Main Factors Affecting Post-Harvest Grain Loss during the Sales Process: A Survey in Nine Provinces of China

Abstract

:1. Introduction

2. Literature Review and Hypothesis Development

2.1. Personal Characteristics of Grain Sellers

2.2. Separation of Grain Shops and Storage Warehouses

2.3. Grain Seller’s Equipment Level

2.4. Grain Sellers’ Grain Storage Conditions

2.5. Supply of Public Facilities and Market Management Level

2.6. Seasonal Factors

2.7. Government Policies in Support of the Grain Market

3. Materials and Methods

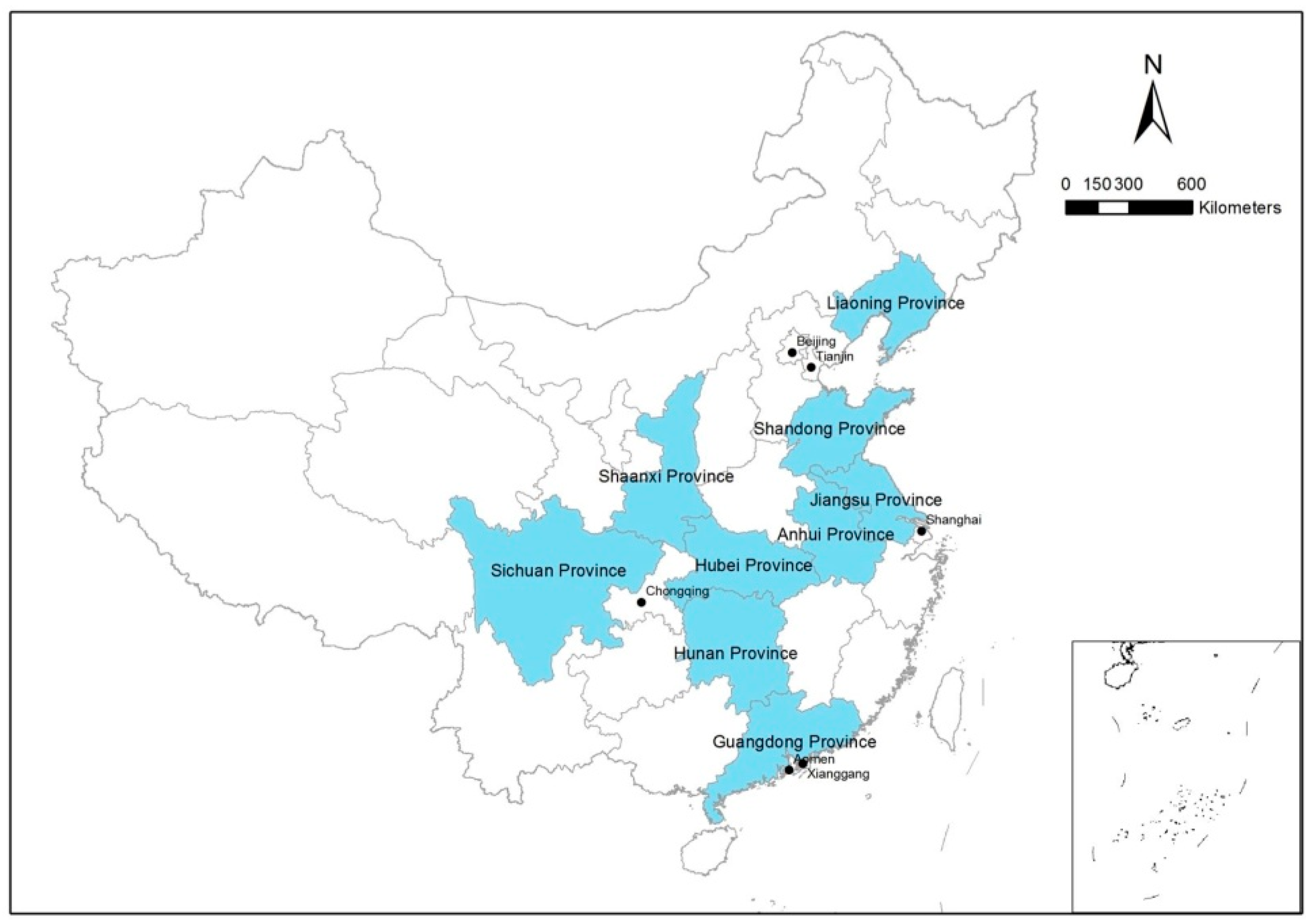

3.1. Description of the Study Region

3.2. Data Collection and Questionnaire Design

4. Results

4.1. Descriptive Statistics

4.1.1. Demographics

4.1.2. Factors that Affect Grain Loss at Different Steps of Grain Sales

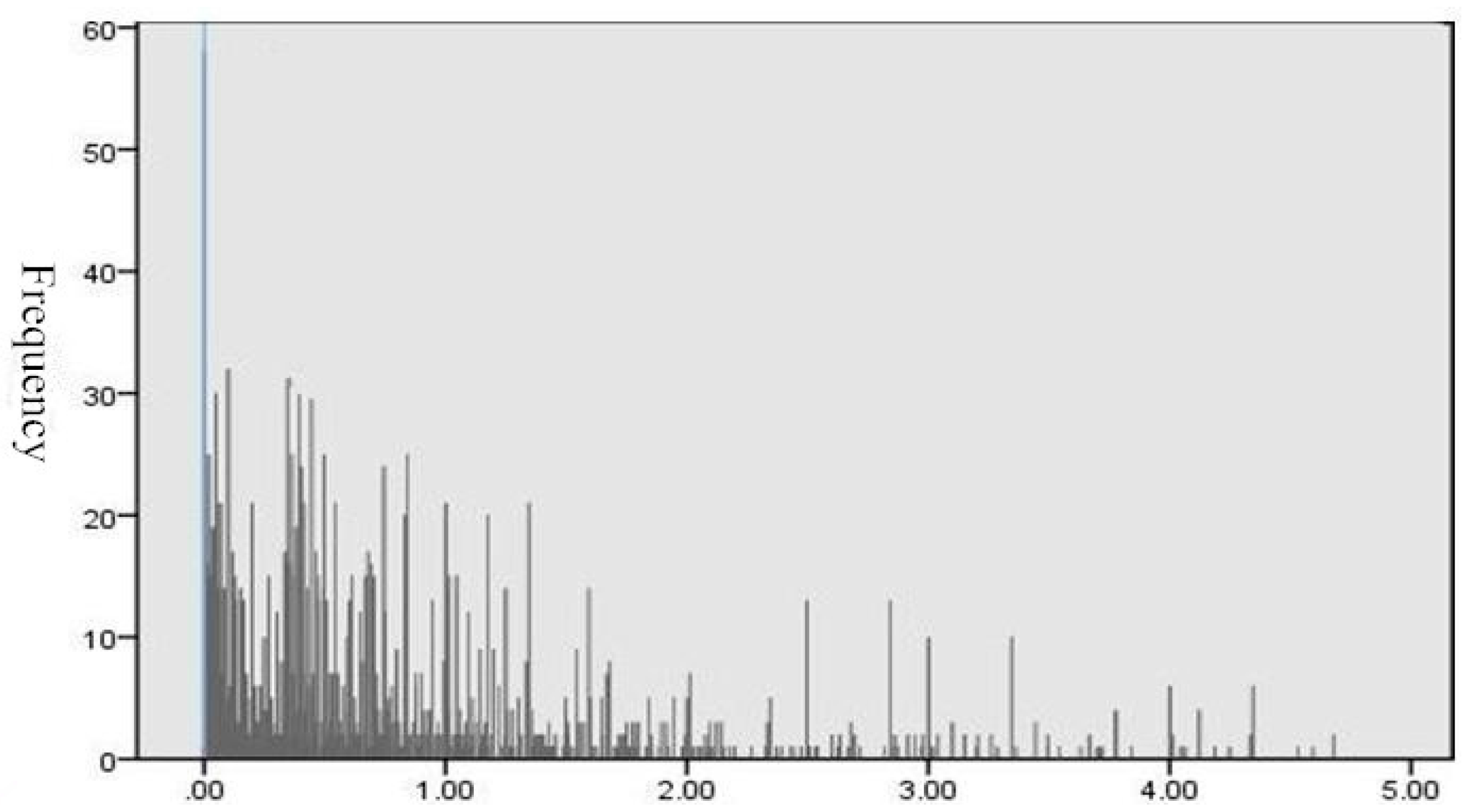

4.2. Variable Selection

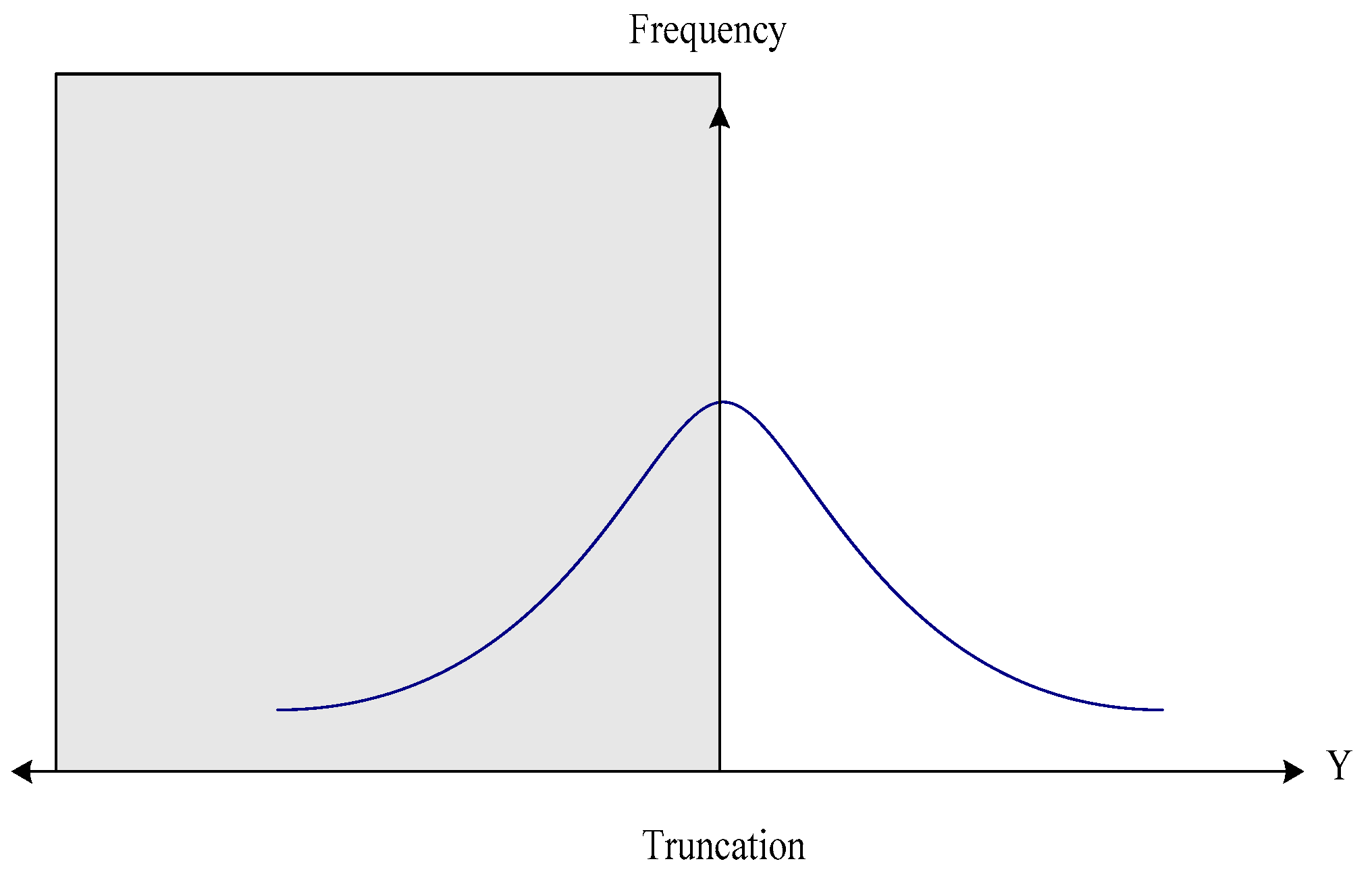

4.3. Tobit Regression Analysis

5. Discussion

5.1. Individual Characteristics of Grain Sellers (Operators)

5.2. Managerial Characteristics of Grain Sellers

5.3. External Factors

6. The Main Conclusions and Policy Implications

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, J.; Zhang, J.; Wang, S.; Kong, F. Assessment of Food Security in China: A New Perspective Based on Production-Consumption Coordination. Sustainability 2016, 8, 183. [Google Scholar] [CrossRef]

- Population Reference Bureau. World Population Data Sheet; PRB: Washington, DC, USA, 2012. [Google Scholar]

- Anderson, K.; Strutt, A. Food security policy options for China: Lessons from other countries. Food Policy 2014, 49, 50–58. [Google Scholar] [CrossRef]

- Jiao, X.; Lyu, Y.; Wu, X.; Li, H.; Cheng, L.; Zhang, C.; Yuan, L.; Jiang, R.; Jiang, B.; Zed, R.; Zhang, F.; William, D. Grain production versus resource and environmental costs: towards increasing sustainability of nutrient use in China. J. Exp. Bot. 2016, 67, 4935–4949. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Folberth, C.; Yang, H.; Röckström, J.; Abbaspour, K.; Zehnder, A.J.B.A. Global and Spatially Explicit Assessment of Climate Change Impacts on Crop Production and Consumptive Water Use. PLoS ONE 2013, 8, e57750. [Google Scholar]

- Aulakh, J.; Regmi, A. Post-Harvest Food Losses Estimation-Development of Consistent Methodology. In Proceedings of the Agricultural & Applied Economics Association’s 2013 AAEA & CAES Joint Annual Meeting, Washington, DC, USA, 4–6 August 2013. [Google Scholar]

- Huang, J.; Wang, X.; Dang, H. Impacts of and attitudes toward GM technology in China: Challenges, policy and research implications. China Agric. Econ. Rev. 2017, 9, 334–339. [Google Scholar] [CrossRef]

- Forecast of Chinese Grain Demand and Supply Gap. Available online: http://www.grainnet.cn/zt/forecast.html (accessed on 12 October 2017).

- Guo, Y.Z.; Chen, R.; Guo, J.L. Analysis and countermeasure of the grain loss in the whole industry chain from field to table. Agric. Econ. 2014, 1, 23–24. (In Chinese) [Google Scholar]

- Boxall, R.A. A Critical Review of the Methodology for Assessing Farm-Level Grain Losses after Harvest (G191); Nature Resource Institute, University of Greenwich: London, UK, 1986; ISBN 0 85954-208-4. Available online: http://gala.gre.ac.uk/10793 (accessed on 18 August 2016).

- Song, H.Y.; Zhang, H.C.; Li, J.; Wu, Z.G. Loss of Harvest of China's Grain—A Case Study of Wheat in Henan Province. J. Huazhong Agric. Univ. (Social Sciences Edition) 2015, 4, 1–6. (In Chinese) [Google Scholar]

- Wu, L.H.; Hu, Q.P.; Wang, J.H.; Zhu, D. Empirical analysis of the main factors influencing rice harvest losses based on sampling survey data of ten provinces in China. China Agric. Econ. Rev. 2017, 9, 287–302. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. [Google Scholar]

- Tefera, T.; Kanampiu, F.; De Groote, H.; Hellin, J.; Mugo, S.; Kimenju, S.; Beyene, Y.; Boddupalli, P.M.; Shiferaw, B.; Banziger, M. The metal silo: An effective grain storage technology for reducing post-harvest insect and pathogen losses in maize while improving smallholder farmers’ food security in developing countries. Crop Prot. 2011, 30, 240–245. [Google Scholar] [CrossRef]

- Mutambuki, K.; Ngatia, C.M.; Mbugua, J.N. Post-Harvest Technology Transfer to Reduce on Farm Grain Losses in Kitui District, Kenya. J. Agric. Sci. Tech. B 2011, 1, 392–399. [Google Scholar]

- Mendoza, J.R.; Sabillón, L.; Martinez, W.; Campabadal, C.; Hallen-Adams, H.E.; Bianchini, A. Traditional maize post-harvest management practices amongst smallholder farmers in Guatemala. J. Stored Prod. Res. 2017, 71, 14–21. [Google Scholar] [CrossRef]

- Kitinoja, L.; Saran, S.; Roy, S.K.; Kader, A.A. Postharvest technology for developing countries: Challenges and opportunities in research, outreach and advocacy. J. Sci. Food Agric. 2011, 91, 597–603. [Google Scholar] [CrossRef] [PubMed]

- Kaminski, J.; Christiaensen, L. Post-harvest loss in sub-Saharan Africa—What do farmers say? Glob. Food Secur. 2014, 3, 149–158. [Google Scholar] [CrossRef]

- Premanandh, J. Factors affecting food security and contribution of modern technologies in food sustainability. J. Sci. Food Agric. 2011, 91, 2707–2714. [Google Scholar] [CrossRef] [PubMed]

- Koester, U. Food Loss and Waste as an Economic and Policy Problem. Intereconomics 2014, 49, 348–354. [Google Scholar] [CrossRef]

- An, X.Y.; Liu, C.R.; Cao, D.J.; Cai, W. Discussion on the management of machinery and equipment in the process of grain warehousing in pingfang warehouse. Cereal Food Ind. 2012, 4, 44–47. (In Chinese) [Google Scholar]

- Qin, F.; Li, X.D.; Lv, X.Y.; Lu, X.H. Study on cost and benefit of wheat industry chain of Henan. Issues Agric. Econ. 2008, 5, 13–19. (In Chinese) [Google Scholar]

- Mishra, A.; Prabuthas, P.; Mishra, H.N. Grain storage: methods and measurements. Qual. Assur. Saf. Crop Foods 2012, 4, 144. [Google Scholar] [CrossRef]

- Munesue, Y.; Masui, T.; Fushima, T. The effects of reducing food losses and food waste on global food insecurity, natural resources, and greenhouse gas emissions. Environ. Econ. Policy Stud. 2015, 17, 43–77. [Google Scholar] [CrossRef]

- Paragyropoulou, E.; Lozano, R.; Steinberger, J.K.; Nigel, W.; Zaini bin, U. The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Thyberg, K.L.; Tonjes, D.J. Drivers of food waste and their implications for sustainable policy development. Resour. Conserv. Recycl. 2016, 106, 110–123. [Google Scholar] [CrossRef]

- Wooldridge, J.M. Introductory Econometrics: A Modern Approach; South-Western College Publishing: Cincinnati, OH, USA, 2000. [Google Scholar]

- Mena, C.; Adenso-Diaz, B.; Yurt, O. The causes of food waste in the supplier–retailer interface: Evidences from the UK and Spain. Resour. Conserv. Recycl. 2011, 55, 648–658. [Google Scholar] [CrossRef]

- Beretta, C.; Stoessel, F.; Baier, U.; Hellwega, S. Quantifying food losses and the potential for reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef] [PubMed]

- Giuseppe, A.; Mario, E.; Cinzia, M. Economic benefits from food recovery at the retail stage: An application to Italian food chains. Waste Manag. 2014, 34, 1306–1316. [Google Scholar] [CrossRef] [PubMed]

- Minnich, D.; Maier, F.H. Supply Chain Responsiveness and Efficiency–Complementing or Contradicting Each Other? In Proceedings of the 24th International Conference of the System Dynamics Society, Nijmegen, The Netherlands, 23–27 July 2006.

- Sun, H. Characteristics and control techniques of condensation of banker storage. J. Henan Univ. Technol. 2014, 3, 75–78. (In Chinese) [Google Scholar]

- Zhang, W.; Song, H. Causes and control methods of condensation during grain storage. J. Agric. Mech. R. 2003, 3, 162. (In Chinese) [Google Scholar]

| Characteristic | Characteristic Categories | Count | Percentage (%) |

|---|---|---|---|

| Gender | Male | 863 | 51.93 |

| Female | 799 | 48.07 | |

| Age | ≤25 years old | 65 | 3.91 |

| 26–35 years old | 397 | 23.89 | |

| 36–45 years old | 675 | 40.61 | |

| 46–55 years old ≥56 years old | 428 97 | 25.75 5.84 | |

| Education | Primary school and lower | 267 | 16.06 |

| Junior high school | 743 | 44.71 | |

| High school or vocational school | 473 | 28.46 | |

| Junior college | 116 | 6.98 | |

| Undergraduate and higher | 63 | 3.79 | |

| Years of working | ≤2 years | 145 | 8.72 |

| 3–5 years | 394 | 23.71 | |

| 6–10 years | 552 | 33.21 | |

| 11–15 years | 319 | 19.19 | |

| ≥16 years | 252 | 15.16 | |

| Shop size | ≤20 m2 | 160 | 9.63 |

| 20–50 m2 | 780 | 46.93 | |

| 50–100 m2 | 429 | 25.81 | |

| 100–200 m2 | 172 | 10.35 | |

| 200–500 m2 | 62 | 3.73 | |

| ≥500 m2 | 59 | 3.55 | |

| Annual revenue (RMB) | ≤100,000 | 328 | 19.73 |

| 100,000–500,000 | 706 | 42.48 | |

| 500,000–1,000,000 | 224 | 13.48 | |

| 1,000,000–2,000,000 | 155 | 9.33 | |

| 2,000,000–5,000,000 | 98 | 5.89 | |

| 5,000,000–8,000,000 | 101 | 6.08 | |

| ≥8,000,000 | 50 | 3.01 |

| Grain Sales Step | Factors | Limited Impact (%) | Relatively Little Impact (%) | Medium Impact (%) | Relatively Important Impact (%) | Significant Impact (%) |

|---|---|---|---|---|---|---|

| Transportation | Loading and unloading methods | 40.07 | 30.93 | 19.68 | 8.00 | 1.32 |

| Handling of tools | 40.55 | 30.21 | 19.92 | 8.18 | 1.14 | |

| Packaging quality | 21.06 | 24.79 | 24.49 | 22.98 | 6.68 | |

| Weather conditions | 6.98 | 18.77 | 24.49 | 36.16 | 13.60 | |

| Storage | Storage equipment conditions | 8.00 | 13.36 | 31.29 | 35.68 | 11.67 |

| Ventilation, humid and hot conditions | 6.62 | 13.78 | 21.54 | 42.18 | 15.88 | |

| Mold contamination | 10.65 | 16.19 | 20.22 | 33.21 | 19.73 | |

| Display and sales | Grain display | 40.01 | 32.37 | 18.71 | 6.68 | 2.23 |

| Shelf life | 29.18 | 28.64 | 21.78 | 14.44 | 5.96 |

| Variable | Definitions and Assigned Values | Mean | Mode | Standard Deviation | |

|---|---|---|---|---|---|

| Grain loss ratio (Y) | Continuous variable; specific grain loss ratio (%) | 0.53 | 0.00 | 1.02 | |

| Individual characteristics of grain sellers | Gender (X1) | Discrete variable; male = 1, female = 0 | 0.52 | 1 | 0.50 |

| Age (X2) | Continuous variable; actual age (years old) | 41.89 | 41.5 | 8.51 | |

| Education level (X3) | Continuous variable (years old); specific education length (years) | 10.07 | 9 | 2.71 | |

| Years of working (X4) | Continuous variable; specific employment length (years) | 8.70 | 8 | 4.58 | |

| Management characteristics of grain sellers | Separation of sales shops and warehouses (X5) | Discrete variable; yes = 1, no = 0 | 0.36 | 0 | 0.48 |

| Equipment level (X6) | Continuous variable; amount of equipment investment (10,000 RMB) | 5.63 | 3.0 | 8.00 | |

| Grain storage conditions (X7) | Dummy variable (no or little equipment = 0, otherwise = 1) | 0.55 | 1 | 0.50 | |

| External factors | Supply and management level of public facilities (X8) | Dummy variable (lack of management = 0, otherwise = 1) | 0.59 | 1 | 0.49 |

| Seasonal factors: spring season (X9) | Discrete variable; whether spring is the worst season for grain loss (yes = 1, no = 0) | 0.08 | 0 | 0.27 | |

| Seasonal factors: summer season (X10) | Discrete variable; whether summer is the worst season for grain loss (yes = 1, no = 0) | 0.87 | 1 | 0.33 | |

| Seasonal factors: fall season (X11) | Discrete variable; whether fall is the worst season for grain loss (yes = 1, no = 0) | 0.03 | 0 | 0.18 | |

| Government policy support for grain market (X12) | Dummy variable (little = 0, otherwise = 1) | 0.28 | 0 | 0.45 | |

| Variable | Coefficient | Standard Error | t Value | p Value |

|---|---|---|---|---|

| Gender (X1) | −0.065 | 0.050 | –1.320 | 0.188 |

| Age (X2) | 0.009 ** | 0.003 | 2.980 | 0.003 |

| Education level (X3) | –0.033 ** | 0.010 | –3.330 | 0.001 |

| Years of working (X4) | –0.023 ** | 0.006 | –4.020 | 0.000 |

| Separation of sales shops and warehouses (X5) | 0.188 ** | 0.054 | 3.520 | 0.000 |

| Equipment level (X6) | 0.005 | 0.053 | 1.660 | 0.096 |

| Grain storage conditions (X7) | –0.171 ** | 0.052 | –3.300 | 0.001 |

| Supply and management level of public facilities (X8) | –0.183 ** | 0. 052 | –3.550 | 0.000 |

| Spring season (X9) | 0.008 | 0.219 | –0.040 | 0.972 |

| Summer season (X10) | –0.101 | 0.202 | –0.500 | 0.619 |

| Fall season (X11) | 1.019 ** | 0.242 | 4.220 | 0.000 |

| Government policy support for grain market (X12) | 0.061 | 0.056 | 1.090 | 0.275 |

| _cons | 0.821 | 0.273 | 3.000 | 0.003 |

| Likelihood function value, Log likelihood = –2321.535 | ||||

| Overall significance, LR chi2 (12) = 144.200 | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wu, L.; Shan, L.; Zang, Q. Main Factors Affecting Post-Harvest Grain Loss during the Sales Process: A Survey in Nine Provinces of China. Sustainability 2018, 10, 661. https://doi.org/10.3390/su10030661

Chen X, Wu L, Shan L, Zang Q. Main Factors Affecting Post-Harvest Grain Loss during the Sales Process: A Survey in Nine Provinces of China. Sustainability. 2018; 10(3):661. https://doi.org/10.3390/su10030661

Chicago/Turabian StyleChen, Xiujuan, Linhai Wu, Lijie Shan, and Qiuxia Zang. 2018. "Main Factors Affecting Post-Harvest Grain Loss during the Sales Process: A Survey in Nine Provinces of China" Sustainability 10, no. 3: 661. https://doi.org/10.3390/su10030661