Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment

Abstract

:1. Introduction

2. Goal and Scope

3. Materials and Methods

3.1. Residential Building

3.2. Life Cycle Assessment Methodology

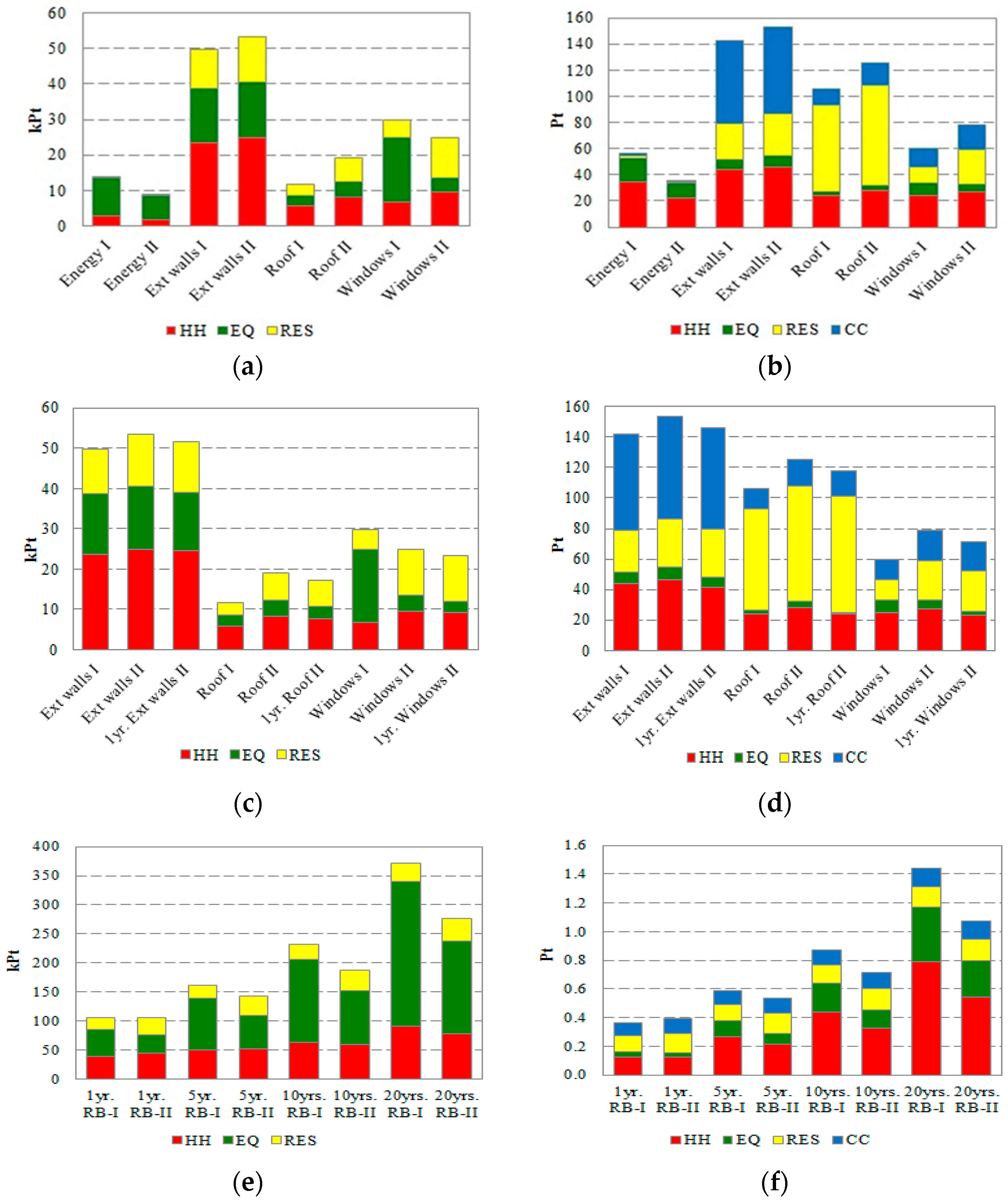

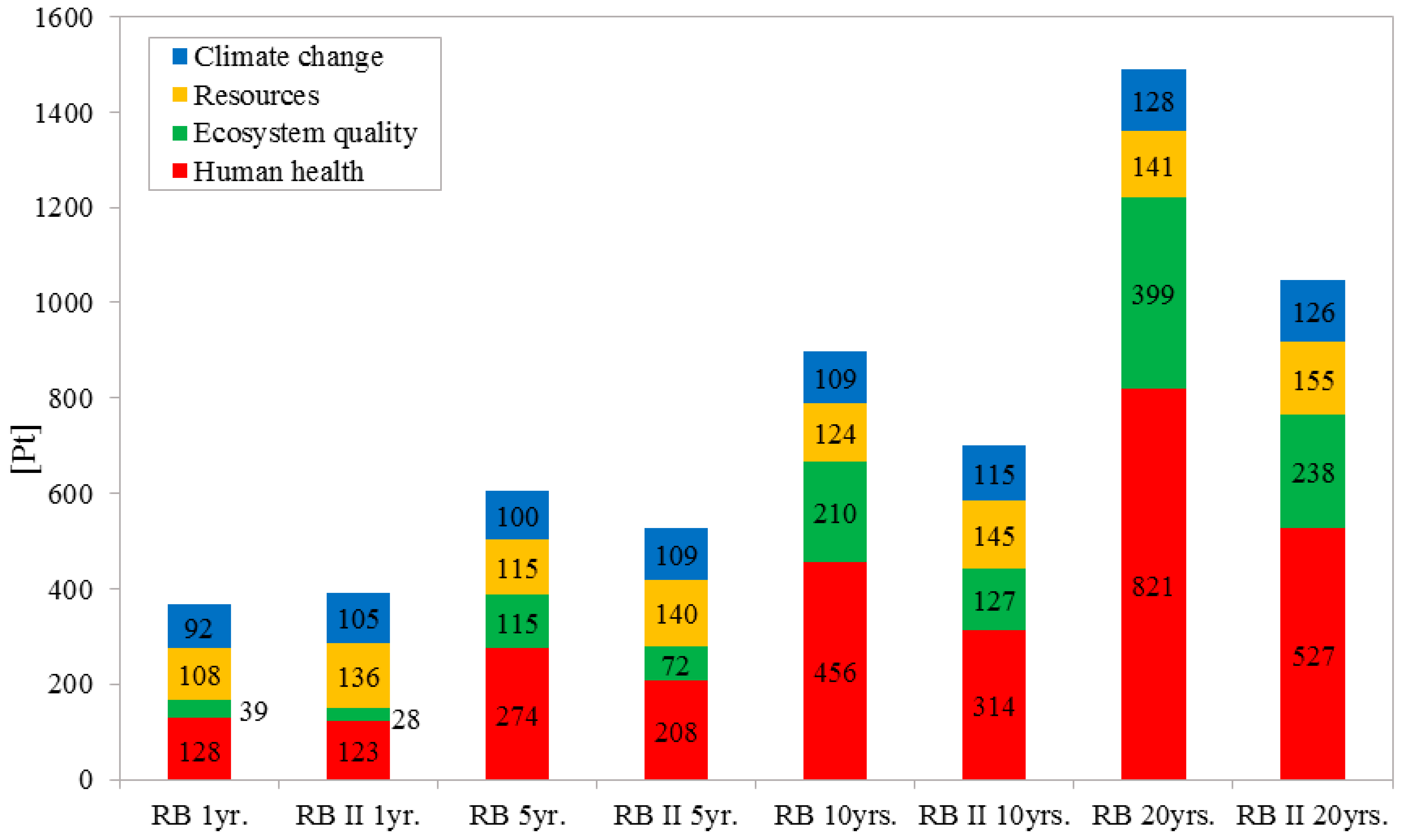

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Agenda 21 on Sustainable Construction. Available online: http://cic.vtt.fi/eco/cibw82/A21text.pdf (assessed on 1 December 2016).

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Materials composition or energy characteristic—What is more important in environmental life cycle of buildings? Build. Environ. 2014, 72, 15–27. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Lee, S.; Tae, S.; Roh, S.; Kim, T. Green Template for Life Cycle Assessment of Buildings Based on Building Information Modeling: Focus on Embodied Environmental Impact. Sustainability 2015, 7, 16498–16512. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Intergovernmental Panel On Climate Change (IPCC). Climate Change 2007: The Physical Science Basis, Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Ondova, M.; Estokova, A. Environmental impact assessment of building foundation in masonry family houses related to the total used building materials. Environ. Prog. Sustain. Energy 2016, 35, 1113–1120. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Guardigli, L.; Monari, F.; Bragadin, M.A. Assessing Environmental Impact of Green Buildings through LCA Methods: Acomparison between Reinforced Concrete and Wood Structures in the European Context. Procedia Eng. 2011, 21, 1199–1206. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on life cycle assessment, life cycle energy assessment and life cycle carbon emissions assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Lewandowska, A.; Noskowiak, A.; Pajchrowski, G. Comparative life cycle assessment of passive and traditional residential buildings’ use with a special focus on energy-related aspects. Energy Build. 2013, 67, 635–646. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Potential of total site process integration for balancing and decreasing the key environmental footprints. Chem. Eng. Trans. 2012, 29, 61–66. [Google Scholar]

- Oregi, X.; Hernandez, P.; Gazulla, C.; Isasa, M. Integrating Simplified and Full Life Cycle Approaches in Decision Making for Building Energy Refurbishment: Benefits and Barriers. Buildings 2015, 5, 354–380. [Google Scholar] [CrossRef]

- Zheng, G.; Jing, Y.; Huang, H.; Zhang, X.; Gao, Y. Application of Life Cycle Assessment (LCA) and extenics theory for building energy conservation assessment. Energy 2009, 34, 1870–1879. [Google Scholar] [CrossRef]

- Nicolae, B.; George-Vlad, B. Life cycle analysis in refurbishment of the buildings as intervention practices in energy saving. Energy Build. 2015, 86, 74–85. [Google Scholar] [CrossRef]

- Bastos, J.; Batterman, S.A.; Freire, F. Life-cycle energy and greenhouse gas analysis of three building types in a residential area in Lisbon. Energy Build. 2014, 69, 344–353. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: http://www.iso.org/iso/catalogue_detail?csnumber=37456 (assessed on 1 December 2016).

- ISO 14044. Environmental Managements—Life Cycle Assessments—Requirements and Guidelines. Available online: http://www.iso.org/iso/catalogue_detail?csnumber=38498 (assessed on 1 December 2016).

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Data Quality Guideline for the Ecoinvent Database Version 3. Available online: http://www.ecoinvent.org/files/dataqualityguideline_ecoinvent_3_20130506.pdf (assessed on 1 December 2016).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; Schryver, A.; De Struijs, J.; van Zelm, R. ReCiPe 2008. Available online: http://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (assessed on 1 December 2016).

- Sleeswijk, A.W.; van Oers, L.F.C.M.; Guinée, J.B.; Struijs, J.; Huijbregts, M.A.J. Normalisation in product life cycle assessment: An LCA of the global and European economic systems in the year 2000. Sci. Total Environ. 2008, 390, 227–240. [Google Scholar] [CrossRef] [PubMed]

- Frischknecht, R.; Editors, N.J.; Althaus, H.; Bauer, C.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Köllner, T.; Loerincik, Y.; et al. Implementation of Life Cycle Impact Assessment Methods. Am. Midl. Nat. 2007, 150, 1–151. [Google Scholar]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Robenbaum, R.K. IMPACT 2002+: A New Life Cycle Impact Assessment Methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Foraboschi, P.; Mercanzin, M.; Trabucco, D. Sustainable structural design of tall buildings based on embodied energy. Energy Build. 2014, 68, 254–269. [Google Scholar] [CrossRef]

- Trabucco, D.; Wood, A. LCA of tall buildings: Still a long way to go. J. Build. Eng. 2016, 7, 379–381. [Google Scholar] [CrossRef]

- Jia Wen, T.; Chin Siong, H.; Noor, Z.Z. Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy Build. 2015, 93, 295–302. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, Turkey. Energy Build. 2015, 102, 417–431. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Estokova, A.; Porhincak, M. Environmental analysis of two building material alternatives in structures with the aim of sustainable construction. Clean Technol. Environ. Policy 2014, 75–83. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Aranda Usón, A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Heinonen, J.; Säynäjoki, A.; Junnonen, J.M.; Pöyry, A.; Junnila, S. Pre-use phase LCA of a multi-story residential building: Can greenhouse gas emissions be used as a more general environmental performance indicator? Build. Environ. 2016, 95, 116–125. [Google Scholar] [CrossRef]

| Building Technology | Prefab Reinforced Concrete Panels |

|---|---|

| Final building approval | 8/1978 |

| Storey/Entrances/Apartments | 5/9/99 |

| Length × width × height | 183.00 m × 12.60 m × 15.00 m |

| Building area | 2305.80 m2 |

| Floor space of apartments | 6777.52 m2 |

| Heated area of apartments | 6362.61 m2 |

| Area of insulation | 7448.00 m2 |

| External walls | 150 mm reinforced concrete panels + 300 mm slag pumice concrete |

| Roof | double skin flat with ventilation air gap |

| Windows | 726.0 m2, double wing |

| External Walls | mm | m2 | m3 | kg |

|---|---|---|---|---|

| Facade silicate plaster | 1.5 | 3596 | 5.4 | 11,328.2 |

| Slag pumice concrete | 300 | 4100 | 1200 | 1,740,000.1 |

| Reinforced concrete panel | 150 | 3925 | 588.8 | 1,236,375.0 |

| Sealant | - | 230 | 23.0 | 34,500.1 |

| External walls, insulation | mm | m2 | m3 | kg |

| Facade silicate plaster | 1.5 | 3503 | 5.3 | 9458.9 |

| Polystyrene | 100 | 3088 | 308.8 | 5558.7 |

| Socle silicate plaster | 1.5 | 327.9 | 0.5 | 885.3 |

| Polystyrene XPS, socle | 50 | 327.9 | 16.4 | 295.1 |

| Base for plaster | 2 | 70.6 | 0.1 | 225.8 |

| Outer core plaster | 10 | 70.6 | 0.7 | 846.7 |

| Window insulation lining | 30 | 415.1 | 12.5 | 224.2 |

| Aluminium socle profile | 328.0 * | - | - | - |

| Aluminium window profile | 2747.0 * | - | - | - |

| Plastic ventilation grille | 198.0 * | - | - | 55.4 |

| Coatings | - | 7.8 | 0 | 53.3 |

| Roof, original construction | mm | m2 | m3 | kg |

| Bitumen layer | 3.5 | 2289 | 8.0 | 9893.3 |

| Asphalt layer | 5.3 | 2289 | 12.1 | 15,527.2 |

| Cement screed | 20 | 2059 | 41.2 | 84,410.8 |

| Gas silicate boards | 150 | 2113 | 316.9 | 174,306 |

| Roof, insulation | mm | m2 | m3 | kg |

| Asphalt layer | 2.7 | 2280 | 6.2 | 8616.6 |

| Asphalt layer | 4.2 | 2747 | 11.5 | 16,149.8 |

| Polystyrene | 60 | 1995 | 119.7 | 3590.2 |

| Windows | W/m2·K | m2 | ks | kg |

| Wooden windows | 1.5 | 725.8 | - | - |

| Plastic window | 1.6 | 725.8 | - | - |

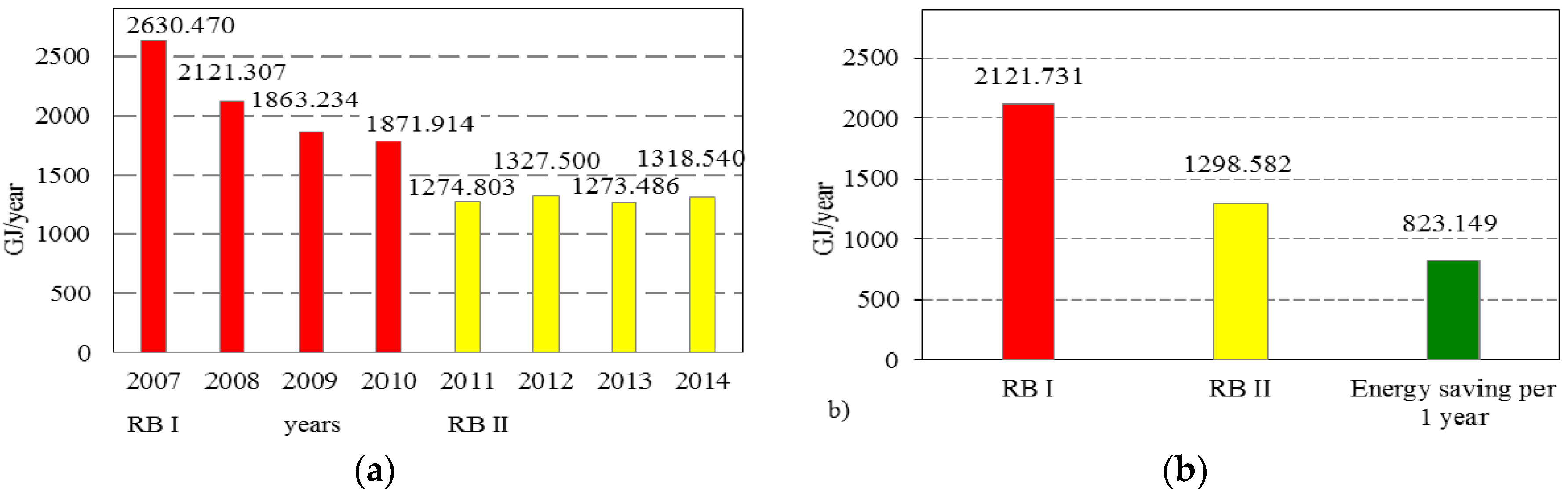

| Energy | GJ/year | |||

| Before insulation | 2121.73 | |||

| After insulation | 1298.58 |

| Impact Category | Unit | RB 1 Year | RB II 1 Year | RB 5 Years | RB II 5 Years | RB 10 Years | RB II 10 Years | RB 20 Years | RB II 20 Years |

|---|---|---|---|---|---|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | 30,290 | 34,591 | 34,158 | 36,844 | 38,992 | 39,660 | 48,661 | 45,291 |

| Non-carcinogens | kg C2H3Cl eq | 24,565 | 22,938 | 60,683 | 43,976 | 105,829 | 70,272 | 196,123 | 122,865 |

| Respiratory inorganics | kg PM2.5 eq | 1044 | 981 | 2360 | 1748 | 4005 | 2706 | 7295 | 4622 |

| Ionizing radiation | kBq 14C eq | 116,197 | 116,157 | 117,421 | 116,870 | 118,952 | 117,762 | 122,012 | 119,544 |

| Ozone layer depletion | kg CF11C eq | 0.055 | 0.714 | 0.063 | 0.718 | 0.073 | 0.724 | 0.092 | 0.735 |

| Respiratory organics | kg C2H4 eq | 273.70 | 463.72 | 410.49 | 543.40 | 581.48 | 642.99 | 923.45 | 842.18 |

| Aquatic ecotoxicity | t TEG water | 153,917 | 115,050 | 444,485 | 284,295 | 807,694 | 495,851 | 1,534,112 | 918,962 |

| Terrestrial ecotoxicity | t TEG soil | 43,869 | 36,299 | 148,990 | 97,528 | 280,391 | 174,064 | 543,194 | 327,137 |

| Terrestrial acid/nutri | kg SO2 eq | 15,836 | 18,723 | 24,354 | 23,684 | 35,002 | 29,886 | 56,298 | 42,290 |

| Land occupation | m2org.arable | 146,905 | 64,368 | 316,160 | 162,953 | 527,729 | 286,184 | 950,866 | 532,646 |

| Aquatic acidification | kg SO2 eq | 3775 | 4299 | 5129 | 5087 | 6821 | 6073 | 10,206 | 8044 |

| Aquatic eutrophication | kg PO4 P-lim | 147 | 152 | 279 | 228 | 443 | 324 | 773 | 516 |

| Global warming | t CO2 eq | 910 | 1038 | 986 | 1082 | 1080 | 1137 | 1269 | 1247 |

| Non-renewable energy | GJ primary | 16,367 | 20,527 | 17,411 | 21,135 | 18,716 | 21,895 | 21,325 | 23,414 |

| Mineral extraction | GJ surplus | 68.080 | 107.413 | 73.096 | 110.335 | 79.366 | 113.987 | 91.907 | 121.292 |

| Years | TES | ReCiPe | IMPACT 2002+ |

|---|---|---|---|

| 1 | +39% | −1% | −7% |

| 5 | +39% | +12% | +9% |

| 10 | +39% | +19% | +18% |

| 20 | +39% | +26% | +25% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitterpach, J.; Hroncová, E.; Ladomerský, J.; Štefko, J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability 2016, 8, 1303. https://doi.org/10.3390/su8121303

Mitterpach J, Hroncová E, Ladomerský J, Štefko J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability. 2016; 8(12):1303. https://doi.org/10.3390/su8121303

Chicago/Turabian StyleMitterpach, Jozef, Emília Hroncová, Juraj Ladomerský, and Jozef Štefko. 2016. "Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment" Sustainability 8, no. 12: 1303. https://doi.org/10.3390/su8121303