Mapping the Landscape and Evolutions of Green Supply Chain Management

Abstract

:1. Introduction

2. Methods and Materials

3. Landscape Analysis

3.1. Basic Bibliometric Analysis

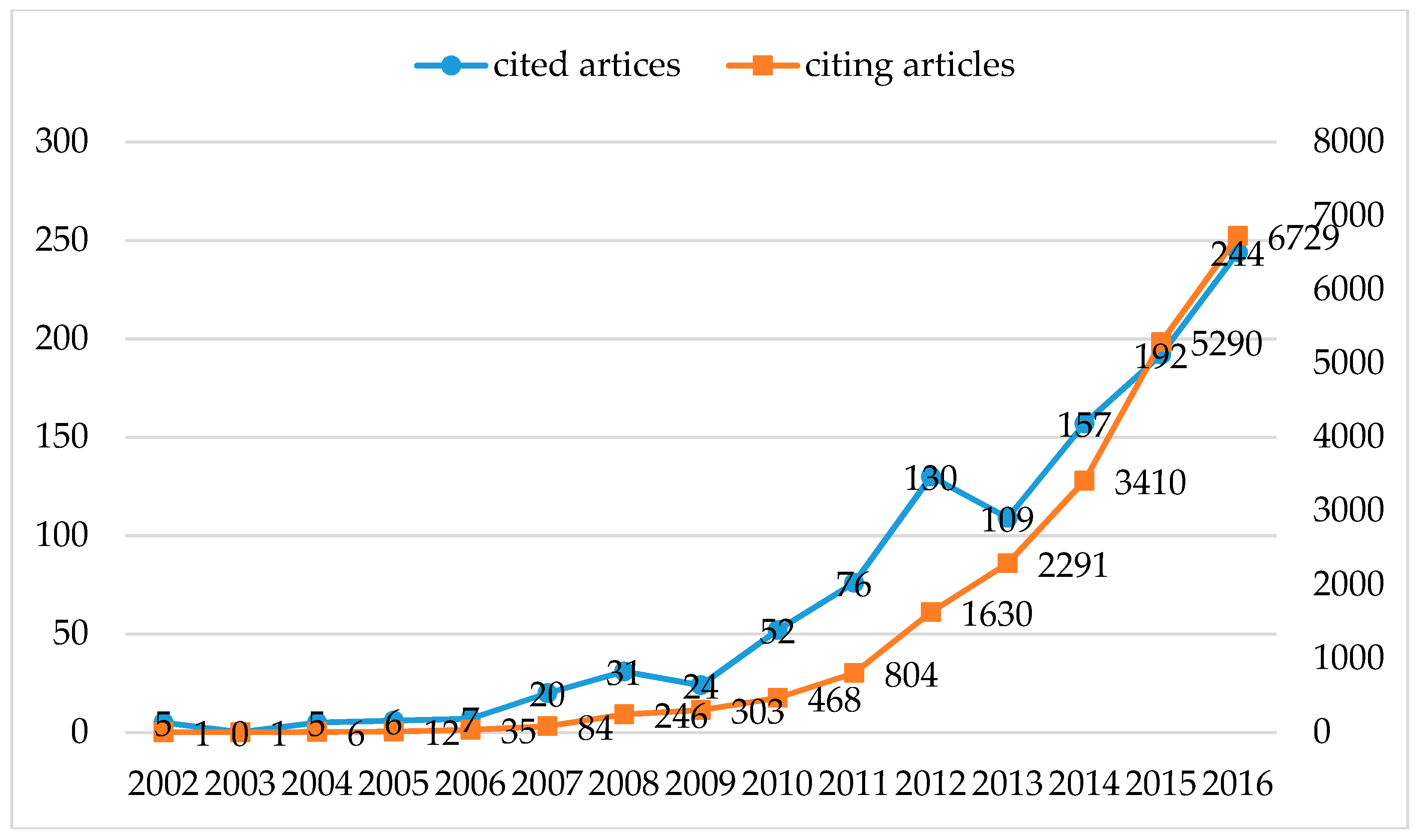

3.1.1. Analysis of Publication Data

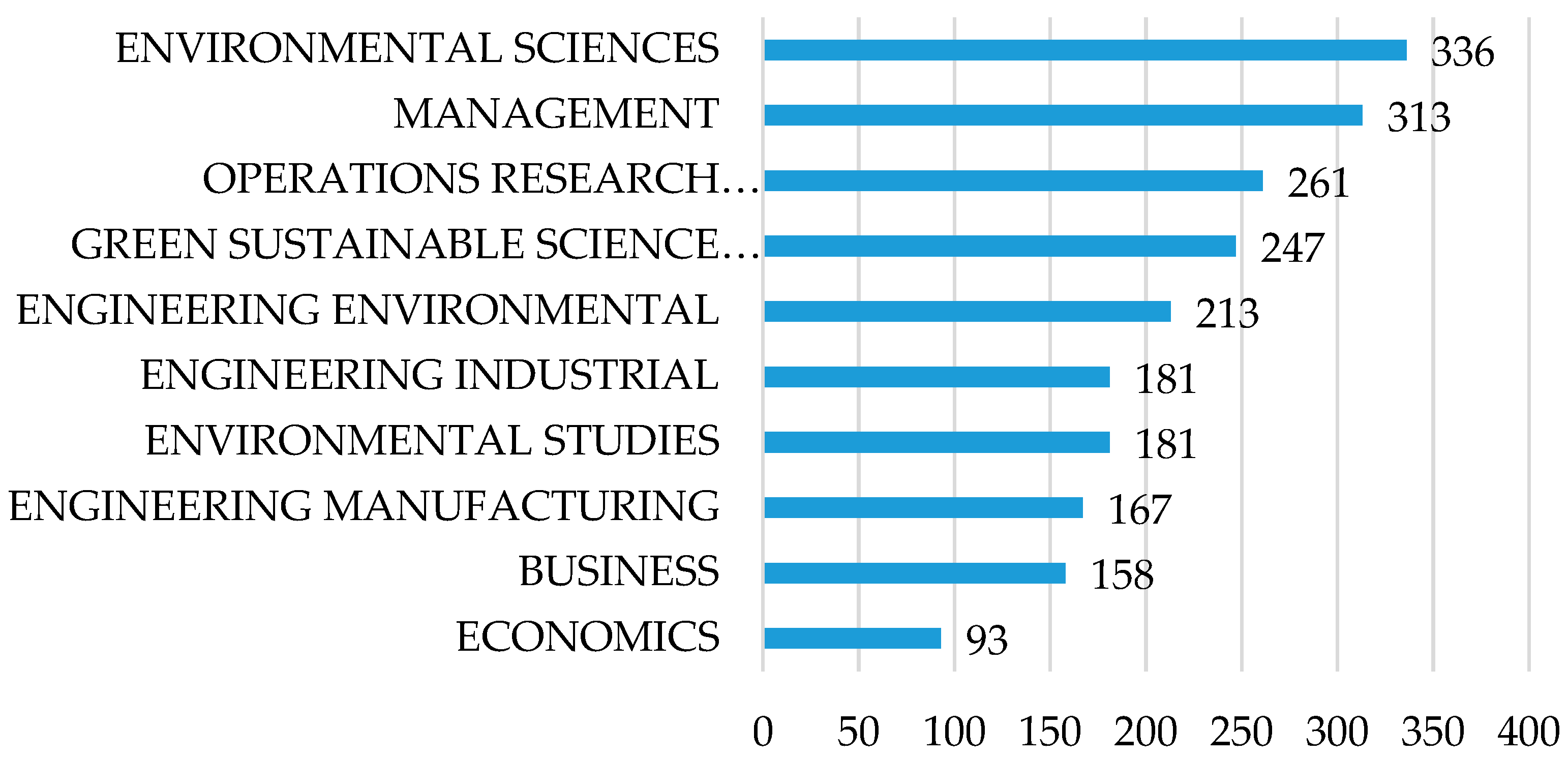

3.1.2. Analysis of Journals and Categories

3.1.3. Analysis of Researchers

3.2. Landscape Analysis

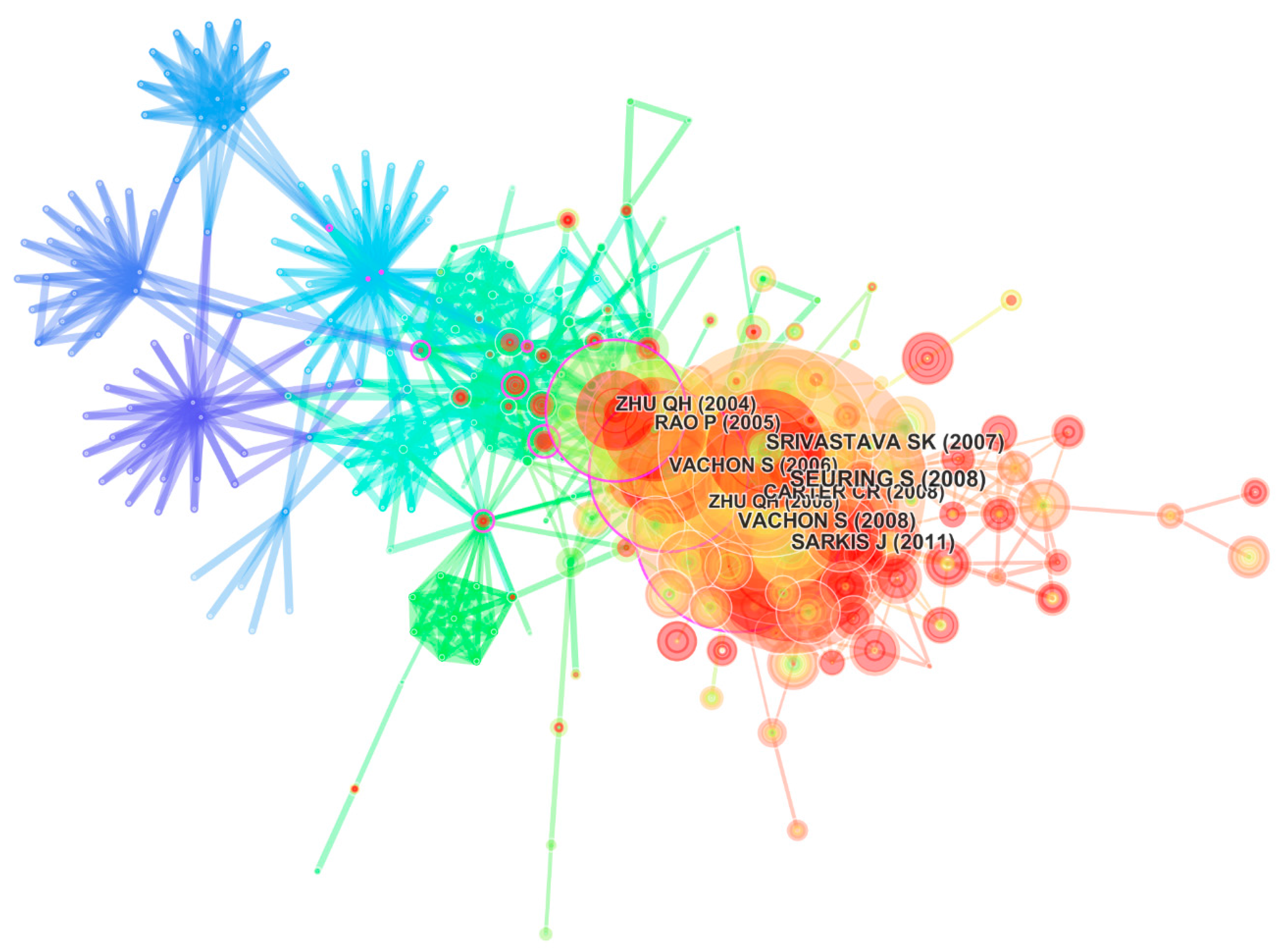

3.2.1. Landscape View

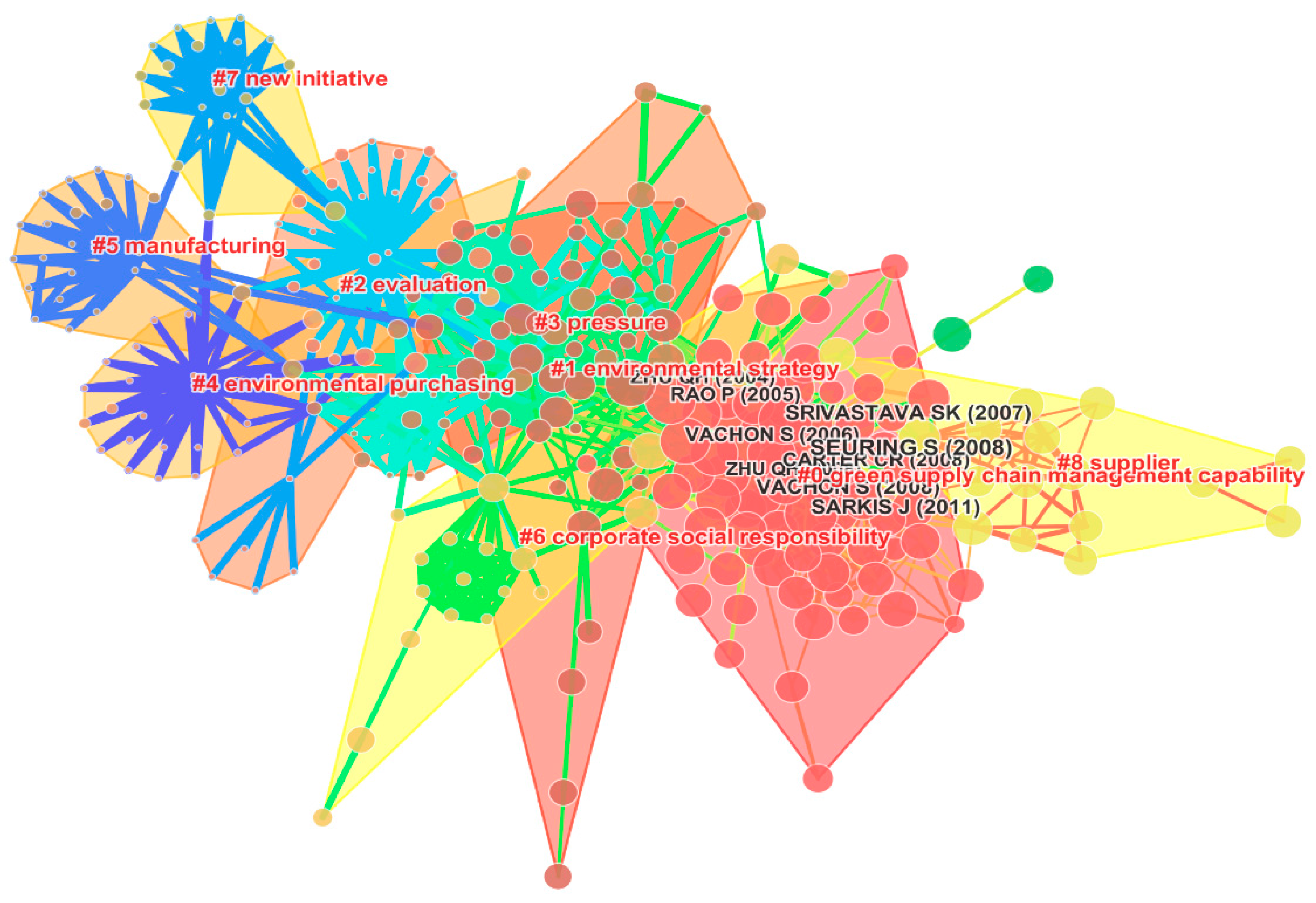

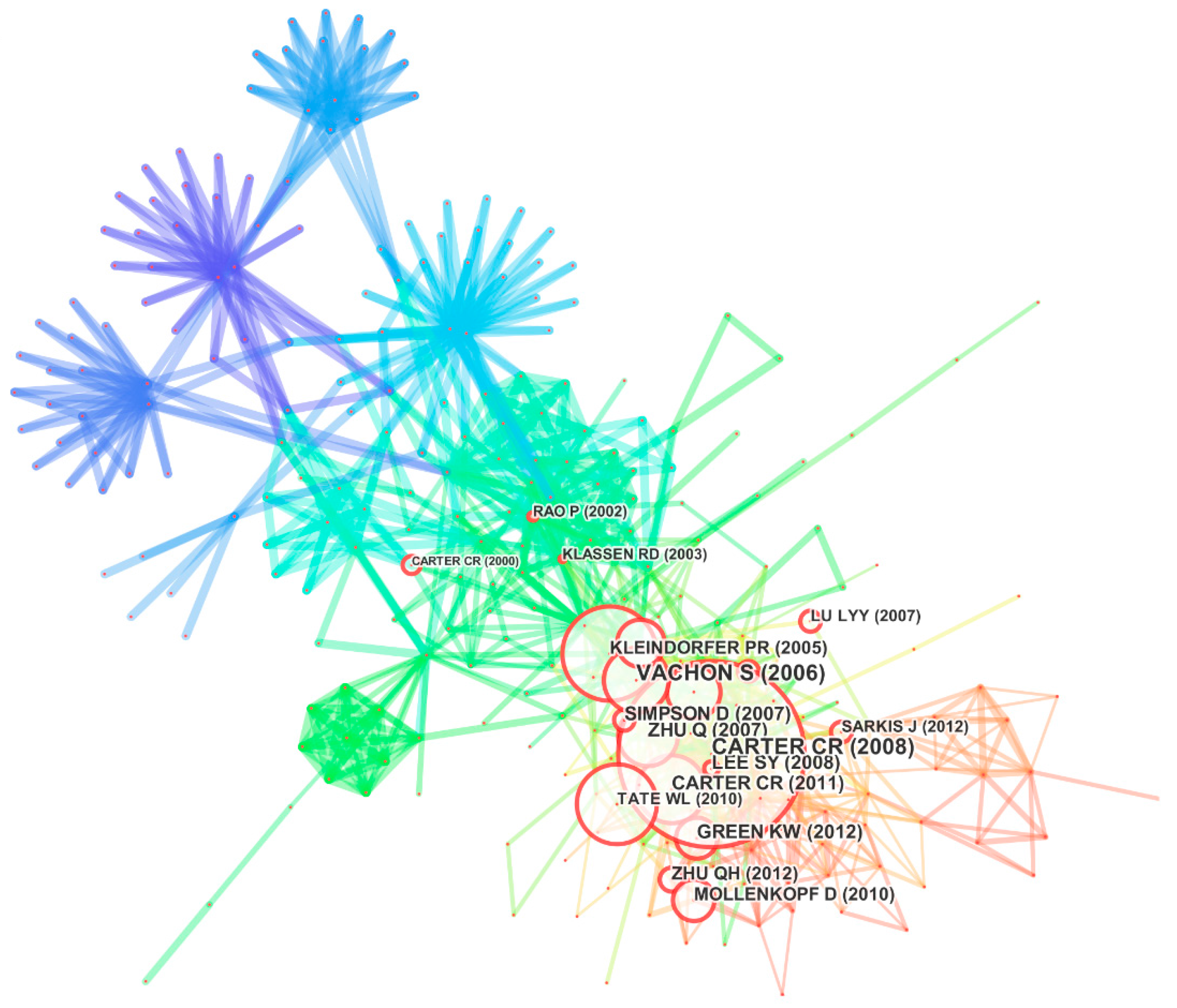

3.2.2. Clustering View

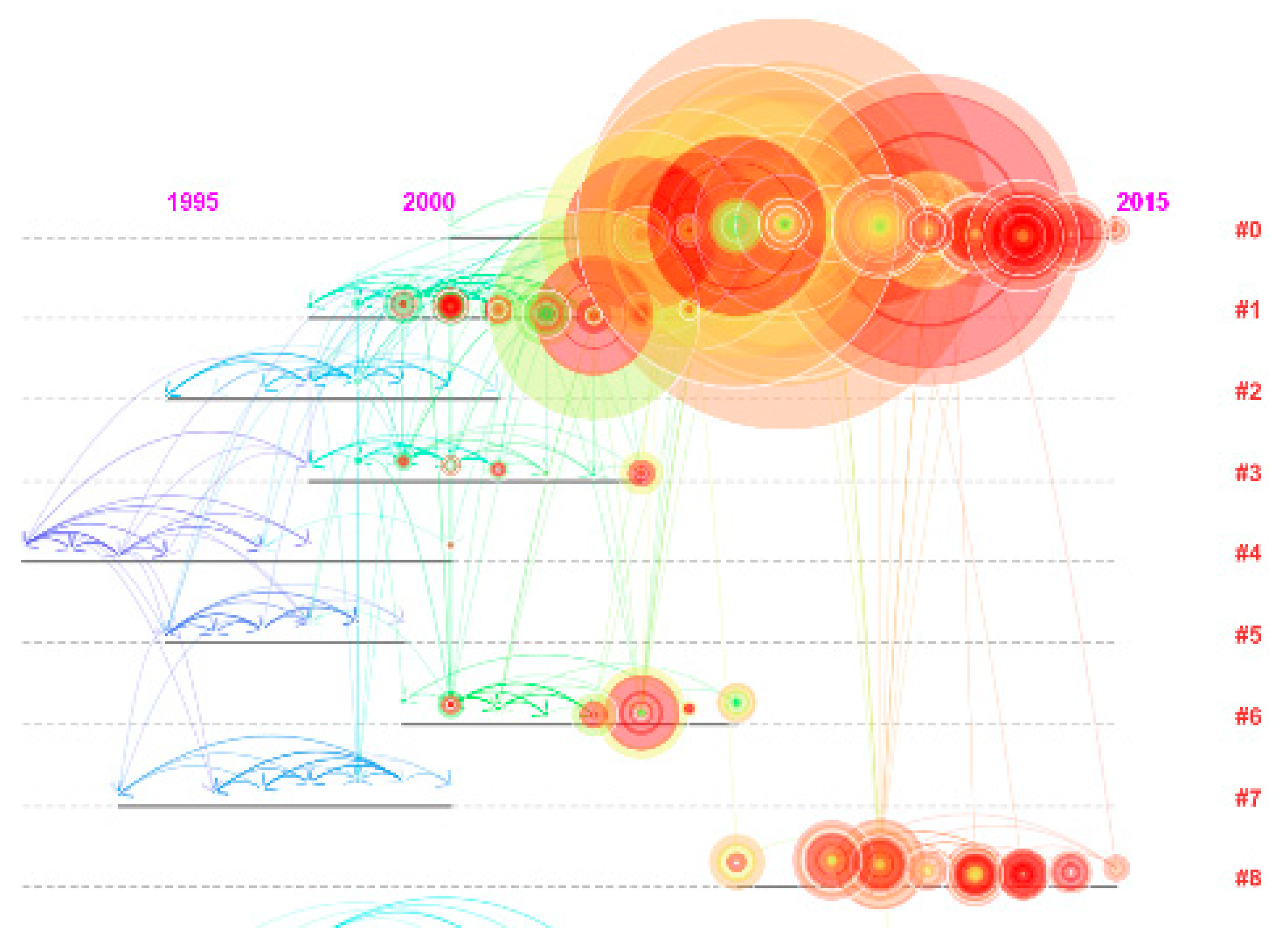

3.2.3. Timeline View

4. Key Issues Analysis

4.1. Citation Frequency

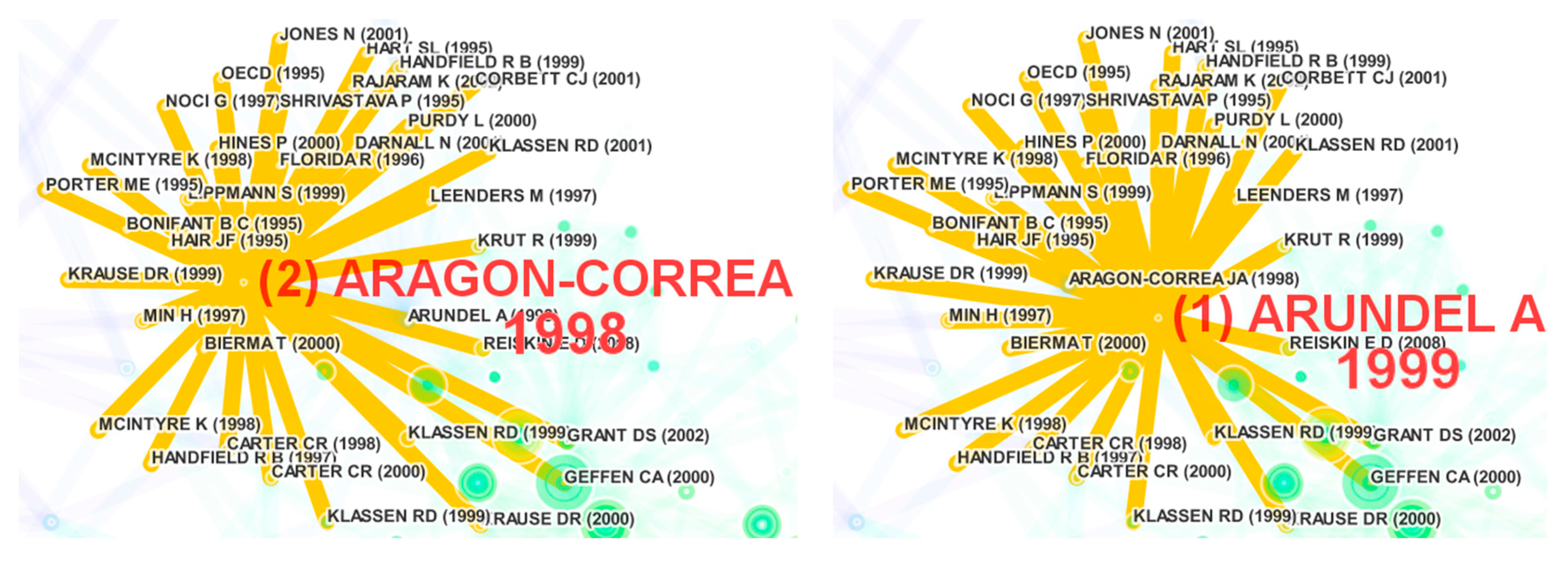

4.2. Betweenness Centrality

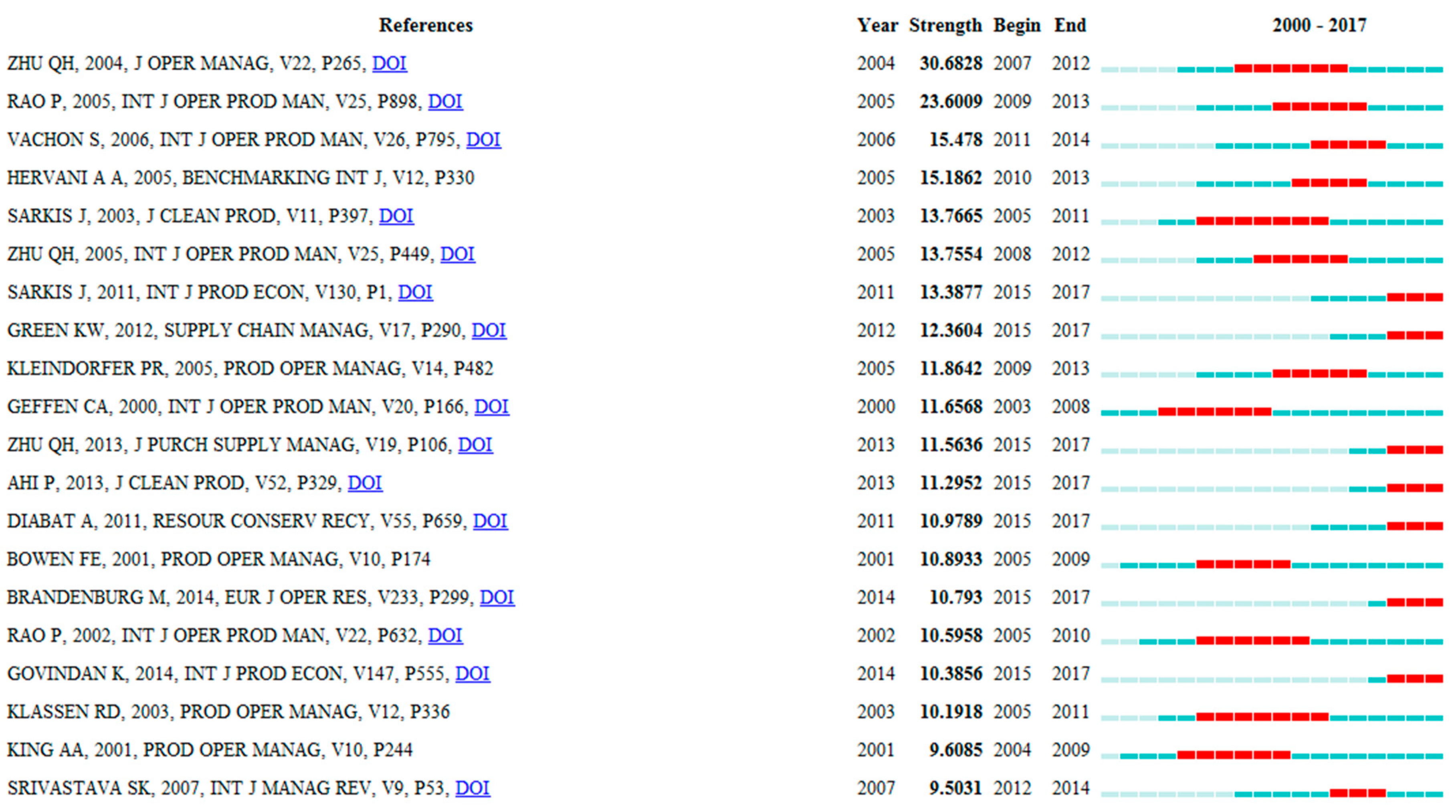

4.3. Burst Detection

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Khan, Z. Cleaner production: An economical option for ISO certification in developing countries. J. Clean. Prod. 2008, 16, 22–27. [Google Scholar] [CrossRef]

- Rutkauskas, A.V. Using Sustainability Engineering to Gain Universal Sustainability Efficiency Using Sustainability Engineering to Gain Universal Sustainability Efficiency. Sustainability 2012, 4, 1135–1153. [Google Scholar] [CrossRef]

- Bras, B.; Isaacs, J.A.; Overcash, M. Environmentally benign manufacturing—A workshop report. J. Clean. Prod. 2006, 14, 527–535. [Google Scholar] [CrossRef]

- Nagel, M.H. Managing the environmental performance of production facilities in the electronics industry: More than application of the concept of cleaner production. J. Clean. Prod. 2003, 11, 11–26. [Google Scholar] [CrossRef]

- Porter, M.E.; Van der Linde, C. Green and competitive. Harv. Bus. Rev. 1995, 73, 120–134. [Google Scholar]

- Porter, M.E.; Van der Linde, C. Toward a new conception of the environment-competitiveness relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the Green Supply Chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Handfield, R.B.; Walton, S.V.; Seegers, L.K.; Melnyk, S.A. Green value chain practices in the furniture industry. J. Oper. Manag. 1997, 15, 293–315. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Handfield, R.B.; Nichols, E.L. Introduction to Supply Chain Management; Prentice-Hall: Upper Saddle River, NJ, USA, 1999; pp. 23–25. ISBN 0136216161. [Google Scholar]

- Sarkis, J. Theory and methodology: Evaluating environmentally conscious business practices. Eur. J. Oper. Res. 1998, 107, 159–174. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Walton, S.V.; Handfield, R.B.; Melnyk, S.A. The green supply chain: Integrating suppliers into environmental management processes. J. Supply Chain Manag. 1998, 34, 2–11. [Google Scholar] [CrossRef]

- Weick, K.E. What Theory is Not, Theorizing Is. Adm. Sci. Q. 1995, 40, 385–390. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD). “Bibliometrics”, the OECD Glossary of Statistical Terms. 2008. Available online: http://stats.oecd.org/glossary/ (accessed on 26 February 2018).

- Nicolaisen, J. Bibliometrics and citation analysis: From the science citation index to Cybermetrics. J. Assoc. Inf. Sci. Tech. 2010, 61, 205–207. [Google Scholar] [CrossRef]

- Coughlin, D.M.; Campbell, M.C.; Jansen, B.J. A web analytics approach for appraising electronic resources in academic libraries. J. Assoc. Inf. Sci. Technol. 2016, 67, 518–534. [Google Scholar] [CrossRef]

- Pilkington, A.; Meredith, J. The evolution of the intellectual structure of operations management, 1980–2006: A citation/co-citation analysis. J. Oper. Manag. 2009, 27, 185–202. [Google Scholar] [CrossRef]

- Henry, S. Co-citation in the scientific literature: A new measure of the relationship between two documents. J. Am. Soc. Inf. Sci. Technol. 1973, 24, 265–269. [Google Scholar] [CrossRef]

- Garfield, E. From Bibliographic Coupling to Co-Citation Analysis via Algorithmic Historio-Bibliography: A Citationist’s Tribute to Belver C. Griffith; Drexel University: Philadelphia, PA, USA, 2001. [Google Scholar]

- Chen, C. Searching for intellectual turning points: Progressive knowledge domain visualization. Proc. Natl. Acad. Sci. USA 2004, 101, 5303–5310. [Google Scholar] [CrossRef] [PubMed]

- Brewerton, P.; Millward, L. Organisational Research Methods; Sage: London, UK, 2001; p. 54. ISBN 9780761971016. [Google Scholar]

- Mayring, P. Qualitative Content Analysis, 8th ed.; Beltz Verlag: Weinheim, Germany, 2003; p. 27. ISBN 978-1-4020-9876-5. [Google Scholar]

- Guan, J.; Ma, N. China’s emerging presence in nanoscience and nanotechnology: A comparative Bibliometric study of several nanoscience ‘giants’. Res. Policy 2007, 36, 880–886. [Google Scholar] [CrossRef]

- De Solla PricePrice, D.J. Little Science, Big Science; Columbia University Press: New York, NY, USA, 1963; ISBN 0231085621. [Google Scholar]

- Tibély, G.; Pollner, P.; Vicsek, T.; Palla, G. Extracting tag-hierarchies. PLoS ONE 2013, 8. [Google Scholar] [CrossRef] [PubMed]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Whitehead, D. Case study research design and methods, 3rd edition. J. Adv. Nurs. 2003, 44, 108. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of green supply chain management practices and their impact on performance: An exploratory study of Indian manufacturing firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Demartini, M.; Orlandi, I.; Tonelli, F.; Anguitta, D. A manufacturing value modeling methodology (MVMM): A value mapping and assessment framework for sustainable manufacturing. In Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; Volume 68, pp. 98–108. [Google Scholar]

- Hoof, B.V.; Thiell, M. Collaboration capacity for sustainable supply chain management: Small and medium-sized enterprises in Mexico. J. Clean. Prod. 2014, 67, 239–248. [Google Scholar] [CrossRef]

- Liu, C.C.; Yu, Y.H.; Wernick, I.K.; Chang, C.Y. Using the Electronic Industry Code of Conduct to Evaluate Green Supply Chain Management: An Empirical Study of Taiwan’s Computer Industry. Sustainability 2015, 7, 2787–2803. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Gavronski, I.; Klassen, R.D.; Vachon, S.; do Nascimento, L.F.M. A resource—Based view of green supply management. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 872–885. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Sharma, A.; Iyer, G.R.; Mehrotra, A.; Krishnan, R. Sustainability and business-to-business marketing: A framework and implications. Ind. Mark. Manag. 2010, 39, 330–341. [Google Scholar] [CrossRef]

- Sarkis, J.; Helms, M.M.; Hervani, A.A. Reverse logistics and social sustainability. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 337–354. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lamming, R.C.; Bowen, F. The role of risk in environment-related supplier initiatives. Int. J. Oper. Prod. Manag. 2004, 24, 554–565. [Google Scholar] [CrossRef]

- Preuss, L. In dirty chains? Purchasing and greener manufacturing. J. Bus. Ethics 2001, 34, 345–359. [Google Scholar] [CrossRef]

- Carter, C.R.; Kale, R.; Mgrimm, C. Environmental purchasing and firm performance: An empirical investigation. Transp. Res. Part E Logist. Transp. Rev. 2000, 36, 219–228. [Google Scholar] [CrossRef]

- Webb, L.L. Green purchasing: Forging a new link in the supply chain. Resource 1994, 1, 14–18. [Google Scholar]

- Min, H.; Galle, W.P. Green purchasing strategies: Trends and implications. J. Supply Chain Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Kumar, V.; Mangal, D. Significance of Green and Sustainable Supply Chain. Int. J. Res. Rev. Eng. Sci. 2016, 5, 56–58. [Google Scholar]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chain management lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2015, 41, 46–62. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J.; Lai, K.H. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Lu, L.Y.Y.; Wu, C.H.; Kuo, T.C. Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. Int. J. Prod. Res. 2007, 45, 4317–4331. [Google Scholar] [CrossRef]

- Tate, W.L.; Ellram, L.M.; Kirchoff, J.F. Corporate social responsibility reports: A thematic analysis related to supply chain management. J. Supply Chain Manag. 2010, 46, 19–44. [Google Scholar] [CrossRef]

- Mollenkopf, D.; Stolze, H.; Tate, W.L. Green, lean, and global supply chains. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 14–41. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Z.; Liu, S.; Tseng, H. Emerging trends in regenerative medicine: A scientometric analysis in CiteSpace. Expert Opin. Biol. Ther. 2012, 12, 593–608. [Google Scholar] [CrossRef] [PubMed]

- Rao, P. Greening the supply chain: A new initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Klassen, R.D.; Vachon, S. Collaboration and evaluation in the supply chain: The impact on plant-level environmental investment. Prod. Oper. Manag. 2003, 12, 336–352. [Google Scholar] [CrossRef]

- Bai, C.G.; Sarkis, J. Green supplier development: Analytical evaluation using rough set theory. J. Clean. Prod. 2010, 18, 1200–1210. [Google Scholar] [CrossRef]

- Buyukozkan, G. A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput. Ind. 2010, 62, 164–174. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Res. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Gonzalez-Benito, J. The role of stakeholder pressure and managerial values in the implementation of environmental logistics practices. Int. J. Prod. Res. 2006, 44, 1353–1373. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational determinants of environmental purchasing: Initial evidence from the consumer products industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Hall, J. Environmental supply chain dynamics. J. Clean. Prod. 2000, 8, 455–471. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A. Strategic Proactivity and Firm Approach to the Natural Environment. Acad. Manag. J. 1998, 41, 556–567. [Google Scholar] [CrossRef]

- Arundel, A.; Sonntag, V. Patterns of Advanced Manufacturing Technology (AMT) Use in Canadian Manufacturing; 1998 AMT Results, Final Report; Statistics Canada: Ottawa, ON, Canada, 1999; Volume 12, pp. 55–63.

- Kleinberg, J. Bursty and hierarchical structure in streams. In Proceedings of the Eighth ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Edmonton, AB, Canada, 23–26 July 2002; Volume 7, pp. 91–101. [Google Scholar]

- Sarkis, J. A strategic decision framework for green supply chain management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Geffen, C.A.; Rothenberg, S. Suppliers and environmental innovation: The automotive paint process. Int. J. Oper. Prod. Manag. 2000, 20, 166–186. [Google Scholar] [CrossRef]

- King, A.A.; Lenox, M. Lean and green? An empirical examination of the relationship between lean production and environmental performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- Handfield, R.; Steven, V. Applying environmental criteria to supplier assessment: A study in the application of the Analytical Hierarchy Process. Eur. J. Oper. Res. 2002, 141, 70–87. [Google Scholar] [CrossRef]

- Christmann, P.; Taylor, G. Globalization and the environment: Determinants of firm self-regulation in China. J. Int. Bus. Stud. 2001, 32, 439–458. [Google Scholar] [CrossRef]

- Simpson, D.F.; Power, D.J. Use the supply relationship to develop lean and green suppliers. Supply Chain Manag. 2005, 10, 60–68. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Brandenburg, M.; Rebs, T. Sustainable supply chain management: A modeling perspective. Ann. Oper. Res. 2015, 229, 213–252. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why research in sustainable supply chain management should have no future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Sarkis, J.; Lai, K.H. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

| Rank | Journals | Publications | Proportion | Impact Factor | Categories |

|---|---|---|---|---|---|

| 1 | Journal of Cleaner Production | 167 | 14.623 | 5.715 | Green sustainable science technology; Engineering, Environmental; Environmental science. |

| 2 | International Journal of Production Economics | 94 | 8.231 | 3.493 | Engineering, Industrial; Engineering, Manufacturing; Operations research management science. |

| 3 | Sustainability | 47 | 4.116 | 1.789 | Green sustainable science technology; Environmental sciences; Environmental studies. |

| 4 | Supply Chain Management: An International Journal | 38 | 3.327 | 4.072 | Business; Management. |

| 5 | International Journal of Production Research | 37 | 3.24 | 2.325 | Engineering, Industrial; Engineering, Manufacturing; Operations research management science. |

| Rank | Authors | Publications | Proportion | h-Index | Average Citations per Item | Highly Cited Papers |

|---|---|---|---|---|---|---|

| 1 | Sarkis J. | 44 | 3.853 | 25 | 71.63 | 9 |

| 2 | Zhu Q.H. | 26 | 2.277 | 28 | 84.56 | 5 |

| 3 | Lai K.H. | 25 | 2.189 | 17 | 70.63 | 6 |

| 4 | Jabbour C.J.C. | 19 | 1.664 | 9 | 16.38 | 2 |

| 5 | Govidan K. | 18 | 1.576 | 11 | 33.40 | 3 |

| Cluster | Size | Silhouette | Mean | Custer Label |

|---|---|---|---|---|

| 0 | 78 | 0.752 | 2009 | Green supply chain management capability |

| 1 | 45 | 0.764 | 2001 | Environmental strategy |

| 2 | 32 | 0.931 | 1998 | Evaluation |

| 3 | 24 | 0.856 | 2001 | Pressure |

| 4 | 23 | 0.92 | 1994 | Environmental purchasing |

| 5 | 22 | 0.907 | 1997 | Manufacturing |

| 6 | 20 | 0.913 | 2002 | Corporate social responsibility |

| 7 | 18 | 0.939 | 1997 | New initiative |

| 8 | 16 | 0.954 | 2011 | Supplier |

| Freq | Authors | Year | Title | Journal | Cluster |

|---|---|---|---|---|---|

| 177 | Seuring S.; Müller M. | 2008 | From a literature review to a conceptual framework for sustainable supply chain management | J. CLEAN. PROD. | 0 |

| 141 | Srivastava S.K. | 2007 | Green supply-chain management: A state-of-the-art literature review | INT. J. MANAG. REV. | 0 |

| 134 | Vachon S.; Klassen R.D. | 2008 | Environmental management and manufacturing performance: The role of collaboration in the supply chain | INT. J. PROD. ECON. | 0 |

| 134 | Sarkis J.; Zhu Q.H.; Lai K.H. | 2011 | An organizational theoretic review of green supply chain management literature | INT. J. PROD. ECON. | 0 |

| 118 | Carter C.R.; Rogers D.S. | 2008 | A framework of sustainable supply chain management: moving toward new theory | INT. J. PHYS. DISTR. LOG. | 0 |

| 102 | Vachon S.; Klassen R.D. | 2006 | Extending green practices across the supply chain: the impact of upstream and downstream integration. | INT. J. OPER. PROD. MANAG. | 0 |

| 93 | Zhu Q.H.; Sarkis J. | 2004 | Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. | J. OPER. MANAG. | 1 |

| 92 | Rao P.; Holt D. | 2005 | Do green supply chain management lead to competitiveness and economic performance? | INT. J. OPER. PROD. MANAG. | 0 |

| 88 | Zhu Q.H.; Sarkis J.; Lai K.H. | 2008 | Confirmation of a measurement model for green supply chain management practices implementation. | INT. J. PROD. ECON. | 0 |

| 80 | Linton J.D.; Klassen R.; Jayaraman V. | 2007 | Sustainable supply chains: an introduction. | J. OPER. MANAG. | 0 |

| Freq | Authors | Year | Freq | Author | Year |

|---|---|---|---|---|---|

| 118 | Carter C.R.; Rogers D.S. | 2008 | 44 | Mollenkopf D.; Stolze H.; Tate W.L. | 2010 |

| 102 | Vachon S.; Klassen R.D. | 2006 | 41 | Kleindorfer P.R. | 2005 |

| 92 | Rao P.; Holt D. | 2005 | 36 | Zhu Q.H.; Sarkis J.; Lai K.H. | 2012 |

| 62 | Zhu Q.H.; Sarkis J. | 2007 | 32 | Tate W.L.; Ellram L.M.; Kirchoff J.F. | 2010 |

| 58 | Zhu Q.H.; Sarkis J; Geng Y. | 2005 | 31 | Sarkis J. | 2012 |

| 52 | Carter C.R.; Rogers D.S. | 2011 | 30 | Lu L.Y.Y.; Wu C.H.; Kuo T.C. | 2007 |

| 48 | Green K.W.; Zelbst P.J.; Meacham J.; Bhadauria V.S. | 2012 | 25 | Gonzalez P. | 2008 |

| 48 | Simpson D.; Power D.J. | 2007 | 23 | Vachon S. | 2007 |

| 47 | Lee S.Y. | 2008 | 23 | Klassen R.D.; Vachon S. | 2003 |

| 46 | Vachon S. | 2007 | 22 | Carter C.R.; Carter J.R. | 2004 |

| Centr | Authors | Year | Title | Journal | Cluster |

|---|---|---|---|---|---|

| 0.2 | Zhu Q.H.; Sarkis J. | 2004 | Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. | J. OPER. MANAG. | 1 |

| 0.16 | King A.A.; Lenox M. | 2001 | Lean and green? An empirical examination of the relationship between lean production and environmental performance. | PROD. OPER. MANAG. | 6 |

| 0.15 | Rao P. | 2002 | Greening the supply chain: a new initiative in South East Asia. | INT. J. OPER. PROD. MANAG. | 1 |

| 0.14 | Vachon S.; Klassen R.D. | 2008 | Extending green practices across the supply chain: The impact of upstream and downstream integration. | INT. J. OPER. PROD. MANAG. | 0 |

| 0.13 | Vachon S.; Klassen R.D. | 2006 | Environmental management and manufacturing performance: The role of collaboration in the supply chain | INT. J. PROD. ECON. | 0 |

| 0.11 | Klassen R.D.; Vachon S. | 2003 | Collaboration and evaluation in the supply chain: The impact on plant-level environmental investment | PROD. OPER. MANAG. | 1 |

| 0.11 | Hall J. | 2000 | Environmental supply chain dynamics | J. CLEAN. PROD. | 1 |

| 0.11 | Handfield R.B.; Nichols E.L. | 1999 | Introduction to supply chain management | – | 7 |

| 0.11 | Aragon-correa J.A. | 1998 | Strategic proactivity and firm approach to the natural environment | ACAD. MANAG. J. | 2 |

| 0.11 | Arundel A.; Sonntag V. | 1999 | Patterns of advanced manufacturing technology (AMT) use in Canadian manufacturing: 1998 AMT results: final report | – | 2 |

| Burst | Authors | Year | Title | Source | Cluster |

|---|---|---|---|---|---|

| 30.68 | Zhu Q.H.; Sarkis, J. | 2004 | Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. | J. OPER. MANAG. | 1 |

| 23.6 | Rao P.; Holt D. | 2005 | Do green supply chain management lead to competitiveness and economic performance? | INT. J. OPER. PROD. MANAG. | 0 |

| 15.48 | Vachon S.; Klassen R.D. | 2006 | Extending green practices across the supply chain. The impact of upstream and downstream integration | INT. J. OPER. PROD. MAN. | 0 |

| 15.19 | Hervani A.A.; Helms M.M.; Sarkis J. | 2005 | Performance measurement for green supply chain management. | BENCHMARKING. INT. J. | 0 |

| 13.77 | Sarkis J. | 2003 | A strategic decision framework for green supply chain management | J CLEAN PROD | 1 |

| 13.76 | Zhu Q.H.; Sarkis J.; Geng Y. | 2005 | Green supply chain management in China: pressures, practices and performance | INT. J. OPER. PROD. MANAG. | 0 |

| 13.39 | Sarkis J.; Zhu Q.H.; Lai K.H. | 2011 | An organizational theoretic review of green supply chain management literature. | INT. J. PROD. ECON. | 0 |

| 12.36 | Green K.W.; Zelbst P.J.; Meacham J.; Bhadauria V.S. | 2012 | Green supply chain management practices: impact on performance | SUPPLY CHAIN MANAG. | 0 |

| 11.86 | Kleindorfer P.R. | 2005 | Managing disruption risk in supply chains | PROD. OPER. MANAG. | 6 |

| 11.66 | Geffen C.A.; Rothenberg S. | 2000 | Suppliers and environmental innovation: The automotive paint process | INT. J. OPER. PROD. MANAG. | 1 |

| 11.56 | Zhu Q.H.; Sarkis J.; Lai K.H. | 2013 | Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices | J. PURCH. SUPPLY MANAG. | 0 |

| 11.3 | Ahi P.; Searcy C.A. | 2013 | A comparative literature analysis of definitions for green and sustainable supply chain management | J. CLEAN. PROD. | 0 |

| 10.98 | Diabat A.; Govindan K. | 2011 | An analysis of the drivers affecting the implementation of green supply chain management | RESOUR. CONSERV. RECYCL. | 0 |

| 10.89 | Bowen F.E.; Cousins P.D.; Lamming R.C. | 2001 | the Role of Supply Management Capbilities in green supply chain management | PROD. OPER. MANAG. | 1 |

| 10.79 | Brandenburg M.; Govindan K.; Sarkis J. | 2014 | Quantitative models for sustainable supply chain management: Developments and directions | EUR. J. OPER. RES. | 0 |

| 10.6 | Rao P. | 2002 | Greening the supply chain: a new initiative in South East Asia | INT. J. OPER. PROD. MANAG. | 1 |

| 10.39 | Govindan K.; Kaliyan M.; Kannan D. | 2014 | Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process | INT. J. PROD. ECON. | 0 |

| 10.19 | Klassen R.D.; Vachon S. | 2003 | Collaboration and evaluation in the supply chain: The impact on plant-level environmental investment | PROD. OPER. MANAG. | 1 |

| 9.61 | King A.A.; Lenox M. | 2001 | Lean and green? An empirical examination of the relationship between lean production and environmental performance | PROD. OPER. MANAG. | 6 |

| 9.5 | Srivastava S.K. | 2007 | Green supply-chain management: A state-of-the-art literature review | INT. J. MANAG. REV. | 0 |

| 7.29 | Hassini E.; Surti C.; Searcy C. | 2012 | A literature review and a case study of sustainable supply chains with a focus on metrics | INT. J. PROD. ECON. | 0 |

| 7.26 | Linton J.D.; Klassen R.; Jayaraman V. | 2007 | Sustainable supply chains: an introduction. | J. OPER. MANAG. | 0 |

| 7.15 | Kannan D. et al. | 2013 | Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain | J. CLEAN. PROD. | 8 |

| 6.87 | Handfield R.; Steven V. | 2002 | Applying environmental criteria to supplier assessment: A study in the application of the Analytical Hierarchy Process | EUR. J. OPER. RES. | 3 |

| 6.87 | Christmann P.; Taylor G. | 2001 | Globalization and the environment: Determinants of firm self-regulation in China | J. INT. BUS. STUD. | 3 |

| 6.85 | Tseng M.L.; Anthony S.F. Chiu | 2013 | Evaluating firm’s green supply chain management in linguistic preferences | J CLEAN PROD. | 8 |

| 6.85 | Govindan K.; Kaliyan M.; Kannan D. | 2013 | A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach | J. CLEAN PROD. | 8 |

| 6.79 | Pagell M.; Shevchenko A. | 2014 | Why research in sustainable supply chain management should have no future | J. SUPPLY CHAIN MANAG. | 8 |

| 6.68 | Simpson D.E.; Power D.J. | 2005 | Use the supply relationship to develop lean and green suppliers | SUPPLY CHAIN MANAG. | 3 |

| 6.56 | Carter C.R.; Kale R.; Mgrimm C. | 2000 | Environmental purchasing and firm performance: An empirical investigation | TRANSPORT RES. E-LOG | 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, W.; Wang, J. Mapping the Landscape and Evolutions of Green Supply Chain Management. Sustainability 2018, 10, 597. https://doi.org/10.3390/su10030597

Shan W, Wang J. Mapping the Landscape and Evolutions of Green Supply Chain Management. Sustainability. 2018; 10(3):597. https://doi.org/10.3390/su10030597

Chicago/Turabian StyleShan, Wei, and Jingyi Wang. 2018. "Mapping the Landscape and Evolutions of Green Supply Chain Management" Sustainability 10, no. 3: 597. https://doi.org/10.3390/su10030597