2.1. The Desired Dynamics Equation (DDE) Method

Consider the transfer function given by:

where

and

are unknown parameters. It can be transformed to the following state space form:

where

are the plant input and its derivatives;

is the plant output;

are the system states;

is a proper positive constant number; and

is the total disturbance.

The desired dynamic equation is as follows:

To reach Equation (3), the corresponding control law should be:

where

and

are the coefficient of the desired dynamic and are determined by the requirements of the control system; and

is the estimation of total disturbance

.

To obtain the estimation of total disturbance

, the following disturbance observer is used.

where

is the coefficient of the disturbance observer and indicates the speed of tracking disturbance; and

is an intermediate variable.

Equation (5) structures a disturbance observer. Equation (4) offers the control law to achieve the desired dynamic Equation (3). The disturbance observer estimates the total disturbance and compensates the systems to be the desired dynamic in real time and dynamically.

By substituting Equations (2), (3) and (5) into Equation (4), we can obtain

where

is the target value; and

is the error between the plant output and the target value. The detailed derivation is shown in

Appendix A.

From Equation (6), we can obtain the two-degree-of-freedom PID controller parameters,

The corresponding two-degree-of-freedom PID controller structure is shown in

Figure 1.

When the desired dynamic equation is as follows:

we can analogously obtain the two-degree-of-freedom PID controller parameters,

In general, the DDE endows the 2-DOF PID controller parameters with clear physical meaning, which makes some of the parameters specified and then decreases the number of unknown parameters. Moreover, the model error is imposed into the total disturbance and is compensated, so the precise model is not necessary.

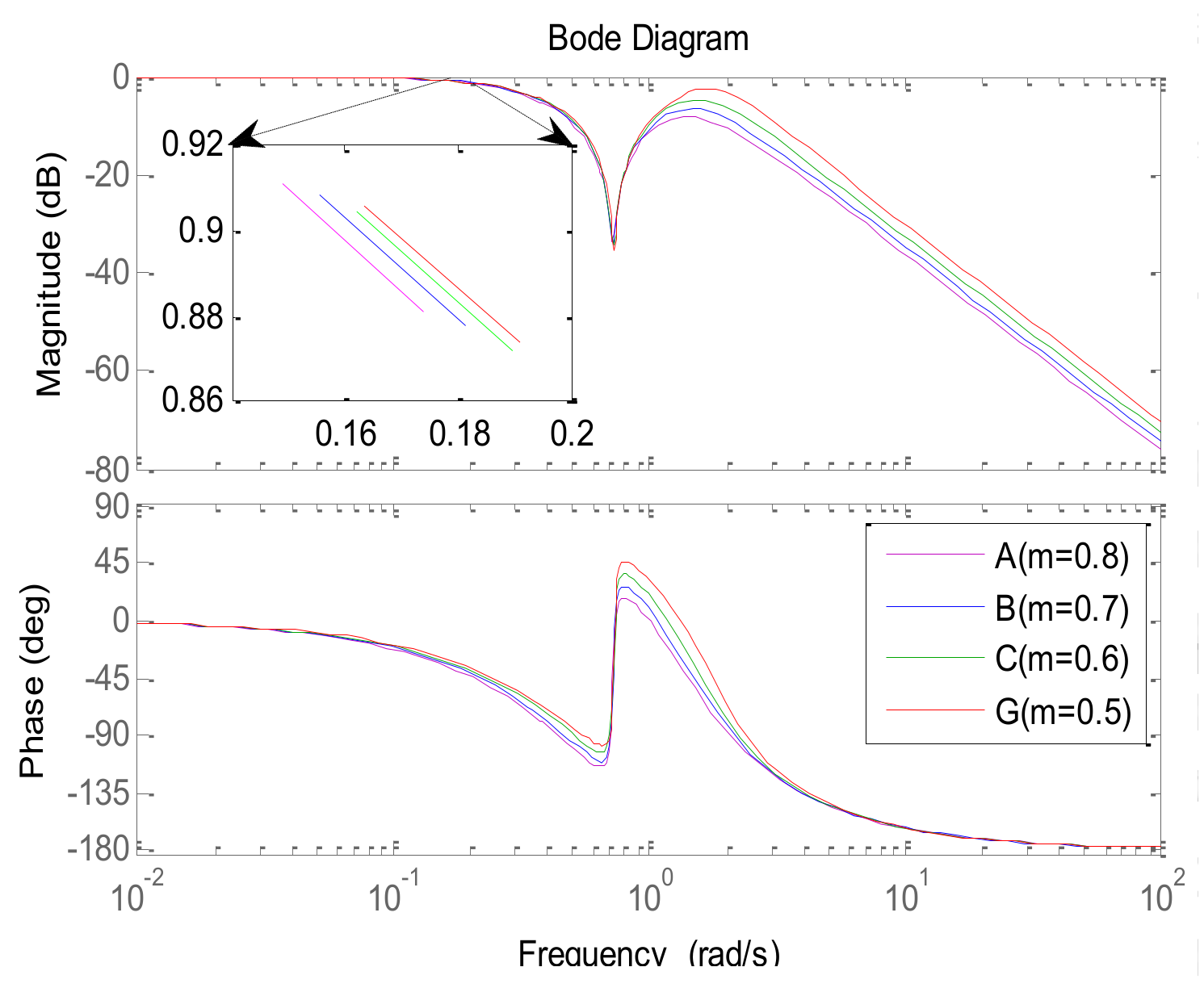

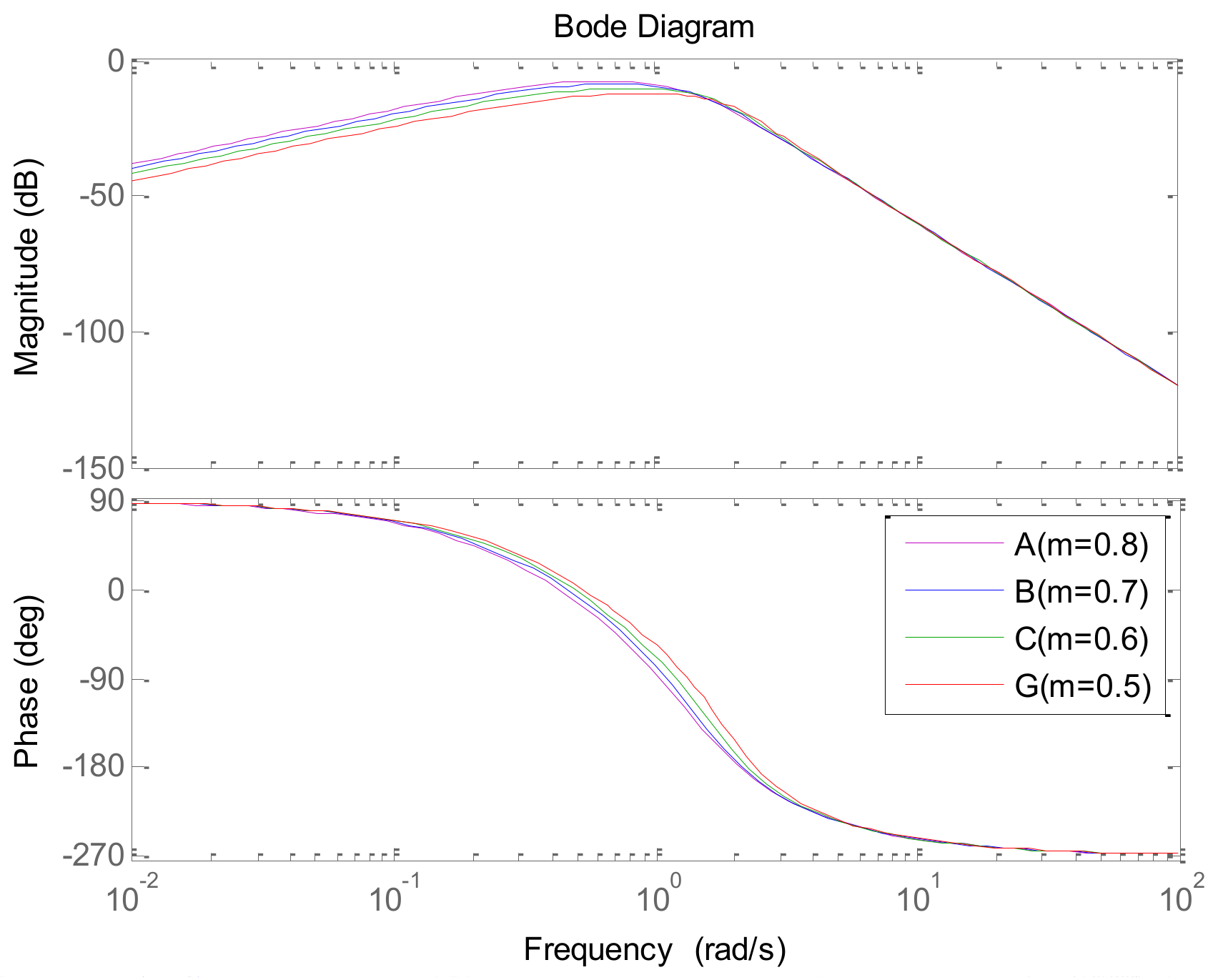

2.2. Generalized Frequency Method (GFM)

The GFM can calculate the controller parameters directly and analytically and can accurately guarantee the specified stability margin with only one parameter, which is called the attenuation index

. The attenuation index

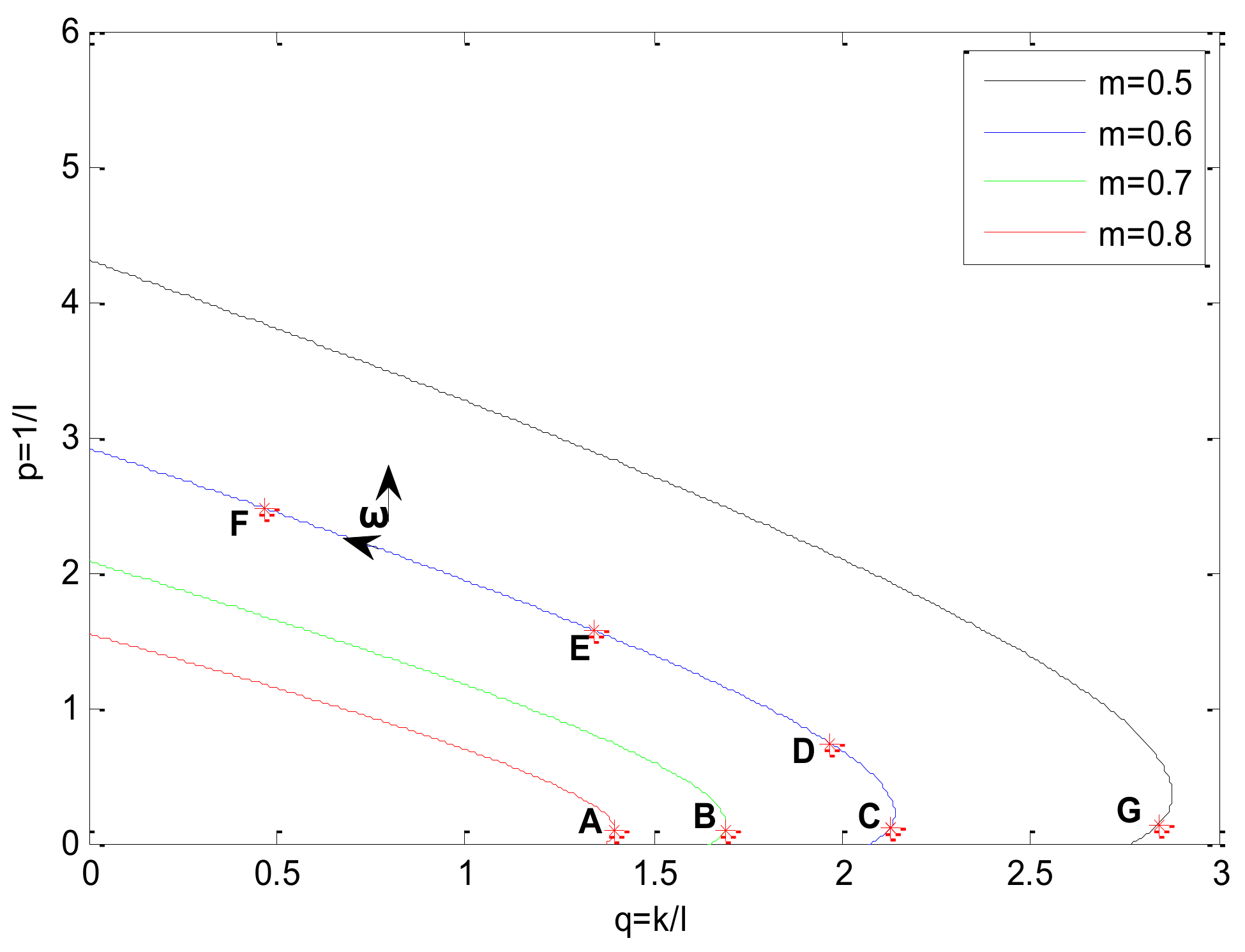

determines the two rays, which shape a sector area shown in

Figure 2, and the GFM can make all the closed-loop poles lie in the resulting sector area. The equation of the two rays is

, where

,

.

is a constant and

is the included angle between the ray and the imaginary axis.

The stability margin increases with attenuation index . Each pair of conjugate complex poles have a corresponding , and the corresponding equal to infinity for the real poles. The minimum is equal to the specified attenuation index , i.e., .

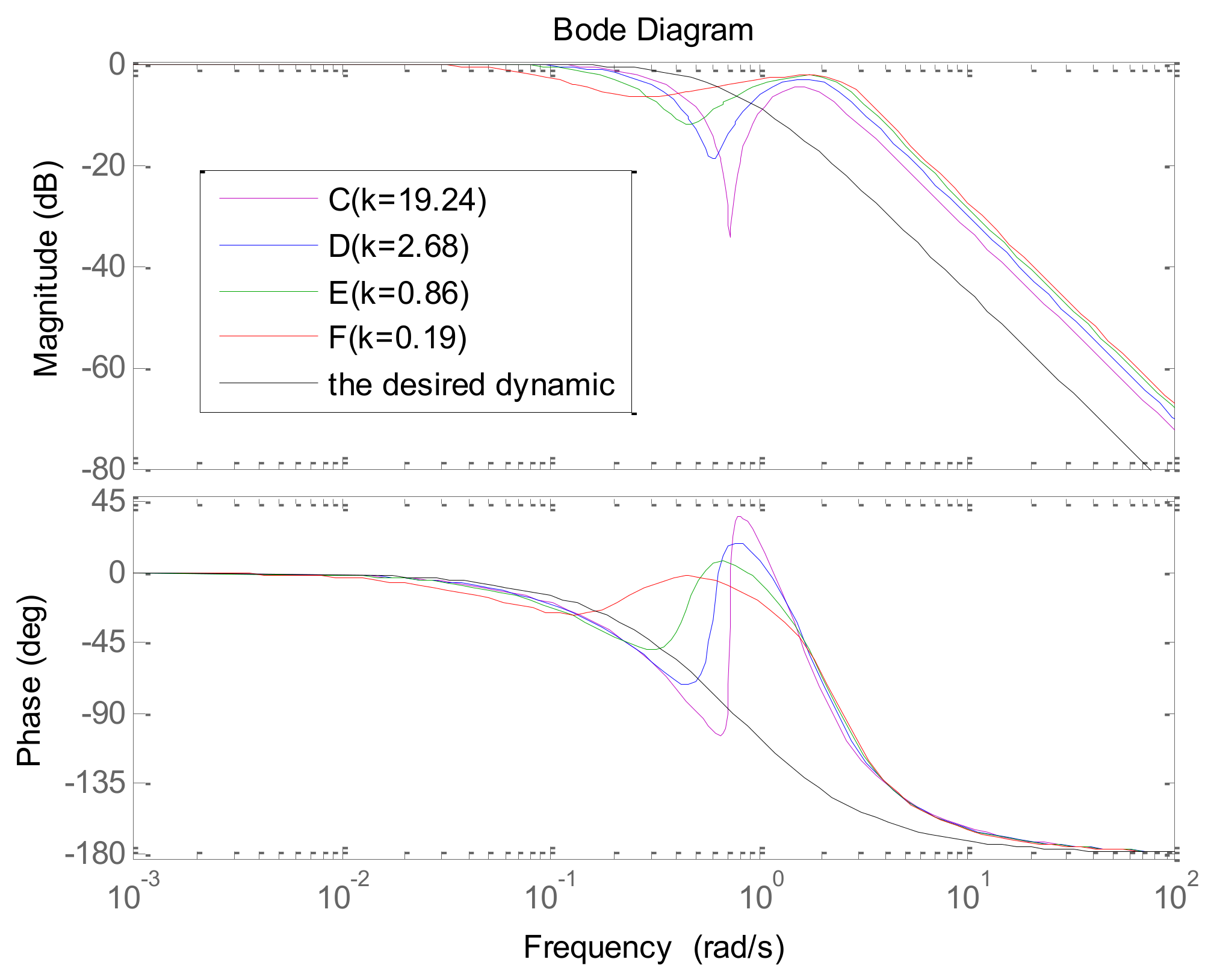

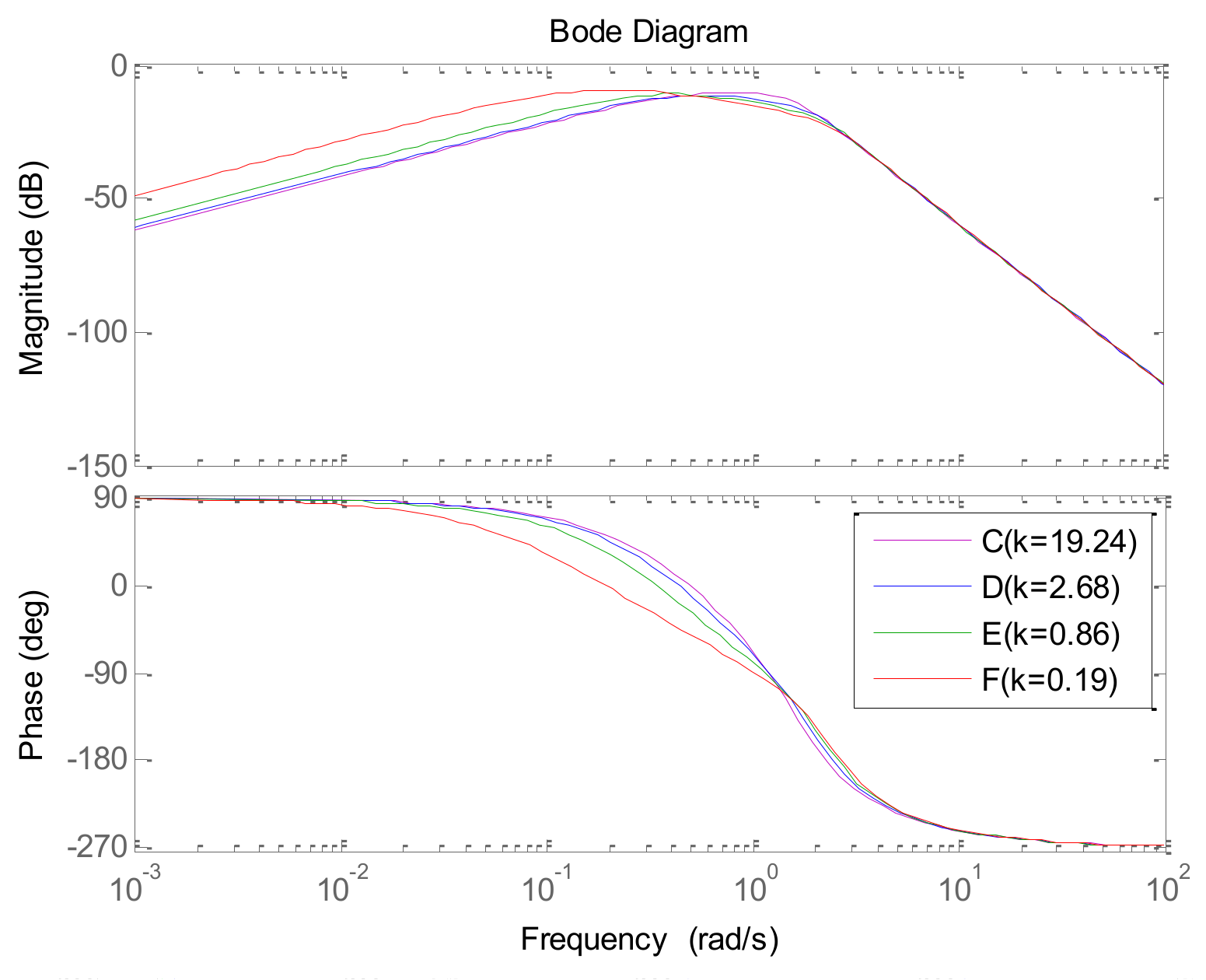

Next, we will illustrate the relationship between the maximum sensitivity (

) and the attenuation index

to explain the rationality of the attenuation index

as the stability margin criterion.

is taken as an example. Substitute

into

, and the Nyquist plots of

are shown in

Figure 3.

In

Figure 3, the Nyquist plots are shown with full lines, and

,

, and

are respectively shown with a red line, green line, and blue line; dashed lines represent the maximum sensitivity

and the dashed red line, green line, and blue line respectively represent

,

, and

. The stability margin of

decreases with the attenuation index

increasing. So, when designing the controller parameters, make the transfer function

to give

as the stability margin, where

represents the transfer function of the controller. From above, the attenuation index

can give a system stability margin in parameter design stage, and thus, it can be a stability margin criterion.

2.3. Setting PID Controllers Parameters

In this subsection, first a set of tuning equations is derived, and then, controller parameters are analyzed. Finally, the steps of the tuning method are given.

For the control system in

Figure 1, its stability is determined by the closed-loop characteristic equation:

Substitute

into Equation (10), define

, and compare the real and imaginary parts; the following equation is obtained

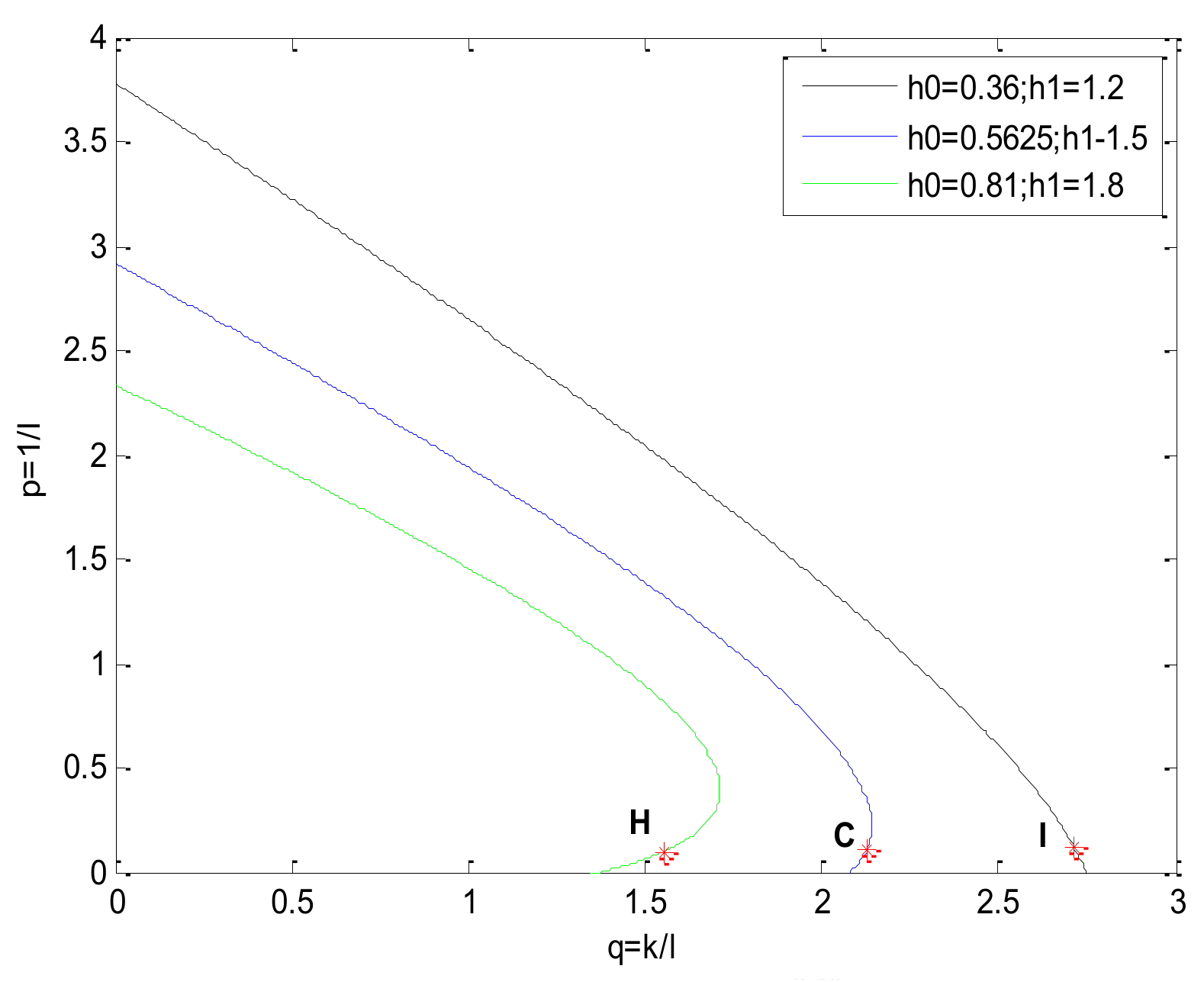

Under certain , Equation (11) structures a marginal stability surface with various . The marginal stability surface divides the space into two parts: meeting stability margin and not meeting stability margin.

Employing the following variable substitution,

Equation (7) is expressed as

Substitute Equation (13) into Equation (11), and the following equation is obtained

Under certain , , and , Equation (14) becomes a linear equation. Then, if its Jacobian determinant J is nonsingular, it has a unique local solution . Under various and certain , and , Equation (14) has a unique local solution curve (i.e., marginal stability curve). The marginal stability curve divides the plane into two parts: meeting stability margin and not meeting stability margin. The curve is the contour. Then, once an appropriate work point in the contour is obtained, the controller parameters can be calculated. The method of choosing a work point is shown after the analysis of the parameter , because the parameter can influence the choosing method.

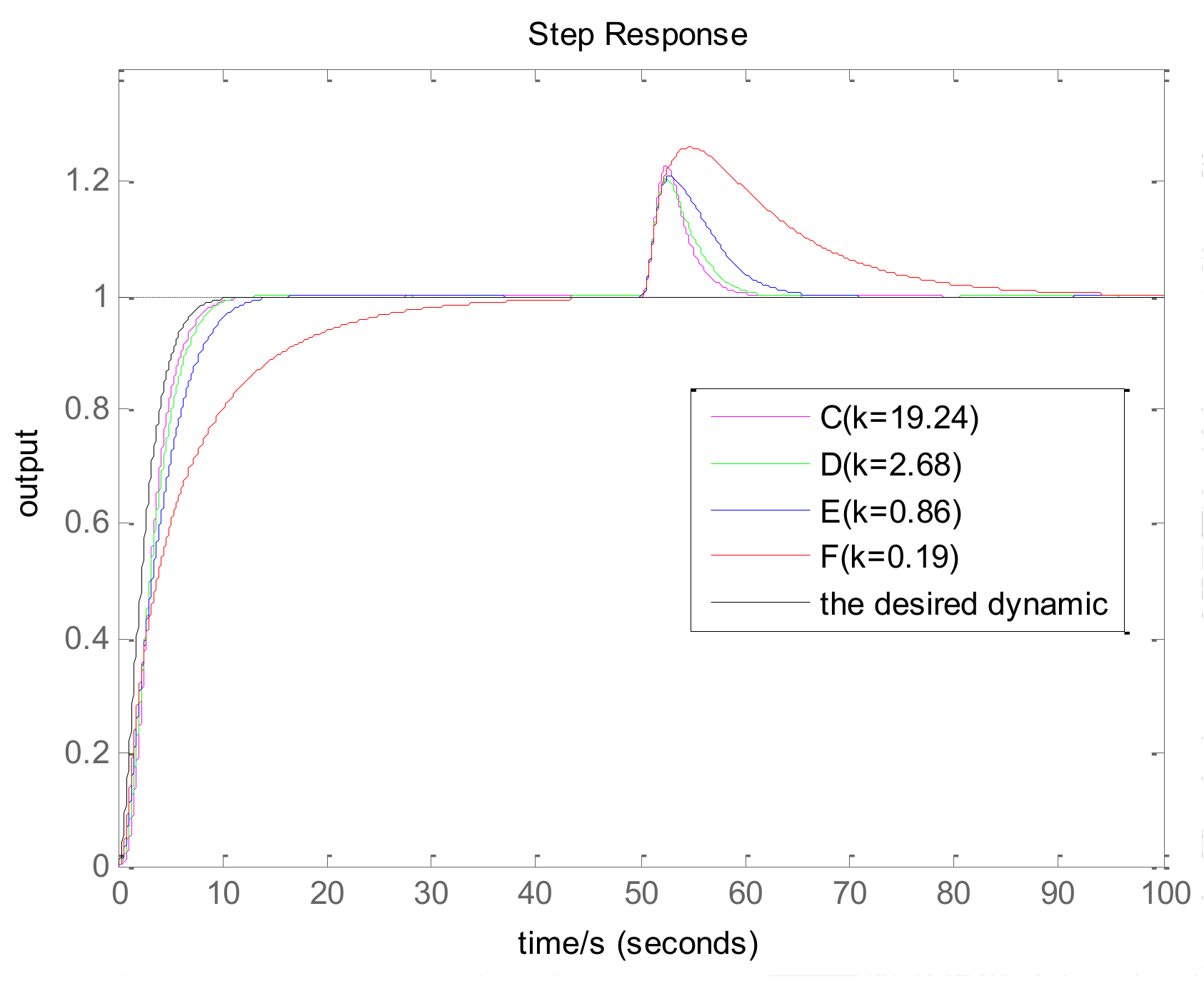

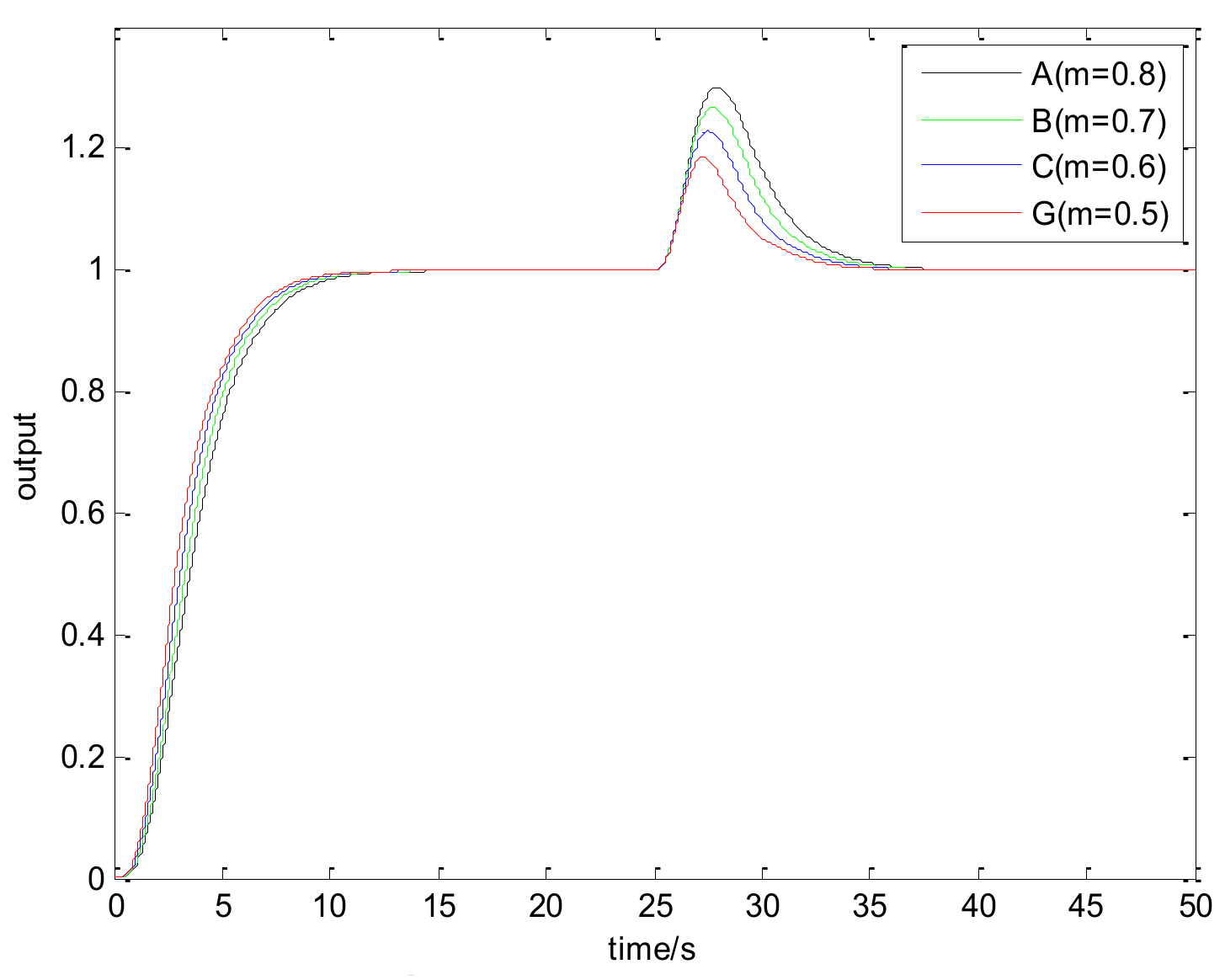

Next, the function of the controller parameters is analyzed, and the method for obtaining them is shown.

and

are coefficients of the desired dynamic equation. They are chosen based on the requirements of control system, such as settling time, overshooting, and so on. Because the desired dynamic equation is a second-order system,

and

can be calculated according to the second-order system, as follows:

where

is the desired settling time;

is the damping of desired dynamic system; and

is the natural frequency of desired dynamic system.

In order to make the overshooting as small as possible and make the settling time as short as possible,

is chosen. Considering the error between the actual dynamic and the desired dynamic, Equation (15) becomes

The stability margin increases with the increasing of the attenuation index

. It is well-known that there is a trade-off between performance and robustness [

26,

27]. Therefore, choosing an appropriate

is important to avoid the conflict with both

and

. According to our experience, the reasonable selecting region of

is generally

. One other thing to note is that a greater

is needed when the model is imprecise.

Combine Equation (2) with Equation (5) and do a Laplace transform, and the following equation is obtained:

As shown in Equation (17), the response rate of the disturbance observer speeds up with increasing. So, the work point should be chosen nearby the q-axis in order to make as large as possible because in the plane.

The work point is chosen as follows.

First, substitute

into Equation (14), and the following equation is obtained.

Solve Equation (18), and and can be obtained.

Then, define

and substitute

into Equation (14), so

and

can be obtained. The point

is the work point in the

plane.

Finally, substitute and into Equation (13), and the controller parameters are obtained.

The steps of setting the controller parameters are shown as follows:

- (1)

Obtain the system model and choose proper , and values according to the requirements of system;

- (2)

Solve Equation (18), and then get and ;

- (3)

Get from Equation (19), substitute into Equation (14), and then get and ;

- (4)

Substitute and into Equation (13) to calculate the controller parameters. If there are closed-loop poles outside of the sector area, decrease both and simultaneously or only , and then turn to step (2); otherwise, continue;

- (5)

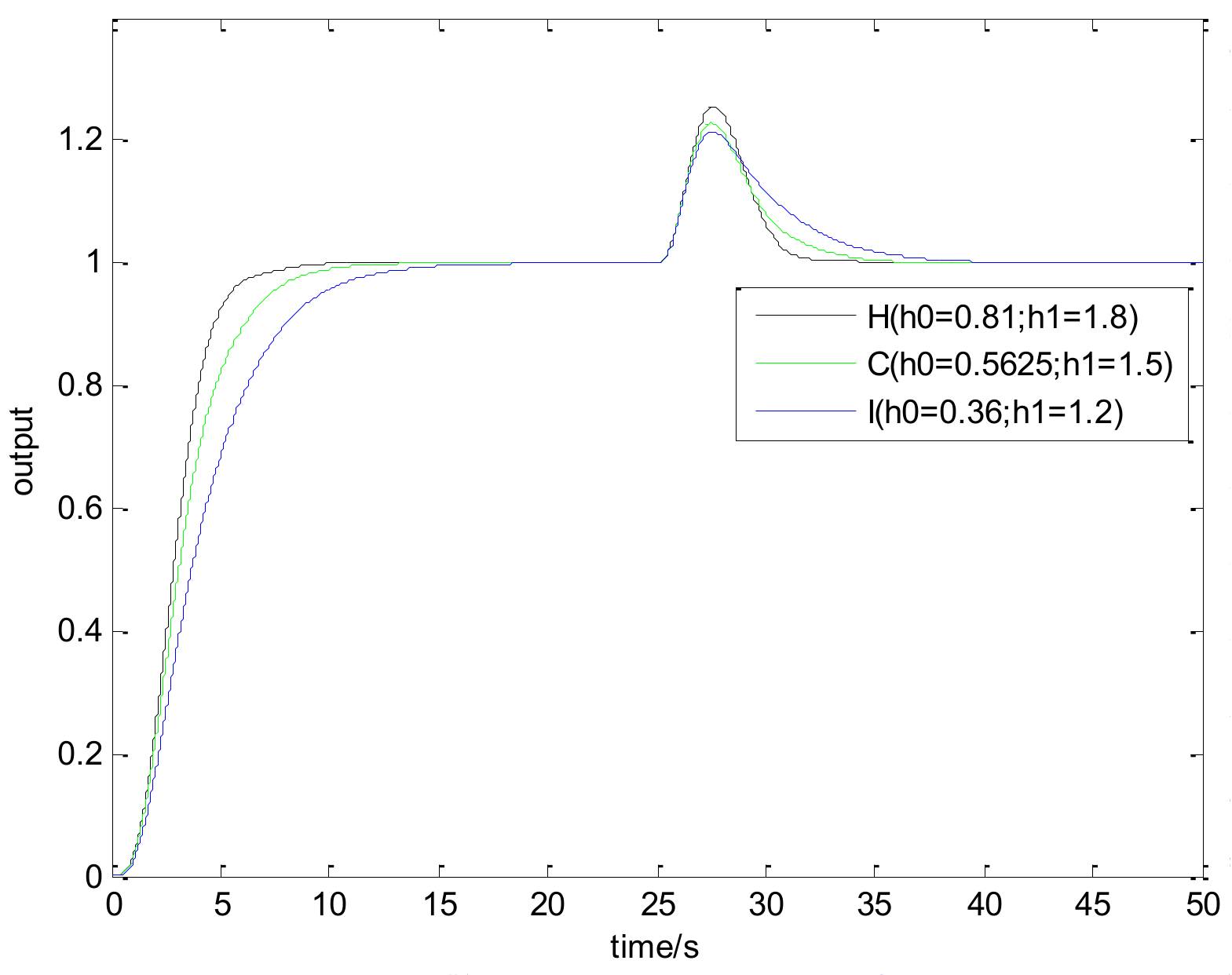

Do the step response and calculate the settling time and overshooting. If the settling time is not met, then increase both and or decrease , and turn to step (2); if the overshooting is too great, then decrease both and or increase , and turn to step (2); otherwise, continue;

- (6)

End.