1. Introduction

Eco-efficiency is an instrument for sustainability analysis, and indicates an empirical relationship between environmental cost or value and environmental impact in economic activities [

1]. So, eco-efficiency plays an important role in expressing how efficient economic activity is with regards to nature’s goods and services. The concept can be traced back to the 1950s, when the notions of resource utilization coefficients and technical efficiency were first proposed [

2], and to the 1970s, when the concept of environmental efficiency was introduced [

3]. In the 1990s, the notion of eco-efficiency was developed to incorporate both resource efficiency and environmental efficiency, and was defined as the ratio of value added to environmental impact [

4]. Because eco-efficiency plays an increasingly important role in ensuring efficient industrial activities with regard to the use of natural resources, that the concept has received significant attention in the literature is not surprising [

5,

6,

7,

8,

9,

10,

11,

12,

13]. Koskela [

5] argued that eco-efficiency can be seen either as an indicator of environmental performance, or as a business strategy for sustainable development. The World Business Council for Sustainable Development (WBCSD) [

6] described eco-efficiency as “being concerned with creating more value with less impact.” Huppes [

7] held that clarifying the why and what of eco-efficiency was a first step toward providing support in decision-making on sustainability. Brattebø [

9] put forward a framework for eco-efficiency analysis. Ehrenfeld [

10] insisted that eco-efficiency can be a useful tool for strategists and policy makers. Oggioni [

11] provided an eco-efficiency measure for 21 prototypes of cement industries operating in many countries by applying a data envelopment analysis. Ekins [

12] analyzed the objective, drivers, and economic implications of eco-efficiency, while Kuosmanen [

13] discussed some general issues and challenges in the quantification of eco-efficiency.

The industrial system, which is the core of the economic system, has been suggested in recent years by a number of studies on industrial systems’ eco-efficiency as having a mutual relationship with the ecological system [

1,

14,

15,

16,

17]. Zhang [

1] calculated the eco-efficiency of regional industrial systems in China, which was found to be in line with the spatial distribution of economic development in the country. Gumus [

14] used an integrated input–output life cycle assessment and multi-criteria decision-making approach to evaluate the eco-efficiency of 276 manufacturing sectors in the USA. Caneghem [

16] found that, despite the improved eco-efficiency, the industry sector remains one of the main polluters in Flanders. Camarero [

17] analyzed the convergence in the eco-efficiency of a group of 22 OECD (The Organization for Economic Cooperation and Development) countries during 1980–2008. Most existing studies focused on industries [

18,

19] or firms [

20,

21,

22,

23]. Charmondusit [

20] maintained that eco-efficiency was a tool for the analysis of the sustainability of industries. Lahouel [

21] showed that company size, expressed in terms of turnover and number of employees, was inversely related to eco-efficiency scores. Kamande [

22] suggested that there was a potential gain in the profitability of the firm by improving eco-efficiency in resource use. Thant [

23] presented an eco-efficiency assessment of the pulp and paper industry in Myanmar by using some key indicators. Through an EU-funded research project, EcoWater has developed a conceptual framework and methodology for assessing eco-efficiency on the meso level [

24], and the proposed methodological framework has been applied to eight alternative water use systems, revealing their environmental weaknesses and identifying potential opportunities for eco-efficiency improvement [

25]. However, it seems that studies focused on the basin environment still need to be strengthened. The river basin is uniquely composed of closely connected upstream and downstream regions, which gives rises to conflict between industrial and environmental systems.

The Songhua River basin is used to carry out an empirical study in order to provide a scientific basis for the sustainable development of both the industrial and environmental systems in the basin and provide reference to other similar basins. As one of the most important rivers in China, the Songhua River is the foundation and lifeblood for the survival and development of Northeast China. However, environmental pollution from rapid urbanization and industrialization [

26], population agglomeration, and excess production is worsening. The current environmental situation has captured the attention of many international communities after the occurrence of a major water pollution incident in 2005.

Another innovative feature of this study is its method of analysis. Most eco-efficiency studies use data envelopment analysis (DEA)-based models as instruments for aggregating different sources of environmental pressure to encompass eco-efficiency indicators. Applying a DEA model for eco-efficiency analysis highlights different combinations in the modes used to treat undesirable outputs and model choices. However, DEA measurement requires a large number of relatively accurate and reliable data points, and putting forward specific proposals from conclusions based on DEA-based models is arduous. In addition, DEA identifies weights that maximize the efficiency score of the evaluated unit or activity in comparison with a group of similar units or activities. An analysis of the decomposition model approach can solve this problem. The approach can be used to decompose eco-efficiency into the efficiency of different production processes. Moreover, eco-efficiency can be combined with concrete production processes.

In the Western context, numerous theories concerning economic development and environmental change have been developed. Among them, the Environmental Kuznets Curve (EKC) theory has far-reaching influence. The EKC theory can be traced back to the 1940s and hypothesizes a relationship between the relative levels of environmental damage and the values of Gross Domestic Products (GDP) per capita in a country. According to this theory, the environmental impact is an inverse U-shaped curve, in which the environment deteriorates before it improves with economic growth [

27,

28]. However, some researchers noted that the inverted U-shaped relationship did not always exist, and it might be inverted U-shaped [

29] or N-shaped [

30]. Given the differences between China and the West, many of these theories or findings may not be suitable for Chinese contexts. In view of the importance of industrial systems’ eco-efficiency and the insufficient number of studies examining this topic, this paper discusses the topic of industrial systems’ eco-efficiency within the Chinese context. This study aims to measure the eco-efficiency of the Songhua River basin using the decomposition model. It analyzes evolutionary characteristics and impact factors of eco-efficiency. Eco-efficiency can be decomposed into resource efficiency, cleaner production efficiency, and terminal control efficiency to construct a measurement model of eco-efficiency. Using this measurement method, this article answers the following questions: What are the evolutionary pathways of eco-efficiency that cities in the Songhua River basin might follow? Which factors account for the change in eco-efficiency?

Given a policy focused towards reforming and opening up, China’s economy has been developing rapidly and has entered the middle stage of industrialization. However, scale-driven economic development relies heavily on the massive consumption of energy and resources. Furthermore, traditional industries with a high volume of energy consumption and pollution emissions still occupy a dominant position in the economy. Undoubtedly, achieving fundamental change in a short period is difficult. Therefore, the pressure in maintaining a balance between resource utilization and environmental protection will continue to increase. A key problem that needs to be solved is maintaining rapid economic development and reducing its environmental impact, while moving towards sustainable development. As an instrument for sustainability analysis, eco-efficiency establishes an empirical relationship between environmental cost or value and environmental impact in economic activities, and can highlight the pathway towards sustainable development.

4. Factors Determining Industrial Systems’ Eco-Efficiency

The findings above indicate that the eco-efficiency shows a significant difference. The main question, therefore, is what factors lead to the spatial difference. Addressing this question will be crucial to the promotion of industrial ecosystems and the improvement of eco-efficiency.

4.1. Economic Development

The rapid development of the economy contributes to enterprises’ spatial agglomeration and the creation of the scale effect. In addition, economic development can accumulate more funds to improve production processes and construct pollutant disposal facilities. Undoubtedly, economic development is also conducive to the remarkable improvement in people’s living standards. Individuals’ rapid growth of their material and cultural needs will also expand the industrial scale, upgrade industrial technology, and improve environmental quality. The EKC theory assumes that an “inverted U” relationship exists between environmental pollution and per capita income. Consequently, the ratio of pollution-intensive enterprises will first increase and then decrease, thus first leading to environmental pollution increases and then decreases. As the industrial base, the economics of Northeast China’s growth have been hampered because of the gradual depletion of mineral resources. Since the revitalization of Northeast China in 2003, economic development has improved. The GDP growth rates of Heilongjiang province and Jilin province were above 10% in 2002–2013, which was much higher than the national average.

4.2. Government Guidance

Northeast China is abundant in natural resources, which formed the foundation of its development. Moreover, the development of Northeast China has largely been driven by the government. Since the founding of the People’s Republic of China, a large number of state-owned enterprises have emerged to exploit natural resources. Since the reform and opening-up process began, the low efficiency and lack of competition for state-owned enterprises has become more and more apparent in the new market economy. To a certain extent, state-owned enterprises hinder the development of private enterprises. Additionally, social and environmental problems caused by the exploitation of mineral resources under the lead of state-owned enterprises have been highlighted. However, the number of private enterprises gradually declines from the South to the North, whereas the number of state-owned enterprises increases [

86].

4.3. Regional Industrial Structure

The regional industrial structure has a direct impact on industrial pollution. In the middle stage of industrialization, especially during a period in which the heavy chemical industry is highly active, significantly high energy consumption and pollution emission levels are present and cause serious disturbances to the environment. Upgrading the industrial structure, especially the onset of the post-industrialization stage, decreased the proportion of high-polluting industries and caused technology-intensive industries to become dominant—changes that could reduce industrial pollution emissions. The industries dominant in Northeast China are automobiles, energy coal, petrochemical metallurgy, biopharmaceutical machinery, building materials, textiles, and garments. The current heavy industrial structure is deeply rooted, and the average annual growth rate of gross industrial output value in the Jilin province is 21.81%, whereas that of Heilongjiang province is 14.49%. Moreover, Northeast China is in the middle stage of industrialization, which has stimulated the development of heavy industry and increased the vulnerability of the industrial ecosystem.

4.4. Foreign Capital

The pollution haven hypothesis holds that pollution-intensive foreign enterprises tend to establish factories in countries or regions with relatively low environmental standards. Since the reform and opening-up of China, a large number of foreign investments have been concentrated in Northeast China. The average annual growth rate during 2002–2013 of foreign investments in Heilongjiang and Jilin provinces was as high as 15.50% and 19.99%, respectively, much higher than the national average of 7.56%. Another important cause of this phenomenon, in addition to the broad market and preferential policies, is the relatively lax environmental controls. Therefore, total regional pollution emissions will increase due to an increase in foreign investments. However, the introduction of foreign capital also undoubtedly results in technology spillover, which is beneficial to improving regional production processes and reducing the intensity of pollution emissions.

4.5. Human Resources

Technology is indispensable to environmental protection, and improving technology can ameliorate production processes and promote the efficiency of resource utilization. Northeast China’s human resources are high in quantity and rich in quality. However, the development of human resources in this area does not occur in step with the economy. Human resources face problems such as structural limitations and imbalances among different areas. The average annual growth rate for 2002–2013 of R&D expenditures in Heilongjiang and Jilin province was 15.43% and 12.08%, respectively, which lags significantly behind the national average of 22.35%. Other human resources in Northeast China are concentrated in Shenyang, Harbin, and Changchun, and indicate significant differences from other areas.

4.6. Empirical Analysis

To this point, we have theoretically analyzed the impact factors of industrial systems’ eco-efficiency. We now turn to the quantitative analysis. Seven factors were selected: (1) per capita GDP, which represents the economic development level (ED); (2) the ratio of the number of on-the-job workers at state-owned enterprises and at collective enterprises to the total number of on-the-job workers, which represents ownership structure (OS); (3) the ratio of the secondary industry to the tertiary industry, which represents industrial structure (IS); (4) the attainment rate of industrial waste water, which represents environmental management (EM); (5) the ratio of foreign direct investment to GDP, which represents foreign investment (FI); (6) the ratio of financial expenditures to GDP, which represents government regulations (GR); and, (7) the ratio of persons engaged in science and technology activities to the total number of on-the-job workers, which represents science technology (ST). Gai et al. [

87] proposed that industrial structure and economic development have positive effects on eco-efficiency. Guan and Xu [

88] stated that energy resources and population should also be included. Tong et al. [

89] argued that production scale, foreign investments, and environmental management did not play an increasingly important role in the environmental efficiency of the coastal economic belt in Liaoning province. Through principal component analysis (PCA) we have synthesized numerous indexes, eliminated overlapping sample information, and conducted regression analysis.

As shown in

Table 6, ownership structure, government regulations, economic development, and science and technology are key to optimizing the eco-efficiency of the upstream area, as well as the factors of government regulation, economic development, and foreign investments in the midstream and downstream areas. The results show that, on the one hand, the improvement in industrial systems’ eco-efficiency depends on large-scale investments of material capital. On the other hand, the internal driving forces of a “soft factor,” such as science and technology, are obvious and the driving forces become increasingly diversified. Compared with the upstream area, the driving forces in the midstream and downstream areas depend heavily on external investment.

Ownership structure has an inhibitive effect on eco-efficiency (

Table 6), mainly because state-owned enterprises still occupy a dominant position in the economy, and their restructuring and upgrading of the industrial structure have unclear effects. Economic development, environmental management, and government regulations have a positive effect on eco-efficiency. Moreover, economic development and government regulation show a geographical gradient effect, indicating that the eco-efficiency of an industrial system in the upstream area can maintain its advanced status for a certain period.

5. Conclusions

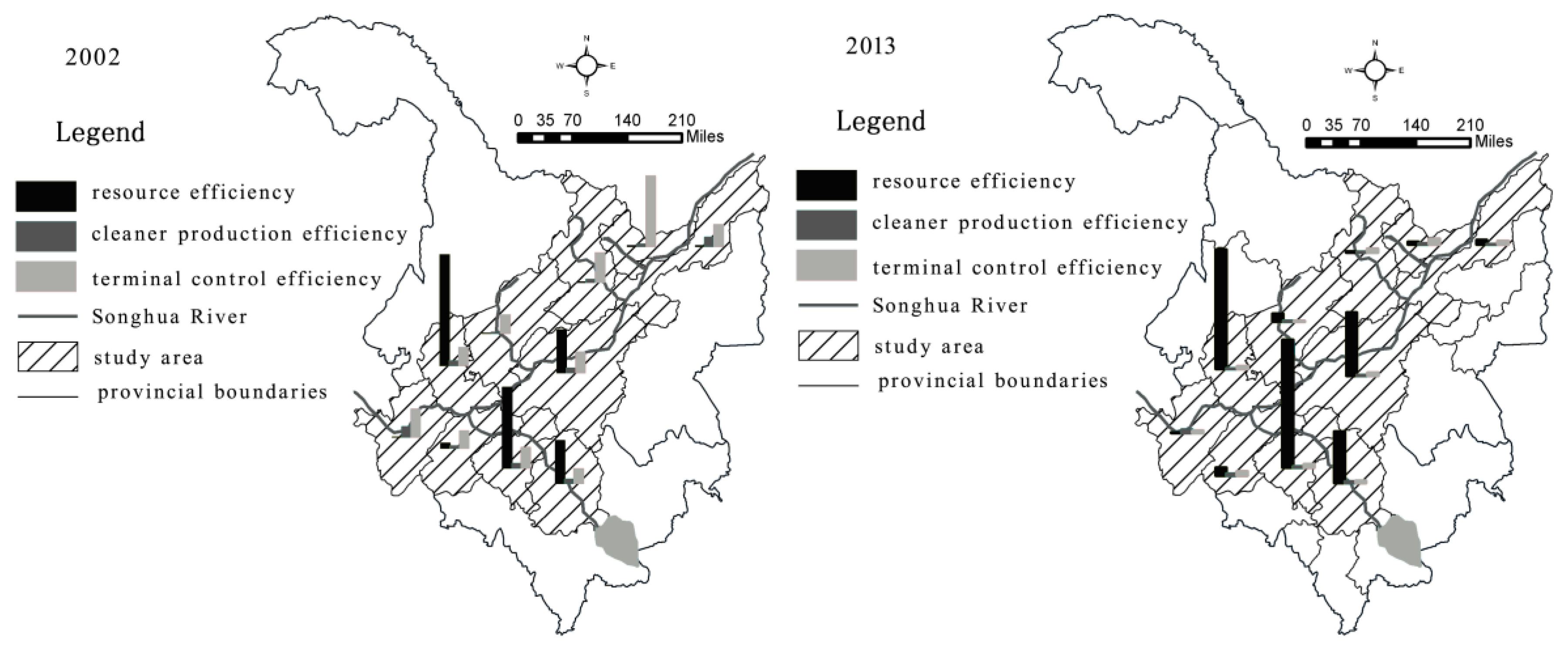

We used the decomposition approach to measure the eco-efficiency that can distinguish the effects of different production processes. In contrast to other methods, the decomposition approach takes into account the pollutant weight calculated using an objective weighting method, such as the entropy method, which could eliminate the subjective element of the valuator. Moreover, the decomposition model can be used to decompose eco-efficiency into different production process efficiencies, including resource efficiency, cleaner production efficiency, and terminal control efficiency, and can determine which specific type of efficiency has the strongest impact on eco-efficiency. The results suggest that the differences in eco-efficiency are notable in the Songhua River basin from 2002 to 2013. We also found that different production efficiencies exhibit different characteristics. Cities in the upstream and the midstream area focus on improving resource efficiency, whereas cities in the downstream area focus on improving terminal control efficiency. Overall, the economic development of the Songhua River basin is represented by low resource input and utilization, and low-pollution emissions. In terms of resource efficiency, the findings indicate that the cities with high resource efficiency are mainly distributed in the upstream and midstream areas, representing significant spatial differences from cities in the downstream area. However, both resource-based cities and comprehensive cities appear to concentrate on improving resource efficiency to achieve the aim of optimizing eco-efficiency. The spatial distribution characteristics of cleaner production efficiency are similar to resource efficiency; however, cleaner production efficiency has on the whole remained at a low level, which indicates that current industrial development is unsustainable and the ecological industrial activities are not yet evident. Unlike resource efficiency and cleaner production efficiency, terminal control efficiency shows a fluctuating and decreasing trend, implying that economic development still depends on material resource consumption, and the pressure of environmental protection is still significant.

Similar to EKC theory, economic development plays a significant role in changes in eco-efficiency, leading to different evolutionary characteristics at different stages of economic development. However, other factors also affect eco-efficiency in a national context, such as ownership structure, industrial structure, environmental management, foreign investment, government regulations, and technological advances. According to an analysis of the factors, the government plays an increasing role in eco-efficiency, and significant differences exist in the relative importance of factors among the upstream, midstream, and downstream areas. For the upstream area, the internal driving forces of a “soft factor,” such as technology, are significant and are becoming increasingly diversified. In contrast, those of the midstream and downstream areas heavily depend on external investments, indicating that the eco-efficiency of an industrial system in the upstream area has been able to maintain its advantages for the studied period.

At present, the shares of sectors with high energy consumption and pollution emissions, such as transportation equipment manufacturing, petrochemicals, pharmaceuticals, building materials, and energy production, still occupy a dominant position in the economy. As the leading sectors in the Songhua River basin, their shares are unlikely to be significantly reduced in a short period. However, the change in the industrial structure has a beneficial effect on eco-efficiency. Hence, coordinated development of an optimized strategy for an industrial and an ecological system should be promoted. To enhance eco-efficiency, it is necessary to increase the proportion of the tertiary industry and reduce that of sectors with high energy consumption and emissions.

In addition, resource utilization and contaminant disposal are the decisive factors regarding industrial systems’ eco-efficiency in the Songhua River basin. It can be concluded that improving resource use efficiency and enhancing the level of pollutant treatment are key problems to be urgently solved. Governments should take steps to guide enterprises to produce more environmentally friendly and high-value-added products. At the same time, it is necessary to develop new industries and enhance industrial concentration through a combination of administrative, legal, and economic means. Upgrading the industrial structure, together with improving eco-efficiency, can contribute to realizing the goal of sustainable economic development.

Research on eco-efficiency has been carried out for many years and a significant amount of relevant literature already exists. However, this study sheds new light on industrial systems’ eco-efficiency. Because of data acquisition limitations, this paper does not examine the eco-efficiency of specific industries and only chooses four representative pollutants to analyze. At the same time, the impact factors of industrial systems’ eco-efficiency are attributed to economic development, ownership structure, industrial structure, environmental management efforts, foreign investment, government regulations, and science technology. However, additional factors directly or indirectly influence the eco-efficiency of the industrial system, such as industry clustering, public awareness, and entrepreneurs’ social responsibility. In the future, we will collect more data and search for new indicators and methods to continue an in-depth study.