Optoelectronic Properties and the Electrical Stability of Ga-Doped ZnO Thin Films Prepared via Radio Frequency Sputtering

Abstract

:1. Introduction

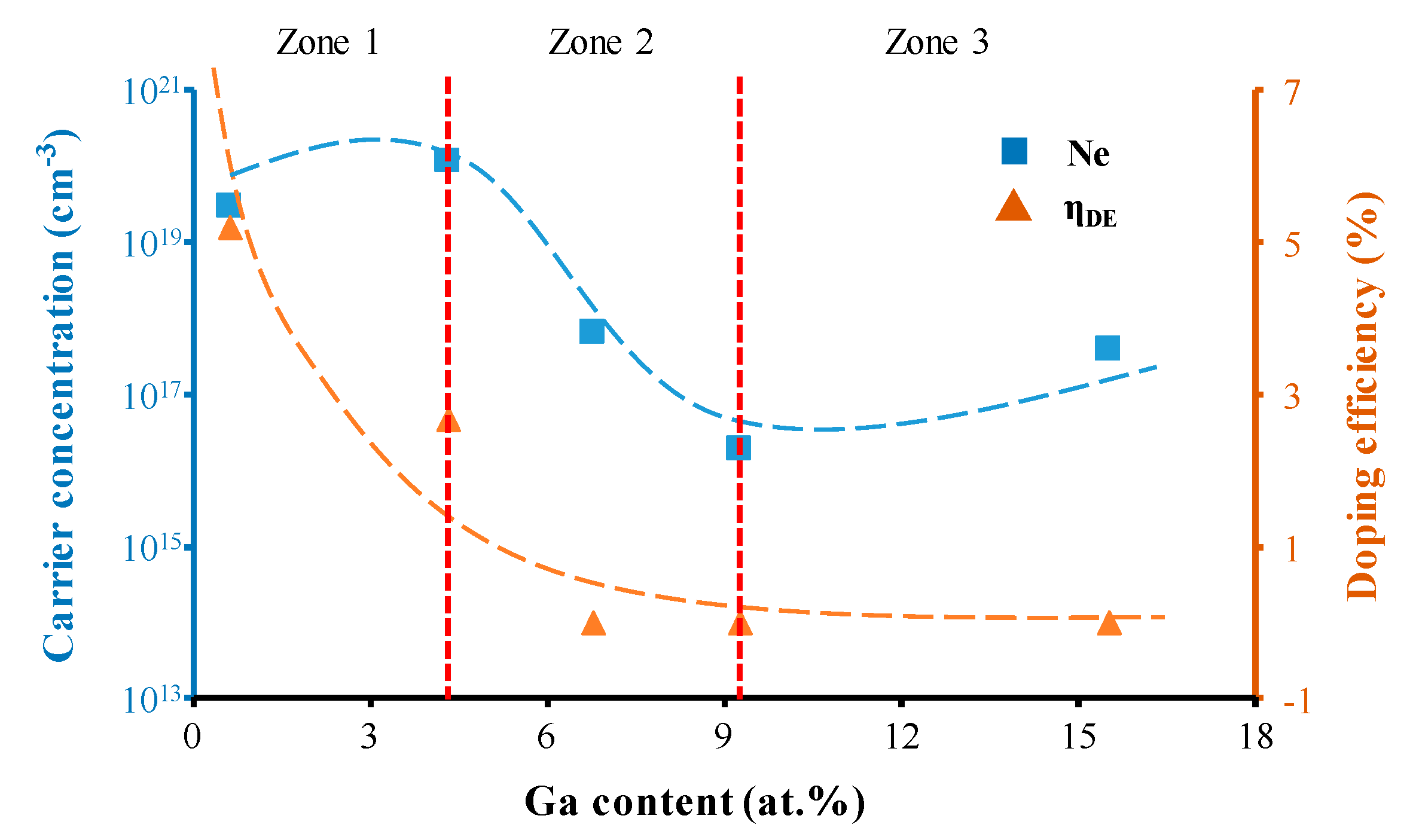

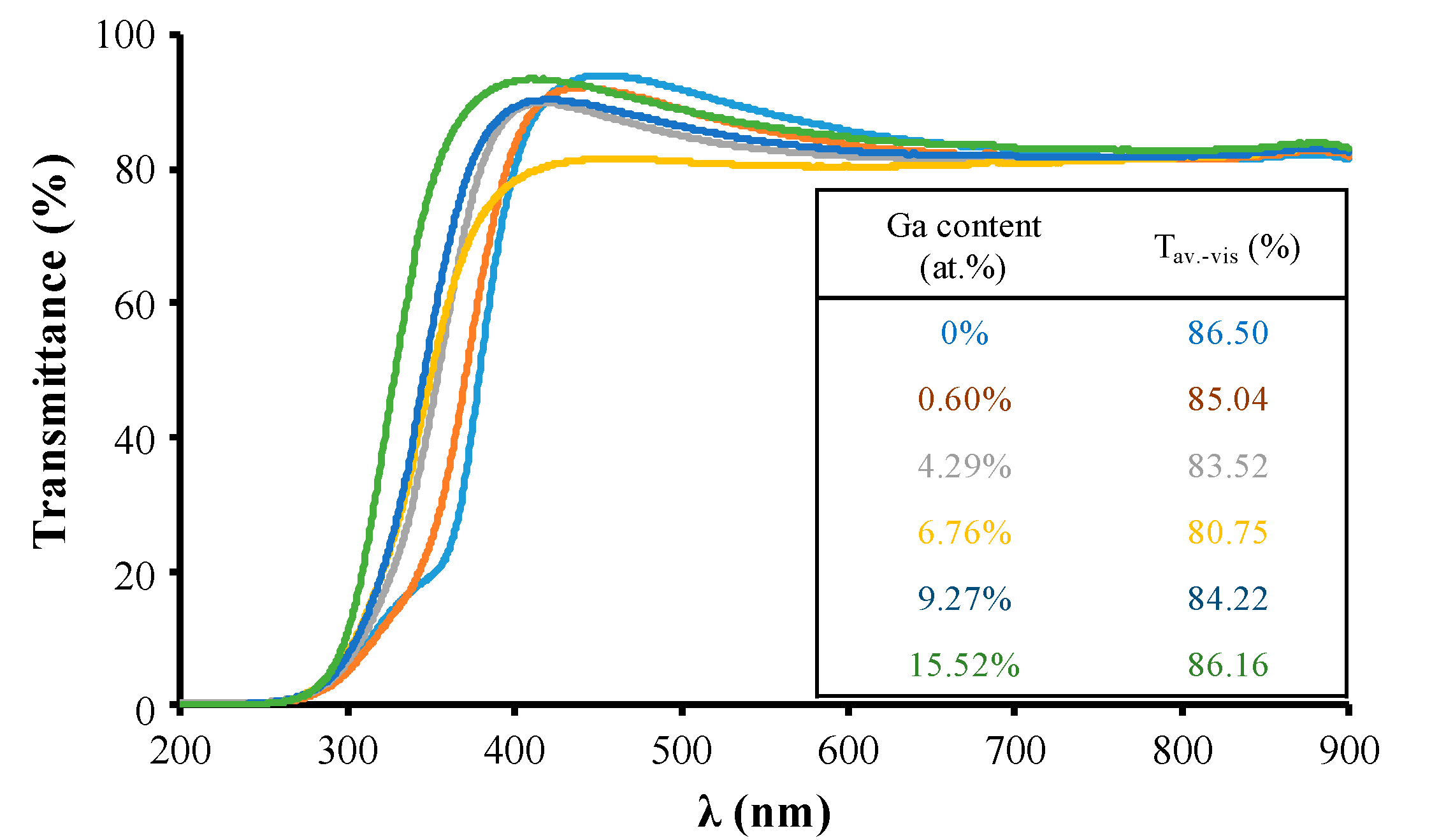

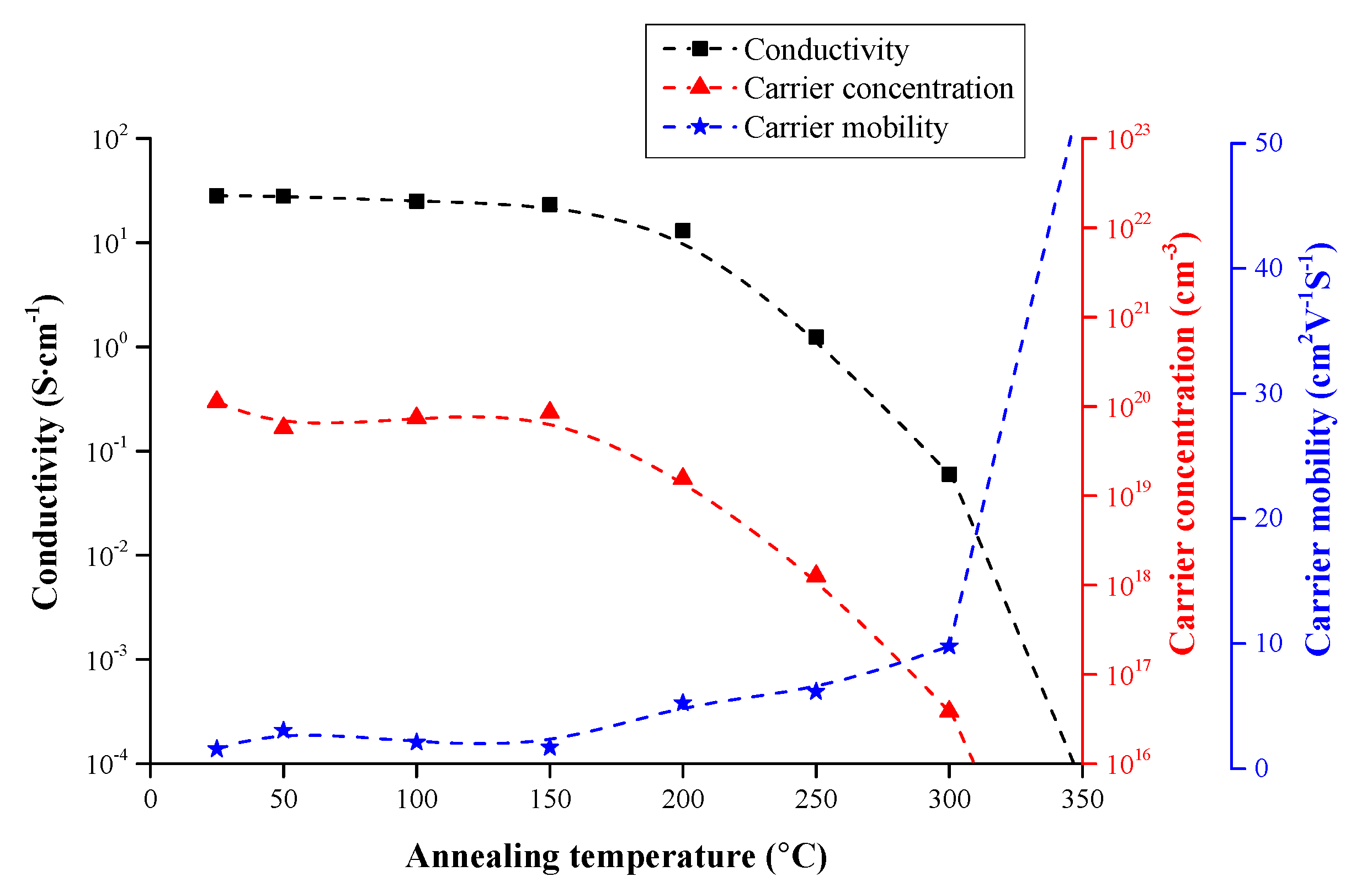

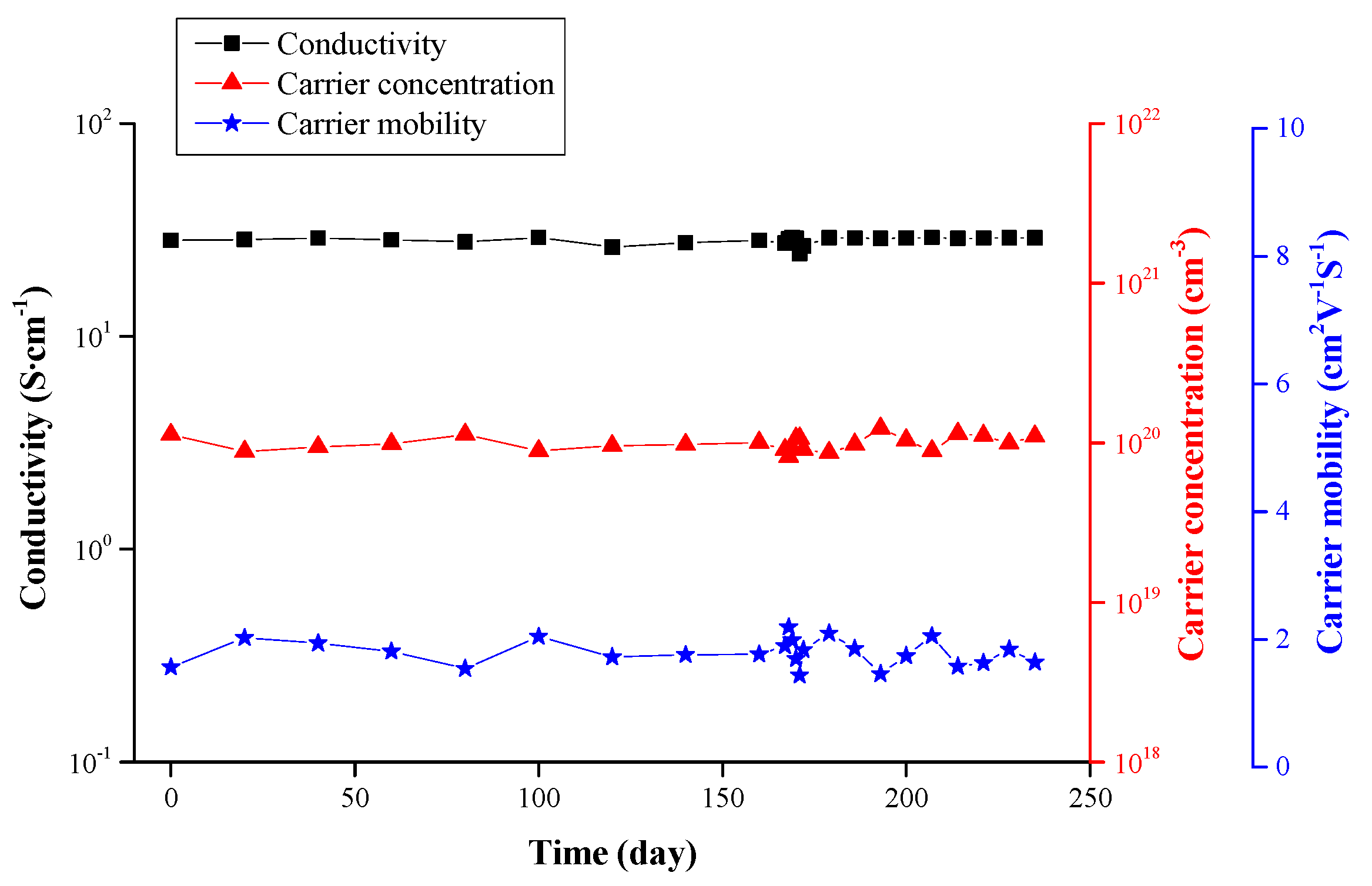

2. Results and Discussion

3. Materials and Methods

3.1. Deposition Parameters

3.2. Materials Characterizations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, X.L.; Liu, J.M.; Ni, J.; Zhao, Y.; Zhang, X.D. Wide-spectrum Mg and Ga co-doped ZnO TCO thin films for solar cellsgrown via magnetron sputtering with H2 introduction. Appl. Surf. Sci. 2015, 328, 193–197. [Google Scholar] [CrossRef]

- Kim, S.I.; Cho, S.H.; Choi, S.R.; Oh, M.C.; Jang, J.H.; Song, P.K. Crystallization and electrical properties of ITO: Ce thin films for flat panel display applications. Thin Solid Films 2009, 5107, 4061–4064. [Google Scholar] [CrossRef]

- Ko, Y.D.; kim, K.C.; Kim, Y.S. Effects of substrate temperature on the Ga-doped ZnO films as an anode material of organic light emitting diodes. Superlattices Microstruct. 2012, 51, 933–941. [Google Scholar] [CrossRef]

- Bartens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Domaradzki, J. Perspectives of development of TCO and TOS thin films based on (Ti-Cu) oxide composites. Surf. Coat. Technol. 2016, 290, 28–33. [Google Scholar] [CrossRef]

- Sibin, K.P.; Swain, N.; Chowdhury, P.; Dey, A.; Sridhara, N.; Shashikala, H.D.; Sharma, A.K.; Barshilia, H.C. Optical and electrical properties of ITO thin films sputtered on flexible FEP substrate as passive thermal control system for space applications. Sol. Energy Mater. Sol. Cells 2016, 145, 314–322. [Google Scholar] [CrossRef]

- Yu, S.H.; Yang, W.H.; Li, L.X.; Zhang, W.F. Improved chemical stability of ITO transparent anodes with a SnO2 buffer layer for organic solar cells. Sol. Energy Mater. Sol. Cells 2016, 144, 652–656. [Google Scholar] [CrossRef]

- Li, Y.P.; Sun, J. The modification of electrical properties of Au/n-Hg3In2Te6 Schottky contact by the introduction of ITO interlayer. Curr. Appl. Phys. 2016, 16, 623–627. [Google Scholar] [CrossRef]

- Aleksandrova, M.; Kurtev, N.; Videkov, V.; Tzanova, S.; Schintke, S. Material alternative to ITO for transparent conductive electrode in flexible display and photovoltaic devices. Microelectron. Eng. 2015, 145, 112–116. [Google Scholar] [CrossRef]

- Linss, V. Comparison of the large-area reactive sputter processes of ZnO:Al and ITO using industrial size rotatable targets. Surf. Coat. Technol. 2016, 290, 43–57. [Google Scholar] [CrossRef]

- Tubtimtae, A.; Lee, M.W. ZnO nanorods on undoped and indium-doped ZnO thin films as a TCO layer on nonconductive glass for dye-sensitized solar cells. Superlattices Microstruct. 2012, 52, 987–996. [Google Scholar] [CrossRef]

- Chen, S.C.; Wang, C.H.; Sun, H.; Wen, C.K.; Lu, C.F.; Tsai, C.L.; Fu, Y.K.; Chuang, T.H. Microstructures, electrical and magnetic properties of (Ga, Co)-ZnO films by radio frequency magnetron co-sputtering. Surf. Coat. Technol. 2016, 303, 203–208. [Google Scholar] [CrossRef]

- Jayaraman, V.K.; Alvarez, A.M.; Kuwabara, Y.M.; Koudriavstev, Y.; Amador, M.O. Effect of co-doping concentration on structural, morphological, optical and electrical properties of aluminium and indium co-doped ZnO thin films deposited by ultrasonic spray pyrolysis. Mater. Sci. Semicond. Process. 2016, 47, 32–36. [Google Scholar] [CrossRef]

- Wang, F.H.; Chang, C.L. Effect of substrate temperature on transparent conducting Al and Fco-doped ZnO thin films prepared by rf magnetron sputtering. Appl. Surf. Sci. 2016, 370, 83–91. [Google Scholar] [CrossRef]

- Jin, C.; Narayan, R.; Tiwari, A.; Zhou, H.H.; Kvit, A.; Narayan, J. Epitaxial growth of zinc oxide thin films on silicon. Mater. Sci. Eng. B 2005, 117, 348–354. [Google Scholar] [CrossRef]

- Snure, M.; Tiwari, A. Structure, electrical, and optical characterizations of epitaxial films grown on sapphire (0001) substrate. J. Appl. Phys. 2007, 101, 124912. [Google Scholar] [CrossRef]

- Jang, C.; Jiang, Q.J.; Lu, J.G.; Ye, Z.Z. Structural, optical and electrical properties of Ga doped ZnO/Cu grid/Ga doped ZnO transparent electrodes. J. Mater. Sci. Technol. 2015, 31, 1108–1110. [Google Scholar] [CrossRef]

- Yamada, Y.; Kadowaki, K.; Kikuchi, H.; Funaki, S.; Kubo, S. Positional variation and annealing effect in magnetron sputtered Ga-doped ZnO films. Thin Solid Films 2016, 609, 25–29. [Google Scholar] [CrossRef]

- Kim, J.H.; Yer, I.H. Characterization of ZnO nanowires grown on Ga-doped ZnO transparent conductive thin films: Effect of deposition temperature of Ga-doped ZnO thin films. Ceram. Int. 2016, 42, 3304–3308. [Google Scholar] [CrossRef]

- Bhosle, V.; Tiwari, A.; Narayan, J. Electrical properties of transparent and conducting Ga doped ZnO. J. Appl. Phys. 2006, 100, 033713. [Google Scholar] [CrossRef]

- Bhosle, V.; Tiwari, A.; Narayan, J. Metallic conductivity and metal-semiconductor transition in Ga-doped ZnO. Appl. Phys. Lett. 2006, 88, 032106. [Google Scholar] [CrossRef]

- Gomez, H.; Olvera, M.L. Ga-doped ZnO thin films: Effect of deposition temperature, dopant concentration, and vacuum-thermal treatment on the electrical, optical, structural and morphological properties. Mater. Sci. Eng. B 2006, 134, 20–26. [Google Scholar] [CrossRef]

- Wang, R.P.; Sleight, A.W. High Conductivity in Gallium-Doped Zinc Oxide Powders. Chem. Mater. 1996, 8, 433–439. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Khan, A. Work function determination of zinc oxide films. J. Vac. Sci. Technol. A 1997, 15, 428–430. [Google Scholar] [CrossRef]

- Snure, M.; Tiwari, A. Band-gap engineering of Zn1-xGaxO nanopowders: Synthesis, structural and optical characterizations. J. Appl. Phys. 2008, 104, 073707. [Google Scholar] [CrossRef]

- Kohan, A.F.; Ceder, G.; Morgan, D.; van de Walle, C.G. First-principles study of native point defects in ZnO. Phys. Rev. B 2000, 61, 15019–15027. [Google Scholar] [CrossRef]

- Dadzis, K.; Lukin, G.; Meier, D.; Bonisch, P.; Sylla, L.; Patzold, O. Directional melting and solidification of gallium in a traveling magnetic field as a model experiment for silicon processes. J. Cryst. Growth 2016, 445, 90–100. [Google Scholar] [CrossRef]

| Power (W) | Power Density (W/cm2) |

|---|---|

| 80 | 3.95 |

| Power (W) | Power Density (W/cm2) |

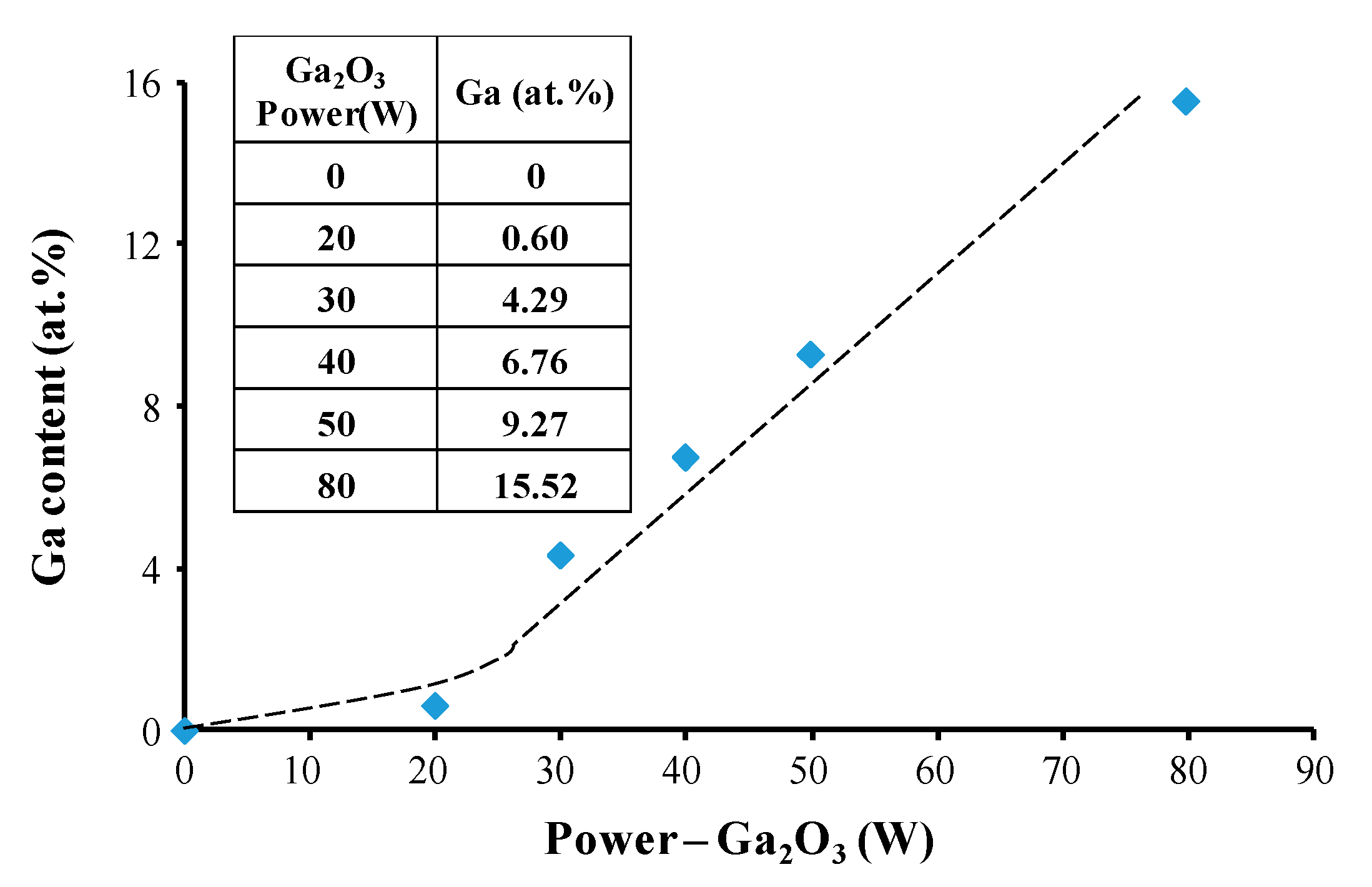

|---|---|

| 0 | 0 |

| 20 | 0.99 |

| 30 | 1.48 |

| 40 | 1.97 |

| 50 | 2.47 |

| 80 | 3.95 |

| Parameter | Values | |

|---|---|---|

| Background pressure (Pa) | <6.7 × 10−4 | |

| Working pressure (Pa) | 0.67 | |

| Films thickness (nm) | 100 | |

| Rotation speed (rpm) | 10 | |

| Substrate | Glass/Silicon | |

| Power (W) | ZnO | 80 |

| Ga2O3 | 0–80 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jen, S.-U.; Sun, H.; Chiang, H.-P.; Chen, S.-C.; Chen, J.-Y.; Wang, X. Optoelectronic Properties and the Electrical Stability of Ga-Doped ZnO Thin Films Prepared via Radio Frequency Sputtering. Materials 2016, 9, 987. https://doi.org/10.3390/ma9120987

Jen S-U, Sun H, Chiang H-P, Chen S-C, Chen J-Y, Wang X. Optoelectronic Properties and the Electrical Stability of Ga-Doped ZnO Thin Films Prepared via Radio Frequency Sputtering. Materials. 2016; 9(12):987. https://doi.org/10.3390/ma9120987

Chicago/Turabian StyleJen, Shien-Uang, Hui Sun, Hai-Pang Chiang, Sheng-Chi Chen, Jian-Yu Chen, and Xin Wang. 2016. "Optoelectronic Properties and the Electrical Stability of Ga-Doped ZnO Thin Films Prepared via Radio Frequency Sputtering" Materials 9, no. 12: 987. https://doi.org/10.3390/ma9120987