3.1. Factors Determining the Production of Granular Fertilizer Using the ORTWED Method

The basic substrates for the production of fertilizer granules were sorghum and maize silage. Due to their lignocellulose structure, they were an excellent “scaffolding” to make organic-mineral granular fertilizer. The cost of acquire maize is very high, which is why sorghum was selected as a granule base. Based on the continuous anaerobic digestion process reflecting the work of the actual agricultural biogas plant, it was found that a mix of substrates was used to produce the granulate fertilizer, which included: sorghum, beet, rye, and grass in the following proportions: 20%:60%:10%:10%. These cosubstrates were stand-out the highest biogas and methane yield and also harvest of plant compared to the other five proposed mixes.

Table 1 presents the basic parameters of substrate mixtures for which biogas yields are shown in

Figure 1. Particularly the content of VS, C/N as well as content of P and K seem to be important for biogas yield. The multiple regression analysis (

Table 2) confirmed the significant impact at the level of

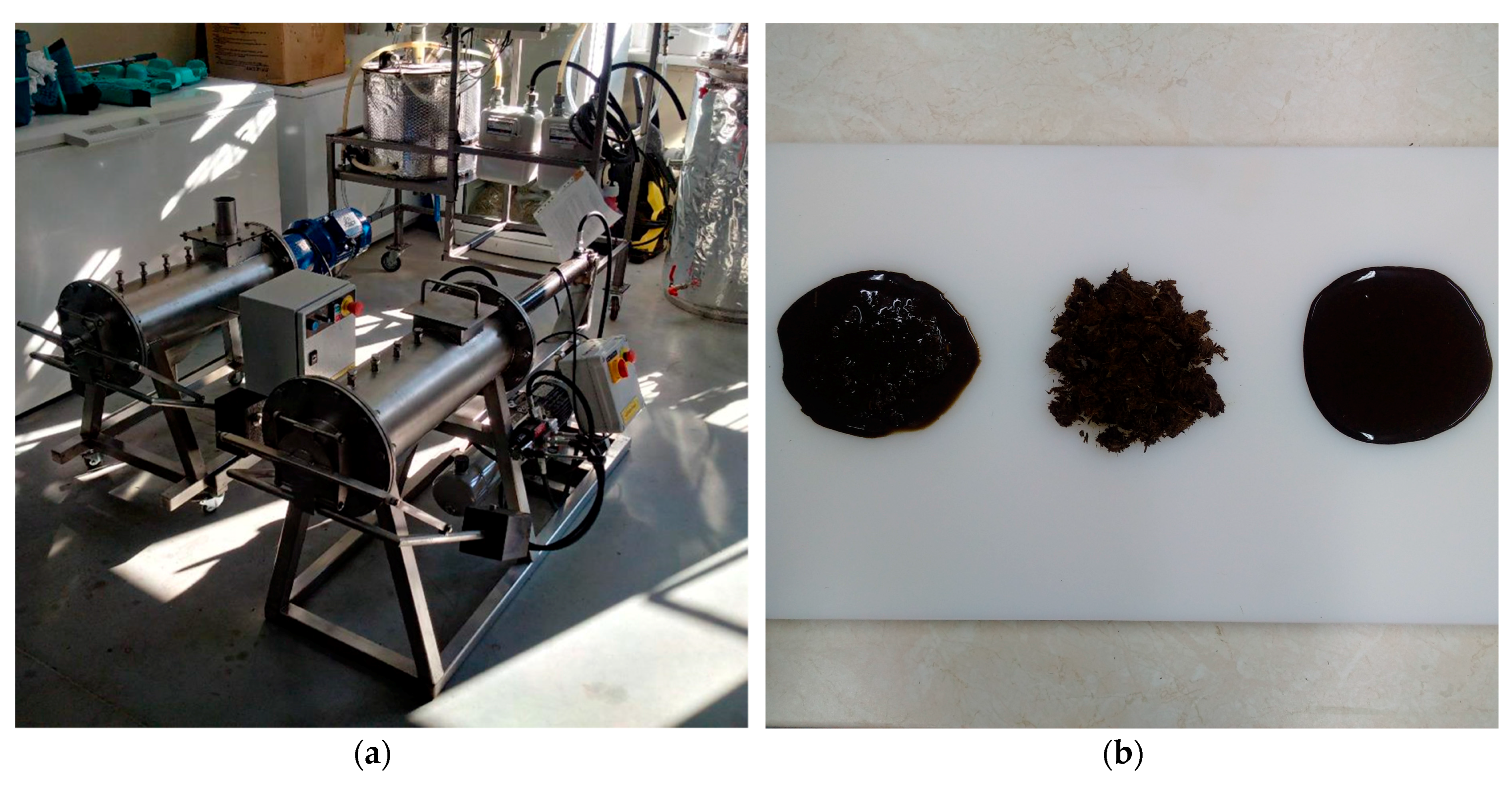

p < 0.0001 vs. content and C/N ratio on the biogas yield. These results explain biogas yields for six substrate mixtures tested. After anaerobic digestion on separator was pressed digestate upon process, obtained solid fraction was used for further research (

Figure 2).

Solid fraction was fragmented to 3 mm and pre-dried to a total solid value of around 24% (

Figure 3).

To describe the kinetics of the anaerobic digestion, the process of tested batches was used the kinetic Equation (1) of the first order Tabasarana model [

21]:

where

Gt is the cumulative volume of biogas obtained by the end of the process, Nm

3/t VS,

G0 kinetic biogas production from the unit of batch Nm

3/t VS,

k—rate constant, 1/day, and

t is duration of anaerobic digestion, day.

Modeling was performed for each trial by iterating the start parameters. In order to check the degree of fit of the model to the results of the experiment, R

2 (Coefficient of determination of matching the model to the data) and RSME (Root Mean Squared Error) were determined, which was estimated based on the Formula (2):

where

ti(p) and

yi(p) are measured and calculated values of the output vector and

n is number of measurement. In addition, for the determined rate constants, based on the dependence (3):

the degradation of half-lives of individual batches was calculated [

22]. The parameters and Tabasarana model coefficients are given in

Table 1.

Statistical analysis of the coefficient of determination R

2 and the root mean squared error RSME showed that the applied model describing the biogas production process is well suited to the experiment data for the analyzed batch (

Table 3). The value of R

2 and RMSE determination coefficients for the selected batch amounted respectively: 0.985 and 20.96. The kinetic biogas production for the selected batch, determined from the first order equation, was the highest among all mix of cosubstrates and reached the value of 593 Nm

3/t VS. (normal cubic meters per ton of volatile solid). The least biogas was formed from a batch consisting of 20% sorghum and topinambour 80%—456 Nm

3/t VS. The modeling of rate constant k was 0.175 and degradation half-lives

T1/2—2.44 day. For individual substrates, the biggest biogas yield was formed from beet silage, and the least from sorghum silage and topinambour silage, respectively: 490 and 414 Nm

3/t VS. The constant rate (

k) values for the cosubstrates were between 0.130 and 0.257. For individual substrates,

k values ranged from 0.124 to 0.223. However, the degradation half-lives and duration of process values for all cosubstrates and individual substrates were very similar. The remaining coefficients for individual substrates were similar to those for the selected batch. Only the RMSE coefficient for beet silage was much higher—40.96 and for sorghum silage, the lowest—11.55. The obtained process kinetics parameters for a batch based on sorghum are favorable. However, those parameters are lower values the an obtained for single substrates: maize silage and beet pulp [

23]. Biogas production described by the Tabasarana model in this case for maize silage and beet pulp was higher and amounted to 677 and 649 Nm

3/t VS. The rate constant of reaction was respectively: 0.173 and 0.318, degradation half-lives—2.449 and 1.840 and the coefficient of determination

—0.990 and 0.994. On the other hand, the values of the RMSE coefficient were lower (18.09 and 12.5).

In addition to the biogas yield, the composition of the biogas production was also studied. After stabilization of the continuous anaerobic digestion process for the selected batch consisting of four substrates, the average methane content was: 54.2%; carbon dioxide: 45.0%. In addition, the content of trace compounds was also measured, the average oxygen in the biogas was: 0.6%; ammonia: 10.5 ppm; hydrogen sulfide: 46.5 ppm. Before the beginning of anaerobic digestion, physicochemical analyzes of four substrates, inoculum and batch were made (

Table 4). These researches were designed to exclude the abnormalities during the anaerobic digestion process. The highest total solid (TS) was characterized by: rye and sorghum, and the smallest: batch and inoculum, respectively: 38.4; 29.4; 6.0 and 5.5%. On the other hand, beet and sorghum had the highest volatile solid (95.7 and 94.9% TS). In this case, also the batch and the inoculum had the lowest parameter (76.2 and 74.2% TS). The pH was alkaline for rye, batch, and inoculum, for the remaining substrates the pH was acidic. The inoculum was characterized by the highest nitrogen content (9.84% TS), while the batch had the largest content of the remaining elements with ammoniacal nitrogen in comparison with other substrates and inoculum.

After the anaerobic digestion process, further physicochemical analyzes of the digestate, solid fraction and effluent resulting from the separation of the digestate were carried out (

Table 5). The granulation technology requires the fragmentation of the solid fraction to 3 mm and drying it so that the total mass was higher than 20%. The total solid and volatile solid content of solid fraction after grinding and drying were respectively: 20.7% and 91.7%. The liquid digestate had slightly higher values of total solid and volatile solid in relation to the effluent. The solid fraction before grinder and after fragmentation differed slightly from each other by individual parameters. The solid fraction after grinder and effluent contained the least nitrogen, phosphorus, and potassium in relation to the other tested forms of digestate. That is why it is necessary to increase the proportion of these elements to obtain the appropriate proportions of elements in the granular fertilizer.

The granule production research was phased. The parameters of granular fertilizer obtained for two sample (

Table 6) were not satisfactory in terms of nutrient elements content and significantly differed from the assumed N:P:K:Mg:S—:2:4:1.4:1.8 ratio.

In the current situation, it was necessary to make further attempts to produce further granulates with a satisfactory composition and effective impact on plants in fertilizing experiments. It has been found that the amount of added calcium during the granulation process cannot be significantly reduced due to a significant process temperature reduction and thus a deterioration in the durability of the granules. It is necessary to increase the amount of added mineral nutrients (mainly nitrogen) during granulation, which is against the original assumptions. Increased addition of mineral nutrients during the granulation process causes also a big problem, as there are large losses mainly of nitrogen. As a result, it causes difficulties in maintaining a stable level of content and composition of N:P:K:Mg:S in granular. Therefore, it is necessary to increase the content of nutrients in the granules so that in 1 ton of granular fertilizer there is a minimum of 50 kg N, 90 kg P and 120 kg K. These values are dictated by the standard requirement of plants for nutrients, however, the maximum nitrogen dose of 170 kg/ha can be achieved in several doses. Finally, it was shown that the only parameter that can control and change the properties of the granular is the mineral content of nutrients. As a source of nitrogen supplementing its possible absence in the solid fraction of digestate, urea (NH2CONH2) was used, in the absence of phosphorus, this element was supplemented with monoammonium phosphate (NH4H2PO4). To supplement the lack of potassium, magnesium, and sulfur in the solid fraction, respectively: potassium hydrogen phosphate (KH2PO4), magnesium nitrate (Mg(NO3)2), sodium thiosulphate (Na2S2O3) were used.

Granular fertilizer was produced with a content of: N 5% TS, P 9% TS, and K 12% TS so in 1 ton of fertilizer there would be 50 kg N, 90 kg P and 120 kg K. This means a significant increase in percentage of N, P, K, Mg, S in the fertilizer granulate, which differs from the original idea of a minimal nutrient addition to the granulate (

Table 7). It was found that at the beginning of the fertilizing experiments plants will receive a starting dose of fertilizer in a mineral form. Organic-mineral granular also were produced which was immediately sown in vase experiments. These granular, according to assumptions, slowly release nutrients into the soil solution (

Figure 4.).