The Tension and Puncture Properties of HDPE Geomembrane under the Corrosion of Leachate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. HDFE Geomembrane

| Parameters | Thickness | Density | Tensile strength (crossbar) | Elongation at break (crossbar) |

|---|---|---|---|---|

| HDPE geomembrane | 1 mm | 0.95 g/cm3 | ≥25 MPa | ≥550% |

| Parameters | Tangential breaking strength (crossbar) | Permeability coefficient of water vapor | Oxidation induction time in 200 °C | – |

| HDPE geomembrane | ≥110 N/mm | <1.0 × 10−16 m/s | ≥20 min | – |

2.1.2. Landfill Leachate

| Chemical components | pH | COD | BOD | TOC | Cl− | Na+ | NH4–N | Pb2+ | Cd2+ |

|---|---|---|---|---|---|---|---|---|---|

| Contents | 8.56 | 21562 | 871.2 | 9032 | 2708 | 852 | 746.8 | 0.17 | 0.107 |

| Chemical components | Cu | Fe | Zn | Phenol | Ca2+ | K+ | Mg2+ | Hardness(CaCO3) | SO42− |

| Contents | 0.11 | 7.26 | 0.48 | 0.1117 | 2072 | 794 | 1537 | 3401 | 385 |

2.2. Test Methods

| Test conditions | Tensile test at longitudinal grain direction, z | Tensile test at cross grain direction, h | Puncture test | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Corrosion time, t (days) | Corrosion time, t (days) | Corrosion time, t (days) | ||||||||

| 5 | 10 | 15 | 5 | 10 | 15 | 5 | 10 | 15 | ||

| Temperature, T | 20 °C | z-20-5 | z-20-10 | z-20-15 | h-20-5 | h-20-10 | h-20-15 | 20-5 | 20-10 | 20-15 |

| 50 °C | z-50-5 | z-50-10 | z-50-15 | h-50-5 | h-50-10 | h-50-15 | 50-5 | 50-10 | 50-15 | |

| 80 °C | z-80-5 | z-80-10 | z-80-15 | h-80-5 | h-80-10 | h-80-15 | 80-5 | 80-10 | 80-15 | |

3. Results and Analysis

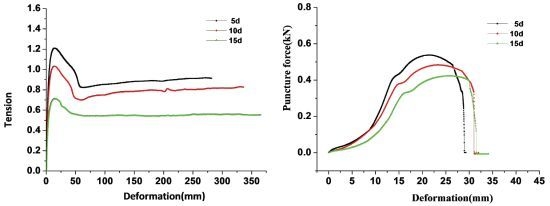

3.1. The Tension and Puncture Properties of Intact Geomembrane Specimens

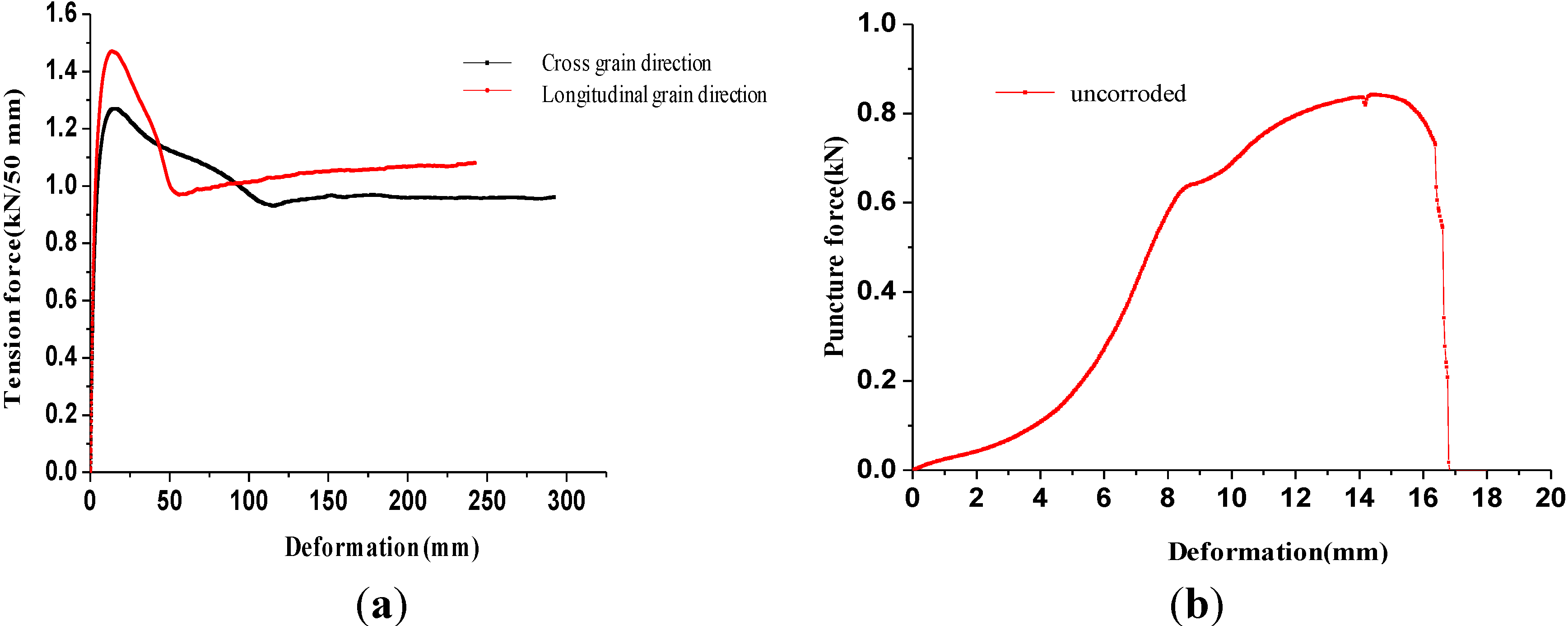

3.2. Impact of Corrosion Time on the Tensile Strength Properties of Geomembrane Specimens

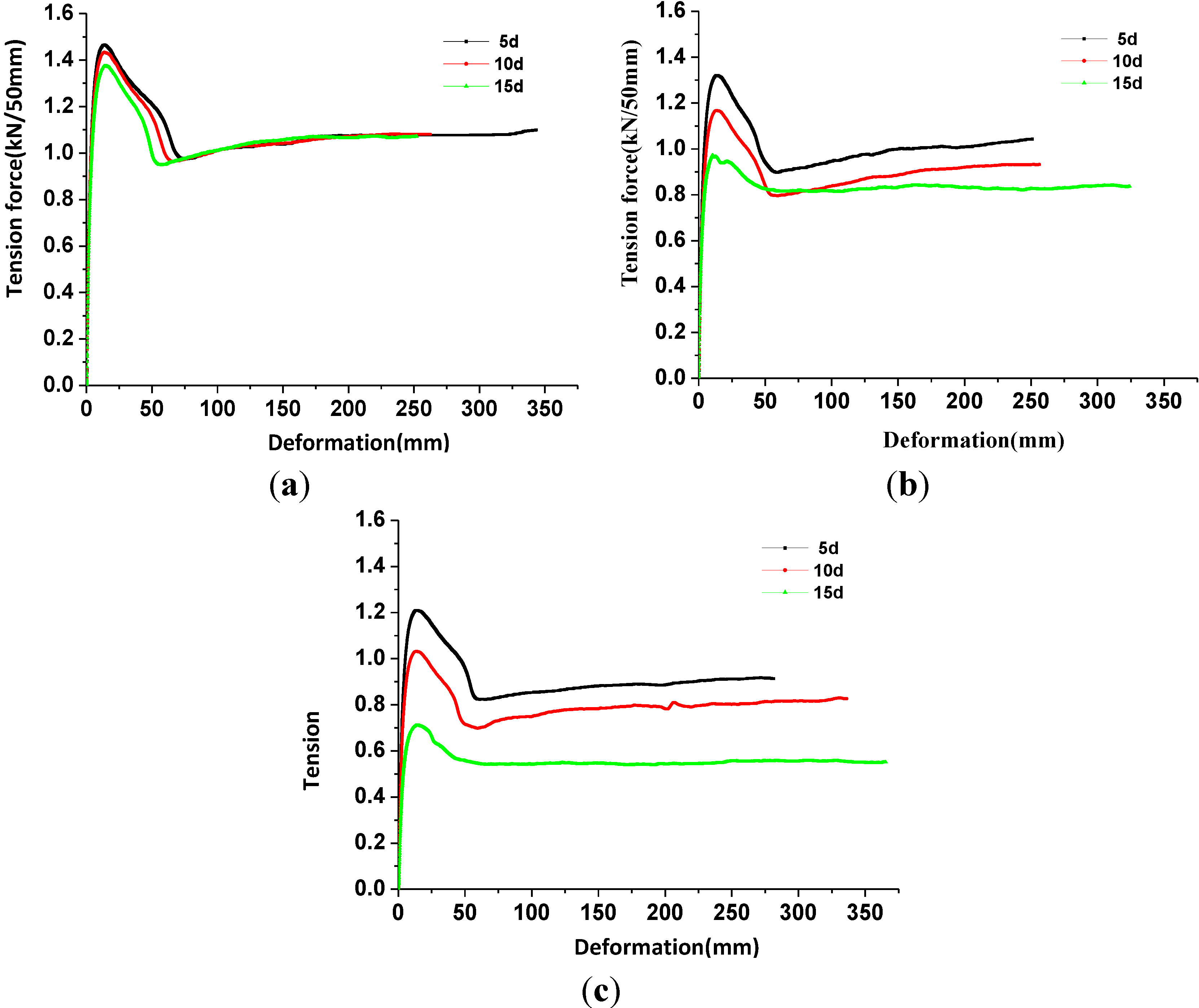

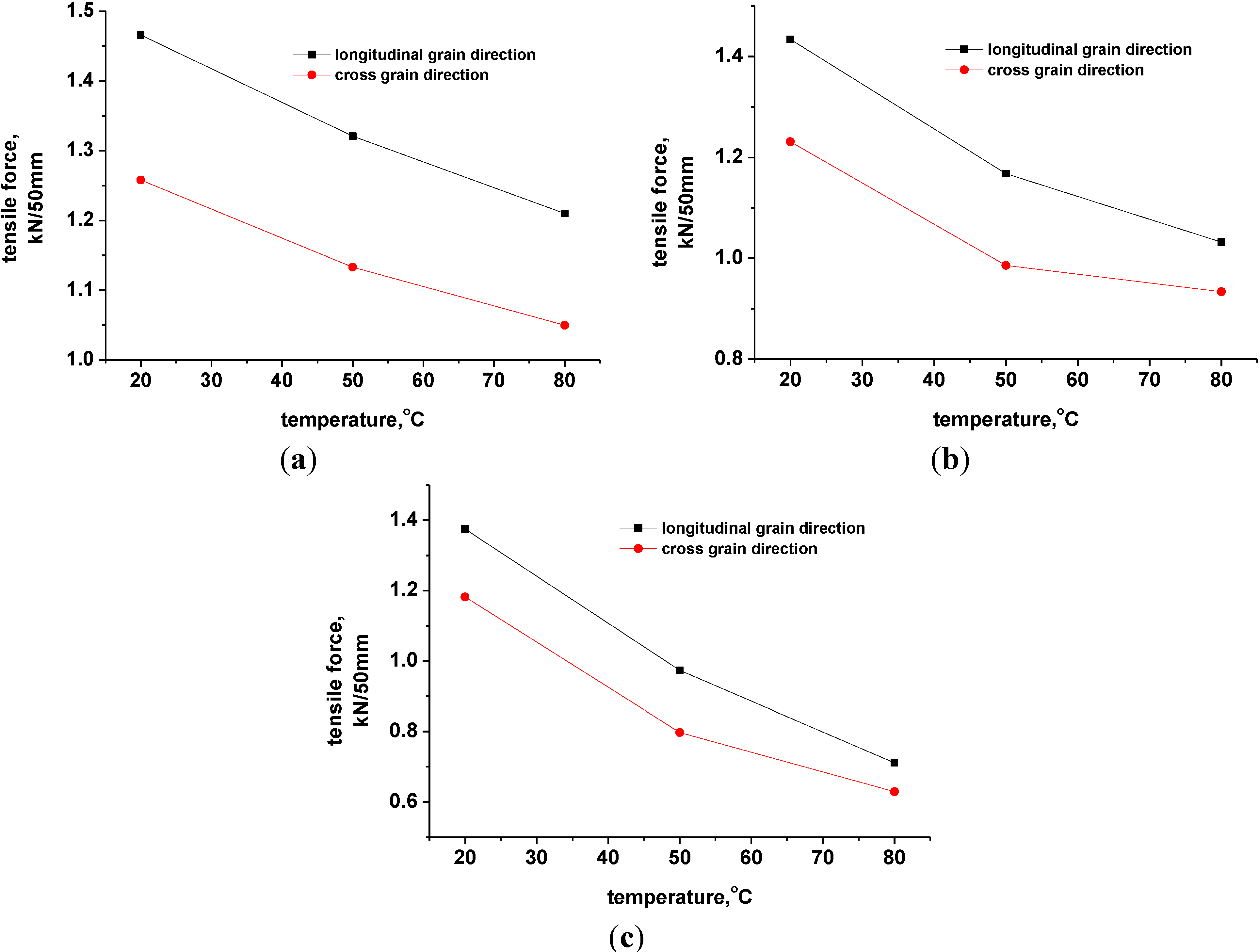

3.3. Impact of Corrosion Temperature on the Tensile Strength Properties of Geomembrane Specimens

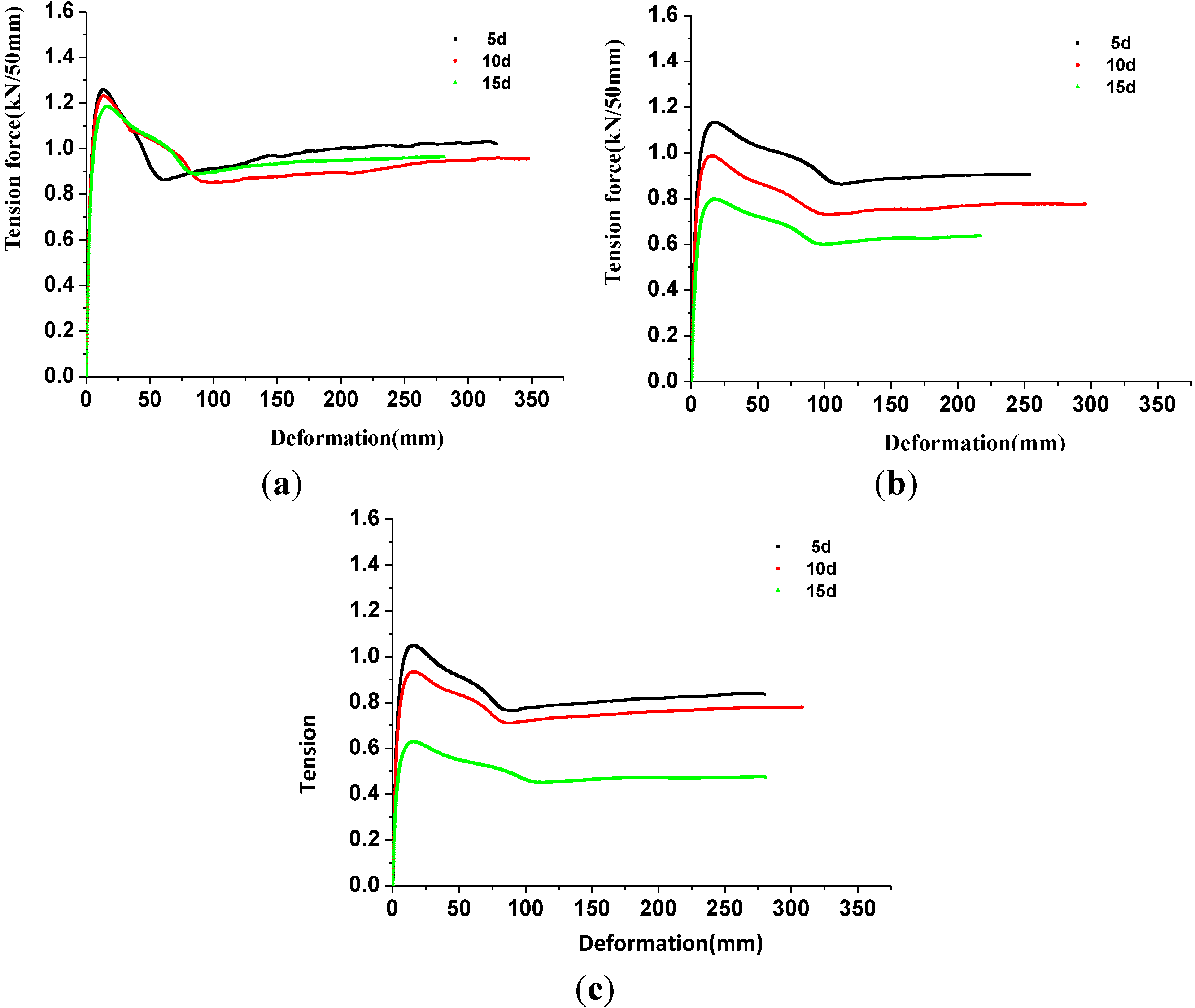

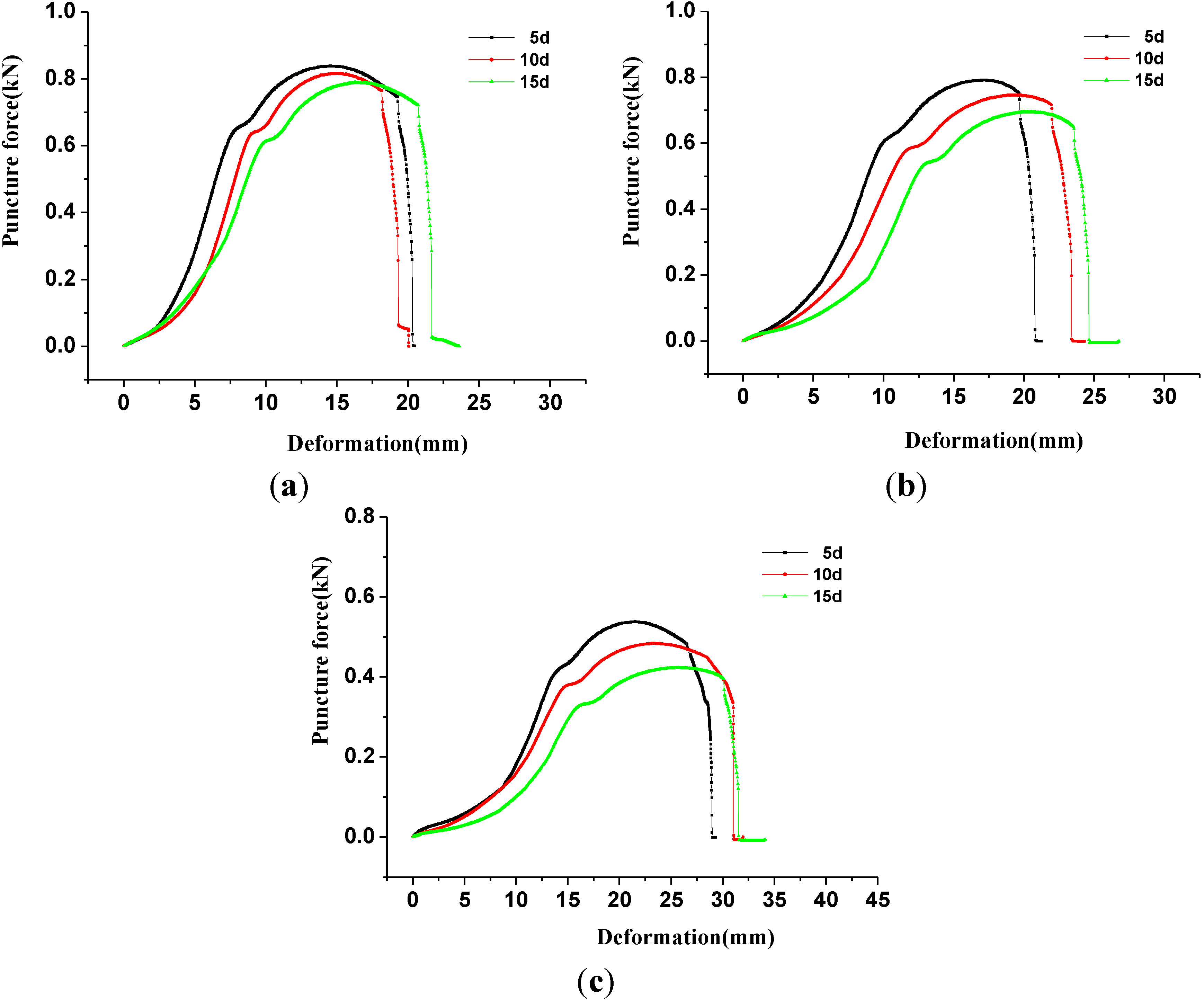

3.4. The Puncture Strength Properties of Geomembrane Specimens Corroded with Leachate

3.5. The Strength/Elongation/Deformation Variations of HDPE Geomembrane Specimens

| Project | Longitudinal grain direction | Cross grain direction | |||||

|---|---|---|---|---|---|---|---|

| 5 days | 10 days | 15 days | 5 days | 10 days | 15 days | ||

| Tensile strength variations/kN | 20 °C | 0.004 | 0.036 | 0.095 | 0.012 | 0.039 | 0.088 |

| 50 °C | 0.149 | 0.302 | 0.497 | 0.137 | 0.284 | 0.473 | |

| 80 °C | 0.260 | 0.438 | 0.759 | 0.220 | 0.336 | 0.641 | |

| Residual strength variations/kN | 20 °C | −0.019 | −0.001 | 0.009 | −0.06 | 0.003 | −0.002 |

| 50 °C | 0.037 | 0.148 | 0.243 | 0.055 | 0.184 | 0.324 | |

| 80 °C | 0.166 | 0.254 | 0.530 | 0.124 | 0.180 | 0.486 | |

| Elongation variations/% | 20 °C | 0.6 | 0.4 | 0.6 | 0.1 | 0.9 | 1.3 |

| 50 °C | 0.9 | 1.3 | 1.6 | 1.4 | 2.1 | 2.5 | |

| 80 °C | 1 | 0.7 | 0.3 | 1.3 | 0.9 | 0.5 | |

| Project | Puncture strength variations/kN | Puncture deformation variations/mm | |||||

| 5 days | 10 days | 15 days | 5 days | 10 days | 15 days | ||

| Puncture test | 20 °C | 0.004 | 0.026 | 0.054 | 0.1 | 0.6 | 1.8 |

| 50 °C | 0.051 | 0.097 | 0.148 | 2.8 | 4.3 | 5.5 | |

| 80 °C | 0.305 | 0.359 | 0.420 | 7.0 | 8.7 | 11.2 | |

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Eithe, A.W.; Koerner, G.R. Assessment of HDPE geomembrane performance in a municipal waste landfill double liner system after eight years of service. Geotext. Geomembr. 1997, 15, 277–287. [Google Scholar] [CrossRef]

- Kodikara, J. Analysis of tension development in geomembranes placed on landfill slopes. Geotext. Geomembr. 2000, 18, 47–61. [Google Scholar] [CrossRef]

- Wasti, Y.; Özdüzgün, Z.B. Geomembnare-geotextile interface shear properties as determined by inclined board and direct shear box tests. Geotext. Geomembr. 2001, 19, 45–57. [Google Scholar] [CrossRef]

- Ling, H.I.; Burke, C.; Mohri, Y.; Matsushima, K. Shear strength parameters of soil-geosynthetic interfaces under low confining pressure using a tilting table. Geosynth. Int. 2002, 9, 373–380. [Google Scholar] [CrossRef]

- Akpinar, M.V.; Benson, C.H. Effect of temperature on shear strength of two geomembrane-geotextile interfaces. Geotext. Geomembr. 2005, 23, 443–453. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K. Shear strength parameters of compacted fly ash-HDPE geomembrane interfaces. Geotext. Geomembr. 2006, 24, 91–102. [Google Scholar] [CrossRef]

- Vukelic, A.; Szavits-Nossan, A.; Kvasnicka, P. The influence of bentonite extrusion on shear strength of GCL/geomembrane interface. Geotext. Geomembr. 2008, 26, 82–90. [Google Scholar] [CrossRef]

- Brachman, R.W.I.; Gudina, S. Gravel contacts and geomembrane strains for a GM/CCL composite liner. Geotext. Geomembr. 2008, 26, 448–459. [Google Scholar] [CrossRef]

- Brachman, R.W.I.; Gudina, S. Geomembrane strains from coarse gravel and wrinkles in a GM/GCL composite liner. Geotext. Geomembr. 2008, 26, 488–497. [Google Scholar] [CrossRef]

- Fox, P.J.; Kim, R.H. Effect of progressive failure on measured shear strength of geomembrane/GCL interface. J. Geotech. Geoenviron. Eng. 2008, 134, 459–469. [Google Scholar] [CrossRef]

- Pitanga, H.N.; Gourc, J.-P.; Vilar, O.M. Interface shear strength of geosynthetics: Evaluation and analysis of inclined plane tests. Geotext. Geomembr. 2009, 27, 435–446. [Google Scholar] [CrossRef]

- Chen, Y.-M.; Lin, W.-A.; Zhan, T.L.T. Investigation of mechanisms of bentonite extrusion from GCL and related effects on the shear strength of GCL/GM interfaces. Geotext. Geomembr. 2010, 28, 63–71. [Google Scholar] [CrossRef]

- Xiao, Z.Y.; Tu, F. HDPE geomembrane-geotextile interface shear properties determined by large size direct shear test. Eng. Mech. 2010, 27, 186–191. [Google Scholar]

- Bacas, B.M.; Konietzky, H.; Berini, J.C.; Sagaseta, C. A new constitutive model for textured geomembrane/geotextile interfaces. Geotex. Geomembr. 2011, 29, 137–148. [Google Scholar] [CrossRef]

- Lin, W.A.; Zhang, H.W.; Zhan, L.T.; Chen, Y.M. Large-scale ramp model tests on geomembrane/geotextile interface. Chin. J. Geotech. Eng. 2012, 34, 1950–1956. [Google Scholar]

- Wesseloo, J.; Visser, A.T.; Rust, E. A mathematical model for the strain-rate dependent stress-strain response of HDPE geomembranes. Geotext. Geomembr. 2004, 22, 273–295. [Google Scholar] [CrossRef]

- Zhang, W.H.; Xu, S.F.; Yang, Y. Experimental study on puncture resistance of geomembrane. New Build. Mater. 2007, 1, 56–59. [Google Scholar]

- Brachman, R.W.I.; Sabir, A. Geomembrane puncture and strains from stones in an underlying clay layer. Geotext. Geomembr. 2010, 28, 335–343. [Google Scholar] [CrossRef]

- Koerner, R.M.; Hsuan, Y.G.; Koerner, G.R.; Gryger, D. Ten year creep puncture study of HDPE geomembranes protected by needle-punched nonwoven geotextiles. Geotext. Geomembr. 2010, 28, 503–513. [Google Scholar] [CrossRef]

- Mueller, W.; Jakob, I. Oxidative resistance of high-density polyethylene geomembranes. Polym. Degrad. Stab. 2003, 79, 161–172. [Google Scholar] [CrossRef]

- Rowe, R.K.; Rimal, S.; Sangam, H. Ageing of HDPE geomembrane exposed to air, water and leachate at different temperatures. Geotext. Geomembr. 2009, 27, 137–151. [Google Scholar] [CrossRef]

- Rowe, R.K.; Abdelaal, F.B.; Islam, M.Z.; Hsuan, Y.G. The Strange Effect of Increasing Temperature in Accelerated Ageing of HDPE Geomembranes Immersed in Liquids. In Proceedings of 9th International Conference on Geosynthetics, Guaruja, Brazil, 23–27 May 2010.

- National Science Library, Chinese Academy of Science. Code for Test and Measurement of Geosynthetics (SL/T 235-1999). Available online: http://www.las.ac.cn/standard/standardAdvancedSearch.jsp?query=dc.identifier.recordid=1088359&version=1.1&recordPacking=xml&maximumRecords=1&startRecord=1 (accessed on 1 April 1999).

- National Science Library, Chinese Academy of Science. Geotextiles and Geotextile-Related Products-Determination of Puncture Resistance (GB/T 19978-2005). Available online: http://www.las.ac.cn/standard/standardAdvancedSearch.jsp?query=dc.identifier.recordid=5010996&version=1.1&recordPacking=xml&maximumRecords=1&startRecord=1 (accessed on 1 May 2006).

- Hsuan, Y.G.; Koerner, R.M. Antioxidant depletion lifetime in high density polyethylene geomembranes. J. Geotech. Geoenviron. Eng. ASCE 1998, 124, 532–541. [Google Scholar]

- Rowe, R.K.; Islam, M.Z.; Hsuan, Y.G. Leachate chemical composition effects on OIT depletion in an HDPE geomembrane. Geosynth. Int. 2008, 15, 136–151. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Xue, Q.; Zhang, Q.; Li, Z.-Z.; Xiao, K. The Tension and Puncture Properties of HDPE Geomembrane under the Corrosion of Leachate. Materials 2013, 6, 4109-4121. https://doi.org/10.3390/ma6094109

Xue Q, Zhang Q, Li Z-Z, Xiao K. The Tension and Puncture Properties of HDPE Geomembrane under the Corrosion of Leachate. Materials. 2013; 6(9):4109-4121. https://doi.org/10.3390/ma6094109

Chicago/Turabian StyleXue, Qiang, Qian Zhang, Zhen-Ze Li, and Kai Xiao. 2013. "The Tension and Puncture Properties of HDPE Geomembrane under the Corrosion of Leachate" Materials 6, no. 9: 4109-4121. https://doi.org/10.3390/ma6094109