Factors Affecting the Effectiveness of Inorganic Silicate Sealer Material through Multi-Quality Characteristics

Abstract

:1. Introduction

2. Experimental Procedure

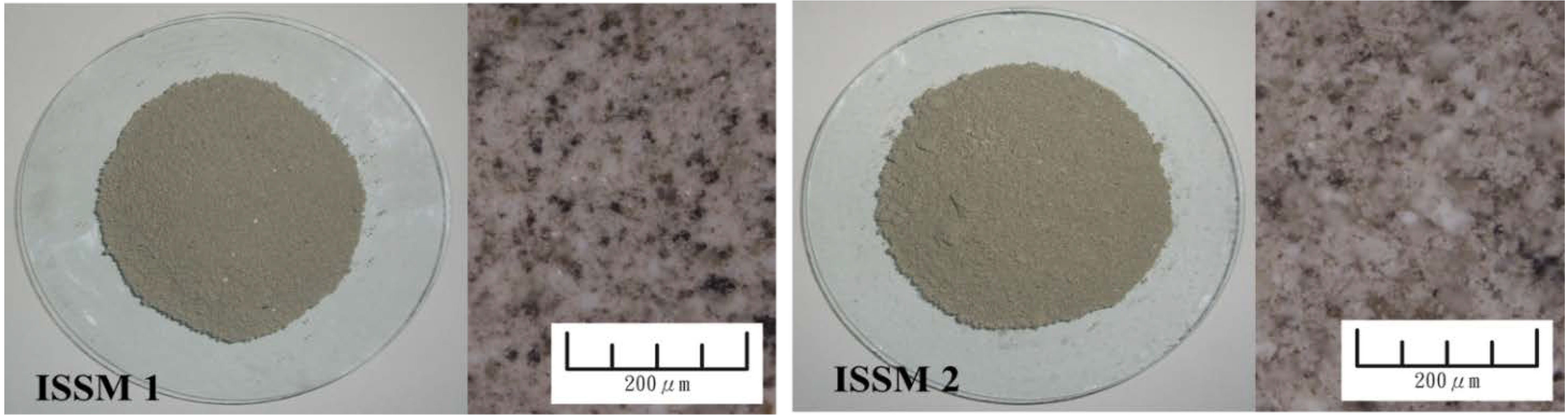

2.1. Materials and Specimens

| Chemical compositions (%) | Substrate | Inorganic silicate sealer material | ||

|---|---|---|---|---|

| cement | fly ash | ISSM1 | ISSM2 | |

| Calcium oxide, CaO | 63.56 | 2.82 | 25.23 | 34.33 |

| Silicon dioxide, SiO2 | 21.04 | 56.48 | 33.77 | 28.46 |

| Aluminum oxide, Al2O3 | 5.46 | 20.34 | 5.90 | 4.47 |

| Ferric oxide, Fe2O3 | 2.98 | 6.61 | 5.27 | 4.75 |

| Sulfur trioxide, SO3 | 2.01 | 0.25 | 1.07 | 1.38 |

| Sodium oxide, Na2O | 0.32 | 0.33 | 15.00 | 12.12 |

| Potassium oxide, K2O | 0.70 | 0.80 | 0.83 | 1.10 |

| Magnesium oxide, MgO | 2.52 | 0.93 | 6.20 | 7.43 |

| Loss on ignition, L.O.I. | 1.38 | 2.76 | 1.54 | 1.84 |

| Others | 0.03 | 8.68 | 5.19 | 4.12 |

| Mixture | Mix proportions of mortar (kg/m3) | ||||

|---|---|---|---|---|---|

| W/C ratio | Cement | Water | Fly ash | Sand | |

| Mix 1 | 0.45 | 523 | 235 | 0 | 1437 |

| Mix 2 | 0.45 | 413 | 233 | 103 | 1421 |

| Mix 3 | 0.65 | 471 | 306 | 0 | 1295 |

| Mix 4 | 0.65 | 373 | 303 | 93 | 1282 |

2.2. Experiments

2.3. Taguchi Method

2.3.1. Quality Characteristics

2.3.2. Orthogonal Array

| Control factors | Level | ||

|---|---|---|---|

| A | Sealer Materials type | ISSM1 | ISSM2 |

| B | Sealer Materials ratio | 5:2 | 5:3 |

| C | Sealer layers | 1 | 2 |

| D | Sealer cumulative time (days) | 28 | 3 |

| E | Water-binder ratio of substrate | 0.45 | 0.65 |

| F | Moist curing age (days) | 3 | 28 |

| G | Adding fly ash in substrate | 0% | 20% |

| Experiment No. | Control factors and levels | ||||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

| 3 | 1 | 1 | 2 | 2 | 2 | 1 | 1 |

| 4 | 1 | 2 | 1 | 2 | 2 | 1 | 2 |

| 5 | 1 | 2 | 2 | 1 | 2 | 2 | 1 |

| 6 | 1 | 2 | 2 | 2 | 1 | 2 | 2 |

| 7 | 2 | 1 | 2 | 2 | 1 | 1 | 2 |

| 8 | 2 | 1 | 2 | 1 | 2 | 2 | 2 |

| 9 | 2 | 1 | 1 | 2 | 2 | 2 | 1 |

| 10 | 2 | 2 | 2 | 1 | 1 | 1 | 1 |

| 11 | 2 | 2 | 1 | 2 | 1 | 2 | 1 |

| 12 | 2 | 2 | 1 | 1 | 2 | 1 | 2 |

2.3.3. Analysis of Variance

2.4. Grey Relational Analysis (GRA)

3. Results and Discussion

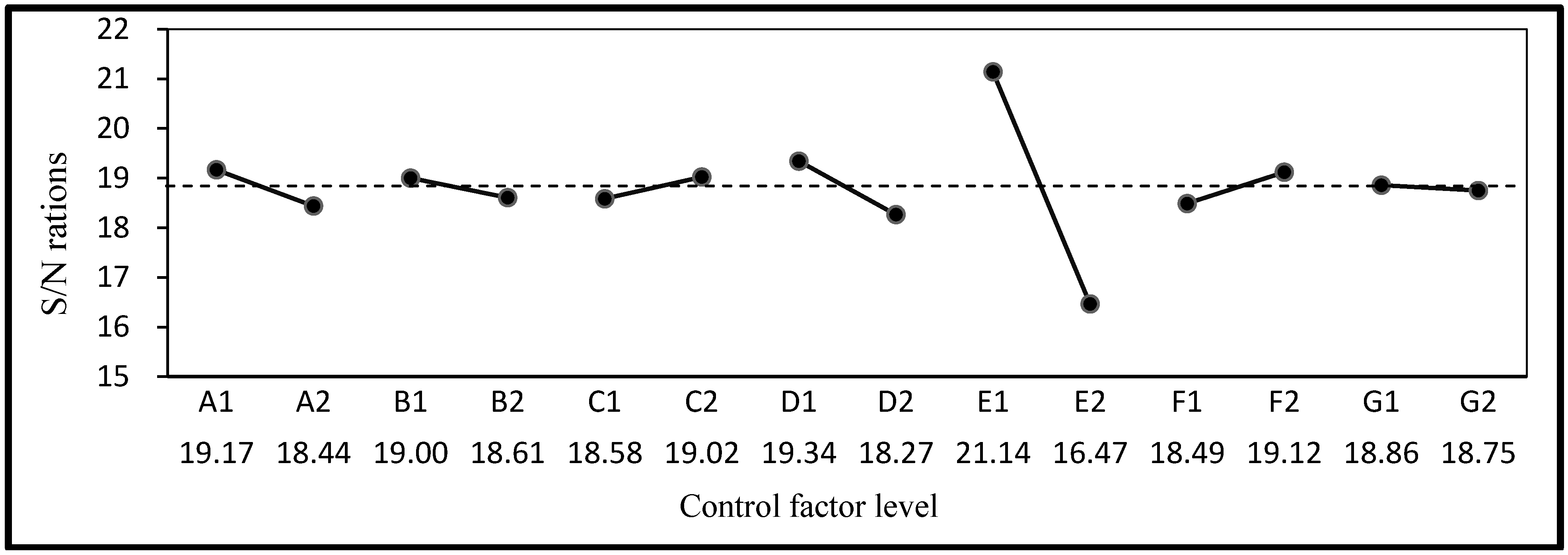

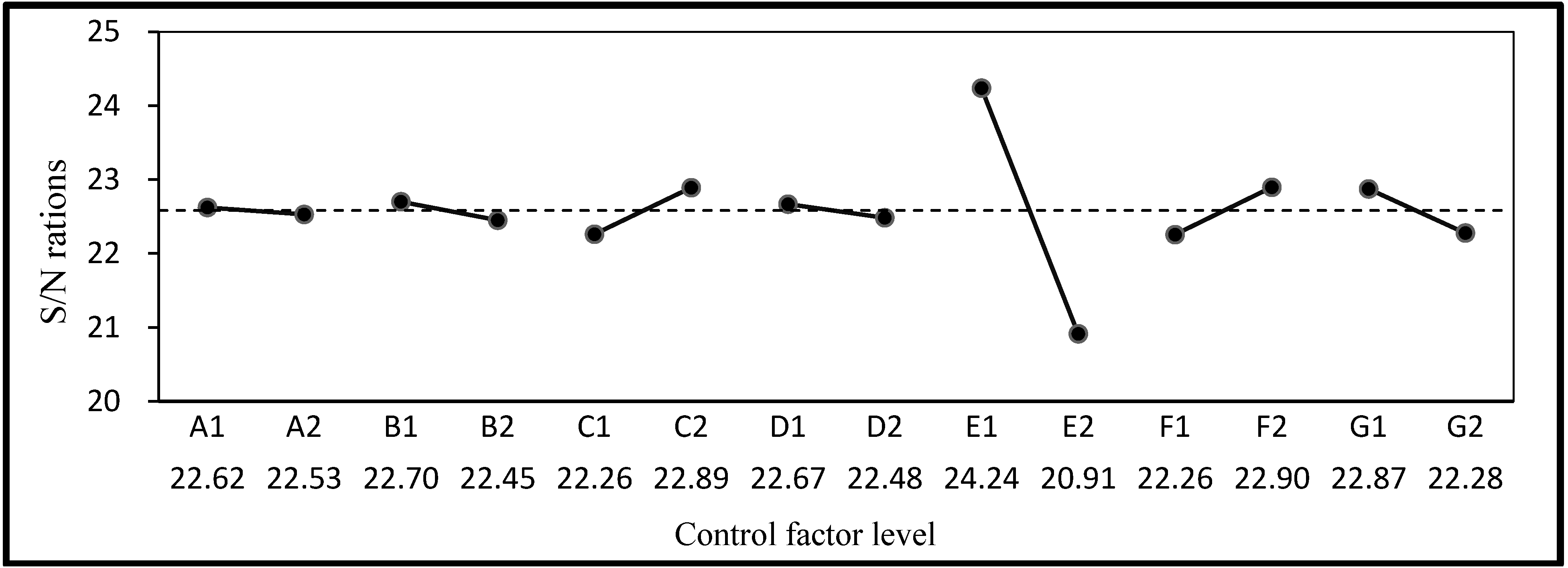

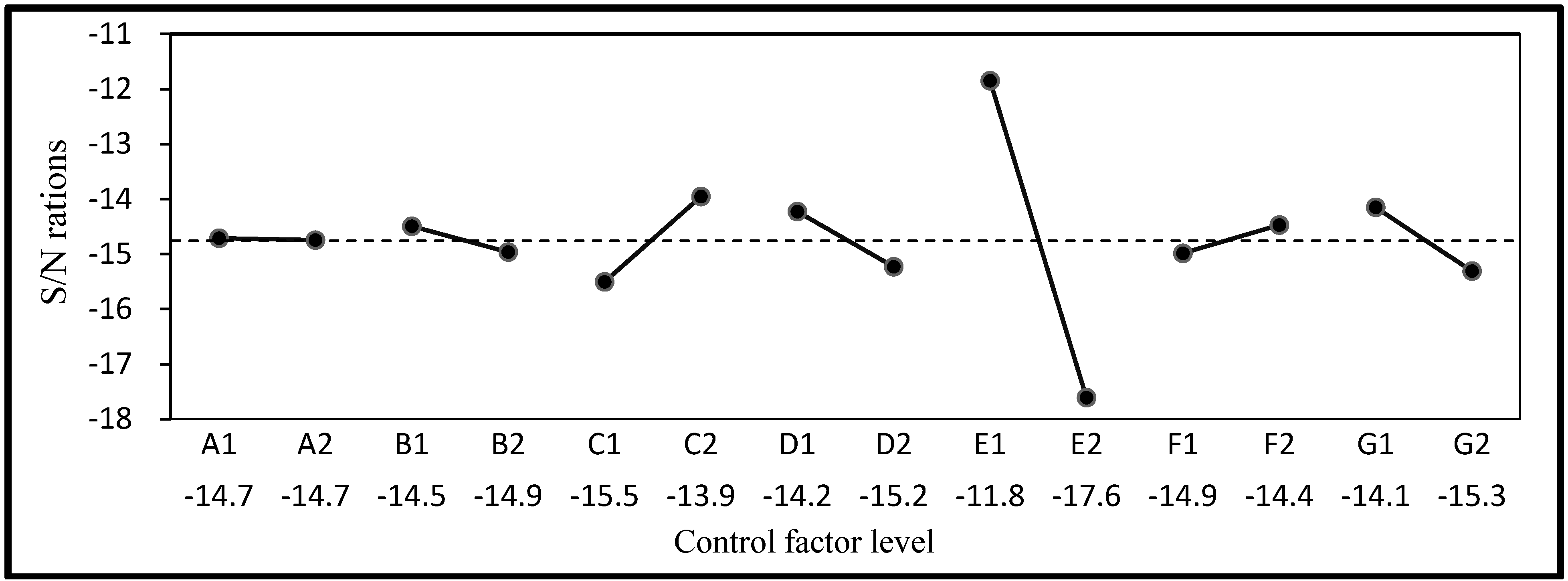

3.1. S/N Ratios Calculations of Taguchi Method

| No. | Compressive strength | Resistivity | Water absorption | Permeability | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ave | S | S/N (dB) | Ave | S | S/N (dB) | Ave | S | S/N (dB) | Ave | S | S/N (dB) | |

| (MPa) | mV | (%) | (g) | |||||||||

| 1 | 71.63 | 1.49 | 37.10 | 12.67 | 0.50 | 22.04 | 6.02 | 0.0023 | 24.40 | 3.75 | 0.30 | −11.49 |

| 2 | 69.73 | 2.12 | 36.86 | 12.60 | 0.17 | 22.01 | 6.33 | 0.0016 | 23.97 | 4.07 | 0.61 | −12.26 |

| 3 | 46.94 | 1.51 | 33.42 | 6.37 | 0.12 | 16.08 | 8.84 | 0.0022 | 21.07 | 6.71 | 1.78 | −16.73 |

| 4 | 40.25 | 2.17 | 32.07 | 6.83 | 0.32 | 16.67 | 9.91 | 0.0020 | 20.08 | 9.08 | 0.54 | −19.17 |

| 5 | 47.68 | 1.07 | 33.56 | 7.53 | 0.35 | 17.52 | 8.09 | 0.0017 | 21.84 | 6.34 | 1.06 | −16.12 |

| 6 | 65.44 | 1.12 | 36.31 | 10.87 | 0.60 | 20.70 | 6.04 | 0.0011 | 24.38 | 4.22 | 0.14 | −12.51 |

| 7 | 59.94 | 2.43 | 35.54 | 10.07 | 0.38 | 20.05 | 6.38 | 0.0023 | 23.90 | 4.25 | 0.49 | −12.60 |

| 8 | 45.15 | 1.26 | 33.09 | 8.33 | 0.40 | 18.40 | 8.21 | 0.0025 | 21.71 | 5.99 | 0.57 | −15.58 |

| 9 | 39.39 | 0.72 | 31.90 | 5.93 | 0.32 | 15.44 | 8.75 | 0.0038 | 21.15 | 8.21 | 0.83 | −18.32 |

| 10 | 70.49 | 2.66 | 36.95 | 11.77 | 0.31 | 21.41 | 5.99 | 0.0016 | 24.45 | 3.21 | 0.46 | −10.19 |

| 11 | 68.42 | 1.50 | 36.70 | 10.80 | 0.36 | 20.66 | 6.08 | 0.0012 | 24.33 | 3.97 | 0.66 | −12.05 |

| 12 | 38.10 | 1.41 | 31.61 | 5.43 | 0.25 | 14.68 | 10.42 | 0.0052 | 19.64 | 9.68 | 0.86 | −19.74 |

3.2. Analysis of Variance

| Control factor | Compressive strength | Resistivity | Water absorption | Permeability |

|---|---|---|---|---|

| A | 1.99% | 2.05% | 0.07% | 0.00% |

| B | 0.08% | 0.60% | 0.51% | 0.56% |

| C | 1.10% | 0.74% | 3.18% | 6.11% |

| D | 1.64% | 4.45% | 0.27% | 2.55% |

| E | 90.02% | 83.98% | 88.77% | 84.19% |

| F | 0.48% | 1.53% | 3.30% | 0.67% |

| G | 2.74% | 0.04% | 2.85% | 3.41% |

| Error | 1.94% | 6.61% | 1.05% | 2.52% |

| Total | 100% | 100% | 100% | 100% |

3.3. Grey Relational Analysis

| No. | Grey relational coefficients | Grey relational grades | ||||||

|---|---|---|---|---|---|---|---|---|

| Compressive strength | Resistivity | Water absorption | Permeability | Equally weighted | Rank | Entropy weights | Rank | |

| 1 | 1.0000 | 1.0000 | 0.9814 | 0.7858 | 0.9418 | 2 | 0.9486 | 1 |

| 2 | 0.9205 | 0.9909 | 0.8339 | 0.6979 | 0.8608 | 3 | 0.8723 | 3 |

| 3 | 0.4275 | 0.3815 | 0.4161 | 0.4220 | 0.4118 | 9 | 0.4116 | 9 |

| 4 | 0.3532 | 0.4067 | 0.3551 | 0.3471 | 0.3655 | 11 | 0.3666 | 10 |

| 5 | 0.4371 | 0.4487 | 0.4795 | 0.4461 | 0.4529 | 8 | 0.4509 | 8 |

| 6 | 0.7780 | 0.7324 | 0.9713 | 0.6731 | 0.7887 | 5 | 0.7817 | 5 |

| 7 | 0.6381 | 0.6485 | 0.8128 | 0.6647 | 0.6910 | 6 | 0.6823 | 6 |

| 8 | 0.4063 | 0.5023 | 0.4678 | 0.4698 | 0.4615 | 7 | 0.4587 | 7 |

| 9 | 0.3458 | 0.3579 | 0.4221 | 0.3700 | 0.3740 | 10 | 0.3700 | 11 |

| 10 | 0.9490 | 0.8533 | 1.0000 | 1.0000 | 0.9506 | 1 | 0.9450 | 2 |

| 11 | 0.8732 | 0.7271 | 0.9511 | 0.7192 | 0.8176 | 4 | 0.8155 | 4 |

| 12 | 0.3333 | 0.3333 | 0.3333 | 0.3333 | 0.3333 | 12 | 0.3333 | 12 |

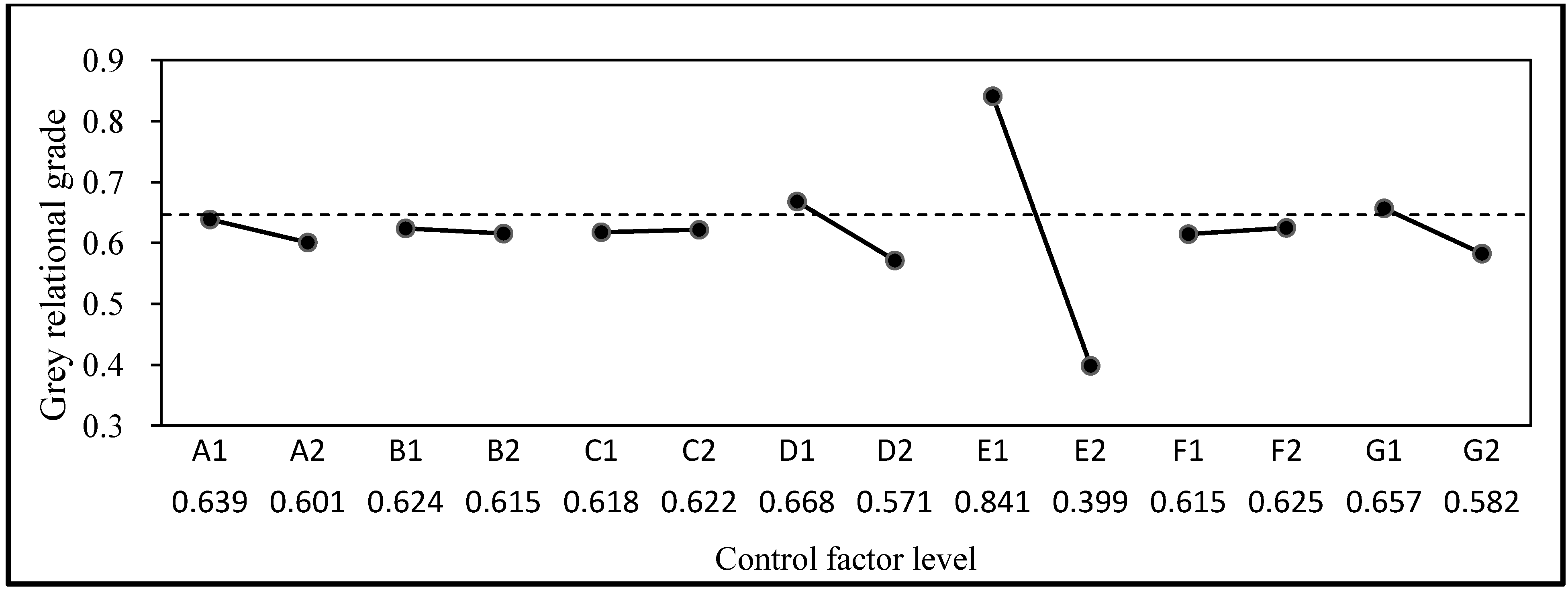

3.4. The Weighted Grey-Taguchi Method

| Control factor | Sum of squares | Degrees of freedom | Variance | F-test | Contribution ratio |

|---|---|---|---|---|---|

| A | 0.004 | 1 | 0.004 | 1.092 | 0.66% |

| B | 0.000 | 1 | 0.000 | 0.054 | 0.03% |

| C | 0.000 | 1 | 0.000 | 0.012 | 0.01% |

| D | 0.028 | 1 | 0.028 | 7.164 | 4.31% |

| E | 0.587 | 1 | 0.587 | 149.439 | 89.99% |

| F | 0.000 | 1 | 0.000 | 0.080 | 0.05% |

| G | 0.017 | 1 | 0.017 | 4.228 | 2.55% |

| Error | 0.016 | 4 | 0.004 | - | 2.41% |

| Total | 0.652 | 11 | - | - | 100.00% |

3.5. Investigation of Key Protective Factors

4. Conclusions

- The weighted Grey-Taguchi method quantifies the performance of multi-quality characteristics, thus providing assistance in the search for key factors for ISSM in concrete protection.

- Regarding the contribution percentage of the multi-quality characteristics, factors A, D, E, and G showed the higher contribution percentages than any others. Factors A and D affect the protective property of the specimen quality because of the property of the sealer material. In contrast, the effects of factors E and G are caused by the quality of the substrate.

- The optimal results for the parameters of the multi-quality characteristics are obtained by using GRA. The optimal results from the equal weights occur in the tenth ranking of the grey relational grades, while for entropy weights the optimal results occur in the first ranking.

- The Standard deviation in experimental data is a key element influencing factor. A higher discrete degree in standard deviation affects the importance of individual influence factors as well as the entropy weights of grey relational grades.

- The ISSM1(A1), sealer materials ratio of 5:2(B1), and 2 sealer layers(C2) have the superior performance for the surface protection of concrete in coating materials, whereas sealer cumulative time 28days(D1) and moist curing age 28days(F2) in environmental conditions. In addition, the less effectiveness of concrete protection results in the more density of concrete.

References

- Zhang, M.H.; Gjorv, O.E. Effect of silica fume on pore structure and chloride diffusivity of low porosity cement pastes. Cem. Concr. Res. 1991, 21, 1006–1014. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice Hall: Upper Saddle River, NJ, USA, 2003; pp. 477–504. [Google Scholar]

- Male, R.L.A. Pore structure and permeability of cementitious materials. Mater. Res. Soc. Symp. Proc. 1998, 137, 403–410. [Google Scholar] [CrossRef]

- Harutyunyan, V.S.; Abovyan, E.S.; Monteiro, P.J.M.; Mkrtchyan, V.P.; Balyan, M.K. Microstrain distribution in calcium hydroxide present in the interfacial transition zone. Cem. Concr. Res. 2000, 30, 709–713. [Google Scholar] [CrossRef]

- Gallucci, E.; Scrivener, K. Crystallisation of calcium hydroxide in early age model and ordinary cementitious systems. Cem. Concr. Res. 2007, 37, 492–501. [Google Scholar] [CrossRef]

- Brandt, M. Cement-based Composites Materials, Mechanical Properties and Performance; E & FN SPON: London, UK, 1995; pp. 116–118. [Google Scholar]

- Garboczi, E.J. Permeability, diffusivity and microstructural parameters: A critical review. Cem. Concr. Res. 1990, 20, 591–601. [Google Scholar] [CrossRef]

- Halit, Y. The effect of curing conditions on compressive strength of ultra high strength concrete with high volume mineral admixtures. Build. Environ. 2007, 42, 2083–2089. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrez, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Han, Y.M.; Dong, G.S.; Doo, S.C. Evaluation of the durability of mortar and concrete applied with inorganic coating material and surface treatment system. Constr. Build. Mater. 2007, 21, 362–369. [Google Scholar] [CrossRef]

- Michael, T.K. Construction Waterproofing Handbook, 2nd ed.; McGraw-Hill Professional: New York, NY, USA, 2008. [Google Scholar]

- Geoff, M. Durability of Concrete Structures: Investigation, Repair, Protection; Taylor & Francis: Oxford, UK, 1992; Chapter 5. [Google Scholar]

- Mamaghani, I.H.P.; Moretti, C.J.; Dockter, B.A. Application of Sealing Agents in Concrete Durability of Infrastructure Systems; University of North Dakota: Grand Forks, ND, USA, 2007. [Google Scholar]

- Ozbay, E.; Oztasb, A.; Baykasogluc, A.; Ozbebekd, H. Investigating mix proportions of high strength self compacting concrete by using Taguchi method. Constr. Build. Mater. 2009, 23, 694–702. [Google Scholar] [CrossRef]

- Chang, C.Y.; Huang, R.; Lee, P.C.; Weng, T.L. Application of a weighted Grey-Taguchi method for optimizing recycled aggregate concrete mixtures. Cem. Concr. Compos. 2011, 33, 1038–1049. [Google Scholar] [CrossRef]

- Tarng, Y.S.; Juang, S.C.; Chang, C.H. The use of grey-based Taguchi methods to determine submerged arc welding process parameters in hard facing. J. Mater. Process. Technol. 2002, 128, 1–6. [Google Scholar] [CrossRef]

- Pan, L.K.; Wang, C.C.; Wei, S.L. Optimizing multi-quality characteristics via Taguchi method-based Grey analysis. J. Mater. Process. Technol. 2007, 182, 107–116. [Google Scholar] [CrossRef]

- Seneviratne, A.M.G.; Sergi, G.; Page, C.L. Performance characteristics of surface coatings applied to concrete for control of reinforcement corrosion. Constr. Build. Mater. 2000, 14, 55–59. [Google Scholar] [CrossRef]

- Moradllo, M.K.; Shekarchi, M.; Hoseini, M. Time-dependent performance of concrete surface coatings in tidal zone of marine environment. Constr. Build. Mater. 2012, 30, 198–205. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Peyronnard, O.; Benzaazoua, M. Alternative by-product based binders for cemented mine backfill: Recipes optimisation using Taguchi method. Miner. Eng. 2012, 29. [Google Scholar] [CrossRef]

- Xie, Y.; Mao, Z. Evaluation of residential energy-saving buildings based on grey relational analysis method. Procedia Eng. 2011, 29, 3149–3153. [Google Scholar] [CrossRef]

- Thompson, L.J. Characterization of silicate sealers on concrete. Cem. Concr. Res. 1997, 27, 1561–1567. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zou, S.-Y.; Huang, R.; Chi, M.-C.; Hsu, H.-M. Factors Affecting the Effectiveness of Inorganic Silicate Sealer Material through Multi-Quality Characteristics. Materials 2013, 6, 1191-1204. https://doi.org/10.3390/ma6031191

Zou S-Y, Huang R, Chi M-C, Hsu H-M. Factors Affecting the Effectiveness of Inorganic Silicate Sealer Material through Multi-Quality Characteristics. Materials. 2013; 6(3):1191-1204. https://doi.org/10.3390/ma6031191

Chicago/Turabian StyleZou, Si-Yu, Ran Huang, Mao-Chieh Chi, and Hui-Mi Hsu. 2013. "Factors Affecting the Effectiveness of Inorganic Silicate Sealer Material through Multi-Quality Characteristics" Materials 6, no. 3: 1191-1204. https://doi.org/10.3390/ma6031191