Optimum Insulation Thickness for Building Exterior Walls in 32 Regions of China to Save Energy and Reduce CO2 Emissions

Abstract

:1. Introduction

2. Materials and Methodology

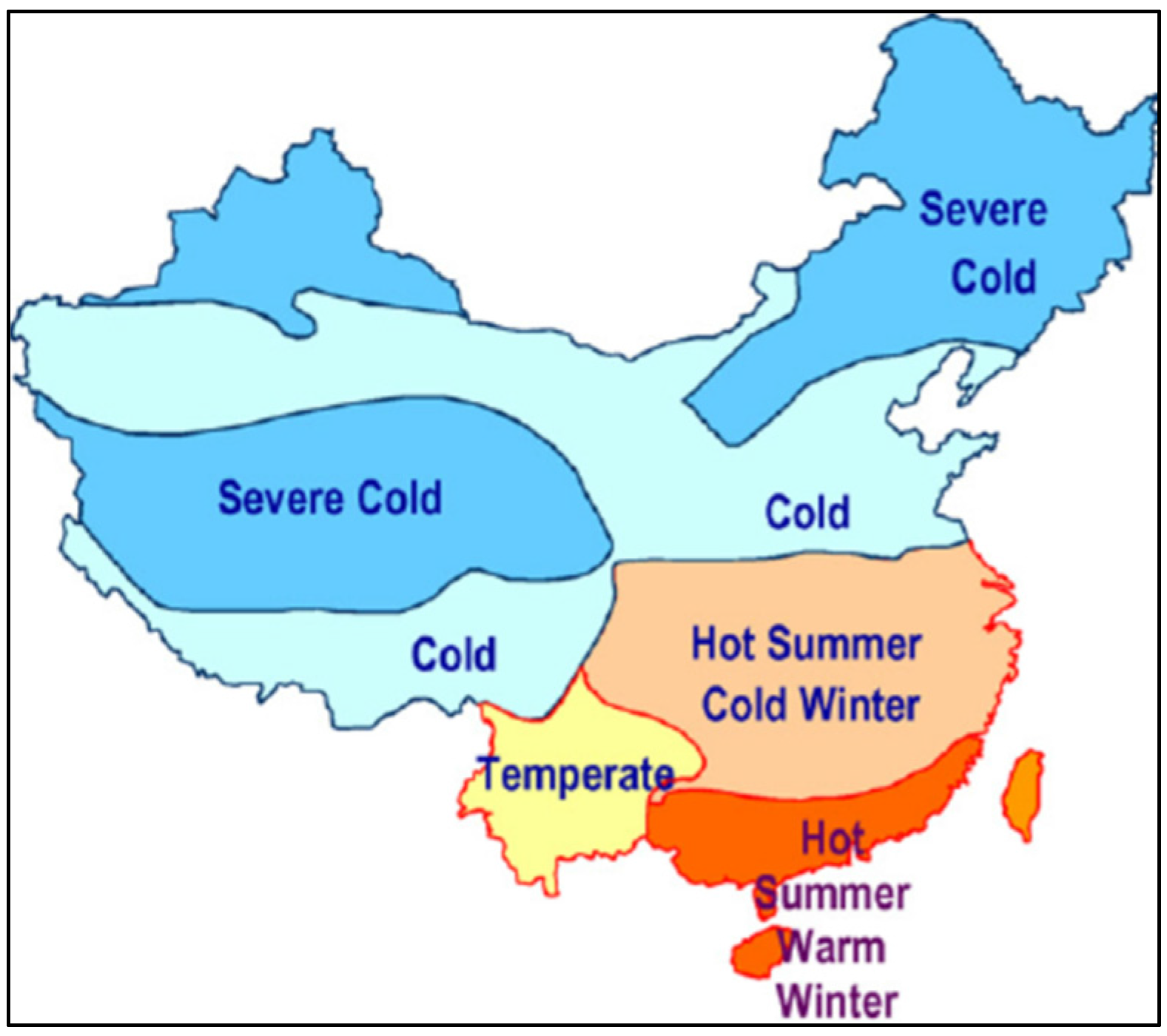

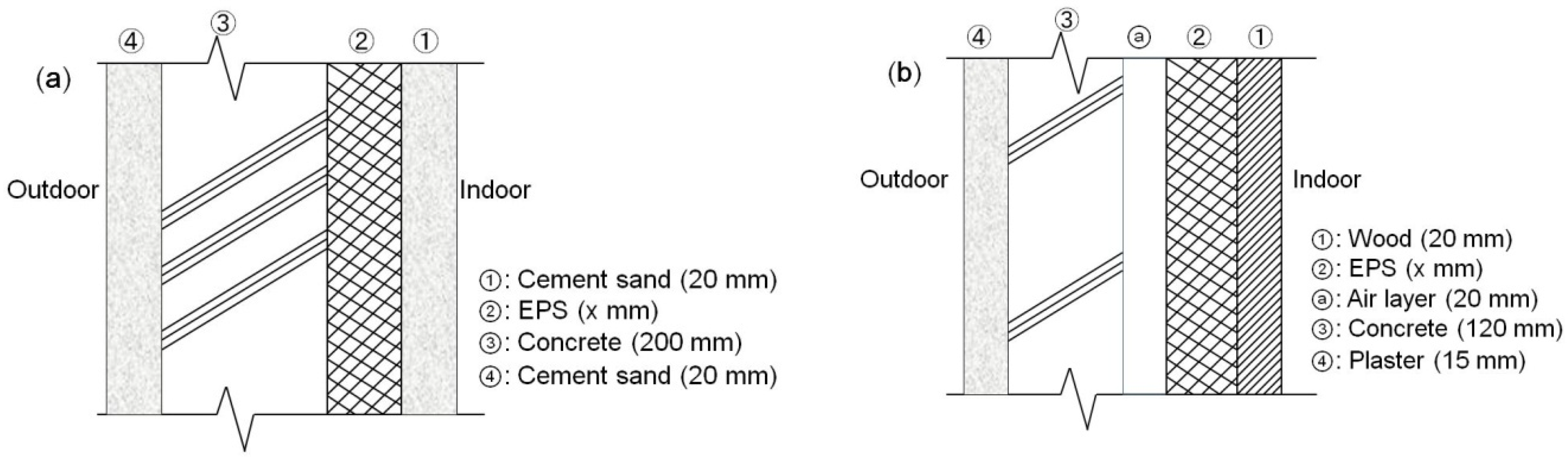

2.1. Regions of China

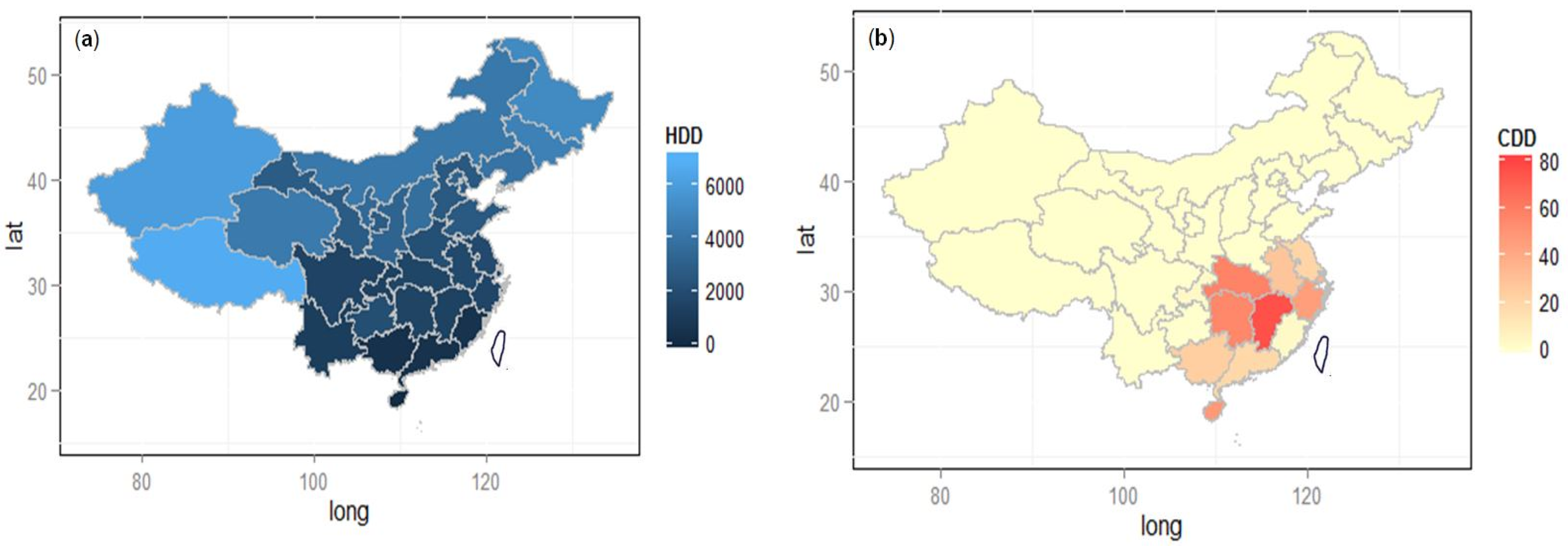

2.2. Determination of HDD and CDD

2.3. Total Energy Cost Analysis

2.4. Determination of Optimum Insulation Thickness

2.5. Energy Cost Saving Analysis

2.6. CO2 Emission Calculation

3. Results and Discussion

3.1. HDD and CDD for 32 Regions

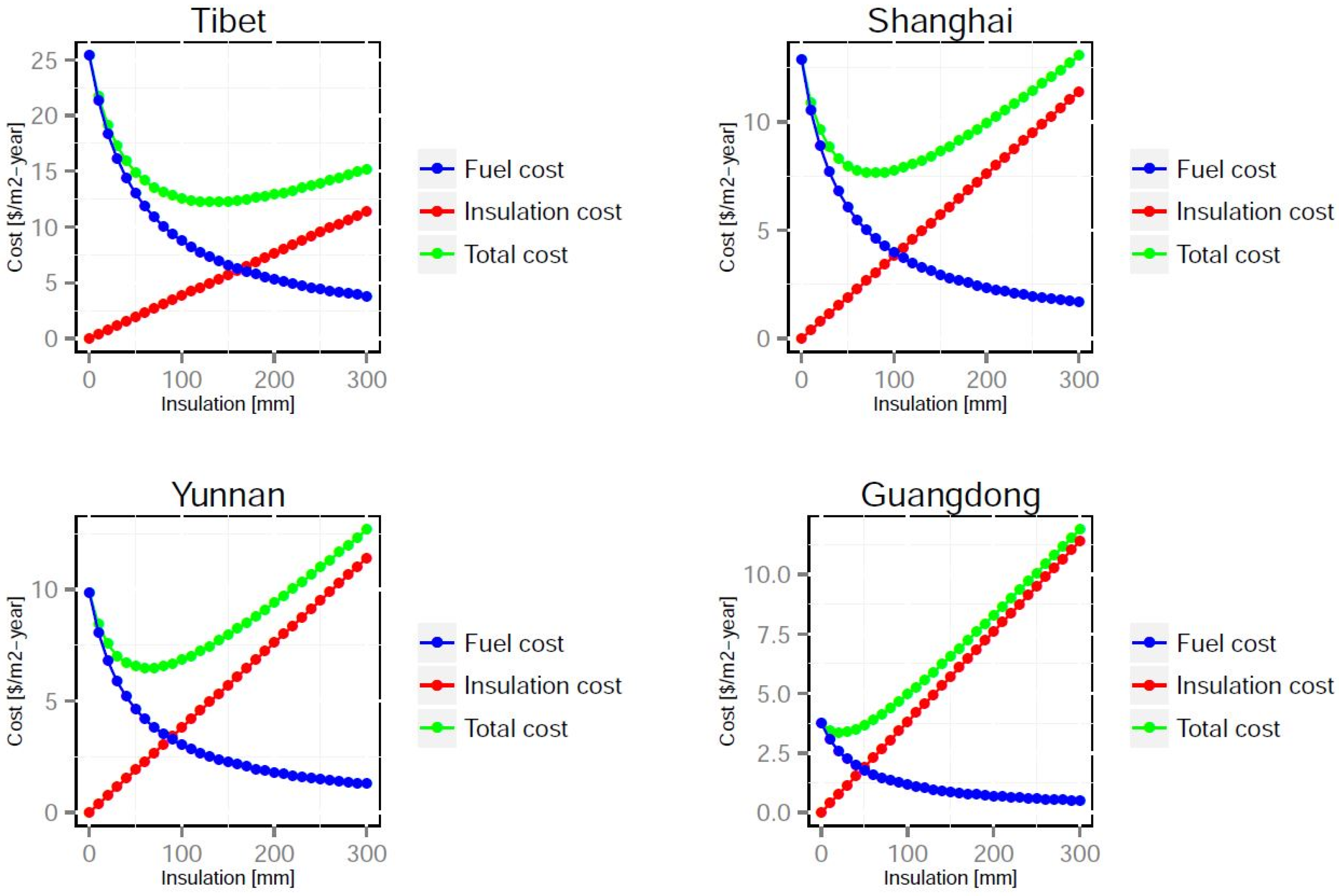

3.2. Optimum Insulation Thickness

- The weather data sources for HDD and CDD calculations are different; the weather data used in Zhu et al.’s research was obtained from the EnergyPlus weather file and the data used in this study was obtained from the CMDC weather file.

- Two kinds of exterior wall structures are assumed in this paper; one is applied to Severe Cold and Cold climatic zones and the other one is applied to Hot Summer & Cold Winter, Temperate and Hot Summer & Warm Winter climatic zones. However, only one general exterior wall structure was considered in Zhu et al.’s research.

- The base temperature of 28 °C is adopted for determining the annual CDD in this paper, however a relatively lower base temperature of 26 °C is adopted in Zhu et al.’s research.

3.3. Annual Total Cost

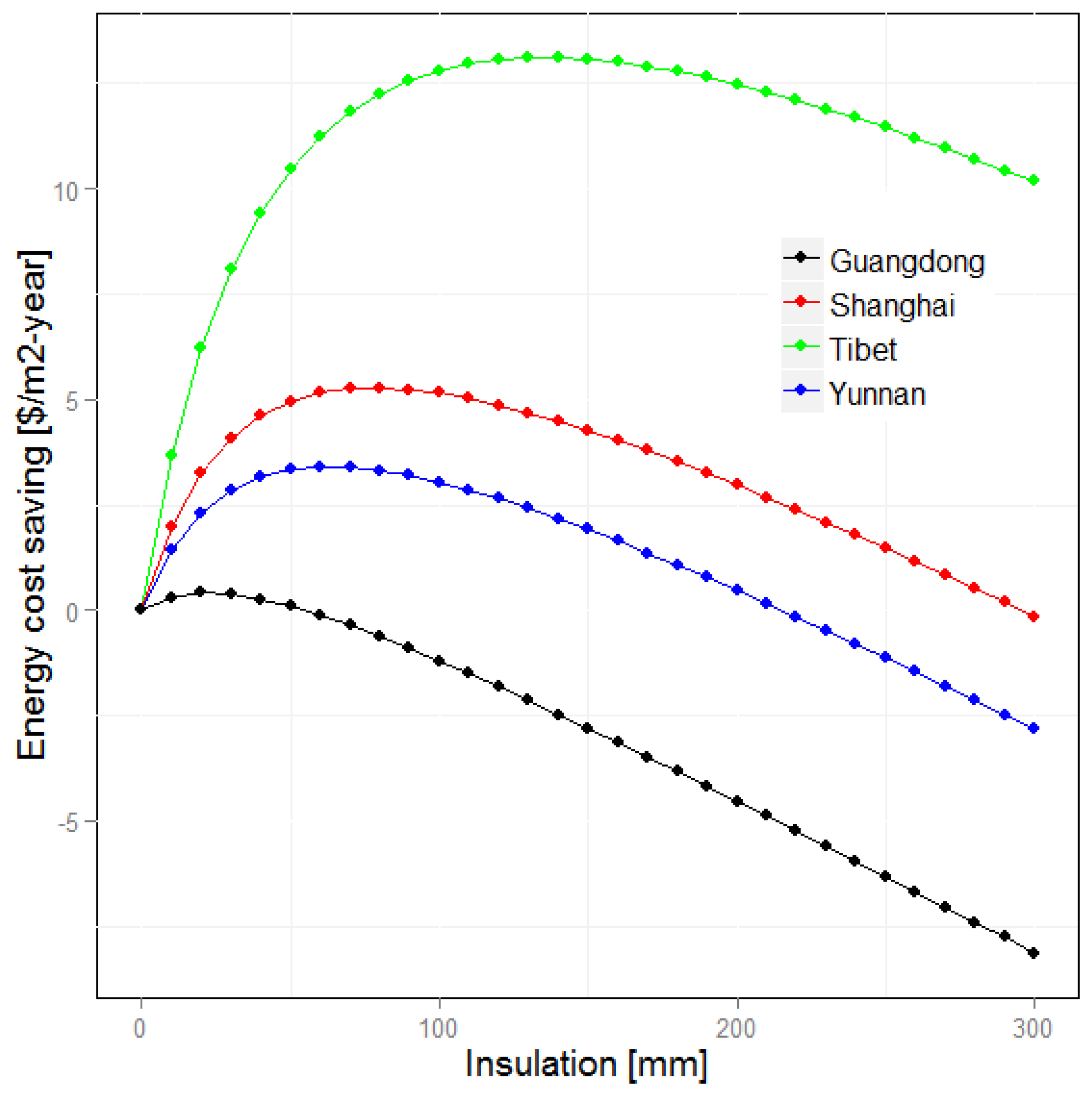

3.4. Potential Annual Energy Cost Savings

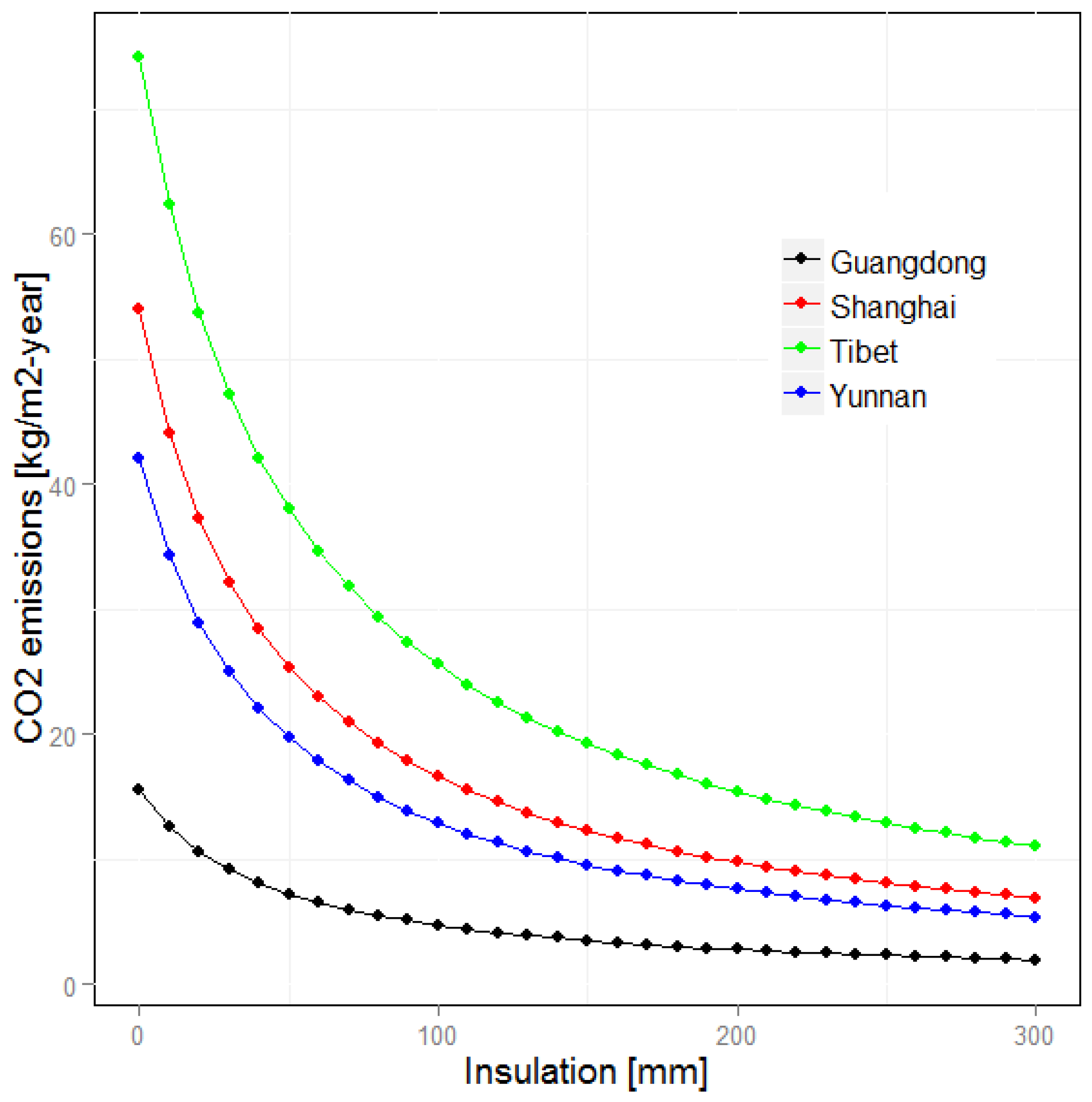

3.5. Potential Annual CO2 Emissions

4. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dombaycı, Ö.A. Investigation of the Effect of Thermal Insulation for a Model House in Cold Regions: A Case Study of Turkey. Environ. Progress Sustain. Energy 2013, 33, 527–537. [Google Scholar] [CrossRef]

- Mardookhy, M.; Sawhney, R.; Ji, S.; Zhu, X.; Zhou, W. A Study of Energy Efficiency in Residential Buildings in Knoxville, Tennessee. J. Clean. Prod. 2014, 85, 241–249. [Google Scholar] [CrossRef]

- Baniassadi, A.; Sajadi, B.; Amidpour, M.; Noori, N. Economic optimization of PCM and insulation layer thickness in residential buildings. Sustain. Energy Technol. Assess. 2016, 14, 92–99. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, M.; Hiller, J.E. Theoretical and experimental studies on the daily accumulative heat gain from cool roofs. Energy 2017, 129, 138–147. [Google Scholar] [CrossRef]

- Yuan, J.; Farnham, C.; Emura, K.; Alam, M.A. Proposal for optimum combination of reflectivity and insulation thickness of building external walls for annual thermal load in Japan. Build. Environ. 2016, 103, 228–237. [Google Scholar] [CrossRef]

- Ozel, M. Effect of wall orientation on the optimum insulation thickness by using a dynamic method. Appl. Energy 2011, 88, 2429–2435. [Google Scholar] [CrossRef]

- Sisman, N.; Kahya, E.; Aras, N.; Aras, H. Determination of optimum insulation thicknesses of the external walls and roof (ceiling) for Turkey’s different degree-day regions. Energy Policy 2007, 35, 5151–5155. [Google Scholar] [CrossRef]

- Yu, J.; Yang, C.; Tian, L.; Liao, D. A study on optimum insulation thicknesses of external walls in hot summer and cold winter zone of China. Appl. Energy 2009, 86, 2520–2529. [Google Scholar] [CrossRef]

- Dombaycı, Ö.A.; Gölcü, M.; Pancar, Y. Optimization of insulation thickness for external walls using different energy-sources. Appl. Energy 2006, 83, 921–928. [Google Scholar] [CrossRef]

- Özkan, D.B.; Onan, C. Optimization of insulation thickness for different glazing areas in buildings for various climatic regions in Turkey. Appl. Energy 2011, 88, 1331–1342. [Google Scholar] [CrossRef]

- Kurekci, N.A. Determination of optimum insulation thickness for building walls by using heating and cooling degree-day values of all Turkey’s provincial centers. Energy Build. 2016, 118, 197–213. [Google Scholar] [CrossRef]

- Dombayci, Ö.A.; Ozturk, H.K.; Atalay, Ö.; Acar, Ş.G.; Ulu, E.Y. The Impact of Optimum Insulation Thickness of External Walls to Energy Saving and Emissions of CO2 and SO2 for Turkey Different Climate Regions. Energy Power Eng. 2016, 8, 327–348. [Google Scholar] [CrossRef]

- Uçar, A.; Balo, F. Effect of fuel type on the optimum thickness of selected insulation materials for the four different climatic regions of Turkey. Appl. Energy 2009, 86, 730–736. [Google Scholar] [CrossRef]

- Hwaish, A.N.A. Impact of heat exchange on building envelope in the hot climates. Int. J. Emerg. Technol. Adv. Eng. 2015, 5, 47–57. [Google Scholar]

- Wati, E.; Meukam, P.; Nematchoua, M.K. Influence of external shading on optimum insulation thickness of building walls in a tropical region. Appl. Therm. Eng. 2015, 90, 754–762. [Google Scholar] [CrossRef]

- Lee, M.J.; Lee, K.G.; Seo, W.D. Analyses on performances of heat and multilayer reflection insulators. J. Cent. South Univ. 2012, 19, 1645–1656. [Google Scholar] [CrossRef]

- Kossecka, E.; Kosny, J. Influence of insulation configuration on heating and cooling loads in a continuously used building. Energy Build. 2002, 34, 321–331. [Google Scholar] [CrossRef]

- Ozel, M. The influence of exterior surface solar absorptivity on thermal characteristics and optimum insulation thickness. Renew. Energy 2012, 39, 347–355. [Google Scholar] [CrossRef]

- Granzotto, N.; Bettarello, F.; Ferluga, A.; Marsich, L.; Schmid, C.; Fausti, P.; Caniato, M. Energy and acoustic performances of windows and their correlation. Energy Build. 2017, 136, 189–198. [Google Scholar] [CrossRef]

- Baldinelli, G.; Asdrubali, F.; Baldassarri, C.; Bianchi, F.; D’Alessandro, F.; Schiavoni, S.; Basilicata, C. Energy and environmental performance optimization of a wooden window: A holistic approach. Energy Build. 2014, 79, 114–131. [Google Scholar] [CrossRef]

- Thalfeldt, M.; Pikas, E.; Kurnitski, J.; Voll, H. Facade design principles for nearly zero energy buildings in a cold climate. Energy Build. 2013, 67, 309–321. [Google Scholar] [CrossRef]

- China Climate Change Info-Net (CCCIN). Global Carbon Dioxide Emissions in 2016. Available online: http://www.ccchina.gov.cn (accessed on 20 February 2017).

- Ministry of Construction of the People’s Republic of China. Thermal Design Code of Civil Building (GB 50176─93); China Plan Publishing House: Beijing, China, 1993. (In Chinese)

- Li, B.; Yao, R. Urbanization and its impact on building energy consumption and efficiency in China. Renew. Energy 2009, 34, 1994–1998. [Google Scholar] [CrossRef]

- Zhu, P.; Huckemann, V.; Fisch, M.N. The optimum thickness and energy saving potential of external wall insulation in different climate zones of China. Procedia Eng. 2011, 21, 608–616. [Google Scholar] [CrossRef]

- China Meteorological Data Service Center (CMDC). 2016. Available online: http://data.cma.cn (accessed on 21 February 2017).

- Cengel, Y.A. Heat Transfer: A Practical Approach; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- Hasan, A. Optimum insulation thickness for buildings using life cycle cost. Appl. Energy 1999, 63, 115–124. [Google Scholar] [CrossRef]

- Dombayci, Ö.A. The environment impact of optimum insulation thickness for external walls of buildings. Build. Environ. 2007, 42, 3855–3859. [Google Scholar] [CrossRef]

- Polyurethane Price from Alibaba Global Trade. 2017. Available online: https://www.alibaba.com/showroom/price-of-polyurethane-resin.html (accessed on 21 February 2017).

- Natural Gas Price from energy.cngold.org. 2017. Available online: http://energy.cngold.org/tianranqi.html (accessed on 21 March 2017).

- Coal Price from energy.cngold.org. 2017. Available online: http://www.cngold.org/meitan/ (accessed on 21 February 2017).

- Electricity Price from State Grid Corporation of China. Available online: http://www.sgcc.com.cn/ (accessed on 21 March 2017).

- Yildiz, A.; Gurlek, G.; Erkek, M.; Özbalta, N. Economical and Environmental Analysis of Thermal Insulation Thickness in Buildings. J. Therm. Sci. Technol. 2008, 28, 25–34. [Google Scholar]

- China Interest Rate. 2017. Available online: http://www.tradingeconomics.com/china/interest-rate (accessed on 25 March 2017).

- China Inflation Rate. 2017. Available online: http://www.tradingeconomics.com/china/inflation-cpi (accessed on 25 March 2017).

- Andreola, F.; Barbieri, L.; Lancellotti, I. Valorization of tyres waste pyrolysis residue in lightweight materials. Environ. Eng. Manag. J. 2016, 15, 1907–1914. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Cost of insulation material (Cins) | ||

| Expanded polyurethane (EPS) [30] | $/m3 | 38 |

| Fuel price (CH and CC) | ||

| Natural gas [31] | $/m3 | 0.48 |

| Coal [32] | $/kg | 0.09 |

| Electricity [33] | $/kWh | 0.09 |

| Fuel value (HH and HC) | ||

| Natural gas [11] | kJ/m3 | 48,570 |

| Coal [11] | kJ/kg | 25,122 |

| Electricity [25] | KJ/kWh | 3600 |

| Efficiency of heating system (ηH) | ||

| Natural gas [34] | [-] | 0.93 |

| Coal [29] | [-] | 0.65 |

| Present worth factor (PWF) | ||

| Interest rate (i) [35] | [-] | 4.35% |

| Inflation rate (g) [36] | [-] | 2.3% |

| N | [yr] | 10 |

| Regions | HDD18.0 [°C-day] | CDD28.0 [°C-day] | OIT [mm] (Optimum Rins [m2K/W]) | Ecs [$/m2-yr] | mco2 Reduction [kg/m2-yr] |

|---|---|---|---|---|---|

| Bejing | 3155.4 | 0 | 75.14 (1.79) | 4.07 | 20.80 |

| Gansu | 2773.3 | 0 | 67.16 (1.60) | 3.25 | 17.30 |

| Hebei | 2625.1 | 0 | 63.91 (1.52) | 2.94 | 15.29 |

| Heilongjiang | 5121.7 | 0 | 110.16 (2.62) | 8.76 | 37.86 |

| Henan | 2141.0 | 0 | 52.62 (1.25) | 2.00 | 11.40 |

| Jilin | 4690.4 | 0 | 103.15 (2.46) | 7.68 | 33.59 |

| Liaoning | 3975.3 | 0 | 90.79 (2.16) | 5.95 | 27.41 |

| Inner Mongolia | 4230.6 | 0 | 95.32 (2.27) | 6.56 | 30.29 |

| Ningxia | 3515.4 | 0 | 82.24 (1.96) | 4.87 | 24.25 |

| Qinghai | 4321.1 | 0 | 96.89 (2.31) | 6.78 | 30.94 |

| Shaanxi | 3220.6 | 0 | 76.46 (1.82) | 4.22 | 21.22 |

| Shandong | 2641.7 | 0 | 64.28 (1.53) | 2.97 | 16.48 |

| Shanxi | 3753.7 | 0 | 86.73 (2.07) | 5.43 | 25.88 |

| Tianjin | 2731.5 | 0 | 66.25 (1.58) | 3.17 | 17.04 |

| Xinjiang | 6085.0 | 0 | 124.81 (2.97) | 11.24 | 47.34 |

| Tibet | 6786.9 | 0 | 134.76 (3.21) | 13.11 | 52.80 |

| Anhui | 1775.8 | 27.3 | 89.67 (2.14) | 6.91 | 43.56 |

| Chongqing | 1308.5 | 3.0 | 70.12 (1.67) | 4.23 | 29.32 |

| Fujian | 496.6 | 2.6 | 26.30 (0.63) | 0.59 | 7.34 |

| Guangdong | 423.2 | 18.6 | 21.86 (0.52) | 0.41 | 4.82 |

| Guangxi | 381.6 | 23.5 | 18.94 (0.45) | 0.31 | 4.35 |

| Guizhou | 2035.8 | 0 | 98.28 (2.34) | 8.30 | 51.61 |

| Hainan | 14.1 | 47.8 | 0 (0) | 0 | 0 |

| Hubei | 1569.1 | 57.5 | 82.67 (1.97) | 5.87 | 36.99 |

| Hunan | 1454.3 | 55.5 | 78.01 (1.86) | 5.23 | 34.29 |

| Jiangsu | 1831.5 | 20.7 | 91.54 (2.18) | 7.20 | 44.92 |

| Jiangxi | 1353.8 | 75.8 | 74.51 (1.77) | 4.76 | 31.94 |

| Paracel Islands | 31.6 | 0.5 | 0 (0) | 0 | 0 |

| Shanghai | 1478.4 | 34.6 | 78.32 (1.86) | 5.27 | 34.83 |

| Sichuan | 1430.8 | 0 | 75.24 (1.79) | 4.86 | 33.69 |

| Yunnan | 1150.3 | 0 | 62.89 (1.50) | 3.40 | 24.21 |

| Zhejiang | 1542.4 | 45.6 | 81.24 (1.93) | 5.67 | 36.35 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Farnham, C.; Emura, K. Optimum Insulation Thickness for Building Exterior Walls in 32 Regions of China to Save Energy and Reduce CO2 Emissions. Sustainability 2017, 9, 1711. https://doi.org/10.3390/su9101711

Yuan J, Farnham C, Emura K. Optimum Insulation Thickness for Building Exterior Walls in 32 Regions of China to Save Energy and Reduce CO2 Emissions. Sustainability. 2017; 9(10):1711. https://doi.org/10.3390/su9101711

Chicago/Turabian StyleYuan, Jihui, Craig Farnham, and Kazuo Emura. 2017. "Optimum Insulation Thickness for Building Exterior Walls in 32 Regions of China to Save Energy and Reduce CO2 Emissions" Sustainability 9, no. 10: 1711. https://doi.org/10.3390/su9101711