Allocation of Storage Yards in Management Plans in the Amazon by Means of Mathematical Programming

Abstract

:1. Introduction

2. Materials and Methods

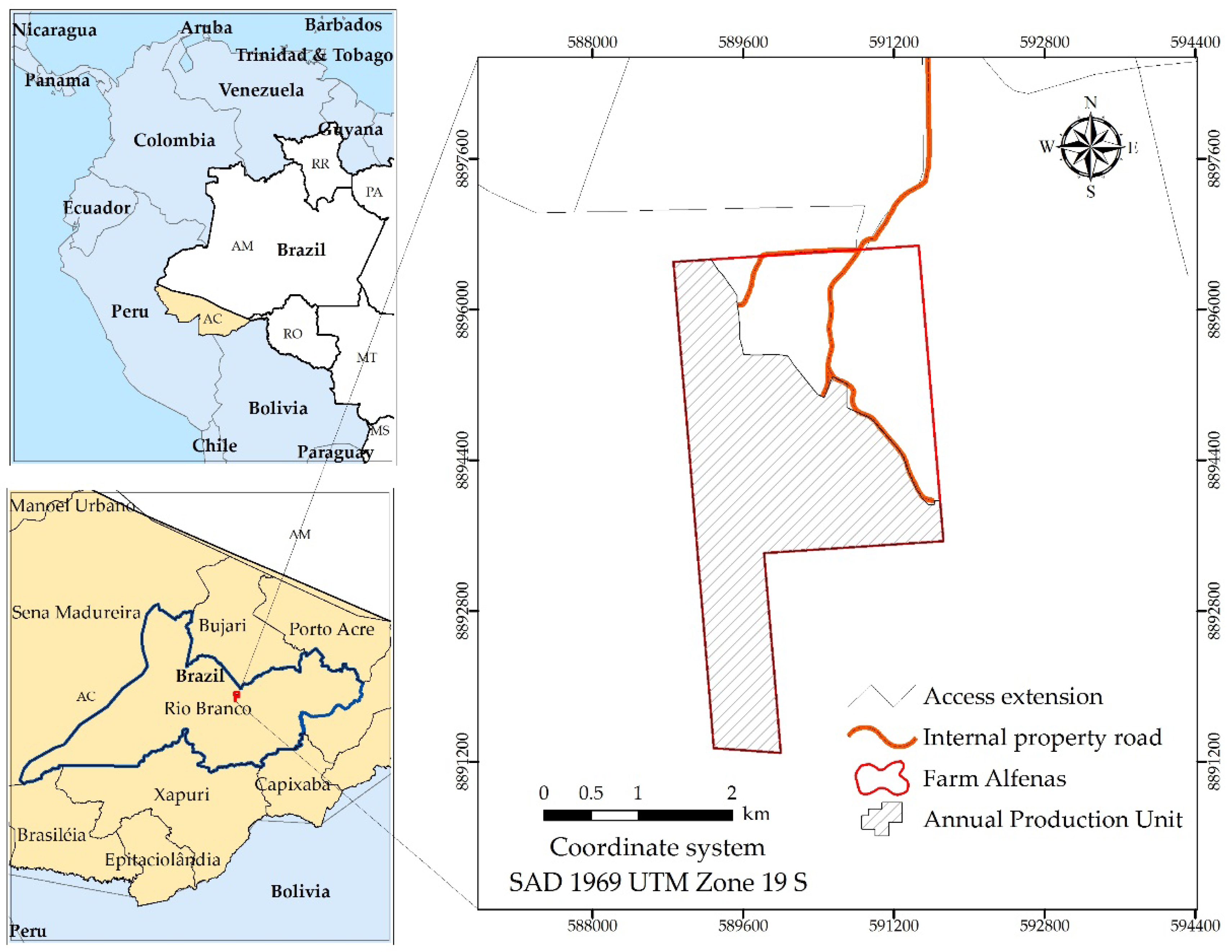

2.1. Description of the Study Area

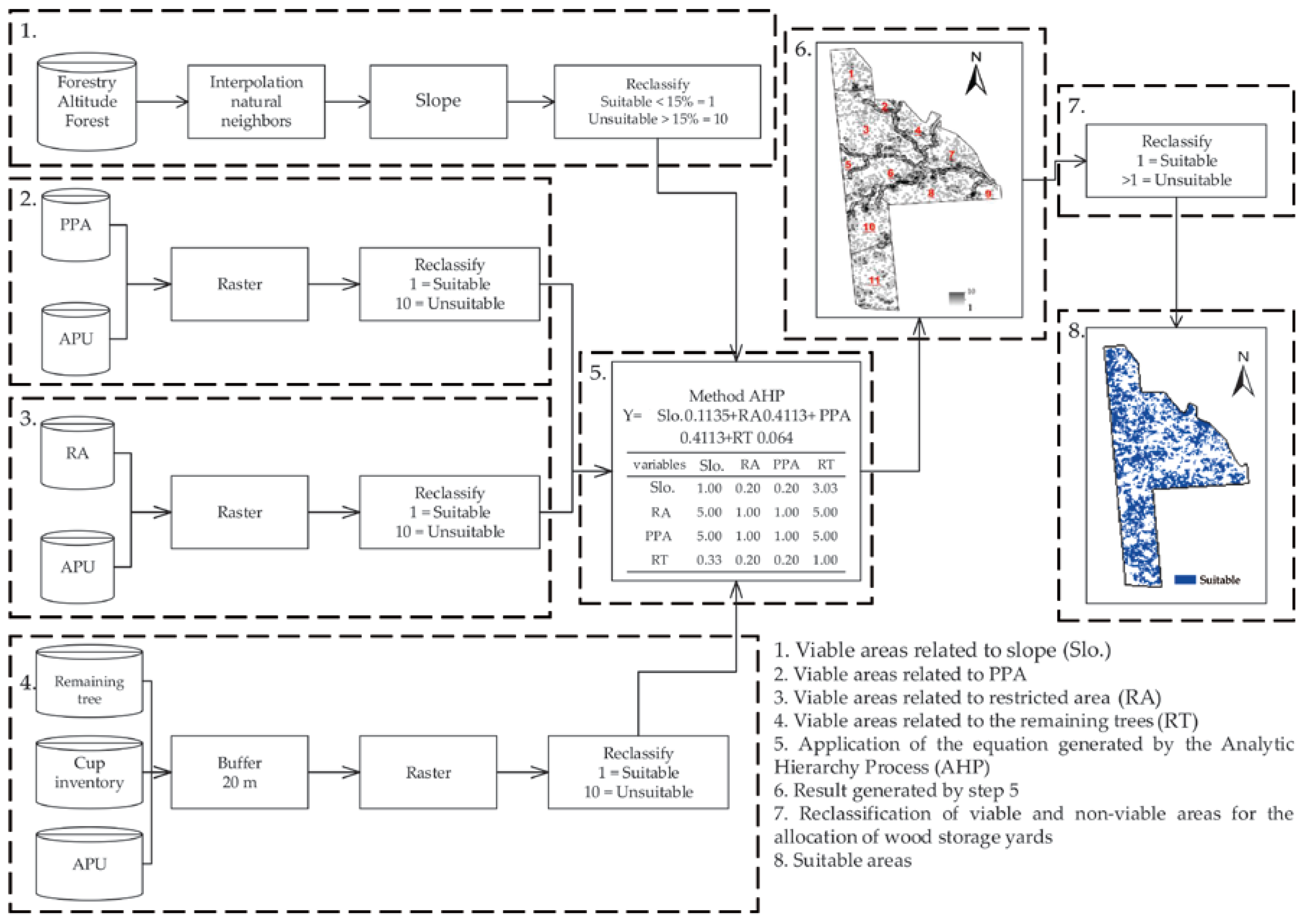

2.2. Definition of Suitable Areas for the Allocation of Storage Yards

2.2.1. Definition of Areas Eligible Based on Slope

2.2.2. Influence of the PPA in the Definition of Eligible Areas

2.2.3. Obtaining Suitable Areas Relating to Restricted Areas

2.2.4. Definition of Areas Suitable for the Remaining Trees

2.2.5. Weighted Overlay of Raster Images

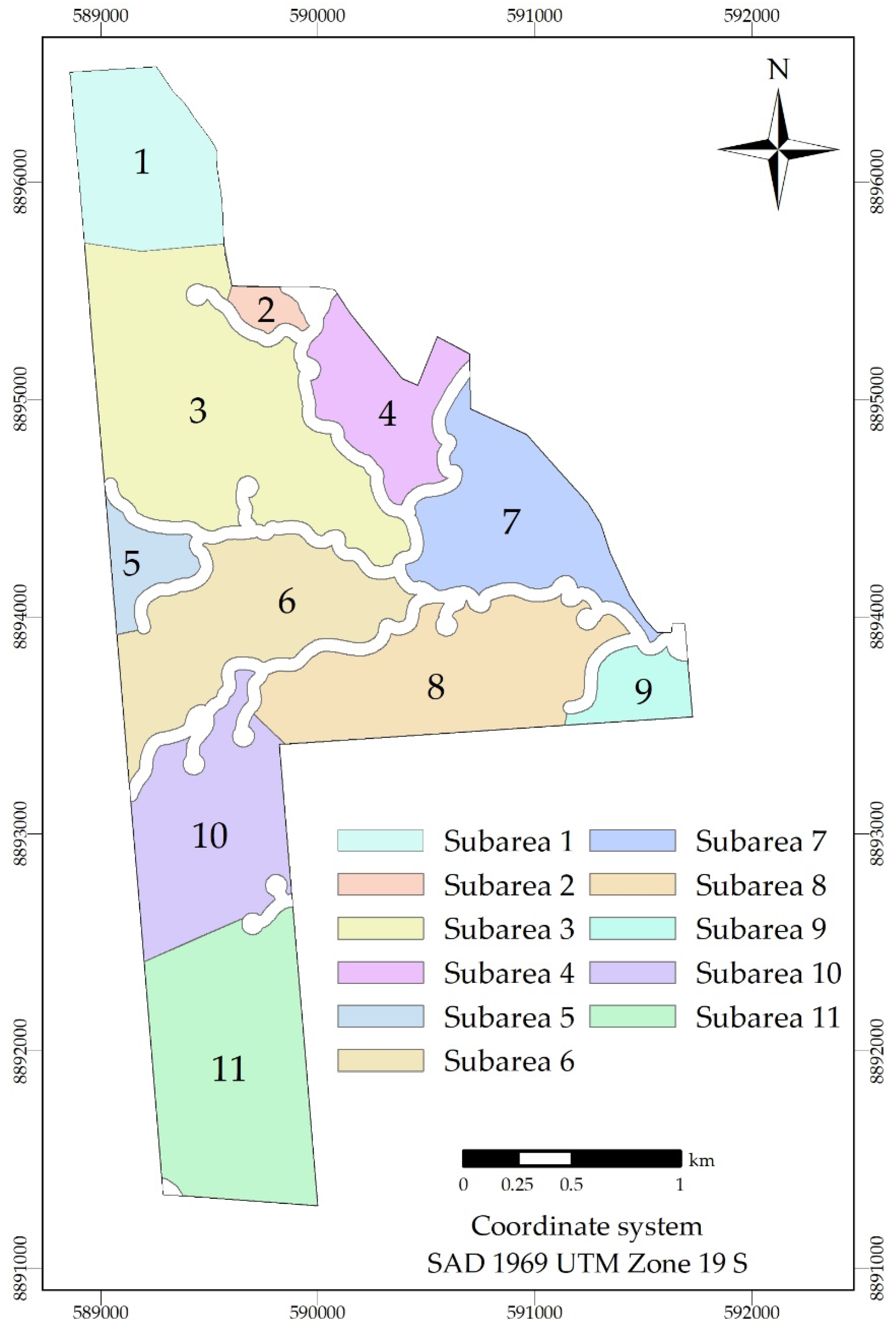

2.2.6. Division of Suitable Area in Subareas

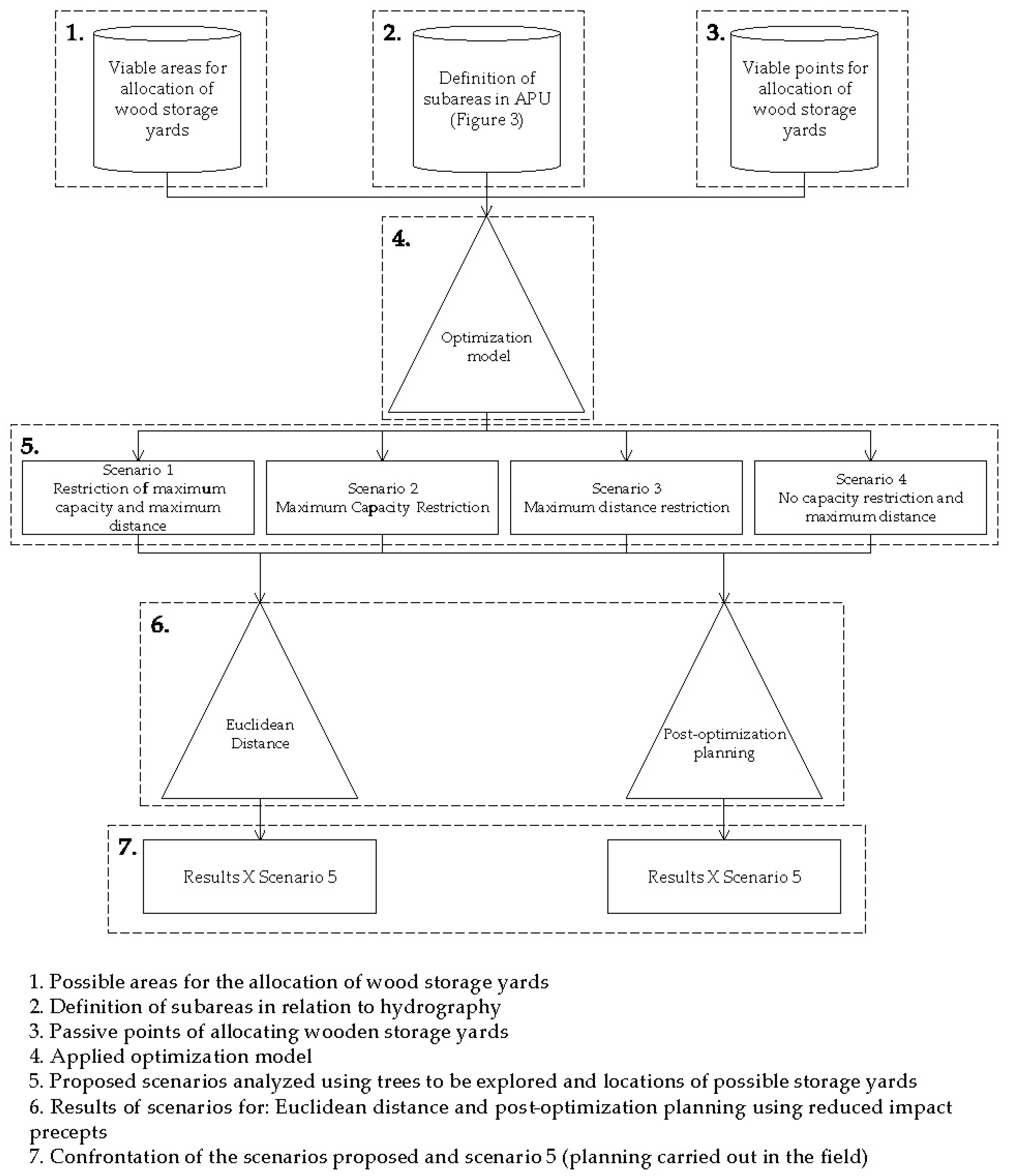

2.3. Optimization Model for the Allocation of Storage Yards

2.4. Comparison of the Scenarios with the Project Approved for Implementation

2.5. Planning of Forest Roads and Skidtrails

2.6. Estimate of Environmental Impacts in the Harvest Planning from the Opening of Roads and Skidtrails

3. Results

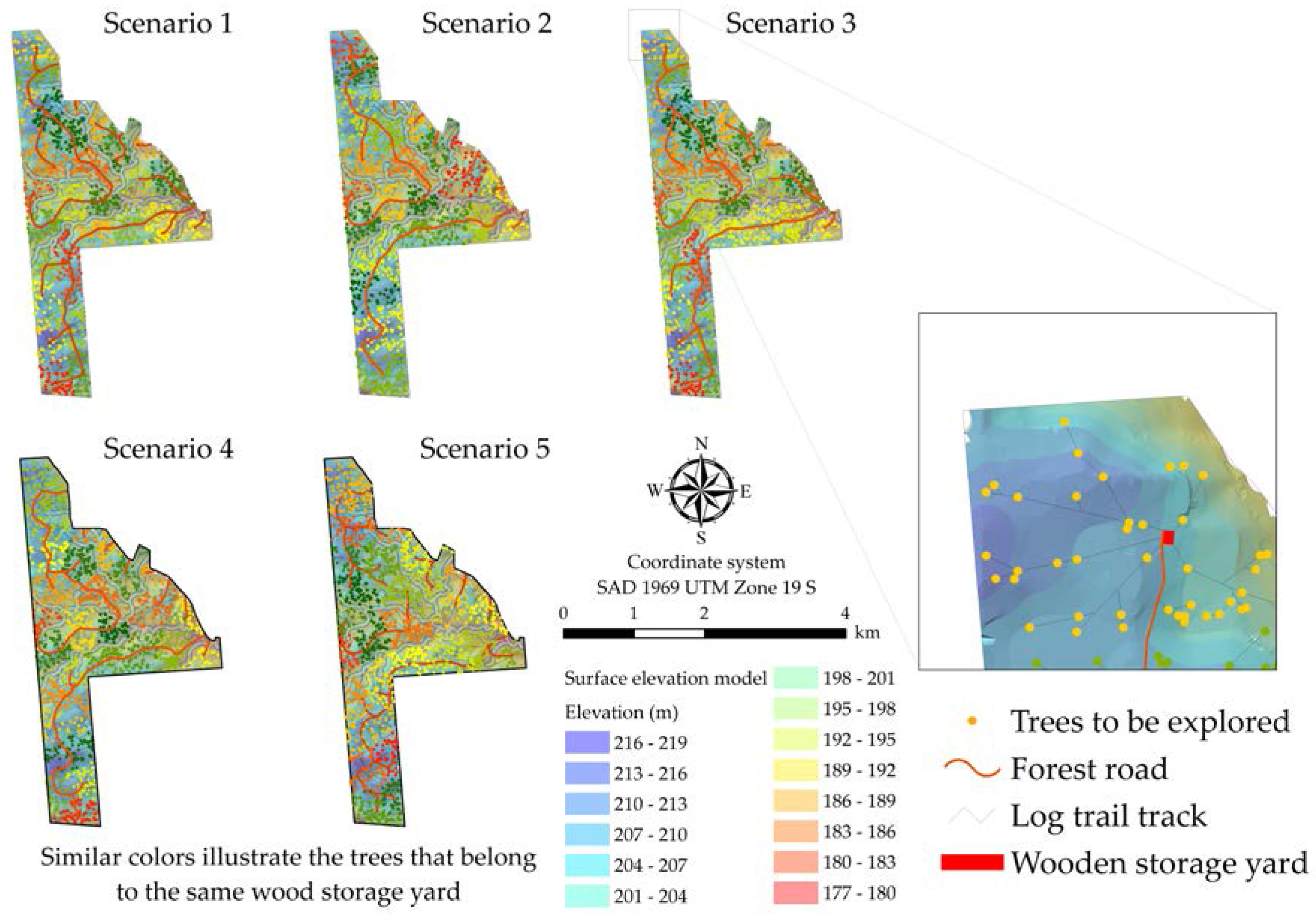

3.1. Allocation of Storage Yards Based on the Euclidean Distance

3.2. Distribution of Individual Trees in Relation to the Euclidean Distances of Extraction of the Scenarios

3.3. Allocation of Storage Yards, Forest Roads, and Skidtrails of Post-Optimized Planning

4. Discussion

4.1. Allocation of Storage Yards Based on the Euclidean Distance

4.2. Distribution of Individual Trees in Relation to the Euclidean Distances of Extraction of the Scenarios

4.3. Allocation of Storage Yards, Forest Roads, and Skidtrails of Post-Optimized Planning

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Corlett, R.T. The Impacts of Droughts in Tropical Forests. Trends Plant Sci. 2016, 21, 584–593. [Google Scholar] [CrossRef] [PubMed]

- Poorter, L.; van der Sande, M.T.; Thompson, J.; Arets, E.J.M.M.; Alarcón, A.; Álvarez-Sánchez, J.; Ascarrunz, N.; Balvanera, P.; Barajas-Guzmán, G.; Boit, A.; et al. Diversity enhances carbon storage in tropical forests. Glob. Ecol. Biogeogr. 2015, 24, 1314–1328. [Google Scholar] [CrossRef]

- Wolfslehner, B.; Vacik, H.; Lexer, M.J. Application of the analytic network process in multi-criteria analysis of sustainable forest management. For. Ecol. Manag. 2005, 207, 157–170. [Google Scholar] [CrossRef]

- Brazil, LEI No 12.651, DE 25 DE MAIO DE 2012.L12651, Dispõe Sobre a Proteção da Vegetação Nativa. Available online: http://www.planalto.gov.br/ccivil_03/_ato2011-2014/2012/lei/l12651.htm (accessed on 1 August 2017).

- Hosokawa, R.T.; Moura, J.B.; Cunha, U.S. Introdução ao Manejo Economia de Floresta; UFPR: Curitiba, Brazil, 1998. [Google Scholar]

- Rotta, G.W.; Micol, L.; dos Santos, N.B. Manejo Sustentável no Portal da Amazônia: Um Benefício Econômico, Social e Ambiental; ICV: Alta Floresta, Brazil, 2006.

- IBAMA, Norma de Execução n.o 1, de 24 Abril de 2007 do Instituto Brazileiro do Meio Ambiente e Recursos Hídricos. Available online: https://www.legisweb.com.br/legislacao/?id=91545 (accessed on 25 August 2017).

- Amaral, P.; Veríssimo, A.; Barreto, P.; Vidal, E. Floresta Para Sempre: Um Manual Para Produção de Madeira na AMAZÔNIA; Imazon: Belém, Brazil, 1998. [Google Scholar]

- Braz, E.M. Subsídios Para o Planejamento do Manejo de Florestas Tropicais da Amazônia. Ph.D. Thesis, Universidade Federal de Santa Maria, Santa Maria, Rio Grande do Sul, Brazil, 2010. [Google Scholar]

- Timofeiczyk Júnior, R.; Graça, L.R.; Berger, R.; Sousa, R.A.T.M.; Hosokawa, R.T. Estrutura de custos do manejo de baixo impacto em florestas tropicais—Um estudo de caso. Floresta 2005, 35, 89–103. [Google Scholar] [CrossRef]

- Sá, C.P.; de Araujo, H.J.B.; Figueiredo, E.O.; de Oliveira, L.C. Coeficientes Técnicos Para o Manejo Florestal Madeireiro em Áreas de Reserva Legal de Pequenas Propriedades no Estado do Acre; Embrapa Acre: Rio Branco, Brazil, 2008. [Google Scholar]

- Da Silva, J.C.; de Almeida, A.N.; de Pompermaye, R.S. Análise estratégica do manejo florestal na Amazônia Brazileira. Floresta 2014, 44, 341–348. [Google Scholar] [CrossRef]

- Gama, J.R.V.; de Bentes-Gama, M.M.; Scolforo, J.R.S. Manejo sustentado para floresta de várzea na amazônia oriental. Rev. Árvore 2005, 29, 719–729. [Google Scholar] [CrossRef]

- De Pinho, G.S.C.; Fiedler, N.C.; Guimarães, P.P.; Silva, G.F.; dos Santos, J. Análise de custos e rendimentos de diferentes métodos de corte de cipós para produção de madeira na floresta nacional do Tapajós. Acta Amazon. 2009, 39, 555–560. [Google Scholar] [CrossRef]

- Huth, A.; Drechsler, M.; Ko, P. Multicriteria evaluation of simulated logging scenarios in a tropical rain forest. J. Environ. Manag. 2004, 71, 321–333. [Google Scholar] [CrossRef] [PubMed]

- Søvde, N.E.; Løkketangen, A.; Talbot, B. Applicability of the GRASP metaheuristic method in designing machine trail layout. For. Sci. Technol. 2013, 9, 187–194. [Google Scholar] [CrossRef]

- Contreras, M.; Chung, W. A computer approach to finding an optimal log landing location and analyzing influencing factors for ground-based timber harvesting. Can. J. For. Res. 2007, 37, 276–292. [Google Scholar] [CrossRef]

- Murray, A.T.; Snyder, S. Spatial Modeling in Forest Management and Natural Resource Planning. For. Sci. 2000, 46, 153–156. [Google Scholar] [CrossRef]

- Karlsson, J.; Rönnqvist, M.; Bergström, J. An optimization model for annual harvest planning. Can. J. For. Res. 2004, 34, 1747–1754. [Google Scholar] [CrossRef]

- Shahi, S.; Pulkki, R. Supply Chain Network Optimization of the Canadian Forest Products Industry: A Critical Review. Am. J. Ind. Bus. Manag. 2013, 3, 631. [Google Scholar] [CrossRef]

- Figueiredo, E.O.; Braz, E.M.; d’Oliveira, M.V.N. Manejo de Precisão em Florestas Tropicais: Modelo Digital de Exploração Florestal; Embrapa Acre: Rio Branco, Brazil, 2007. [Google Scholar]

- Figueiredo, E.O.; d’Oliveira, M.V.N.; Braz, E.M.; de Almeida Papa, D.; Fearnside, P.M. LIDAR-based estimation of bole biomass for precision management of an Amazonian forest: Comparisons of ground-based and remotely sensed estimates. Remote Sens. Environ. 2016, 187, 281–293. [Google Scholar] [CrossRef]

- Liu, K.; Sessions, J. Preliminary Planning of Road Systems Using Digital Terrain Models. Int. J. For. Eng. 1993, 4, 27–32. [Google Scholar] [CrossRef]

- Newnham, R.M. ROADPLAN: A Tool for Designing Forest Road Networks. Int. J. For. Eng. 1995, 6, 17–26. [Google Scholar] [CrossRef]

- Baskent, E.Z.; Keles, S. Spatial forest planning: A review. Ecol. Model. 2005, 188, 145–173. [Google Scholar] [CrossRef]

- Ezzati, S.; Najafi, A.; Yaghini, M.; Hashemi, A.A.; Bettinger, P. An optimization model to solve skidding problem in steep slope terrain. J. For. Econ. 2015, 21, 250–268. [Google Scholar] [CrossRef]

- McDonald, T.P.; Taylor, S.E.; Rummer, R.B.; Valenzuela, J. Information needs for increasing log transport efficiency. In Proceedings of the First International Precision Forestry Symposium, Seattle, WA, USA, 17–20 June 2001; United States Department of Agriculture: Washington, DC, USA, 2001. [Google Scholar]

- Bredström, D.; Jönsson, P.; Rönnqvist, M. Annual planning of harvesting resources in the forest industry. Int. Trans. Oper. Res. 2010, 17, 155–177. [Google Scholar] [CrossRef]

- Putz, F.E.; Zuidema, P.A.; Synnott, T.; Peña-Claros, M.; Pinard, M.A.; Sheil, D.; Vanclay, J.K.; Sist, P.; Gourlet-Fleury, S.; Griscom, B.; et al. Sustaining conservation values in selectively logged tropical forests: The attained and the attainable. Conserv. Lett. 2012, 5, 296–303. [Google Scholar] [CrossRef]

- Schwartz, G.; Peña-Claros, M.; Lopes, J.C.A.; Mohren, G.M.J.; Kanashiro, M. Mid-term effects of reduced-impact logging on the regeneration of seven tree commercial species in the Eastern Amazon. For. Ecol. Manag. 2012, 274, 116–125. [Google Scholar] [CrossRef]

- Darrigo, M.R.; Venticinque, E.M.; dos Santos, F.A.M. Effects of reduced impact logging on the forest regeneration in the central Amazonia. For. Ecol. Manag. 2016, 360, 52–59. [Google Scholar] [CrossRef]

- Boltz, F.; Holmes, T.P.; Carter, D.R. Economic and environmental impacts of conventional and reduced-impact logging in Tropical South America: A comparative review. For. Policy Econ. 2003, 5, 69–81. [Google Scholar] [CrossRef]

- Holmes, T.P.; Blate, G.M.; Zweede, J.C.; Pereira, R.; Barreto, P.; Boltz, F.; Bauch, R. Financial and ecological indicators of reduced impact logging performance in the eastern Amazon. For. Ecol. Manag. 2002, 163, 93–110. [Google Scholar] [CrossRef]

- Huth, A.; Ditzer, T. Long-term impacts of logging in a tropical rain forest—A simulation study. For. Ecol. Manag. 2001, 142, 33–51. [Google Scholar] [CrossRef]

- Braz, E.M.; D’Oliveira, M.V.N. Planejamento de Arraste Mecanizado em Floresta Tropical; Embrapa Acre: Rio Branco, Brazil, 1997. [Google Scholar]

- Machado, M.P.O. Custo do manejo florestal madeireiro na Amazônia: Um estudo de caso no Estado do Acre. Bachelor, Universidade Federal do Acre: Rio Branco, AC, Brazil, 2012. [Google Scholar]

- Vidal, E.; West, T.A.P.; Putz, F.E. Recovery of biomass and merchantable timber volumes twenty years after conventional and reduced-impact logging in Amazonian Brazil. For. Ecol. Manag. 2016, 376, 1–8. [Google Scholar] [CrossRef]

- Da Lopes, E.S.; Missel, J.W.P.; Dias, A.N.; Fiedler, N.C. Technical evalution of a skidder with different wheeled types in log extraction activies of pine plantation. Rev. Árvore 2007, 31, 1053–1061. [Google Scholar] [CrossRef]

- Pierzchała, M.; Talbot, B.; Astrup, R. Estimating Soil Displacement from Timber Extraction Trails in Steep Terrain: Application of an Unmanned Aircraft for 3D Modelling. Forests 2014, 5, 1212–1223. [Google Scholar] [CrossRef]

- Bramucci, M.; Seixas, F. Determinação e quantificação de fatores de influência sobre a produtividade de “harvesters” na colheita florestal. Sci. For. 2002, 62–74. [Google Scholar] [CrossRef]

- Eriksson, L.O. Planning under uncertainty at the forest level: A systems approach. Scand. J. For. Res. 2006, 21, 111–117. [Google Scholar] [CrossRef]

- Chung, W.; Stückelberger, J.; Aruga, K.; Cundy, T.W. Forest road network design using a trade-off analysis between skidding and road construction costs. Can. J. For. Res. 2008, 38, 439–448. [Google Scholar] [CrossRef]

- Walker, R.; Arima, E.; Messina, J.; Soares-Filho, B.; Perz, S.; Vergara, D.; Sales, M.; Pereira, R.; Castro, W. Modeling spatial decisions with graph theory: Logging roads and forest fragmentation in the Brazilian Amazon. Ecol. Appl. Publ. Ecol. Soc. Am. 2013, 23, 239–254. [Google Scholar] [CrossRef]

- Sterenczak, K.; Moskalik, T. Use of LIDAR-based digital terrain model and single tree segmentation data for optimal forest skid trail network. iForest Biogeosci. For. 2014, 8, 661–667. [Google Scholar] [CrossRef]

- Philippart, J.; Sun, M.; Doucet, J.-L.; Lejeune, P. Mathematical formulation and exact solution for landing location problem in tropical forest selective logging, a case study in Southeast Cameroon. J. For. Econ. 2012, 18, 113–122. [Google Scholar] [CrossRef]

- Shirasawa, H.; Hasegawa, H. A comparative study of heuristic algorithms for the multiple target access problem. J. For. Res. 2014, 19, 437–449. [Google Scholar] [CrossRef]

- Nørstebø, V.S.; Johansen, U. Optimal transportation of logs and location of quay facilities in coastal regions of Norway. For. Policy Econ. 2013, 26, 71–81. [Google Scholar] [CrossRef]

- Ezzati, S.; Najafi, A.; Bettinger, P. Finding feasible harvest zones in mountainous areas using integrated spatial multi-criteria decision analysis. Land Use Policy 2016, 59, 478–491. [Google Scholar] [CrossRef]

- Gomide, L.R.; de Moura, A.L.M.; de Mello, J.M. Simulação Otimizada da Exploração Florestal de Impacto Reduzido em Uma Mata Nativa Localizada em Lavras. In Proceedings of the Anais do XX Congresso de pós-graduação da UFLA, Lavras, Brazil, 2011. [Google Scholar]

- Issac Júnior, M.A.; Gomide, L.R.; Silva, P.H.; de Alves, J.A.; Figueiredo, E.O. Alocação de Pátios de Armazenamento de Madeira em um Plano de Manejo Florestal na Amazônia Ocidental; Anais do XLVI Simpósio Brazileiro de Pesquisa Operacional: Salvador, Brazil, 2014. [Google Scholar]

- Martinhago, A.Z. Otimização Para a Locação de Pátios de Estocagem Para Exploração de Impacto Reduzido na Amazônia Brazileira. Ph.D. Thesis, Universidade Federal de Lavras, Lavras, Minas Gerais, Brazil, 2012. [Google Scholar]

- Da Silva, P.H. Desenvolvimento de um Modelo Para Alocação Ótima de Pátios de Estocagem de madeira. Master’s Thesis, Universidade Federal de Lavras, Lavras, Minas Gerais, Brazil, 2014. [Google Scholar]

- Luenberger, D.G.; Ye, Y. Linear and Nonlinear Programming; Springer International Publishing: Cham, Switzerland, 2016; Volume 228, ISBN 978-33-1-918841-6. [Google Scholar]

- Goldbarg, M.C.; Henrique Pacca, L.L. Otimização Combinatória e Programação Linear: Modelos e Algoritmos, 2nd ed.; Elsevier: Rio de Janeiro, Brazil, 2005; ISBN 978-85-3-521520-5. [Google Scholar]

- Fávero, L.P.; Belfiore, P. Pesquisa Operacional Para Cursos de Engenharia; Elsevier: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Klose, A.; Drexl, A. Facility location models for distribution system design. Eur. J. Oper. Res. 2005, 162, 4–29. [Google Scholar] [CrossRef]

- Zanjirani Farahani, R.; Hekmatfar, M. Contributions to Management Science; Drezner, Z., Hamacher, H.W., Eds.; Physica-Verlag HD: Heidelberg, Germany, 2009; ISBN 978-37-9-082150-5. [Google Scholar]

- Arenales, M.; Armentano, V.; Morabito, R.; Yanasse, H. Pesquisa Operacional; Elsevier: Rio de Janeiro, Brazil, 2011; ISBN 978-85-3-525193-7. [Google Scholar]

- Eiselt, H.; Marianov, V. Foundations of Location; Springer: Boston, MA, USA, 2011; Volume 155, ISBN 978-14-4-197571-3. [Google Scholar]

- Hurter, A.P.; Martinich, J.S. Facility Location and the Theory of Production; Springer: Dordrecht, The Netherlands, 1989; ISBN 978-94-010-7637-1. [Google Scholar]

- IBGE. Projeto de Proteção do Meio Ambiente e das Comunidades Indígenas—PMACI I.—Diagnóstico Geoambiental e Socioeconômico—Área de Influência da Br-364 trecho Rio Branco/Cruzeiro do Sul; IBGE: Rio de Janeiro, Brazil, 1994.

- ACRE. Programa Estadual de Zoneamento Ecológico-Econômico do Estado do Acre. Zoneamento Ecológico-Econômico do Acre Fase II: documento Síntese—Escala 1:250.000; SEMA: Rio Branco, Brazil, 2006. [Google Scholar]

- IBAMA. Norma de execução n.o 1, de 24 abril de 2007 do Instituto Brazileiro do Meio ambiente e Recursos Hídricos; IBAMA: Brazilia, Brazil, 2007; p. 33.

- Environmental Systems Research Institute (ESRI). ArcGis Professional GIS for the Desktop; Environmental Systems Research Institute: Redlands, CA, USA, 2015. [Google Scholar]

- EMBRAPA. Súmula da X Reunião Técnica de Levantamento de Solos; EMBRAPA: Rio de Janeiro, Brazil, 1979. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Louzada, F.L.R.; Santos, A.R.; Silva, A.G. Delimitação de Corredores Ecológicos no ArcGIS 9.3; CAUFES: Alegre, Brazil, 2010. [Google Scholar]

- Kühmaier, M.; Kanzian, C.; Stampfer, K. Identification of potential energy wood terminal locations using a spatial multicriteria decision analysis. Biomass Bioenergy 2014, 66, 337–347. [Google Scholar] [CrossRef]

- Teixeira, T.R.; Soares Ribeiro, C.A.A.; Rosa dos Santos, A.; Marcatti, G.E.; Lorenzon, A.S.; de Castro, N.L.M.; Domingues, G.F.; Leite, H.G.; da Costa de Menezes, S.J.M.; Santos Mota, P.H.; et al. Forest biomass power plant installation scenarios. Biomass Bioenergy 2018, 108, 35–47. [Google Scholar] [CrossRef]

- Handfield, R.; Walton, S.V.; Sroufe, R.; Melnyk, S.A. Applying environmental criteria to supplier assessment: A study in the application of the Analytical Hierarchy Process. Eur. J. Oper. Res. 2002, 141, 70–87. [Google Scholar] [CrossRef]

- Beasley, J.E. A note on solving large p-median problems. Eur. J. Oper. Res. 1985, 21, 270–273. [Google Scholar] [CrossRef]

- Church, R.L. BEAMR: An exact and approximate model for the p-median problem. Comput. Oper. Res. 2008, 35, 417–426. [Google Scholar] [CrossRef]

- Costa, B.B.; Nassi, C.D.; Ribeiro, G.M. A Methodology for Location of Logistics Platforms Using Geographic Information Systems. J. Traffic Logist. Eng. 2013, 1, 104–110. [Google Scholar] [CrossRef]

- Daskin, M.S. Median Problems. In Network and Discrete Location; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 198–246. [Google Scholar]

- Daskin, M.S.; Maass, K.L. The p-Median Problem. In Location Science; Springer International Publishing: Cham, Switzerland, 2015; pp. 21–45. ISBN 9783319131115. [Google Scholar]

- Domínguez, E.; Muñoz, J. A neural model for the p-median problem. Comput. Oper. Res. 2008, 35, 404–416. [Google Scholar] [CrossRef]

- Isler, C.A.; Bonassa, A.C.; Cunha, C.B. da Algoritmo genético para resolução do problema de p-medianas capacitado associado à distribuição de peças automotivas. Transportes 2012, 20, 5–14. [Google Scholar] [CrossRef]

- Park, G.; Lee, Y.; Han, J. A two-level location-allocation problem in designing local access fiber optic networks. Comput. Oper. Res. 2014, 51, 52–63. [Google Scholar] [CrossRef]

- Pirkul, H.; Gupta, R.; Rolland, E. VisOpt: A visual interactive optimization tool for P-median problems. Decis. Support Syst. 1999, 26, 209–223. [Google Scholar] [CrossRef]

- Rolland, E.; Schilling, D.A.; Current, J.R. An efficient tabu search procedure for the p-Median Problem. Eur. J. Oper. Res. 1997, 96, 329–342. [Google Scholar] [CrossRef]

- Food and Agriculture Organization/Swedish International Development Authority (FAO/SIDA). El Transporte de Madera en Paises de America Latina. In Proceedings of the Seminar on Wood Transportation in Latin American Countries, Oaxtepec, Mexico, 23 February–21 March 1975. [Google Scholar]

- Figueiredo, E.O.; Lima, Q.S. Coeficientes Técnicos para o Inventário e Manejo Florestal com Emprego do Modelo Digital de Exploração Florestal (Modeflora); EMBRAPA-ACRE: Rio Branco, Brazil, 2008. [Google Scholar]

- Matthews, D.M. Cost Control in the Logging Industry; McGraw-Hill: New York, NY, USA, 1942; p. 374. [Google Scholar]

- IBM. International Business Machine ILOG CPLEX Optimization; IBM: Armonk, NY, USA, 2015. [Google Scholar]

| Subarea | OF (km) | ||||

|---|---|---|---|---|---|

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | CVFO (%) | |

| 1 | 18.26 | 18.02 | 18.26 | 23.18 | 12.88 |

| 2 | 1.23 | 1.23 | 1.23 | 1.23 | 0.00 |

| 3 | 58.99 | 66.35 | 58.99 | 60.17 | 5.77 |

| 4 | 14.04 | 16.43 | 14.04 | 16.43 | 9.05 |

| 5 | 5.04 | 5.04 | 5.04 | 5.04 | 0.00 |

| 6 | 36.57 | 36.32 | 36.57 | 36.32 | 0.40 |

| 7 | 17.49 | 26.46 | 17.49 | 21.76 | 20.56 |

| 8 | 31.88 | 37.29 | 37.87 | 37.29 | 7.80 |

| 9 | 3.09 | 2.63 | 2.63 | 2.63 | 8.50 |

| 10 | 23.77 | 37.29 | 23.77 | 48.53 | 35.90 |

| 11 | 40.07 | 52.26 | 40.07 | 37.85 | 15.38 |

| Parameters | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 |

|---|---|---|---|---|---|

| TD (km) | 250.43 | 299.32 | 255.96 | 290.43 | 301.01 |

| AMD (m) | 310.10 | 383.90 | 314.37 | 368.33 | 393.16 |

| AD (m) | 163.30 | 190.80 | 165.61 | 184.82 | 195.23 |

| CVvp (%) | 36.62 | 34.11 | 40.27 | 38.58 | 39.50 |

| Scenario | D ≤ 258 m | 258 m < D ≤ 300 m | D > 300 m |

|---|---|---|---|

| 1 | 86.2% | 8.8% | 5.0% |

| 2 | 77.0% | 11.0% | 12.0% |

| 3 | 86.0% | 9.0% | 5.0% |

| 4 | 80.0% | 9.0% | 11.0% |

| 5 | 72.0% | 13.0% | 15.0% |

| Scenario | TAP (n) | TFR (km) | TSF (km) |

|---|---|---|---|

| 1 | 33 | 14.19 | 75.99 |

| 2 | 23 | 11.25 | 79.21 |

| 3 | 32 | 13.75 | 77.24 |

| 4 | 27 | 12.51 | 80.23 |

| 5 | 27 | 13.80 | 92.50 |

| Scenario | TIP | TIFR | TIS | Total | ||||

|---|---|---|---|---|---|---|---|---|

| ha | % * | ha | % * | ha | % * | ha | % * | |

| 1 | 1.65 | 0.26 | 7.08 | 1.11 | 30.39 | 4.76 | 39.12 | 6.13 |

| 2 | 1.15 | 0.18 | 5.64 | 0.88 | 31.58 | 4.95 | 38.37 | 6.01 |

| 3 | 1.60 | 0.25 | 6.89 | 1.08 | 30.86 | 4.83 | 39.35 | 6.16 |

| 4 | 1.35 | 0.21 | 6.25 | 0.98 | 32.02 | 5.02 | 39.62 | 6.21 |

| 5 | 1.35 | 0.21 | 6.88 | 1.07 | 36.34 | 5.69 | 44.57 | 6.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira da Silva, E.; Da Silva, G.F.; Orfanó Figueiredo, E.; Breda Binoti, D.H.; Ribeiro de Mendonça, A.; Moreira Miquelino Eleto Torres, C.; Macedo Pezzopane, J.E. Allocation of Storage Yards in Management Plans in the Amazon by Means of Mathematical Programming. Forests 2018, 9, 127. https://doi.org/10.3390/f9030127

Ferreira da Silva E, Da Silva GF, Orfanó Figueiredo E, Breda Binoti DH, Ribeiro de Mendonça A, Moreira Miquelino Eleto Torres C, Macedo Pezzopane JE. Allocation of Storage Yards in Management Plans in the Amazon by Means of Mathematical Programming. Forests. 2018; 9(3):127. https://doi.org/10.3390/f9030127

Chicago/Turabian StyleFerreira da Silva, Evandro, Gilson Fernandes Da Silva, Evandro Orfanó Figueiredo, Daniel Henrique Breda Binoti, Adriano Ribeiro de Mendonça, Carlos Moreira Miquelino Eleto Torres, and José Eduardo Macedo Pezzopane. 2018. "Allocation of Storage Yards in Management Plans in the Amazon by Means of Mathematical Programming" Forests 9, no. 3: 127. https://doi.org/10.3390/f9030127