Impact of Competitive Capabilities on Sustainable Manufacturing Applications in Romanian SMEs from the Textile Industry

Abstract

:1. Introduction

2. Research Hypotheses and Theoretical Model

2.1. Technology-Organization-Environment Framework Applications for SMP

2.2. Competitive Capabilities and SMP

3. Research Methodology

3.1. Instrument Development and Validity

3.2. Data Collection

3.3. Data Analysis and Results

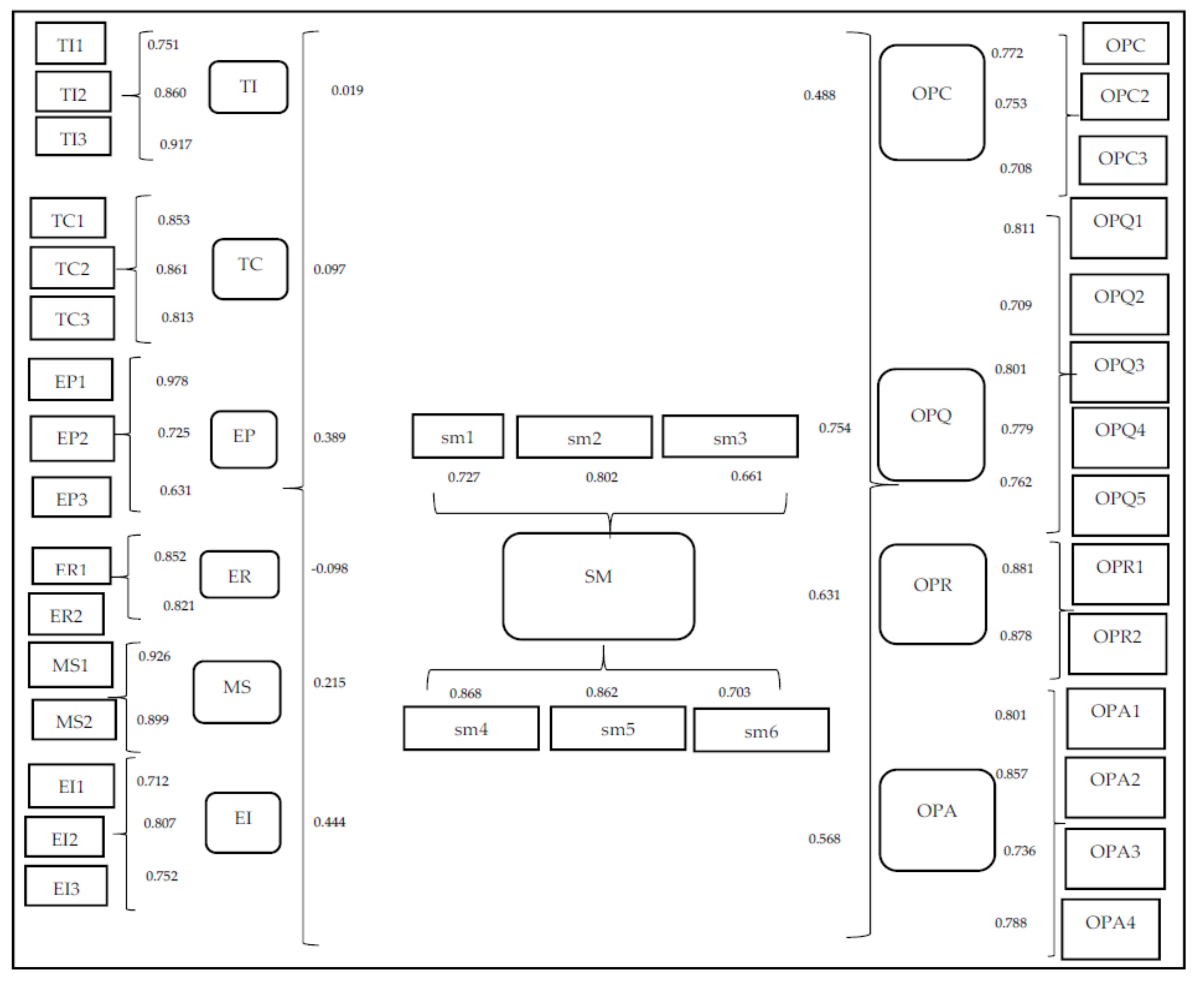

3.4. Testing the Structural Model

4. Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Garetti, M.; Mummolo, G.; Taisch, M. Special issue on “sustainable manufacturing”. Prod. Plan. Control 2012, 23, 79–82. [Google Scholar] [CrossRef]

- Jakob, M.; Marschinski, R.; Hübler, M. Between a rock and a hard place: A trade-theory analysis of leakage under production- and consumption-based policies. Environ. Resour. Econ. 2013, 56, 47–72. [Google Scholar] [CrossRef]

- International Trade Administration. How Does Commerce Define Sustainable Manufacturing? U.S. Department of Commerce, 2007. Available online: https://www.oecd.org/sti/ind/45010349.pdf (accessed on 22 December 2017).

- Huang, A.; Badurdeen, F. Sustainable Manufacturing Performance Evaluation: Integrating Product and Process Metrics for Systems Level Assessement. Procedia Manuf. 2017, 8, 563–570. [Google Scholar] [CrossRef]

- Richards, D. Environmentally conscious manufacturing. World Class Des. Manuf. 1994, 1, 15–22. [Google Scholar] [CrossRef]

- Seliger, G. Sustainability in Manufacturing: Recovery of Resources in Product and Material Cycles; Springer: Berlin, Germany, 2007. [Google Scholar]

- Despeisse, M.; Mbaye, F.; Ball, P.; Levers, A. The emergence of sustainable manufacturing practices. Prod. Plan. Control 2012, 23, 354–376. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Olugu, E.U.; Fallahpour, A. Fuzzy-based sustainable manufacturing assessment model for SMEs. Clean Technol. Environ. Policy 2014, 16, 847–860. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.; Musa, S. Decoupling growth from resource use development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. Procedia CIRP 2016, 40, 608–613. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Agan, Y.; Acar, M.; Borodin, A. Drivers of environmental processes and their impact on performance: A study of Turkish SMEs. J. Clean. Prod. 2013, 51, 23–33. [Google Scholar] [CrossRef]

- Thanki, S.; Govindan, K.; Thakkar, J. An investigation on lean-green implementation practices in Indian SMEs using analytical hierarchy process (AHP) approach. J. Clean. Prod. 2016, 135, 284–298. [Google Scholar] [CrossRef]

- Entr, D. Public Policy Initiative to Promote the Uptake of Environmental Management Systems in Small and Medium-Sized Enterprises; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- Chen, D.; Thiede, S.; Schudeleit, T.; Herrmann, C. A holistic and rapid sustainability assessment tool for manufacturing SMEs. CIRP Ann. 2014, 63, 437–440. [Google Scholar] [CrossRef]

- Ramayah, T.; Leen, J.; Marimuthu, M.; Omar, A.; Mohamad, O. Green Manufacturing Practices and Performance among SMEs: Evidence from a Developing Nation; IGI-Global: Hershey, PA, USA, 2013. [Google Scholar]

- DePietro, R.; Wiarda, E.; Fleischer, M. The Context for Change: Organization, technology and environment. In The Processes of Technological Innovation; Tornatzky, L.G., Fleischer, M., Eds.; Lexington Books: Lexington, MA, USA, 1990; pp. 151–175. [Google Scholar]

- Hwang, B.-N.; Huang, C.; Wu, C. A TOE approach to establish a green supply chain adoption decision model in the semiconductor industry. Sustainability 2016, 8, 168. [Google Scholar] [CrossRef]

- Hernandez, A.; Ona, S. Exploring green IT adoption: A case of a business process outsourcing firm. Int. J. Green Comput. 2014, 5, 13–28. [Google Scholar] [CrossRef]

- Angeles, R. Wal-Mart’s sustainable packaging scorecard initiative through the lens of the technology-organisation-environment (TOE) framework. Int. J. Sustain. Strateg. Manag. 2012, 3, 270–281. [Google Scholar] [CrossRef]

- Angeles, R. Using the technology-organization-environment framework for analyzing Nike’s considered index green initiative, a decision support system driven system. J. Manag. Sustain. 2014, 4, 96–103. [Google Scholar] [CrossRef]

- Routroy, S.; Kumar, S. An approach to develop green capability in manufacturing supply chain. Int. J. Process Manag. Benchmarking 2016, 6, 1–28. [Google Scholar] [CrossRef]

- Chuang, S.; Yang, C. Key Success factors when implementing a green manufacturing system. Prod. Plan. Control 2014, 25, 923–937. [Google Scholar] [CrossRef]

- Ifinedo, P. Internet e-business technologies acceptance in Canada’s SMEs: An exploratory investigation. Internet Res. 2011, 21, 255–281. [Google Scholar] [CrossRef]

- Bhardwaj, B. Role of green policy on sustainable supply chain management. Benchmarking Int. J. 2016, 23, 456–468. [Google Scholar] [CrossRef]

- Wong, C.; Lai, W.; Shang, K.; Lu, C.; Leung, T. Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance. Int. J. Prod. Econ. 2012, 140, 283–294. [Google Scholar] [CrossRef]

- Roni, M.; Jabar, J.; Mohamad, M.; Yusof, M. Conceptual study on sustainable manufacturing practices and firm performance. In Proceedings of the International Symposium on Research in Innovation and Sustainability, ISoRIS’14, Malacca, Malaysia, 15–16 October 2014; pp. 1459–1465. [Google Scholar]

- Shankar, K.; Kumar, K.; Kannan, D. Analyzing the drivers of advanced sustainable manufacturing system using AHP approach. Sustainability 2016, 8, 824. [Google Scholar] [CrossRef] [Green Version]

- Mittal, V.; Sangwan, K. Development of a model of barriers to environmentally conscious manufacturing implementation. Int. J. Prod. Res. 2014, 52, 584–594. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Shankar, M. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y. Drivers and barriers of extended supply chain practices for energy saving and emission reduction among Chinese manufacturers. J. Clean. Prod. 2013, 40, 6–12. [Google Scholar] [CrossRef]

- Schrettle, S.; Hinz, A.; Scherrer-Rathje, M.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. Int. J. Prod. Econ. 2014, 147, 73–84. [Google Scholar] [CrossRef]

- Schrader, U.; Fricke, V.; Doyle, D.; Thoresen, V.W. Enabling Responsible Living; Springer: Berlin, Germany, 2013. [Google Scholar]

- Hamann, R.; Smith, J.; Tashman, P.; Marshall, R. Why do SMEs go green? An analysis of wine firms in South Africa. Bus. Soc. 2017, 56, 23–56. [Google Scholar] [CrossRef]

- Vinodh, S.; Ramesh, K.; Arun, C. Application of interpretive structural modelling for analysing the factors influencing integrated lean sustainable system. Clean Technol. Environ. Policy 2016, 18, 413–428. [Google Scholar] [CrossRef]

- Yusoff, R.; Imran, A.; Qureshi, M.; Kazi, A. Investigating the relationship of employee empowerment and sustainable manufacturing performance. Int. Rev. Manag. Mark. 2016, 6, 284–290. [Google Scholar]

- Schoenherr, T. The role of environmental management in sustainable business development: A multi-country investigation. Int. J. Prod. Econ. 2012, 140, 116–128. [Google Scholar] [CrossRef]

- Porter, M.; van der Linde, C. Green and competitive: Ending the stalemate. Harv. Bus. Rev. 1995, 73, 128–134. [Google Scholar]

- Paul, I.; Bhole, G.; Chaudhari, J. A review on green manufacturing: It’s important, methodology and its application. Procedia Mater. Sci. 2014, 6, 1644–1649. [Google Scholar] [CrossRef]

- Deif, A. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Sezen, B.; Çankaya, S. Effects of green manufacturing and eco-innovation on sustainability performance. Procedia Soc. Behav. Sci. 2013, 99, 154–163. [Google Scholar] [CrossRef]

- Rusinko, C.A. Green manufacturing: An evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes. IEEE Trans. Eng. Manag. 2007, 54, 445–454. [Google Scholar] [CrossRef]

- Conceptia Software Technologies Supplier Scorecard. Available online: http://www.conceptia.in/ (accessed on 18 December 2017).

- Roberts, N.; Varun, G. Leveraging Information Technology Infrastructure to Facilitate a Firm’s Customer Agility and Competitive Activity: An Empirical Investigation. J. Manag. Inf. Syst. 2012, 28, 231–270. [Google Scholar] [CrossRef]

- Cooper, D.; Schindler, P. Business Research Methods, 12th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Hair, J. Multivariate Data Analysis, 7th ed.; Pearson: Harlow, UK, 2014. [Google Scholar]

- Rotundo, G.; Ausloos, M.; Herteliu, C.; Ileanu, B. Hurst exponent of very long birth time series in XX century Romania. Social and religious aspects. Phys. A Stat. Mech. Appl. 2015, 429, 109–117. [Google Scholar] [CrossRef]

- Lohr, S. Sampling: Design and Analysis, 2nd ed.; Brooks/Cole: Boston, MA, USA, 2010. [Google Scholar]

- Hair, J. A Primer on Partial Least Squares Structural Equation Modelling (PLS-SEM), 2nd ed.; SAGE: Los Angeles, CA, USA, 2017. [Google Scholar]

- Henseler, J.; Sarstedt, M. Goodness-of-fit indices for partial least squares path modelling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef]

- Straub, D.; Boudreau, M.; Gefen, D. Validation guidelines for is positivist research. Commun. Assoc. Inf. Syst. 2004, 13, 380–427. [Google Scholar]

- Henseler, J.; Ringle, C.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Henseler, J.; Hubona, G.; Ray, P. Using PLS path modeling in new technology research: Updated guidelines. Ind. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Langwell, C.; Heaton, D. Using human resource activities to implement sustainability in SMEs. J. Small Bus. Enterp. Dev. 2016, 23, 652–670. [Google Scholar] [CrossRef]

- Madsen, H.; Ulhøi, J. Stakeholder pressures, environmental impact and managerial initiatives of SMEs: A longitudinal study. J. Transdiscipl. Environ. Stud. 2015, 14, 13–22. [Google Scholar]

- Hart, S. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar]

- Dragan, I.M.; Isaic-Maniu, A. An Alternate for Indicators that Characterize the Structure of Economic Systems. Entropy 2017, 19, 346. [Google Scholar] [CrossRef]

- Ceptureanu, S.I.; Ceptureanu, E.G.; Visileanu, E. Comparative analysis of small and medium enterprises organizational performance in clothing industry. Ind. Textila 2017, 68, 156–162. [Google Scholar]

- Bey, N.; Hauschild, M.; McAloone, T. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Phungrassami, H. Eco-efficiency as a decision tool for cleaner production: Application for SMEs in Thailand. Environ. Res. J. 2008, 2, 217–221. [Google Scholar]

- Wang, L.; Li, Y.; He, W. The Energy Footprint of China’s Textile Industry: Perspectives from Decoupling and Decomposition Analysis. Energies 2017, 10, 1461. [Google Scholar] [CrossRef]

- Osadolor, O.A.; Lennartsson, P.R.; Taherzadeh, M.J. Introducing Textiles as Material of Construction of Ethanol Bio reactors. Energies 2014, 7, 7555–7567. [Google Scholar] [CrossRef]

- Panda, B.; Garg, A.; Jian, Z.; Heidarzadeh, A.; Gao, L. Characterization of the tensile properties of friction stir welded aluminium alloy joints based on axial force, traverse speed, and rotational speed. Front. Mech. Eng. 2016, 11, 289–298. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.; Gao, L. Power consumption and tool life models for the production process. J. Clean. Prod. 2016, 131, 754–764. [Google Scholar] [CrossRef]

| Competitive Capabilities | |

|---|---|

| CCC1 | Overhead cost is low |

| CCC2 | Low prices |

| CCC3 | Low costs of raw materials |

| CCQ1 | High quality of textile products |

| CCQ2 | Low rate of defects on textile products |

| CCQ3 | Appropriate specifications of textile products |

| CCQ4 | Appropriate working conditions and safety in the company |

| CCQ5 | Textile products do not harm the environment |

| CCR1 | Rapid response to our customer needs and behaviour |

| CCR2 | R&D responsiveness to the market |

| CCF1 | Amount of products are quickly altered |

| CCF2 | Rapid introduction of products on the market |

| CCF3 | A broad range of textile products |

| CCF4 | We customize textile products to customer needs |

| Sustainable Manufacturing Practices | |

| SMP1 | Reducing energy use |

| SMP2 | Improving water use |

| SMP3 | Reducing material use |

| SMP4 | Reducing emissions |

| SMP5 | Reducing waste water |

| SMP6 | Reducing solid waste |

| Environmental Regulations | |

| ER1 | Level of national environmental regulations |

| ER2 | Level of local environmental regulations |

| Environmental Pressures | |

| EP1 | Extent of environmental pressures from customers |

| EP2 | Extent of environmental pressures from suppliers |

| EP3 | Extent of environmental pressures from competitors |

| Technology Infrastructure | |

| TI1 | Our firm uses information, communication and networking technology |

| TI2 | Our firm uses smart devices and appliances that can be used to save waste and energy |

| TI3 | Our firm uses new innovations on manufacturing |

| Technology Competence | |

| TC1 | Our employees have the skills to manage new technology and smart devices |

| TC2 | Our employees are trained in using new technology and smart devices |

| TC3 | Our firm recruits staff with advanced technology skills |

| Management Support | |

| MS1 | Top/middle managers are committed to reduce waste and save energy |

| MS2 | Top/middle managers take necessary decisions to foster sustainability in the firm |

| Employees’ involvement | |

| EI1 | Our employees have motivation and control over their work |

| EI2 | Our employees share the responsibility for sustainability |

| EI3 | Our employees are concerned with protecting the environment |

| Items | EI | EP | ER | MS | OPC | OPD | OPA | OPQ | SM | TC | TI | VIF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EI1 | 0.712 | 1.203 | ||||||||||

| EI2 | 0.807 | 1.271 | ||||||||||

| EI3 | 0.752 | 1.287 | ||||||||||

| EI1 | 0.978 | 1.997 | ||||||||||

| EP2 | 0.725 | 2.041 | ||||||||||

| EP3 | 0.631 | 2.295 | ||||||||||

| ER1 | 0.852 | 1.203 | ||||||||||

| ER2 | 0.821 | 1.202 | ||||||||||

| MS1 | 0.926 | 1.847 | ||||||||||

| MS2 | 0.899 | 1.845 | ||||||||||

| OPC1 | 0.772 | 1.213 | ||||||||||

| OPC2 | 0.753 | 1.278 | ||||||||||

| OPC3 | 0.708 | 1.167 | ||||||||||

| OPD1 | 0.881 | 1.472 | ||||||||||

| OPD2 | 0.878 | 1.471 | ||||||||||

| OPA1 | 0.801 | 1.726 | ||||||||||

| OPA2 | 0.857 | 1.963 | ||||||||||

| OPA3 | 0.736 | 1.652 | ||||||||||

| OPA4 | 0.788 | 1.763 | ||||||||||

| OPQ1 | 0.811 | 1.872 | ||||||||||

| OPQ2 | 0.709 | 1.525 | ||||||||||

| OPQ3 | 0.801 | 1.849 | ||||||||||

| OPQ4 | 0.779 | 1.694 | ||||||||||

| OPQ5 | 0.762 | 1.77 | ||||||||||

| TC1 | 0.853 | 1.759 | ||||||||||

| TC2 | 0.861 | 1.803 | ||||||||||

| TC3 | 0.813 | 1.628 | ||||||||||

| TI1 | 0.751 | 2.075 | ||||||||||

| TI2 | 0.86 | 2.04 | ||||||||||

| TI3 | 0.917 | 1.831 | ||||||||||

| SM1 | 0.727 | 2.023 | ||||||||||

| SM2 | 0.802 | 2.511 | ||||||||||

| SM3 | 0.661 | 1.698 | ||||||||||

| SM4 | 0.868 | 3.187 | ||||||||||

| SM5 | 0.862 | 3.711 | ||||||||||

| SM6 | 0.703 | 2.096 |

| Variable | Cronbach’s Alpha | Rho_A | CR | AVE | EI | EP | ER | MS | OPC | OPD | OPA | OPQ | SM | TC | TI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EI | 0.707 | 0.72 | 0.803 | 0.577 | 0.75 | ||||||||||

| EP | 0.728 | 0.7 | 0.807 | 0.587 | 0.22 | 0.76 | |||||||||

| ER | 0.761 | 0.88 | 0.862 | 0.765 | 0.17 | 0.22 | 0.82 | ||||||||

| MS | 0.802 | 0.78 | 0.908 | 0.833 | 0.18 | 0.08 | 0.04 | 0.88 | |||||||

| OPC | 0.768 | 0.69 | 0.788 | 0.558 | 0.29 | 0.35 | 0.08 | 0.16 | 0.73 | ||||||

| OPD | 0.721 | 0.71 | 0.875 | 0.781 | 0.4 | 0.41 | 0 | 0.11 | 0.44 | 0.84 | |||||

| OPA | 0.809 | 0.81 | 0.871 | 0.634 | 0.35 | 0.36 | 0.02 | 0.22 | 0.35 | 0.57 | 0.78 | ||||

| OPQ | 0.832 | 0.82 | 0.879 | 0.6 | 0.49 | 0.55 | 0.06 | 0.15 | 0.53 | 0.69 | 0.57 | 0.74 | |||

| SM | 0.863 | 0.84 | 0.898 | 0.599 | 0.54 | 0.47 | 0.03 | 0.31 | 0.43 | 0.59 | 0.55 | 0.73 | 0.75 | ||

| TC | 0.799 | 0.78 | 0.88 | 0.711 | 0.01 | −0.01 | 0.01 | 0.08 | 0.04 | 0.08 | 0.03 | 0.02 | 0.11 | 0.81 | |

| TI | 0.835 | 0.9 | 0.881 | 0.718 | −0.07 | −0.03 | 0.03 | −0.24 | −0.08 | −0.03 | 0.01 | −0.05 | −0.09 | −0.17 | 0.83 |

| EI | EP | ER | MS | OPC | OPR | OPA | OPQ | SM | |

|---|---|---|---|---|---|---|---|---|---|

| EI | |||||||||

| EP | 0.34 | ||||||||

| ER | 0.21 | 0.43 | |||||||

| MS | 0.2 | 0.12 | 0.09 | ||||||

| OPC | 0.52 | 0.52 | 0.18 | 0.25 | |||||

| OPR | 0.61 | 0.56 | 0.04 | 0.13 | 0.67 | ||||

| OPA | 0.48 | 0.45 | 0.06 | 0.27 | 0.48 | 0.75 | |||

| OPQ | 0.67 | 0.7 | 0.09 | 0.21 | 0.74 | 0.84 | 0.69 | ||

| SM | 0.73 | 0.57 | 0.04 | 0.34 | 0.62 | 0.77 | 0.62 | 0.86 | |

| TC | 0.07 | 0.08 | 0.05 | 0.13 | 0.11 | 0.11 | 0.11 | 0.09 | 0.11 |

| TI | 0.05 | 0.1 | 0.09 | 0.28 | 0.13 | 0.02 | 0.04 | 0.11 | 0.09 |

| Goodness-of-Fit Statistics | Recommended Range | Model 1 | Model 2 | Model 3 |

|---|---|---|---|---|

| 0.961 | 0.958 | 0.966 | ||

| Degree of Freedom | 97 | 97 | 97 | |

| (χ2)/f | <3.0 | 1.525 | 1.532 | 1.503 |

| RMR | close to zero | 0.0743 | 0.0751 | 0.0738 |

| GFI | >0.90 | 0.914 | 0.916 | 0.91 |

| NFI | >0.90 | 0.836 | 0.898 | 0.827 |

| RFI | >0.90 | 0.928 | 0.963 | 0.919 |

| TLI | >0.90 | 0.972 | 0.981 | 0.969 |

| CFI | >0.90 | 0.975 | 0.978 | 0.973 |

| RMSEA | <0.08 | 0.044 | 0.045 | 0.043 |

| PCLOSE | >0.50 | 0.552 | 0.561 | 0.683 |

| Hypothesis | Path | β | t-Value | Result |

|---|---|---|---|---|

| H1 | TI-SM | 0.019 | 0.27 | Not supported |

| H2 | TC-SM | 0.097 | 1.42 | Not supported |

| H3 | EP-SM | 0.389 | 6.86 ** | Supported |

| H4 | ER-SM | −0.098 | 1.38 | Not supported |

| H5 | MS-SM | 0.215 | 2.51 * | Supported |

| H6 | EI-SM | 0.444 | 6.83 ** | Supported |

| H7 | SM-OPC | 0.488 | 6.73 ** | Supported |

| H8 | SM-OPQ | 0.754 | 16.12 ** | Supported |

| H9 | SM-OPR | 0.631 | 11.27 ** | Supported |

| H10 | SM-OPA | 0.568 | 9.36 ** | Supported |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceptureanu, E.G.; Ceptureanu, S.I.; Bologa, R.; Bologa, R. Impact of Competitive Capabilities on Sustainable Manufacturing Applications in Romanian SMEs from the Textile Industry. Sustainability 2018, 10, 942. https://doi.org/10.3390/su10040942

Ceptureanu EG, Ceptureanu SI, Bologa R, Bologa R. Impact of Competitive Capabilities on Sustainable Manufacturing Applications in Romanian SMEs from the Textile Industry. Sustainability. 2018; 10(4):942. https://doi.org/10.3390/su10040942

Chicago/Turabian StyleCeptureanu, Eduard Gabriel, Sebastian Ion Ceptureanu, Razvan Bologa, and Ramona Bologa. 2018. "Impact of Competitive Capabilities on Sustainable Manufacturing Applications in Romanian SMEs from the Textile Industry" Sustainability 10, no. 4: 942. https://doi.org/10.3390/su10040942