A Sustainable Industry-Environment Model for the Identification of Urban Environmental Risk to Confront Air Pollution in Beijing, China

Abstract

:1. Introduction

2. Methodology

2.1. Two-Stage Stochastic Programming for Risk Control (TSR)

2.2. Dual Stochastic Programming for Risk Control with Laplace’s Criterion Scenario Analysis (DSLS)

2.3. A Dual Stochastic Mixed Fuzzy Risk Analysis Method with Laplace’s Criterion (DSFRL)

3. Application

3.1. Overview of the Study Area

- Step 1:

- Recognition of the regional features of economic development, production scale, pollutant emission and meteorological conditions in Beijing.

- Step 2:

- Construction of a linkage of production-emission to reflect the relationship between production scale/structure and pollutant emission in the study region.

- Step 3:

- Establishment of an emission-permit trading mechanism to reallocate the emission permit from lower to higher value, regulating the regional production layout and emission scale.

- Step 4:

- Identification of various uncertainties and their interactions in an IEST issue in Beijing.

- Step 5:

- Incorporation of two-stage stochastic programming, risk-analysis control method, Laplace scenario and fuzzy credibility programming into a framework to propose a RPEL method to deal with multiple uncertainties in an IEST issue.

- Step 6:

- Formulation of a sustainable industry-environment model for identifying environmental risk under uncertainties and meanwhile calculating optimized results. The model has been calculated by Lingo 12.0, that has the advantage of providing a capacity to deal with unlimited variables and constraints in a friendly way compared to ORS, WinQSB and Matlab. The Lingo 12.0 is an effective tool for policymakers to describe the complex system and interactions among components based on a series of equations and functions.

- Step 7:

- Analysis of obtained results associated with production reduction, adjustment of industrial layout patterns, emission-permit transactions, pollutant mitigation and system benefits under various Laplace criterion cases.

- Step 8:

- Generation of a sustainable industry-environment plan to adjust regional strategies to conform integrity between the regional economy and environment. Complete a plan process.

3.2. Modeling Formulation

- (1)

- Pollutant-mitigation requirement:

- (2)

- Pollutant-mitigation capacity:

- (3)

- Available emission permit for transaction:

- (4)

- Ambient air-quality requirement:

- (5)

- Industrial production scale:

- (6)

- Economic risk based on DSFRL method:

- (7)

- Non-negativity:

3.3. Data Collection

4. Results

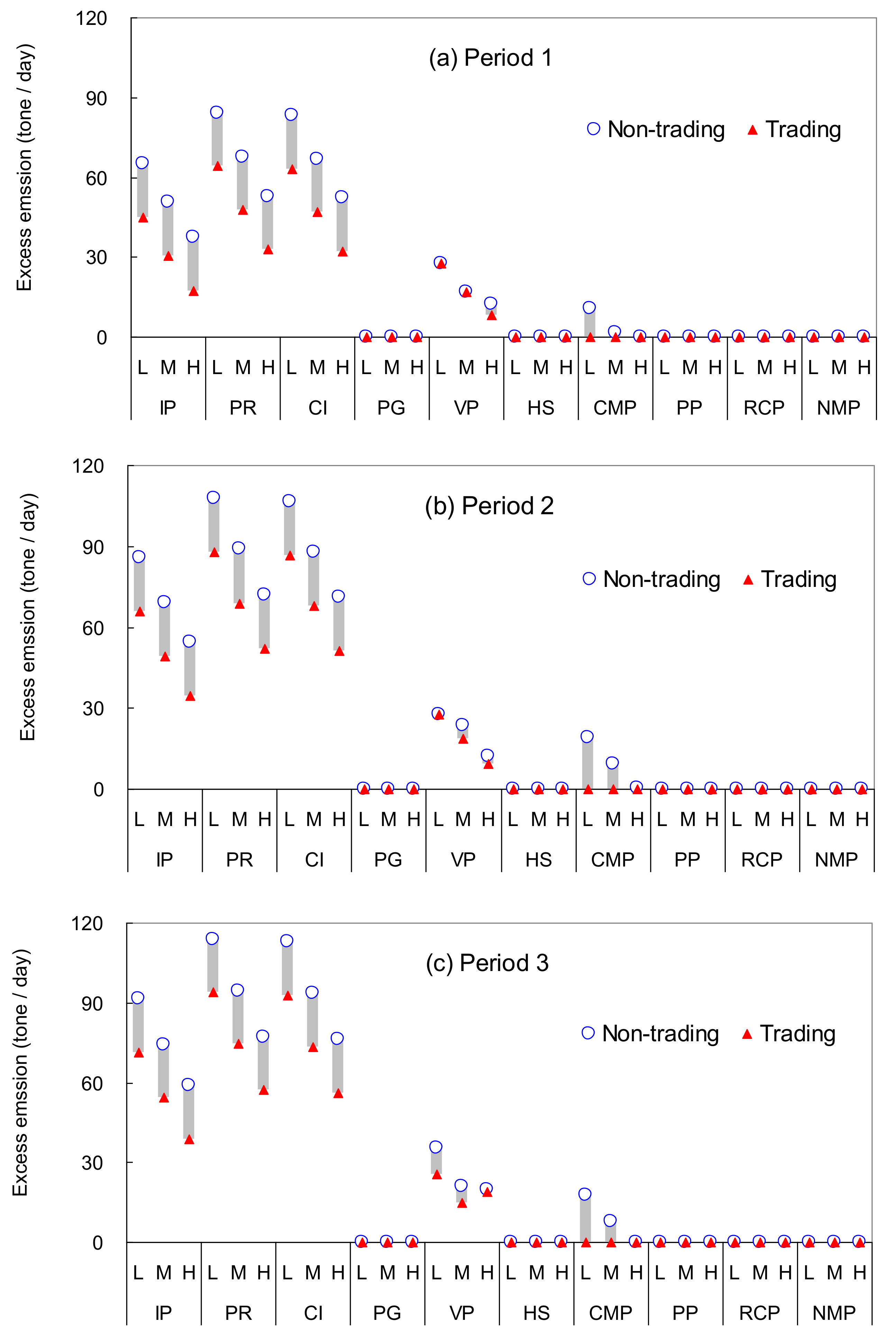

4.1. Emission Quality without Trading Mechanism

4.2. Analysis of Emission-Permit Trading Mechanism

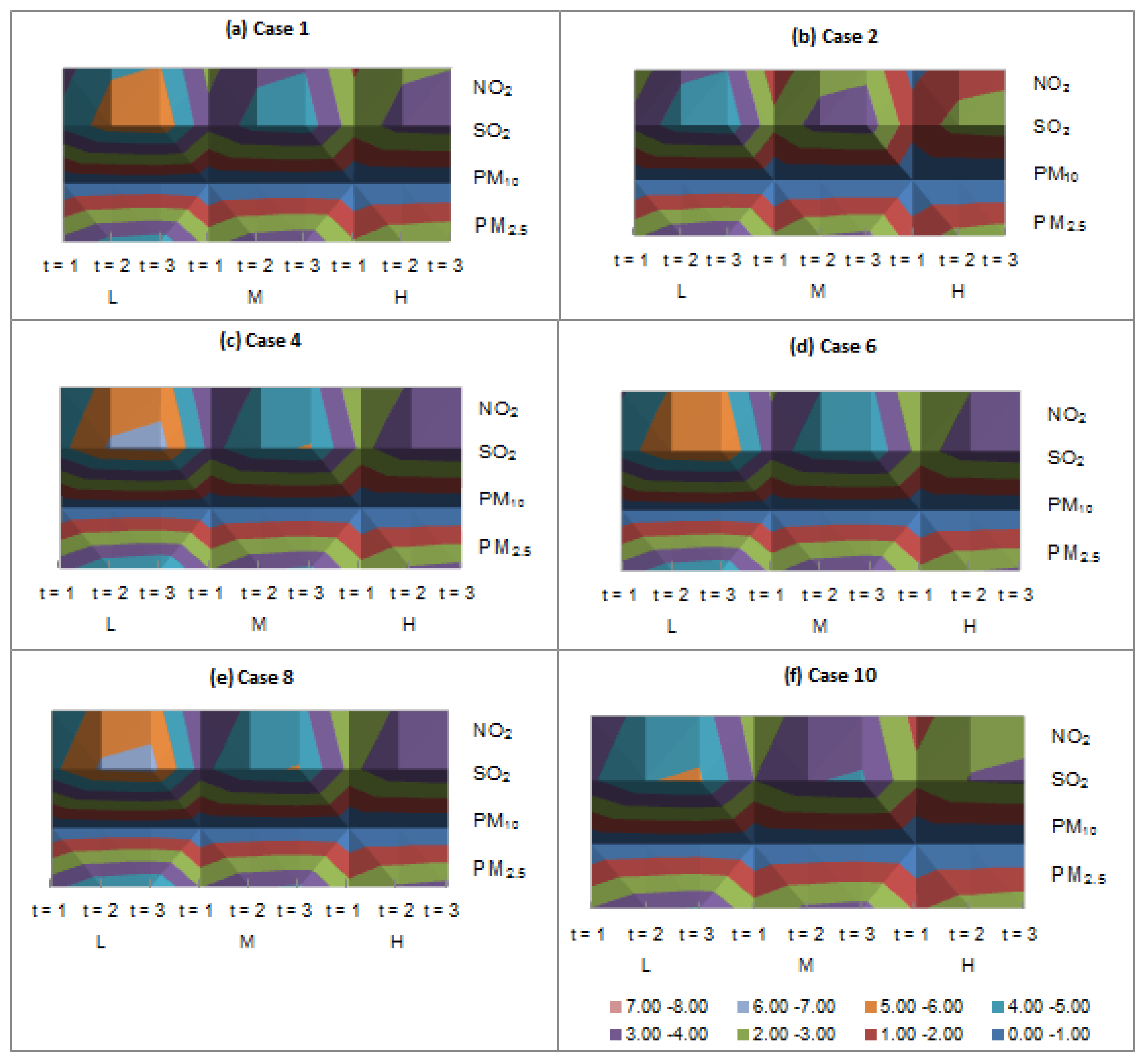

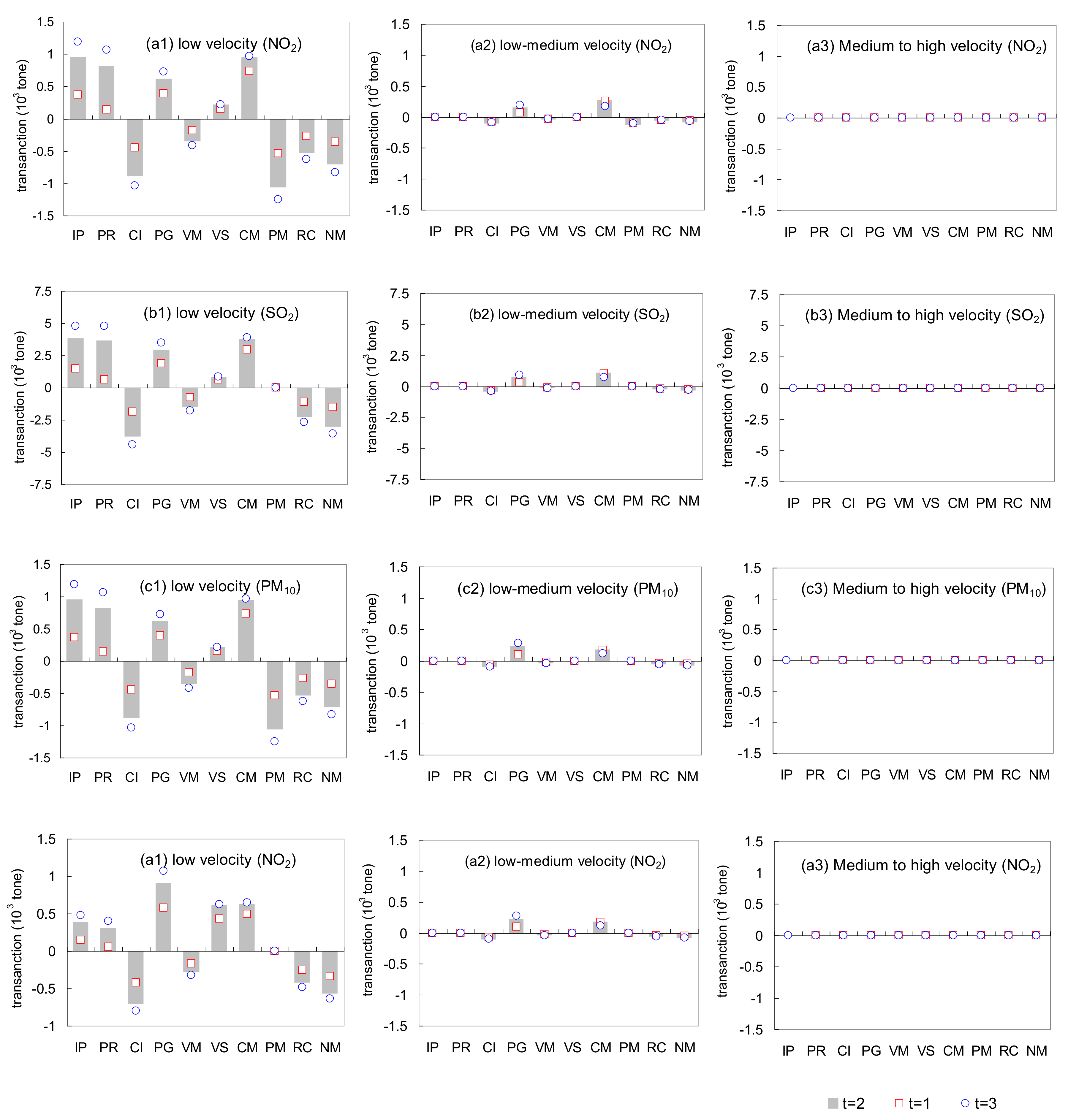

4.2.1. Amount of Pollutant Emission-Permit Transaction

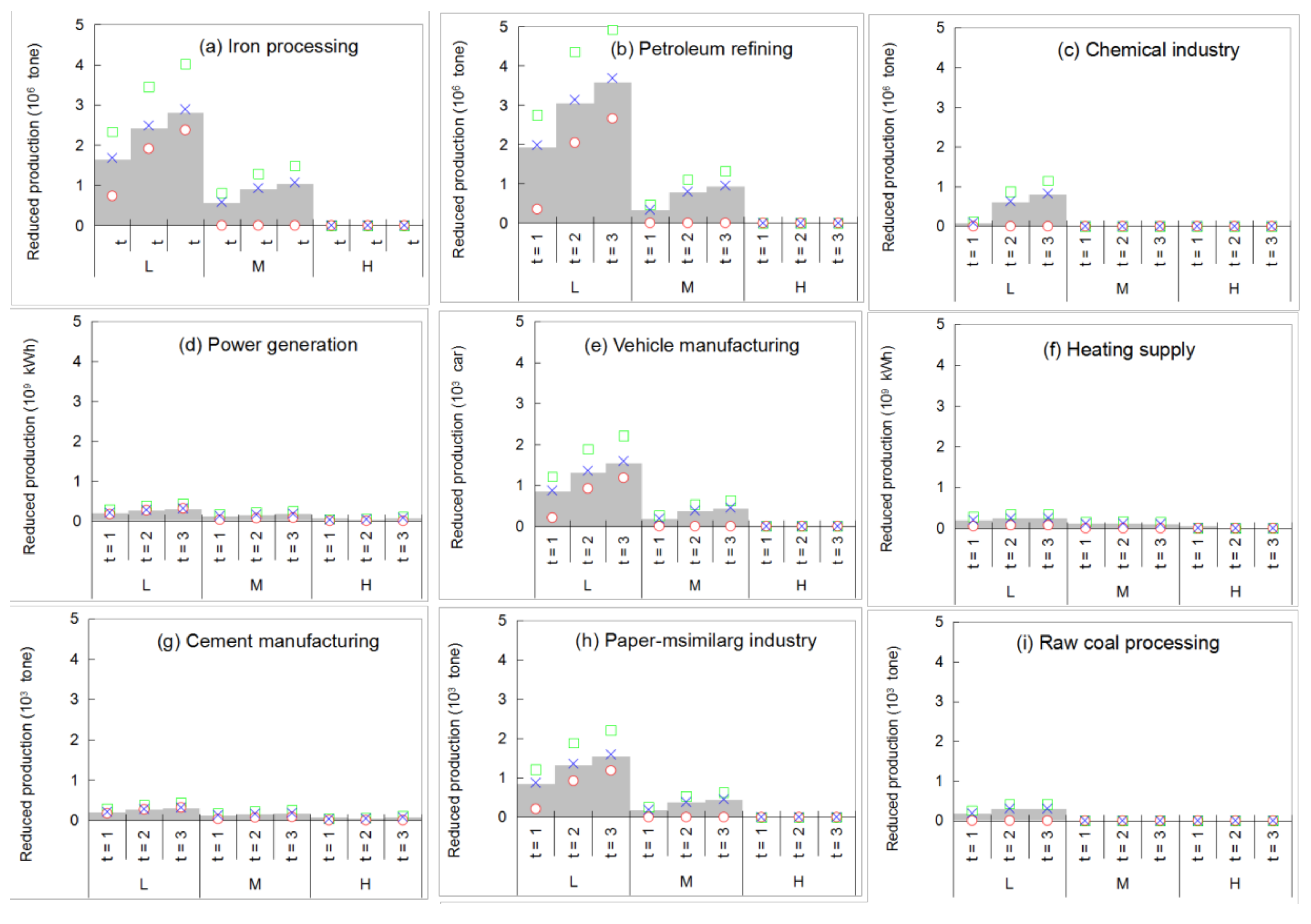

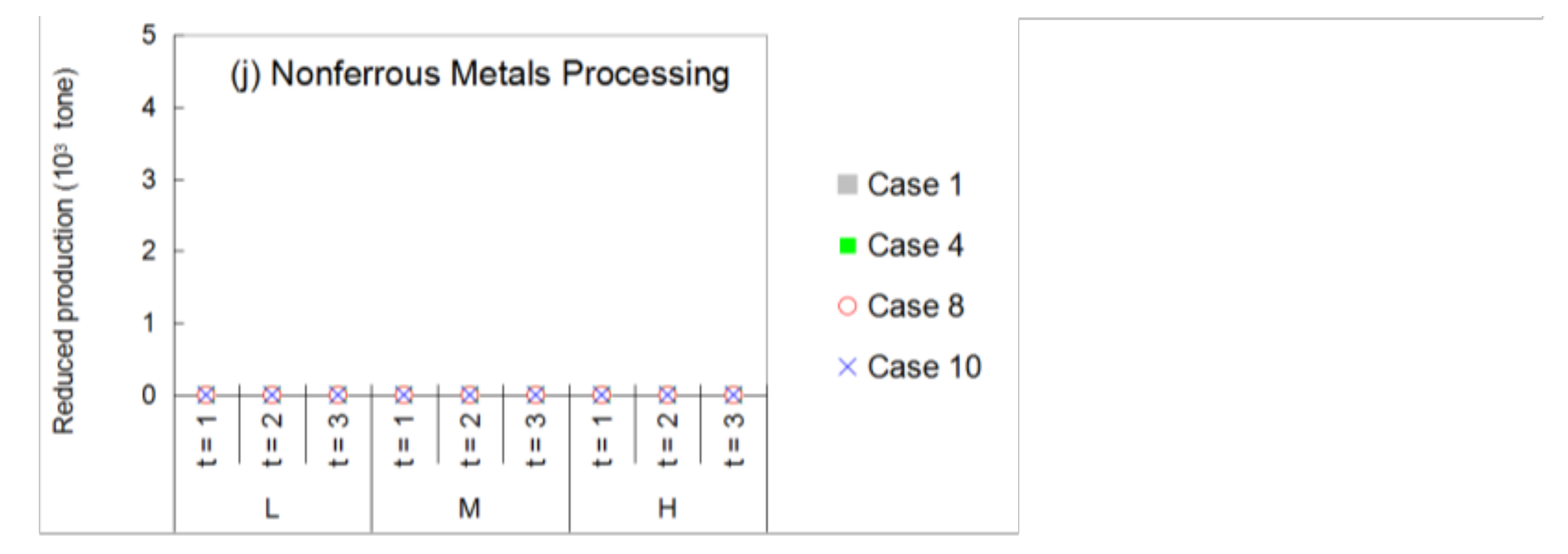

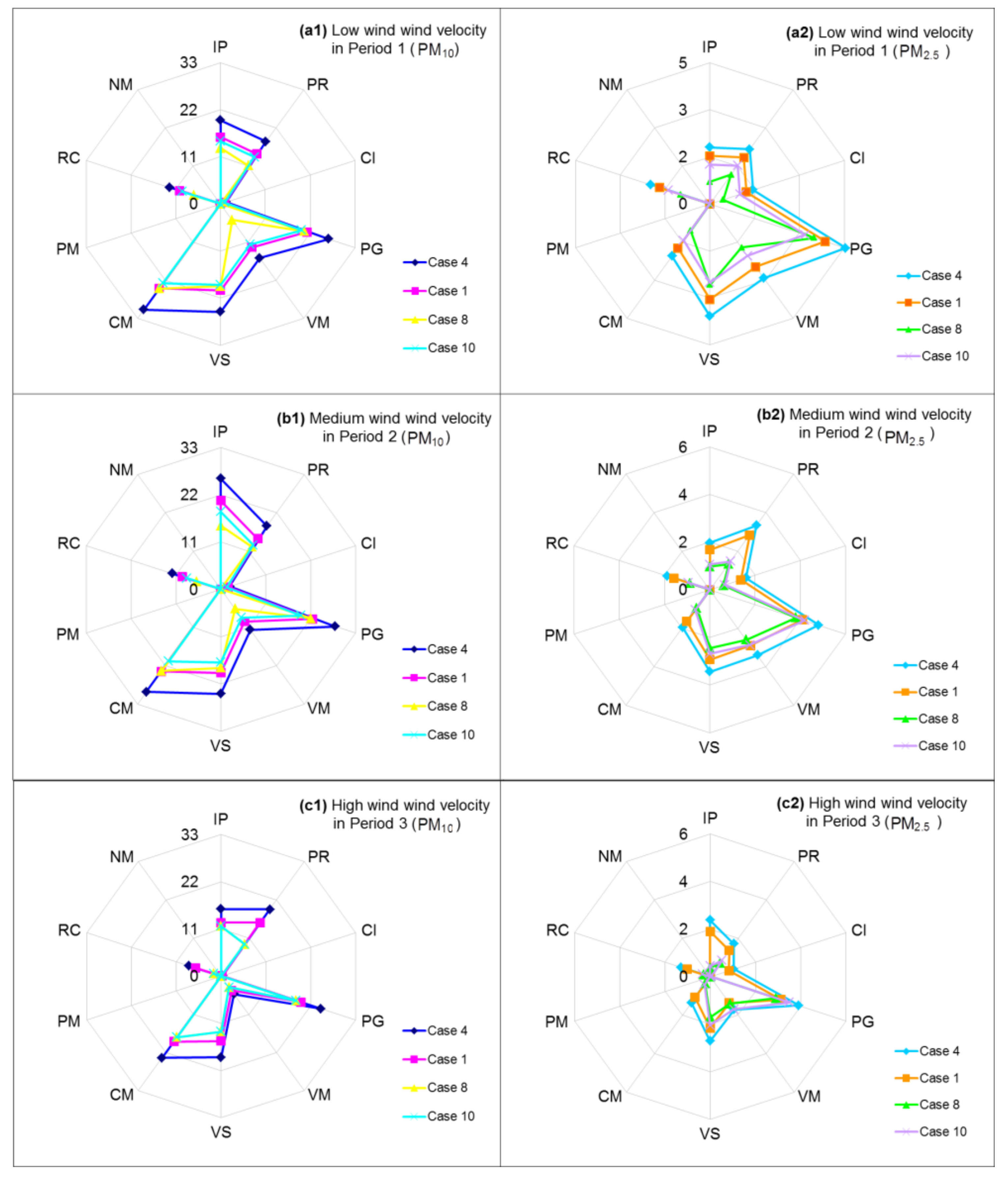

4.2.2. Production Scale Adjustment with Trading Mechanism

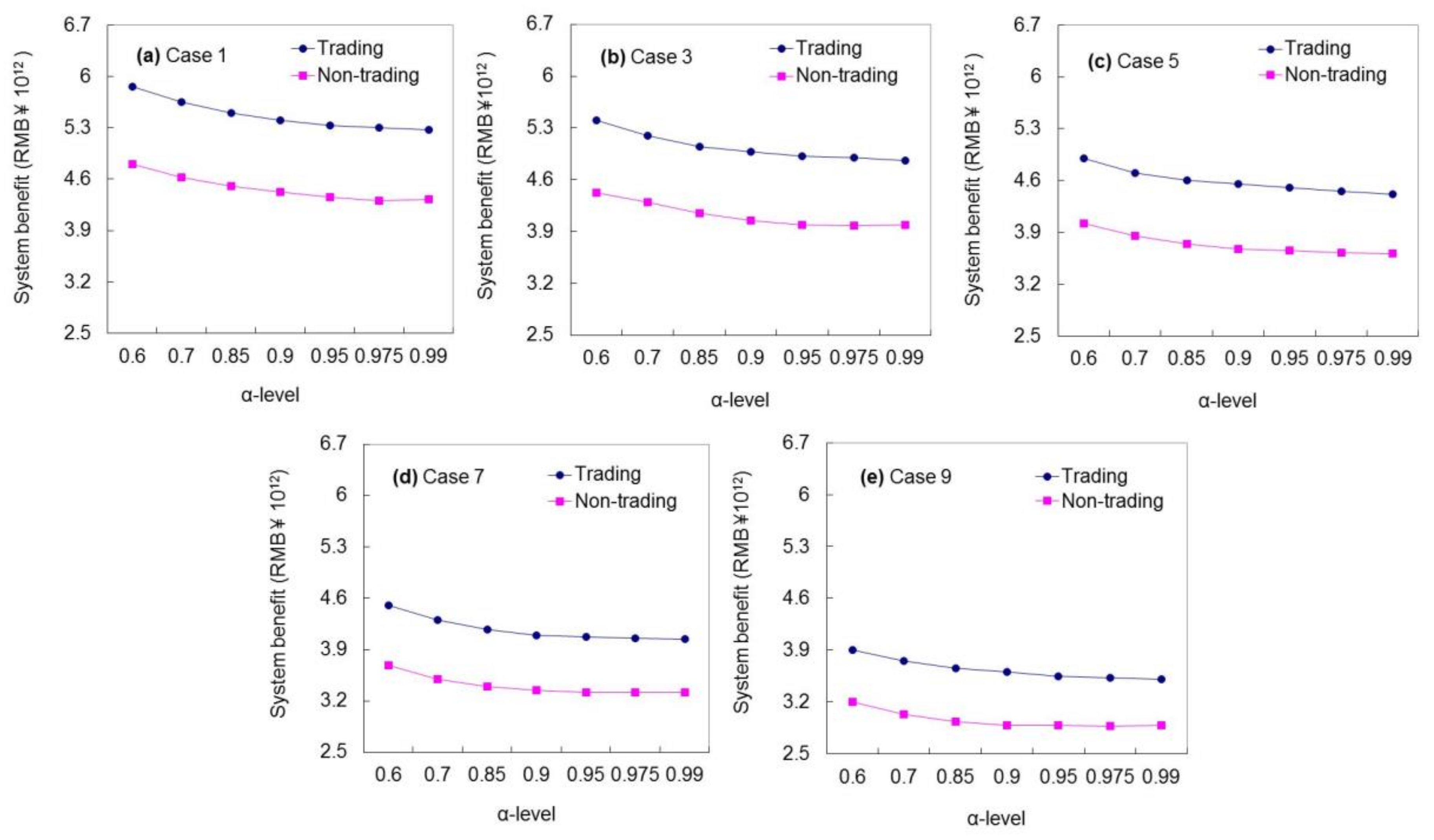

4.3. Risk Analysis

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Subscript | |

| j | Pollutant emission: j = 1 SO2, j = 2 NO2, j = 3 PM10, j = 4 PM2.5 |

| t | Period: t = 1 period 1, t = 2 period 2, t = 3 period 3 |

| h | Wind velocity level: h = 1 Low, h = 2 Medium, h = 3 High |

| m | Heavy consumption/pollution industry: m = 1 Iron processing, m = 2 Petroleum refining, m = 3 Chemical industry, m = 4 Power generation, m = 5 Heating supply |

| n | Medium consumption/pollution industry: n = 1 Paper-msimilarg industry, n = 2 Cement manufacturing, n = 3 Raw coal processing |

| i | Light consumption/pollution industry: i = 1 Vehicle manufacturing, i = 2 Nonferrous metals processing |

| Notation | |

| , , | production target for heavy/medium/light consumption and pollution industrial activity m/n/i in period t (unit) |

| , , | net benefit for heavy/medium/light consumption and pollution industrial activity m per unit production being generated in period t (RMB ¥/unit) |

| , , | the coefficient of pollution generation for heavy/medium/light consumption and pollution industry activity m/n/i per unit of production being generated in period t |

| the changes of coefficient of pollutant retreatment (%) | |

| , , | loss for heavy/medium/light consumption and pollution industry activity m per unit production being reduced in period t (RMB ¥/unit) |

| , , | reduced production for heavy/medium/light consumption and pollution industry activity m/n/i in period t (person) |

| , , | environmental penalty of excessive emission for heavy/medium/light consumption and pollution industry activity m in period t (RMB ¥/unit) |

| the changes of coefficient of industrial productiveness (%) | |

| , , | retreatment cost for heavy/medium/light consumption and pollution industry activity m per unit of production in period t (RMB ¥/unit) |

| , , | emission-permit transaction for heavy/medium/light consumption and pollution industry activity m per unit of production in period t (tone) |

| , , | net benefit from emission-permit transaction for heavy/medium/light consumption and pollution industry activity m per unit of production in period t (RMB ¥/tone) |

| , , | net trading cost from emission-permit transaction for heavy/medium/light consumption and pollution industry activity m per unit of production in period t (RMB ¥/tone) |

| average efficiencies of retreatment for each pollutant emission j in period t | |

| , , , | pollutant-mitigation requirement for heavy/medium/light consumption and pollution industry activity m/n/i in period t in period t (tone/day) |

| the change of pollutant-mitigation requirement (%) | |

| , , , | maximum pollutant-mitigation capacity for heavy/medium/light consumption and pollution industry activity m/n/i in period t in period t (tone/day) |

| , , , | pollutant-emission allowance for heavy/medium/light consumption and pollution industry activity m/n/i in period t in period t |

| , , , | available emission-permit for trading at the four emission types in period t (µg/m3) |

| , , , | allowance pollutant-loading level at the four emission types in period t (µg/m3) |

| , , , | input pollutant level from nearby regions at the four emission types in period t (µg/m3) |

| , , , | output pollutant level to nearby regions at the four emission types in period t (µg/m3) |

| the probability under scenario h | |

| , | minimum/maximum population growth scale in period t (person) |

| , , , , , , | minimum/maximum industrial production scale in period t (tone) |

| s | wind velocity in period t (m/s) |

| H | the height of pollutant emission diffusion (m) |

| , | the coefficient of standard deviations of the plume at and z directions (m) |

References

- Kathleen, B.A.; Raymond, R.T.; Alvin, B.C.; Jose, B.C. Fuzzy input/output model for optimizing eco-industrial supply chains under water footprint constraints. J. Clean. Prod. 2011, 19, 187–196. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, H.; Zhao, T.; Li, T.; Che, H. Modeling study of PM2.5 pollutant transport across cities in China’s Jing-Jin-Ji region during a severe haze episode December 2013. Atmos. Chem. Phys. 2015, 15, 5803–5814. [Google Scholar] [CrossRef]

- Cheng, Z.; Ma, X.; He, Y.; Jiang, J.; Wang, X.; Wang, Y.; Sheng, L.; Hu, J.; Yan, N. Mass extinction efficiency and extinction hygroscopicity of ambient PM2.5 in urban China. Environ. Res. 2017, 156, 239–246. [Google Scholar] [CrossRef] [PubMed]

- Forster, P.M.F.; Shine, K.P.; Stuber, N. It is premature to include non-CO2 effects of aviation in emission trading schemes. Atmos. Environ. 2006, 40, 1117–1121. [Google Scholar] [CrossRef]

- Clemens, B.; Bamford, C.E.; Douglas, T.J. Choosing strategic responses to address emerging environmental regulations: Size, perceived influence and uncertainty. Bus. Strategy Environ. 2008, 17, 493–511. [Google Scholar] [CrossRef]

- Boldo, E.; Linares, C.; Aragonés, N.; Lumbreras, J.; Borge, R.; de la Paz, D.; Pérez-Gómez, B.; Fernández-Navarro, P.; García-Pérez, J.; Pollán, M.; et al. Air quality modeling and mortality impact of fine particles reduction policies in Spain. Environ. Res. 2014, 128, 15–26. [Google Scholar] [CrossRef] [PubMed]

- ApSimon, H.M.; Warren, R.F.; Kayin, S. Addressing uncertainty in environmental modelling: A case study of integrated assessment of strategies to combat long-range transboundary air pollution. Atmos. Environ. 2002, 36, 5417–5426. [Google Scholar] [CrossRef]

- Scellato, S.; Fortuna, L.; Frasca, M.; Gómez-Gardeñes, J.; Latora, V. Traffic optimization in transport networks based on local routing. Eur. Phys. J. B 2010, 73, 303–308. [Google Scholar] [CrossRef]

- Haar, L.N.; Haar, L. Policy-making under uncertainty: Commentary upon the European Union Emissions Trading Scheme. Energy Policy 2006, 34, 2615–2629. [Google Scholar] [CrossRef]

- Nahorski, Z.; Horabik, J. Compliance and emission trading rules for asymmetric emission uncertainty estimates. Clim. Chang. 2007, 103, 303–325. [Google Scholar] [CrossRef]

- Chen, W.T.; Li, Y.P.; Huang, G.H.; Chen, X.; Li, Y.F. A two-stage inexact-stochastic programming model for planning carbon dioxide emission trading under uncertainty. Appl. Energy 2010, 87, 1033–1047. [Google Scholar] [CrossRef]

- Caponetto, R.; Fortuna, L.; Graziani, S.; Xibilia, M.G. Genetic algorithms and applications in system engineering: A survey. Trans. Inst. Meas. Control 1993, 15, 143–156. [Google Scholar] [CrossRef]

- Weinhofer, G.; Busch, T. Corporate Strategies for Managing Climate Risks. Bus. Strategy Environ. 2013, 22, 121–144. [Google Scholar] [CrossRef]

- Li, Y.P.; Huang, G.H. Interval-parameter two-stage stochastic nonlinear programming for water resources management under uncertainty. Water Resour. Manag. 2008, 22, 681–698. [Google Scholar] [CrossRef]

- Ahmed, S.; Sahinidis, N.V. Robust process planning under uncertainty. Ind. Eng. Chem. Res. 1998, 37, 1883–1892. [Google Scholar] [CrossRef]

- Barbaro, A.; Bagajewicz, M.J. Managing financial risk in planning under uncertainty. AIChE J. 2004, 50, 963–989. [Google Scholar] [CrossRef]

- Peterson, G.D.; Graeme, S.C.; Stephen, R.C. Scenario Planning: A Tool for Conservation in an Uncertain World. Conserv. Biol. 2003, 17, 358–366. [Google Scholar] [CrossRef]

- Zeng, X.T.; Huang, G. A simulation-based resource-environment management model for regional sustainability in compound wetland ecosystem under uncertainties. Ecol. Model. 2016, 334, 60–77. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.K. Expected value of fuzzy variable and fuzzy expected value models. IEEE Trans. Fuzzy Syst. 2002, 10, 45–50. [Google Scholar] [CrossRef]

- Inuiguchi, M. Robust optimization by fuzzy linear programming in Managing Safety of Heterogeneous Systems. Lect. Notes Econ. Math. Syst. 2012, 658, 219–239. [Google Scholar] [CrossRef]

- Huang, G.H.; Loucks, D.P. An inexact two-stage stochastic programming model for water resources management under uncertainty. Civil Eng. Environ. Syst. 2000, 17, 95–118. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Torabi, S.A.; Razmi, J. Credibility-based fuzzy mathematical programming model for green logistics design under uncertainty. Comp. Ind. Eng. 2012, 62, 624–632. [Google Scholar] [CrossRef]

- Swarta, R.J.; Raskinb, P.; Robinsonc, J. The problem of the future: Sustainability science and scenario analysis. Glob. Environ. Chang. 2004, 14, 137–146. [Google Scholar] [CrossRef]

- Beijing Municipal Bureau of Statistics. Beijing Statistical Yearbook (BSY) 2000; Beijing Municipal Bureau of Statistics: Beijing, China, 2001.

- Beijing Municipal Bureau of Statistics. Beijing Statistical Yearbook (BSY) 2013; Beijing Municipal Bureau of Statistics: Beijing, China, 2014.

- Xu, Y.; Huang, G.H. Development of an improved fuzzy robust chance-constrained programming model for air quality management. Environ. Model. Assess. 2015, 20, 535–548. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection. Ambient Air Quality Standard (GB 3095 2012); Ministry of Environmental Protection: Beijing, China, 2012.

- Beijing Municipal Environmental Protection Bureau. Integrated Emission Standards of Air Pollutants (DB11/501 2017); Beijing Municipal Environmental Protection Bureau: Beijing, China, 2017.

| Industrial Activities | Planning Period | ||

|---|---|---|---|

| t = 1 | t = 2 | t = 3 | |

| Net system benefit for industrial activities | |||

| Iron processing (103 RMB ¥/tonne) | 13.55 | 14.97 | 16.32 |

| Petroleum refining (103 RMB ¥/tonne) | 6.55 | 7.21 | 7.62 |

| Chemical industry (103 RMB ¥/tonne) | 2.06 | 2.82 | 3.07 |

| Power generation (103 RMB ¥/106 kWh) | 0.88 | 0.97 | 1.11 |

| Vehicle manufacturing (103 RMB ¥/car) | 13.72 | 14.21 | 14,84 |

| Heating supply (103 RMB ¥/106 kj) | 0.32 | 0.39 | 0.59 |

| Cement manufacturing (103 RMB ¥/tonne) | 0.38 | 0.43 | 0.51 |

| Paper-making industry (103 RMB ¥/tonne) | 3.23 | 3.57 | 3.81 |

| Raw cow processing (103 RMB ¥/tonne) | 0.45 | 0.58 | 0.69 |

| Non-ferrous metal processing (103 RMB ¥/tonne) | 9.00 | 9.56 | 9.91 |

| Penalty for excess emission of unit production | |||

| Iron processing (103 RMB ¥/tonne) | 15.55 | 16.97 | 18.32 |

| Petroleum refining (103 RMB ¥/tonne) | 7.55 | 8.21 | 8.62 |

| Chemical industry (103 RMB ¥/tonne) | 2.46 | 3.12 | 3.77 |

| Power generation (103 RMB ¥/106 kWh) | 0.98 | 1.27 | 1.81 |

| Vehicle manufacturing (103 RMB ¥/car) | 15.72 | 16.21 | 16,84 |

| Heating supply (103 RMB ¥/106 kj) | 0.42 | 0.49 | 0.69 |

| Cement manufacturing (103 RMB ¥/tonne) | 0.52 | 0.65 | 0.77 |

| Paper-making industry (103 RMB ¥/tonne) | 4.23 | 4.57 | 4.81 |

| Raw cow processing (103 RMB ¥/tonne) | 0.51 | 0.68 | 0.79 |

| Non-ferrous metal processing (103 RMB ¥/tonne) | 9.78 | 10.46 | 9.90 |

| Level of Wind Velocity | Probability (%) | Velocity | ||

|---|---|---|---|---|

| t = 1 | t = 2 | t = 3 | ||

| L | 0.3 | (2.22, 2.46, 2.52) | (2.55, 2.53, 2.62) | (2 63, 2.74, 2.92) |

| M | 0.5 | (2.97, 3.06, 3.19) | (3.26, 3.35, 3.93) | (3.95, 4.19, 4.29) |

| H | 0.2 | (4.22, 4.36, 4.47) | (4.53, 4.62, 4.72) | (4.80, 4.99, 5.13) |

| Abbreviation | Scheme | |

|---|---|---|

| Case1 | Basic scenario | Expected industrial development target equal to current plan. |

| Case 2 | Conservative scenario | Expected industrial development target is 3% lower than the need of economic development to accommodate the environment |

| Case 3 | Expected industrial development target is 5% lower than the need of economic development to accommodate the environment | |

| Case 4 | Expected industrial development target is 8% lower than the need of economic development to accommodate the environment | |

| Case 5 | Expected industrial development target is 10% lower than the need of economic development to accommodate the environment | |

| Case 6 | Progressive scenario | Expected industrial development target is increased by the speed of economic development (3%) absolutely |

| Case 7 | Expected industrial development target is increased by the speed of economic development (5%) absolutely | |

| Case 8 | Expected industrial development target is increased by the speed of economic development (8%) absolutely | |

| Case 9 | Expected industrial development target is increased by the speed of economic development (10%) absolutely | |

| Case 10 | Laplace scenario | Expected industrial development target is calculated according to Laplace criterion. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Zeng, X.; An, C.; Yu, L. A Sustainable Industry-Environment Model for the Identification of Urban Environmental Risk to Confront Air Pollution in Beijing, China. Sustainability 2018, 10, 962. https://doi.org/10.3390/su10040962

Gao G, Zeng X, An C, Yu L. A Sustainable Industry-Environment Model for the Identification of Urban Environmental Risk to Confront Air Pollution in Beijing, China. Sustainability. 2018; 10(4):962. https://doi.org/10.3390/su10040962

Chicago/Turabian StyleGao, Guilin, Xueting Zeng, Chunjiang An, and Lei Yu. 2018. "A Sustainable Industry-Environment Model for the Identification of Urban Environmental Risk to Confront Air Pollution in Beijing, China" Sustainability 10, no. 4: 962. https://doi.org/10.3390/su10040962