Nano-Inclusions Applied in Cement-Matrix Composites: A Review

Abstract

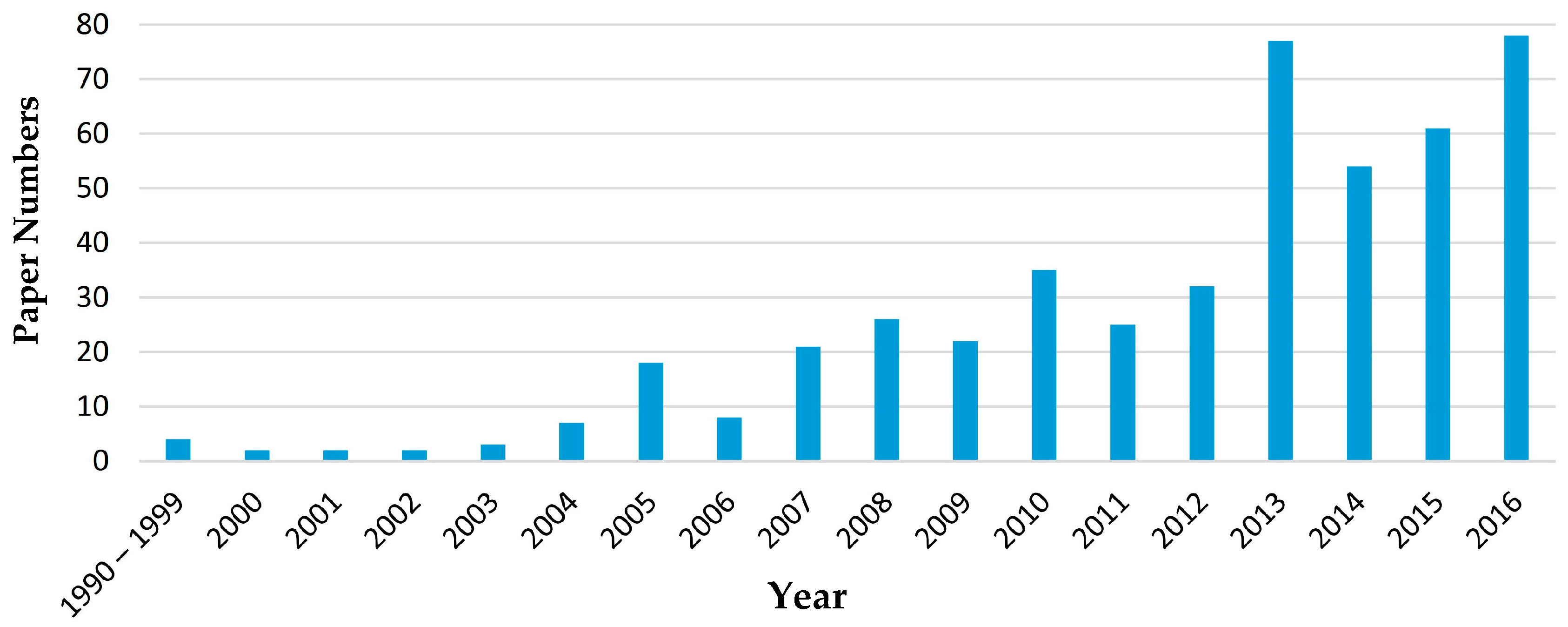

:1. Introduction

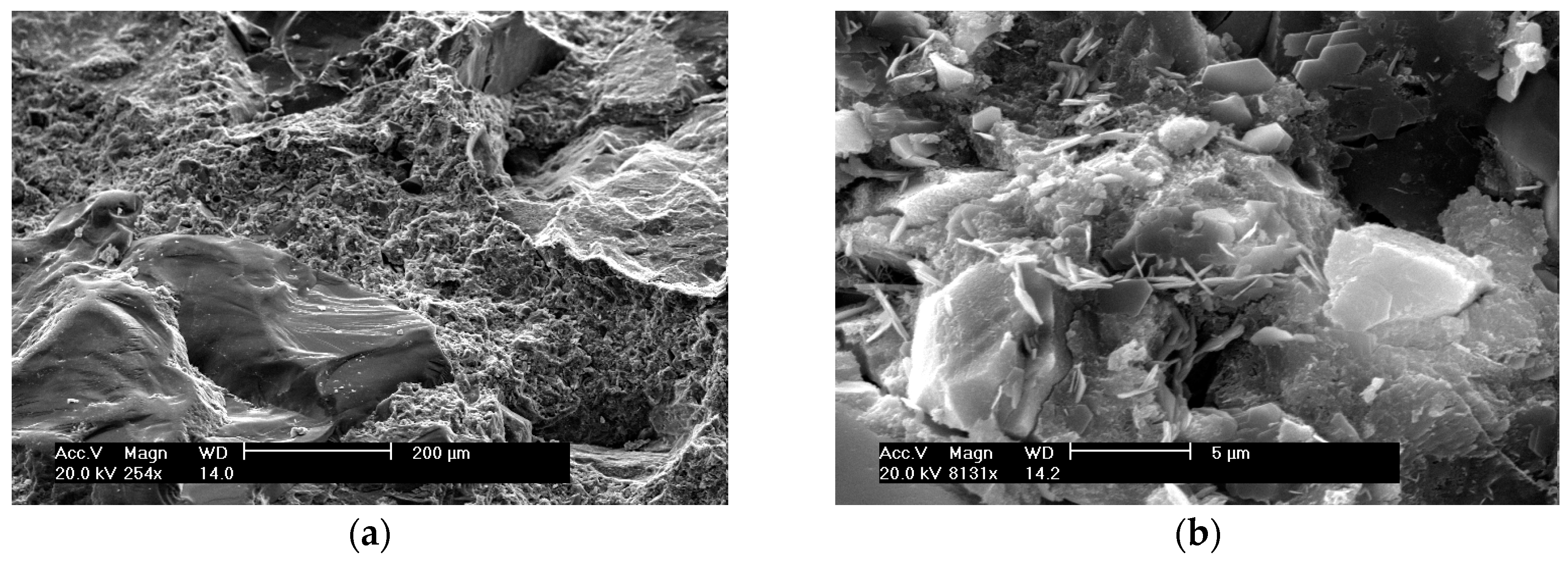

2. Concepts of Nanoscience and Nanotechnology Applied to Cement-Based Composites

3. Dispersion of Nanoinclusions in the Cement Matrix

4. Nanoinclusions

4.1. Non-Carbon-Based Nanoinclusions: Nanoparticles

4.1.1. Nanosilica

4.1.2. Nanotitania

4.1.3. Most Relevant Lines of Study Using Other Nanoparticles

4.2. Carbon-Based Nanoinclusions

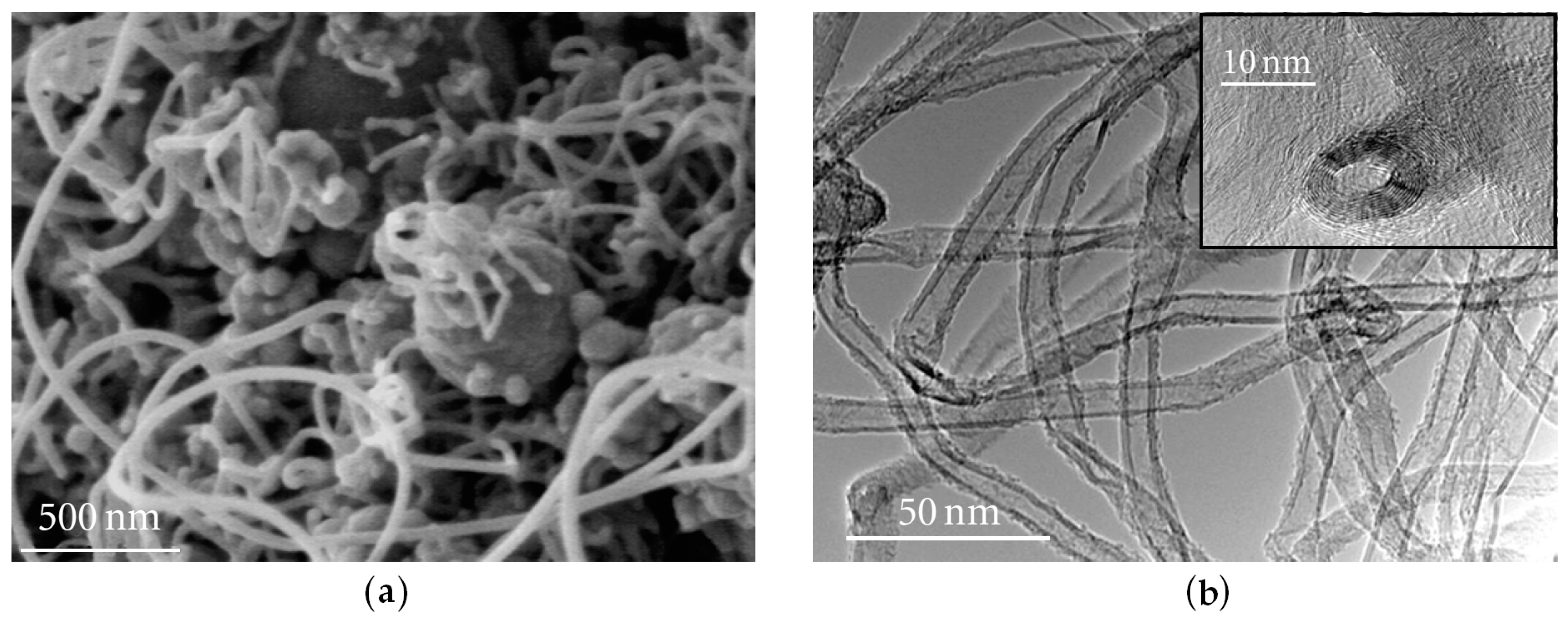

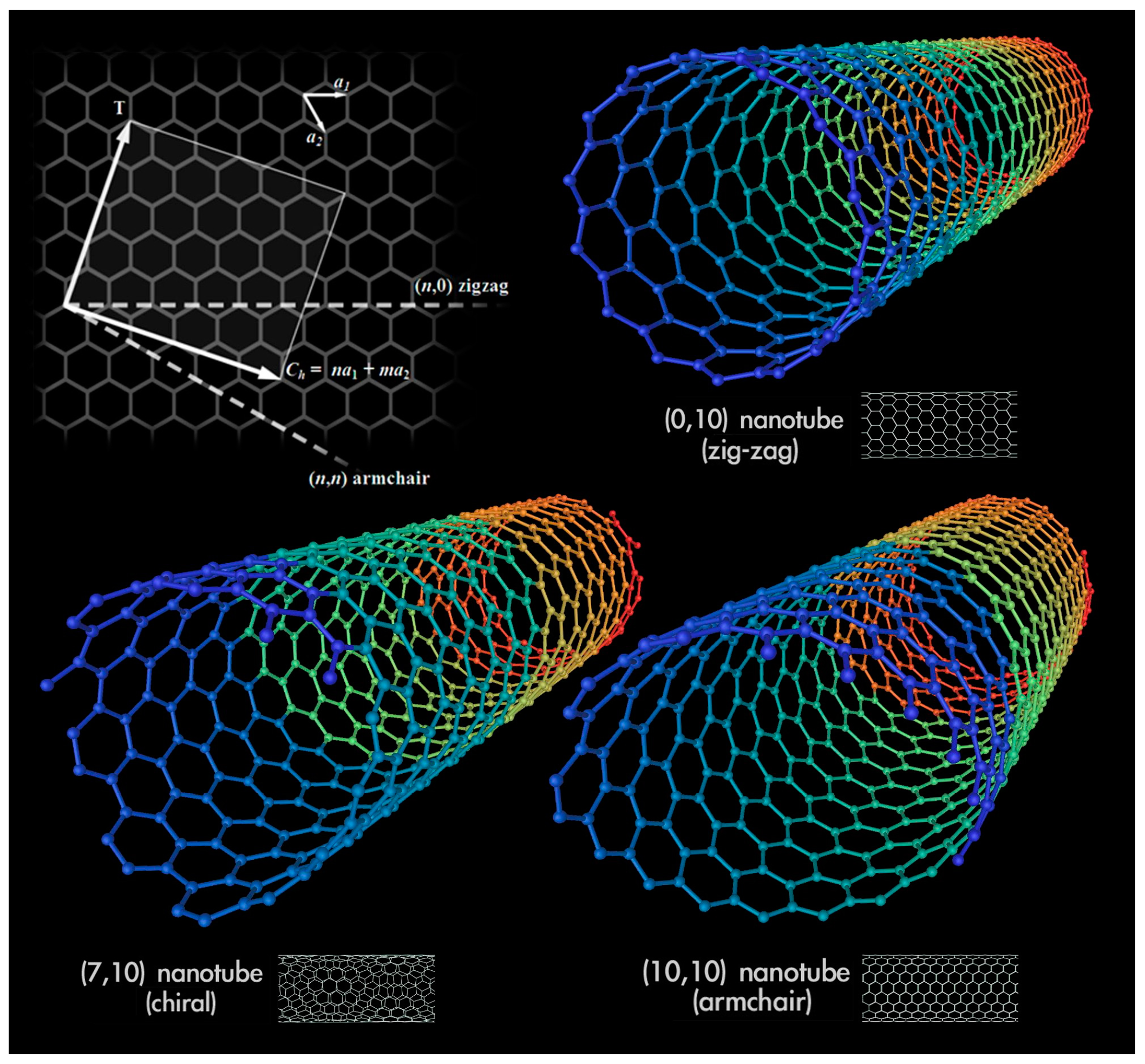

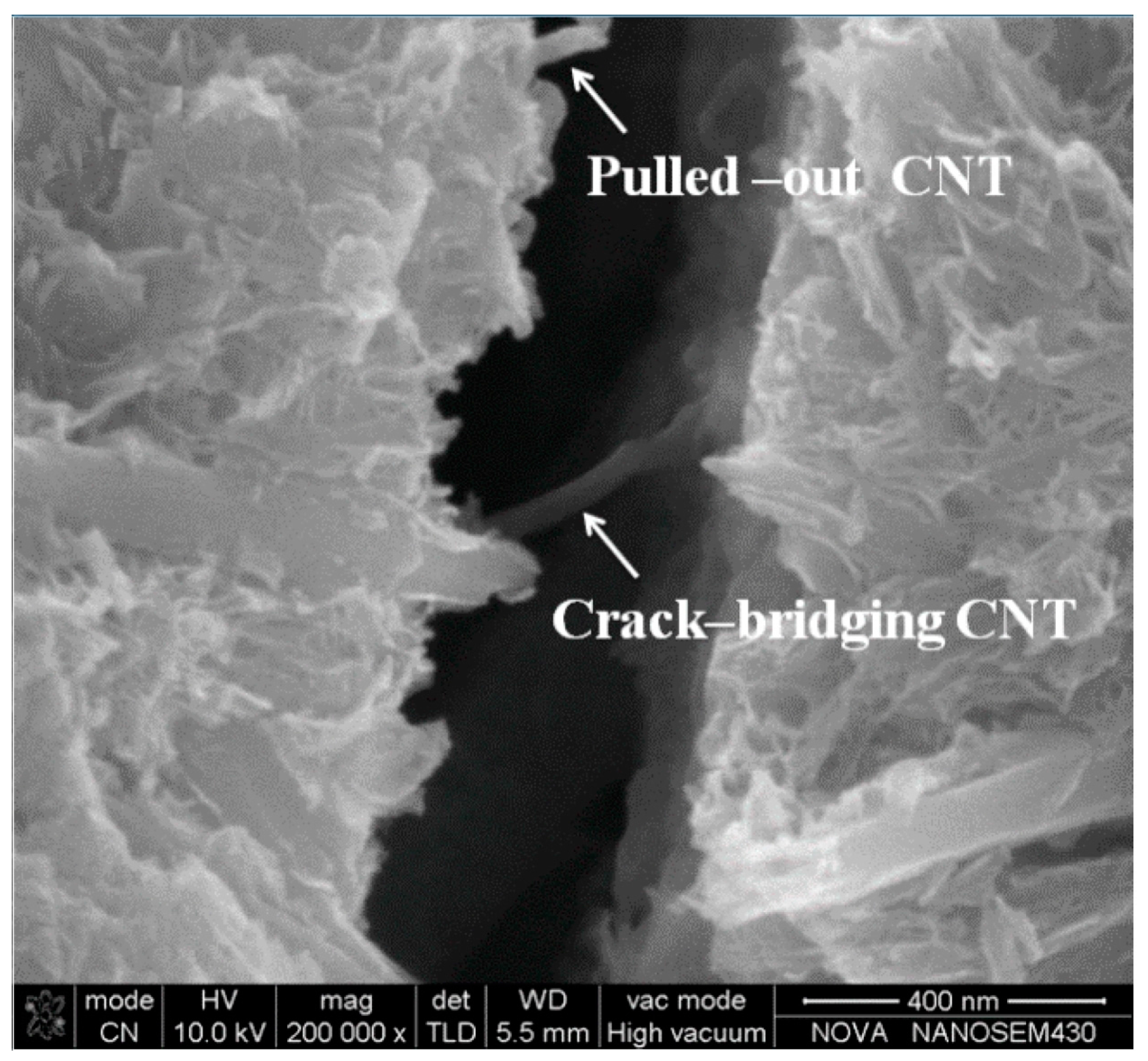

4.2.1. Carbon Nanotubes

4.2.2. Carbon Nanofibres

4.2.3. Graphene Oxide

4.2.4. Pristine Graphene and Graphite Nanoplatelets

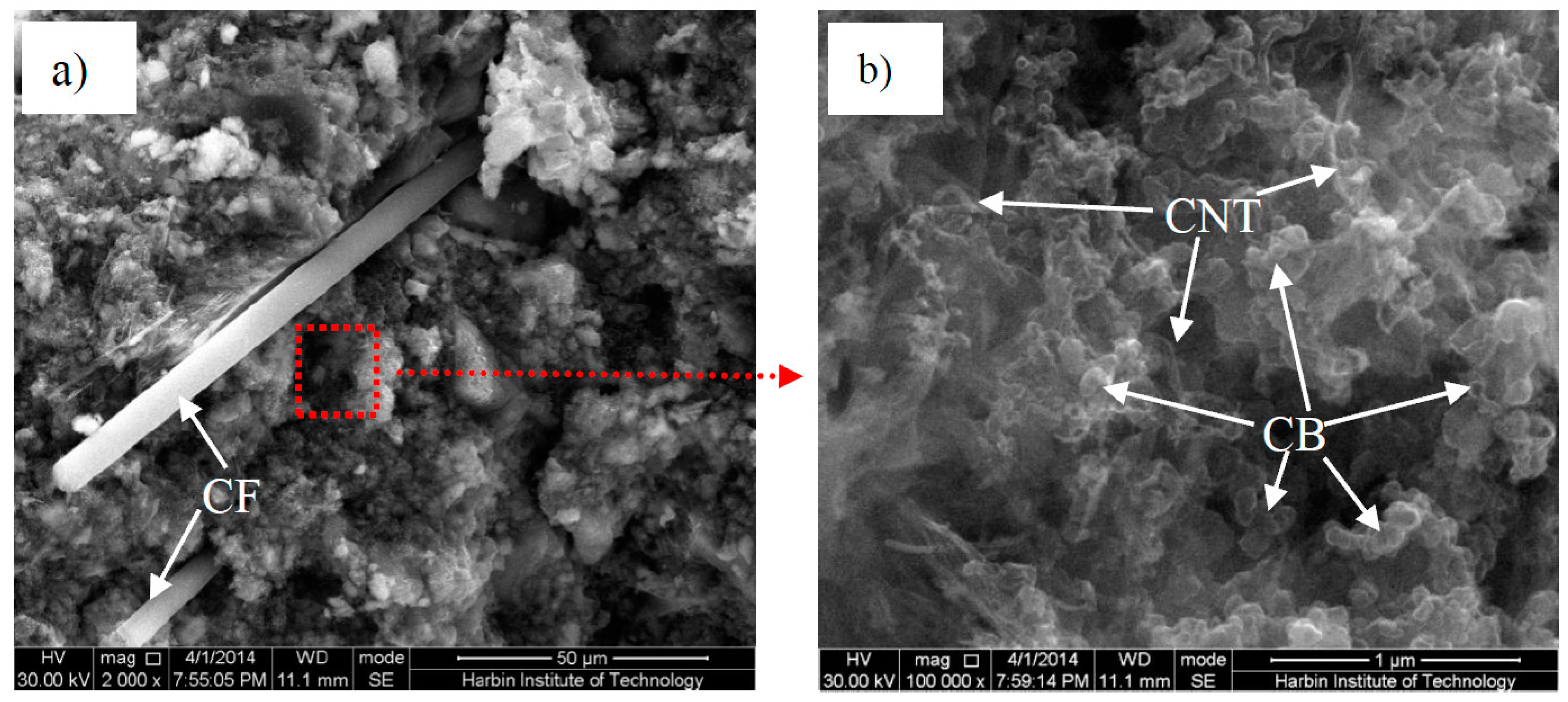

4.2.5. Carbon Black (CB) Nanoparticles

5. Health impact of Nanomaterials

6. Discussion of Results

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Aïtcin, P.-C. High-Performance Concrete; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Brandt, A.M. Cement-Based Composites: Materials, Mechanical Properties and Performance, 2nd ed.; Routledge: Abingdon, UK, 2009. [Google Scholar]

- Chung, D.D.L. Composite Materials. Science and Applications, 2nd ed.; Springer: London, UK, 2010. [Google Scholar]

- Loh, K.; Ryu, D. Multifunctional materials and nanotechnology for assessing and monitoring civil infrastructures. In Sensor Technologies for Civil Infrastructures; Wang, M.L., Lynch, J.P., Sohn, H., Eds.; Woodhead Publishing: Sawston, UK, 2014; Volume 1, pp. 295–326. [Google Scholar]

- Suominen, A.; Li, Y.; Youtie, J.; Shapira, P. A bibliometric analysis of the development of next generation active nanotechnologies. J. Nanopart. Res. 2016, 18, 270. [Google Scholar] [CrossRef]

- Dong, H.; Gao, Y.; Sinko, P.J.; Wu, Z.; Xu, J.; Jia, L. The nanotechnology race between China and the United States. Nanto Today 2016, 11, 7–12. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Diamanti, M.; Nazari, A.; Granqvist, C. Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Sawston, UK, 2013. [Google Scholar]

- Sanjuan, M.; Zaragoza, A.; Lopez, J. Standardization for an innovative world. Cem. Concr. Res. 2011, 41, 767–774. [Google Scholar] [CrossRef]

- Bavasso, I.; Vilardi, G.; Stoller, M.; Chianese, A.; Di Palma, L. Perspectives in nanotechnology based innovative applications for the environment. Chem. Eng. Trans. 2016, 47, 55–60. [Google Scholar]

- Naganathan, S.; Singh, C.S.J.; Shen, Y.W.; Kiat, P.E.; Thiruchelvam, S. Nanotechnology in civil engineering—A review. Adv. Mater. Res. 2014, 935, 151–154. [Google Scholar] [CrossRef]

- Rabbani, M.M.; Ahmed, I.; Park, S.-J. Application of nanotechnology to remediate contaminated soils. In Environmental Remediation Technologies for Metal-Contaminated Soils; Hasegawa, H., Rahman, I.M., Rahman, M.A., Eds.; Springer: Tokyo, Japan, 2016; pp. 219–229. [Google Scholar]

- Adeleye, A.S.; Conway, J.R.; Garner, K.; Huang, Y.; Su, Y.; Keller, A.A. Engineered nanomaterials for water treatment and remediation: Costs, benefits, and applicability. Chem. Eng. J. 2016, 286, 640–662. [Google Scholar] [CrossRef]

- Boostani, H.; Modirrousta, S. Review of nanocoatings for building application. Procedia Eng. 2016, 145, 1541–1548. [Google Scholar] [CrossRef]

- Dhar, R.; Elezzabi, A.; Al-Hussein, M. Smart window technologies: Electrochromics and nanocellulose thin film membranes and devices. SDRP J. Nanotechnol. Mater. Sci. 2016, 1, 1. [Google Scholar]

- Arnall, A.; Parr, D. Moving the nanoscience and technology (NST) debate forwards: Short-term impacts, long-term uncertainty and the social constitution. Technol. Soc. 2005, 27, 23–38. [Google Scholar] [CrossRef]

- Verma, S.; Vijaysingh, K.; Kushwaha, R. Nanotechnology: A review. In Proceedings of the Emerging Trends in Engineering & Management for Sustainable Development, Jaipur, India, 19–20 February 2016.

- Sobolev, K.; Gutiérrez, M.F. How nanotechnology can change the concrete world. Part one. Am. Ceram. Soc. Bull. 2005, 84, 14–18. [Google Scholar]

- Sobolev, K.; Gutiérrez, M.F. How nanotechnology can change the concrete world. Part two. Am. Ceram. Soc. Bull. 2005, 84, 16–19. [Google Scholar]

- Balaguru, P.N. Nanotechnology and concrete: Background, opportunities and challenges. In Proceedings of the International Conference on Applications of Nanotechnology in Concrete Design, Dundee, UK, 5–7 July 2005; pp. 113–122.

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Shih, J.-Y.; Chang, T.-P.; Hsiao, T.-C. Effect of nanosilica on characterization of Portland cement composite. Mater. Sci. Eng. A 2006, 424, 266–274. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Ou, J.-P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; He, S.; Lu, Y.; Wang, M. Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater. Lett. 2006, 60, 356–359. [Google Scholar] [CrossRef]

- Chang, T.-P.; Shih, J.-Y.; Yang, K.; Hsiao, T.-C. Material properties of Portland cement paste with nano-montmorillonite. J. Mater. Sci. 2007, 42, 7478–7487. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.-M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Li, H. The influence of surfactants on the processing of multi-walled carbon nanotubes in reinforced cement matrix composites. Phys. Status Solidi A Appl. Res. 2009, 206, 2783–2790. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef] [Green Version]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Aslani, F. Nanoparticles in self-compacting concrete—A review. Mag. Concr. Res. 2015, 67, 1048–1100. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Miraldo, S.; Ding, Y.; Labrincha, J.A. Targeting HPC with the help of nanoparticles: An overview. Constr. Build. Mater. 2013, 38, 365–370. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.-H.; Xie, N.; Feng, L.-C.; Zhong, J. Applications of nanostructured carbon materials in constructions: The state of the art. J. Nanomater. 2015, 2015, 807416. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon nanotube reinforced cementitious composites: An overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Xu, S. Progress in research on carbon nanotubes reinforced cementitious composites. Adv. Mater. Sci. Eng. 2015, 2015, 307435. [Google Scholar] [CrossRef]

- Bachilo, S.M.; Brown, E.; D’Alessandro, A.; Ding, S.; Dong, S.; Glisic, B.; Gupta, S.; Han, B.; Hou, T.-C.; Laflamme, S.; et al. Innovative Developments of Advanced Multifunctional Nanocomposites in Civil and Structural Engineering; Loh, K., Nagarajaiah, S., Eds.; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Han, B.; Yu, X.; Ou, J.; Steyn, W.J.; Selvam, R.P.; Hall, K.D.; Subramani, V.J.; Murray, S.J.; Makar, J.; Li, H.; et al. Nanotechnology in Civil Infrastructure; Gopalakrishnan, K., Birgisson, B., Taylor, P., Attoh-Okine, N.O., Eds.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Birgisson, B.; Mukhopadhyay, A.K.; Geary, G.; Khan, M.; Sobolev, K. Nanotechnology in Concrete Materials—A Synopsis; Transportation Research Circular E-C170; Transportation Research Board: Washington, DC, USA, 2012. [Google Scholar]

- Casini, M. Smart Buildings. Advanced Materials and Nanotechnology to Improve Energy-Efficiency and Environmental Performance; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Leone, M.F. Nanotechnology for architecture. Innovation and eco-efficiency of nanostructured cement-based materials. J. Architec. Eng. Technol. 2012, 1, 1–9. [Google Scholar] [CrossRef]

- Kumar, N.; Kumbhat, S. Essentials in Nanoscience and Nanotechnology; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Acharya, A.; Kamilla, S.K.; Nayak, M.K.; Roy, G.S. Nano the revolution of 21st century. Lat. Am. J. Phys. Educ. 2011, 5, 418–422. [Google Scholar]

- Sobolev, K. Modern developments related to nanotechnology and nanoengineering of concrete. Front. Struct. Civ. Eng. 2016, 10, 131–141. [Google Scholar] [CrossRef]

- Interagency Working Group on Nanoscience, Engineering and Technology. National Nanotechnology Initiative: Leading to the Next Industrial Revolution. Available online: https://www.whitehouse.gov/files/documents/ostp/NSTC%20Reports/NNI2000.pdf (accessed on 3 October 2016).

- Grove, J.; Vanikar, S.; Crawford, G. Nanotechnology: New tools to address old problems. Transp. Res. Rec. 2010, 2141, 47–51. [Google Scholar] [CrossRef]

- Hewlett, P. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

- Chae, S.R.; Moon, J.; Yoon, S.; Bae, S.; Levitz, P.; Winarski, R.; Monteiro, P.J.M. Advanced nanoscale characterization of cement based materials using X-ray synchrotron radiation: A review. Int. J. Concr. Struct. Mater. 2013, 7, 95–110. [Google Scholar] [CrossRef]

- Sharif, A. Review on advances in nanoscale microscopy in cement research. Micron 2016, 80, 45–58. [Google Scholar] [CrossRef] [PubMed]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Trapote-Barreira, A.; Porcar, L.; Cama, J.; Soler, J.; Allen, A.J. Structural changes in C–S–H gel during dissolution: Small-angle neutron scattering and Si-NMR characterization. Cem. Concr. Res. 2015, 72, 76–89. [Google Scholar] [CrossRef]

- Sebastiani, M.; Moscatelli, R.; Ridi, F.; Baglioni, P.; Carassiti, F. High-resolution high-speed nanoindentation mapping of cement pastes: Unravelling the effect of microstructure on the mechanical properties of hydrated phases. Mater. Des. 2016, 97, 372–380. [Google Scholar] [CrossRef]

- Scrivener, K.; Kirkpatrick, R. Innovation in use and research on cementitious material. Cem. Concr. Res. 2008, 38, 128–136. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Wang, W.; Ouyang, D.; Wang, P.; Xing, F. Pozzolanic reactivity of silica fume and ground rice husk ash as reactive silica in a cementitious system: A comparative study. Materials 2016, 9, 146. [Google Scholar] [CrossRef]

- Papatzani, S.; Paine, K.; Calabria-Holley, J. A comprehensive review of the models on the nanostructure of calcium silicate hydrates. Constr. Build. Mater. 2015, 74, 219–234. [Google Scholar] [CrossRef]

- Raki, L.; Beaudoin, J.; Alizadeh, R.; Makar, J.; Sato, T. Cement and concrete nanoscience and nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A Review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 1–19. [Google Scholar] [CrossRef]

- Hassan, N.M.; Fattah, K.; Tamimi, A. Standardizing protocol for incorporating cnts in concrete. In Proceedings of the World Congress on New Technologies (NewTech 2015), Barcelona, Spain, 15–17 July 2015.

- Basiuk, E.; Basiuk, V. Solvent-free functionalization of carbon nanomaterials. In Green Processes for Nanotechnology—From Inorganic to Bioinspired Nanomaterials; Springer: Cham, Switzerland, 2015; pp. 163–205. [Google Scholar]

- Chen, D.; Feng, H.; Li, J. Graphene oxide: Preparation, functionalization, and electrochemical applications. Chem. Rev. 2012, 112, 6027–6053. [Google Scholar] [CrossRef] [PubMed]

- Georgakilas, V.; Otyepka, M.; Bourlinos, A.B.; Chandra, V.; Kim, N.; Kemp, K.C.; Hobza, P.; Zboril, R.; Kim, K.S. Functionalization of graphene: Covalent and non-covalent approaches, derivatives and applications. Chem. Rev. 2012, 112, 6156–6214. [Google Scholar] [CrossRef] [PubMed]

- Hanus, M.J.; Harris, A.T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Compos. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Katsnelson, M. Graphene: Carbon in two dimensions. Mater. Today 2007, 10, 20–27. [Google Scholar] [CrossRef]

- Metaxa, Z.; Konsta-Gdoutos, M.; Shah, S. Carbon nanofiber-reinforced cement-based materials. Transp. Res. Rec. 2010, 2142, 114–118. [Google Scholar] [CrossRef]

- Mendoza, O. Efecto Híbrido de los Nanotubos de Carbono y la Nanosílice Sobre las Propiedades Mineralógicas l Mecánicas de Morteros de Cemento Pórtland. Master’s Thesis, Universidad Nacional de Colombia, Medellin, Colombia, 1 August 2013. [Google Scholar]

- Decuzzi, P.; Mitragotri, S. Introduction to special issue on “Nanoparticles in medicine: Targeting, optimization and clinical applications”. Bioeng. Transl. Med. 2016, 1, 8–9. [Google Scholar] [CrossRef]

- Stark, W.J.; Stoessel, P.R.; Wohlleben, W.; Hafner, A. Industrial applications of nanoparticles. Chem. Soc. Rev. 2015, 44, 5793–5805. [Google Scholar] [CrossRef] [PubMed]

- Khaloo, A.; Mobini, M.H.; Hosseini, P. Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr. Build. Mater. 2016, 113, 188–201. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of nanoclay and calcined nanoclay-cement nanocomposites. Compos. Part B 2015, 78, 174–184. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Xie, N. Mechanical and environmental resistance of nanoparticle-reinforced pavement materials. In Innovative Developments of Advanced Multifunctional Nanocomposites in Civil and Structural Engineering; Loh, K., Nagarajaiah, S., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 217–246. [Google Scholar]

- Chithra, S.; Senthil Kumar, S.R.R.; Chinnaraju, K. The effect of colloidal nano-silica on workability, mechanical and durability properties of high performance concrete with copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 15, 794–804. [Google Scholar] [CrossRef]

- Kumar, D.; Sharma, N. Study of Compressive Strength of Concrete Using Nano Silica. Available online: http://matjournals.in/index.php/JoCCS/article/view/581 (accessed on 21 October 2016).

- Zhang, L.; Ma, N.; Wang, Y.; Han, B.; Cui, X.; Yu, X.; Ou, J. Study on the reinforcing mechanisms of nano silica to cement-based materials with theoretical calculation and experimental evidence. J. Compos. Mater. 2016, 1–12. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Asaad, D.S.; Muhyaddin, G.F. Properties of low binder ultra-high performance cementitious composites: Comparison of nanosilica and microsilica. Constr. Build. Mater. 2016, 102, 706–713. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Tae, G.; Park, J.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Ghazy, M.F.; Elaty, M.A.A.; Elkhoriby, R.S. Performance of blended cement mortars incorporating nano-metakaolin particles at elevated temperatures. In Proceeding of the International Conference on Advances in Structural and Geotechnical Engineering, Hurghada, Egypt, 6–9 April 2015.

- Al-Rifaie, W.; Ahmed, W. Effect of nanomaterials in cement mortar characteristics. J. Eng. Sci. Technol. 2016, 11, 1321–1332. [Google Scholar]

- Moradpour, R.; Taheri-Nassaj, E.; Parhizkar, T.; Ghodsian, M. The effects of nanoscale expansive agents on the mechanical properties of non-shrink cement-based composites: The influence of nano-MgO addition. Compos. Part B 2013, 55, 192–202. [Google Scholar] [CrossRef]

- Gonzalez, M.; Tighe, S.; Hui, K.; Rahman, S.; Oliveira Lima, A. Evaluation of freeze/thaw and scaling response of nanoconcrete for Portland cement concrete (PCC) pavements. Constr. Build. Mater. 2016, 120, 465–472. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Awang, A.B.; Wong, S.S.; Nhavene, C.P. Properties of nano silica modified rubbercrete. J. Clean. Prod. 2016, 119, 66–75. [Google Scholar] [CrossRef]

- Li, W.; Luo, Z.; Long, C.; Wu, C.; Duan, W.H.; Shah, S.P. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater. Des. 2016, 112, 58–66. [Google Scholar] [CrossRef]

- Harbec, D.; Bahri, H.; Tagnit-Hamou, A.; Gitzhofer, F. New silica fume from recycled glass. In Proceedings of the Fifth international Symposium on Nanotechnology in Construction, Chicago, IL, USA, 24–26 May 2015.

- Aly, M.; Hashmi, M.; Olabi, A.; Messeiry, M.; Abadir, E.; Hussain, A. Effect of colloidal nano-silica on the mechanical and physical behaviour of waste-glass cement mortar. Mater. Des. 2012, 33, 127–135. [Google Scholar] [CrossRef]

- Hamaali, A. A Study of Selecting an Efficient Procedure for Intermittent Electromechanical Chloride Extraction. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2010. [Google Scholar]

- Díaz-Peña, I.; Gonzalez-Lopez, R.; Sanchez, M.; Alonso, M.C.; Zaldivar-Cadena, A.; Hernández-Sandoval, J.; Guzmán, A.M. Effect of the electrochemical migration of colloidal nano-SiO2 on the durability performance of hardened cement mortar. Int. J. Electrochem. Sci. 2015, 10, 10261–10271. [Google Scholar]

- Fajardo, G.; Cruz-López, A.; Cruz-Moreno, D.; Valdez, P.; Torres, G.; Zanella, R. Innovative application of silicon nanoparticles (SN): Improvement of the barrier effect in hardened Portland cement-based materials. Constr. Build. Mater. 2015, 76, 158–167. [Google Scholar] [CrossRef]

- Shan, H.; Xu, J.; Wang, Z.; Jiang, L.; Xu, N. Electromechanical chloride removal in reinforced concrete structures: Improvement of effectiveness by simultaneous migration of silicate ion. Constr. Build. Mater. 2016, 127, 344–352. [Google Scholar] [CrossRef]

- Climent, M.; Carmona, J.; Garcés, P. Graphite-cement paste: A new coating of reinforced concrete structural elements for the application of electrochemical anti-corrosion treatments. Coatings 2016, 6, 32. [Google Scholar] [CrossRef]

- Mendes, T.; Hotza, D.; Repette, W. Nanoparticles in cement based materials: A review. Rev. Adv. Master. Sci. 2015, 40, 89–96. [Google Scholar]

- Cerro-Prada, E.; Manso, M.; Torres, V.; Soriano, J. Microstructural and photocatalytic characterization of cement-paste sol-gel synthesized titanium dioxide. Front. Struct. Civ. Eng. 2016, 10, 189–197. [Google Scholar] [CrossRef]

- Ganji, N.; Allahverdi, A.; Naeimpoor, F.; Mahinroosta, M. Photocatalytic effect of nano-TiO2 loaded cement on dye decolorization and Escherichia coli inactivation under UV irradiation. Res. Chem. Intermediat. 2016, 42, 5395–5412. [Google Scholar] [CrossRef]

- Cohen, J.D.; Sierra-Gallego, G.; Tobón, J.I. Evaluation of photocatalytic properties of Portland cement blended with titanium oxynitride (TiO2−xNy) nanoparticles. Coatings 2015, 5, 465–476. [Google Scholar] [CrossRef]

- Zhao, A.; Yang, J.; Yang, E.H. Self-cleaning engineered cementitious composites. Cem. Concr. Compos. 2015, 64, 74–83. [Google Scholar] [CrossRef]

- Waked, A. Nano materials applications for conservation of cultural heritage. In Proceedings of the Structural Studies, Repairs and Maintenance of Heritage Architecture XII, Chianciano Terme, Italy, 5–7 September 2011.

- Jafari, H.; Afshar, S. Improved photodegradation of organic contaminants using nano-TiO2 and TiO2-SiO2 deposited on Portland cement concrete blocks. Photochem. Photobiol. 2016, 92, 87–101. [Google Scholar] [CrossRef] [PubMed]

- Broekhuizen, F.; Broekhuizen, P. Nano-Products in the European Construction Industry—State of the Art 2009; IVAM: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Quagliarini, E.; Bondioli, F.; Goffredo, G.; Licciulli, A.; Munafò, P. Smart surfaces for architectural heritage: Preliminary results about the application of TiO2-based coatings on travertine. J. Cult. Herit. 2012, 13, 204–209. [Google Scholar] [CrossRef]

- Faraldos, M.; Kropp, R.; Anderson, M.A.; Sobolev, K. Photocatalytic hydrophobic concrete coatings to combat air pollutions. Catal. Today 2015, 259, 228–236. [Google Scholar] [CrossRef]

- Ramachandran, R.; Kozhukhova, M.; Sobolev, K.; Nosonovsky, M. Anti-icing superhydrophobic surfaces: Controlling entropic molecular interactions to design novel icephobic concrete. Entropy 2016, 18, 132. [Google Scholar] [CrossRef]

- Mutuk, H.; Mutuk, T.; Gümüş, H.; Oktay, B.M. Shielding behaviors and analysis of mechanical treatment of cements containing nanosized powders. Acta Phys. Pol. A 2016, 130, 172–174. [Google Scholar] [CrossRef]

- Zhang, L.; Han, B.; Ding, S.; Yu, X.; Sun, S.; Ou, J. Nano-scale behaviour and nano-modification of cement and concrete materials. In Advanced Research on Nanotechnology for Civil Engineering Applications; Khitab, A., Anwar, W., Eds.; Engineering Science Reference: Hershey, PA, USA, 2016; pp. 28–79. [Google Scholar]

- Liu, M.; Zhou, Z.; Zhang, X.; Yang, X.; Cheng, X. The synergistic effect of nano-silica with blast furnace slag in cement based materials. Constr. Build. Mater. 2016, 126, 624–631. [Google Scholar] [CrossRef]

- Garg, R.; Bansal, M.; Aggarwal, Y. Strength, rapid chloride penetration and microstructure study of cement mortar incorporating micro and nano silica. Int. J. Electrochem. Sci. 2016, 11, 3697–3713. [Google Scholar] [CrossRef]

- Ismael, R.; Silva, J.; Carmo, R.; Soldado, E.; Lourenço, C.; Costa, H.; Júlio, E. Influence of nano-SiO2 and nano-Al2O3 additions on steel-to-concrete bonding. Constr. Build. Mater. 2016, 125, 1080–1092. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2014, 57, 64–67. [Google Scholar] [CrossRef]

- Cai, Y.; Hou, P.; Zhou, Z.; Cheng, X. Effects of nano-CaCO3 on the properties of cement paste: Hardening process and shrinkage at different humidity levels. In Proceedings of the 5th International Conference on Durability of Concrete Structures, Shenzhen, China, 30 June–1 July 2016.

- Shah, S.; Hou, P.; Konsta-Gdoutos, M. Nano-modification of cementitious material: Toward a stronger and durable concrete. J. Sustain. Cem. Based Mater. 2015, 5, 1–22. [Google Scholar] [CrossRef]

- Jayapalan, A.R.; Lee, B.Y.; Kurtis, K.E. Can nanotechnology be “green”? Comparing efficacy of nano and microparticles in cementitious materials. Cem. Concr. Compos. 2013, 36, 16–24. [Google Scholar] [CrossRef]

- Dreyer, D.; Ruoff, R.; Bielawski, C. From conception to realization: An historial account of graphene and some perspectives for its future. Angew. Chem. 2010, 49, 9336–9344. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.; Novoselov, K. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Kysar, J.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhass, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Dikin, D.A.; Stankovich, S.; Zimney, E.J.; Piner, R.D.; Dommett, G.H.B.; Evmenenko, G.; Nguyen, S.T.; Ruoff, R.S. Preparation and characterization of graphene oxide paper. Nature 2007, 448, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Peigney, A.; Laurent, C.; Flahaut, E.; Bacsa, R.R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Shapira, P.; Gok, A.; Salehi, F. Graphene enterprise: Mapping innovation and business development in a strategic emerging technology. J. Nanopart. Res. 2016, 269, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Somani, S.; Pawar, S. Graphene: A review. Int. Res. J. Eng. Technol. 2016, 3, 375–378. [Google Scholar]

- Lee, H.; Liu, W.-W.; Chai, S.; Mohamed, A.; Lai, C.; Khe, C.-S.; Voon, C.; Hashim, U.; Hidayah, N. Synthesis of single-layer graphene: A review of recent development. Procedia Chem. 2016, 19, 916–921. [Google Scholar] [CrossRef]

- Guo, H.-L.; Wang, X.-F.; Qian, Q.-Y.; Wang, F.-B.; Xia, X. A green approach to the synthesis of graphene nanosheets. ACS Nano 2009, 3, 2653–2659. [Google Scholar] [CrossRef] [PubMed]

- Volder, M.; Tawfick, S.; Baughman, R.; Hart, A. Carbon nanotubes: Present and future commercial applications. Science 2013, 1, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Kothiyal, N. Facile growth of carbon nanotubes coated with carbon nanoparticles: A potential low-cost hybrid nanoadditive for improved mechanical, electrical, microstructural and crystalline properties of cement mortar matrix. Constr. Build. Mater. 2016, 123, 829–846. [Google Scholar] [CrossRef]

- Mudimela, P.R.; Nasibulina, L.I.; Nasibulin, A.G.; Cwirzen, A.; Valkeapää, M.; Habermehl-Cwirzen, K.; Malm, J.E.M.; Karppinen, M.J.; Penttala, V.; Koltsova, T.S.; et al. Synthesis of carbon nanotubes and nanofibers on silica and cement matrix materials. J. Nanomater. 2009, 2009, 29. [Google Scholar] [CrossRef]

- Hummers, W.; Offeman, R. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Guo, S.; Dong, S. Graphene nanosheet: Synthesis, molecular engineering, thin film, hybrids, and energy and analytical applications. Chem. Soc. Rev. 2011, 40, 2644–2672. [Google Scholar] [CrossRef] [PubMed]

- Kotrechko, S.; Mikhailovskij, I.; Mazilova, T.; Sadanov, E.; Timoshevskii, A.; Stetsenko, N.; Matviychuk, Y. Mechanical properties of carbyne: Experiment and simulations. Nanoscale Res. Lett. 2015, 10, 24. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Carbon nanotubes: Past, present, and future. Phys. B Condens. Matter 2002, 323, 1–5. [Google Scholar] [CrossRef]

- Alrekabi, S.; Cundy, A.; Lampropoulos, A.; Savina, I. Experimental investigation on the effect of ultrasonication on dispersion and mechanical performance of multi-wall carbon nanotube-cement mortar composites. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2016, 10, 268–274. [Google Scholar]

- Serp, P.; Corrias, M.; Kalck, P. Carbon nanotubes and nanofibers in catalysis. Appl. Catal. A Gen. 2003, 253, 337–358. [Google Scholar] [CrossRef]

- Dai, H. Carbon nanotubes: Synthesis, integration, and properties. Acc. Chem. Res. 2002, 35, 1035–1044. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Dresselhaus, G.; Eklund, P.C. Science of Fullerenes and Carbon Nanotubes; Academic Press: San Diego, CA, USA, 1996. [Google Scholar]

- Fattah, K.; Hassan, N.; Tamimi, A. Effect of adding polar impurities on carbon nanotubes and concrete bonding strength. In Proceedings of the 10th International Conference on Composite Science and Technology, Lisboa, Portugal, 2–4 September 2015.

- Ströck, M. Wikipedia—Types of Carbon Nanotubes. Available online: https://en.wikipedia.org/wiki/File:Types_of_Carbon_Nanotubes.png (accessed on 8 November 2016).

- Del Carmen Camacho, M.; Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Mechanical properties and durability of CNT cement composites. Materials 2014, 7, 1640–1651. [Google Scholar] [CrossRef]

- Vera-Agullo, J.; Chozas-Ligero, V.; Portillo-Rico, D.; García-Casas, M.J.; Gutiérrez-Martínez, A.; Mieres-Royo, J.M.; Grávalos-Moreno, J. Mortar and concrete reinforced with nanomaterials. Nanotechnol. Constr. 2009, 3, 383–388. [Google Scholar]

- Lu, L.; Ouyang, D.; Xu, W. Mechanical properties and durability of ultra high strength concrete incorporating multi-walled carbon nanotubes. Materials 2016, 9, 419. [Google Scholar] [CrossRef]

- Bekyarova, E.; Sarkar, S.; Wang, F.; Itkis, M.E.; Kalinina, I.; Tian, X.; Haddon, R.C. Effect of covalent chemistry on the electronic structure and properties of carbon nanotubes and graphene. Acc. Chem. Res. 2013, 46, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Isfahani, F.T.; Li, W.; Redaelli, E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites. Cem. Concr. Compos. 2016, 74, 154–163. [Google Scholar] [CrossRef]

- Stynoski, P.; Mondal, P.; Wotring, E.; Marsh, C. Characterization of silica-functionalized carbon nanotubes dispersed in water. J. Nanopart. Res. 2013, 15, 1396. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Tamimi, A.; Hassan, N.M.; Fattah, K.; Talachi, A. Performance of cementitious materials produced by incorporating surface treated multiwall carbon nanotubes and silica fume. Constr. Build. Mater. 2016, 114, 934–945. [Google Scholar] [CrossRef]

- Hassani, A.; Fakhim, B.; Rashidi, A.; Ghodoosi, P. The influence of graphene oxide on mechanical properties and increase in durability of concrete pavement. Int. J. Transp. Eng. 2016, 2, 119–130. [Google Scholar]

- Wang, Q.; Wang, J.; Lu, C.-X.; Liu, B.-W.; Zhang, K.; Li, C.-Z. Influence of graphene oxide additions on the microstructure and mechanical strength of cement. New Carbon Mater. 2015, 30, 349–356. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.; Leung, C.K.Y. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr. Build. Mater. 2016, 1220, 457–464. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Influence of graphene oxide as dispersed phase in cement mortar matrix in defining the crystal patterns of cement hydrates and its effect on mechanical, microstructural and crystalization properties. RSC Adv. 2015, 5, 52642–52657. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Al-Nuaimi, N.; Al-Rub, R.K.A.; Senouci, A.; Bani-Hani, K.A. Effect of mixing duration on flexural strength of multiwalled carbon nanotubes cementitious composites. Constr. Build. Mater. 2016, 126, 586–598. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Metaxa, Z. Exfoliated graphene nanoplatelet cement-based nanocomposites as piezoresistive sensors: Influence of nanoreinforcement lateral size on monitoring capability. Sci. Technol. Mater. 2016, 28, 73–79. [Google Scholar] [CrossRef]

- Du, H.; Pang, S. Mechanical response and strain sensing of cement composites added with graphene nanoplatelet under tension. In Nanotechnology in Construction; Sobolev, K., Shah, S.P., Eds.; Springer: Cham, Switzerland, 2015; pp. 377–382. [Google Scholar]

- Mo, Y.L.; Roberts, R.H. Carbon nanofiber concrete for damage detection of infrastructure. In Advances in Nanofibers; Maguire, R., Ed.; In Tech: Rijeka, Croatia, 2013. [Google Scholar]

- Chen, P.-W.; Chung, D.D. Concrete as a new strain/stress sensor. Compos. Part B Eng. 1996, 27, 11–23. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Zuo, J.; Yao, W.; Liu, X.; Qin, J. Sensing properties of carbon nanotube–carbon fiber/cement nanocomposites. J. Test. Eval. 2012, 40, 1–6. [Google Scholar] [CrossRef]

- Micheli, D.; Pastore, R.; Vricella, A.; Morles, R.B.; Marchetti, M.; Delfini, A.; Moglie, F.; Primiani, V.M. Electromagnetic characterization and shielding effectiveness of concrete composite reinforced with carbon nanotubes in the mobile phones frequency band. Mater. Sci. Eng. B 2014, 188, 119–129. [Google Scholar] [CrossRef]

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Govind; Chandra, A.; Mathur, R.B.; Dhawan, S.K. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Khushnood, R.; Ahmad, S.; Savi, P.; Tulliani, J.-M.; Giorcelli, M.; Ferro, G. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar] [CrossRef]

- Li, P.; Lin, J.; Poo, C.H.; Low, A.S.; Yin, X.J. Carbon nanotube coatings for building EMI shielding. In Advances in Civil Engineering and Building Materials; Chang, S.-Y., Al Bahar, S.K., Zhao, J., Eds.; CRC Press: Boca Raton, FL, USA, 2013; pp. 83–86. [Google Scholar]

- Yazdani, N.; Mohanam, V. Carbon nano-tube and nano-fiber in cement mortar: Effect of age and dosage rate. Int. J. Mater. Sci. 2014, 4, 45–52. [Google Scholar] [CrossRef]

- Yazdani, N.; Brown, E. Carbon nanofibers in cement composites: Mechanical reinforcement. In Innovative Developments of Advanced Multifunctional Nanocomposites in Civil and Structural Engineering; Loh, K., Nagarajaiah, S., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 217–246. [Google Scholar]

- Kim, Y.A.; Hayashi, T.; Endo, M.; Dresselhaus, M.S. Springer Handbook of Nanomaterials; Vajtai, R., Ed.; Springer: Berlin, Germany, 2013; pp. 233–262. [Google Scholar]

- Danoglidis, P.A.; Falara, M.G.; Kalontriotou, M.K.; Konsta-Gdoutos, M.S.; Gdoutos, E.E. MWCNT and CNF cementitious nanocomposites for enhanced strength and toughness. In Mechanics of Composites and Multi-Functional Materials; Ralph, C., Silberstein, M., Thakre, P.R., Singh, R., Eds.; Springer International: Cham, Switzerland, 2016; Volume 7, pp. 241–246. [Google Scholar]

- Metaxa, Z.S.; Konsta-Gdoutos, M.S.; Shah, S.P. Mechanical properties and nanostructure of cement-based materials reinforced with carbon nanofibers and Polyvinyl Alcohol (PVA) microfibers. In Advances in the Material Science of Concrete, Proceedings of the Session at the ACI Spring 2010 Convention, Chicago, IL, USA, 21–25 March 2010; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2010; pp. 115–126. [Google Scholar]

- Wang, J.; Sun, L.; Wu, Y.; Li, M.; Jiang, K.; Fan, S. Nanocarbon/Metal oxide hybrids for lithium ion batteries. In Nanocarbons for Advanced Energy Storage; Feng, X., Ed.; Wiley-VCH: Weinheim, Germany, 2015; Volume 1, pp. 87–118. [Google Scholar]

- Lide, D.R. Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Galao, O.; Bañón, L.; Baeza, F.J.; Carmona, J.; Garcés, P. Highly conductive carbon fiber reinforced concrete for icing prevention and curing. Materials 2016, 9, 281. [Google Scholar] [CrossRef]

- Gomis, J.; Galao, O.; Gomis, V.; Zornoza, E.; Garcés, P. Self-heating and deicing conductive cement: Experimental study and modeling. Constr. Build. Mater. 2015, 75, 442–449. [Google Scholar] [CrossRef]

- Gao, D.; Strum, M.; Mo, Y.L. Electrical resistance of carbon-nanofiber concrete. Smart Mater. Struct. 2009, 18, 1–7. [Google Scholar] [CrossRef]

- Sanchez, F. Carbon nanofibre/cement composites: Challenges and promises as structural materials. Int. J. Mater. Struct. Integr. 2009, 3, 217–226. [Google Scholar] [CrossRef]

- Paulchamy, B.; Arthi, G.; Lignesh, B. A simple approach to stepwise synthesis of graphene oxide nanomaterial. J. Nanomed. Nanotechnol. 2015, 6, 1–4. [Google Scholar]

- Palermo, V.; Kinloch, I.; Ligi, S.; Pugno, N. Nanoscale mechanics of graphene and graphene oxide in composites: A scientific and technological perspective. Adv. Mater. 2016, 28, 6232–6238. [Google Scholar] [CrossRef] [PubMed]

- Babak, F.; Abolfazl, H.; Alimorad, R.; Parviz, G. Preparation and Mechanical properties of graphene oxide: cement nanocomposites. Sci. World J. 2014, 2014, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Duan, W.; Li, D.; Collins, F. Graphene Oxide Reinforced Cement and Concrete. Patent WO2013096990 A1, 4 July 2013. [Google Scholar]

- Wu, Y.; Yi, N.; Huang, L.; Zhang, T.; Fang, S.; Chang, H.; Li, N.; Oh, J.; Lee, J.; Kozlov, M. Three-dimensionally bonded spongy graphene material with super compressive elasticity and near-zero Poisson’s ratio. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Nika, D.L.; Balandin, A.A. Thermal properties of graphene and few-layer graphene: Applications in electronics. IET Circuits Devices Syst. 2015, 9, 4–12. [Google Scholar] [CrossRef]

- Cao, M.-S.; Wang, X.-X.; Cao, W.-Q.; Yuan, J. Ultrathin graphene: Electrical properties and highly efficient electromagnetic interference shielding. J. Mater. Chem. C 2015, 3, 6589–6599. [Google Scholar] [CrossRef]

- Mizuta, H. Recent progress of graphene-based nanoelectronic and NEM device technologies for advanced applications. In Proceedings of the 2016 IEEE International Conference on Semiconductor Electronics (ICSE), Kuala Lumpur, Malaysia, 17–19 August 2016.

- Hankins, N.; Singh, R. Emerging Membrane Technology for Sustainable Water Treatment; Elsevier Science & Technology Books: Oxford, UK, 2016. [Google Scholar]

- Reynolds, M.; Brown, M.; McGill, K.; Davidson, P.; Lammerding, J.; Minot, E.; Goldberg, J.; McEuen, P. Kirigami graphene transistors for biological sensing. In Proceedings of the APS March Meeting 2016, Baltimore, MD, USA, 14–18 March 2016.

- Fink, D. The polymers. In Fundamentals of Ion-Irradiated Polymers; Fink, D., Ed.; Springer: Berlin, Germany, 2004; pp. 3–34. [Google Scholar]

- Huang, X.; Yin, Z.; Wu, S.; Qi, X.; He, Q.; Zhang, Q.; Yan, Q.; Boey, F.; Zhang, H. Graphene-based materials: Synthesis, characterization, properties, and applications. Small 2011, 7, 1876–1902. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Gao, H.J.; Pang, S. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete; Publication Number FHWA-HRT-11-038; Federal Highway Administration (FHWA), U.S. Department of Transportation: Washington, DC, USA, 2011.

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the mechanical properties and microstructure of graphene nanoplatelet-cement composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Seifan, M.; Samani, A.; Berenjian, A. Bioconcrete: Next generation of self-healing concrete. Appl. Microbiol. Biotechnol. 2016, 100, 2591–2602. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.; Youn, H. Microbially induced calcite precipitation employing environmental isolates. Materials 2016, 9, 468. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Yasouja, S.E.M.; Ganiyu, A.A.; Kouchaksaraei, M.S.; Kamyab, H.; Taheri, M.M.; et al. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- Norman, D.T. Rubber Grade Carbon Blacks. Available online: http://www.continentalcarbon.com/pdfs/What_Is_Carbon_Black.pdf (accessed on 21 October 2016).

- Wen, S.; Chung, D.D.L. Partial replacement of carbon fiber by carbon black in multifunctional cement-matrix composites. Carbon 2007, 45, 505–513. [Google Scholar] [CrossRef]

- Masadeh, S. The effect of added carbon black to concrete mix on corrosion of steel in concrete. J. Miner. Mater. Charact. Eng. 2015, 3, 271–276. [Google Scholar] [CrossRef]

- Qiao, G.; Guo, B.; Hong, Y.; Ou, J. Multi-scale carbon-admixtures enhanced cementitious anodic materials for the impressed current cathodic protection of RC structures. Int. J. Electrochem. Sci. 2015, 10, 8423–8436. [Google Scholar]

- Xiao, H.; Lan, C.; Ji, X.; Li, H. Mechanical and sensing properties of structural materials with nanophase materials. Pac. Sci. Rev. 2003, 5, 7–11. [Google Scholar]

- Monteiro, A.; Cachim, P.; Costa, P. Carbon nanoparticles cement-based materials for service life monitoring. In Proceedings of the International RILEM Conference on Materials, Systems and Structures in Civil Engineering, Lyngby, Denmark, 22–24 August 2016.

- Chung, D.D.L. Carbon materials for structural self-sensing, electromagnetic shielding and thermal interfacing. Carbon 2012, 50, 3342–3353. [Google Scholar] [CrossRef]

- Aschberger, K.; Christensen, F.M.; Rasmussen, K.; Jensen, K.A. Feasibility and challenges of human health risk assessment for engineered nanomaterials. In Engineered Nanoparticles and the Environment; Xing, B., Vecitis, C.D., Senesi, N., Eds.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Jamuna, B.A.; Ravishankar, R.V. Environmental risk, human health, and toxic effects of nanoparticles. In Nanomaterials for Environmental Protection; Kharisov, B.I., Kharissova, O.V., Dias, H.V., Eds.; Wiley Blackwell: Hoboken, NJ, USA, 2015. [Google Scholar]

- Lee, J.; Mahendra, S.; Alvarez, P.J.J. Nanomaterials in the construction industry: A review of their applications and environmental health and safety considerations. ACS Nano 2010, 4, 7. [Google Scholar] [CrossRef] [PubMed]

- Jones, W.; Gibb, A.; Goodier, C.; Bust, P. Managing the unknown—Addressing the potential health risks of nanomaterials in the built environment. Constr. Manag. Econ. 2016, 1–15. [Google Scholar] [CrossRef]

- Li, N.; Georas, S.; Alexis, N.; Fritz, P.; Xia, T.; Williams, M.A.; Horner, E.; Nel, A. A work group report on ultrafine particles (American Academy of Allergy, Asthma & Immunology): Why ambient ultrafine and engineered nanoparticles should receive special attention for possible adverse health outcomes in human subjects. J. Allergy Clin. Immunol. 2016, 138, 386–396. [Google Scholar] [PubMed]

- Murr, L.E.; Garza, K.M. Natural and anthropogenic environmental nanoparticulates: Their microstructural characterisation and respiratory health implications. Atmos. Environ. 2009, 43, 2683–2692. [Google Scholar] [CrossRef]

- Rancan, F.; Gao, Q.; Graf, C.; Troppens, S.; Hadam, S.; Vogt, A. Skin penetration and cellular uptake of amorphous silica nanoparticles with variable size. Surface functionalization and colloidal stability. ACS Nano 2012, 8, 6829–6842. [Google Scholar] [CrossRef] [PubMed]

- Hirai, T.; Yoshikawa, T.; Nabeshi, H.; Yoshida, T.; Akase, T.; Yoshioka, Y.; Itoh, N.; Tsutsumi, Y. Dermal absorption of amorphous nanosilica particles after topical exposure for three days. Pharmazie 2012, 67, 742–743. [Google Scholar] [PubMed]

- Filon, F.L.; Mauro, M.; Adami, G.; Bovenzi, M.; Crosera, M. Nanoparticles skin absorption: New aspects for a safety profile evaluation. Regul. Toxicol. Pharmacol. 2015, 72, 310–322. [Google Scholar] [CrossRef] [PubMed]

- Piccinno, F.; Gottschalk, F.; Seeger, S.; Nowack, B. Industrial production quantities and uses of ten engineered nanomaterials in Europe and the world. J. Nanopart. Res. 2012, 14, 1–11. [Google Scholar] [CrossRef]

- Chang, X.; Zhang, Y.; Tang, M.; Wang, B. Health effects of exposure to nano-TiO2: A meta-analysis of experimental studies. Nanoscale Res. Lett. 2013, 8, 51. [Google Scholar] [CrossRef] [PubMed]

- Ong, L.-C.; Chung, F.F.-L.; Tan, Y.-F.; Leong, C.-O. Toxicity of single-walled carbon nanotubes. Arch. Toxicol. 2014, 90, 103–118. [Google Scholar] [CrossRef] [PubMed]

- Pacurari, M.; Lowe, K.; Tchounwou, P.B.; Kafoury, R. A review on the respiratory system toxicity of carbon nanoparticles. Int. J. Environ. Res. Public Health 2016, 13, 325. [Google Scholar] [CrossRef] [PubMed]

- Singh, Z. Applications and toxicity of graphene family nanomaterials and their composites. Nanotechnol. Sci. Appl. 2016, 9, 15–28. [Google Scholar] [CrossRef] [PubMed]

- Khan, H.A.; Shanker, R. Toxicity of nanomaterials. BioMed Res. Int. 2015, 2015, 551014. [Google Scholar] [CrossRef] [PubMed]

- Stone, V.; Johnston, H.J.; Balharry, D.; Gernand, J.M.; Gulumian, M. Approaches to develop alternative testing strategies to inform human health risk assessment of nanomaterials. Risk Anal. 2016, 36, 1538–1550. [Google Scholar] [CrossRef] [PubMed]

- Potthoff, A.; Weil, M.; Meißner, T.; Kühnel, D. Towards sensible toxicity testing for nanomaterials: Proposal for the specification of test design. Sci. Technol. Adv. Mater. 2015, 16. [Google Scholar] [CrossRef] [PubMed]

- Aithal, S.; Aithal, S. Nanotechnology Innovations and Commercialization—Opportunities, Challenges & Reasons for Delay; Munisch Personal RePEc Archive (MPRA): Munich, Germany, 2016. [Google Scholar]

- Ciriminna, R.; Zhang, N.; Yang, M.-Q.; Meneguzzo, F.; Xu, Y.-J.; Pagliaro, M. Commercialization of graphene-based technologies: A critical insight. Chem. Commun. 2015, 51, 7090–7095. [Google Scholar] [CrossRef] [PubMed]

- Mahdavinejad, M.; Nazari, M.; Khazforoosh, S. Commercialization strategies for industrial applications of nanomaterials in building construction. Adv. Mater. Res. 2014, 829, 879–883. [Google Scholar] [CrossRef]

- The Concrete Centre. Concrete and BREEAM; TCC/05/28; MPA—The Concrete Centre: London, UK, 2015. [Google Scholar]

| Weight-to-Cement Ratio of Inclusion | Type of Cement-Matrix Composite 1 | Dispersion Technique | Increase in Performance (%) 2 | References |

|---|---|---|---|---|

| 1% NS 3 | Concrete | Mixer | 12.96% Compressive Str. 4 | [77] |

| 2% NS | Mortar | Ultrasonication | 48.7% Compressive Str.; 16.0% Flexural Str. | [78] |

| 2% NS | Cement Paste; superplasticiser; Quartz Aggregate; | Mixer | 8.0% Compressive Str.; 37.5% Tensile Str. | [79] |

| 2% NS, 10% SF | Cement paste; Superplasticiser; Quartz aggregate; | Mixer | 6.0% Compressive Str.; 19.4% Tensile Str. | [79] |

| 6% NS | Mortar; Superplasticiser | Mixer | 142% Compressive Str. | [80] |

| 5% Nano-MK | Mortar; Superplasticiser | Mixer | 28.0% Compressive Str. | [81] |

| 0.6% Nanoclay | Cement Paste | (Not Specified) | 13.24% Compressive str. | [25] |

| 10% NS; 18% Nanoclay; | Mortar; Superplasticiser | (Not Specified) | 201.7% Compressive Str.; 413.8% Tensile Str. | [82] |

| 1% Nano-MgO | Mortar | Ultrasonication; Superplasticiser; Surfactant | 80% Compressive Str.; 70% Flexural Str. | [83] |

| Material | Elastic Modulus (GPa) | Tensile Strength (GPa) | Elongation at Break (%) | Diameter/Thickness (nm) | Aspect Ratio | References |

|---|---|---|---|---|---|---|

| Graphene | 1000 | 130 | 0.8 | ~0.08 | 6000–600,000 | [116,117] |

| CNTs | 950 | 11–63 | 12 | 15–40 | 1000–10,000 | [118,119] |

| GO | 23–42 | ~13 | 0.6 | ~0.67 | 1500–45,000 | [120,121] |

| Weight-to-Cement Ratio of Nanoinclusion 1 | Type of Cement-Matrix Composite 2 | Dispersion Technique | Increase Referred to OPC Specimen (%) 3 | References |

|---|---|---|---|---|

| 0.3% GNPs; 40% FA; 5% SF | UHPC 4; Portland ASTM Type III | Bath Sonication; Polycarboxylate Superplasticiser | 45% Tensile Str.; 153% Energy Absorption | [146] |

| 0.3% CNFs; 40% FA; 5% SF | UHPC; Portland ASTM Type III | Bath Sonication; Polycarboxylate Superplasticiser | 56% Tensile Str.; 108% Energy Absorption | [146] |

| 1% CNTs | Mortar | CNT–COOH | 40% Compressive Str. | [137] |

| 0.15% CNTs; 30% SF | Mortar | CNT–COOH; CNT–OH 5 | 20% Compressive Str.; 50% Flexural Str. | [147] |

| 1.5% GO | Pavement Concrete | Polycarboxylate Superplasticiser | 48% Tensile Str. | [148] |

| 0.05% GO | Cement Paste | Polycarboxylate Superplasticiser | 40.4% Compressive Str.; 90.5% Flexural Str. | [149] |

| 0.05% GO | Mortar | Superplasticiser | 24.4% Compressive Str.; 70.5% Flexural Str. | [149] |

| 0.08% GO; 80% FA; 2% SF; 2% vol. PVA fibres | Mortar | Superplasticiser | 24.8% Compressive Str.; 37.7% Tensile Str.; 80.6% Flexural Str. | [150] |

| 1% GO | Mortar | Polycarboxylate Superplasticiser | 86.3% Compressive Str. | [151] |

| Nanoinclusion | Compressive Str. and Pore-Filling | Flexural Str. | Freeze/thaw Cycles Resist. | Steel–Matrix Bond | Hydration Accelerator | Hydration Retarder | Shrinkage Reducer | Photocatalytic | Hydrophilic Coatings | Hydrophobic Coatings |

|---|---|---|---|---|---|---|---|---|---|---|

| Nano-SiO2 | ● | ● | ● | ● | ● | - | - | - | - | ● |

| Nano-Al2O3 | ● | ● | - | ● | - | ● | - | - | - | - |

| Nano-Fe2O3 | ● | ● | - | - | - | - | - | - | - | - |

| Nano-CaCO3 | ● | ● | - | - | ● | - | ● | - | - | - |

| Nano-MK | ● | ● | - | - | - | - | - | - | - | - |

| Nanoclay | ● | ● | - | - | - | - | - | - | - | - |

| Waste glass Nanoparticles | ● | ● | - | - | - | - | - | - | - | - |

| Nano-MgO | ● | ● | - | - | - | - | ● | - | - | - |

| Nano-TiO2 | ● | ● | - | - | - | - | - | ● | ● | - |

| Nano-TiO2-xNy | ● | ● | - | - | - | - | - | ● | - | - |

| Nanoinclusion | Compressive Str. and Pore-Filling | Flexural Str. | Strain-Sensing | Encapsulating of Bacteria for Healing Capability | Thermal Sensing | Electromagnetic Interferences Shielding | Electrical Heating | Cathodic Protection for Steel Elements |

|---|---|---|---|---|---|---|---|---|

| GNPs | ● | ● | ● | ● | - | - | - | - |

| CNTs | ● | ● | ● | - | ● | ● | ● | ● |

| CNFs | ● | ● | ● | - | - | - | ● | - |

| CB | - | - | ● | - | - | ● | ● | ● |

| GO | ● | ● | - | - | - | - | - | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, G.; Patiño-Barbeito, F.; Patiño-Cambeiro, F.; Armesto, J. Nano-Inclusions Applied in Cement-Matrix Composites: A Review. Materials 2016, 9, 1015. https://doi.org/10.3390/ma9121015

Bastos G, Patiño-Barbeito F, Patiño-Cambeiro F, Armesto J. Nano-Inclusions Applied in Cement-Matrix Composites: A Review. Materials. 2016; 9(12):1015. https://doi.org/10.3390/ma9121015

Chicago/Turabian StyleBastos, Guillermo, Faustino Patiño-Barbeito, Faustino Patiño-Cambeiro, and Julia Armesto. 2016. "Nano-Inclusions Applied in Cement-Matrix Composites: A Review" Materials 9, no. 12: 1015. https://doi.org/10.3390/ma9121015