz full width at half maximum (FWHM), divided by the size of the two-dimensional Brillouin zone

q0, is connected to the coherence domain size in the direct space

D (which will be understood in the following as a typical lateral size of crystalline ordered domains) via the following equation Δ

q/

q0 ≈

a/

D, where

a is the surface lattice constant, about 4.0 Å for Ge(001). The obtained normalized Lorentz FWHM is Δ

q/

q0 ≈ 0.086 for clean Ge(001) and 0.095 for FeGe(001). From this normalized Lorentz width one has to subtract the transfer width of the setup, of about 0.01 [

26]. The net result is a coherence length

D of about 5.2 nm for clean Ge(001), which decreases to about 4.6 nm for FeGe(001). Therefore, the crystalline parts of the surface are not that affected by the presence of Fe.

3.2. X-ray Photoelectron Spectroscopy

The X-ray photoelectron spectra (XPS) are represented in

Figure 2 for Ge 3d core levels and in

Figure 3 for Fe 2p core levels. The XPS data analysis was performed by simulations using Voigt lines and Voigt inelastic backgrounds [

28]. The results of these “deconvolutions” are summarized in

Table 1. All the other parameters obtained from fit were in good agreement with previous work: The branching ratios were fixed to their theoretical values (1.5 for Ge 3d and 2 for Fe 2p); allowing variation of these parameters did not improve the quality of the fits. The spin-orbit splittings obtained for Ge 3d were 0.585 ± 0.003 eV, in good agreement with [

29] and with our previous work [

3]. The Fe 2p spin-orbit splitting yielded 12.95 ± 0.03 eV. Fe 2p has also considerable inelastic background ratios, pointing on the bulk origin of both Fe components [

30].

The second Fe 2p component, Fe(2), at higher binding energies, might eventually be due to some contamination of the Fe layer. Its energy (708.5–709.0 eV) is close to some old reports on Fe

3O

4 or on oxygen adsorbed on Fe layers, according to the NIST XPS database. In [

22] also, 709 eV was reported for surface Fe–O. Since we did not identify carbon or oxygen in the XPS spectra, we cannot immediately assume the presence of iron oxide on the surface; however, in the following we will be rather pessimistic and exclude this smaller, higher binding energy Fe component from the analysis.

The Ge 3d spectra could be simulated with only two components. For clean Ge, these components correspond to surface atoms (the higher binding energy component) and bulk atoms (the lower binding energy component, of higher intensity). Subsurface atoms and an eventual different signature of higher or lower atoms from the buckled dimmers [

31] are not clearly identifiable within the resolution of the actual experiment. In the following, we will constantly attribute the component at 29.4 ± 0.1 eV to bulk germanium. With Fe deposition, it seems that an important part of the Ge 3d signal is concentrated in this lower binding energy component. Also, its amplitude decreases constantly with Fe deposition. Therefore, we suggest that this component represents Ge atoms not affected by the presence of Fe.

Figure 2.

Ge 3d electron distribution curves (EDCs) for clean Ge(001) and for Fe/Ge(001) deposited at 500 °C. The experimental data (red markers) are simulated with a fit with two spin-orbit split Voigt doublets. The separate components are the blue and the green curve; the total fitting function is the black curve.

Figure 2.

Ge 3d electron distribution curves (EDCs) for clean Ge(001) and for Fe/Ge(001) deposited at 500 °C. The experimental data (red markers) are simulated with a fit with two spin-orbit split Voigt doublets. The separate components are the blue and the green curve; the total fitting function is the black curve.

In

Table 1, the integral amplitudes obtained by fit were already corrected by the XPS atomic sensitivity factors [

32] of 0.38 for Ge 3d and 3.0 for Fe 2p.

A first evaluation may be done by dividing the Fe(1) main component, with binding energy close to that of metal Fe (about 707 eV) to the total Ge signal. One obtains the ratios from the third column from the right hand side of

Table 1. This implies that Fe is embedded in germanium with percentages ranging from 2.4 to 8.6 at %.

Figure 3.

Fe 2p EDCs for all Fe depositions on Ge(001). Same comments as for

Figure 2 are applicable. This time the spin-orbit splitting is quite visible between the 2p

3/2 and 2p

1/2 components.

Figure 3.

Fe 2p EDCs for all Fe depositions on Ge(001). Same comments as for

Figure 2 are applicable. This time the spin-orbit splitting is quite visible between the 2p

3/2 and 2p

1/2 components.

A second evaluation may be done by dividing the Fe(1) signal to the second component of germanium, Ge(2), which should represent germanium that reacted with Fe. It may be surprising to attribute a higher binding energy component to Ge reacted with Fe, since usually semiconductors reacting with metals develop lower binding energy components [

26,

27]; however, for Fe–Ge, a similar binding energy (29.8 eV) was reported in [

22]. The Fe(1):Ge(2) ratios represented in the next to the last column in

Table 1 suggests the presence of surface compounds of approximate compositions ranging from FeGe

3 to Fe

3Ge

5, as indicated in the last column of

Table 1. As mentioned in the Introduction, the Fe–Ge phase diagram [

23] does not show too many stable Ge-rich stable compounds. The only stable compound is represented by FeGe

2. This is a layered compound of (C16) structure, antiferromagnetic at low temperature and with a spiral spin configuration at temperatures between 263 and 289 K [

25]. However, as will be discussed in the following paragraph, our samples exhibited a clear ferromagnetic behavior at room temperature (298 K). This is again proof that magnetism at interfaces may differ significantly from the bulk, owing to symmetry breaking or surface charge depletion [

1,

7].

Table 1.

Results obtained from the simulation of XPS spectra. Amplitude columns are integral amplitudes, expressed in 10

3 counts/s × eV ≡ kcps × eV (abbreviated kV), normalized to integral amplitude atomic sensitivity factors (0.38 for Ge 3d, 3 for Fe 2p) [

32]. Errors are ±0.005 eV for energies, ±10% for amplitudes (uncertainities are mainly from the atomic sensitivity factors). The last three columns represent amplitude ratio of the lower binding energy of Fe [Fe(1)] to the total Ge signal [Ge(1) + Ge(2)], and the lower binding energy Fe [Fe(1)] divided by the “reacted” Ge component [Ge(2)]. The last column represents a proposed interface compound based on the [Fe(1)]/[Ge(2)] ratio. Italics represent values of lower confidence (see text for details).

Table 1.

Results obtained from the simulation of XPS spectra. Amplitude columns are integral amplitudes, expressed in 103 counts/s × eV ≡ kcps × eV (abbreviated kV), normalized to integral amplitude atomic sensitivity factors (0.38 for Ge 3d, 3 for Fe 2p) [32]. Errors are ±0.005 eV for energies, ±10% for amplitudes (uncertainities are mainly from the atomic sensitivity factors). The last three columns represent amplitude ratio of the lower binding energy of Fe [Fe(1)] to the total Ge signal [Ge(1) + Ge(2)], and the lower binding energy Fe [Fe(1)] divided by the “reacted” Ge component [Ge(2)]. The last column represents a proposed interface compound based on the [Fe(1)]/[Ge(2)] ratio. Italics represent values of lower confidence (see text for details).

| Level θ(Å) | Ge 3d (1) | Ge 3d (2) | Fe 2p (1) | Fe 2p (2) | Fe(1):Getot | Fe(1):Ge(2) | Compound |

|---|

| E(eV) | A(kV) | E(eV) | A(kV) | E(eV) | A(kV) | E(eV) | A(kV) |

|---|

| 0 | 29.46 | 82.5 | 29.59 | 11.8 | – | – | – | – | – | – | Ge |

| 1 | 29.33 | 88.3 | 29.67 | 7.6 | 706.98 | 2.3 | 711.25 | 0.08 | 0.024 | 0.305 | FeGe3 |

| 3 | 29.52 | 76.5 | 29.85 | 10.5 | 707.27 | 4.1 | 708.88 | 0.80 | 0.047 | 0.392 | Fe2Ge5 |

| 6 | 29.35 | 63.3 | 29.66 | 9.5 | 707.03 | 5.6 | 709.05 | 0.73 | 0.077 | 0.590 | Fe3Ge5 |

| 12 | 29.37 | 37.8 | 29.68 | 6.3 | 707.16 | 3.8 | 708.49 | 0.99 | 0.086 | 0.603 | Fe3Ge5 |

The strongest conclusion from the XPS analysis is related to the Ge-rich character of the interface. One might argue that electron inelastic mean free path (IMFP) effects on the order of 1 nm for Fe 2p electrons and of 2 nm for Ge 3d electrons [

33] have to be taken into account; however, a detailed analysis reveals the fact that for the thickest layer investigated in this study, its total thickness is on the order of 3

λαωγ, where

λavg is the average IMFP, about 1.5 nm. Moreover, working only with the “reacted” Ge 3d component ensures that the composition estimates are related only to the Fe–Ge reacted layer. It may happen that the composition varies with the depth from the sample surface; therefore, all estimates from the last two columns of

Table 1 may be regarded just as averages on the investigated thickness of 4–5 nm.

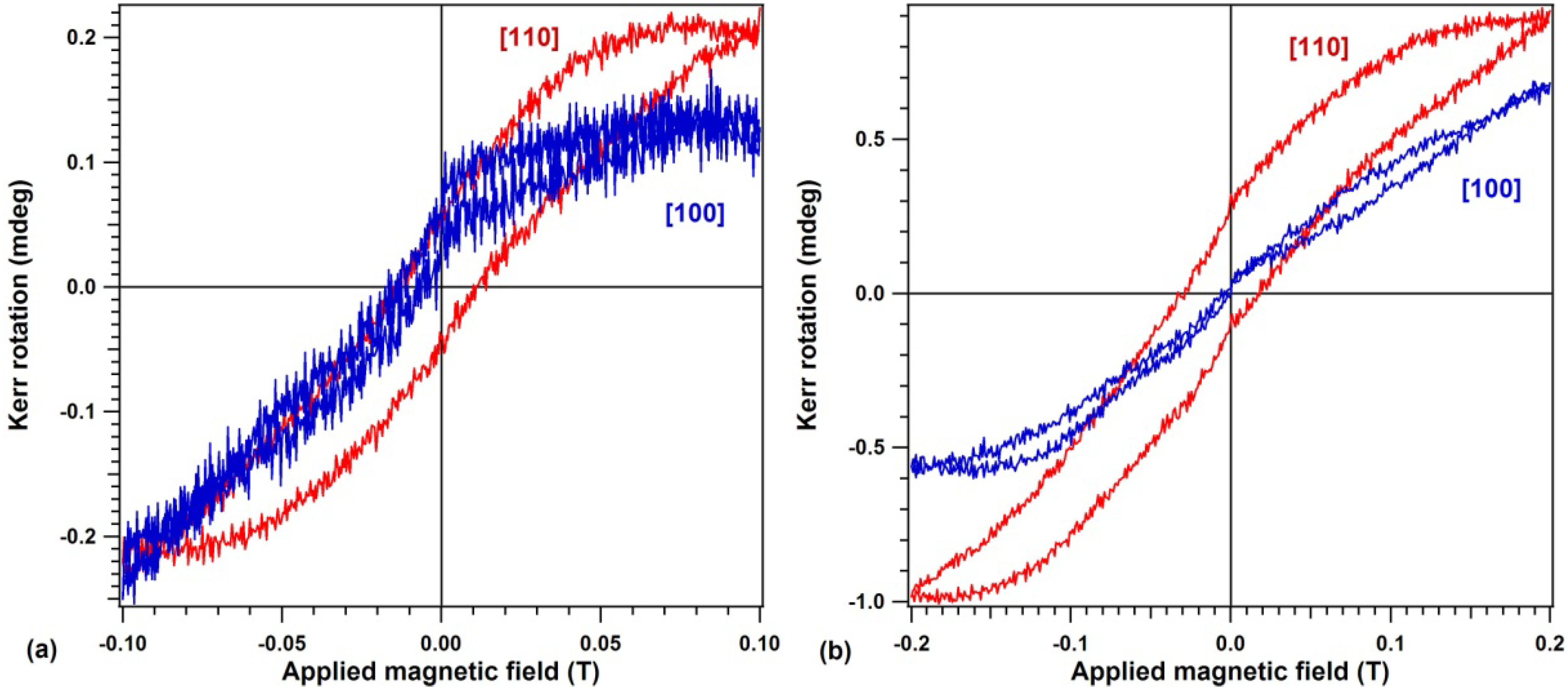

3.3. Magneto-Optical Kerr Effect

Figure 4 represents magneto-optical Kerr effect (MOKE) hysteresis loops obtained on the capped 12 ML FeGe(001) sample with the linear polarization of the light contained in the plane defined either by the [001] off-normal direction with one in-plane [100] direction (or, equivalently, with the magnetic field vector oriented along the [101] direction), or with the sample rotated by 45° along its surface normal [001],

i.e., with the light linear polarization contained in the plane defined by [001] and one in-plane [110] direction, equivalent to magnetic field oriented along [111]. A different behavior is observed along these directions. It seems that the [110] axis behaves like an easy magnetization axis, whereas the [100] axis behaves as a hard magnetization axes. This observation is in line with most reports on the uniaxial magnetic anisotropy in Fe layers grown on Ge in different conditions [

16,

17,

18,

19,

20,

21]. Nevertheless, this is the first time that such a phenomenon is observed for a so diluted Fe system in Ge(001). For the origin of the magnetic anisotropy, one cannot invoke in this case preparation conditions, such as e.g., oblique evaporation, since the evaporation proceeded here almost normal to the surface and, anyway, the substrate temperature washes out any initial momentum of the incoming atoms. We rather prefer to infer that this uniaxial magnetic anisotropy is an intrinsic property of magnetic metals accommodating either into, or on, diamond-like (or zincblende) structures. If, for instance, we try to simulate a hypothetical Fe

3Ge

5 (or even a Fe

2Ge

6) compound as starting from a zincblende Fe

4Ge

4 cell and substituting one Fe atom by one Ge, there will still be a high probability to find a second order Fe neighbor for a Fe atom. The line connecting these two neighbors belongs to the {110} family of lines. It is then straightforward that an eventual arrangement of the momenta is favored when the orienting field is applied along one of these directions.

Figure 4.

Magneto-optical (MOKE) hysteresis loop for a sample consisting of 12 ML Fe deposited in Ge(001) at 500 °C, with the linear polarization vector of the incident light in the plane defined by the [001] and [100] direction (blue curve), and in the plane defined by the [001] and [110] direction (red curve). (a) Maximum applied field 0.1 T; (b) Maximum applied field 0.2 T.

Figure 4.

Magneto-optical (MOKE) hysteresis loop for a sample consisting of 12 ML Fe deposited in Ge(001) at 500 °C, with the linear polarization vector of the incident light in the plane defined by the [001] and [100] direction (blue curve), and in the plane defined by the [001] and [110] direction (red curve). (a) Maximum applied field 0.1 T; (b) Maximum applied field 0.2 T.

The total MOKE signal obtained from

Figure 4b of about 1 mdeg may be used to estimate the magnetic moment of Fe, together with the XPS data. For the calibration of the present setup [

26], 2.5 mdeg of MOKE signal corresponds to 1 nm of a bulk bcc Fe layer with a density of 0.85 × 10

23 cm

−3) and with 2.2 μ

B per atom. In the actual sample there are about 1.7 nm of Fe deposited, computed with respect to the bulk

bcc Fe density. Therefore, the MOKE signal implies an atomic magnetic moment of (1/2.5) × (1/1.7) × 2.2 μ

B ≈ 0.75 μ

B per Fe atom. A similar computation yields about 0.1 μ

B per Fe atom for the lower field hysteresis curves from

Figure 4a. Therefore, the maximum magnetic moment observed in this experiment is about one third from the signal of the bulk Fe at room temperature. Small Fe moments were reported also in other cases for Fe atoms located at the interface with Ge [

34]. On the other hand, although measurements at larger fields were not performed during this series of experiments, there are serious reasons to believe that the hysteresis loop from

Figure 4b is still a minor loop and the maximum Fe moment approaches about 1 μ

B, which seems to be a universally accepted value for the atomic magnetic moment measured at room temperature on reacted Fe layers deposited on III–V semiconductors [

6,

7,

9]. We must stress here that this is the first time that ferromagnetism is detected in a Ge-rich Fe–Ge surface compound. Also, along the [110] in-plane direction the ferromagnetism is quite robust, since the coercitive field is about 230 Oe, much larger than the reported coercitive fields for Fe grown on Ge [

16,

17,

18,

19,

20,

21]. The measured coercitive fields for FeGe(001) largely exceed that of metal Fe or even of reacted Fe on Si(001) [

10,

11]. There seems to be also a small exchange bias pf about 50 Oe in

Figure 4b, since for the measurement with maximum applied field 0.2 T the two coercitive fields are 180 Oe in the positive direction and 280 Oe in the negative direction. In the absence of more detailed investigations, we cannot yet suggest the origin of the eventual two phases (ferromagnetic and antiferromagnetic) present at the sample’s surface. It is tempting to assess the overall composition derived in

Table 1 for the 12 ML sample as Fe

3Ge

5 being composed of FeGe

2 (antiferromagnetic) + FeGe (ferromagnetic). If this were true, then Fe in the ferromagnetic phase would have an atomic magnetic moment close to that of the bulk Fe, since only one third of the Fe atoms would be ferromagnetic ordered. However, in absence of more detailed determinations by high resolution XPS using synchrotron radiation and/or photoelectron diffraction (planned for the future), one cannot be completely sure about this hypothesis. Also, future measurements on temperature dependence of magnetization will be investigated to elucidate this aspect.

In the case of Fe deposited on Si(001) at similar elevated temperatures (470 °C), Reference [

35] reported AFM images exhibiting elongated islands of approximate size (10 × 20) to (10 × 50) nm

2, with the long edge aligned along the [110] directions. Such elongated islands might be the origin of the observed easier magnetization axis along [110]. In order to check this hypothesis, we performed a similar AFM investigation under air (Asylum research, at room temperature), represented in

Figure 5. It can easily be seen that the sample surface is nanostructured, with the formation of regular islands of approximate size of 20–30 nm. We did not observe the formation of elongated islands, as exhibited by

Figure 2 of [

35], although several scans were performed. The surface looks quite homogenous and

Figure 5 represents a typical example of a surface topology. The computed root mean square (RMS) roughness is 2.34 nm, which is slightly larger than the equivalent thickness of the deposited Fe film (12 ML ≈ 1.72 nm), but considerably lower than the equivalent thickness of a diamondlike FeGe(001) structure obtained with the same amount of Fe deposited: the density of Fe atoms of such a structure is about four times lower than in bulk

bcc Fe, therefore the equivalent thickness of FeGe formed at the surface would be in the range of 6.88 nm. We recall that, anyway, the absence of elongated Fe-containing stripes excludes the hypothesis that some shape anisotropy is responsible for the observed anisotropy in the MOKE hysteresis loops. We conclude by proposing that the observed anisotropy is a true microscopic property, not connected to the surface morphology.

Finally, the small displaced loops obtained with the field along the [100] direction for a maximum applied field of 0.2 T (

Figure 4b) are not a sign of ferromagnetism; they were recorded also for a separate sample consisting on 3 nm Cu deposited on Ge(001), used to test the MOKE system for any spurious signal. Therefore, one may infer that the area of the hysteresis loop when the field is applied along [100] is almost zero.

Figure 5.

Atomic force microscopy images obtained at room temperature and in air on 12 ML Fe deposited on Ge(001) at 500 °C, amplitude signal.

Figure 5.

Atomic force microscopy images obtained at room temperature and in air on 12 ML Fe deposited on Ge(001) at 500 °C, amplitude signal.