1. Introduction

The most common problems related to the degradation of flexible pavements [

1] can be grouped into three categories: thermal cracking; surface deformations due to viscoelastic behaviour of the material; surface defects. The first two are closely linked to the type of material used, the third depends only on the quality of the material processing. Literature reports papers on the assessment of the performance and the rheological properties of polymer-modified [

2,

3,

4,

5] or inorganic filler—modified [

6,

7,

8], bitumen. However, it is easy to note that the use of artificial modifiers, either organic (i.e., polymer-based) or inorganic, may set additional environmental problems. This framework tries to address the challenge to demonstrate an innovative and integrated approach for the sustainable construction of roads considering the whole life cycle of the infrastructure. Usually, several actions could be considered: enhancing the resource and cost-efficient use of alternative materials or implementing a “circular economy approach” by taking advantage of the actual by-products and waste produced by the local industry.

Among polymer-based modifiers, SBS (styrene-butadiene-styrene) copolymer is well known from the literature [

2] as it can significantly enhance the rheological properties of a bitumen [

9,

10]. SBS is an elastomer obtained from monomer units of styrene and butadiene, typically containing 23.5% of styrene and the remaining 76.5% of butadiene. SBS is often used by road engineers in bitumen-based mixtures in order to obtain a greater resistance to the deformation caused by “rutting” and by the stresses linked to the cracking [

11].

Experimental evidence [

12,

13] showed that low concentrations of SBS (usually less than 4% by weight but the threshold is variable) lead to bituminous mixtures with a continuous phase where the copolymer is dispersed. The result is a mixture with reduced fragility at low temperatures, nevertheless the characteristics of the mixture are still dependent on the used bituminous binder. At higher SBS concentrations (more than 5–7% by weight) a continuous polymeric matrix has been observed, where the bitumen acts as a plasticizing agent. The properties of the obtained system mainly depend on those of the copolymer. When the copolymer amount is intermediate (i.e., around 4–6% by weight), microstructures may form, where the two phases are continuous and interconnected. This kind of dispersion and its final properties are difficult to investigate, since the properties are often dependent on thermal history. When SBS is blended with a 70–100 bitumen, the elastomeric phase typically absorbs the maltenic fraction (oil fraction) and swells, increasing its volume up to nine times depending on the bitumen quality. Intermediate to high percentages of copolymer, around 5–7% by weight, create a three-dimensional polymeric net that radically changes the properties of the bitumen.

Asphaltenes and copolymer compete for the solvent power of maltenic fraction and if the amount of malthenes is insufficient, a phase separation can be created; this separation is an index of the incompatibility of bituminous matrix with polymer phase.

Bitumen added with SBS have an elasto-plastic behaviour range which is wider than that of the original bitumen and, furthermore, a better behaviour at high and low temperatures together with a greater resistance to fatigue and wear. The typical defect associated with the use of SBS copolymer is the creation of a thermally unstable structure.

The additive effectiveness, together with the stability of the blend during transport, storage and commissioning of the product are dependent on the optimization of multiple parameters, such as additive amount, bitumen composition, thermal profile of the mixing process, shear stress and mixing time.

The complex behaviour of bituminous binders, due to the rheological behaviour of these viscoelastic materials (which can vary with temperature, load application time and bitumen age), has been investigated in the reported literature. In particular, in order to evaluate the dynamic response of bitumen modified with fillers, dynamic shear rheometer is used to determine the elastic and viscous components of the materials subjected to deformation. Dynamic shear rheological tests allow to estimate some fundamental properties of the bitumen, such as the complex modulus |G*|, the storage modulus G′, the loss modulus G” and the phase angle δ. The determination of these values typically allows assessing the improvements imparted by the modifiers to the bitumen.

With regard to modification of bitumen with metal oxides, such as iron oxides, the literature does not report, to our best knowledge, systematic studies about their influence on the mechanical and rheological properties but only on colour modifications they can possibly cause: high filler amounts usually lead to a typical reddish colour. In fact, a bitumen modified with iron oxide is particularly suitable in urban areas, in order to delimit the floorings used as cycle paths.

However, it is of significant interest to consider the possibility to reduce the environmental impacts related to a bitumen modified with inorganic fillers such as metal oxides. In particular this study debate how, this could be obtained by replacing high purity iron oxides (such as hematite) with recycled metal oxides coming as by-products from metallurgical processes. For instance, it would be even more interesting to recycle, for modified bitumen preparation, metal oxides coming as by-products from regeneration processes of spent pickling solutions. In fact, these processes are already known to improve the sustainability of metallurgical operations involving the use of large amounts of acid solutions to perform surface pre-treatments of steel items [

14] and a suitable re-use of the by-products (such as metal oxides) would further improve their attractivity.

The opportunity to test such metal oxides deriving by industrial processes and which are considered as dangerous waste, is also important in order finding the most suitable way to recycle and to minimize overall disposal costs.

Therefore, in this work, the effects that the addition of metal oxides and the possible combination with elastomers can cause to the endurance capacity of a flexible pavement [

15,

16], when subjected to the action of traffic loads and to intense solar radiation, have been investigated via softening point measurements and dynamic shear rheological characterization.

2. Materials and Methods

2.1. Bitumen 70/100

Bitumen contains a complex mixture of aliphatic compounds, cyclic alkanes, aromatic hydrocarbons, PAHs and heterocyclic compounds containing nitrogen, oxygen and sulphur atoms and metals (e.g. iron, nickel and vanadium).

Elemental analyses indicate that most bitumen contain primarily hydrocarbons, i.e., carbon, 79–88%; hydrogen, 7–13%; sulphur, traces to 8%; oxygen, 2–8%; nitrogen, 3%; and the metals vanadium and nickel in parts per million. The exact chemical composition of a bitumen varies depending on the chemical complexity of the original crude petroleum and the manufacturing processes. In addition, the products of other refining processes, e.g. flux or solvent from petroleum distillate, may be blended with bitumen to achieve the desired performance specifications.

The bitumen chosen for this study have a “70–100” (soft bitumen) penetration index class [

17], frequently used in road and airport applications, especially in southern Italy, for flexible superstructures.

Table 1 reports the typical average performance characteristics of 70/100 bitumen.

2.2. Metal Oxides

The metal oxides used in this work were secondary products of solid particulate nature [

14,

18], obtained from regeneration processes of spent acid solutions. When these oxides are not [

7] further processed, they appear as a reddish-brown powder, containing metal oxides of various natures. In particular, the metal oxides used in this study were mainly composed by iron oxides but also by zinc, manganese, calcium, nickel and very small amounts of other metals.

2.3. Hematite

Hematite Fe

2O

3, is a natural or synthetic inorganic pigment, generally red in colour, which suitably added to a bitumen-based blend, can give a typical reddish colour to the blend itself (

Table 2). As discussed in the following, the tests conducted have allowed assessing the possible changes induced on the rheology of the bituminous matrix and, in general, hematite was considered as a benchmark for the above-described metal oxides coming from regeneration processes.

2.4. SBS

Physical architecture and chemical composition of the added polymers influences bitumen thermal stability during storage. In this work, one of the most widely used linear SBS copolymers for bitumen modification, i.e., Hi-Cis BR, KIBIPOL® PR-040 (Chimei Corporation, Taiwan), having bound styrene of 30–32 wt %, was chosen. Comprehensive thermal and rheological studies have been carried out on PR-040 polymer modified bitumen.

The SBS copolymer was added at a 5 phr concentration.

2.5. Method

The bitumen was first heated at 180 °C in a tin container and the required amount of polymer or metal oxide was slowly added into the liquefied bitumen. Homogeneous mixing of the polymer was done at 180 °C using a IKA (Germany) T50 Digital Turrax high shear mixer at 4000 rpm for 120 min. After mixing the modifier under high shear regime, the material was further homogenized at 180 °C using the same high shear mixer at 600 rpm for 120 min. The so-obtained bitumen was then stored inside an oven at 180 °C for 24 h, to allow stabilization of the blend.

Then, an amount of 20 g of melted bitumen was poured into a Ø (25 ± 0.5) mm iron pan and the thickness of the sample was about 1.13 mm. After cooling the samples to room temperature, they were subjected to the following characterizations.

The tests were performed taking into account five different bituminous mixtures (

Table 3): BIT_A, the actual bitumen, type 70/100; SBS_5, consisting of 70/100 bitumen mixed with SBS at 5 phr; EMA, consisting of modified bitumen with Hematite at concentrations 5 phr, 10 phr, 15 phr and 30 phr; OXMETR, consisting of modified bitumen with iron oxides resulting from regeneration processes of spent acid solutions, at 10.0 phr and 30 phr; EMASBS, consists of modified bitumen with 5 phr SBS and 30 phr of Hematite.

The BIT_A and SBS_5 mixtures are useful to assess, respectively, the lower and upper limits of the |G*| variation range upon varying the frequency of load application. The EMA_5 EMA_10, EMA_15, EMA_30, mixtures, help in evaluating the rheological properties of the bituminous mixtures upon varying the amount of Hematite. Similarly, the OXMETR_10 and OXMETR_30 mixtures help in evaluating the interactions between metal oxides and bitumen.

EMASBS_530, finally, helps in evaluating how iron oxides and SBS, as well as their mutual interactions, affect the viscosity and therefore the rheological properties of the mixture.

The performance characteristics of bituminous mixtures were examined through laboratory tests, following CNR (Roma, Italy) and UNI EN (EU) regulations:

Dynamic Frequency Sweep Test [

20].

The “Softening point” method, as well known, allows determining the softening point of the bitumen, i.e., it is crucial to assess the quality of the bitumen since it allows to identify the set temperature for performing the dynamic frequency sweep tests.

2.6. Characterization

The Softening point is defined as the mean of the temperatures at which the bitumen disks soften and sag downwards a distance of 25 mm under the weight of a steel ball.

Dynamic Frequency Sweep tests (DFS) were performed with the help of a HAAKE (Germany) Mars III dynamic rotational rheometer, in order calculating the complex modulus |G*| and the related storage (G′) and loss (G″) components.

The parameters for the execution of dynamic frequency sweep tests were selected by previously running strain sweep tests for each mixture, in order to not exceed the limits of linear viscoelastic range. In particular, a frequency range of 0.63 to 62.83 rad/s was chosen, as well as a reference temperature of 65 °C, i.e., the temperature that is frequently detectable on the road surface after a regular prolonged period of solar irradiation [

21].

Moreover, around the temperature of 65 °C the bitumen behaviour shifts from elasto-plastic to viscoelastic; as discussed above, the study was designed to test asphalt moisture improvement coming from special blends of additives able to enhance the resistance to plastic deformation.

In

Table 4, setting parameters used for the determination of the rheological properties are shown.

3. Results and Discussion

In order to evaluate the effects related to modifying the bituminous mixtures reported in

Table 2, it has been chosen first to evaluate the possible enhancements of the softening point, according to UNI-EN 1427:2015.

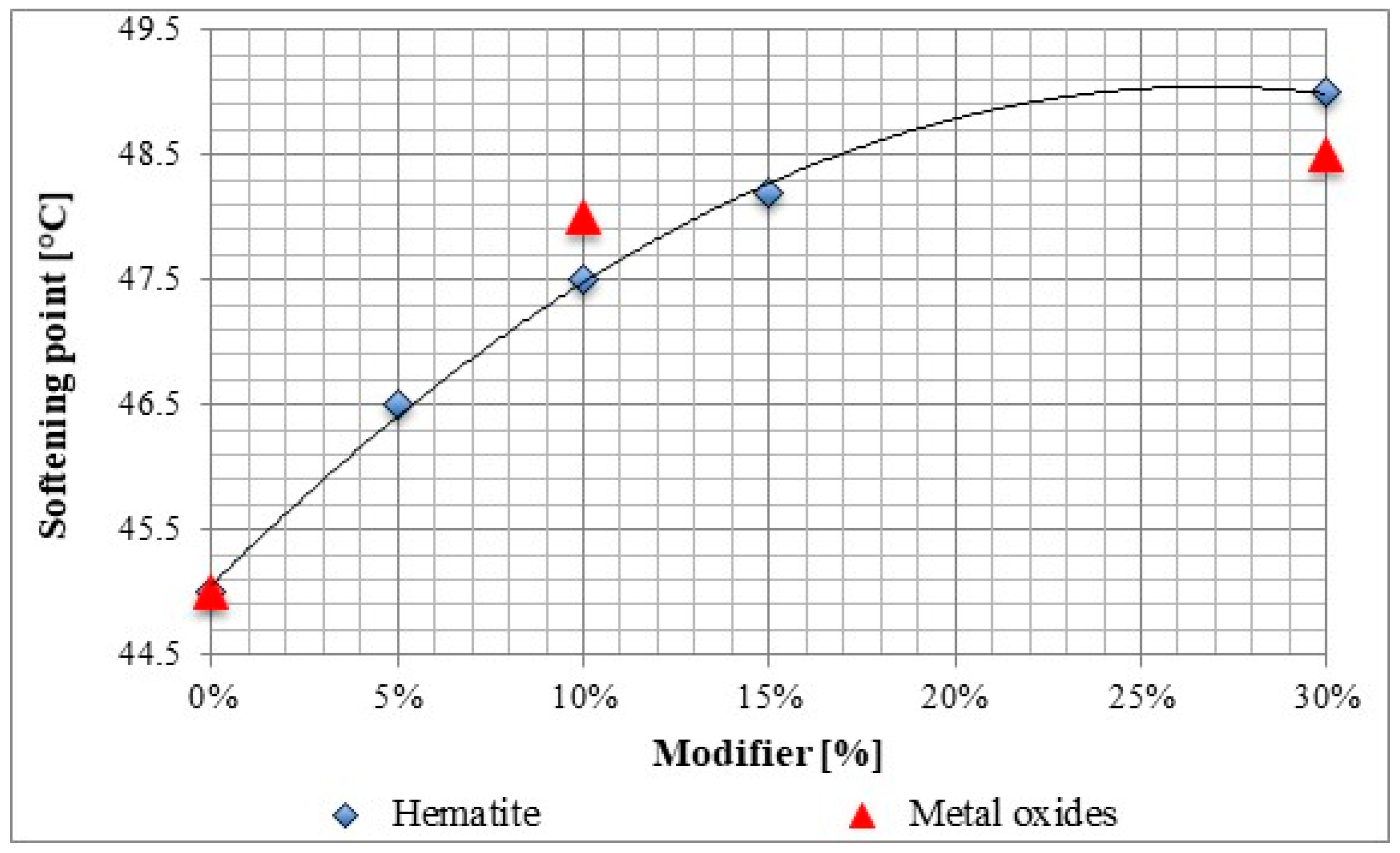

From

Table 5, it can be observed how the addition of iron oxide (hematite) to the bitumen results in a slight increase of the softening point, from 45.0 °C to 49.0 °C when the iron oxide concentration increases from 0 phr to 30 phr.

It can be also noticed that the increase of the softening point is not proportional to the increase in the amount of hematite added to the mixture, see

Figure 1.

From

Figure 1 it is possible to observe the variation law which links the percentage of hematite to the softening point, i.e.,

where:

It can be also observed that the same variation law can be used to determine the softening point of mixture added with treated metal oxides (i.e., those coming from regeneration processes of spent acid liquors), since it provides a good interpolation of the experimental points found for the metal oxides containing mixtures.

Table 5 also shows that the addition of SBS to the bitumen determines an increase of the softening point of approximately 18.0%.

As regards the bitumen added with both hematite and the SBS copolymer, significant increase of the softening point was found. It increases from 45 °C (70–100 bitumen) to 53.2 °C (SBS modified bitumen) to 55.7 °C (bitumen modified with both metal oxides and SBS).

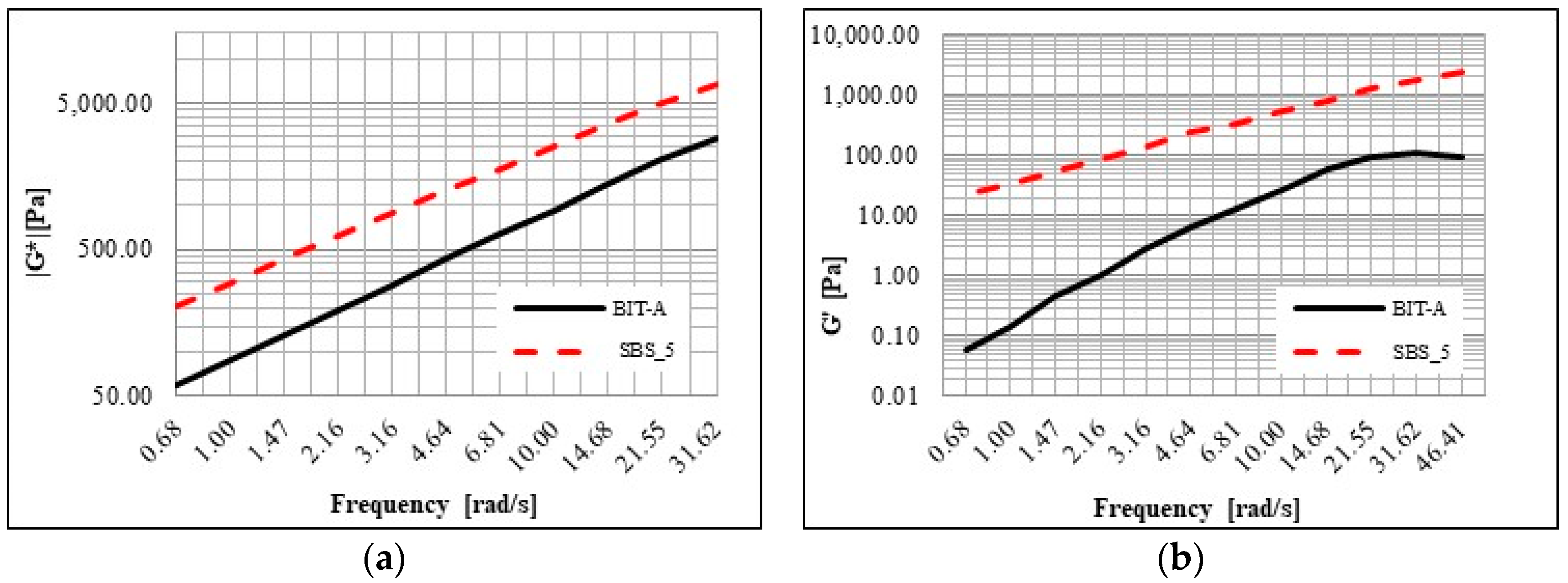

In order to assess the changes in the bitumen rheology, the complex modulus (G*) and the storage modulus (G′) were measured by performing dynamic frequency sweep tests. The investigated samples were the 70/100 bitumen and the 70/100 bitumen modified with SBS. The results obtained are reported in

Figure 2a,b, which clearly show that significant increases of |G*| and G′ were obtained upon adding SBS to the 70/100 bitumen.

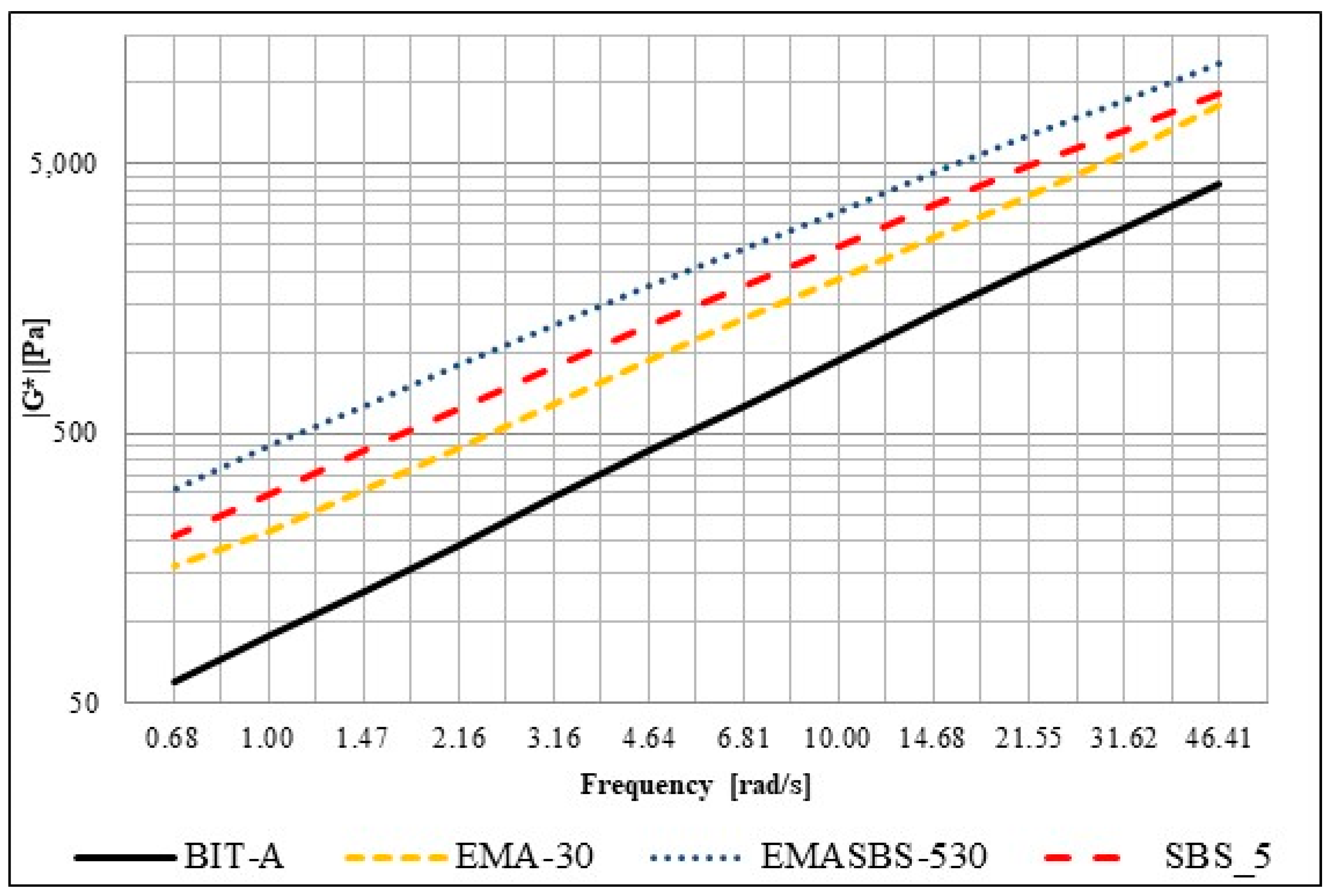

Figure 3a,b report, respectively, G* and G′ for the 70/100 bitumen, as well as the bitumen modified with SBS, Hematite and metal oxides.

It can be observed that the addition of hematite to the bitumen at a concentration of 5 phr (EMA_5) does not lead to substantial variation of the complex modulus but when the concentration increases up to 30 phr (EMA_30) it is observed that the complex modulus achieves an increase of 68.0%, reaching values close to those shown by the SBS_5 mixture; at any frequency in the range from 0.62 rad/s to 6.28 rad/s, the G′ values are comparable, if not superior, to those shown by SBS_5 mixture; at any frequency from 6.28 rad/s to 62.83 rad/s, G′ achieves an increase of 17.0%.

When the bitumen is modified with metal oxides, it can be noticed that, for concentrations below 10.0% (OXMETR_30), there is no significant change to G* and G′. When the metal oxides concentration reaches the highest level, i.e., 30 phr (OXMETR_10), the increase of |G*| and G′ is not comparable with the values found when using hematite at the same concentration. This latter phenomenon could be attributed to the presence of impurities (zinc, manganese and calcium) which significantly altered the overall system rheology.

Although the metal oxides coming from metallurgical regeneration processes are clearly the more interesting than pure hematite, the above discussed results suggested to further investigate the behaviour of hematite. In particular, it was chosen to verify the possible additional effects from the presence of both hematite and SBS; therefore, specimens containing 30 phr hematite and 5 phr SBS were tested (

Figure 4). These concentrations were chosen since they individually gave the highest increments to |G*| and G′.

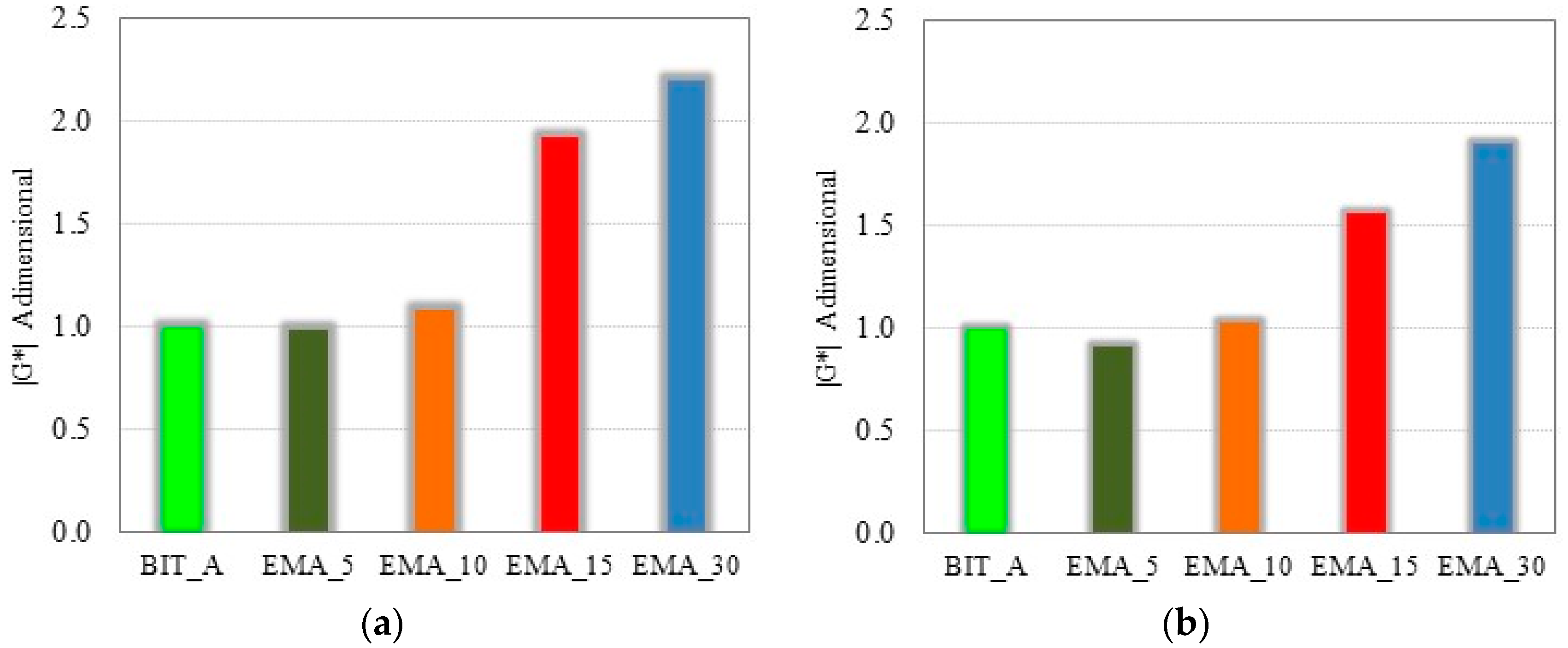

The enhancement due to the presence of both the metal-based and the polymeric modifiers was evaluated also by calculating the dimensionless variation of the complex modulus. The normalization was carried out by dividing the actual value of the modulus by the value of the virgin bitumen (

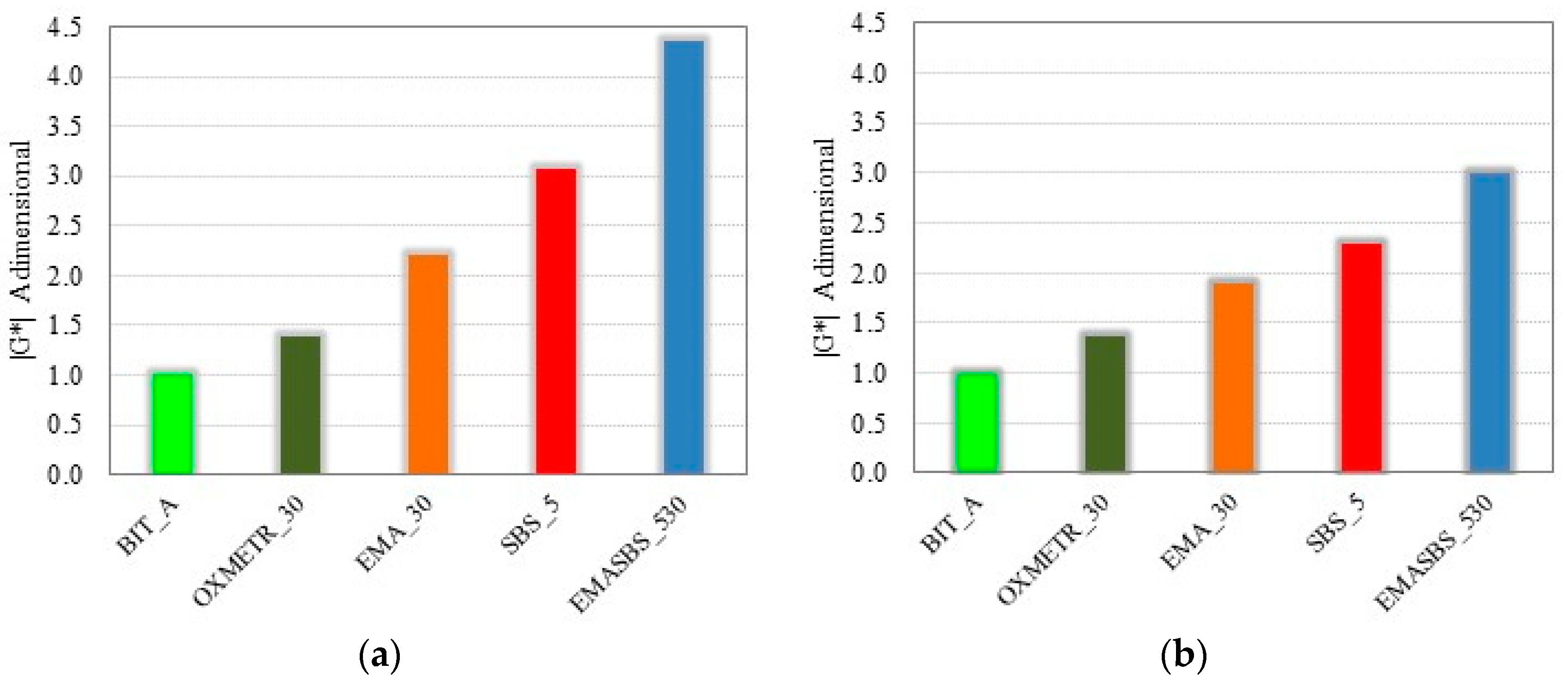

Figure 5a,b).

In order to better assess the variations in the rheological properties upon changing the frequency, the values measured at 4.14 rad/s and 31.41 rad/s are reported in the following.

Figure 5a,b clearly show that, at both frequencies, the hematite content which leads to the highest modulus enhancements is equal to 30 phr, which was therefore chosen for the following experiments.

In particular, from

Figure 6a,b, it can be observed that the enhancement of the complex modulus is higher at lower frequencies; however, enhancements are significant even at the higher frequencies. More in details, at 3.14 rad/s, the increments were equal to 220% upon adding the bitumen with hematite, 306% upon adding SBS and 435% upon adding both hematite and SBS; at 31.41 rad/s, they were 190%, 229% and 300%, respectively.

These results clearly point out the beneficial effect of incorporating both the modifiers in the bitumen.

However, since the possible use of the metal oxides coming as by-products from metallurgical regeneration processes (rather than pure hematite) is more interesting from the point of view of the environmental impacts, although the improvements of rheological properties were found to be lower, in a following paper we will address the optimization of issues such as metal oxides amount, SBS amount and mutual interactions and present some on-field tests which will provide the fundamental link between lab-observed bitumen rheology and real-life implementations.

4. Conclusions

The present study was focused on assessing the changes in the rheological behaviour of a bitumen modified by means of a SBS copolymer and pure iron oxide (hematite), or metal oxides coming as by-products of regeneration processes of spent acid liquors. It was found that the softening point undergoes a significant increase upon adding hematite or metal oxides as 30 phr.

Furthermore, the simultaneous presence of SBS (5 phr) and hematite (30 phr), led to a softening point that was higher than in the bituminous mixtures containing only SBS copolymer; in addition, a significant increase both in terms of complex modulus and of storage modulus with respect to a regular bitumen was found.

It can be therefore concluded that using a bitumen mixture containing 5 phr SBS and 30 phr hematite allows obtaining a modified bitumen, able to assure a large variation of the operating temperature cycles. Such feature allows to minimize the effects produced by thermal cracking. Finally, considering that the elastic component G′ of such bitumen assumes higher values compared to a regular bitumen or to an only-SBS-modified one, it is possible to get a bituminous conglomerate with lower levels of hysteresis or weak surface deformation.

These results could enhance the road pavement technology—using a good approach oriented to recycle and to reuse waste—at the design stage through the right mix design of bitumen modified with SBS and metal oxides such as hematite. While, the findings could improve the resistance to plastic deformation and schedule less frequent rehabilitation activities for the asphalt layers of road pavement. At the same time, it is necessary to say about some limitations of the early stage of the study done. It would be required to find the corroboration of the overall mechanical improvement throughout the result given by the main test for bituminous mixtures such as Marshall or gyratory compactor machine. Moreover, it could be also interesting to refer the right percentage of SBS and metal oxides with different type of bitumen than the 70–100 studied in this paper. Many of those cues are under investigation at the moment and it will be possible to show a full paradigm of bitumen modified with metal oxides for road pavement application.