Self-Healing Characteristics of Damaged Rock Salt under Different Healing Conditions

Abstract

:1. Introduction

2. Experimental Section

2.1. Specimen Preparation

2.2. Test Scheme Design

| Test number | Number of samples | Testing conditions (preparation) | Setting initial damage | Test conditions (recovery) |

|---|---|---|---|---|

| 1 | 2 | room temperature | uniaxial loading stress 30 MPa | room temperature |

| 2 | 2 | room temperature | 50 °C constant temperature and humidity (80% RH ± 2%) | |

| 3 | 2 | room temperature | 70 °C constant temperature and humidity (80% RH ± 2%) | |

| 4 | 2 | room temperature | 50 °C constant temperature oven | |

| 5 | 2 | room temperature | 110 °C constant temperature oven | |

| 6 | 2 | room temperature | triaxial compression tests | |

| 7 | 2 | 50 °C oven dry, 48 h | triaxial compression tests | |

| 8 | 2 | 50 °C saturation brine, 48 h | triaxial compression tests |

3. Results and Discussion

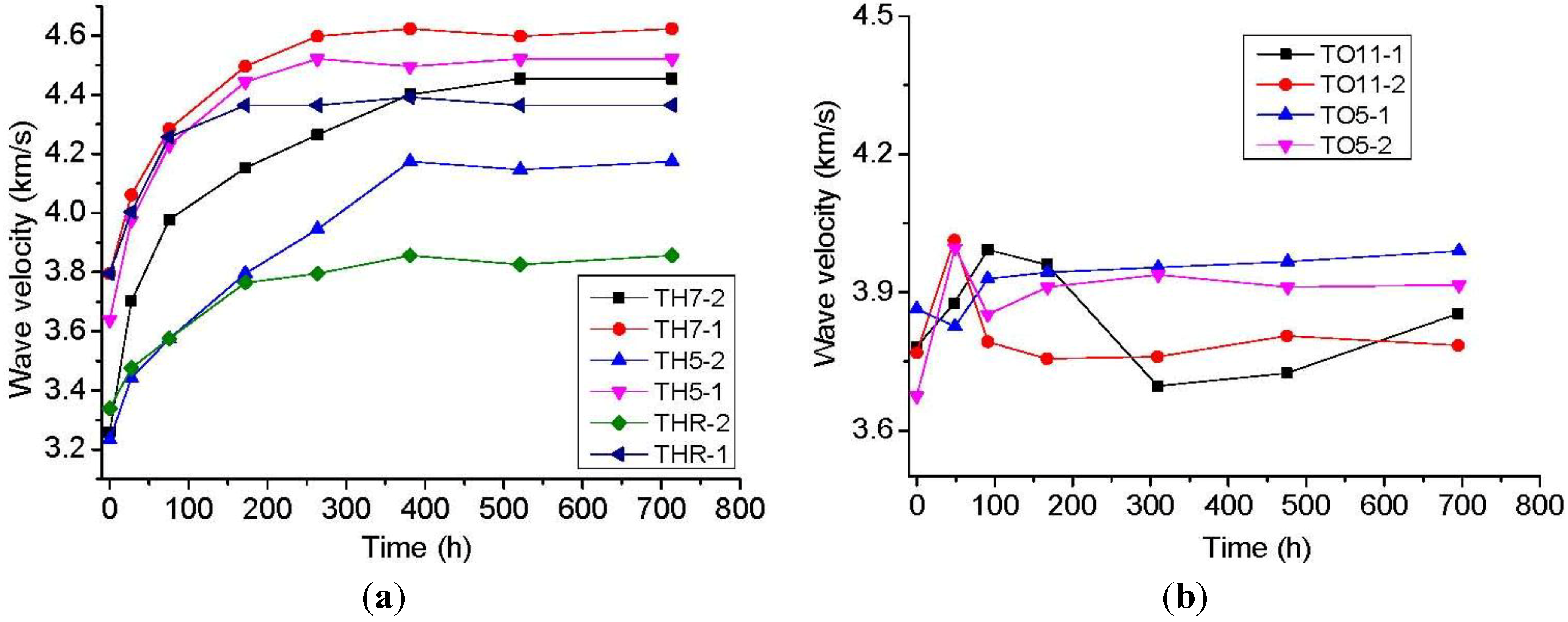

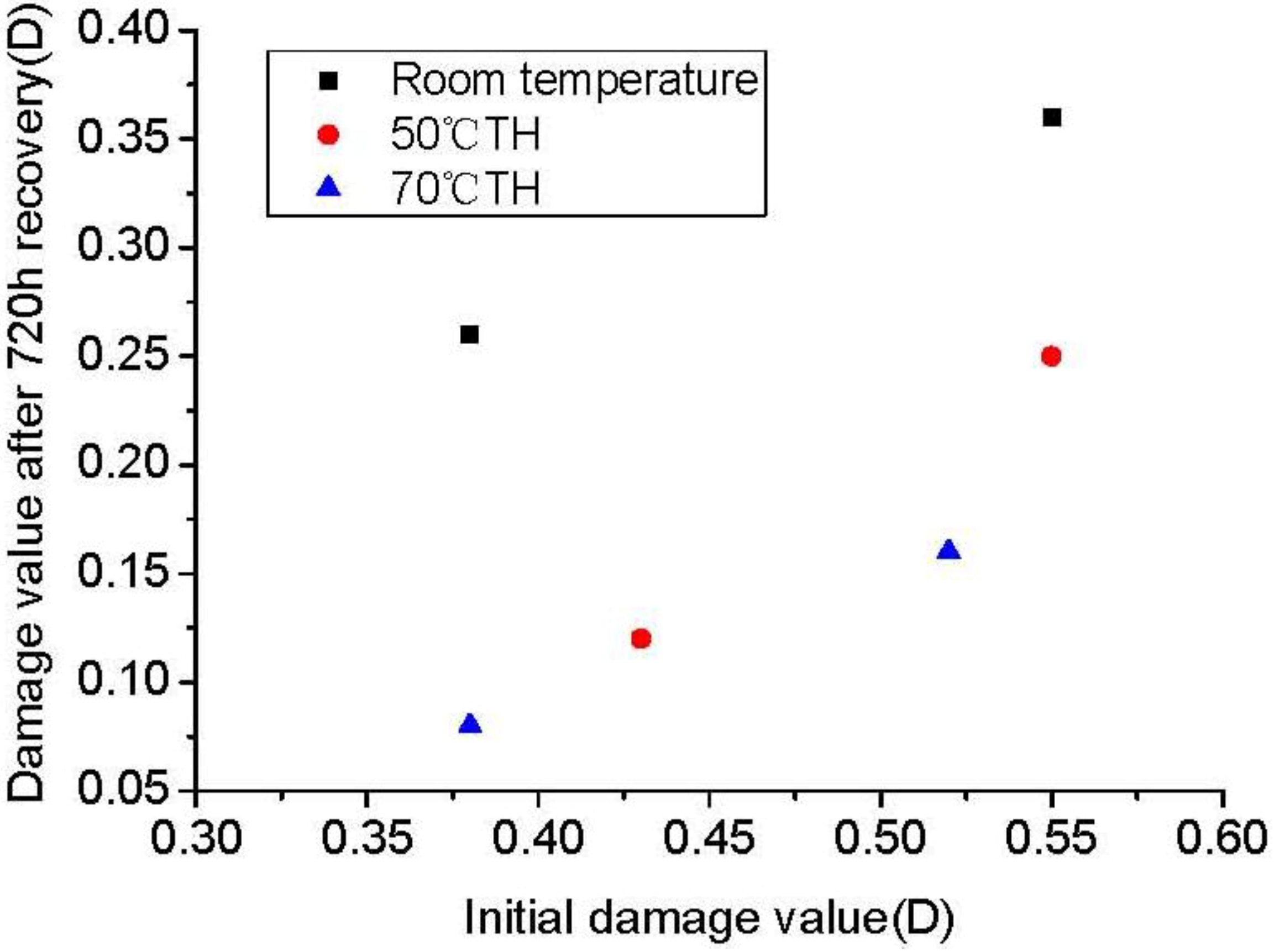

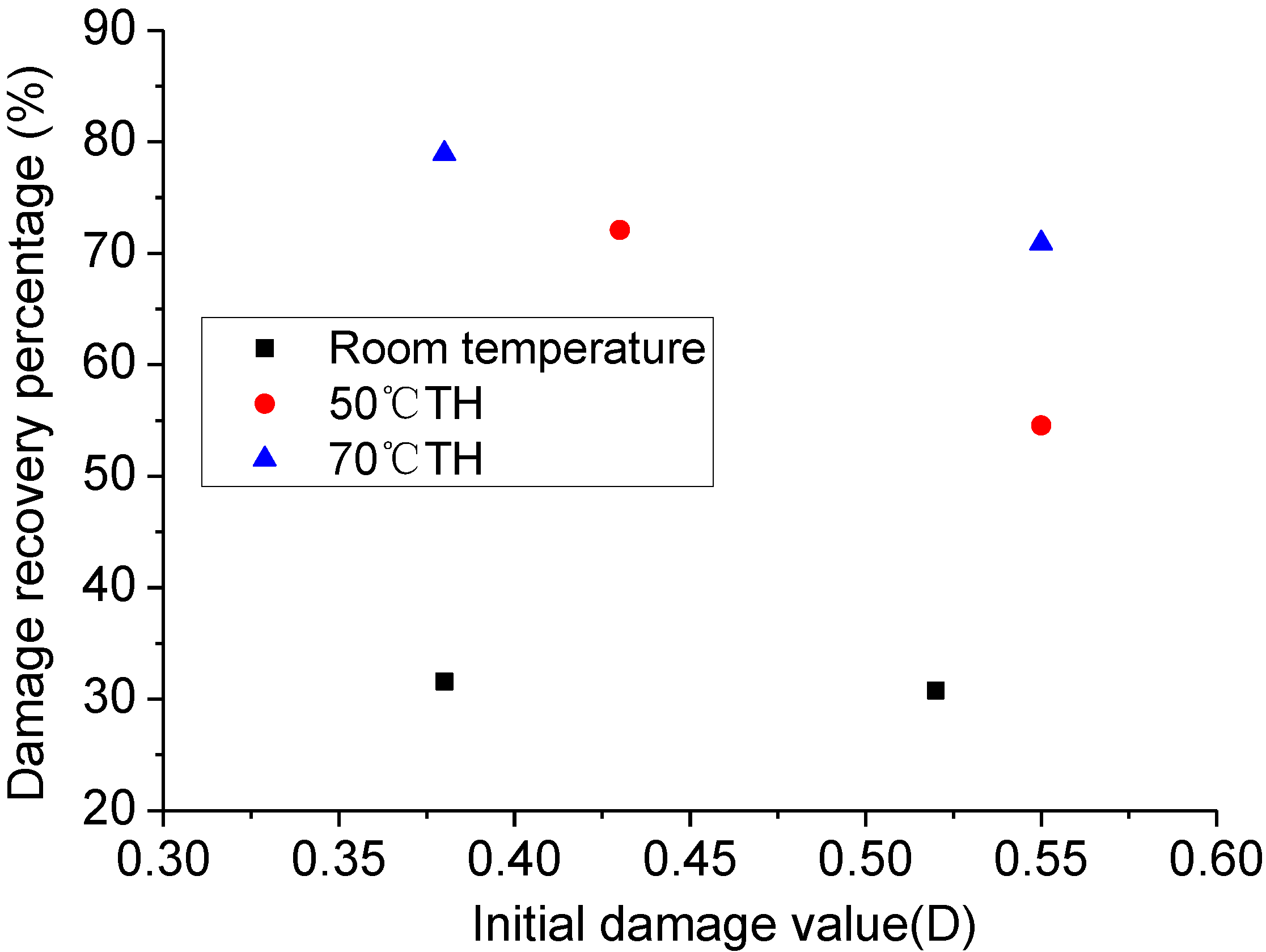

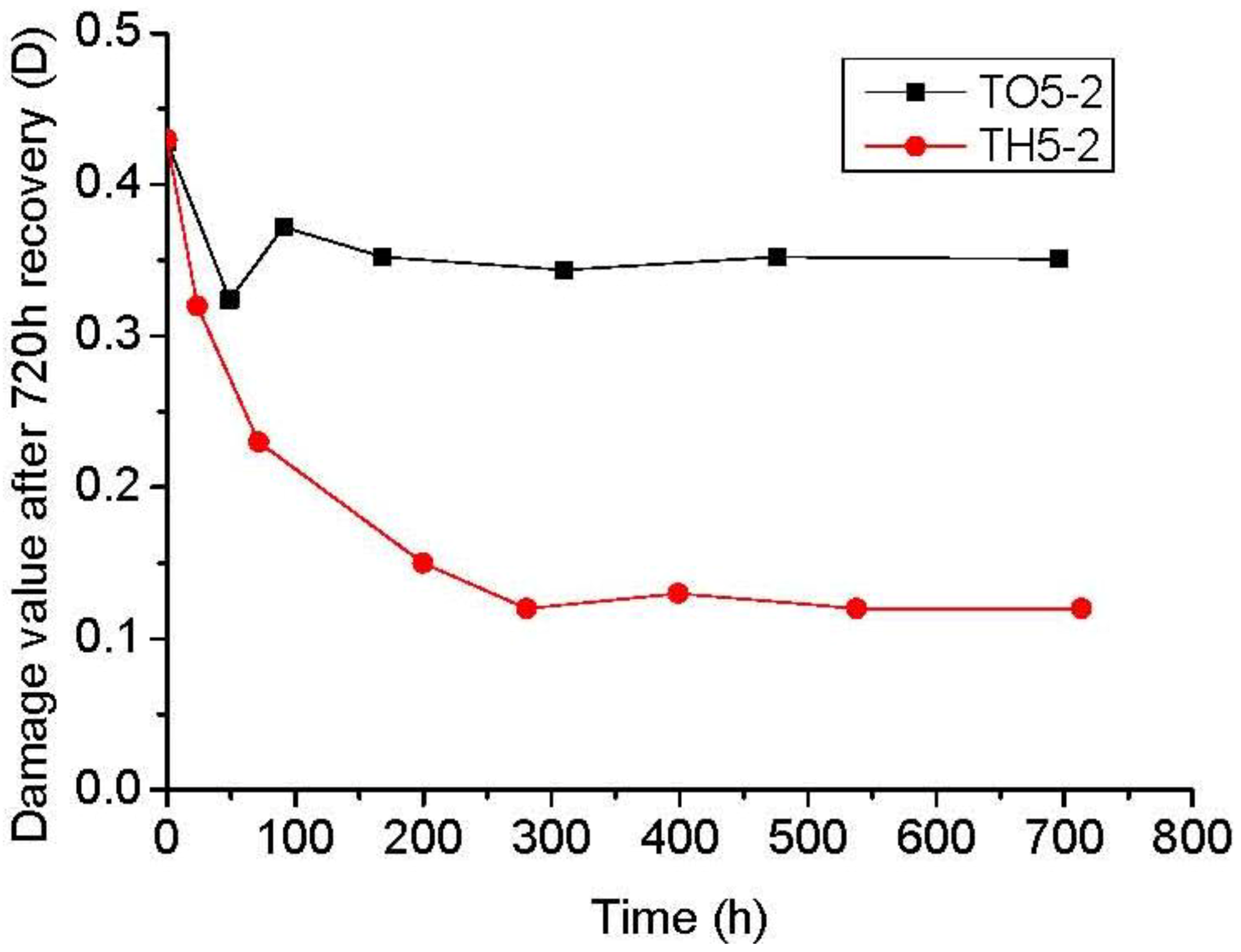

3.1. Analysis of the Self-Healing Ability of Damaged Rock Salt

| Number | Recovery conditions | Damage value | Recovery percentage (%) | ||

| Initial | 200 h recovery | Final recovery | |||

| TH2-1 | Room temperature | 0.38 | 0.28 | 0.26 | 31.58 |

| TH2-2 | 0.52 | 0.38 | 0.36 | 30.77 | |

| TH5-1 | 50 °C constant temperature and humidity | 0.43 | 0.15 | 0.12 | 72.09 |

| TH5-2 | 0.55 | 0.36 | 0.25 | 54.55 | |

| TH7-1 | 70 °C constant temperature and humidity | 0.38 | 0.1 | 0.08 | 78.95 |

| TH7-2 | 0.55 | 0.29 | 0.16 | 70.91 | |

| TO5-1 | 50 °C constant temperature oven | 0.37 | 0.35 | 0.33 | 10.80 |

| TO5-2 | 0.43 | 0.35 | 0.35 | 18.60 | |

| TO11-1 | 110 °C constant temperature oven | 0.39 | 0.41 | 0.37 | 5.13 |

| TO11-2 | 0.40 | 0.40 | 0.39 | 2.50 | |

3.2. Effect of Stress-Induced Initial Damage on Damage Self-healing

3.3. Effects of Temperature and Moisture on Damage Self-Healing

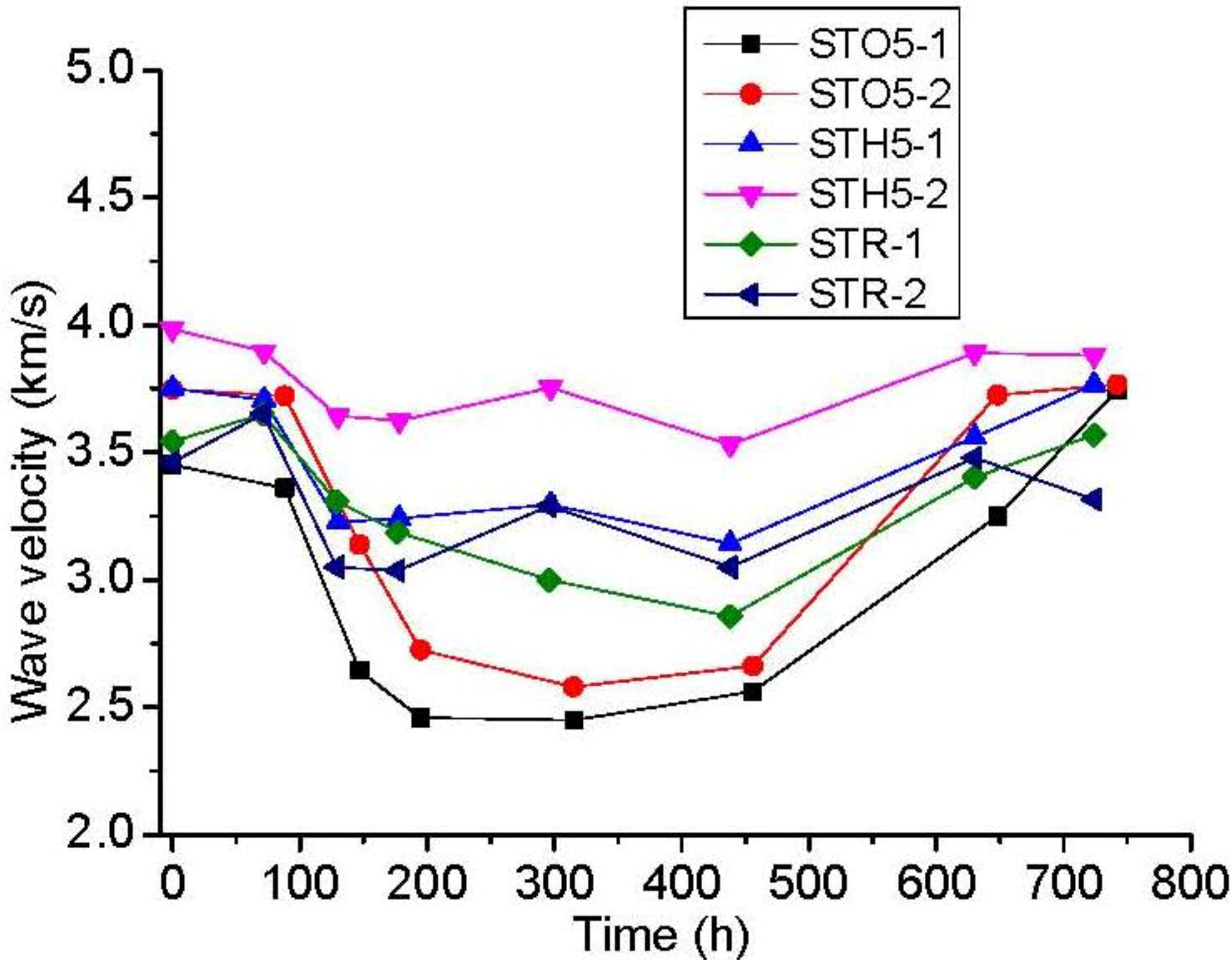

3.4. Effect of Oil on Damage Self-Healing of Rock Salt in Triaxial Compression

| Specimen number | Test conditions (preparation) | Damage value | Recovery percentage (%) | ||

| Initial | 200 h recovery | Final recovery | |||

| STO5-1 | 50 °C oven dry, 48 h | 0.49 | 0.72 | 0.50 | −2.04% |

| STO5-2 | 0.40 | 0.61 | 0.40 | 0 | |

| STH5-1 | 50 °C saturation brine, 48 h | 0.40 | 0.56 | 0.40 | 0 |

| STH5-2 | 0.42 | 0.54 | 0.45 | −7.14% | |

| STR-1 | Room temperature | 0.46 | 0.59 | 0.46 | 0 |

| STR-2 | 0.49 | 0.68 | 0.53 | −8.16% | |

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Hansen, F.D.; Mellegard, K.D.; Senseny, P.E. Elasticity and Strength of Ten Natural Rock Salts. In Proceedings of the First Conference on Mechanical Behavior of Salt, Harrisburg, PA, USA, 9–11 November 1984; pp. 71–83.

- Cristeseu, N. The Mechanical Behavior of Salt: The 4th Conference; Trans. Tech. Pub. Ltd.: Clausthal-Zellerfeld, Germany, 1996. [Google Scholar]

- Tsang, C.F.; Bernier, F.; Davies, C. Geohydromechanical processes in the excavation damaged zone in crystalline rock, rock salt, and indurated and plastic clays—In the context of radioactive waste disposal. Int. J. Rock Mech. Min. Sci. 2005, 42, 109–125. [Google Scholar] [CrossRef]

- Alkana, H.; Cinarb, Y.; Pusch, G. Rock salt dilatancy boundary from combined acoustic emission and triaxial compression tests. Int. J. Rock Mech. Min. Sci. 2007, 44, 108–119. [Google Scholar] [CrossRef]

- Hou, Z. Mechanical and hydraulic behavior of rock salt in the excavation disturbed zone around underground facilities. Int. J. Rock Mech. Min. Sci. 2003, 40, 725–738. [Google Scholar] [CrossRef]

- Chan, K.S.; Munson, D.E.; Bonder, S.R. Recovery and healing of damage in WIPP salt. Int. J. Damage Mech. 1998, 7, 143–166. [Google Scholar] [CrossRef]

- Derby, B.; Ashby, M.F. On dynamic recrystallization. Scr. Metall. 1987, 21, 879–884. [Google Scholar] [CrossRef]

- Shimizu, I. Stress and temperature dependence of recrystallized grain size: A subgrain misorientation model. Geophys. Res. Lett. 1998, 25, 4237–4240. [Google Scholar] [CrossRef]

- De Bresser, J.H.P.; Peach, C.J.; Reijs, J.P.J.; Spiers, C.J. On dynamic recrystallization during solid state flow: Effects of stress and temperature. Geophys. Res. Lett. 1998, 25, 3457–3460. [Google Scholar]

- Chan, K.S.; Bodner, S.R. Constitutive Representation of Damage Development and Healing in WIPP Salt; American Rock Mechanics Association: Reno, NV, USA, 1995. [Google Scholar]

- Chan, K.S.; Munson, D.E.; Fossum, A.F.; Bodner, S.R. A Constitutive Model for Representing Couple Creep, Fracture, and Healing in Rock Salt. Ser. Rock Soil Mech. 1998, 22, 221–234. [Google Scholar]

- Kerry, L.D.; Joel, D.N.; Joe, L.R. Feasibility Study for Loweing the Minimum Gas Pressure in Solution-Mined Caverns Based on Geomechanical Analyses of Creep-Induced Damage and Healing; U.S. Department of Energy Federal Technology Center: Morgantown, WV, USA, 1998.

- Drury, M.R.; Urai, J.L. Deformation-related recrystallization processes. Tectonophysics 1990, 172, 235–253. [Google Scholar] [CrossRef]

- Poirier, J.P. Creep of Crystals High-temperature Deformation Processes in Metals, Ceramics and Minerals; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Urai, J.L.; Spiers, C.J.; Zwart, H.J.; Lister, G.S. Weakening of rock salt by water during long term creep. Nature 1986, 324, 554–557. [Google Scholar] [CrossRef]

- Takeuchi, S.; Argon, A.S. Steady-state creep of single-phase crystalline matter at high temperature. J. Mater. Sci. 1976, 11, 1542–1566. [Google Scholar] [CrossRef]

- Ter Heege, J.H.; De Bresser, J.H.P.; Spiers, C.J. Dynamic recrystallization of wet synthetic polycrystalline halite: Dependence of grain size distribution on flow stress, temperature and strain. Tectonophysics 2005, 396, 35–57. [Google Scholar] [CrossRef]

- Yu, L.Z. Application of Rock Salt Sealing Evaluation Technology in Petroleum System. Resour. Environ. Eng. 2008, 22, 348–353. [Google Scholar]

- Liang, W.G.; Xu, S.G.; Zhao, Y.S. Experimental study on heating recrystallization effect on shear characteristics of damaged rock salt. Chin. J. Rock Mech. Eng. 2004, 23, 3413–3417. [Google Scholar]

- Zhong, W.H.; Wu, Y. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Brodsky, N.S. Crack Closure and Healing Studies in WIPP Salt Using Compressional Wave Velocity and Attenuation Measurements: Test Methods and Results; Sandia National Laboratories: Albuquerque, NM, USA, 1990. [Google Scholar]

- Jiang, D.Y.; Chen, J.; Liu, J.P. Experimental research on acoustic and dissolved properties of stress damaged salt rock. Rock Soil Mech. 2009, 30, 3569–3573. [Google Scholar]

- Chen, J.W.; Yang, C.H.; Gao, X.P. Study on the coupled damage of temperature and mechanics for salt rock. Chin. J. Rock Mech. Eng. 2005, 27, 1986–1991. [Google Scholar]

- Luo, G.F. Crystallography Introduction; Geological Publishing House: Beijing, China, 1985. [Google Scholar]

- Koelemeijer, P.J.; Peach, C.J.; Spiers, C.J. Surface diffusivity of cleaved NaCl crystals as a function of humidity: Impedance spectroscopy measurements and implications for crack healing in rock salt. J. Geophys. Res. Solid Earth 2012, 117, 1205–1217. [Google Scholar] [CrossRef]

- Watanabe, T.; Peach, C.J. Electrical impedance measurement of plastically deforming halite rocks at 125 °C and 50 MPa. J. Geophys. Res. Solid Earth 2002, 107, 1–12. [Google Scholar]

- Peach, C.J.; Spiers, C.J.; Trimby, P.W. Effect of confining pressure on dilatation, recrystallization, and flow of rock salt at 150 °C. J. Geophys. Res. Solid Earth 2001, 106, 315–328. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chen, J.; Ren, S.; Yang, C.; Jiang, D.; Li, L. Self-Healing Characteristics of Damaged Rock Salt under Different Healing Conditions. Materials 2013, 6, 3438-3450. https://doi.org/10.3390/ma6083438

Chen J, Ren S, Yang C, Jiang D, Li L. Self-Healing Characteristics of Damaged Rock Salt under Different Healing Conditions. Materials. 2013; 6(8):3438-3450. https://doi.org/10.3390/ma6083438

Chicago/Turabian StyleChen, Jie, Song Ren, Chunhe Yang, Deyi Jiang, and Lin Li. 2013. "Self-Healing Characteristics of Damaged Rock Salt under Different Healing Conditions" Materials 6, no. 8: 3438-3450. https://doi.org/10.3390/ma6083438