Phase Change Material (PCM) Application in a Modernized Korean Traditional House (Hanok)

Abstract

:1. Introduction

2. Methods

- (1)

- select a new-Hanok model, materials and simulation assumptions including infiltration;

- (2-1)

- analyze the basic heating and cooling energy load to determine the adoptable PCMs;

- (2-2)

- diversify temperature variables of PCM, which is aimed at minimizing the energy load and the peak-load shift by sensitive analysis; and

- (3)

- analyze and compare the application of several types of PCM on the building model for minimizing the heating and cooling load and optimize the PMV range for human comfort.

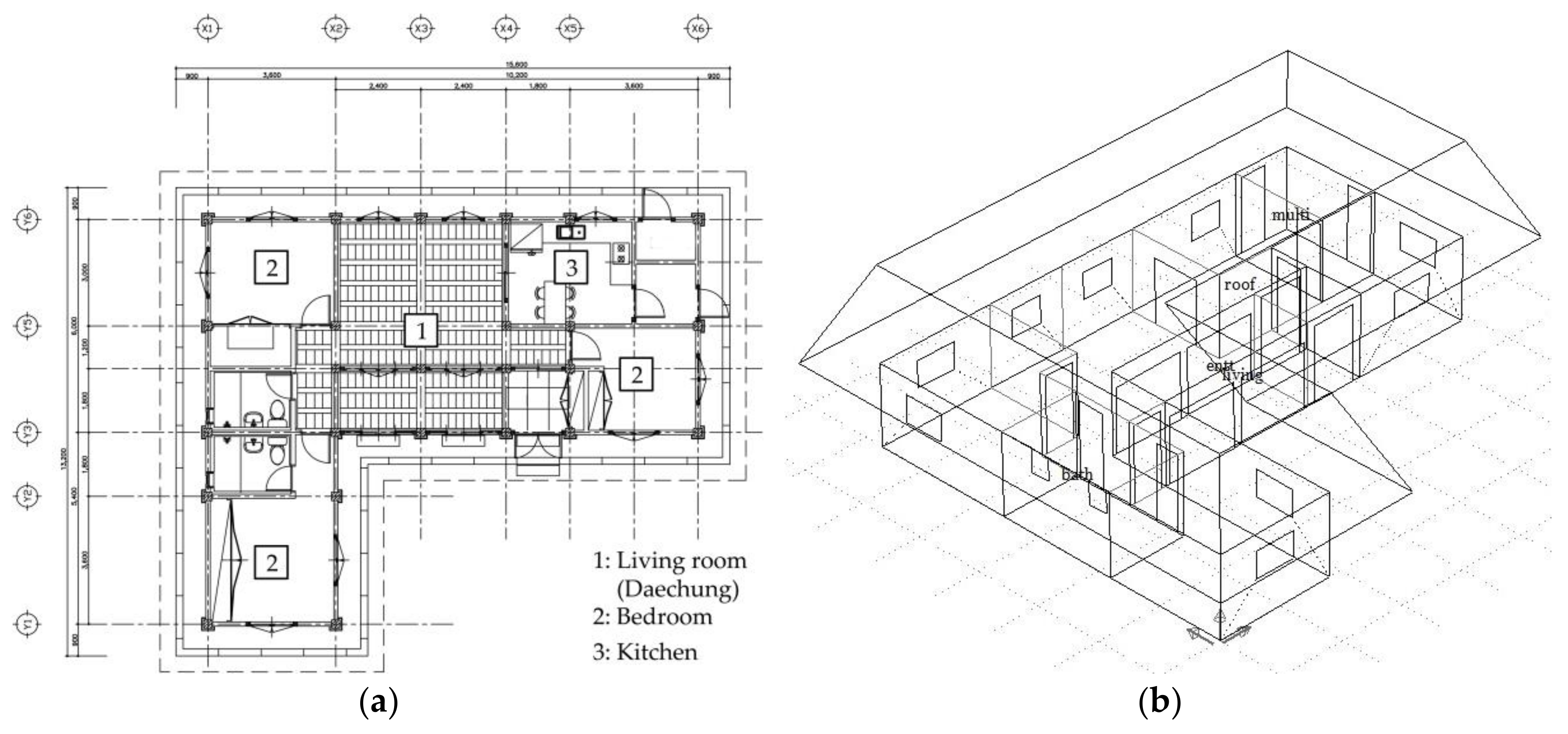

2.1. New-Hanok Drawing

2.2. Esp-r Computer Simulation and Setting

2.3. Material Properties

2.4. PCM (Phase Change Material)

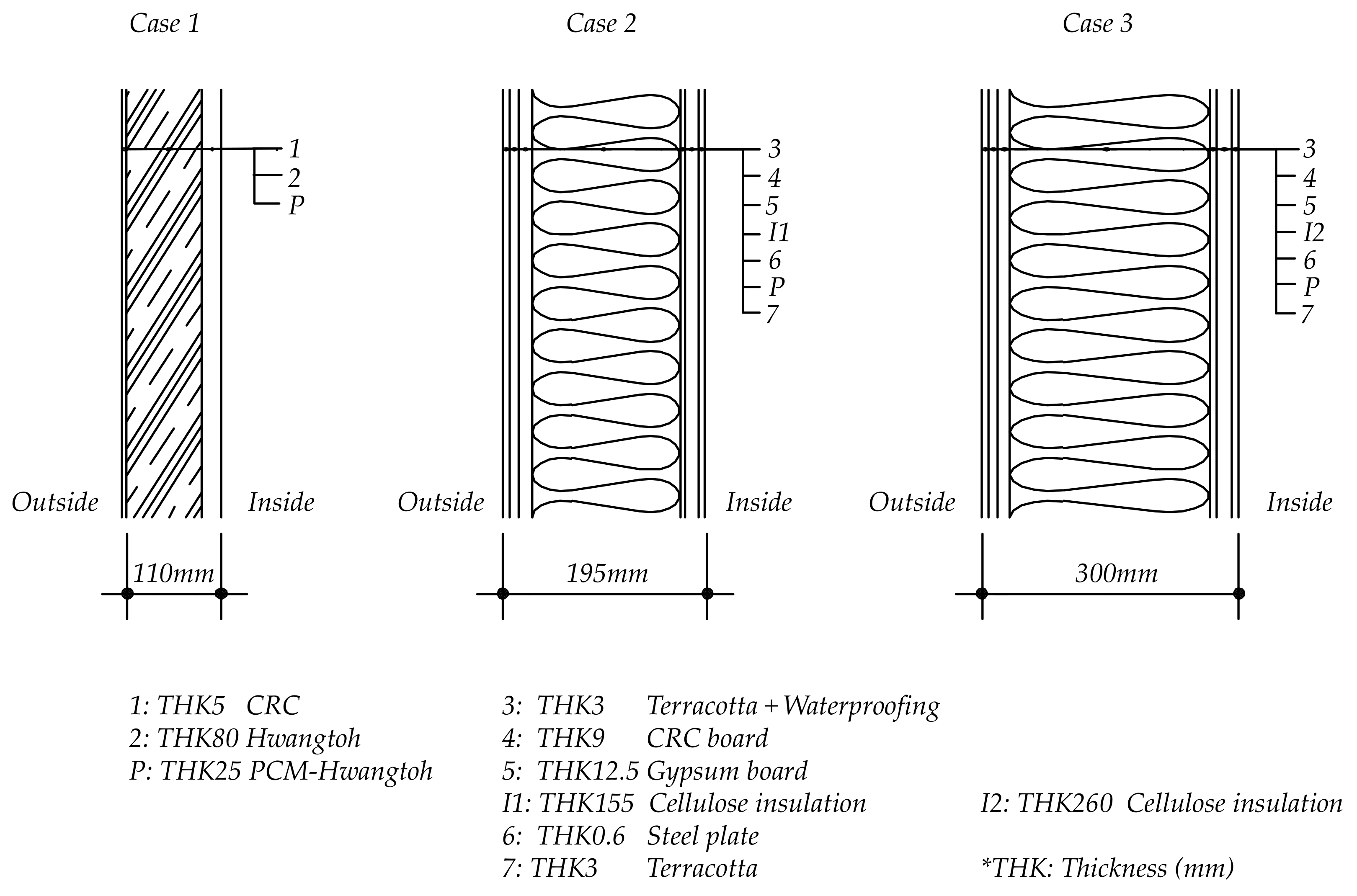

2.5. Wall Composite with PCM

2.6. PMV (Predicted Mean Vote)

3. Results and Discussion

3.1. Energy Performance According to the Insulation Material and Infiltration Level Change

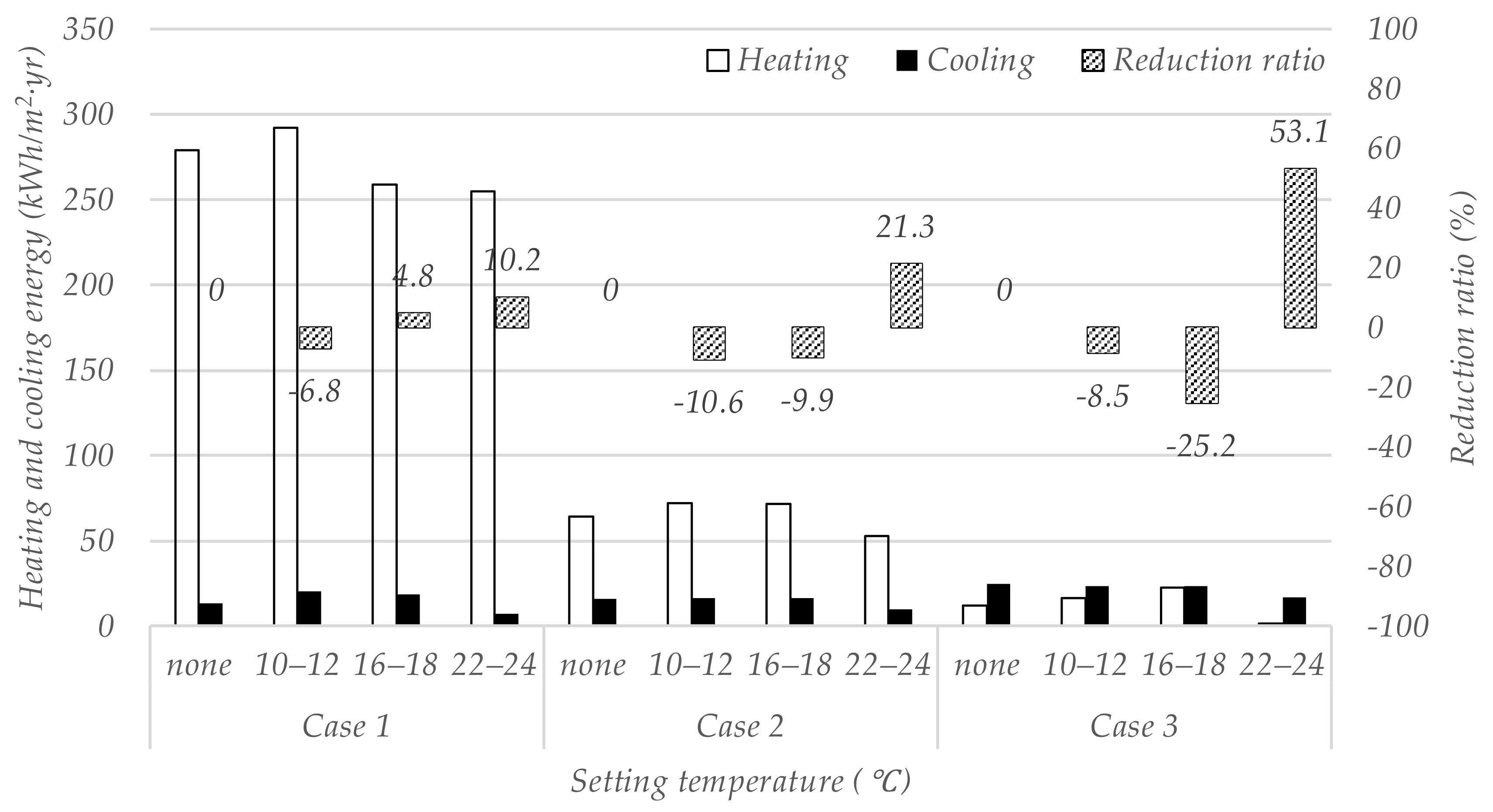

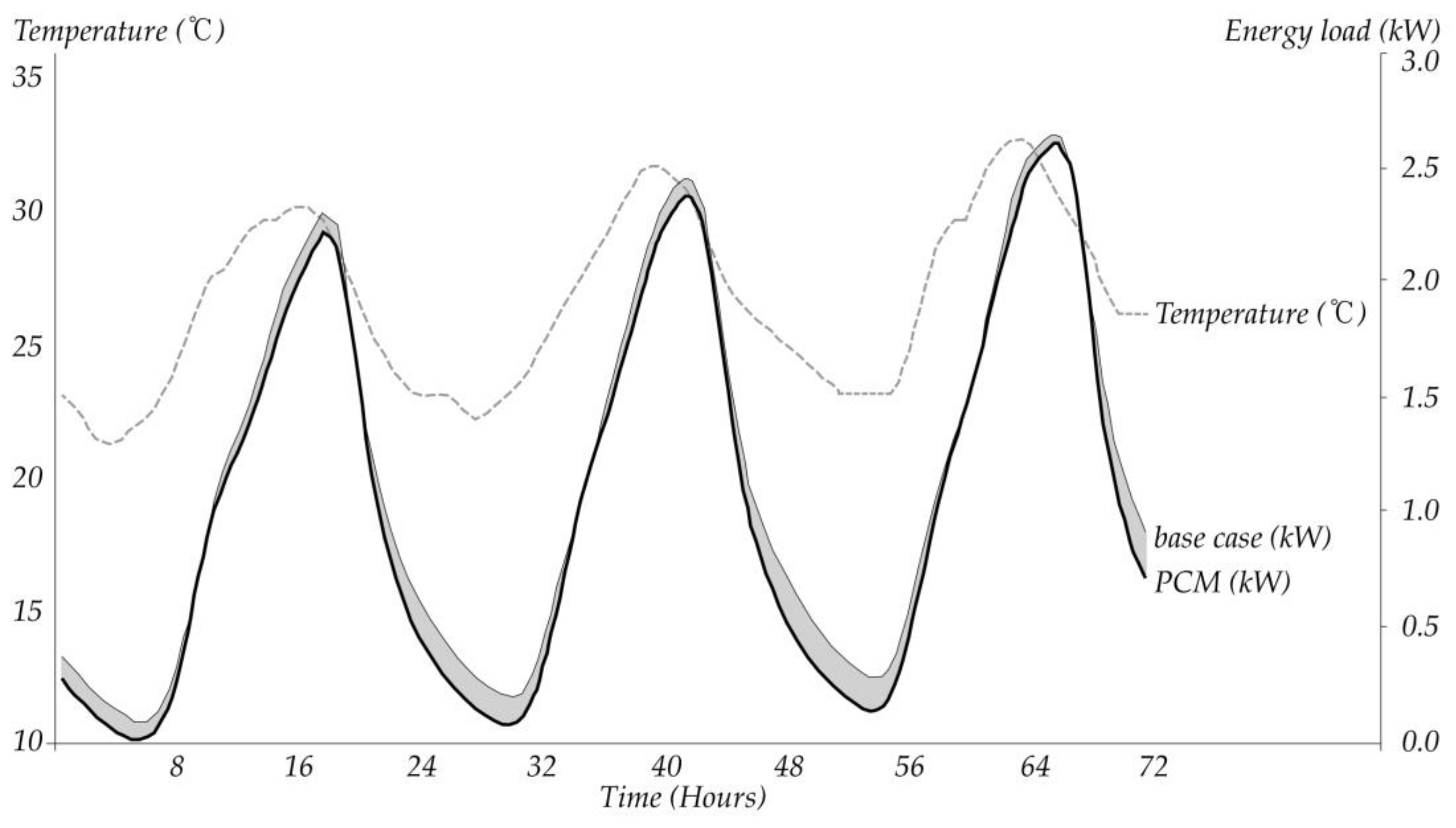

3.2. Energy Performance Based on the Variation of the PCM-Hwangtoh Composite

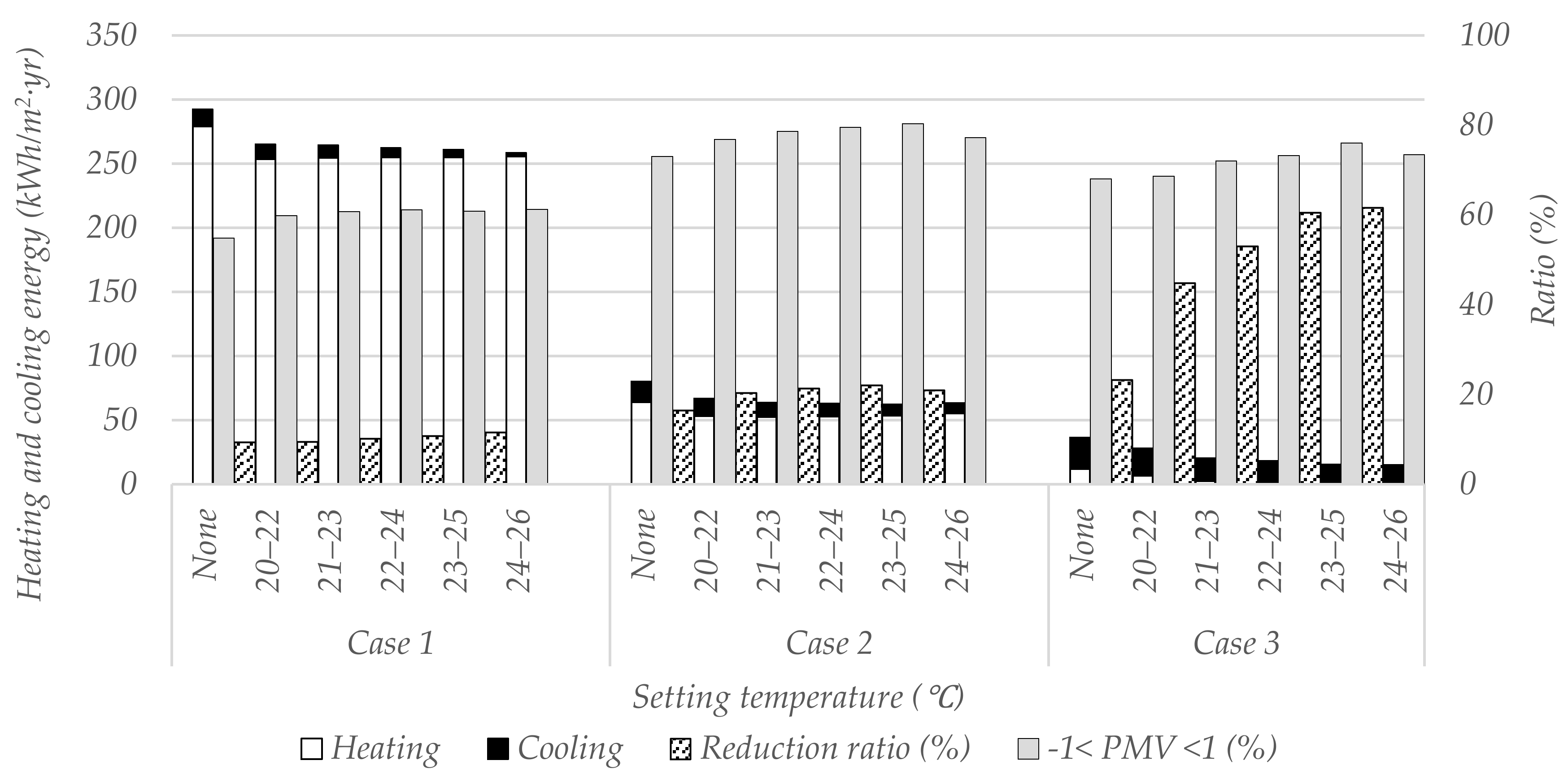

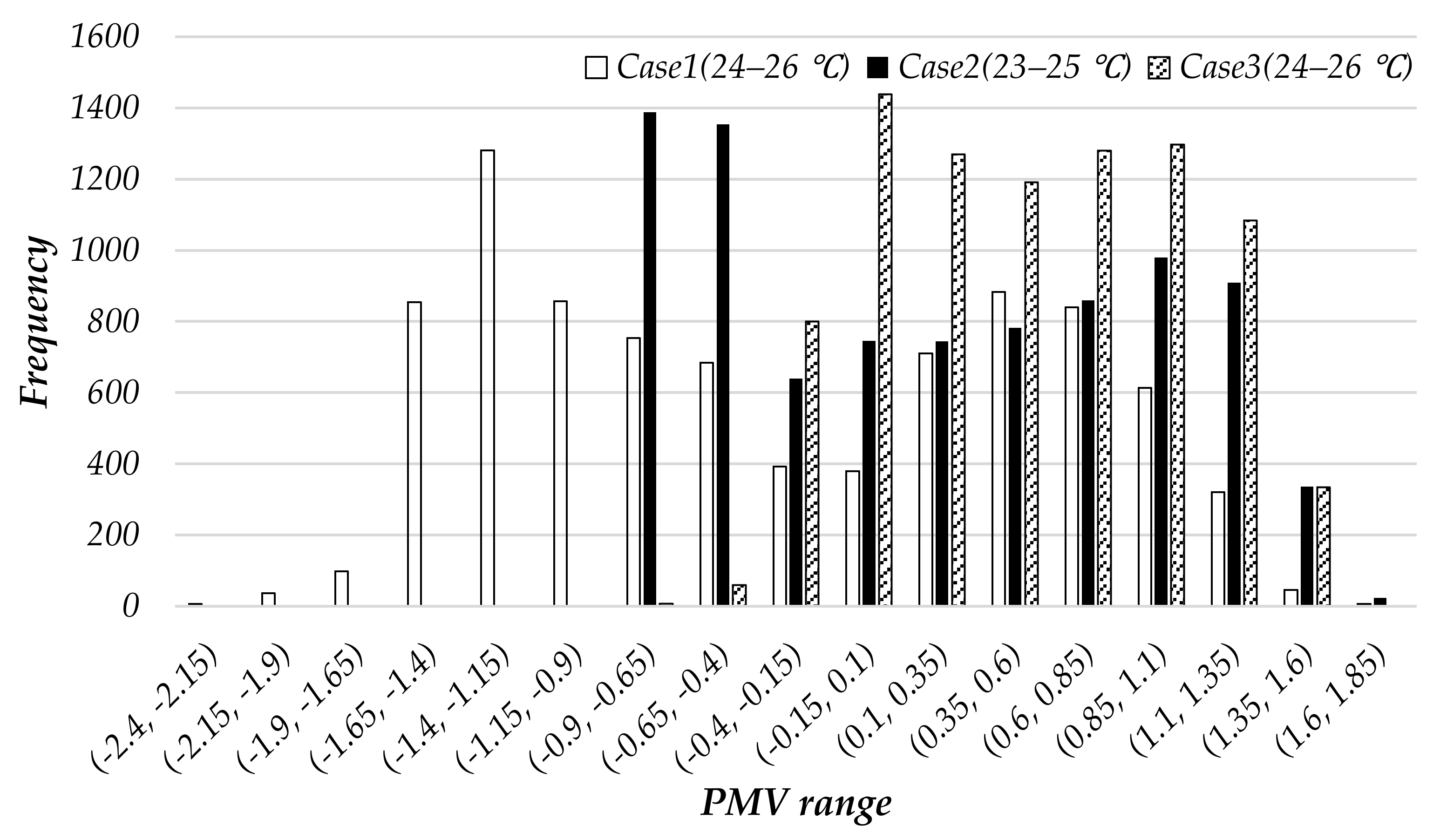

3.3. Thermal Performance with PMV Analysis Based on the Variation of the PCM-Hwangtoh Composite

4. Conclusions

- -

- Infiltration revealed a significant effect on the energy consumed. In particular, Hanok, which is constructed by mixing various materials, has considerably low infiltration, so it is important to strengthen it.

- -

- Compared to traditional Hanok materials, strengthening insulation based on passive house regulation for nZEB can reduce the heating and cooling energy by approximately 73%.

- -

- The PCM helps reduce the energy consumption when it approaches the passive house regulation material property. The heating and cooling load reduction ratio compared to the non-PCM application are as follows: Case 1 (old-Hanok), 10.2%; Case 2 (Korean Building Act), 21.3%; and Case 3 (passive house regulation), 53.1%.

- -

- The optimal set point of the PCM for energy saving has a different value depending on the material properties. The optimal phase change temperature of a PCM for a new-Hanok is as follows: Case 1, 24–26 °C; Case 2, 23–25 °C; and Case 3, 24–26 °C.

- -

- In PMV analysis, the use of a PCM can narrow the comfort range and centralize the optimal point, which is 0 point. The results confirm that a PCM has a “flattening” influence inside the zone temperature.

- -

- PMV is affected significantly by the operation schedule and occupant behavior. Dividing the basic types of the occupant schedule can allow the PMV effect to be measured more accurately by applying a PCM.

- -

- Studies of the life cycle cost and life cycle CO2 analysis are the major points for economic analysis. The price of the PCM will need to be in the acceptable range and a long-term heating and cooling load calculation will be needed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- National Hanok Center Official Website. Available online: http://www.hanokdb.kr (accessed on 25 February 2018).

- Image (Myeongjaegotak, Korea). Available online: http://first.designdb.com/imagedata/survey/P/60_6_3_P.jpg (accessed on 25 February 2018).

- Image (Hwagyeongdang, Korea). Available online: http://www.dtoday.co.kr/news/articleView.html?idxno=92052 (accessed on 25 February 2018).

- Kim, D. The Natural Environment Control System of Korean Traditional Architecture: Comparison with Korean Contemporary Architecture. Build. Environ. 2006, 41, 1905–1912. [Google Scholar] [CrossRef]

- Ryu, Y.; Kim, S.; Lee, D. The Influence of Wind Flows on Thermal Comfort in the Daechung of a Traditional Korean House. Build. Environ. 2009, 44, 18–26. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive Building Energy Savings: A Review of Building Envelope Components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Cheung, C.; Fuller, R.; Luther, M. Energy-Efficient Envelope Design for High-Rise Apartments. Energy Build. 2005, 37, 37–48. [Google Scholar] [CrossRef]

- Lee, J.; Jung, H.; Park, J.; Lee, J.; Yoon, Y. Optimization of Building Window System in Asian Regions by Analyzing Solar Heat Gain and Daylighting Elements. Renew. Energy 2013, 50, 522–531. [Google Scholar] [CrossRef]

- Yang, K.; Hwang, H.; Kim, S.; Song, J. Development of a Cementless Mortar Using Hwangtoh Binder. Build. Environ. 2007, 42, 3717–3725. [Google Scholar] [CrossRef]

- Johansen, O. Thermal Conductivity of Soils; Cold Regions Research and Engineering Lab: Hanover, NH, USA, 1977. [Google Scholar]

- Abdou, A.A.; Budaiwi, I.M. Comparison of Thermal Conductivity Measurements of Building Insulation Materials under Various Operating Temperatures. J. Build. Phys. 2005, 29, 171–184. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M. Thermal Energy Storage: Systems and Applications, 2nd ed.; John Wiley & Sons, Inc.: Haboken, NJ, USA, 2010; ISBN 0470747064, 9780470747063. [Google Scholar]

- Paksoy, H.Ö. Thermal Energy Storage for Sustainable Energy Consumption: Fundamentals, Case Studies and Design; Springer: Berlin, Germany, 2007; Volume 234, ISBN 1402052901, 9781402052903. [Google Scholar]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A. Materials Used as PCM in Thermal Energy Storage in Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A Review on Phase Change Material (PCM) for Sustainable Passive Cooling in Building Envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Hassan, A.; Shakeel Laghari, M.; Rashid, Y. Micro-Encapsulated Phase Change Materials: A Review of Encapsulation, Safety and Thermal Characteristics. Sustainability 2016, 8, 1046. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.; Seo, J.; Jeong, S.; Kim, S. Application of PCM Thermal Energy Storage System to Reduce Building Energy Consumption. J. Therm. Anal. Calorim. 2013, 111, 279–288. [Google Scholar] [CrossRef]

- Memon, S.A. Phase Change Materials Integrated in Building Walls: A State of the Art Review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; De Simone, M.; Arcuri, N. Analytical Model for Solidification and Melting in a Finite PCM in Steady Periodic Regime. Int. J. Heat Mass Transfer 2015, 88, 844–861. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Arcuri, N. A Method for Thermal Dimensioning and for Energy Behavior Evaluation of a Building Envelope PCM Layer by Using the Characteristic Days. Energies 2017, 10, 659. [Google Scholar] [CrossRef]

- Memon, S.A.; Cui, H.; Zhang, H.; Xing, F. Utilization of Macro Encapsulated Phase Change Materials for the Development of Thermal Energy Storage and Structural Lightweight Aggregate Concrete. Appl. Energy 2015, 139, 43–55. [Google Scholar] [CrossRef]

- Ye, H.; Long, L.; Zhang, H.; Zou, R. The Performance Evaluation of Shape-Stabilized Phase Change Materials in Building Applications Using Energy Saving Index. Appl. Energy 2014, 113, 1118–1126. [Google Scholar] [CrossRef]

- Sayyar, M.; Weerasiri, R.R.; Soroushian, P.; Lu, J. Experimental and Numerical Study of Shape-Stable Phase-Change Nanocomposite toward Energy-Efficient Building Constructions. Energy Build. 2014, 75, 249–255. [Google Scholar] [CrossRef]

- Isa, M.H.M.; Zhao, X.; Yoshino, H. Preliminary Study of Passive Cooling Strategy Using a Combination of PCM and Copper Foam to Increase Thermal Heat Storage in Building Facade. Sustainability 2010, 2, 2365–2381. [Google Scholar] [CrossRef]

- Hasan, A.; Al-Sallal, K.A.; Alnoman, H.; Rashid, Y.; Abdelbaqi, S. Effect of Phase Change Materials (PCMs) Integrated into a Concrete Block on Heat Gain Prevention in a Hot Climate. Sustainability 2016, 8, 1009. [Google Scholar] [CrossRef]

- Kośny, J.; Biswas, K.; Miller, W.; Kriner, S. Field Thermal Performance of Naturally Ventilated Solar Roof with PCM Heat Sink. Sol. Energy 2012, 86, 2504–2514. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical Analysis on Thermal Performance of Roof Contained PCM of a Single Residential Building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Grynning, S.; Goia, F.; Rognvik, E.; Time, B. Possibilities for Characterization of a PCM Window System Using Large Scale Measurements. Int. J. Sustain. Built Environ. 2013, 2, 56–64. [Google Scholar] [CrossRef]

- Koláček, M.; Charvátová, H.; Sehnálek, S. Experimental and Numerical Research of the Thermal Properties of a PCM Window Panel. Sustainability 2017, 9, 1222. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y.; Lin, K.; Di, H.; Yang, R. Modeling and Simulation on the Thermal Performance of Shape-Stabilized Phase Change Material Floor Used in Passive Solar Buildings. Energy Build. 2005, 37, 1084–1091. [Google Scholar] [CrossRef]

- Royon, L.; Karim, L.; Bontemps, A. Optimization of PCM Embedded in a Floor Panel Developed for Thermal Management of the Lightweight Envelope of Buildings. Energy Build. 2014, 82, 385–390. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM; Springer: Berlin, Germany, 2008; ISBN 3540685561, 9783540685562. [Google Scholar]

- Kenisarin, M.; Mahkamov, K. Solar Energy Storage Using Phase Change Materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Tyagi, V.; Pandey, A.; Kaushik, S.; Tyagi, S. Thermal Performance Evaluation of a Solar Air Heater with and without Thermal Energy Storage. J. Therm. Anal. Calorim. 2012, 107, 1345–1352. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J.; Johannes, K. In-Situ Study of Thermal Comfort Enhancement in a Renovated Building Equipped with Phase Change Material Wallboard. Renew. Energy 2011, 36, 1458–1462. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L.; Sicurella, F. A methodology for Investigating the Effectiveness of PCM Wallboards for Summer Thermal Comfort in Buildings. Build. Environ. 2013, 59, 517–527. [Google Scholar] [CrossRef]

- Roberti, F.; Oberegger, U.F.; Gasparella, A. Calibrating Historic Building Energy Models to Hourly Indoor Air and Surface Temperatures: Methodology and Case study. Energy Build. 2015, 108, 236–243. [Google Scholar] [CrossRef]

- Mazzarella, L. Energy Retrofit of Historic and Existing Buildings. The Legislative and Regulatory Point of View. Energy Build. 2015, 95, 23–31. [Google Scholar] [CrossRef]

- Ventolà, L.; Vendrell, M.; Giraldez, P. Newly-Designed Traditional Lime Mortar with a Phase Change Material as an Additive. Constr. Build. Mater. 2013, 47, 1210–1216. [Google Scholar] [CrossRef]

- Lee, J.; Park, J. Application of PCM-Hwangtoh Composites for Thermal Comfort in Newly Proposed Korean Traditional House. In Proceedings of the IAPS International Network Symposium, Daegu, Korea, 10–14 October 2011. [Google Scholar]

- Kim, M.; Kim, Y.; Lee, Y.; Jung, Y. Comparative Analysis of Construction Productivity for Modernized Korean Housing (Hanok). Korean J. Covstr. Eng. Manag. 2013, 14, 107–114. [Google Scholar] [CrossRef]

- Clarke, J.A. Energy Simulation in Building Design, 2nd ed.; Routledge: Oxford, UK, 2001; ISBN 0750650826, 9780750650823. [Google Scholar]

- Strachan, P.; Kokogiannakis, G.; Macdonald, I. History and Development of Validation with the ESP-r Simulation Program. Build. Environ. 2008, 43, 601–609. [Google Scholar] [CrossRef] [Green Version]

- Heim, D.; Clarke, J.A. Numerical Modelling and Thermal Simulation of PCM–Gypsum Composites with ESP-r. Energy Build. 2004, 36, 795–805. [Google Scholar] [CrossRef]

- Kośny, J. PCM-EnhancedBuilding Components: An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer: Berlin, Germany, 2015; ISBN 3319142852, 9783319142852. [Google Scholar]

- Yoon, K.; Yun, G.; Jeon, J.; Kim, K.S. Evaluation of Hourly Solar Radiation on Inclined Surfaces at Seoul by Photographical Method. Sol. Energy 2014, 100, 203–216. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc (ASHRAE). ASHARE Standard 90.2-2007: Energy-Efficient Design of Low-Rise Residential Buildings. 2007. Available online: https://ashrae.iwrapper.com/ViewOnline/Standard_90.2-2007 (accessed on 25 February 2018).

- Selkowitz, S.; Hitchcock, R.; Mitchell, R.; McClintock, M.; Settlemyre, K. Comfen—Early Design Tool for Commercial Facades and Fenestration Systems; Building Technologies Department, Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2014. Available online: https://windows.lbl.gov/sites/default/files/comfen-software-tool.pdf (accessed on 25 February 2018).

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J. Energyplus: Creating a New-Generation Building Energy Simulation Program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J.; Park, H. A Study on the Conservative Building Improvements for Indoor Thermal Environment in a Traditional House of Genjaegotaek. J. Korean Inst. Archit. 2004, 20, 251–258. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE). ASHARE Standard 55–2004: Thermal Environmental Conditions for Human Occupancy; ASHRAE: Atlanta, GA, USA, 2004. [Google Scholar]

- Sherman, M. The Use of Blower-Door Data. Indoor Air 1995, 5, 215–224. [Google Scholar] [CrossRef]

- Feist, W.; Pfluger, R.; Kaufmann, B.; Schnieders, J.; Kah, O. Passive House Planning Package 2007; Passive House Institute: Darmstadt, Germany, 2007; Available online: http://www.passivhaus.org.uk/filelibrary/Contents_Manual.pdf (accessed on 25 February 2018).

- International Standard Organisation (ISO). ISO 13790: 2008 Energy Performance of Buildings–Calculation of Energy Use for Space Heating and Cooling. 2008. Available online: https://www.iso.org/standard/41974.html (accessed on 25 February 2018).

- Chen, C.; Guo, H.; Liu, Y.; Yue, H.; Wang, C. A New Kind of Phase Change Material (PCM) for Energy-Storing Wallboard. Energy Build. 2008, 40, 882–890. [Google Scholar] [CrossRef]

- Ockendon, J.R.; Hodgkins, W. Moving Boundary Problems in Heat Flow and Diffusion, 1st ed.; Oxford Univeristy Press: Oxford, England, 1975; ISBN 0198533454, 9780198533450. [Google Scholar]

- Zalba, B.; Marın, J.M.; Cabeza, L.F.; Mehling, H. Review on Thermal Energy Storage with Phase Change: Materials, Heat Transfer Analysis and Applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A Review on Energy Conservation in Building Applications with Thermal Storage by Latent Heat Using Phase Change Materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM Thermal Storage in Buildings: A State of Art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Mehling, H.; Hiebler, S.; Ziegler, F. Heat Transfer Enhancement in Water When Used as PCM in Thermal Energy Storage. Appl. Therm. Eng. 2002, 22, 1141–1151. [Google Scholar] [CrossRef]

- Hawes, D.; Feldman, D.; Banu, D. Latent Heat Storage in Building Materials. Energy Build. 1993, 20, 77–86. [Google Scholar] [CrossRef]

- Abhat, A. Low Temperature Latent Heat Thermal Energy Storage: Heat Storage Materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort. Analysis and Applications in Environmental Engineering; The McGraw-Hill Companies, Inc.: New York, NY, USA, 1972; ISBN 0070199159, 9780070199156. [Google Scholar]

- Yang, K.; Su, C. An Approach to Building Energy Savings Using the PMV Index. Build. Environ. 1997, 32, 25–30. [Google Scholar] [CrossRef]

- Hwang, R.-L.; Shu, S.-Y. Building Envelope Regulations on Thermal Comfort in Glass Facade Buildings and Energy-Saving Potential for PMV-Based Comfort Control. Build. Environ. 2011, 46, 824–834. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, Z.; Fang, J.; Cao, S.-J. Impact of Ventilation Rates on Indoor Thermal Comfort and Energy Efficiency of Ground-Source Heat Pump System. Sustain. Cities Soc. 2018, 37, 154–163. [Google Scholar] [CrossRef]

- Yeo, M.; Yang, I.; Kim, K. Historical Changes and Recent Energy Saving Potential of Residential Heating in Korea. Energy Build. 2003, 35, 715–727. [Google Scholar] [CrossRef]

- Hasan, M.H.; Alsaleem, F.; Rafaie, M. Sensitivity Study for the PMV Thermal Comfort Model and the Use of Wearable Devices Biometric Data for Metabolic Rate Estimation. Build. Environ. 2016, 110, 173–183. [Google Scholar] [CrossRef]

- Ioannou, A.; Itard, L. In-Situ and Real Time Measurements of Thermal Comfort and Its Determinants in Thirty Residential Dwellings in the Netherlands. Energy Build. 2017, 139, 487–505. [Google Scholar] [CrossRef]

- De Dear, R.J.; Brager, G.S. Thermal Comfort in Naturally Ventilated Buildings: Revisions to ASHRAE Standard 55. Energy Build. 2002, 34, 549–561. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Economic Impact of Integrating PCM as Passive System in Buildings Using Fanger Comfort Model. Energy Build. 2016, 112, 159–172. [Google Scholar] [CrossRef]

| Types | ACH (50 Pa) | ACH | |

|---|---|---|---|

| Passive House Planning Package (PHPP) | 0.6 | 0.038 | |

| ASHRAE | A | 1 | 0.064 |

| B | 2 | 0.128 | |

| C | 3 | 0.192 | |

| D | 5 | 0.321 | |

| old-Hanok | - | - | |

| Types | Wall | Roof | Floor | Window |

|---|---|---|---|---|

| Old-Hanok (Case 1) | 3.270 | 0.788 | 0.590 | 5.879 |

| Korean Building Act (Case 2) | 0.210 | 0.150 | 0.180 | 1.200 |

| Passive house guideline (Case 3) | 0.150 | 0.150 | 0.150 | 0.800 |

| Names | Type | Tm (°C) | Ts (°C) | Latent Heat of Fusion (kJ/kg) | Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat Capacity (J/kg·K) |

|---|---|---|---|---|---|---|---|

| Tetrabutylammonium bromide [60] | Organic | 10 | 12 | 193 | 0.6 | 1500 | 2000 |

| Propyl palmitate [61] | Organic | 16 | 18 | 186 | 0.6 | 1500 | 2000 |

| Paraffin C13–C24 [62] | Organic | 22 | 24 | 189 | 0.6 | 1500 | 2000 |

| Types | Heating and Cooling Energy | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Case 1 | Heating (kWh) | 6511 | 5328 | 3604 | 2018 | 729 | 106 | 2 | 4 | 68 | 1119 | 3239 | 5794 |

| Cooling (kWh) | 0 | 0 | 0 | 0 | 32 | 157 | 333 | 586 | 198 | 43 | 0 | 0 | |

| PCM (24–26) | Heating (kWh) | 6370 | 5163 | 3247 | 1468 | 380 | 7 | 0 | 0 | 0 | 768 | 2948 | 5783 |

| Cooling (kWh) | 0 | 0 | 0 | 0 | 1 | 6 | 68 | 200 | 4 | 4 | 0 | 0 | |

| Case 2 | Heating (kWh) | 1647 | 1255 | 785 | 402 | 97 | 8 | 0 | 0 | 1 | 189 | 724 | 1459 |

| Cooling (kWh) | 0 | 1 | 26 | 42 | 150 | 234 | 299 | 457 | 257 | 142 | 14 | 0 | |

| PCM (21–23) | Heating (kWh) | 1459 | 1106 | 569 | 177 | 47 | 0 | 0 | 0 | 0 | 51 | 542 | 1328 |

| Cooling (kWh) | 1 | 2 | 10 | 7 | 31 | 100 | 230 | 442 | 89 | 62 | 14 | 0 | |

| Case 3 | Heating (kWh) | 382 | 234 | 115 | 37 | 10 | 0 | 0 | 0 | 0 | 9 | 89 | 336 |

| Cooling (kWh) | 0 | 3 | 65 | 106 | 326 | 384 | 372 | 515 | 423 | 300 | 35 | 0 | |

| PCM (24–26) | Heating (kWh) | 9 | 7 | 7 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 7 | 9 |

| Cooling (kWh) | 2 | 5 | 24 | 18 | 77 | 179 | 263 | 454 | 183 | 156 | 35 | 0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Park, J. Phase Change Material (PCM) Application in a Modernized Korean Traditional House (Hanok). Sustainability 2018, 10, 948. https://doi.org/10.3390/su10040948

Lee J, Park J. Phase Change Material (PCM) Application in a Modernized Korean Traditional House (Hanok). Sustainability. 2018; 10(4):948. https://doi.org/10.3390/su10040948

Chicago/Turabian StyleLee, Jaewook, and Jiyoung Park. 2018. "Phase Change Material (PCM) Application in a Modernized Korean Traditional House (Hanok)" Sustainability 10, no. 4: 948. https://doi.org/10.3390/su10040948