1. Introduction

Approximately 80% of the human population is expected to live in cities by 2050 [

1]. Humans spend up to 90% of their time in buildings, while buildings contribute up to 40% to humanity’s energy demand, and are responsible for 33% of the total resources consumption [

2]. Technical efforts for the construction, service, and maintenance of centralized infrastructures that are state-of-art in the developed world today lead to increased economic and environmental costs. For example, almost 70% of the primary energy required for centralized electricity production in conventional coal power plants is lost [

3]. Therefore, new sustainable solutions are required in order to enhance the effectiveness and efficiency of infrastructures and to preserve limited resources.

A very promising approach to reduce (urban) resource consumption is the application of decentralized systems for the improvement of resource efficiency and renewable resource production. A framework utilizing this approach is the so-called Zero Emission Buildings (ZEBs). ZEBs do not produce harmful emissions, and can even exert positive impacts on the environment by producing energy, water, and other resources [

4]. The international research project Zero Emission Building—Integrating Sustainable Technologies and Infrastructure Systems (ZEBISTIS) [

4] aimed to enforce and improve the design of ZEBs. A specific goal of ZEBISTIS was the development of tools and methods to achieve zero emissions from a building. Potential emissions from a building in terms of air, water, and soil can be assigned to the main categories “biomass”, “water”, and “energy”. The development of toolboxes for each of the three categories and the linkage and combination of these toolboxes aimed to support architects and planners from different disciplines in the planning process of ZEBs during the early design and planning stages.

A basic requirement for a ZEB is the maximization of both the building’s energy efficiency and its renewable energy productivity. This also reflects the European “Energy in Buildings Performance” directive, which demands that by 2021 all new buildings in the EU must be built as nearly zero energy buildings with an energy demand of “zero” or “nearly zero” for heating, cooling, and domestic hot water production [

5]. The remaining energy demand should be provided by renewable energy produced on the building property or within its neighborhood [

4]. A basic characteristic of the Net Zero-Energy Buildings is to meet the energy demand of a building onsite with integrated renewable energy production systems, such as using Building Integrated Photovoltaics (BIPVs) [

6].

This paper discusses the development of a general framework for a Microsoft Excel based Energy Toolbox (ETB) for the planning of domestic (residential) ZEBs. The minimum requirement for the application of the ETB is the design of energy efficient homes that meet the so-called Passive-House criteria, defined by the Passive House Institute [

7]. To achieve Net Zero-Energy buildings, the annual energy demand of very energy efficient buildings meeting the Passive-House criteria is met with renewable energy that is produced with sustainable technologies and systems [

6].

The so-called Passive House (PH) standard [

7] and the concept of Net Zero-Energy or Net Plus-Energy Buildings [

6,

8,

9] are the starting basis for the modeling of the energy demand and the specific energy flows of a ZEB [

10] by means of the ETB. To achieve net zero-energy consumption for a building over the period of one year, the total renewable energy production of a building must either exceed, or at least be similar to, the total final energy demand of the particular building [

6]. After quantitative and qualitative determination of the specific thermal and electric energy demands, the ETB facilitates the identification of appropriate technologies and systems for the provision and production of the building’s energy demand by means of renewable energies, and for achieving at least a net Zero-Energy Balance for the operation of the building concerned over the period of one year.

2. Objectives and Methodology

The goals of the ETB development were to facilitate: (i) the estimation of the energy demand of a specific building design; (ii) the optimization of the building design in order to optimize its energy efficiency; and (iii) the determination of required technologies and the specific basic conditions for appropriate building integrated installations (such as the required area) in order to achieve net zero-energy demand. The maximum energy demand and technical background of the building physics in the ETB adhere to the minimum criteria for certified PH according to the PH Institute [

7,

11]. The most important characteristics of the PH concept are the minimization of ventilation and transmission heat losses by ensuring energy efficient mechanical ventilation with heat recovery (HRC), air-tight building envelope, well-insulated building envelope with minimized thermal bridges, and the use of internal and external (solar) heat gains and passive cooling. In general, the limits of the objective to refrain from a conventional heating system are derived from the PH standard [

7]. The maximum heating and/or cooling load is limited to ≤10 W/m

2 and the heating and/or cooling energy demand is limited to 15 kWh/m

2 per year [

12]. Therefore, the heating and/or cooling energy demand can be provided via mechanical ventilation systems, with the minimum required fresh air demand, and without a conventional “active” heating and/or cooling system [

7,

11,

12]. Specific technologies are required for the building integrated provision of the final energy use, and the production of primary renewable energy in order to meet at least 100% of the yearly energy demand. Such specific technologies need to: (i) improve the overall energy efficiency and lower the buildings service energy demand; (ii) reduce the heating and/or cooling loads; and (iii) to generate the required amount of energy for hot water, heating, cooling, and electricity.

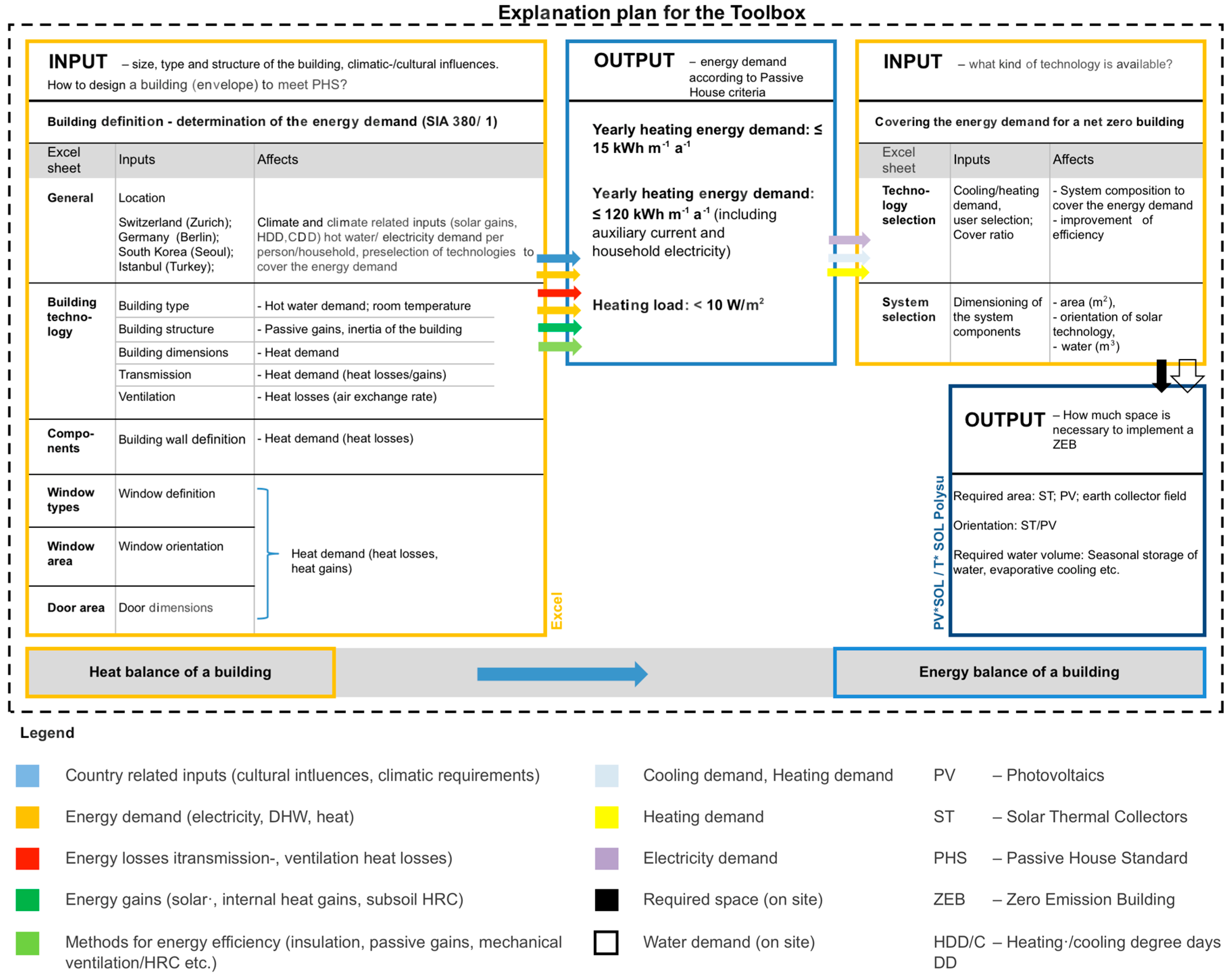

The ETB comprises two parts: (1) “Energy Demand and Efficiency”; and (2) “Energy Conversion and Provision”. In Part 1 of the ETB, the quantity and quality of a building’s energy demand are determined. These demands form the inputs for Part 2 of the ETB. In Part 2 of the ETB, different technologies can be selected in order to meet the demands for specific forms of energies required for the operation of a specified building, and to achieve Net Zero-Energy consumption over the period of one year.

The building’s energy demand consists of the heat demand for domestic hot water (DHW) production and heating, and the electricity demand for appliances and components of the building services engineering system. The energy demand is calculated based on input parameters, such as building utilization, number of residents, building structure, composition of the building envelope, building shape, position, and orientation.

Depending on the property location and site conditions of a building, such as its orientation and climate, some technologies might be more appropriate than others to meet the energy demands. Part 2 of the ETB also quantifies the required dimensions of considered technologies, such as the required areas for photovoltaic (PV) generators with specific cell technology and orientation, or solar thermal (ST) systems with specific absorbers and orientations. Thus, the selection of appropriate technologies is facilitated.

2.1. ETB Part 1 “Energy Demand and Efficiency”

The ETB part 1 “Energy Demand and Efficiency” follows the methodology of the Swiss standard SIA 380/1 [

13] and is based on the international standard EN ISO 13790 [

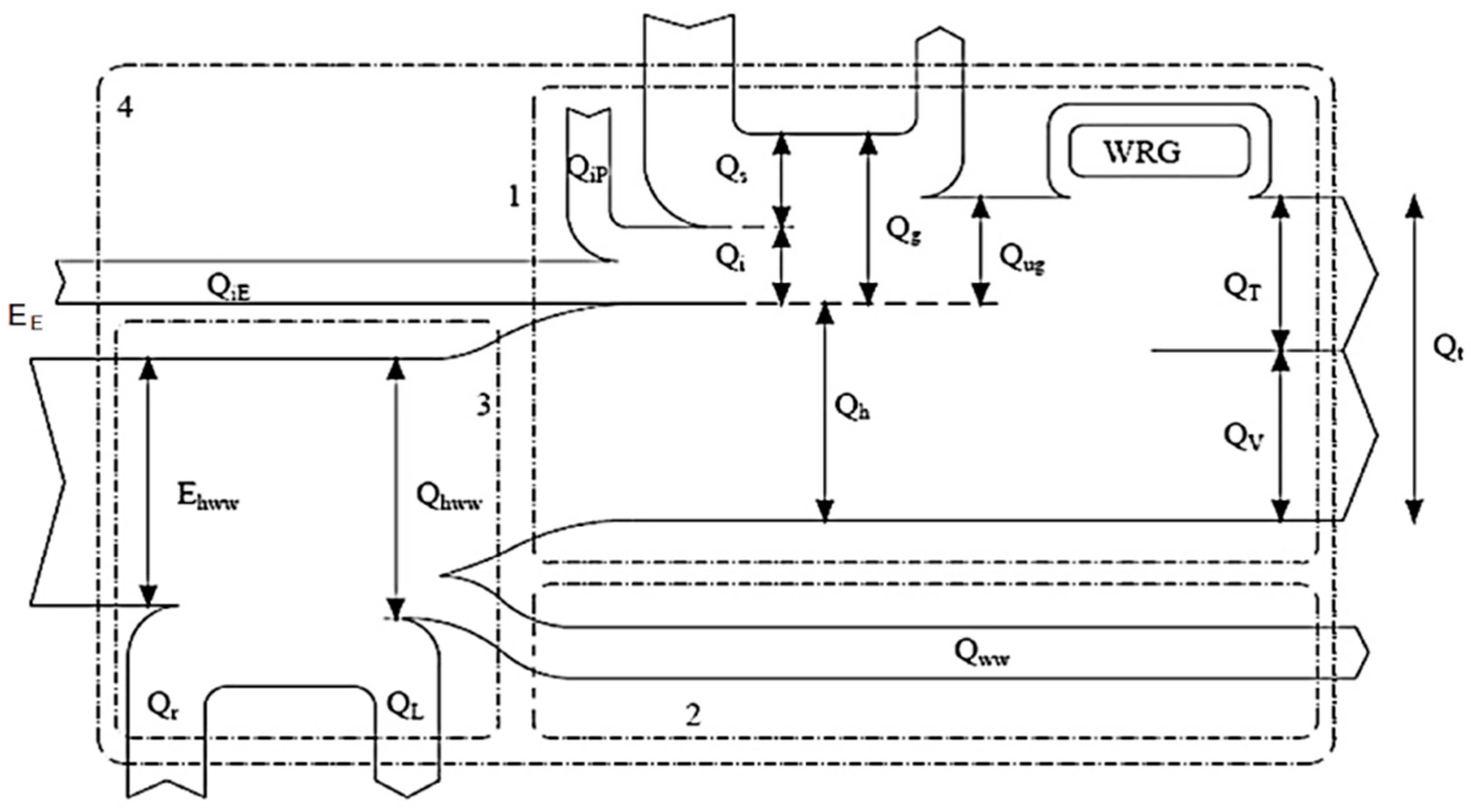

13]. The latter includes a detailed guideline on to the method of calculating the heating and cooling demand of a building. The calculation method refers to the energy balance on the exterior building envelope and relates to the heat fluxes in a building in order to balance the heat demand with the heat gains and losses. The most important energy fluxes within the building envelope are illustrated in

Figure 1 and defined in

Table 1. The equations used to calculate the transmission and ventilation heat losses, as well as the heat gains, are listed in

Table 2.

The equations, used to calculate the thermal behavior of buildings, are presented below (Equations (1)–(8)). They are simplified summaries of the more detailed calculation method according to EN ISO 13790 [

13]. Detailed specifications and the methodology for calculations are described, amongst others, in the Austrian, Swiss, and International guidelines and standards [

13,

14,

15,

16]. The calculations can be made per month or per year, depending on the goals of the study.

The heat demand of the building (Q

h) is calculated according to

where Q

T represents the transmission heat losses; Q

v is the ventilation heat losses; η

g is the performance ratio for the heat gains (depending on the building structure); Q

i denotes the internal heat gains; and Q

s is the solar heat gains (units in (kWh/a)).

The cooling demand of a building (Q

cn) is calculated according to

where Q

gcn, Q

gains per month and Q

losses per month are the total heat gains (kWh/month); and η

g is the performance ratio for heat gains (depending on the building structure. Simplified according to ISO 13790:2008 [

14]: heavy = 1.0; lightweight: 0.9).

The transmission heat losses (Q

T, in

are calculated according to

where L

T represents the transmission–conductance value (W/K); and HDD are heating degree days

.

The heat transmission value for the entire building envelope (LT, in W/K) consists of the sum of all individual heat transmission values for the different building components:

where L

e denotes the building components adjoining ambient air (W/K); L

u denotes the building components adjoining unheated rooms (EN ISO 13789) [

15]; L

g denotes the building components adjoining ground in (W/K) (EN ISO 13370) [

16]; L

ψ is the value for linear heat bridges in (W/K) (EN ISO 10211) [

17]; and L

χ is the value for punctual heat bridges in (W/K) [

17]. The individual heat transmission coefficients of different building components are included in the calculations to describe the thermal properties of the different building components, depending on their location, and their contact with outside air or ground. Further details are described in the EN ISO (European Norm International Standard Organization) 13789 [

18] and EN ISO 13370 [

19]. The calculation of windows heat transmission coefficient is considered and summarized in EN ISO 10077-1 [

20]. In addition, heat losses due to heat bridges are considered with building component related conductivity values, according to EN ISO 10211(Equation (4)) [

17].

The solar heat gains (Q

sS, MJ/(m

2a)) are calculated as:

where G

sS is the global sun radiation (MJ/m

2a) (calculated, e.g., with Meteonorm Version 7.1 Software (Meteotest, Bern Switzerland) [

21]); Aws is the window area south (m

2); g⊥ is the total energy transmittance value for glazing; F

ss is the shading factor south orientation (consisting of elements with the following orientations: horizontal south, vertical, south, vertical east, and vertical west); F

F is the reduction factor—window frame (0.6–0.9 ratio of transparent window area to window area used by SIA380/1 [

13]); and AE is the energy reference area (m

2) (the reduction factor 0.9 is defined by SIA 380/1) [

13].

The internal heat gains (Qi, MJ) are calculated according to:

where q

i is the heat flow density (W/m

2); BGF

h is the heated gross area (m

2); and HT is heat days (d).

The ventilation heat losses (Q

v, in MJ/a) are calculated as:

where HDD are heating degree days

; and L

v is the ventilation conductivity value (W/K).

The heating energy for DHW (Q

DHW, in kJ) is calculated according to

where; c

w is the specific heat capacity of water

; m

DHW is the mass (water) (kg); and ΔT is the temperature difference (K).

The building shape, the thermal conductivity of the building envelope, and the distribution of window areas need to be adjusted in order to meet the PH criteria according to the specific local conditions of the site such as the climate, orientation and potential surrounding shading elements. Climatic influences (heating and cooling degree days (HDD/CDD) and heat days (HT)) are considered in the transmission heat losses (Equation (3)). Furthermore, the solar/internal heat gains (Equations (5) and (6)) and the ventilation losses (Equation (7)) need to be considered.

The climatic conditions at the building location influence the energy demand for heating and cooling. Thus, the climate conditions also influence the climate responsive design of a building as well as the selection of adapted technologies. High heat gains (both, solar and internal) can cause either a reduction of a building’s heating demand during heating periods and/or overheating of a building’s interior during the non-heating periods. A PH is mainly heated by solar- and internal heat gains [

12,

22]. The heating or cooling requirements for a given structure at a specific location are considered to be directly proportional to the number of heating or cooling degree days at that location [

22]. A summary of the climate parameters relevant for the calculation of the energy demand according to EN ISO 13790 [

13] is listed in

Table 2.

2.2. ETB Part 2 “Energy Conversion and Provision”

In ETB Part 2, “Energy Conversion and Provision”, the technologies that facilitate the conversion and provision of specific forms of energy for the operation of a building can be pre-selected. The quantification of specific technologies (such as the definition of the required area for installation) is based on the specific energy efficiency and energy demand of a selected building. The definition of the location, and accordingly of the specific climate conditions, is essential for the calculation of ETB Part 1 and Part 2. The ETB user can decide which technologies should be included in the design of the building. The technologies included in the ETB are divided in two groups. The first group consists of technologies that convert and provide specific forms of energy in order to cover the energy demand, such as ST and PV systems, geothermal (GT) systems, and heat pumps (HPs). The second group consists of technologies that reduce the energy demand, e.g., heat exchangers for HRC from wastewater, dynamic adaptive shading control, and dynamic electric lighting control. Technologies from both these groups can be combined in order to assemble adapted systems for the conversion and provision of energy for the operation of a building.

HPs can for example convert heat from different sources (such as air, GT, waste water or ST) or can be combined with seasonal storage systems, such as the Swiss Jenni system [

28]. The heating and cooling demand covered by HPs, adiabatic cooling systems, or alternative systems, can be for example calculated with factors or ratios given by the Annual Performance Factor (APF) for heating (APF

heating), Energy Efficiency Ratio (EER

cooling), and the Seasonal Energy Efficiency Ratio for cooling (SEER

cooling) [

29]. The results of these calculations provide the required inputs: (i) the electric energy for the operation of a Heat Pump (HP) for heating, cooling, and hot water production; and (ii) the volume of water for adiabatic cooling (

Table 3). The calculation results referring to the estimated electric energy demand and consumption are the input for the simulation of the required space for the onsite production of electricity by means of a PV power plant.

Simulations for the onsite production of PV energy can be executed with the program PV*SOL [

30]. All relevant conditions such as radiation, orientation, angle, potential shading and different module and converter technologies can be considered by the program. For example, ST and HP systems can be calculated with the simulation program T*SOL [

31] or Polysun [

32]. The definition of the APF

heating and the covering ratios of the ST system are mutually dependent. It is therefore important to consider the entire system in order to evaluate the performance of complete systems for the conversion and provision of specific forms of required energies.

The performance numbers given by HP manufacturers often do not reflect the real performance of a specific HP system, especially when compared with an international level [

33]. In this research, performance values were therefore obtained from interviews with experts [

34,

35], and from published and unpublished reports [

36,

37,

38]. In addition, the HP Coefficient of Performance (COP) in many cases does not properly reflect the performance of HP systems. With the APF

heating a more realistic definition is used for applying HP systems in the ETB [

39]. According to the primary energy factor for centrally supplied electricity in Switzerland, the HPs should reach at least an APF of 3.5 to be classified as efficient technology with a positive primary energy balance compared with technologies based on the combustion of fossil fuels for the provision of heat and cold [

40,

41].

The results of the ETB development are discussed in the subsequent section of this paper. To validate the ETB, its application and validation of the results for buildings at different locations around the world would need to be executed. The extensive validation of the ETB exceeds the development of the ETB framework described in this paper and is accordingly not included in the discussion of the results. However, in

Section 3.3, an exemplary building design and building services system configuration was analyzed regarding its energy consumption, energy productivity, and resulting energy balance at four different locations.

It must be assumed that the theory and practice of the calculation of a building’s energy demand does not always coincide with the energy demand and the energy consumption during operation of the realized building [

42]. Cultural differences and user behavior can have a considerable impact on the energy demand and actual energy consumption of buildings. In Zurich for example, more than 20% of the energy saving potential can be attributed to resident’s behavior. Findings regarding the influence of user behavior on the energy consumption of domestic buildings from Switzerland and Germany illustrate the difficulty of predicting the energy consumption of specific domestic buildings by means of building simulations [

43,

44].

The average quantity of domestic drinking water consumption per person varies between the four investigated cities, particularly between Seoul (with the highest average consumption) and Berlin (with the lowest average consumption) [

45]. Accordingly, the DHW demand and the related energy demand differ. The values for both the quantity of water consumption and the quantity of related energy demand for water treatment, supply, and DHW production are therefore based on country related average values per person and day. User group specific differences in quantities are not considered because such detailed estimation would require information about the user groups and agent based modeling of water consumption patterns [

46].

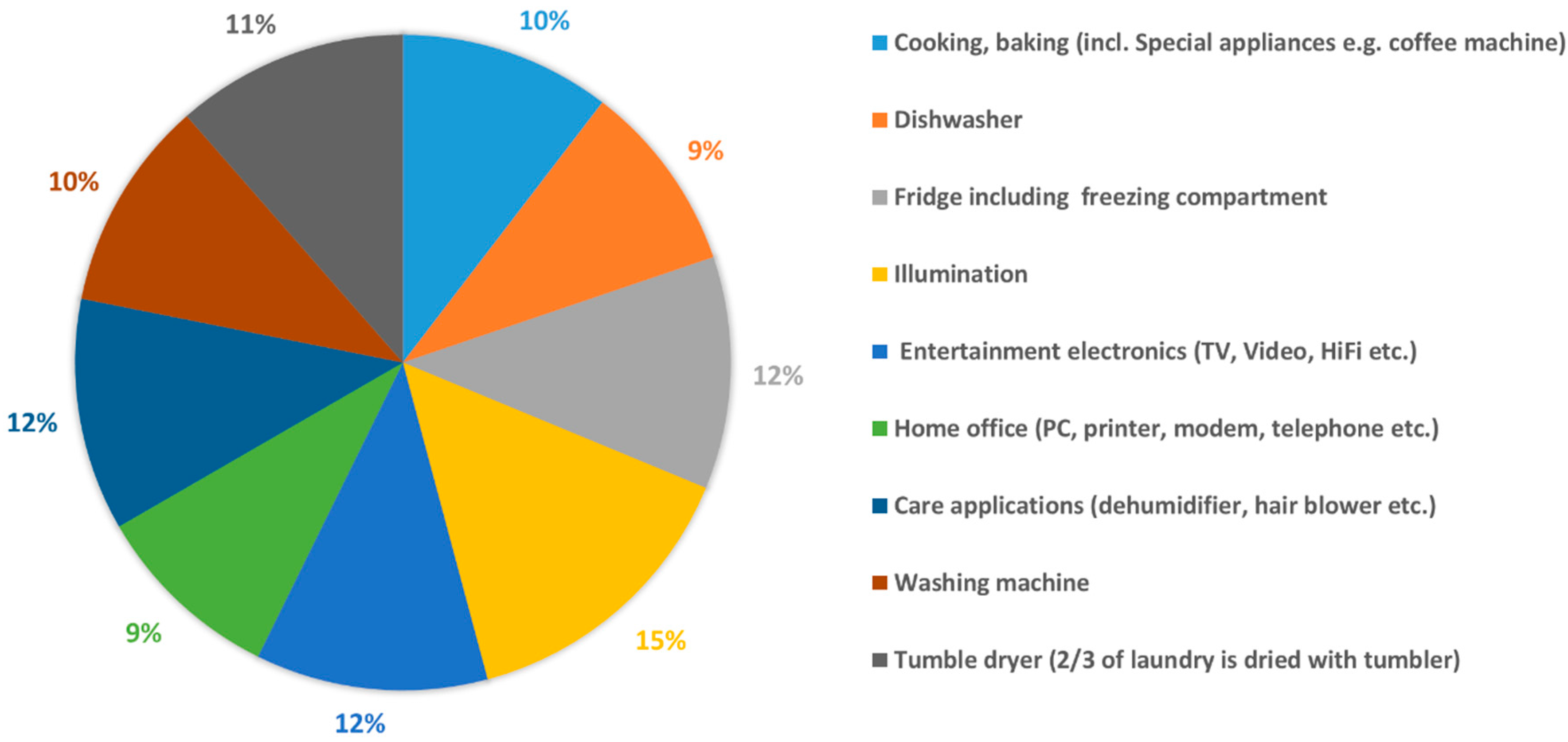

The primary electric energy demand is included in the ETB based on average values per person and year and the number of persons in a household. The values included are estimates based on available data and can only be partially determined without detailed study. The findings of the ZEBISTIS research project show that cultural specific user behavior influences the energy consumption. The number of persons per household must be considered in the ETB because the average electric energy demand for household appliances and lighting per person is higher in a household with a smaller number of persons than in that with a larger number [

47]. In addition, the electrical base consumption of the building technology (ventilation, pumping systems, etc.) is less when more residents share a living space [

47,

48]. For example, the values for the average number of persons per household and the available usable area per person differ between Turkey and Switzerland. Comparing a Swiss household with a Turkish household with the same usable area, the Turkish household is generally occupied by a family of more than two persons, while the Swiss household is typically only occupied by two persons [

47,

48,

49].

While rainwater harvesting and utilization for adiabatic cooling is generally feasible during the cooling periods in Germany, Korea, and Switzerland [

4,

50,

51], rainwater shortages might limit the feasibility of rainwater use for adiabatic cooling in Turkey [

52].

Electricity storage systems would need to be included in the ETB in order to guarantee continuous energy supply [

6,

53]. Computer programs that allow a much deeper insight into the specific building energy demand are available [

54]. Microsoft Excel based toolboxes for the detailed simulation of a building’s heating energy and cooling demand are, for example, already available in the Swiss market [

55]. However, such programs do not facilitate the integrated primary design of ZEBs discussed in this paper.

4. Conclusions and Outlook

This paper presents a framework for the development of the ETB for the primary design of ZEBS in different climate zones and discusses the required physical background that needs to be considered for the calculation of the energy behavior in buildings according to EN ISO 13790, and the Swiss norm SIA 380/1 [

13,

14]. The concepts and basic conditions of certified PH, Net Zero-Energy, and Net Plus-Energy buildings are the basis with which to approach the energy behavior of ZEBs and to develop the framework for the development of the ETB. Technologies for GT, ST, and PV energy production, and the most efficient technologies currently available for a building services engineering system are identified to convert energy to meet the energy demand for the operation of ZEBs. The maximum energy demand for certified PHs [

7] defines the maximum heating load and primary energy demand.

The aim of this research was to provide a primary analysis of the basic conditions, and the identification of basic requirements for the design of ZEBs located in Berlin, Zurich, Istanbul, and Seoul. Accordingly, the feasibility for the design of a ZEB in the four cities with different basic conditions could be confirmed. Based on the summary of the research findings, the following guidelines for the design of ZEBs and the further development of the ETB can be provided.

ETB Part 1: To meet the criteria of a certified PH [

12], the building design and structure must be adapted to the specific climate conditions. The factors to consider include the appropriate thermal insulation of the building envelope, the avoidance of thermal bridges, appropriate size and orientation of transparent building envelope components (such as windows) with low u-values and high g-values, the control of solar radiation to facilitate both passive solar heating and passive cooling, and highly energy efficient appliances, lighting systems and building services engineering systems such as mechanical ventilation systems with HRC. A climate adapted building shape has a positive influence on passive heat gains. Large portions of a PH’s heating demand are comprised by internal gains and external gains in the form of solar radiation [

12]. Thermal energy for both heating and cooling can be stored in building components. Climate adapted design includes green components such as greened roofs, greened façades and external shading systems in order to provide passive, and evaporative cooling and avoid indoor overheating during non-heating periods.

ETB Part 2: The appropriate selection, dimensioning, and combination of efficient, effective and sustainable technologies for the conversion of energy are required to at least balance a building’s total yearly primary energy demand with the yearly onsite production of renewable energy, and to achieve the design of a Net Zero- or a Net Plus-Energy building. Specific local conditions such as climate, soil, surrounding buildings and flora, user behavior, and the legal framework may limit the use of some technologies while favoring the use of others. The use of GT, ST, and HC in combination with thermal storage capacity and high efficiency HP systems can contribute to a comparable low primary energy demand for the provision of heat for heating and DHW production. The derived efficiency factors (APF, EER, and SEER) allow a simple calculation of the required electricity energy for the operation of HPs based on the end energy demand for heating and DHW. The resulting yearly electricity demand, plus the electricity demand for lighting and other facilities can be met by a PV to meet the requirements for Net Zero-Energy and Net Plus-Energy buildings. The appropriate and climate adaptive installation of technologies included in the ETB can contribute effectively to the reduction of the final electric energy demand. Such technologies in the ETB, including HC from wastewater, green facades and roofs, adaptive shading (controlled blinds), dynamic adaptive lighting and/or component activation have positive effects on the building’s efficiency and therefore space of PV and ST.

The purpose of the ETB is a design tool for the primary planning and design of ZEBs. It must be assumed that the theory and practice of the calculation of a building’s energy demand does not necessarily coincide with the energy demand and the energy consumption during operation of the realized building. Therefore, the calculation results of the ETB should be seen as rough estimations. The development of the ETB framework has been finalized in the framework of this research. However, the results delivered by the ETB need to be validated by evaluation and comparison with measured data from case studies at the projected locations in the cities of Berlin, Zurich, Istanbul, and Seoul. Future investigations and adjustment of the ETB input parameters according to the validation results will ensure the reliability of the input parameters for the applied technologies under different climatic and cultural conditions. The climate plays a central role in the energy demand and energy productivity of a specific building design. Climate data are currently only included in the ETB based on Swiss Building Standards. An important task for the future research and development of the ETB will be the transfer of national specifications for climate data, electric energy demand, and building components to an international level. Definitions for HGT, HDD, CDD, and the heating limit are critical values that vary internationally. Cultural differences and user behavior can have a considerable impact on the energy demand and actual energy consumption of buildings.

Simulation programs [

30,

31,

32] are suitable for the configuration, dimensioning, and calculation of yields of HP systems with ST and PV systems in the ETB. However, such simulations require a comparably significant effort because the simulations need to be executed with different orientations of ST collectors and/or PV panels, as well as extra options such as different efficiency ratios, size of storage tanks. For example, about 120 simulations are required to define system layouts for PV power plants at every location.

To simplify the simulation procedure and facilitate the configuration and layout of HP systems with ST and PV systems layout, a database is planned that can be linked to the ETB. The database should include the preset system configurations and yields for different orientations and locations. New technologies that are suitable for the transformation and provision of energy for the operation of ZEBs need to be included in the ETB as soon as they are available in the market.

It is important to include technologies and systems for effective and energy efficient cooling in the ETB due to the increasing cooling demand for buildings which is associated with the increasing proportion of housing stock with well insulated building envelopes and with large areas of transparent glass facades [

65]. The ETB includes the quantification of cooling performances of new and innovative technologies such as green facades or adiabatic cooling technologies and under different climate conditions. Qualitative aspects that are considered in the ETB include the need for combining cooling and dehumidification during the hot and humid summer months in Korea, and accordingly a higher cooling energy demand in order to provide comfortable indoor temperatures and to avoid the potential occurrence of condensation and mold indoors [

25]. The ETB also includes information regarding the availability of local resources for the operation of energy technologies, such as rainwater for adiabatic cooling. In the future the ETB should be extended to technologies that are relevant for the design of ZEBs and that are included in the toolboxes for the categories’ biomass (e.g., for the processing of organic wastes and food production with soil based or hydroponic systems) and water (e.g., rainwater harvesting and management, recycling and reuse of wastewater, and water supply) [

57].

This ETB is based on simplified static calculation methods and data derived from the norms cited in this paper in order to support the primary design and planning of ZEBs. An extension of the ETB to energy-autonomous and self-sufficient ZEBs, which requires no external energy infrastructure but therefore seasonal energy storage on site [

6,

9], has not been addressed in this research. In such an ETB, the layout and dimensioning of on-site renewable energy production (such as ST and PV) and storage systems would need to be included in order to guarantee continuous energy supply [

6,

53]. Therefore, simulations regarding the energy demand and energy production in relatively short time intervals such as days, weeks, and months would need to be executed. Accordingly, the effort needed for these simulations would be much larger than that for the ETB for Net Zero- and Net Plus-Energy addressed in this research, and would require an automation of the simulation process with linkage to a database. Programs that allow a much deeper insight in the specific building energy demand are available [

54]. In addition, Microsoft Excel based toolboxes for the detailed simulation of a building’s heating energy and cooling demand are already available in the Swiss market [

55] and could be further developed at an international level.

It can be concluded that planning an energy layout for a building is a highly complex process. While difficulties due to a vast number of influencing factors can arise, the energy layout process provides creative potential to implement new technologies and building shapes.

This article on the research of the development of a framework for the ETB discussed a new simplified approach that facilities the basic primary design of ZEBs. This ETB facilitates the comparable, easy, and fast selection, appropriate combination, and primary dimensioning of technologies for the on-site conversion, provision, and management of energy required for the operation of ZEBs in four cities in Germany, Switzerland, Turkey, and Korea. Accordingly, this ETB can be used for the analysis and evaluation of different technologies and systems for the operation of ZEB’s in the cities of similar climate zones. In the future, the ETB is planned to be extended to other climate zones and to include new and innovative technologies that facilitate the efficient conversion, provision and management of energy for the operation of ZEBs. Thus, ETB could become a powerful tool for architects and building planners for the primary design and planning of ZEBs in different countries and climate zones around the world.