A Course of Innovations in Wood Processing Industry within the Forestry-Wood Chain in Slovakia: A Q Methodology Study to Identify Future Orientation in the Sector

Abstract

:1. Introduction

2. Materials and Methods

- Problem definition and development of Q—sample. Based on the Report on Forestry in the Slovak Republic [30] there were the following nine statements (S1–S9) created by grouping the identified elements indicating future development in wood-processing industry as follows:

- S1

- Restructuring of the industry will be related to the closing of wood processing capacities.

- S2

- Restructuring of the industry will be related to the innovations of processing technologies.

- S3

- Technology innovations of the industry will relate to the processing of coniferous raw wood material.

- S4

- Technology innovations of the industry will relate to the processing of non-coniferous raw wood material, namely processing of higher quality classes of timber.

- S5

- From the viewpoint of assortments structure, do you see the future of the industry depending on the import of raw wood material from abroad.

- S6

- Development of the industry will be related to the diversification of production towards higher value products.

- S7

- Development of the industry will be related to the diversification of production towards lower value products (biomass).

- S8

- Direction of technology development in the industry will be focused on the purchase of new technologies.

- S9

- Technologies used in the industry will be innovated only slightly in order to meet the minimum required by standards.

- Based on this information there were individual quality or cost oriented statements [45,46] identified and proposed to be associated either with company owners or company managers. It is assumed that larger companies would have better possibilities to invest into existing technologies or to expand their production capacities (S2) with possible diversification towards non-coniferous timber processing (S4) as the present processing capacities are at low level. Similarly, due to the need to dispose sufficient financial resources, that is not the case for small entrepreneurs [43,44], larger companies are identified with statements S6 (Development of the industry will be related to the diversification of production towards higher value products) and S8 (Direction of technology development in the industry will be focused on the purchase of new technologies). On the other hand, orientation of innovations in the field of coniferous processing (S3) was assigned to small company owners as the most of the present mills are mainly represented by small entrepreneurs and therefore it is not assumed that they would radically change their established production patterns requiring availability of significant financial resources. This assumption is also a basis for the statement 9 that does not even suppose continuous innovation but only the orientation on meeting the required standard requirements (minimum innovations). Statement 5 (From the viewpoint of assortments structure, do you see the future of the industry depending on the import of raw wood material from abroad) is formulated with regard to the changing conditions in wood supplies (increasing share of domestic non-coniferous wood) and is intended for company owners to consider increase the imports of coniferous raw wood material from abroad in order to compensate insufficient domestic supply while staying with established processing technologies. Given that the structure of supplies may change the Statement 1 (Restructuring of the industry will be related to the closing of wood processing capacities) was formulated to find out whether such changes can result in shutting down the existing coniferous mills. Another statement assigned to company owners is the Statement 7 (Development of the industry will be related to the diversification of production towards lower value products—biomass) assuming that small entrepreneurs would be motivated to invest at least to production of biomass instead of investing to higher value added products. Typology of statements is quality oriented for company managers and cost oriented for company owners [45,46].selection of P-sample of respondents sorting the specified statements. For this purposes we contacted professionals in a given field focusing individually on the owners and individually on the managers of wood processing companies. According to [62] large numbers of participants are not required for a Q methodological study as it aims to reveal some of the main viewpoints that are favoured by a particular group of participants. Following the recommendations of Kallay [49] not to include more than 50 participants, the final sample size was set to 33 respondent.

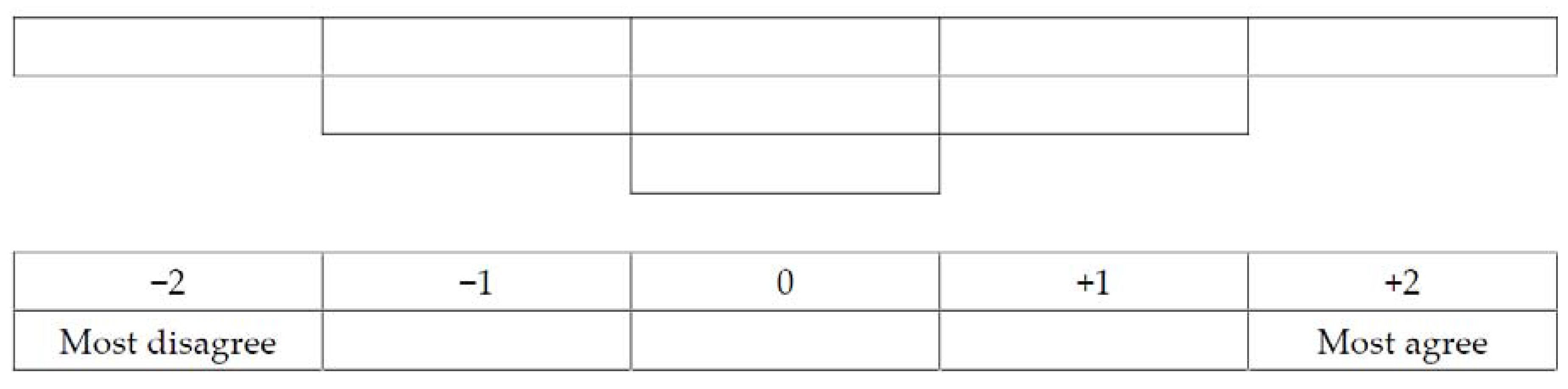

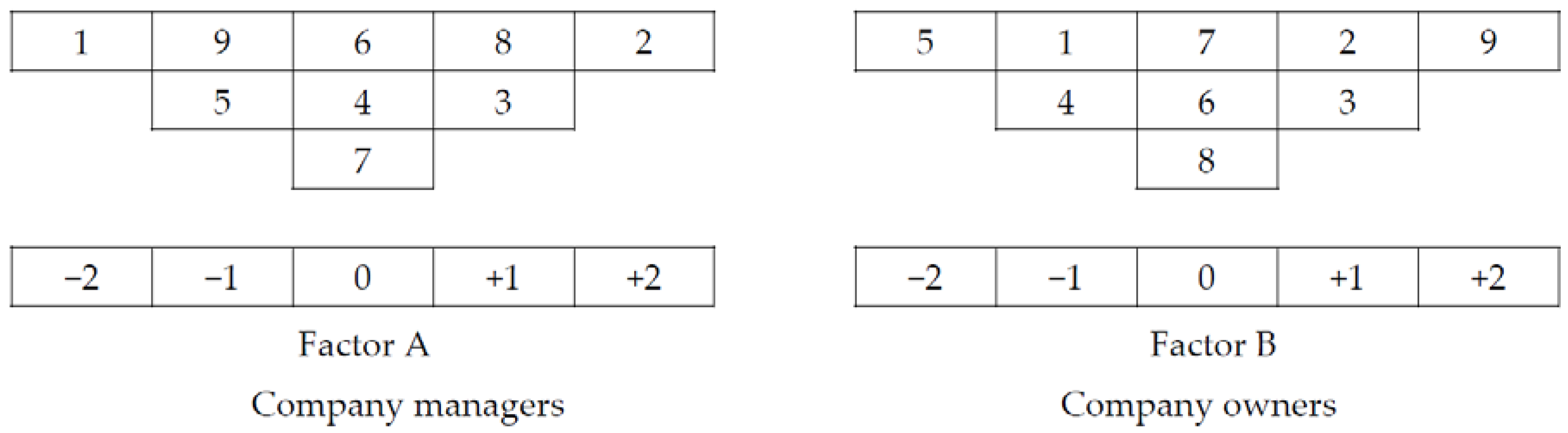

- Selection of Q-distribution. This includes the selection of the way for evaluating Q-sample, determination of the evaluation line ranking values from positive to negative attitude, and determination of the shape of the “forced” distribution [63] indicating the number of items that can be assigned to each ranking position as illustrated in Figure 1.

- Research implementation on determined Q-sample. For the purposes of this paper there was a structured interview used to address 33 respondents representing wood-processing companies, out of which 19 were representatives of capital companies such as limited companies and corporations (company managers) and 14 represented small individual entrepreneurs (company owners). The central task in the interviews was the Q sort, added upon by a number of open questions to gather qualitative data for interpretation of the factors [54,67]. Individual owners were represented by small entrepreneurs for whom a lack of own financial resources to support innovations is typical. This fact leads to the economic instability and difficulties in preparation and implementation of innovations that would increase competitiveness [43].

- Processing and evaluation of collected data was realized using the PQMethod software [68] and the interpretation of results was based on the basis of calculated indicators. The total number of statements that were sorted was 9 (S1–S9). The values of the Q-sort columns ranked from −2 to +2. The number of statements that could be assigned to individual scale values in our case followed the pattern 1 2 3 2 1. Calculated intercorrelations among Q-sorts were factor-analysed with the centroid method and resulting factors were rotated analytically. Finally, after selecting two relevant factors for which z-scores and factor scores were calculated Q-sort values for statements sorted by consensus vs. disagreement were obtained and used as a basis for interpretation.

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shumpeter, J.A. Business Cycle: A Theoretical, Historical, and Statistical Analysis of the Capitalist Process; McGraw-Hill: New Youk, NY, USA, 1939; p. 1095. [Google Scholar]

- OECD. Oslo Manuals. The Measurement of Scientific and Technological Activities. Available online: https://www.oecd.org/sti/inno/2367580.pdf (accessed on 13 May 2017).

- Kotsemir, M.; Abroskin, A. Innovation Concepts and Typology—An Evolutionary Discussion. Available online: https://www.hse.ru/pubs/share/direct/document/76780100 (accessed on 13 May 2017).

- OECD. Oslo Manuals. Guidelines for Collecting and Interpreting Innovation Data, 3rd ed. Available online: http://www.oecd-ilibrary.org/docserver/download/9205111e.pdf?expires=1495107141&id=id&accname=guest&checksum=58906A7AD892177ACBE37578AA30C87E (accessed on 11 May 2017).

- Paluš, H.; Loučanová, E.; Kaputa, V. Kontrakty a manažment rizika inovačného procesu poskytovate’ov lesníckych služieb na Slovensku. Zpr. Lesn. Výzkumu 2015, 61, 77–86. (In Slovak) [Google Scholar]

- Klenk, N.L.; Wyatt, S. The design and management of multi-stakeholder research networks to maximize knowledge mobilization and innovation opportunities in the forest sector. For. Policy Econ. 2015, 61, 77–86. [Google Scholar] [CrossRef]

- Fazey, I.; Bunse, L.; Msika, J.; Pinke, M.; Preedy, K.; Evely, A.C.; Lambert, E.; Hasting, E.; Morrie, S.; Reed, M.S. Evaluating knowledge exchange in interdisciplinary and multi-stakeholder research. Glob. Environ. Chang. 2014, 25, 204–220. [Google Scholar] [CrossRef]

- Rametsteiner, E.; Weiss, G. Innovation and innovation policy in forestry: Linking innovation process with systems models. For. Policy Econ. 2006, 8, 691–703. [Google Scholar] [CrossRef]

- Loučanová, E. Inovačné Analýzy a Stratégie; Technical University in Zvolen: Zvolen, Slovakia, 2016; p. 149. (In Slovak) [Google Scholar]

- Dzian, M. Prognózovanie Vývoja Dodávok Dreva pre Slovenský DSP; Technical University in Zvolen: Zvolen, Slovakia, 2016; p. 78. (In Slovak) [Google Scholar]

- Šupín, M. Európsky trh s Drevom a Výrobkami z Dreva; Technical University in Zvolen: Zvolen, Slovakia, 1997; p. 50. (In Slovak) [Google Scholar]

- Šupín, M.; Paluš, H. Modeling sawnwood demand in the Slovak Republic. In Acta Facultatis Xylologiae Zvolen; Technical University in Zvolen: Zvolen, Slovakia, 1999; pp. 115–122. [Google Scholar]

- Trenčiansky, M. Modelovanie ponuky dreva pre tuzeský trh na príklade vlákninových sortimntov. In Financovanie 2000/1 Lesy—Drevo; Technical University in Zvolen: Zvolen, Slovakia, 2001; p. 50. (In Slovak) [Google Scholar]

- Trenčiansky, M. Dopyt po sortimentoch dreva na trhu v SR. In Acta Facultatis Forestalis Zvolen; Technical University in Zvolen: Zvolen, Slovakia, 2004; pp. 363–375. (In Slovak) [Google Scholar]

- Paluš, H. Modelovanie Dopytu po výrobkoch z dreva na trhu v SR; Technical University in Zvolen: Zvolen, Slovakia, 2002; p. 49. (In Slovak) [Google Scholar]

- Konôpka, J.; Konôpka, B. Vývoj náhodnej ťažby dreva na Slovensku ajej prognóza pre vietor, sneh a námrazu do roku 2025. Lesnícky Časopis-For. J. 2007, 53, 273–291. [Google Scholar]

- Parobek, J.; Paluš, H.; Kaputa, V.; Šupín, M. Analysis of wood flows in Slovakia. BioResources 2014, 9, 6453–6462. [Google Scholar] [CrossRef]

- Härtl, F.; Knoke, T. The influence of the oil price on timber supply. For. Policy Econ. 2014, 39, 32–42. [Google Scholar]

- Hurmekoski, E.; Hetemäki, L.; Linden, M. Factors affecting sawnwood consumption in Europe. For. Policy Econ. 2015, 50, 236–248. [Google Scholar] [CrossRef]

- D´Annunzio, R.; Sandker, M.; Finegold, Y.; Min, Z. Projecting global forest area towards 2030. For. Ecol. Manag. 2015, 352, 124–133. [Google Scholar] [CrossRef]

- Machar, I.; Simon, J.; Rejsek, K.; Pechanec, V.; Brus, J.; Kilianova, H. Assessment of forest management in protected areas based on multidisciplinary research. Forests 2016, 7, 285. [Google Scholar] [CrossRef]

- Hansen, A.; Ireland, K.; Legg, K.; Keane, R.; Barge, E.; Jenkins, M.; Pillet, M. Complex challenges of maintaining whitebark pine in Greater Yellowstone under climate change: A call for innovative research, management, and policy approaches. Forests 2016, 7, 54. [Google Scholar] [CrossRef]

- Riguelle, S.; Hébert, J.; Jourez, B. WIND-STORM: A decision support system for the strategic management of windthrow crises by the forest community. Forests 2015, 6, 3412–3432. [Google Scholar] [CrossRef]

- Ministerstvo pôdohospodárstva a rozvoja vidieka, SR. Správa o Lesnom Hospodárstve v Slovenskej Republike za rok 2015—ZELENÁ SPRÁVA; Ministry of Agriculture and Rural Development of the Slovak Republic: Bratislava, Slovakia, 2016; p. 37. (In Slovak) [Google Scholar]

- Štěrbová, M.; Loučanová, E.; Paluš, H.; Ivan, Ľ.; Šálka, J. Innovation strategy in Slovak forest contractor firms—A SWOT analysis. Forests 2016, 6, 12. [Google Scholar] [CrossRef]

- Ambrušová, L.; Marttila, J. Comparison of Outsourced Operations in Wood Procurement in Finland and Slovakia; Finnish Forest Research Institute: Vantaa, Finland, 2012; p. 22. [Google Scholar]

- Dobšinská, Z.; Sarvašová, Z.; Šálka, J. Changes of innovation behaviour in Slovakian forestry. In The Annals of the "Stefan cel Mare"; University of Suceava; Fascicle of The Faculty of Economics and Public Administration: Suceava, Romania, 2010. [Google Scholar]

- Pudivítrová, L.; Jarský, V. Inovační aktivity v lesním hospodářství České Republiky. Zpr. Lesn. Výzkumu 2011, 56, 320–328. (In Czech) [Google Scholar]

- Jarský, V. Analysis of the sectoral innovation system for forestry of the Czech Republic. Does it even exist? For. Policy Econ. 2015, 59, 56–65. [Google Scholar]

- Anderson, F. A comparison of innovation in two Canadian forest services support industries. For. Policy Econ. 2006, 8, 674–682. [Google Scholar] [CrossRef]

- Stone, I.J.; Benjamin, J.G.; Leahy, J. Applying innovation theory to Maine’s logging industry. J. For. 2011, 109, 462–469. [Google Scholar]

- Hansen, E.N.; Nybakk, E.; Panwar, R. Innovation insights from North American forest sector research: A literature review. Forests 2014, 5, 1341–1355. [Google Scholar] [CrossRef]

- Drolet, S.; LeBel, L. Forest harvesting entrepreneurs, perception of their business status and its influence on performance evaluation. For. Policy Econ. 2010, 12, 287–298. [Google Scholar] [CrossRef]

- Ministerstvo pôdohospodárstva a rozvoja vidieka, SR. Správa o Lesnom Hospodárstve v Slovenskej Republike za rok 2014—ZELENÁ SPRÁVA; Ministry of Agriculture and Rural Development of the Slovak Republic: Bratislava, Slovakia, 2015; p. 86. (In Slovak) [Google Scholar]

- Parobek, J.; Paluš, H.; Loučanová, E.; Kalamárová, M.; Glavonić, B. Competitiveness of central European countries in the EU forest products market with the emphasis on Slovakia. Acta Fac. Xylologiae 2016, 58, 125–136. [Google Scholar]

- Olšiaková, M.; Loučanová, E.; Paluš, H. Monitoring changes in consumer requirements for wood products in terms of consumer behavior. Acta Fac. Xylologiae 2016, 58, 137–149. [Google Scholar]

- Loučanová, E.; Kalamárová, M.; Parobek, J. The competitiveness of wood products from the perspective of used material. Acta Fac. Xylologiae 2014, 57, 155–163. [Google Scholar]

- Paluš, H.; Mat’ová, H.; Križanová, A.; Parobek, J. A survey of awareness of forest certification schemes labels on wood and paper products. Acta Fac. Xylologiae 2014, 56, 129–138. [Google Scholar]

- Loučanová, E.; Parobek, J.; Paluš, H. Identification of Slovak customers’ requirements for storage furniture based on the KANO model. Acta Fac. Xylologiae 2014, 56, 109–117. [Google Scholar]

- Gejdoš, P. Analysis of performance improvement of wood processing companies in Slovakia and the Czech Republic through the implementation of quality management systems. Acta Fac. Xylologiae 2016, 58, 113–124. [Google Scholar]

- Kaputa, V.; Paluš, H.; Vlosky, R.P. Barriers for wood processing companies to enter foreign markets: A case study in Slovakia. Eur. J. Wood Wood Prod. 2016, 74, 109–122. [Google Scholar] [CrossRef]

- Ministry of Agriculture of the, SR. Proposal of the National Program for the Utilization of Wood Potential in the Slovak Republic, 2016. Available online: www.mpsr.sk/download.php?fID=7417 (accessed on 20 November 2016).

- Oravec, M.; Slamka, M. Produkcia a Využívanie Drevnej Biomasy na Slovensku, 2014. Available online: https://www.siea.sk/materials/files/medzinarodne/projekty/biomasspolicies/Oravec_Slamka_Produkcia_a_vyuzivanie_drevnej_biomasy_jun_2014_SIEA_BiomassPolicies.pdf (accessed on 12 November 2016).

- Katz, J.P.; Niehoff, B.P. How owners influence strategy—A comparison of owner-controlled and manager-controlled firms. Long Range Plan. 1998, 31, 755–761. [Google Scholar] [CrossRef]

- Amihud, Y.; Lev, B. Risk reduction as a managerial motive for conglomerate mergers. Bell J. Econ. 1981, 12, 605–617. [Google Scholar] [CrossRef]

- Bucar, B.; Glas, M.; Hisrich, R.D. Ethics and entrepreneurs: An international comparative study. J. Bus. Ventur. 2003, 18, 261–281. [Google Scholar] [CrossRef]

- Hisrich, R.D.; Peters, M.P.; Stepherd, D. Entrepreneurship; McGraw-Hill: Boston, MA, USA, 1998; p. 640. [Google Scholar]

- Kállay, É. Q methodology: The investigation of meaning systems in different life-conditions through proverbs. Cogn. Creier Comport. 2007, 11, 353–369. [Google Scholar]

- Eden, S.; Donaldson, A.; Walker, G. Structuring subjectivities? Using Q methodology in human geography. Area 2005, 37, 413–422. [Google Scholar] [CrossRef]

- O´Riordan, M.; McDonagh, J.; Mahon, M. Local knowledge and environmentality in ligitimacy discourses on Irish peatlands regulation. Land Use Policy 2016, 59, 423–433. [Google Scholar] [CrossRef]

- Barry, J.; Proops, J. Seeking sustainability discourses with Q methodology. Ecol. Econ. 1999, 28, 337–345. [Google Scholar] [CrossRef]

- Hermelingmeier, V; Nicholas, K.A. Identifying five different perspectives on the ecosystem services concept using Q methodology. Ecol. Econ. 2017, 136, 255–265. [Google Scholar] [CrossRef]

- Brown, S.R. Political Subjectivity: Applications of Q Methodology in Political Science; YALE University Press: London, UK, 1980; p. 355. [Google Scholar]

- Müller, F.N.; Kals, E. Die Q-methode. Ein innovatives verfahren zur erhebung subjektiver einstellungen und meinungen. Forum Qual. Sozialforshung 2004, 5, 17. (In German) [Google Scholar]

- Merrick, S.; Farrel, D. Head and neck cancer patients’ experiences of percutaneous endoscopic gastrostomy feeding: A Q-methodology study. Eur. J. Cancer Care 2012, 21, 493–504. [Google Scholar] [CrossRef] [PubMed]

- Dudley, R.; Siitarinen, J.; James, I.; Dodgson, G. What do people with psychosis think caused their psychosis? A Q methodology study. Behav. Cogn. Psychother. 2009, 37, 11–24. [Google Scholar] [CrossRef] [PubMed]

- Asah, S.T.; Bengston, D.N.; Wendt, K.; DeVaney, L. Prognostic framing of stakeholders’ subjectivities: A case of all-terrain vehicle management on state public lands. Environ. Manag. 2012, 49, 192–206. [Google Scholar] [CrossRef] [PubMed]

- Steelman, T.A.; Maguire, L.A. Understanding participant perspectives: Q-methodology in national forest management. J. Policy Anal. Manag. 1999, 18, 361–388. [Google Scholar] [CrossRef]

- Dasqupta, P.; Vira, B. “Q Methodology” for Mapping Stakeholder Perceptions in Participatory Forest Management; University of Cambridge: Cambridge, UK, 2005; p. 49. [Google Scholar]

- Rodriguez-Piñeros, S.; Focht, W.; Lewis, D.K.; Montgomery, D. Incorporating values into community-scale sustainable forest management plans: An application of Q methodology. Small-Scale For. 2012, 11, 167–183. [Google Scholar]

- Stainton, R.; Stenner, P.; Gleeson, K.; Stainton Rogers, W. Social Psychology: A Critical Agenda; Polity Press: Cambridge, UK, 1995; p. 320. [Google Scholar]

- Watts, S.; Stenner, P. Doing Q methodology: Theory, method and interpretation. Qual. Res. Psychol. 2005, 2, 67–91. [Google Scholar] [CrossRef]

- Paluš, H.; Parobek, J. Changing patterns of roundwood deliveries in Slovakia. In Markets for Wood and Wooden Products; WoodEMA: Zagreb, Croatia, 2013; pp. 77–94. [Google Scholar]

- Paluš, H. Changes in energy wood supplies in the Slovak Republic. In Wood Processing and Furniture Manufacturing Challenges on the World Market and Wood-Based Energy Goes Global; WoodEMA: Zagreb, Croatia, 2015; pp. 261–266. [Google Scholar]

- Haluza, I. Drevári, Ktorí Myslia na Odolnejšie Lesy. Available online: https://www.etrend.sk/trend-archiv/rok-2017/cislo-6/drevari-ktori-myslia-na-odolnejsie-lesy.html (accessed on 10 February 2017). (In Slovak).

- Cuppen, E.; Breukers, S.; Hisschemöller, M.; Bergsma, E. Q methodology to select participants for a stakeholder dialogue on energy options from biomass in the Netherlands. Ecol. Econ. 2010, 69, 579–591. [Google Scholar] [CrossRef]

- Schmolck, P. PQMethod Manual. Available online: http://schmolck.userweb.mwn.de/qmethod/pqmanual.htm (accessed on 14 May 2017).

- Hansen, E.N.; Bull, L. An illustration of lessons for forest sector researchers and managers from current new product development research. J. For. Prod. Bus. Res. 2010, 7, 1–7. [Google Scholar]

- Hansen, E.N.; Nybakk, E. When innovativeness determines market orientation: The forest sector and the Great Recession. BioProd. Bus. 2016, 1, 1–12. [Google Scholar]

- Rametsteiner, E.; Hansen, E.N.; Niskanen, A. Introduction to the special issue on innovation and entrepreneurship in the forest sector. For. Policy Econ. 2006, 8, 669–673. [Google Scholar] [CrossRef]

- Kupčák, V.; Pek, R. The level of the wood raw material base processing in the Czech Republic. Procedia Econ. Financ. 2015, 34, 557–564. [Google Scholar]

- Oblak, L.; Glavonijić, B. A model for the evaluation of radio advertisements for the sale of timber products. Drvna Ind. 2014, 65, 303–308. [Google Scholar] [CrossRef]

| Statements | Type | Factors | ||

|---|---|---|---|---|

| A | B | |||

| S1 | Restructuring of the industry will be related to the closing of wood processing capacities. | CO | −1 | −2 |

| S2 | Restructuring of the industry will be related to the innovations of processing technologies. | CM | 1 | 2 |

| S3 | Technology innovations of the industry will relate to the processing of coniferous raw wood material. | CO | 1 | 1 |

| S4 | Technology innovations of the industry will relate to the processing of non-coniferous raw wood material, namely processing of higher quality classes of timber. | CM | −1 | 0 |

| S5 | From the viewpoint of assortments structure, do you see the future of the industry depending on the import of raw wood material from abroad. | CO | −2 | −1 |

| S6 | Development of the industry will be related to the diversification of production towards higher value products. | CM | 0 | 0 |

| S7 | Development of the industry will be related to the diversification of production towards lower value products (biomass). | CO | 0 | 0 |

| S8 | Direction of technology development in the industry will be focused on the purchase of new technologies. | CM | 0 | 1 |

| S9 | Technologies used in the industry will be innovated only slightly in order to meet the minimum required by standards. | CO | 2 | −1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loučanová, E.; Paluš, H.; Dzian, M. A Course of Innovations in Wood Processing Industry within the Forestry-Wood Chain in Slovakia: A Q Methodology Study to Identify Future Orientation in the Sector. Forests 2017, 8, 210. https://doi.org/10.3390/f8060210

Loučanová E, Paluš H, Dzian M. A Course of Innovations in Wood Processing Industry within the Forestry-Wood Chain in Slovakia: A Q Methodology Study to Identify Future Orientation in the Sector. Forests. 2017; 8(6):210. https://doi.org/10.3390/f8060210

Chicago/Turabian StyleLoučanová, Erika, Hubert Paluš, and Michal Dzian. 2017. "A Course of Innovations in Wood Processing Industry within the Forestry-Wood Chain in Slovakia: A Q Methodology Study to Identify Future Orientation in the Sector" Forests 8, no. 6: 210. https://doi.org/10.3390/f8060210