1. Introduction

A nickel-based superalloy always behaves well at high temperatures and has been widely used for critical structural components in aerospace and other industries for many years because of its good mechanical property balance, malleability and weld ability. Investment casting of nickel-based superalloy is often employed for complex-shaped components, such as gas turbines, blades, and rocket engines. However, solidification defects, and especially microporosity, are still the main reason for the high rejection rate of the castings. Microporosity often appears at some special sites, such as large thin-wall and variable cross-section parts in the casting. As is well acknowledged, microporosity deteriorates the fatigue, impact toughness, and tensile properties of the casting severely. The fatigue life of the casting with microporosity is only half of that without defects, as cracks often initiate at the edges of the microporosity [

1].

Based on the local solidification conditions, a large number of studies have focused on the formation of microporosity in the past several decades [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11]. For instance, the volume fraction of microporosity has been predicted quantitatively for a simple plate casting based on the transmission of solutes and Sievert’s law [

12]. An empirical parameter

was used in Niyama criterion to reflect the relationship between pressure drop and solidification conditions, and a threshold parameter was used for microporosity prediction [

13]. The criterion made good predictions for steels; however, serious errors were encountered in Al–Si alloys [

14]. Furthermore, the accurate Niyama value can hardly be obtained in most situations because it often varied with alloy composition and solidification conditions. For nickel-based superalloy, J. Lecomte-Beckers introduced a microporosity prediction model [

15], where the susceptibility of microporosity formation was expressed with an index,

, which is related to the solidification parameters and alloy properties and can be expressed by Equation (1).

Where,

is the viscosity of the liquid,

the solidification shrinkage,

n the number of interdendritic channels,

the tortuosity coefficient,

the density of liquid,

the gravitational constant,

the alloy solidification range,

the mushy zone thermal gradient and

the average solidification rate. However, some shortcomings were found in its practical application. For instance, the number of interdendritic channels and tortuosity coefficient are hard to get quantitatively. Lesoult summarized the physical principles of the formation of microporosity and pointed out that the local composition of liquid, local dendritic microstructure and local pressure drop within the mushy zone were the main causes for microporosity formation [

16]. Campbell found that oxide bifilms formed during turbulent pouring have a great influence on porosity. He pointed out that the interface between the non-wetted surfaces provides a location where porosity can form. Furthermore, clean metal and counter gravity pouring can reduce porosity [

17].

Based on Darcy’ law, Carlson and Beckermann proposed dimensionless Niyama criterion, where local thermal conditions, melt properties, and solidification characteristics were taken into consideration; this criterion can predict feeding-related microporosity caused by shallow temperature gradients other than gas porosity [

18]. Compared with the conventional Niyama criterion, the dimensionless one is more maneuverable and quantitative in predicting microporosity formation.

The objective of the present work was to extend the application of the dimensionless Niyama criterion from a simple plate casting to a complex thin-wall superalloy casting, before the ability and accuracy of the criterion were compared to the quantitative metallographic measurements.

2. Mathematical Model [18]

In this section, the main evolution of the dimensionless Niyama criterion was described. The criterion was built based on the directional solidification. The schematic of the physical model is shown in

Figure 1. It assumed that the liquid and solid densities (

,

) and the cooling rate (

) are constant during solidification. The nucleation difficulty of microporosity is negligible in our research; at the moment of microporosity formation, assuming local feeding stopped and the remaining shrinkage would develop with microporosity growing.

Figure 1.

The schematic of mushy zone solidifying. Reproduced from [

18].

Figure 1.

The schematic of mushy zone solidifying. Reproduced from [

18].

In

Figure 1, Darcy’s law can be expressed as:

fLVL = −

KdP/(

μdx), where,

is the liquid volume fraction,

the liquid velocity,

the melt pressure, and

x the spatial coordinate. The permeability

K in the mushy zone is determined by the Kozeny–Carman equation

K =

λ2/[180(1 −

fL)], where

is the secondary dendrite arm spacing (SDAS).

Based on previous assumptions, shrinkage velocity in the interdendritic zone can be expressed as:

VL = −

βR/

G, then,

. As the solid fraction increases, the liquid pressure

of the dendrite spacing decreases; when it reaches some critical pressure

, the shrinkage porosity will form. The critical pressure is determined by the pressure inside the porosity and the capillary pressure according to the Young–Laplace equation. In the vacuum-melted superalloy, dissolved gas is very limited; the equilibrium of the Young–Laplace equation of the microporosity should be determined by the capillary pressure. Therefore,

can be simplified to the surface tension between the microporosity and the surrounding liquid metal:

Pcr = −

Pσ = −2

σ/

r0, where

is the surface tension and the

is the initial radius curvature at microporosity formation. Assuming the constant viscosity, temperature gradient and cooling rate, the formation of microporosity in the mushy zone can be determined by integrating:

where

,

and

are the critical position, critical temperature and critical liquid fraction, respectively. Equation (2) can be rewritten by dimensionless temperature parameter

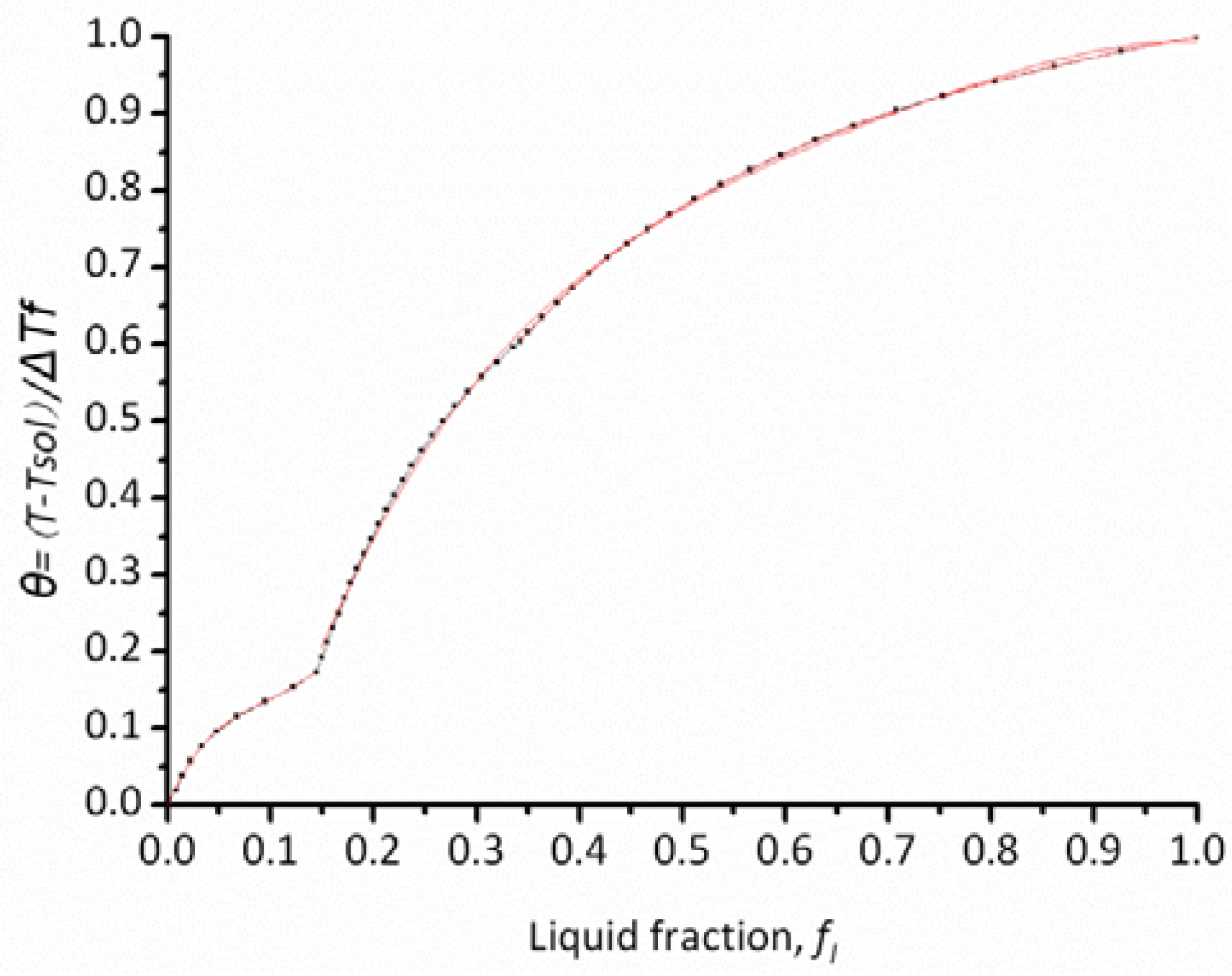

.

,

are the liquid temperature and solid temperature, respectively. So,

Where

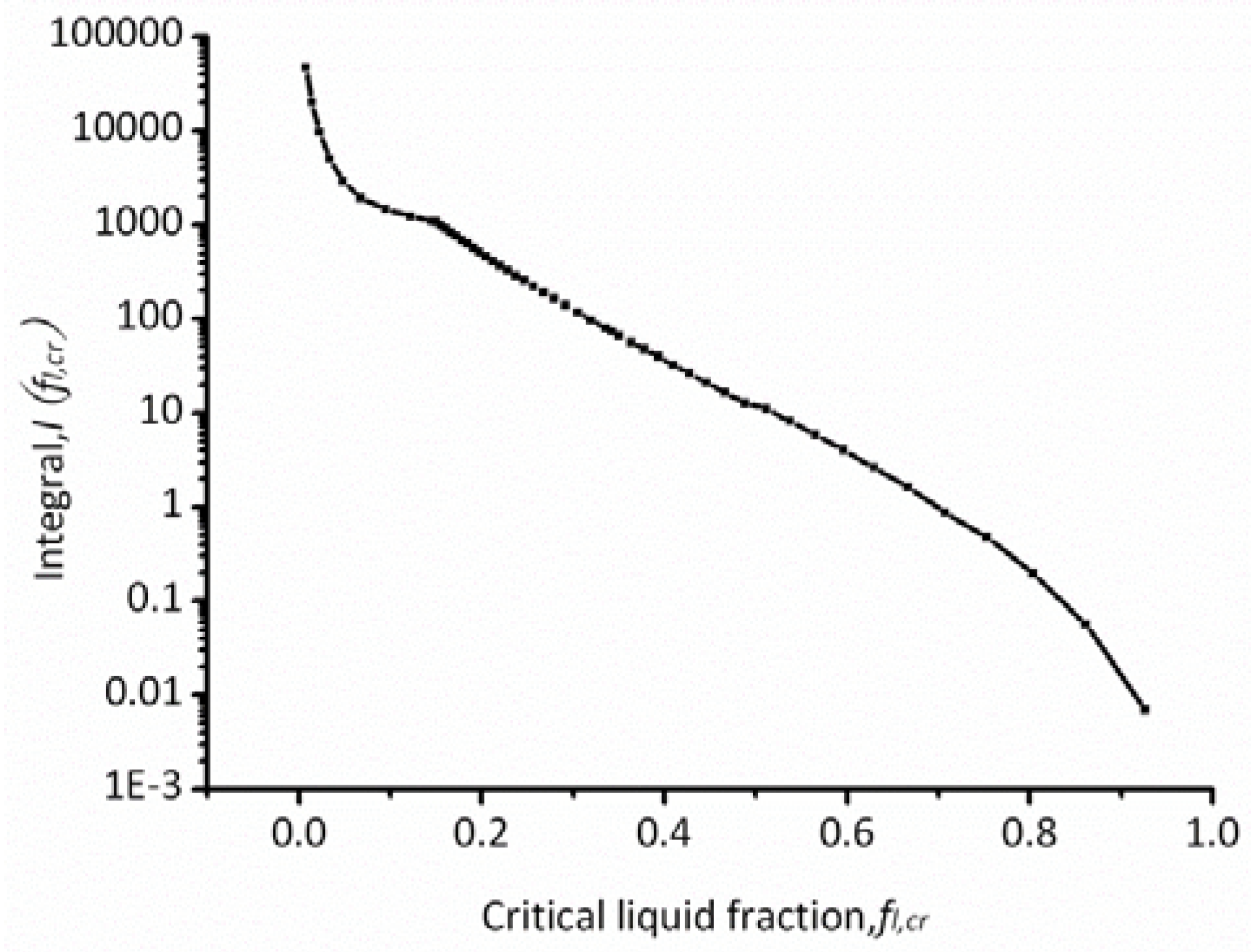

By the solid fraction-temperature curve, the integral can be evaluated and the dimensionless Niyama criterion

can be presented as:

Equation (5) accounts not only for the local solidification conditions, but also for the physical characteristics of the alloy.

When shrinkage porosity forms, the critical liquid fraction can be evaluated using Equations (3) and (5). Finally, the microporosity percentage of the alloy is obtained by Equation (6).

The advantage of the model is that the microporosity percentage can be calculated when the local solidification condition and material properties are given. According to Equations (3)–(6), the volume percentage of microporosity (

fp) can be expressed as the function of threshold dimensionless Niyama values (

). For the specific casting, the

can also be calculated directly using local solidification parameters and alloy properties, as shown in Equation (7)

Once the specific is obtained in the casting, the volume percentage of microporosity can be ensured by the − function.

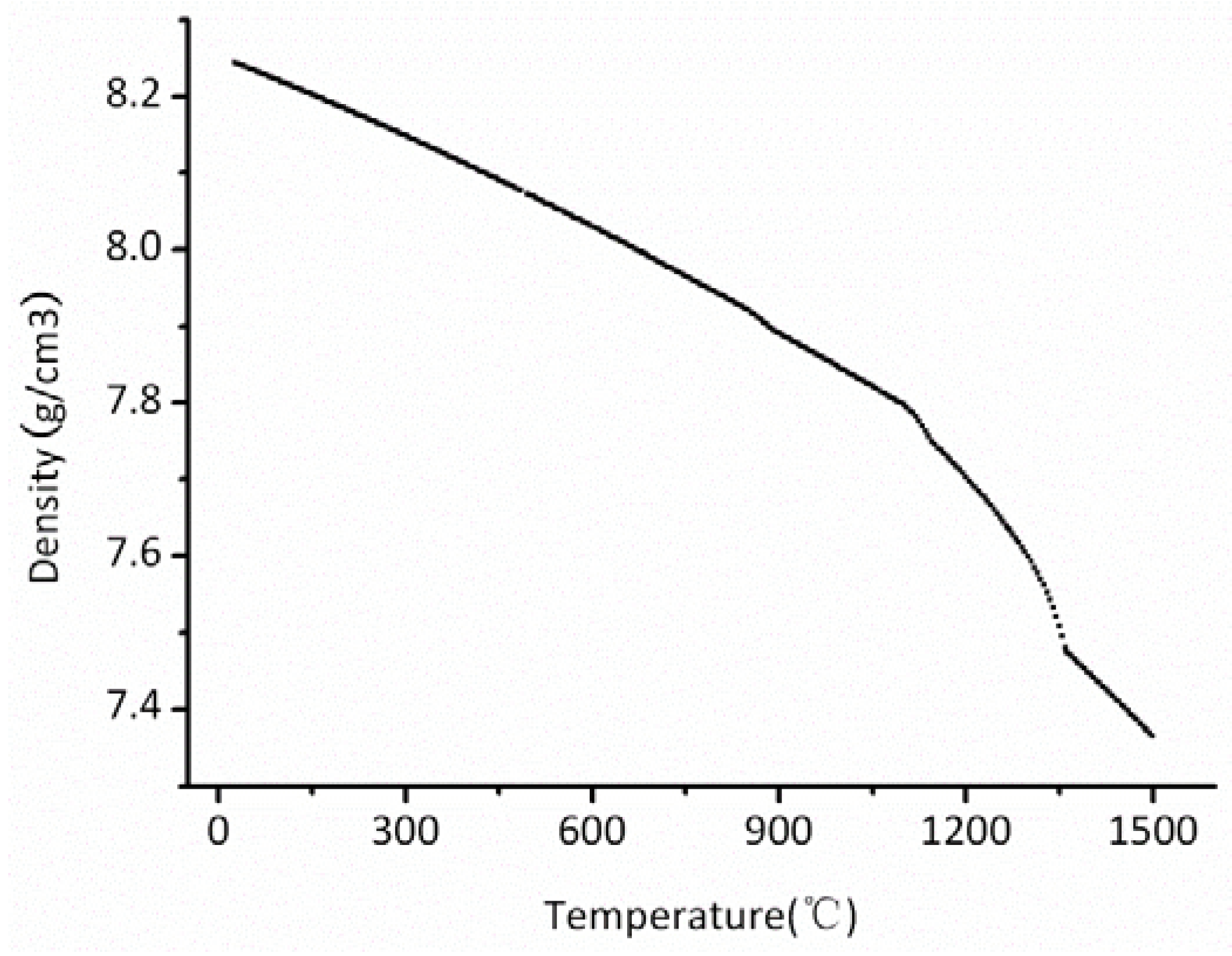

3. Simulation

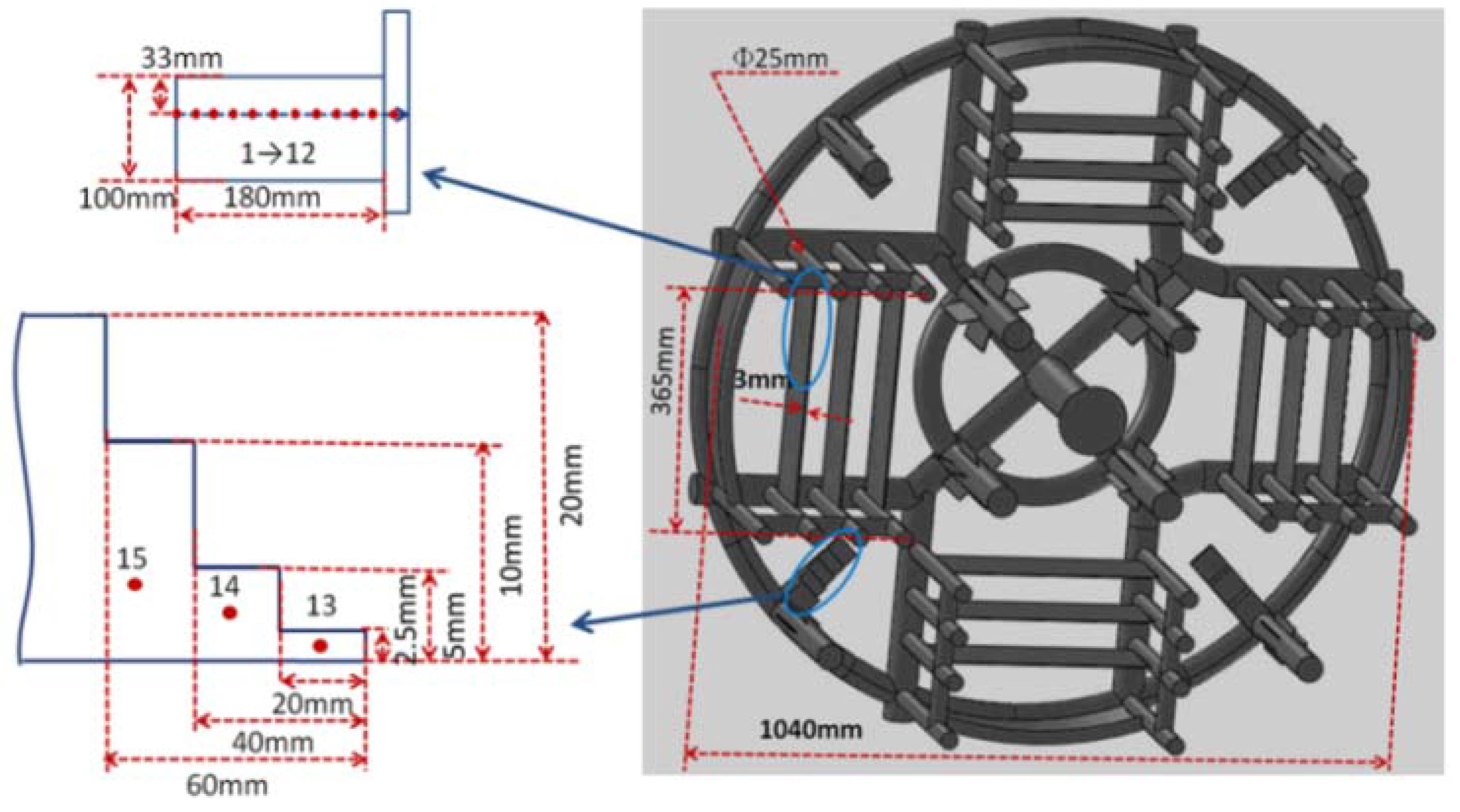

The morphology and thickness of the complex thin-wall casting are shown in

Figure 2. Two widely used softwares, JMatPro and ProCAST, were employed to calculate the parameters in the prediction. The curves of melt density-temperature and solid fraction-temperature were built by JMatPro. The criterion function (

−

) of the nickel-based superalloy were obtained using Equations (3)–(6). In order to calculate the specific threshold Niyama value (Equation 7) for different sites in the nickel-based superalloy casting, thermophyscial parameters, such as liquid dynamic viscosity, freezing range, and density were also calculated using the JMatPro package.

Figure 2.

The casting geometry and the sampling positions (Numbers: 1–15).

Figure 2.

The casting geometry and the sampling positions (Numbers: 1–15).

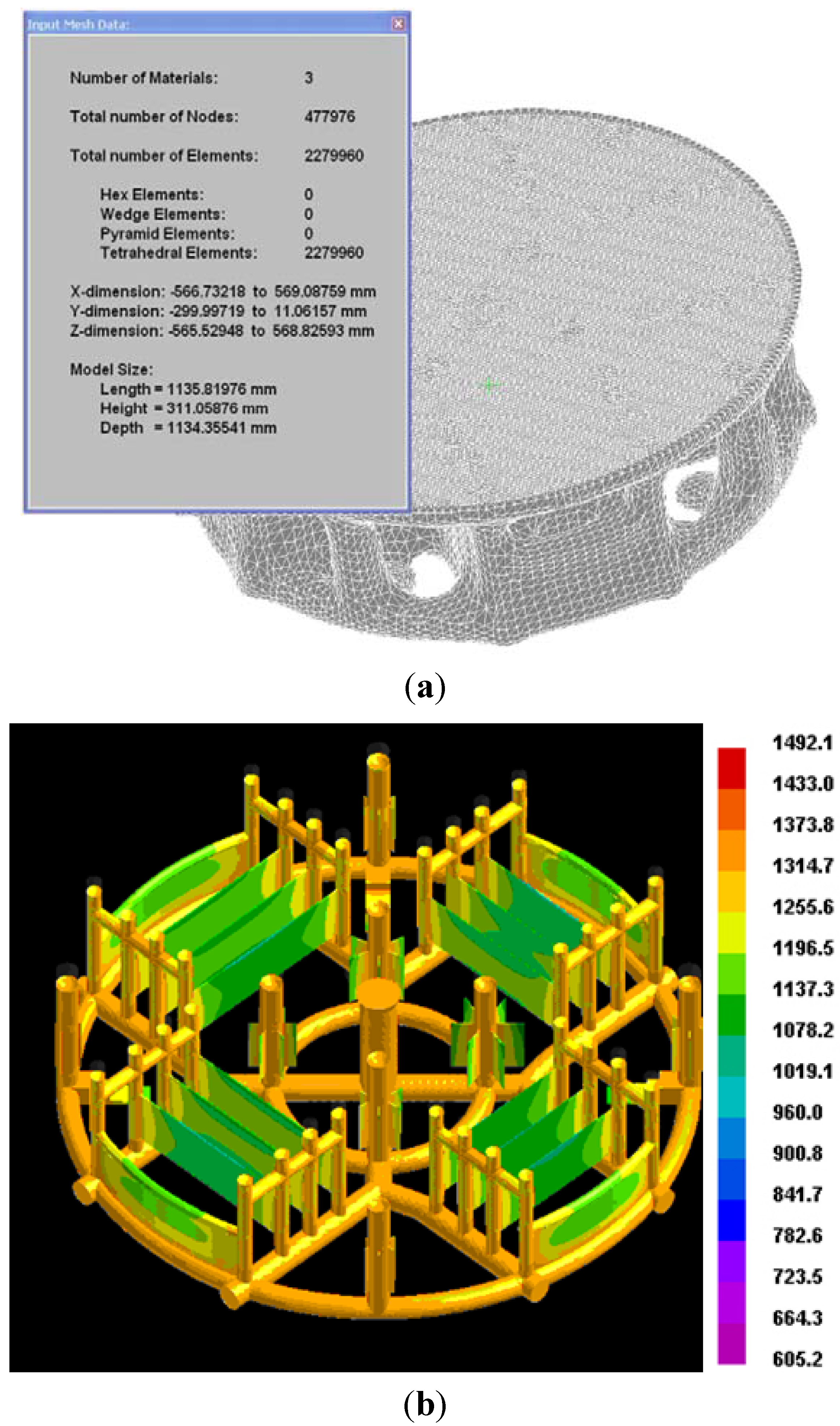

Commercial ProCAST software was used for the solidification simulation of the casting. Under normal circumstances, fine mesh has high precision in calculation. However, excessively fine mesh consumes a great deal of time and computer resources. In this simulation, different grinding sizes were taken to optimize the calculation, 5 mm grid for pouring system and 1 mm for the thin-wall casting. The thinnest parts of the complex thin-wall casting are about 3 mm, so it is reasonable to simulate the solidification process of the thin section with 1 mm mesh size. In ProCAST calculations, the shell was considered made from refractory-fused silica with a thickness of 15 mm. It is assumed that: (1) the shell was filled with the melt at 1500 °C at the speed of 20 kg/s; (2) the initial temperature of the shell kept constant at 1000 °C before pouring; (3) the heat transfer coefficient between melt and shell was constant at 1000 W/m

2·K [

19]; and (4) the radiation from shell to surrounding environment was a constant emissivity of 0.4 without considering heat convection [

20]. The calculation consumed about one day at HP workstations with 4 CPU cores and 4G memories. When ProCAST calculation finished, the temperature gradient and the cooling curve of different sites in the casting were collected directly by visual cast module of the software. The cooling rate at each site in the casting was gotten by the cooling curve.

The corresponding mesh was generated by meshCAST (a mode of ProCAST) (see

Figure 3a). The temperature profile (

Figure 3b) in the stepwise parts and thin-wall parts is approximately directional, so it is suitable for the use of dimensionless criterion.

The SDAS was determined using the research of Fisher and Kurz [

21], the function between SDAS and the cooling rate is shown in Equation (8).

According to previous experimental results, the SDAS of the specimens were measured quantitatively and the relation between SDAS and the cooling rate was established by linear fitting. Then, the coefficient () can be confirmed.

The dimensionless threshold Niyama values in Equation (7) were calculated and then used to predict the volume percentage of microporosity by the function of − (the dimensionless Niyama criterion).

Figure 3.

Finite element mesh and the temperature profile of the casting. (a) Digitized casting with shell; (b) Temperature field.

Figure 3.

Finite element mesh and the temperature profile of the casting. (a) Digitized casting with shell; (b) Temperature field.

4. Experimental

To examine the validity of the dimensionless Niyama criterion, the commercial nickel-based superalloy was used for the experiment. The chemical composition of the alloy was tested by Inductively Coupled Plasma (Model: ICAP 6000 Radial) and high frequency infrared ray carbon sulfur analyzer (Model: CS-206), and the result was shown in

Table 1. Ceramic shells were made from multi-component slurries, including a fine mesh refractory filler system and a colloidal binder system.

Table 1.

Chemical composition of nickel-based superalloy.

Table 1.

Chemical composition of nickel-based superalloy.

| Elements | C | Cr | Ni | Co | Mo | Al | Ti | Fe | Nb | Ta |

|---|

Composition

(wt %) | 0.06 | 19.43 | 52.09 | 0.18 | 3.15 | 0.41 | 1.06 | 19.08 | 4.36 | 0.08 |

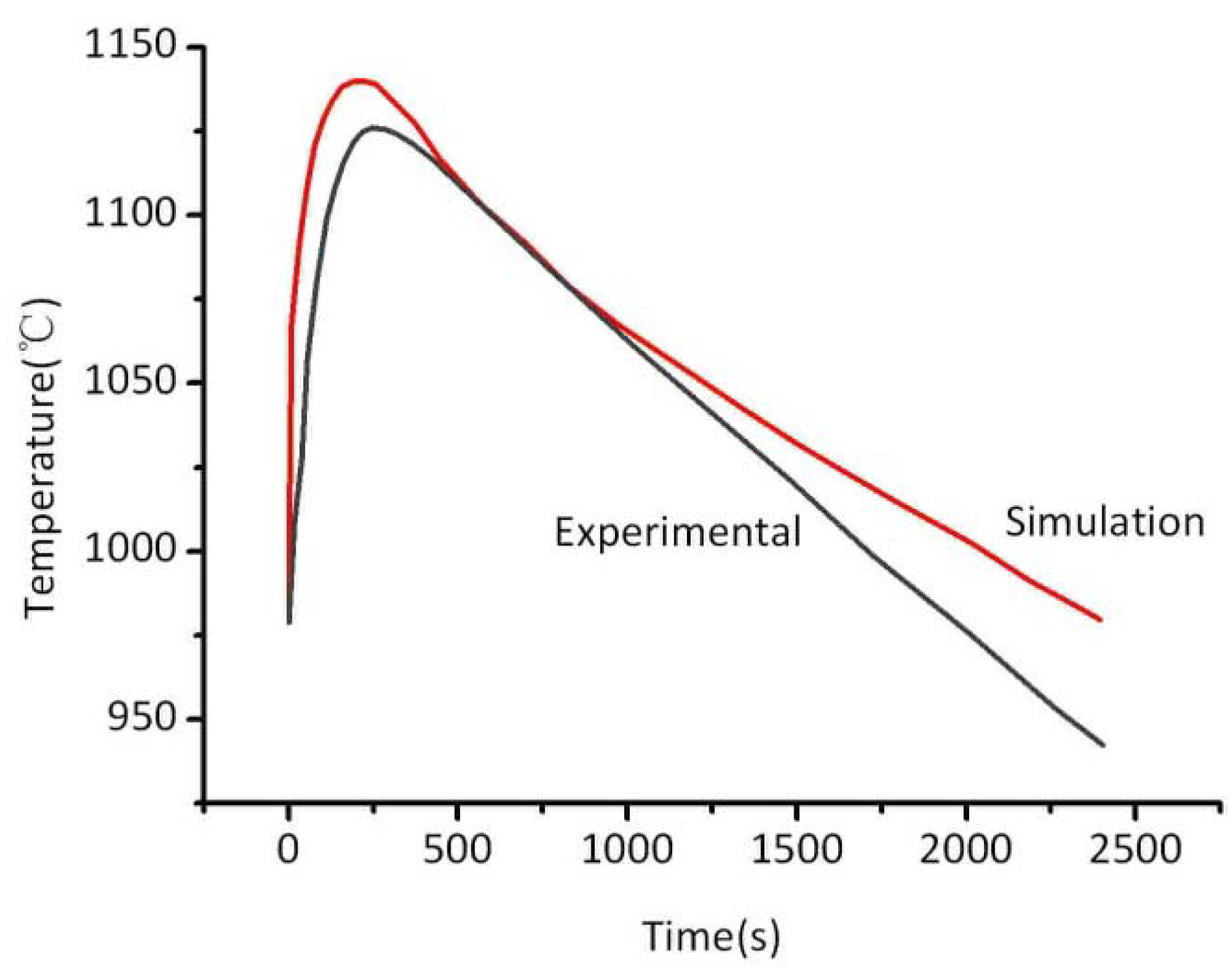

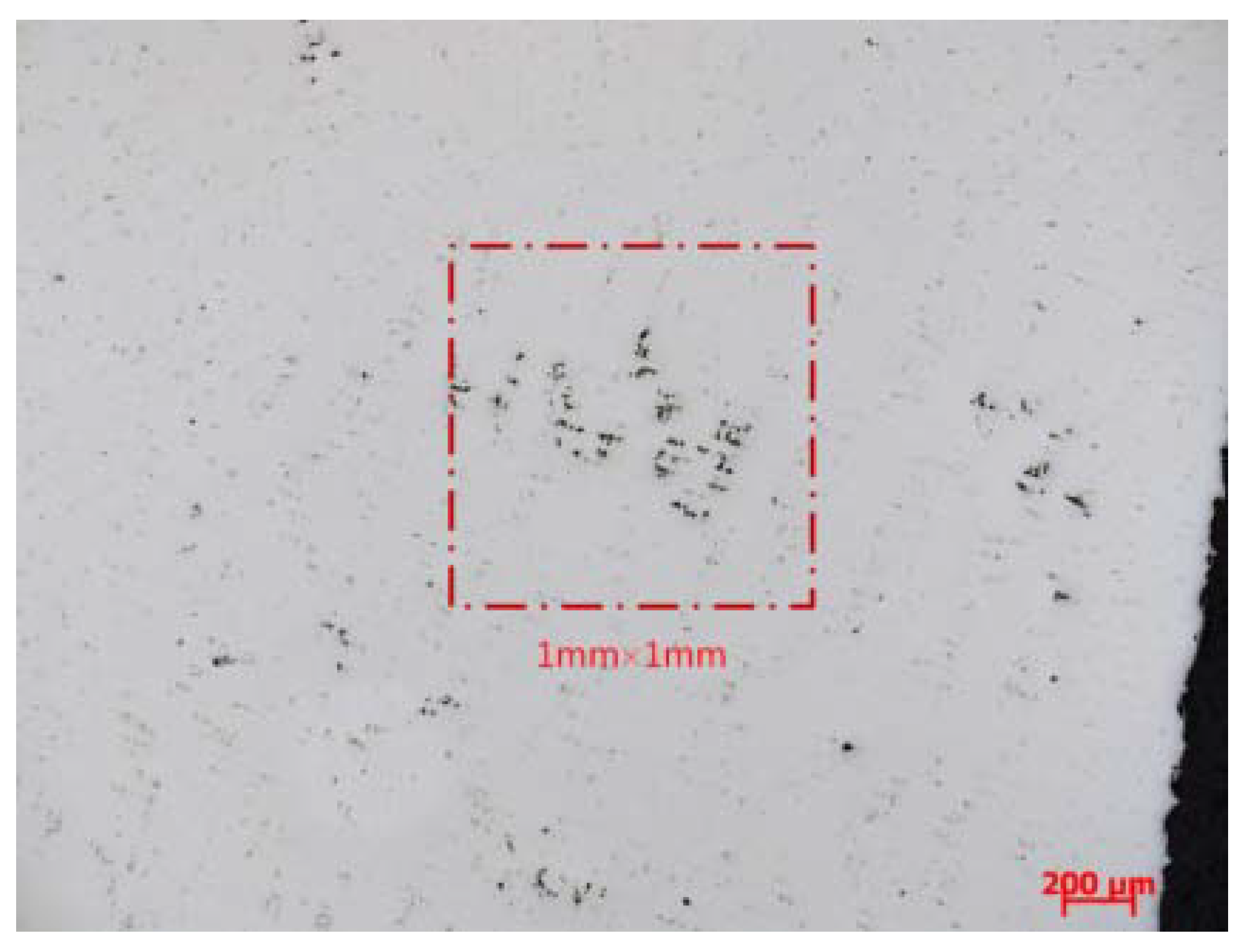

The shell was heated to 1000 °C and held for 20 h before pouring. The superalloy was melted in a vacuum investment casting system, and then poured into the preheated ceramic shell under gravity. To verify the accuracy of parameters given by ProCAST, thermocouples were placed in the ceramic shell to monitor the temperature at some typical sites, as shown in

Figure 4. Other experimental conditions were common with the ProCAST simulation, including pouring temperature, filling velocity,

etc.The microporosity of the casting was investigated using Zeiss optical microscopy. Specimens were cut from the casting and then ground, polished and observed. Microporosity measurement was carried out using DT2000 commercial image analysis system. The percentage of microporosity was characterized within an area of 1 mm × 1 mm (uniform size with simulation) at the magnification of 50, and the maximum value was used as the measurement results.

Figure 4.

The relative position of thermocouple.

Figure 4.

The relative position of thermocouple.

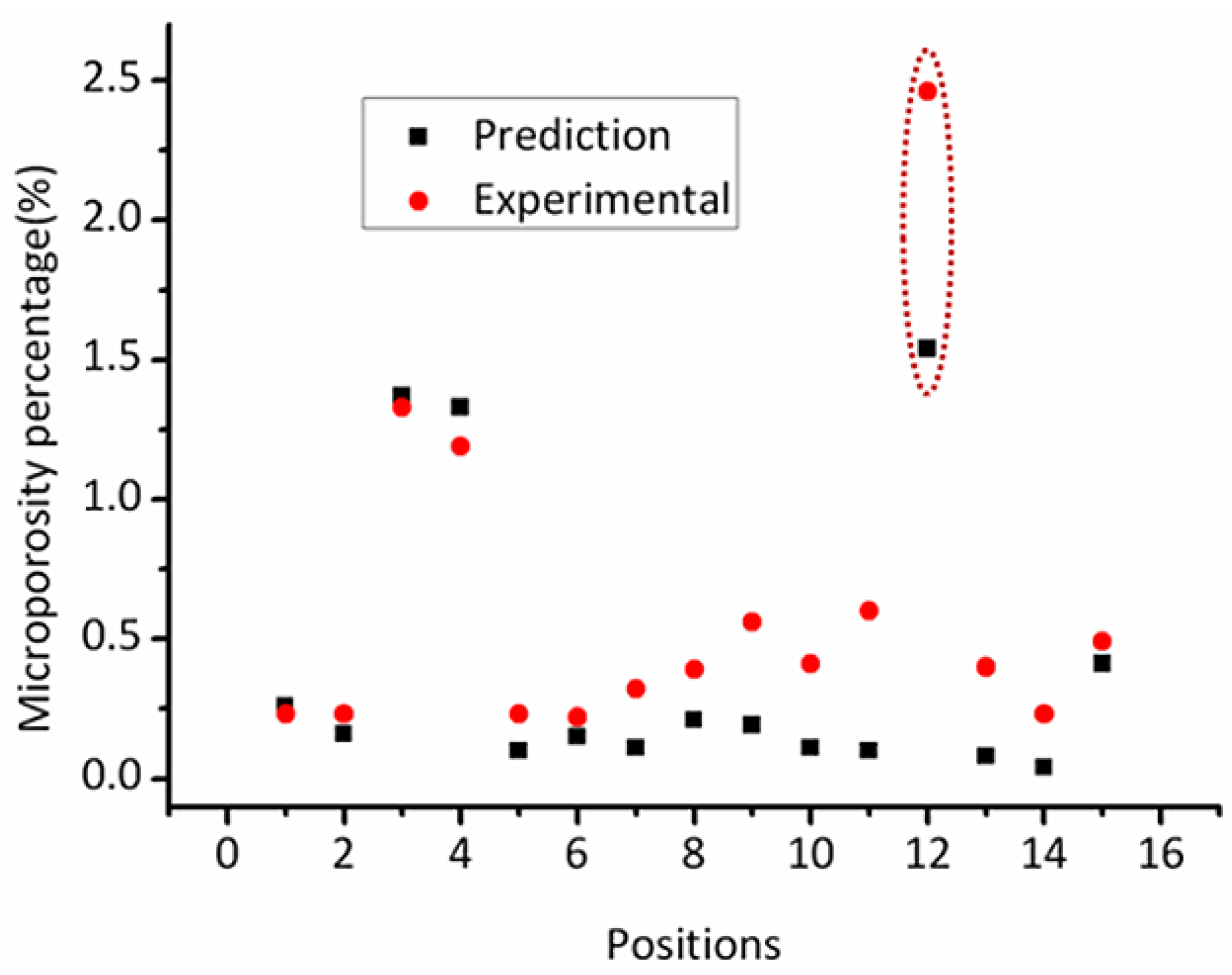

6. Conclusions

(1) Application of the dimensionless Niyama criterion in predicting the volume percentage of microporosity in a nickel-based superalloy casting was investigated.

(2) The relation between the dimensionless Niyama values and the microporosity of the superalloy has been obtained; the prediction results show reasonable agreement but under-predict those of the experiments concerning porosity content in the complex thin-wall casting.

(3) The poor prediction results in the thick parts of the casting revealed that the criterion was not suitable for the shrinkage prediction of isolated liquid pools.