Evaluation of Hydraulic Retention Time on Treatment of Coffee Processing Wastewater (CPWW) in EGSB Bioreactor

Abstract

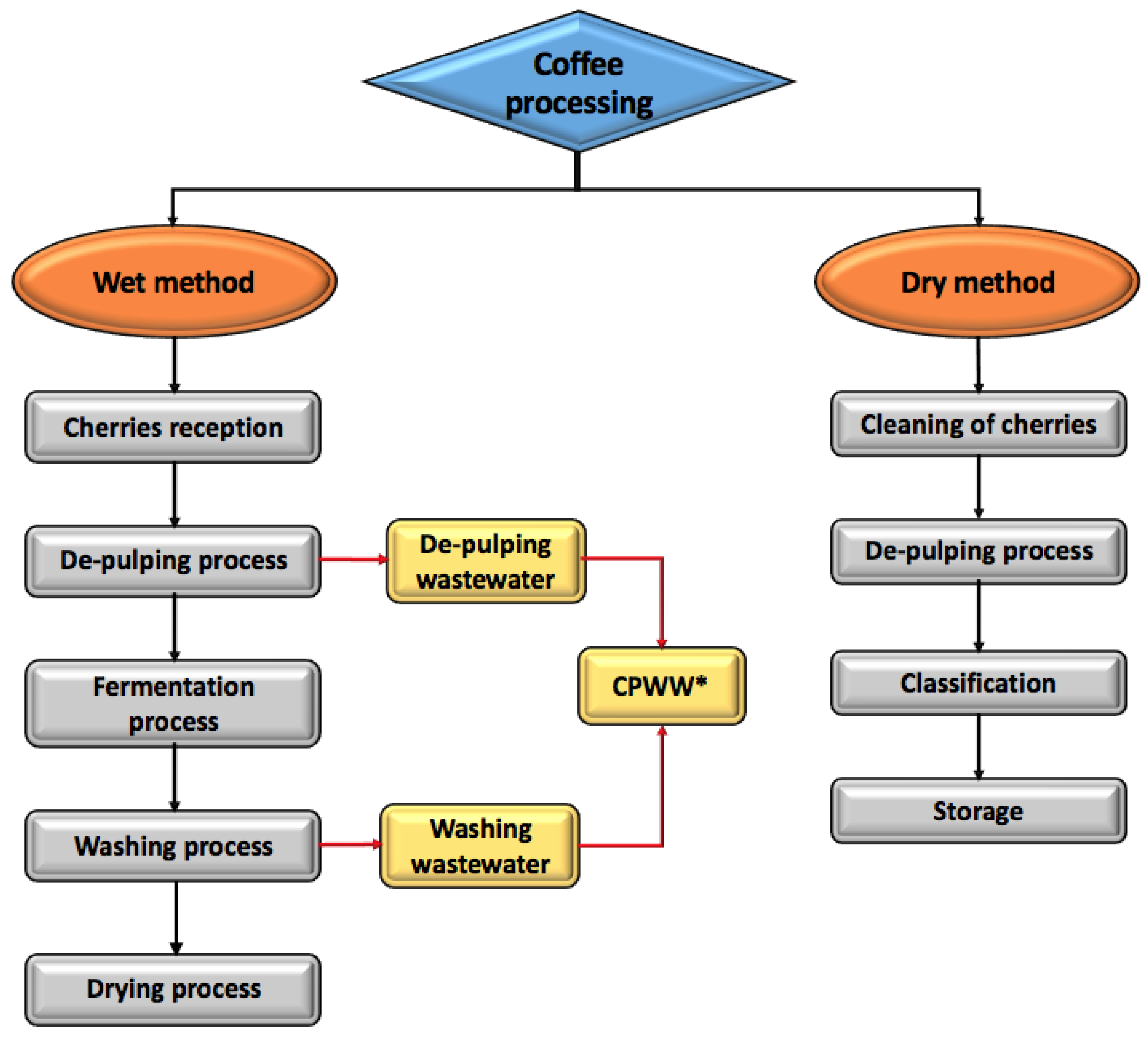

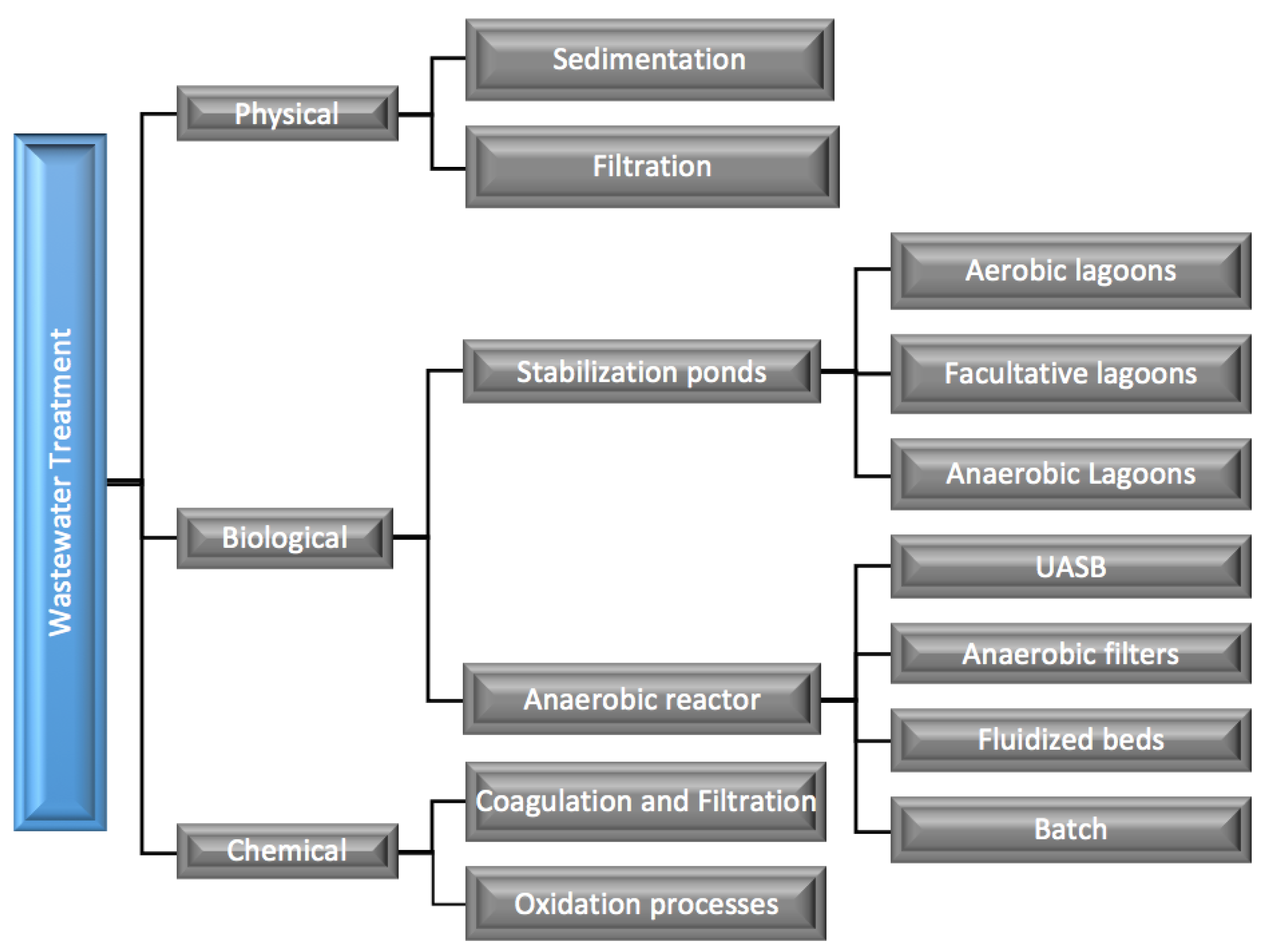

:1. Introduction

2. Materials and Methods

2.1. CPWW Characterization

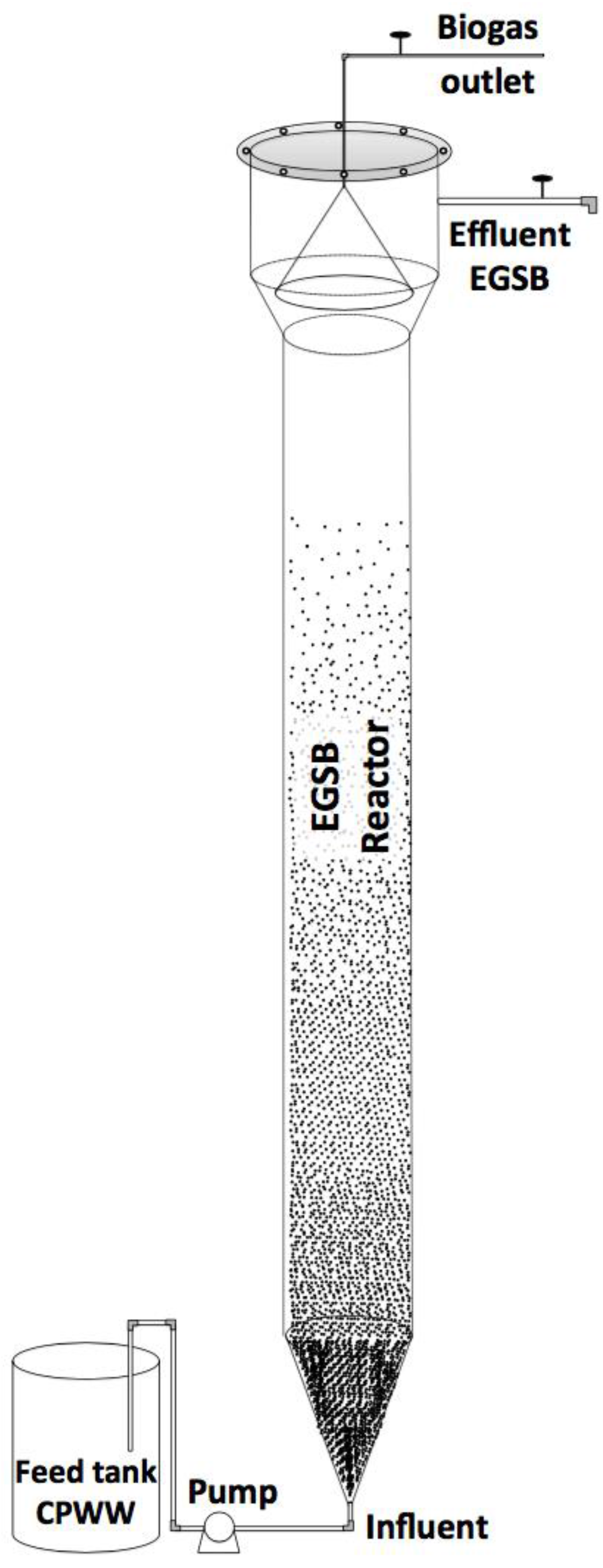

2.2. Bioreactor Set up and Operation

2.3. Effluent Analyses

3. Results and Discussion

3.1. CPWW Physicochemical Characterization

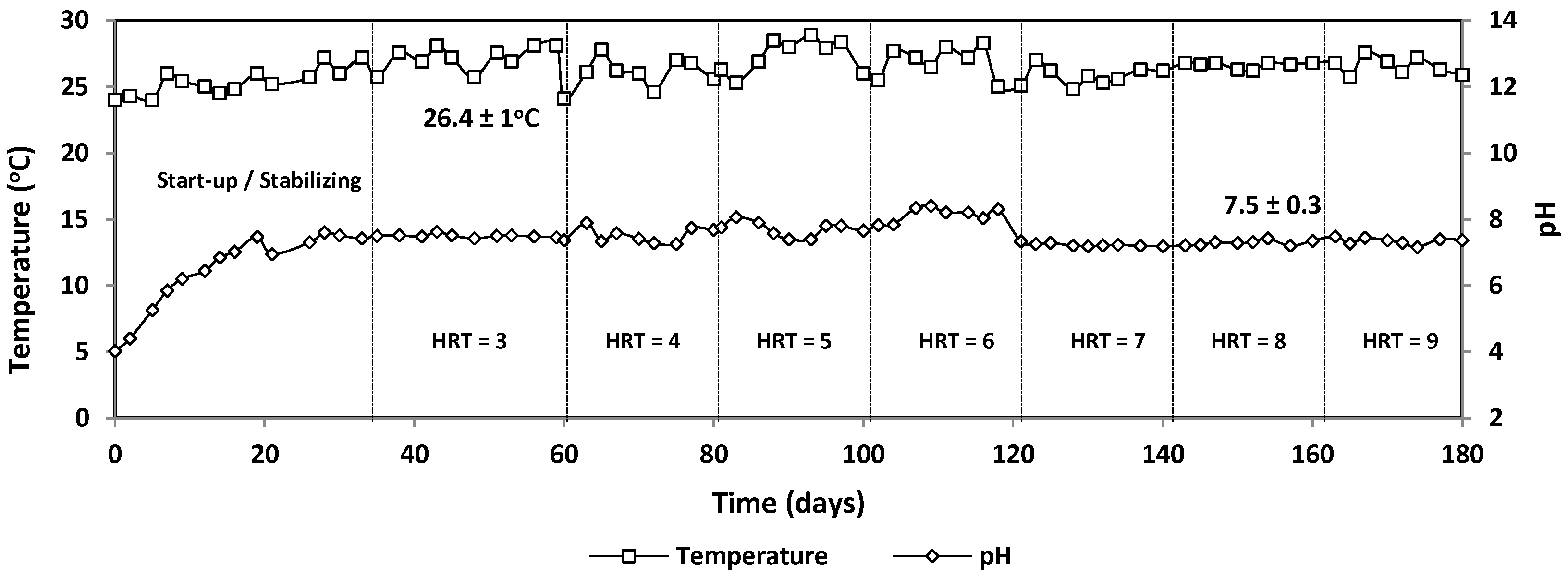

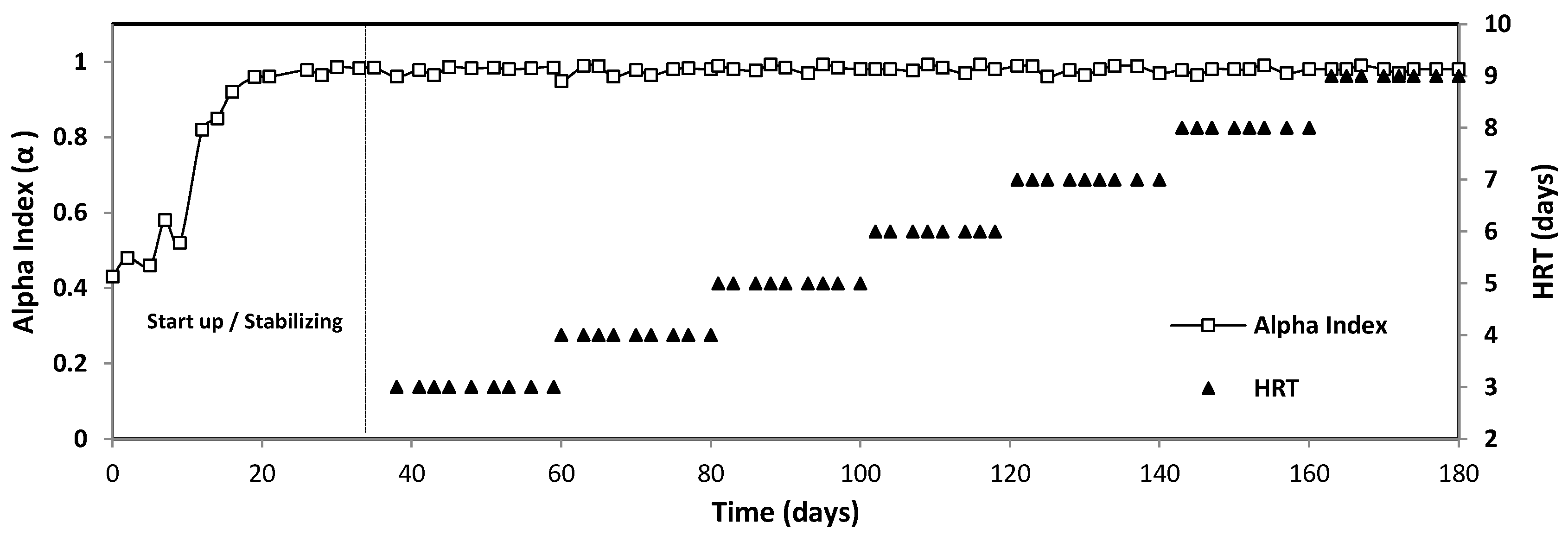

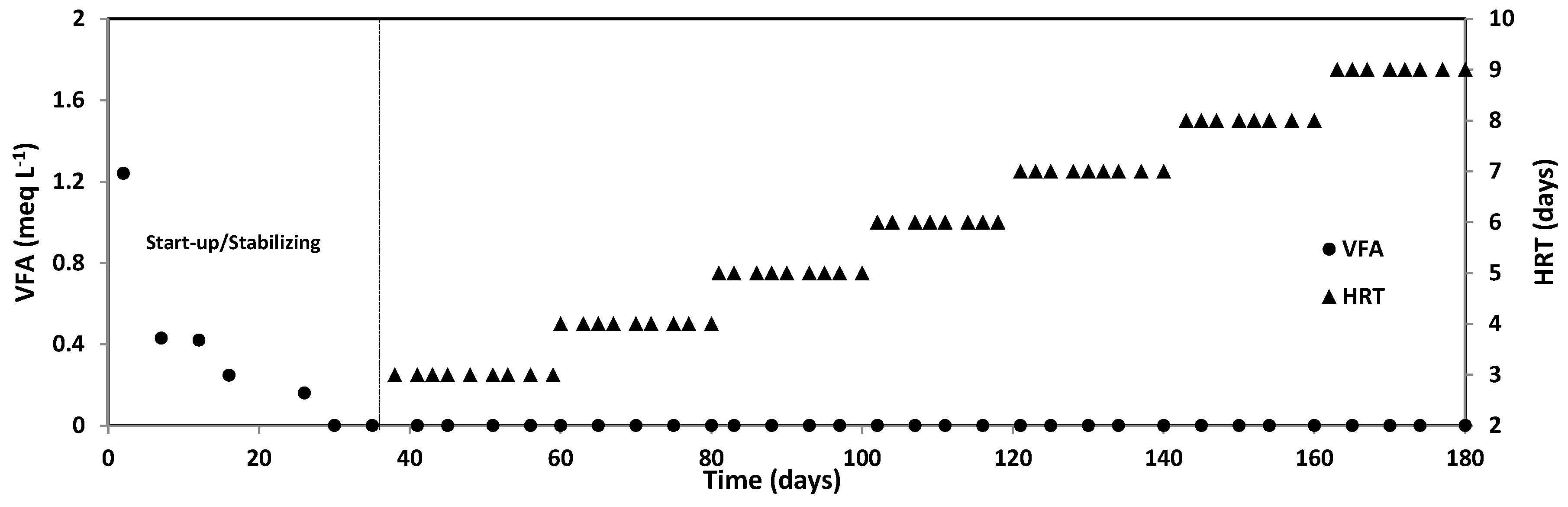

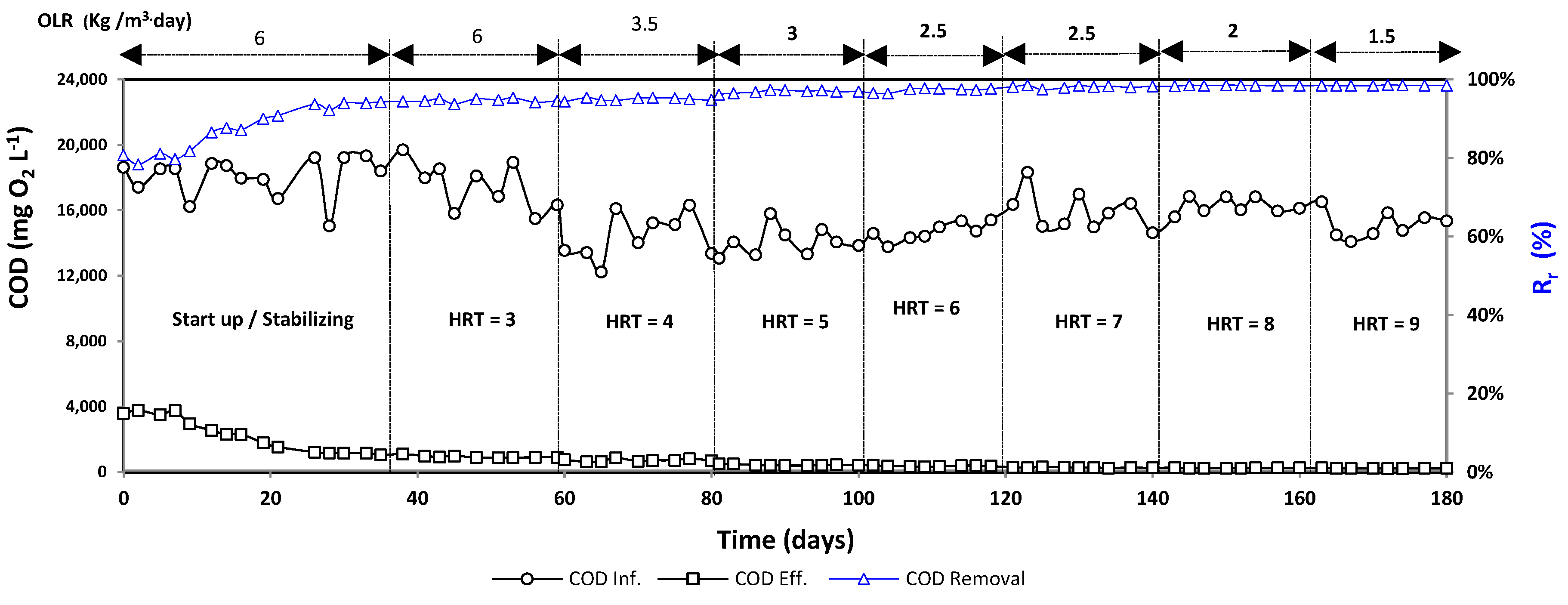

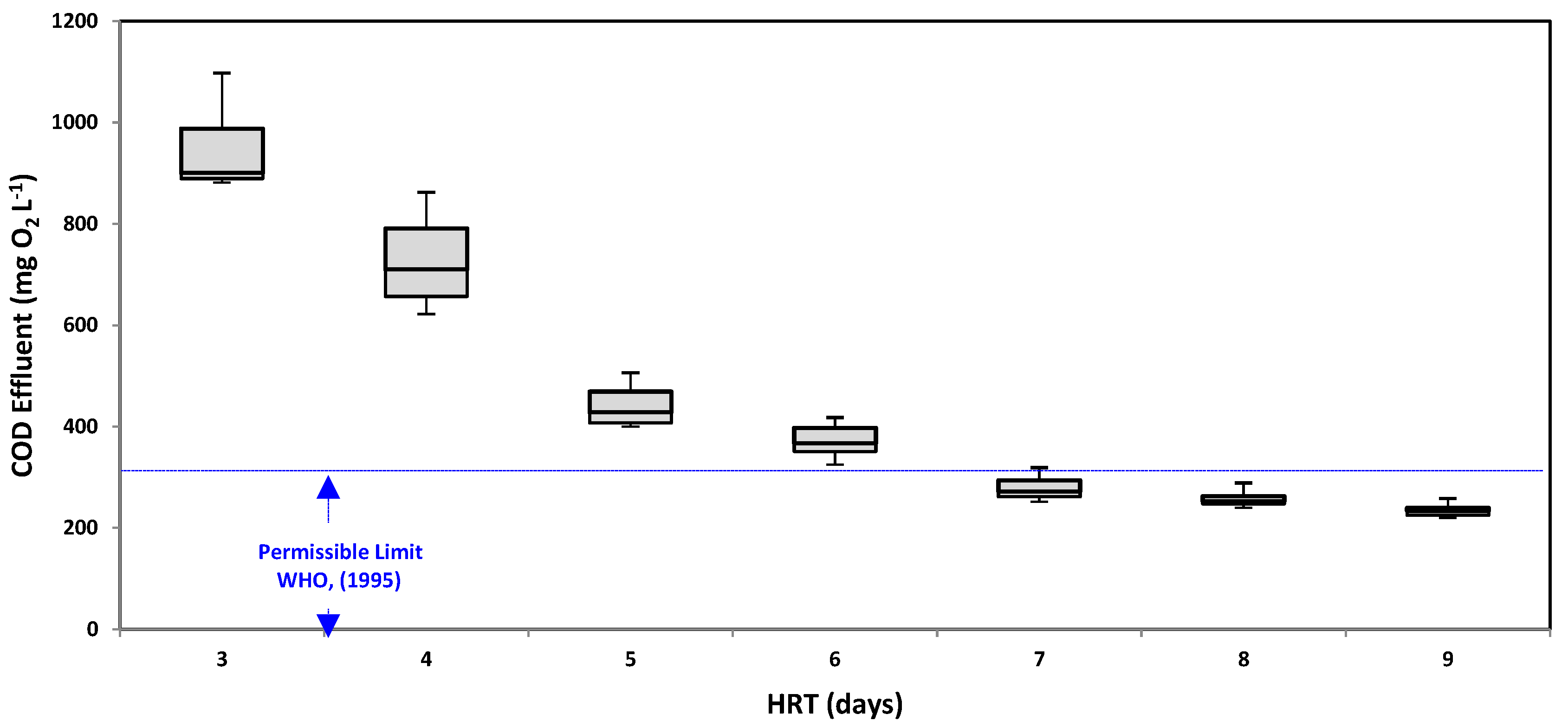

3.2. Reactor Operation Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United States Department of Agriculture, Foreign Agricultural Service (USDA, FAS). Mexico Coffee Annual. Available online: https://gain.fas.usda.gov/Recent%20GAIN%20Publications/Coffee%20Annual_Mexico%20City_Mexico_5-18-2015.pdf (accessed on 7 February 2017).

- Producción Agrícola. Available online: https://www.gob.mx/siap/acciones-y-programas/produccion-agricola-33119 (accessed on 7 February 2017).

- Murthy, N.K.V.; Chandru, B.T.; Antonette, D.S. Report on IEI’s Rural Electricity and Water Supply Utility (REWSU) Project with Special Reference to the Utility at Mavinakere; International Energy Initiative: Bangalore, India, 2003; Available online: http://www.iei-asia.org/ieiblr-rewsureport.pdf (accessed on 7 February 2017).

- Devi, R.; Singh, V.; Kumar, A. COD and BOD reduction from coffee processing wastewater using Avacado peel carbón. Bioresour. Technol. 2008, 99, 1853–1860. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, S.; Pérez, R.M.; Fernández, M. Estudio de la biodegradabilidad anaerobia de las aguas residuales del beneficio húmedo del café. Interciencia 2000, 25, 386–390. [Google Scholar]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Meza-Gordillo, R.; Lagunas-Rivera, S.; Ruíz-Valdiviezo, V.M. Anaerobic treatment of agro-industrial wastewater for COD removal in expanded granular sludge bed bioreactor. Biofuel Res. J. 2017, 16, 715–720. [Google Scholar] [CrossRef]

- Siu, Y.; Mejia, G.; Mejia-Saavedra, J.; Pohlan, J.; Sokolov, M. Heavy metals in wet method coffee processing wastewater in Soconusco, Chiapas, Mexico. Bull. Environ. Contam. Toxicol. 2007, 78, 400–404. [Google Scholar] [CrossRef] [PubMed]

- Rossmann, M.; Teixeira de Matos, A.; Carneiro Abreu, E.; Fonseca e Silva, F.; Carraro Borges, A. Performance of constructed wetlands in the treatment of aerated coffee processing wastewater: Removal of nutrients and phenolic compounds. Ecol. Eng. 2012, 49, 264–269. [Google Scholar] [CrossRef]

- Bello-Mendoza, R.; Castillo-Rivera, M.F. Start-up of an anaerobic hybrid UASB filter reactor treating wastewater from a coffee processing plant. J. Anaerobe Environ. Microbiol. 1998, 4, 219–225. [Google Scholar] [CrossRef] [PubMed]

- Calvert, K.C. The treatment of Coffee Wastewater, The Biogas Option—A Review and Preliminary Report of Ongoing Research; Coffee Research Report (50); Coffee Industry Corporation Ltd.: Kainantu, Papua New Guinea, 1997. [Google Scholar]

- Von Enden, J.C. Best Practices at Wet Processing Pay Financial Benefits to Farmers and Processors. Available online: http://venden.de/pdfs/Wet_Processing_V2.pdf (accessed on 9 February 2017).

- Yemane, D.T.; Beyene, A.H.; Addis, T.W.; Gebresilassie, A.T. Effect of Coffee Processing Plant Effluent on the Physicochemical Properties of Receiving Water Bodies, Jimma Zone Ethiopia. Am. J. Environ. Prot. 2015, 4, 83–90. [Google Scholar] [CrossRef]

- Deepa, G.B.; Chanakya, H.N.; de Alwis, A.A.P.; Manjunath, G.R.; Devi, V. Overcoming pollution of lakes and water bodies due to coffee pulping activities with appropriate technology solutions. In Proceedings of the Symposium on Conservation, Restoration and Management of Aquatic Ecosystems, Bangalore, India, 9–13 December 2002. [Google Scholar]

- Enden, J.C.; Calvert, K.C. Limit Environmental Damage by Basic Knowledge of Coffee Waste Waters. Available online: http://www.venden.de/pdfs/Coffee_Waste_Water_tretamentV4.pdf (accessed on 9 February 2017).

- Selvamurugan, M.; Doraisamy, P.; Maheswari, M.; Nandakumar, N.B. High rate anaerobic treatment of coffee processing wastewater using upflow anaerobic hybrid reactor. Iran. J. Environ. Health Sci. Eng. 2010, 7, 129–136. [Google Scholar]

- Haddis, A.; Devi, R. Effect of effluent generated from coffee processing plant on the water bodies and human health in its vicinity. J. Hazard. Mater. 2008, 152, 259–262. [Google Scholar] [CrossRef] [PubMed]

- Elliott, M.; de Jonge, V.N. The management of nutrients and potential eutrophication in estuaries and other restricted water bodies. Hydrobiologia 2002, 475, 513–524. [Google Scholar] [CrossRef]

- Nadais, H.; Capela, I.; Arroja, L.; Duarte, A. Effect of organic, hydraulic and fat shocks on the performance of UASB reactor with intermittent operation. Water Sci. Technol. 2001, 44, 49–56. [Google Scholar] [PubMed]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Walkley, A.; Black, I. An examination of the Degtjareff method for determining organic carbon in soils: Effect of variations in digestion conditions and of inorganic soil constituents. Soil Sci. 2006, 63, 251–263. [Google Scholar] [CrossRef]

- Jenkins, S.R.; Morgan, J.M.; Sawyer, C.L. Measuring anaerobic sludge digestion and growth by simple alkalimetric titration. J. Water Pollut. Control Fed. 1983, 55, 448–453. [Google Scholar]

- Iñiguez-Covarrubias, G.; Camacho-López, A. Evaluation of an Upflow Anaerobic Sludge Blanket Reactor (UASB) with Changes in the Upflow Velocity. Ing. Investig. Technol. 2011, 12, 199–208. [Google Scholar]

- Hue, N.V.; Bittenbender, H.C.; Ortiz-Escober, M.E. Managing coffee processing water in Hawaii. J. Hawaii. Pac. Agric. 2006, 13, 15–21. [Google Scholar]

- Shanmukhappa, D.R.; Ananda Alwar, R.P.; Srinivasan, C.S. Water pollution by coffee processing units and its abatement. Indian Coffee 1998, 10, 3–9. [Google Scholar]

- WHO. Guideline for Discharge of Industrial Effluent Characteristics; WHO: Geneva, Switzerland, 1995; Volume 3, pp. 231–236. [Google Scholar]

- Maximum Permissible Limits of Pollutants in Wastewater Discharges into National Waters and Goods. NOM-001-ECOL. 1996. Available online: http://dof.gob.mx/nota_detalle.php?codigo=4863829&fecha=06/01/1997 (accessed on 30 December 2017).

- Padmapriya, R.; Tharian, J.A.; Thirunalasundari, T. Treatment of coffee effluent by Moringa oleifera seed. Int. J. Curr. Microbiol. App. Sci. 2015, 4, 288–295. [Google Scholar]

- Cruz-Salomón, A.; Meza-Gordillo, R.; Rosales-Quintero, A.; Ventura-Canseco, C.; Lagunas-Rivera, S.; Carrasco-Cervantes, J. Biogas production from a native beverage vinasse using a modified UASB biorreactor. Fuel 2017, 198, 170–174. [Google Scholar] [CrossRef]

- Rittmann, B.E.; McCarty, P.L. Environmental Biotechnology: Principles and Applications; McGraw-Hill International: New York, NY, USA, 2007. [Google Scholar]

- Chernicharo, C.A.L. Anaerobic Reactors, Biological Wastewater Treatment Series; IWA Publication: London, UK, 2007; Volume 4. [Google Scholar]

- Buzzini, A.P.; Pires, E.C. Evaluation of an Upflow Anaerobic Sludge Blanket Reactor with Partial Recirculation of Effluent Used to Treat Wastewaters from Pulp and Paper Plants. Bioresour. Technol. 2007, 98, 1838–1848. [Google Scholar] [CrossRef] [PubMed]

- Somasiri, W.; Xiu-Fen, L.; Wen-Quan, R.; Jian, C. Evaluation of the efficacy of upflow anaerobic sludge blanket reactor in removal of colour and reduction of COD in real textile wastewater. Bioresour. Technol. 2008, 99, 3692–3699. [Google Scholar] [CrossRef] [PubMed]

- Anderson, K.; Sallis, P.J.; Uyanik, S. Anaerobic treatment processes. In Handbook of Water and Wastewater Microbiology; Mara, D., Horan, N., Eds.; Academic Press: London, UK, 2003; Chapter 24; pp. 391–426. [Google Scholar]

| Parameter | Values | Permissible Limits | |

|---|---|---|---|

| WHO | NOM-001-ECOL-1996 * | ||

| pH | 3.95 | 6.5–8.5 | 5–10 |

| Color (Pt-Co) | 17,966.7 | - | - |

| Turbidity (NTU) | 1481.7 | 5 | - |

| Density (g mL−1) | 1.1075 | - | - |

| Alkalinity (mg CaCO3 L−1) | ND | - | - |

| Acidity (mg CaCO3 L−1) | 3360 | - | - |

| COD (mgO2 L−1) | 45,955 | 300 | - |

| BOD5 (mgO2 L−1) | 37,944 | 100 | 150 |

| BOD5/COD ratio | 0.82 | - | - |

| Sedimented solids (mL L−1) | 380 | - | 2 |

| TS (mg L−1) | 19,593 | 650 | - |

| TSS (mg L−1) | - | 200 | 125 |

| TVS (mg L−1) | 8208 | - | - |

| TOC (mg L−1) | 11,400 | - | - |

| Phosphorus (mg L−1) | 36.43 | - | 30 |

| Phosphate (mg L−1) | - | 5 | - |

| Nitrogen (mg L−1) | 700 | - | 60 |

| Nitrate (mg L−1) | - | 5 | - |

| Total sulfate (mg L−1) | 10 | 250 | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Meza-Gordillo, R.; Ruíz-Valdiviezo, V.M. Evaluation of Hydraulic Retention Time on Treatment of Coffee Processing Wastewater (CPWW) in EGSB Bioreactor. Sustainability 2018, 10, 83. https://doi.org/10.3390/su10010083

Cruz-Salomón A, Ríos-Valdovinos E, Pola-Albores F, Lagunas-Rivera S, Meza-Gordillo R, Ruíz-Valdiviezo VM. Evaluation of Hydraulic Retention Time on Treatment of Coffee Processing Wastewater (CPWW) in EGSB Bioreactor. Sustainability. 2018; 10(1):83. https://doi.org/10.3390/su10010083

Chicago/Turabian StyleCruz-Salomón, Abumalé, Edna Ríos-Valdovinos, Francisco Pola-Albores, Selene Lagunas-Rivera, Rocío Meza-Gordillo, and Víctor M. Ruíz-Valdiviezo. 2018. "Evaluation of Hydraulic Retention Time on Treatment of Coffee Processing Wastewater (CPWW) in EGSB Bioreactor" Sustainability 10, no. 1: 83. https://doi.org/10.3390/su10010083