The Emergency Vehicle Routing Problem with Uncertain Demand under Sustainability Environments

Abstract

:1. Introduction

2. Mathematical model and Methods

2.1. Model Foundation and Notations

2.2. Mathematical Model

2.3. Solution Method

2.3.1. A Combination with Nearest Assignment and Average Distance

2.3.2. The Improved Genetic Algorithm of the Proposed Problem

3. Results

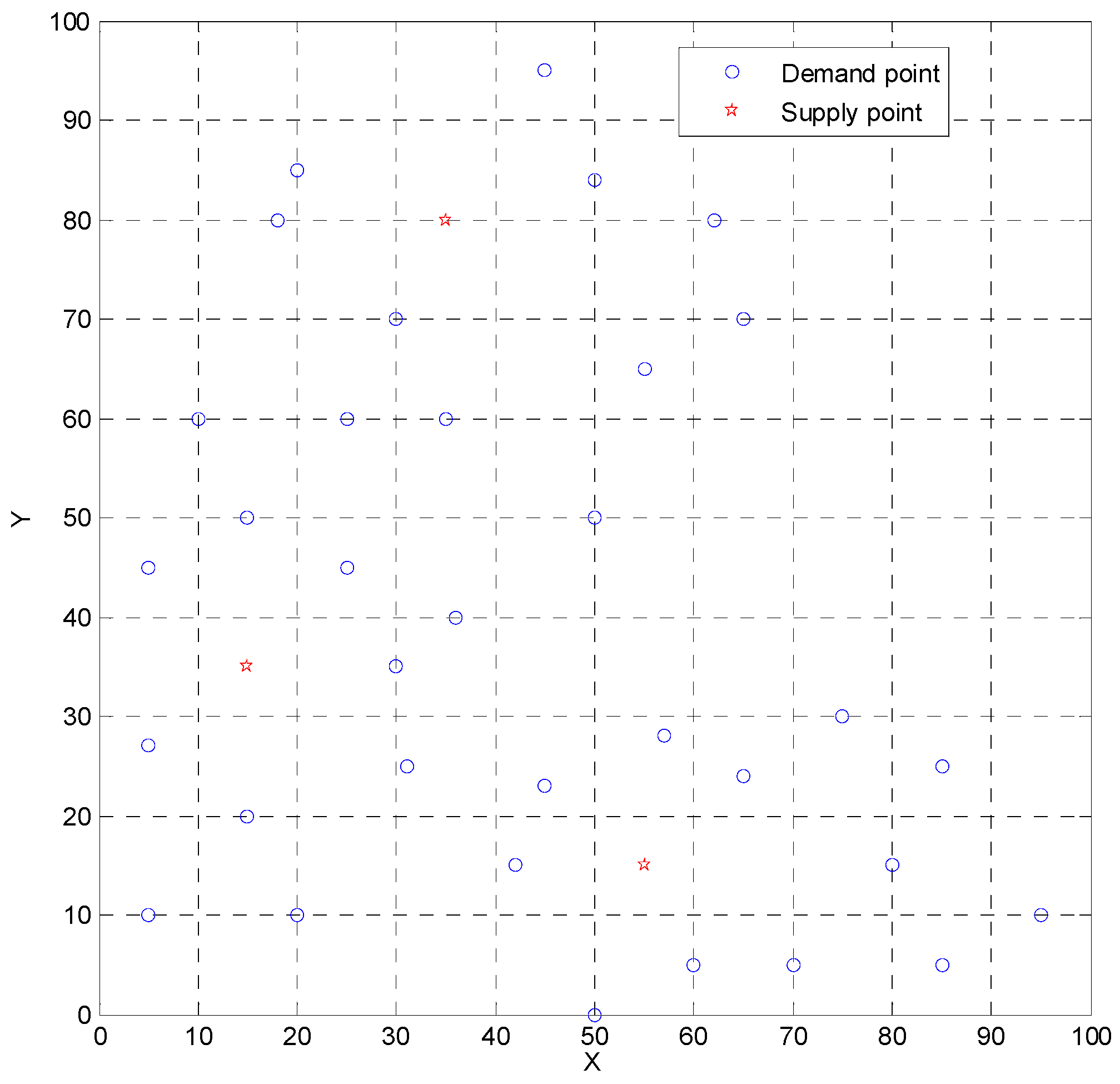

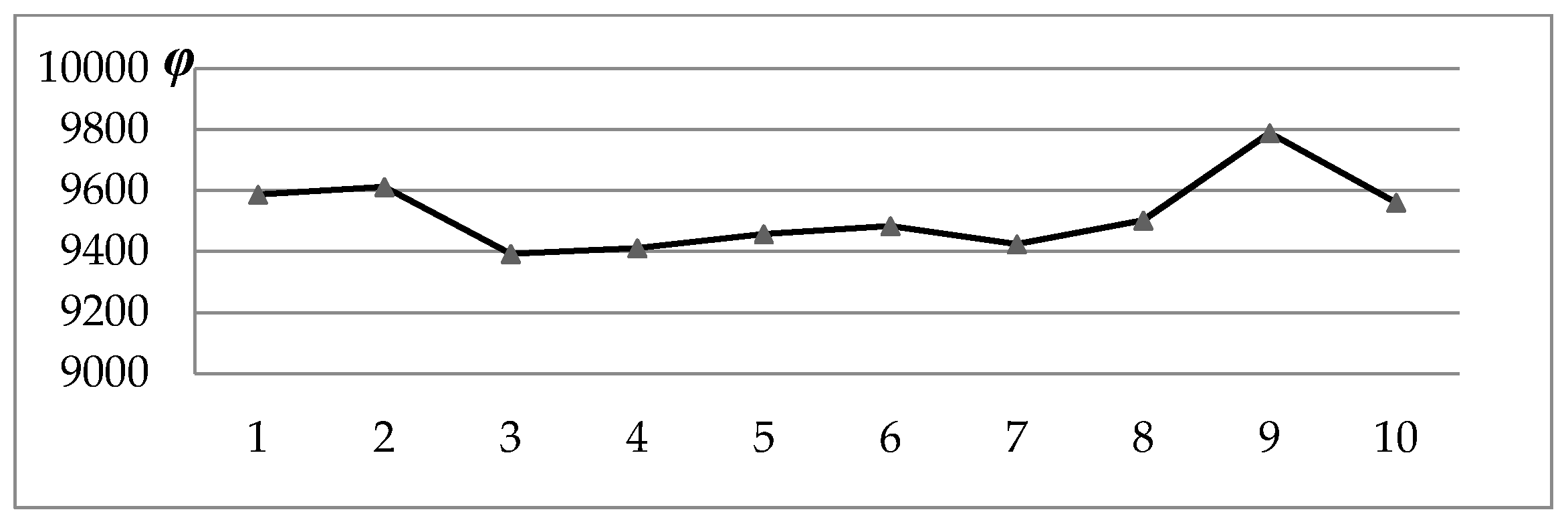

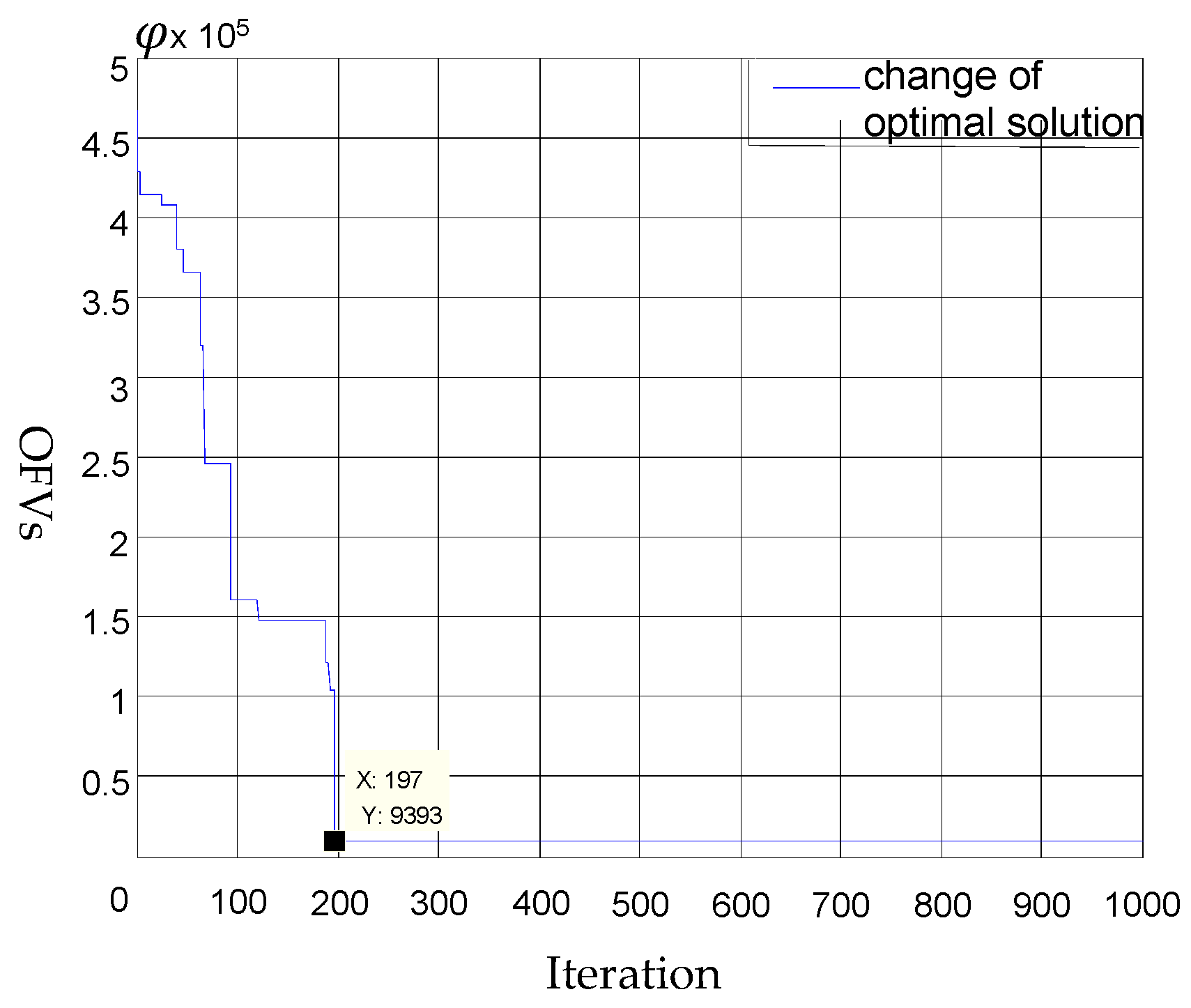

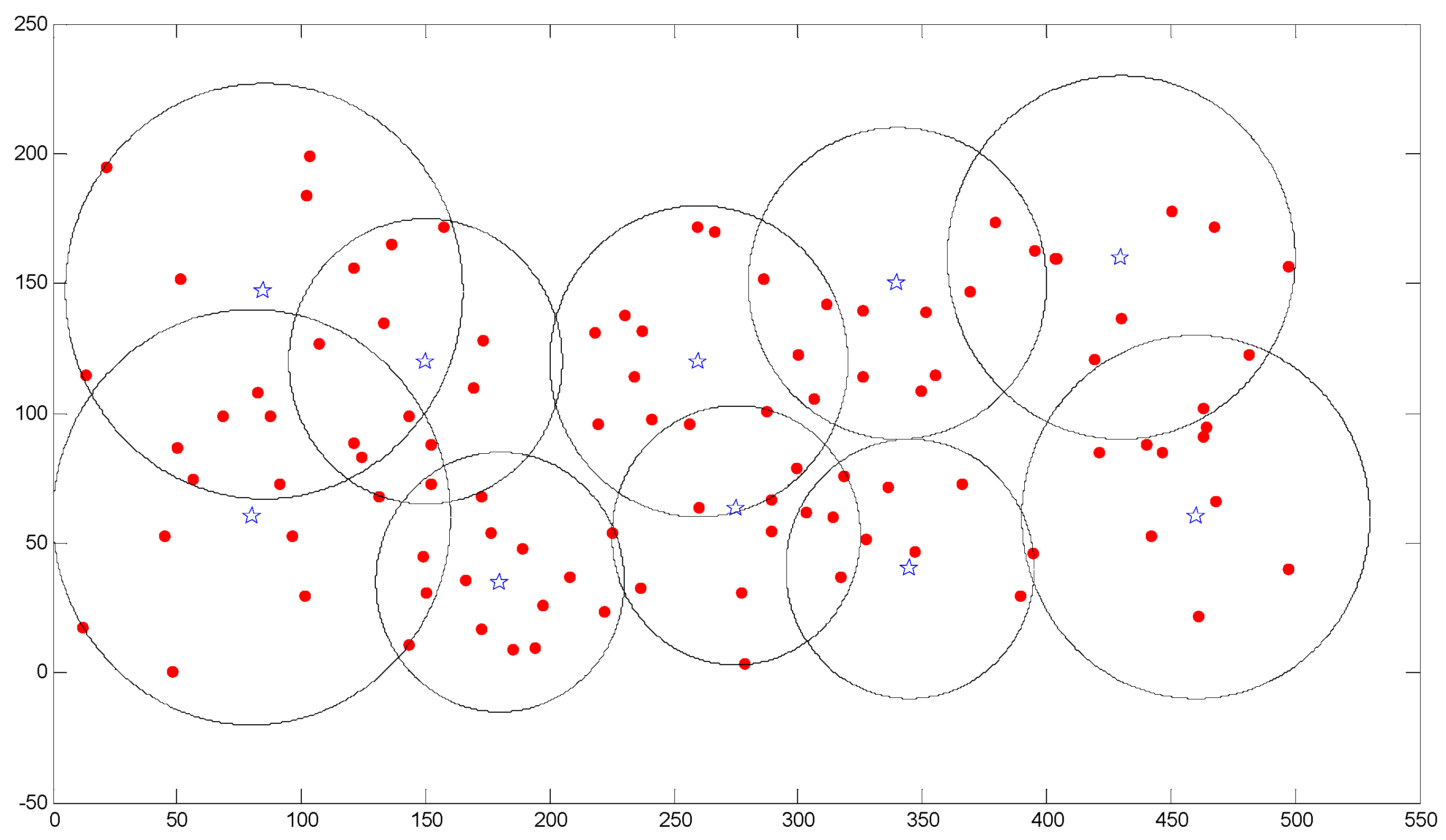

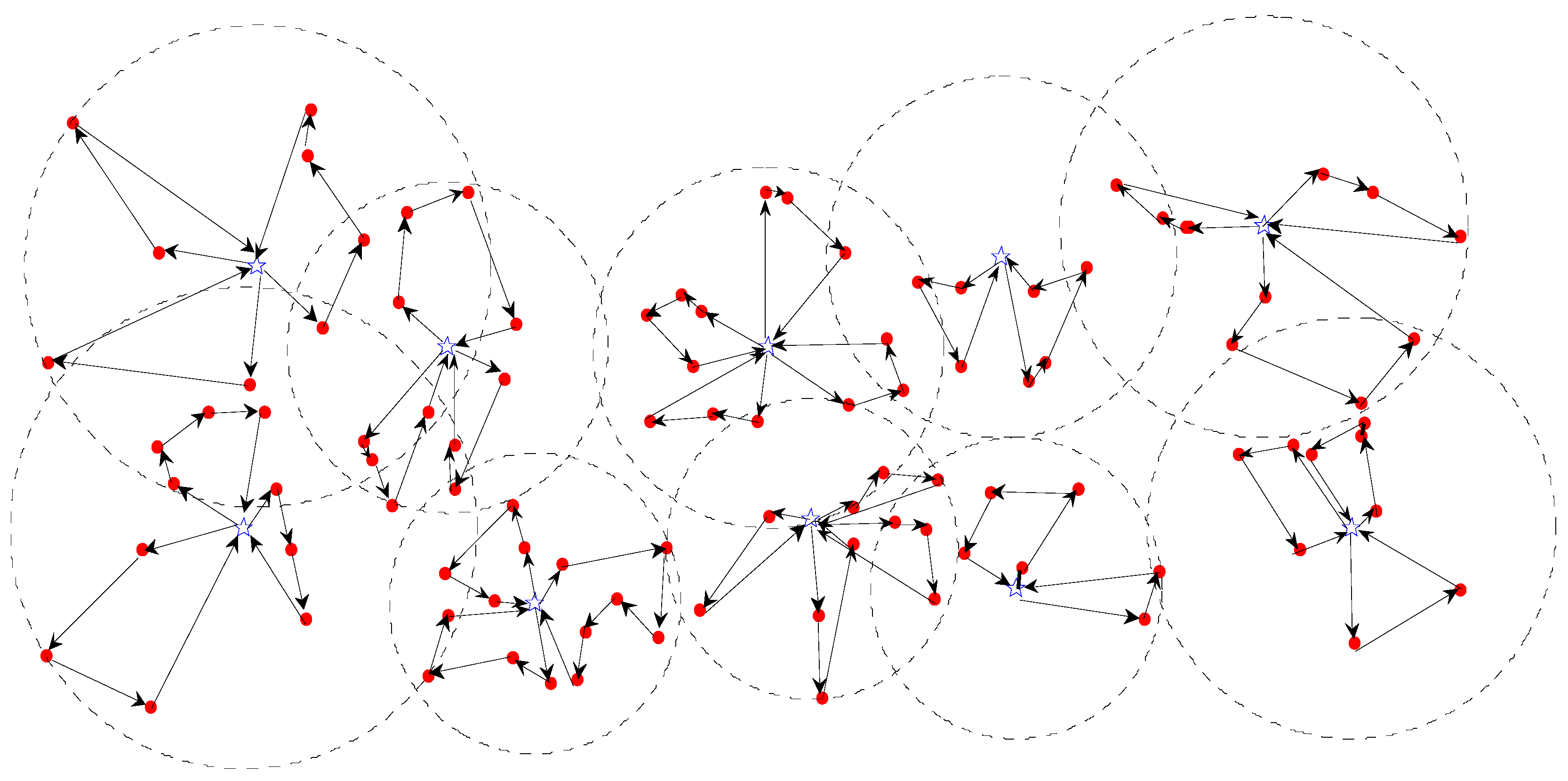

3.1. Numerical Example 1

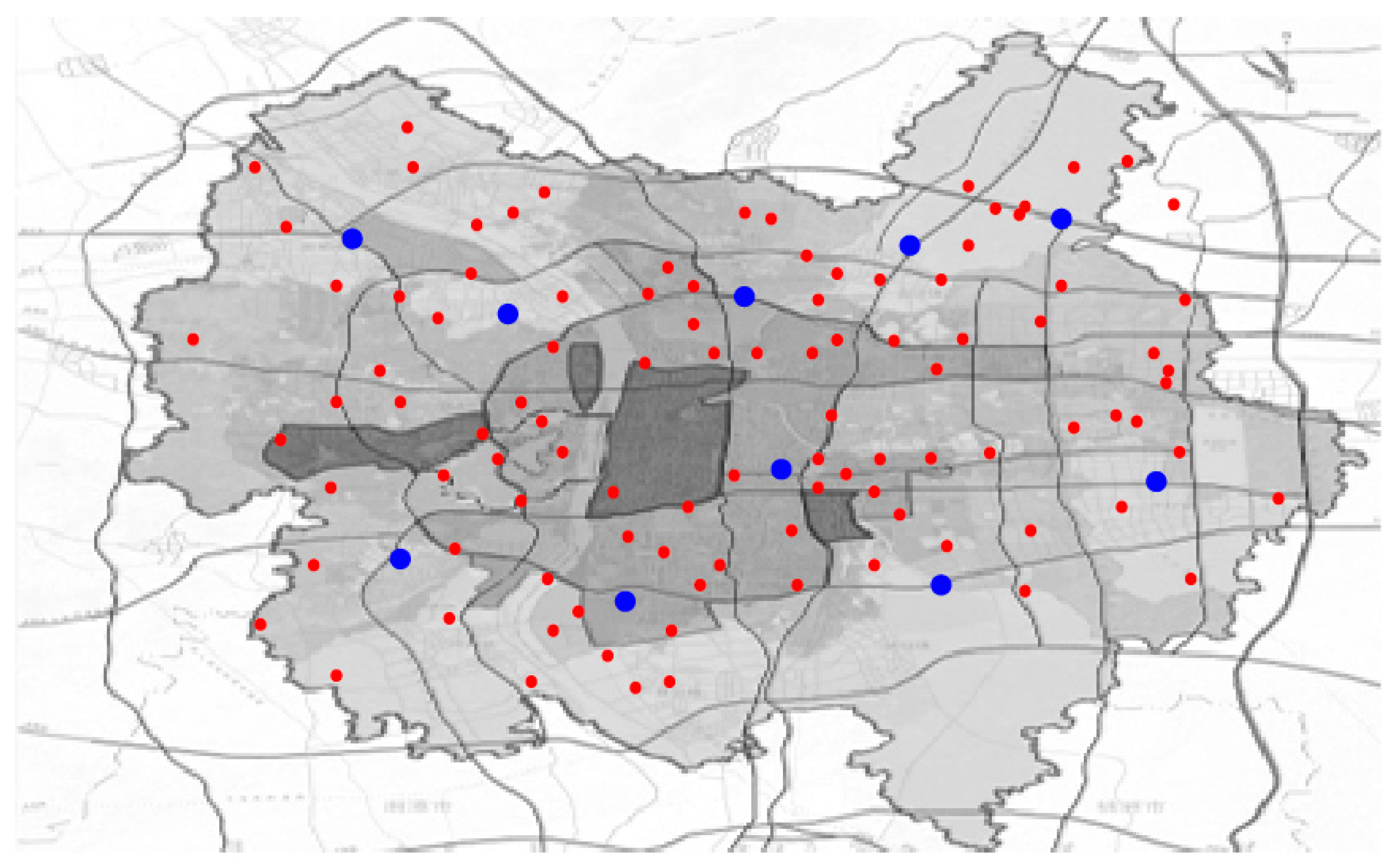

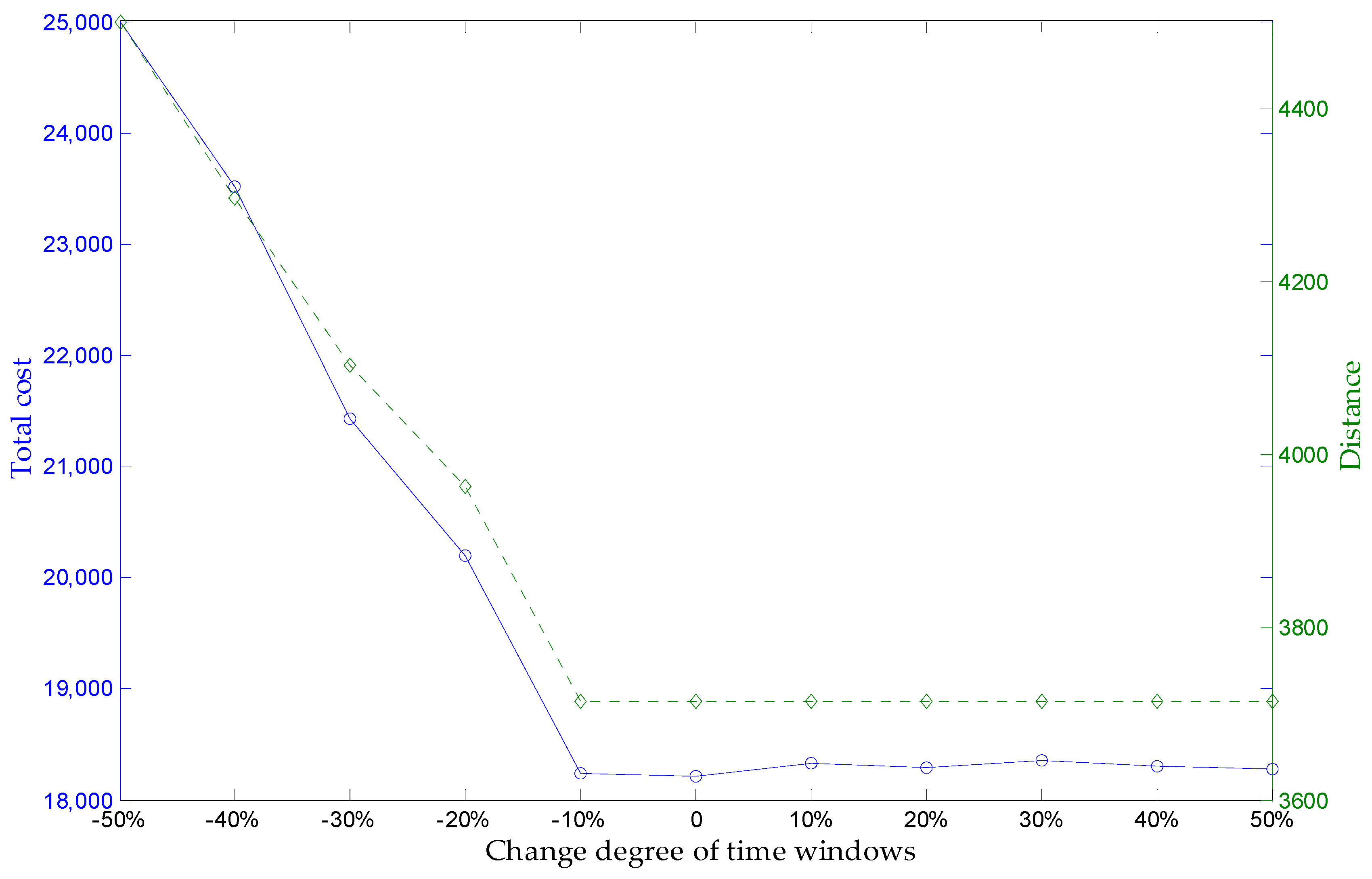

3.2. Numerical Example 2

3.3. Comparison with Other Metaheuristics

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Service Center | Coordinate (x, y) | Number of Available Vehicles |

|---|---|---|

| 1 | (180, 35) | 5 |

| 2 | (275, 63) | 6 |

| 3 | (80, 60) | 5 |

| 4 | (85, 147) | 6 |

| 5 | (460, 60) | 5 |

| 6 | (430, 160) | 5 |

| 7 | (260, 120) | 6 |

| 8 | (345, 40) | 4 |

| 9 | (150, 120) | 6 |

| 10 | (340, 150) | 4 |

| Demand Point | Coordinate (x, y) | Parameters () | Demand Interval (ton) | Time-Window (min) |

|---|---|---|---|---|

| 1 | (237, 132) | (7, 1.52) | [7, 9] | [0, 40] |

| 2 | (103, 199) | (6, 1.32) | [5, 7] | [0, 180] |

| 3 | (421, 85) | (11, 22) | [10, 12] | [0, 100] |

| 4 | (303, 62) | (7, 22) | [7, 9] | [0, 50] |

| 5 | (166, 36) | (9, 22) | [8, 12] | [0, 125] |

| 6 | (351, 139) | (6, 1.52) | [6, 8] | [0, 170] |

| 7 | (314, 60) | (8, 22) | [7, 9] | [0, 65] |

| 8 | (121, 89) | (7, 12) | [6, 9] | [0, 70] |

| 9 | (299, 79) | (11,2.52) | [10, 12] | [0, 55] |

| 10 | (450, 178) | (10, 22) | [9, 12] | [0, 40] |

| 11 | (366, 73) | (5, 1.52) | [4, 6] | [0, 50] |

| 12 | (317, 37) | (10, 22) | [9, 11] | [0, 110] |

| 13 | (102, 184) | (7, 22) | [5, 8] | [0, 160] |

| 14 | (48, 1) | (9, 32) | [8, 10] | [0, 200] |

| 15 | (287, 101) | (8, 12) | [7, 9] | [0, 60] |

| 16 | (157, 172) | (4, 12) | [4, 5] | [0, 125] |

| 17 | (442, 53) | (9, 12) | [8, 11] | [0, 160] |

| 18 | (241, 98) | (11, 1.32) | [10, 13] | [0, 65] |

| 19 | (169, 110) | (11, 22) | [10, 13] | [0, 45] |

| 20 | (197, 26) | (5, 1.42) | [5, 6] | [0, 200] |

| 21 | (327, 52) | (9, 22) | [8, 10] | [0, 140] |

| 22 | (131, 68) | (8, 1.22) | [7, 9] | [0, 120] |

| 23 | (481, 123) | (7, 1.32) | [6, 8] | [0, 180] |

| 24 | (395, 163) | (6, 12) | [5, 7] | [0, 65] |

| 25 | (50, 87) | (7, 1.42) | [6, 9] | [0, 70] |

| 26 | (278, 4) | (9, 1.52) | [8, 10] | [0, 85] |

| 27 | (208, 37) | (5, 1.22) | [5, 7] | [0, 125] |

| 28 | (133, 135) | (6, 0.92) | [5, 7] | [0, 40] |

| 29 | (230, 138) | (5, 0.92) | [4, 6] | [0, 60] |

| 30 | (101, 30) | (8, 1.32) | [6, 9] | [0, 85] |

| 31 | (349, 109) | (8, 1.92) | [7, 9] | [0, 60] |

| 32 | (12, 18) | (9, 1.32) | [8, 11] | [0, 120] |

| 33 | (87, 99) | (8, 2.52) | [8, 10] | [0, 130] |

| 34 | (318, 76) | (11, 1.62) | [10, 13] | [0, 90] |

| 35 | (326, 140) | (6, 22) | [5, 7] | [0, 40] |

| 36 | (369, 147) | (7, 1.32) | [7, 10] | [0, 130] |

| 37 | (336, 72) | (6, 1.22) | [5, 8] | [0, 100] |

| 38 | (21, 195) | (13, 2.52) | [12, 15] | [0, 130] |

| 39 | (497, 40) | (12, 1.62) | [11, 14] | [0, 120] |

| 40 | (149, 45) | (6, 22) | [5, 8] | [0, 100] |

| 41 | (403, 160) | (5, 1.22) | [5, 7] | [0, 45] |

| 42 | (91, 73) | (10, 22) | [9, 11] | [0, 40] |

| 43 | (236, 33) | (14, 2.52) | [13, 15] | [0, 80] |

| 44 | (256, 96) | (9, 1.92) | [8, 11] | [0, 45] |

| 45 | (464, 95) | (10, 1.32) | [9, 12] | [0, 50] |

| 46 | (277, 31) | (8, 22) | [8, 10] | [0, 45] |

| 47 | (260, 64) | (11, 22) | [10, 13] | [0, 35] |

| 48 | (194, 10) | (5, 1.22) | [4, 6] | [0, 230] |

| 49 | (96, 53) | (8, 22) | [7, 10] | [0, 70] |

| 50 | (218, 131) | (8, 1.52) | [8, 10] | [0, 90] |

| 51 | (124, 83) | (8, 1.92) | [8, 10] | [0, 85] |

| 52 | (225, 54) | (4, 1.12) | [3, 5] | [0, 80] |

| 53 | (463, 102) | (5, 22) | [5, 7] | [0, 140] |

| 54 | (176, 54) | (5, 0.92) | [4, 6] | [0, 30] |

| 55 | (497, 157) | (8, 1.72) | [7, 9] | [0, 120] |

| 56 | (389, 30) | (15, 2.32) | [14, 17] | [0, 70] |

| 57 | (440, 88) | (7, 1.92) | [6, 8] | [0, 50] |

| 58 | (300, 123) | (10, 1.32) | [9, 12] | [0, 115] |

| 59 | (51, 152) | (12, 22) | [10,15] | [0, 60] |

| 60 | (463, 91) | (6, 1.62) | [5, 7] | [0, 40] |

| 61 | (143, 99) | (6, 22) | [5, 7] | [0, 170] |

| 62 | (152, 88) | (10, 1.32) | [9, 12] | [0, 130] |

| 63 | (219, 96) | (6, 1.22) | [6, 8] | [0, 110] |

| 64 | (446, 85) | (5, 1.62) | [5, 7] | [0, 85] |

| 65 | (289, 55) | (9, 22) | [9, 11] | [0, 160] |

| 66 | (152, 73) | (6, 22) | [5, 7] | [0, 100] |

| 67 | (13, 115) | (15, 32) | [14, 17] | [0, 160] |

| 68 | (430, 137) | (6, 1.62) | [6, 7] | [0, 40] |

| 69 | (467, 172) | (9, 22) | [8, 10] | [0, 70] |

| 70 | (289, 67) | (6, 1.22) | [6, 8] | [0, 35] |

| 71 | (172, 17) | (7, 1.22) | [6, 8] | [0, 70] |

| 72 | (121, 156) | (7, 1.22) | [6, 8] | [0, 90] |

| 73 | (82, 108) | (9, 1.52) | [8, 10] | [0, 60] |

| 74 | (326, 114) | (12, 1.92) | [10, 14] | [0, 120] |

| 75 | (107, 127) | (7, 1.32) | [6, 8] | [0, 45] |

| 76 | (189, 48) | (3, 0.82) | [3, 4] | [0, 30] |

| 77 | (355, 115) | (7, 1.62) | [6, 8] | [0, 80] |

| 78 | (286, 152) | (10, 22) | [9, 12] | [0, 140] |

| 79 | (306, 106) | (7, 1.32) | [7, 8] | [0, 90] |

| 80 | (185, 9) | (8, 1.42) | [7, 10] | [0, 45] |

| 81 | (45, 53) | (10, 22) | [10, 12] | [0, 60] |

| 82 | (468, 66) | (6, 1.52) | [6, 8] | [0, 30] |

| 83 | (419, 121) | (7, 1.92) | [6, 8] | [0, 70] |

| 84 | (461, 22) | (14, 2.32) | [12, 16] | [0, 60] |

| 85 | (172, 68) | (7, 22) | [6, 9] | [0, 60] |

| 86 | (173, 128) | (7, 1.62) | [8, 10] | [0, 185] |

| 87 | (150, 31) | (9, 22) | [9, 11] | [0, 145] |

| 88 | (347, 47) | (7, 1.62) | [6, 8] | [0, 30] |

| 89 | (379, 174) | (7, 1.42) | [7, 10] | [0, 100] |

| 90 | (56, 75) | (7, 1.32) | [5, 8] | [0, 50] |

| 91 | (394, 46) | (12, 22) | [11, 14] | [0, 100] |

| 92 | (136, 165) | (8, 1.52) | [7, 9] | [0, 85] |

| 93 | (259, 172) | (7, 1.92) | [6, 9] | [0, 80] |

| 94 | (143, 11) | (3, 0.82) | [3, 4] | [0, 115] |

| 95 | (68, 99) | (6, 1.92) | [5, 8] | [0, 100] |

| 96 | (311, 142) | (8, 1.32) | [8, 10] | [0, 70] |

| 97 | (234, 114) | (7, 2.52) | [7, 8] | [0, 130] |

| 98 | (266, 170) | (8, 1.62) | [8, 11] | [0, 100] |

| 99 | (222, 24) | (3, 12) | [3, 4] | [0, 120] |

| 100 | (404, 160) | (8, 22) | [7, 10] | [0, 50] |

| Service Center | Demand Points |

|---|---|

| 1 | 5,20,27,40,48,52,54,71,76,80,85,87,94,99 |

| 2 | 4,7,9,12,26,34,43,46,47,65,70 |

| 3 | 14,25,30,32,33,42,49,81,90,95 |

| 4 | 2,13,38,59,67,72,73,75 |

| 5 | 3,17,39,45,57,60,64,82,84 |

| 6 | 10,23,24,41,53,55,68,69,83,89,100 |

| 7 | 1,15,18,29,44,50,58,63,78,79,93,97,98 |

| 8 | 11,21,37,56,88,91 |

| 9 | 8,16,19,22,28,51,61,62,66,86,92 |

| 10 | 6,31,35,36,74,77,96 |

| Instance Data | Distance | Vehicles | Instance Data | Distance | Vehicles | Instance Data | Distance | Vehicles |

|---|---|---|---|---|---|---|---|---|

| R101 | 1683.8 | 20 | C101 | 828.94 | 10 | RC101 | 1675.86 | 15 |

| R102 | 1526.75 | 18 | C102 | 828.94 | 10 | RC102 | 1488.36 | 14 |

| R103 | 1319.12 | 14 | C103 | 828.06 | 10 | RC103 | 1306.42 | 12 |

| R104 | 1097.63 | 11 | C104 | 825.65 | 10 | RC104 | 1145.79 | 10 |

| R105 | 1415.24 | 15 | C105 | 828.94 | 10 | RC105 | 1608.45 | 15 |

| R106 | 1275.58 | 13 | C106 | 828.94 | 10 | RC106 | 1408.70 | 13 |

| R107 | 1104.76 | 11 | C107 | 830.56 | 10 | RC107 | 1254.26 | 12 |

| R108 | 1008.9 | 10 | C108 | 834.62 | 10 | RC108 | 1187.53 | 11 |

| R109 | 1187.3 | 13 | C109 | 828.94 | 10 | |||

| R110 | 1142.4 | 11 | ||||||

| R111 | 1129.72 | 11 | ||||||

| R112 | 982.14 | 10 |

| Instance Data | Distance | Vehicles | Instance Data | Distance | Vehicles | Instance Data | Distance | Vehicles |

|---|---|---|---|---|---|---|---|---|

| R201 | 1206.27 | 6 | C201 | 591.56 | 3 | RC201 | 1357.35 | 7 |

| R202 | 1046.16 | 5 | C202 | 608.39 | 4 | RC202 | 1167.1 | 6 |

| R203 | 890.50 | 5 | C203 | 591.17 | 3 | RC203 | 951.08 | 5 |

| R204 | 767.92 | 3 | C204 | 596.55 | 3 | RC204 | 796.14 | 4 |

| R205 | 975.83 | 5 | C205 | 588.88 | 3 | RC205 | 1209.83 | 6 |

| R206 | 900.42 | 4 | C206 | 588.49 | 3 | RC206 | 1080.50 | 5 |

| R207 | 847.57 | 3 | C207 | 597.61 | 4 | RC207 | 985.56 | 5 |

| R208 | 738.41 | 5 | C208 | 588.32 | 3 | RC208 | 785.93 | 4 |

| R209 | 885.64 | 5 | ||||||

| R210 | 931.78 | 5 | ||||||

| R211 | 841.39 | 3 |

References

- Caunhye, A.M.; Nie, X.F.; Pokharel, S. Optimization models in emergency logistics: A literature review. Socio-Econ. Plan. Sci. 2012, 46, 4–13. [Google Scholar] [CrossRef]

- Lin, Y.H.; Batta, R.; Rogerson, P.A.; Blatt, A.; Flanigan, M. A logistics model for emergency supply of critical items in the aftermath of a disaster. Socio-Econ. Plan. Sci. 2011, 45, 132–145. [Google Scholar] [CrossRef]

- Sheu, J.B. Challenges of emergency logistics management. Transp. Res. Part E Logist. Transp. Rev. 2007, 43, 655–659. [Google Scholar] [CrossRef]

- Sheu, J.B. An emergency logistics distribution approach for quick response to urgent relief demand in disasters. Transp. Res. Part E Logist. Transp. Rev. 2007, 43, 687–709. [Google Scholar] [CrossRef]

- Lei, H.T.; Laporte, G.; Guo, B. The capacitated vehicle routing problem with stochastic demands and time windows. Comput. Oper. Res. 2011, 38, 1775–1783. [Google Scholar] [CrossRef]

- Zhu, L.; Rousseau, L.M.; Rei, W.; Li, B. Paired cooperative reoptimization strategy for the vehicle routing problem with stochastic demands. Comput. Oper. Res. 2014, 50, 1–13. [Google Scholar] [CrossRef]

- Errico, F.; Desaulniers, G.; Gendreau, M.; Rei, W.; Rousseau, L.M. A priori optimization with recourse for the vehicle routing problem with hard time windows and stochastic service times. Eur. J. Oper. Res. 2016, 249, 55–66. [Google Scholar] [CrossRef]

- Zhang, J.L.; Lam, W.H.K.; Chen, B.Y. On-time delivery probabilistic models for the vehicle routing problem with stochastic demands and time windows. Eur. J. Oper. Res. 2016, 249, 144–154. [Google Scholar] [CrossRef]

- Yin, P.Y.; Chuang, Y.L. Adaptive Memory Artificial Bee Colony Algorithm for Green Vehicle Routing with Cross-Docking. Appl. Math. Model. 2016, 40, 9302–9315. [Google Scholar] [CrossRef]

- Yin, P.Y.; Lyu, S.R.; Chuang, Y.L. Cooperative Coevolutionary Approach for Integrated Vehicle Routing and Scheduling Using Cross-Dock Buffering. Eng. Appl. Artif. Intell. 2016, 52, 40–53. [Google Scholar] [CrossRef]

- Marinakis, Y.; Iordanidou, G.R.; Marinaki, M. Particle swarm optimization for the vehicle routing problem with stochastic demands. Appl. Soft Comput. 2013, 13, 1693–1704. [Google Scholar] [CrossRef]

- Euchi, J.; Chabchoub, H.; Yassine, A. New Evolutionary Algorithm Based on 2-Opt Local Search to Solve the Vehicle Routing Problem with Private Fleet and Common Carrier. Int. J. Appl. Metaheuristic Comput 2011, 2, 58–82. [Google Scholar] [CrossRef]

- Parragh, S.N.; Doerner, K.F.; Hartl, R.F. A survey on pickup and delivery problems: Part I: Transportation between customers and depot. J. Betriebswirtsch. 2008, 58, 21–51. [Google Scholar] [CrossRef]

- Parragh, S.N.; Doerner, K.F.; Hartl, R.F. A survey on pickup and delivery problems: Part II: Transportation between pickup and delivery locations. J. Betriebswirtsch. 2008, 58, 81–117. [Google Scholar] [CrossRef]

- Berghida, M.; Boukra, A.; Boumedienne, H. Resolution of a Vehicle Routing Problem with Simultaneous Pickup and Delivery: A Cooperative Approach. Int. J. Appl. Metaheuristic Comput. 2015, 6, 53–68. [Google Scholar] [CrossRef]

- Maquera, G.; Laguna, M.; Gandelman, D.; Sant’Anna, A. Scatter Search Applied to the Vehicle Routing Problem with Simultaneous Delivery and Pickup. Int. J. Appl. Metaheuristic Comput. 2011, 2, 1–20. [Google Scholar] [CrossRef]

- Wohlgemuth, S.; Oloruntoba, R.; Clausen, U. Dynamic vehicle routing with anticipation in disaster relief. Socio-Econ. Plan. Sci. 2012, 46, 261–271. [Google Scholar] [CrossRef]

- Pillac, V.; Gendreau, M.; Guéret, C.; Medaglia, A.L. A review of dynamic vehicle routing problems. Eur. J. Oper. Res. 2013, 225, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Cao, E.; Lai, M.Y.; Yang, H.M. Open vehicle routing problem with demand uncertainty and its robust strategies. Expert Syst. Appl. 2014, 41, 3569–3575. [Google Scholar] [CrossRef]

- Moghaddama, B.F.; Ruiz, R.; Sadjadi, S.J. Vehicle routing problem with uncertain demands: An advanced particle swarm algorithm. Comput. Ind. Eng. 2012, 62, 306–317. [Google Scholar] [CrossRef]

- Sheu, J.B. Dynamic relief-demand management for emergency logistics operations under large-scale disasters. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 1–17. [Google Scholar] [CrossRef]

- Chang, F.S.; Wu, J.S.; Lee, C.N.; Shen, H.C. Greedy-search-based multi-objective genetic algorithm for emergency logistics scheduling. Expert Syst. Appl. 2014, 41, 2947–2956. [Google Scholar] [CrossRef]

- Wang, H.J.; Du, L.J.; Ma, S.H. Multi-objective open location-routing model with split delivery for optimized relief distribution in post-earthquake. Transp. Res. Part E Logist. Transp. Rev. 2014, 69, 160–179. [Google Scholar] [CrossRef]

- Hochbaum, D.S.; Shmoys, D.B. Best possible heuristics for the bottleneck wandering salesperson and bottleneck vehicle routing problem. Eur. J. Oper. Res. 1986, 26, 380–384. [Google Scholar] [CrossRef]

- Ombuki, B.; Ross, B.J.; Hanshar, F. Multi-objective genetic algorithms for vehicle routing problem with time windows. Appl. Intell. 2006, 24, 17–30. [Google Scholar] [CrossRef]

- Ursani, Z.; Essam, D.; Cornforth, D.; Stocker, R. Localized genetic algorithm for vehicle routing problem with time windows. Appl. Soft Comput. 2011, 11, 5375–5390. [Google Scholar] [CrossRef]

- Karakatič, S.; Podgorelec, V. A survey of genetic algorithms for solving multi depot vehicle routing problem. Appl. Soft Comput. 2015, 27, 519–532. [Google Scholar] [CrossRef]

- Cordeau, J.F.; Maischberger, M. A parallel iterated tabu search heuristic for vehicle routing problems. Comput. Oper. Res. 2012, 39, 2033–2050. [Google Scholar] [CrossRef]

- Belhaiza, S.; Hansen, P.; Laporte, G. A hybrid variable neighborhood tabu search heuristic for the vehicle routing problem with multiple time windows. Comput. Oper. Res. 2014, 52, 269–281. [Google Scholar] [CrossRef]

- Lai, D.S.W.; Demirag, O.C.; Leung, J.M.Y. A tabu search heuristic for the heterogeneous vehicle routing problem on a multigraph. Transp. Res. Part E Logist. Transp. Rev. 2016, 86, 32–52. [Google Scholar] [CrossRef]

- Kuoa, R.J.; Zulvia, F.E.; Suryadi, K. Hybrid particle swarm optimization with genetic algorithm for solving capacitated vehicle routing problem with fuzzy demand—A case study on garbage collection system. Appl. Math. Comput. 2012, 219, 2574–2588. [Google Scholar] [CrossRef]

- Novoa, C.; Storer, R. An approximate dynamic programming approach for the vehicle routing problem with stochastic demands. Eur. J. Oper. Res. 2009, 196, 509–515. [Google Scholar] [CrossRef]

- Allahyari, S.; Salari, M.; Vigo, D. A hybrid metaheuristic algorithm for the multi-depot covering tour vehicle routing problem. Eur. J. Oper. Res. 2015, 242, 756–768. [Google Scholar] [CrossRef]

- Luo, J.P.; Li, X.; Chen, M.R.; Liu, H.W. A novel hybrid shuffled frog leaping algorithm for vehicle routing problem with time windows. Inf. Sci. 2015, 316, 266–292. [Google Scholar] [CrossRef]

- Küçükoğlu, İ.; Öztürk, N. An advanced hybrid meta-heuristic algorithm for the vehicle routing problem with backhauls and time windows. Comput. Ind. Eng. 2015, 86, 60–68. [Google Scholar] [CrossRef]

- Nagurney, A.; Masoumi, A.H.; Yu, M. Supply Chain Network Operations Management of a Blood Banking System with Cost and Risk Minimization. Comput. Manag. Sci. 2012, 9, 205–231. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, D.; Nagurney, A. A Supply Chain Network Equilibrium Model with Random Demands. Eur. J. Oper. Res. 2004, 156, 194–212. [Google Scholar]

- Nagurney, A.; Yu, M.; Qiang, Q. Supply Chain Network Design for Critical Needs with Outsourcing. Reg. Sci. 2011, 90, 123–142. [Google Scholar] [CrossRef]

- Michalewicz, Z.; Janikow, C.Z.; Krawczyk, J.B. A modified genetic algorithm for optimal control problems. Comput. Math. Appl. 1992, 23, 83–94. [Google Scholar] [CrossRef]

- Bräysy, O.; Dullaert, W.; Gendreau, M. Evolutionary Algorithms for the Vehicle Routing Problem with Time Windows. J. Heuristics 2004, 10, 587–611. [Google Scholar] [CrossRef]

- Berger, J.; Barkaoui, M. A Hybrid Genetic Algorithm for the Capacitated Vehicle Routing Problem. In Proceedings of the Gecco03 International Conference on Genetic & Evolutionary Computation, Chicago, IL, USA, 12–16 July 2003; Volume 2723, Part I. pp. 646–656.

| Symbol | Description |

|---|---|

| Set of emergency demand point (affected point). | |

| Set of emergency supply point (service central). | |

| . | |

| Set of vehicle, . | |

| Actual (uncertain) demand for emergency supplies at demand point , which is a random variable. | |

| Assigned amount of emergency supplies at demand point . | |

| Probability density function of demand at demand point . | |

| The time that the vehicle arrives at the demand point . | |

| The latest time that the affected point can receive the emergency supplies, . | |

| Travel time from point to point . | |

| Distance between point and point . | |

| Transportation cost per kilometer from point to point . | |

| Fixed costs of vehicle for delivery one time. | |

| Penalty cost per unit supplies for shortage in any demand point . | |

| Penalty cost per unit supplies for surplus in any demand point . | |

| Maximum number of available vehicles at service center . | |

| Maximum load capacity of a vehicle. | |

| A large enough positive number. |

| Service Center | Coordinate (x, y) | Number of Available Vehicles |

|---|---|---|

| A | (15, 35) | 5 |

| B | (55, 15) | 5 |

| C | (35, 80) | 5 |

| Demand Point | Coordinate (x, y) | Parameters () | Demand Interval (ton) | Time-Window (min) |

|---|---|---|---|---|

| 1 | (20, 85) | (5, 1.72) | [4, 6] | [0, 40] |

| 2 | (5, 45) | (5, 1.52) | [5, 7] | [0, 40] |

| 3 | (42, 15) | (8, 22) | [7, 10] | [0, 50] |

| 4 | (70, 5) | (7, 22) | [7, 9] | [0, 140] |

| 5 | (50, 84) | (6, 22) | [6, 8] | [0, 100] |

| 6 | (85, 25) | (9, 2.52) | [8, 11] | [0, 90] |

| 7 | (62, 80) | (6, 22) | [5, 7] | [0, 170] |

| 8 | (65, 70) | (4, 12) | [4, 5] | [0, 140] |

| 9 | (50, 50) | (11,3.52) | [10, 12] | [0, 85] |

| 10 | (18, 80) | (7, 22) | [7, 8] | [0, 50] |

| 11 | (25, 60) | (5, 1.52) | [4, 6] | [0, 90] |

| 12 | (5, 10) | (7, 22) | [7, 10] | [0, 105] |

| 13 | (45, 23) | (7, 22) | [5, 8] | [0, 50] |

| 14 | (65, 24) | (9, 32) | [8, 10] | [0, 130] |

| 15 | (31, 25) | (3, 12) | [3, 5] | [0, 90] |

| 16 | (15, 50) | (10, 32) | [10, 11] | [0, 85] |

| 17 | (5, 27) | (4, 12) | [4, 6] | [0, 70] |

| 18 | (57, 28) | (1, 0.32) | [1, 3] | [0, 40] |

| 19 | (35, 60) | (4, 12) | [4, 5] | [0, 45] |

| 20 | (30, 35) | (8, 22) | [8, 10] | [0, 100] |

| 21 | (36, 40) | (7, 22) | [7, 9] | [0, 90] |

| 22 | (15, 20) | (5, 1.62) | [5, 6] | [0, 165] |

| 23 | (25, 45) | (4, 1.32) | [4, 5] | [0, 110] |

| 24 | (20, 10) | (3, 12) | [3, 5] | [0, 135] |

| 25 | (55, 65) | (3, 12) | [3, 5] | [0, 115] |

| 26 | (45, 95) | (5, 1.52) | [5, 6] | [0, 45] |

| 27 | (30, 70) | (6, 22) | [6, 7] | [0, 115] |

| 28 | (50, 0) | (3, 0.92) | [2, 4] | [0, 85] |

| 29 | (95, 10) | (3, 0.92) | [2, 5] | [0, 90] |

| 30 | (75, 30) | (4, 1.32) | [4, 5] | [0, 80] |

| 31 | (10, 60) | (6, 1.92) | [6, 7] | [0, 90] |

| 32 | (60, 90) | (4, 1.32) | [4, 5] | [0, 80] |

| 33 | (80, 15) | (8, 2.52) | [8, 10] | [0, 60] |

| 34 | (85, 5) | (5, 1.62) | [5, 7] | [0, 115] |

| 35 | (60, 5) | (6, 22) | [6, 8] | [0, 120] |

| Set 1 | Demand point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 |

| Service Center | C | A | B | B | C | B | C | C | C | A | |

| Set 2 | Demand points | 13 | 14 | 16 | 17 | 18 | 19 | 20 | 22 | 23 | 25 |

| Service Center | B | B | A | A | B | C | A | A | A | C | |

| Set 3 | Demand points | 26 | 27 | 28 | 29 | 30 | 32 | 33 | 34 | 35 | |

| Service Center | C | C | B | B | B | C | B | B | B |

| Parking Lot | Route|Actual Amount | Route|Actual Amount | Route|Actual Amount |

|---|---|---|---|

| A | 17-12-24-22|4.3-7.6-3.3-5.5 | 2-31-16|5.5-6.6-11.0 | 23-21-20-15|4.4-7.6-8.6-3.3 |

| B | 13-3-28-35|7.6-8.6-3.3-6.6 | 18-30-6-14|2.0-4.4-9.8-8.0 | 33-29-34-4|8.8-3.3-5.5-7.6 |

| C | 19-9-25-8|4.3-11.1-3.3-4.3 | 1-10-11-27|5.5-7.4-5.5-6.6 | 26-32-7-5|5.5-4.4-6.6-6.6 |

| Number | OFV of Initial Solution | OFV of Optimal Solution | Relative Cost Savings/% | Operation Time/s |

|---|---|---|---|---|

| 1 | 23,077.8 | 18,736.2 | 18.78 | 22.73 |

| 2 | 22,978.3 | 19,010.8 | 17.27 | 21.64 |

| 3 | 22,621.5 | 18,708.2 | 17.30 | 21.77 |

| 4 | 23,103.7 | 19,087.6 | 17.38 | 21.34 |

| 5 | 21,785.5 | 18,217.7 | 16.38 | 22.19 |

| 6 | 21,952.6 | 18,438.0 | 16.01 | 21.69 |

| 7 | 22,372.4 | 18,217.7 | 18.57 | 23.73 |

| 8 | 23,189.2 | 19,128.4 | 17.12 | 21.80 |

| 9 | 22,478.3 | 18,394.1 | 18.17 | 21.87 |

| 10 | 23,296.7 | 18,747.5 | 19.52 | 23.05 |

| Variation Range | Number of Used Vehicles on Each Demands Points (in Order of Service Center) | Total Cost | Distance |

|---|---|---|---|

| −50% | [3,3,2,2,3,3,3,2,3,2] | 17,314.6 | 3627.5 |

| −40% | [3,3,2,2,3,3,4,2,3,2] | 17,482.7 | 3627.5 |

| −30% | [3,4,3,3,3,3,4,2,3,2] | 17,859.2 | 3713.9 |

| −20% | [3,4,3,3,3,3,4,2,3,2] | 17,985.5 | 3713.9 |

| −10% | [3,4,3,3,3,3,4,2,3,2] | 18,102.4 | 3713.9 |

| 0 | [3,4,3,3,3,3,4,2,3,2] | 18,217.7 | 3713.9 |

| 10% | [3,4,3,3,3,3,4,2,3,2] | 18,391.5 | 3713.9 |

| 20% | [3,4,3,3,3,3,4,2,3,2] | 18,533.9 | 3713.9 |

| 30% | [4,4,3,3,3,3,4,2,3,3] | 19,074.2 | 3795.4 |

| 40% | [4,4,3,3,3,3,4,2,3,3] | 19,208.6 | 3795.4 |

| 50% | [4,4,3,3,3,3,4,2,3,3] | 19,352.3 | 3795.4 |

| Variation Range | Number of Used Vehicles on Each Demands Points(in Order of Service Center) | Total Cost | Distance |

|---|---|---|---|

| −50% | [-,6,5,5,5,5,-,4,-,4] | ||

| −40% | [5,5,4,4,4,5,6,3,5,4] | 23,509.7 | 4296.5 |

| −30% | [4,5,3,4,3,4,5,3,4,3] | 21,430.2 | 4101.9 |

| −20% | [4,4,3,4,3,4,4,2,4,3] | 20,193.6 | 3962.9 |

| −10% | [3,4,3,3,3,3,4,2,3,2] | 18,241.4 | 3713.9 |

| 0 | [3,4,3,3,3,3,4,2,3,2] | 18,217.7 | 3713.9 |

| 10% | [3,4,3,3,3,3,4,2,3,2] | 18,330.5 | 3713.9 |

| 20% | [3,4,3,3,3,3,4,2,3,2] | 18,293.1 | 3713.9 |

| 30% | [3,4,3,3,3,3,4,2,3,2] | 18,351.2 | 3713.9 |

| 40% | [3,4,3,3,3,3,4,2,3,2] | 18,308.6 | 3713.9 |

| 50% | [3,4,3,3,3,3,4,2,3,2] | 18,276.3 | 3713.9 |

| Problem | Average Performance | Best Performance | |

|---|---|---|---|

| R1 | Cost | 15,697.13 | 14,746.00 |

| Distance | 1239.53 | 1234.39 | |

| Vehicles | 13.08 | 13.08 | |

| R2 | Cost | 11,475.46 | 11,293.00 |

| Distance | 911.99 | 907.51 | |

| Vehicles | 4.45 | 4.45 | |

| C1 | Cost | 12,904.28 | 12,859.00 |

| Distance | 829.29 | 828.50 | |

| Vehicles | 10.00 | 10.00 | |

| C2 | Cost | 9558.90 | 9426.00 |

| Distance | 593.87 | 589.86 | |

| Vehicles | 3.25 | 3.25 | |

| RC1 | Cost | 16,257.74 | 15,948.00 |

| Distance | 1384.44 | 1381.56 | |

| Vehicles | 12.75 | 12.75 | |

| RC2 | Cost | 12,632.35 | 12,315.00 |

| Distance | 1041.74 | 1038.95 | |

| Vehicles | 5.25 | 5.25 | |

| Problem | BBB | M | RT | JM | HG | BC | BD | QYC | |

|---|---|---|---|---|---|---|---|---|---|

| R1 | Distance | 1251.40 | 1208 | 1208.50 | 1179.95 | 1212.73 | 1209.19 | 1220.14 | 1239.53 |

| Vehicles | 12.17 | 12.00 | 12.25 | 13.25 | 11.92 | 12.08 | 12.00 | 13.08 | |

| R2 | Distance | 1056.59 | 954 | 961.72 | 878.41 | 955.03 | 963.62 | 977.57 | 911.99 |

| Vehicles | 2.73 | 2.73 | 2.91 | 5.36 | 2.73 | 2.73 | 2.73 | 4.45 | |

| C1 | Distance | 828.50 | 829 | 828.38 | 828.38 | 828.38 | 828.38 | 828.38 | 829.29 |

| Vehicles | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | |

| C2 | Distance | 590.06 | 590 | 589.86 | 589.86 | 589.86 | 589.86 | 589.86 | 593.87 |

| Vehicles | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.25 | |

| RC1 | Distance | 1414.86 | 1387 | 1377.39 | 1343.64 | 1386.44 | 1389.22 | 1397.44 | 1384.44 |

| Vehicles | 11.88 | 11.50 | 11.88 | 13.00 | 11.50 | 11.50 | 11.50 | 12.75 | |

| RC2 | Distance | 1258.15 | 1119 | 1119.59 | 1004.21 | 1123.17 | 1143.70 | 1140.06 | 1041.74 |

| Vehicles | 3.25 | 3.25 | 3.38 | 6.25 | 3.25 | 3.25 | 3.25 | 5.25 | |

| Time(min) | Pentium 400 MHz, 30 min | Pentium III 450 MHz, 150.2 min | Silicon Graphics 100 MHz | Pentium III 1 GHz, 0.8 min | Pentium 400 MHz, -- | 5 × Pentium 850 MHz, 12 min | AMD 700 Mz, 9.1 min | Pentium 3.20 GHz, 1.7 min | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, J.; Ye, Y.; Cheng, B.-r.; Zhao, X.; Ni, L. The Emergency Vehicle Routing Problem with Uncertain Demand under Sustainability Environments. Sustainability 2017, 9, 288. https://doi.org/10.3390/su9020288

Qin J, Ye Y, Cheng B-r, Zhao X, Ni L. The Emergency Vehicle Routing Problem with Uncertain Demand under Sustainability Environments. Sustainability. 2017; 9(2):288. https://doi.org/10.3390/su9020288

Chicago/Turabian StyleQin, Jin, Yong Ye, Bi-rong Cheng, Xiaobo Zhao, and Linling Ni. 2017. "The Emergency Vehicle Routing Problem with Uncertain Demand under Sustainability Environments" Sustainability 9, no. 2: 288. https://doi.org/10.3390/su9020288