Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment

Abstract

:1. Introduction

2. Methods

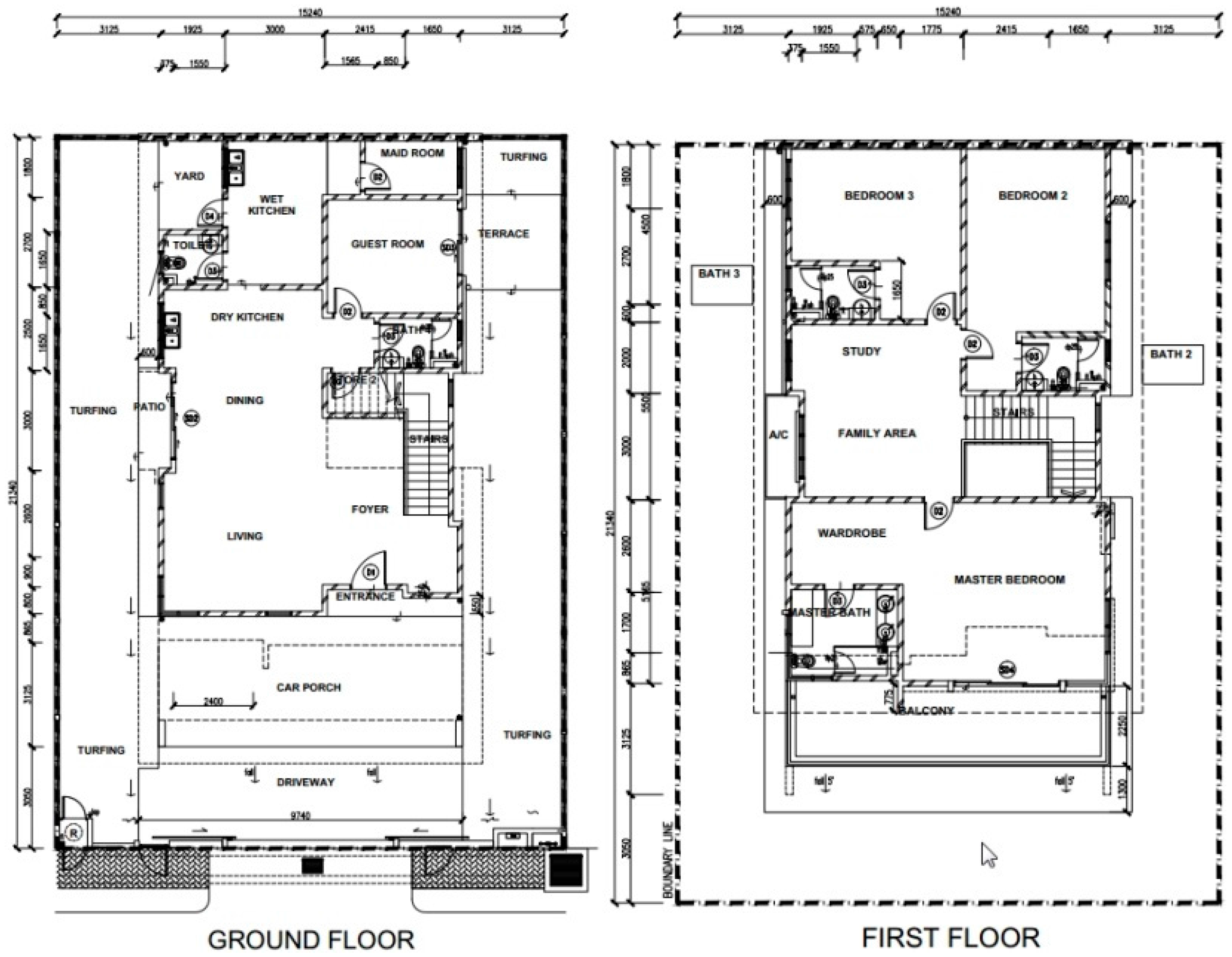

2.1. Goal and Scope Definition

System Boundaries

2.2. Life Cycle Inventory

2.2.1. Pre-Use Phase

- In Malaysia, only steel and aluminium were recycled, whereas other materials are transported to the landfill as suggested by Arham [34]. The building materials related to steel and aluminium i.e., the reinforcement bars, aluminium window and door frames in the case studies were adjusted accordingly by replacing the use of pig iron and primary aluminium to scrap iron and old aluminium scrap, respectively, as suggested in the SimaPro.

- The types and materials were limited to process data equipped in the databases.

- Acrylic emulsion paint was substituted with alkyd paint due to the limitation in the databases.

- The transportation distances from the manufacturer to the construction site were assumed to be 300 km for all materials; meanwhile, the distance is 50 km for a ready-mix concrete, as suggested by Wittstock et al. [35].

- A 16-ton lorry was used to transport materials from manufacturers to the site, whereas a 24-ton ready-mix lorry was used to transport concretes.

- The transportation data were calculated based on impact per ton kilometre (tkm) fleet average from the Ecoinvent database with adaptation of Malaysian data from MYCLID for electricity and diesel. The CO2 emissions for the 16-ton and 24-ton lorry were estimated at 0.84822 kg and 0.93854 kg per tkm, respectively [29,31].

2.2.2. Construction Phase

2.2.3. Use Phase

Operation Data

Maintenance Data

2.2.4. EOL Phase

2.3. Life Cycle Impact Assessment (LCIA)

2.4. Interpretation

3. Results and Discussion

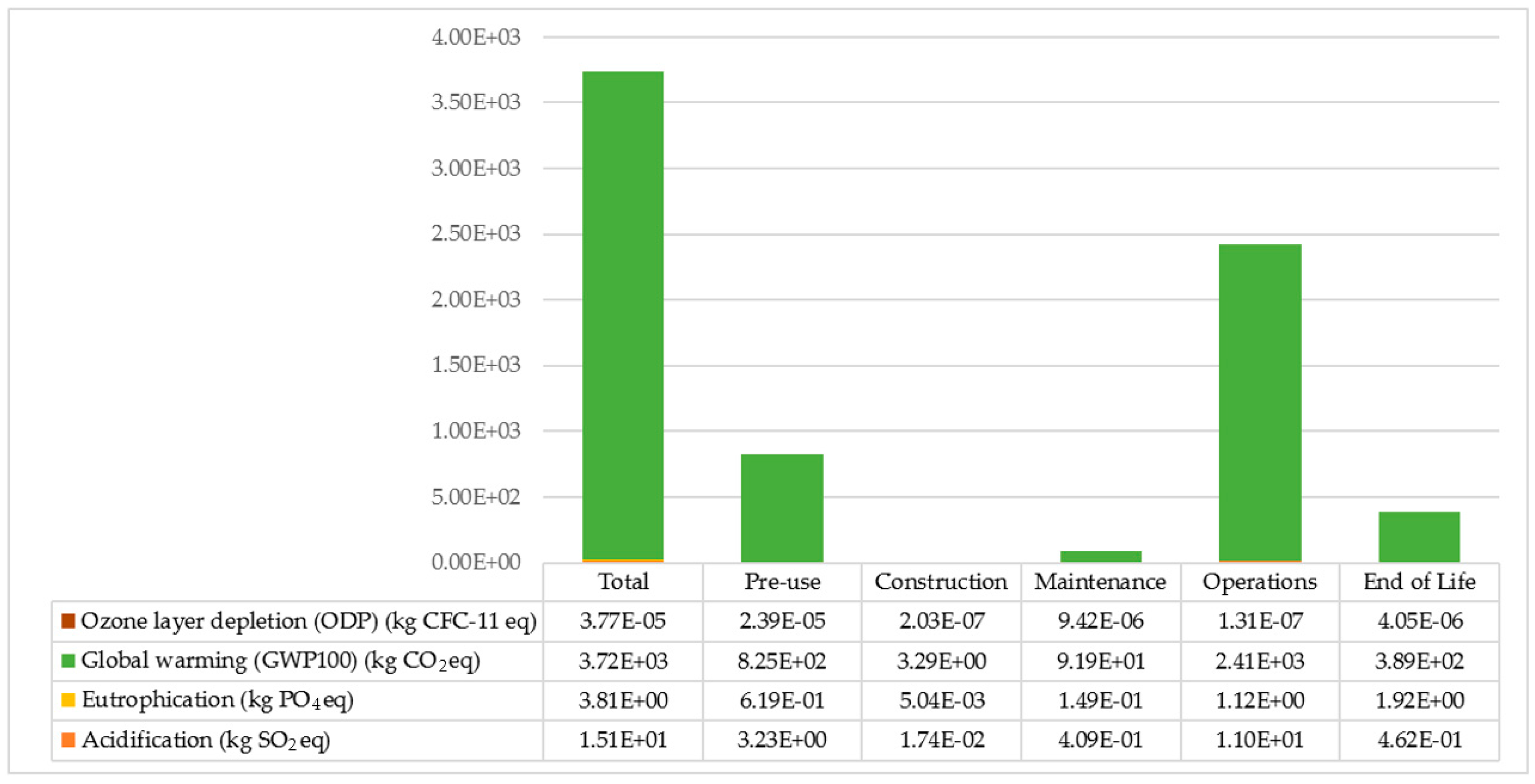

3.1. Overview of the Results

3.2. Process Contribution Analysis

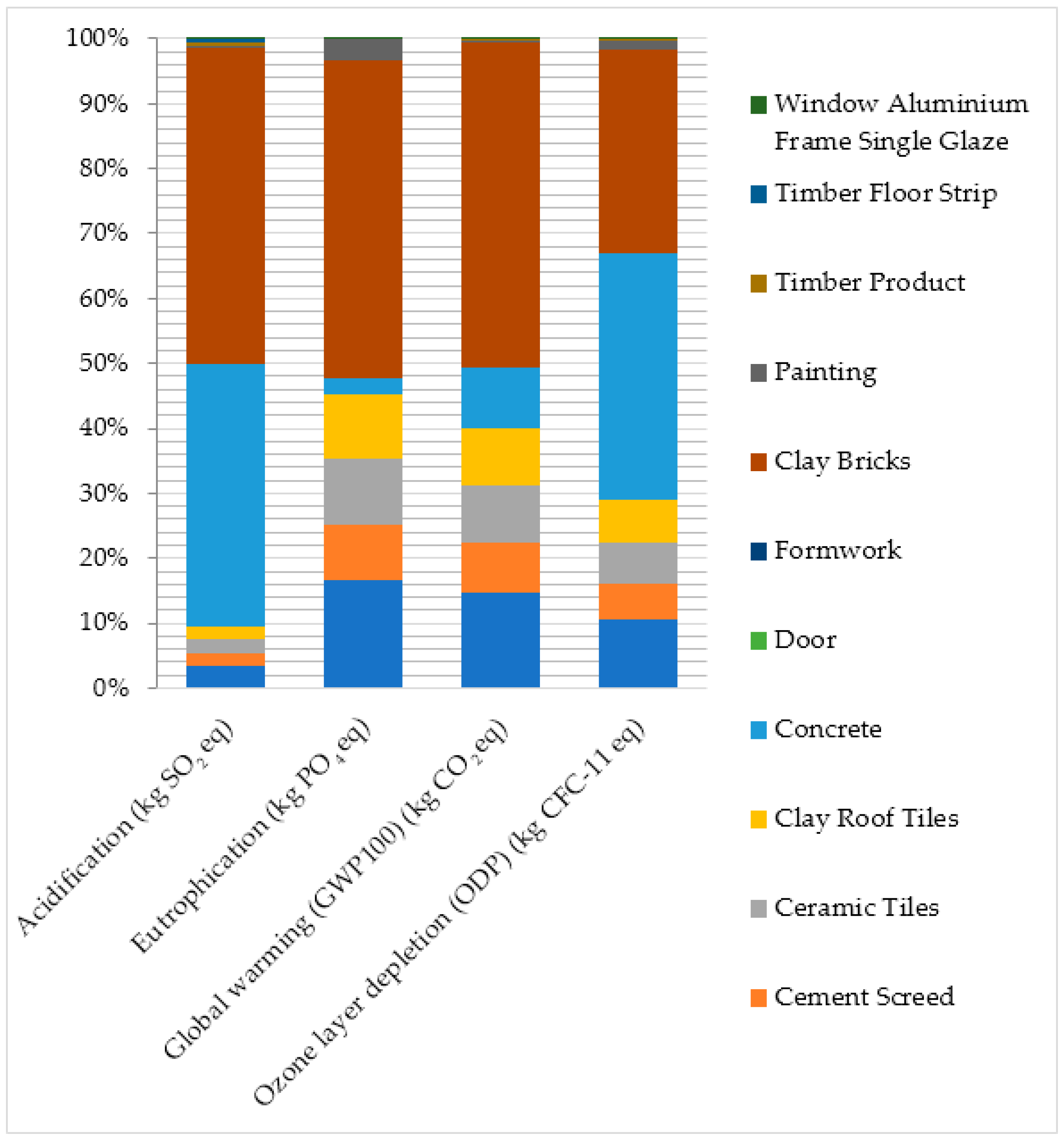

Impact of Materials

3.3. Sensitivity Analysis

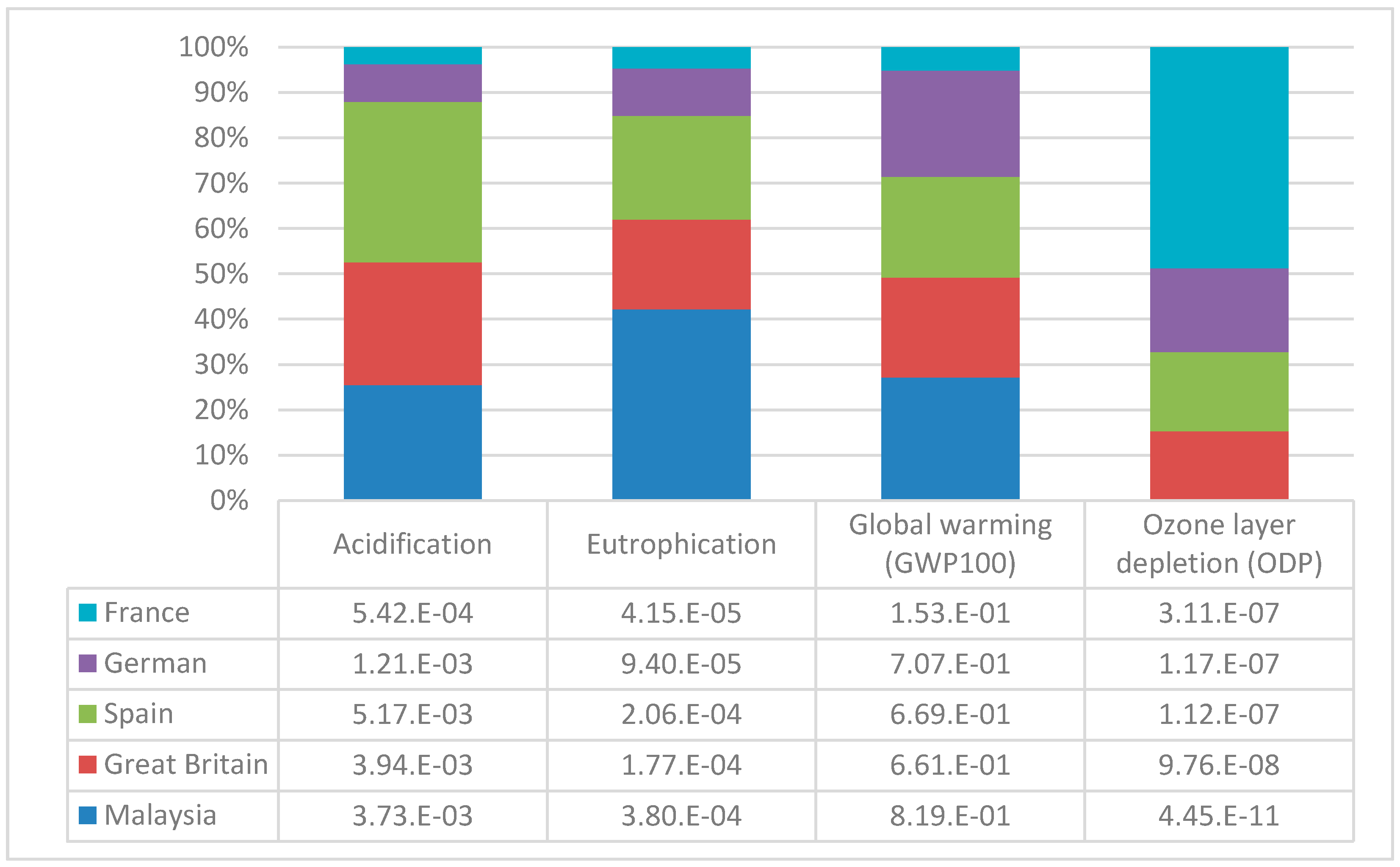

3.4. Comparison with Other Studies

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Arena, A.P.; De Rosa, C. Life Cycle Assessment of Energy and Environmental Implications of the Implementation of Conservation Technologies in School Buildings in Mendoza—Argentina. Build. Environ. 2003, 38, 359–368. [Google Scholar] [CrossRef]

- Roodman, D.; Lenssen, N.; Peterson, J. A Building Revolution: How Ecology and Health Concerns Are Transforming Construction; Worldwatch Institute: Washington, DC, USA, 1995. [Google Scholar]

- Singh, A.; Berghorn, G.; Joshi, S.; Syal, M. Review of Life-Cycle Assessment Applications in Building Construction. J. Archit. Eng. 2011, 17, 15–23. [Google Scholar] [CrossRef]

- Fava, J.; Baer, S.; Cooper, J. Increasing Demands for Life Cycle Assessments in North America. J. Ind. Ecol. 2009, 13, 491–494. [Google Scholar] [CrossRef]

- Oyarzo, J.; Peuportier, B. Life Cycle Assessment Model Applied to Housing in Chile. J. Clean. Prod. 2014, 69, 109–116. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Adalberth, K. Energy Use during the Life Cycle of Buildings: A Method. Build. Environ. 1997, 32, 317–320. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A Review of Life Cycle Assessment Method for Building Industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Ismail, I.; Chen, S. Current Status of Carbon Footprints and LCA in Malaysia; SIRIM: Shah Alam, Selangor, Malaysia, 2010; pp. 1–8. [Google Scholar]

- Syafa Bakri, S.N.; Surif, S.; Ramasamy, R.K. A Case Study of Life Cycle Assessment (LCA) on Ballast for Fluorescent Lamp in Malaysia. In Proceedings of the IEEE International Symposium on Electronics and the Environment (ISEE), San Francisco, CA, USA, 19–22 May 2008; pp. 1–4.

- Thannimalay, L.; Yusoff, S.; Chen, S.S.; Zin Zawawi, N. Eutrophication Potential of Laundry Detergent Used in Malaysia. In Proceedings of the International Conference on Environment, Penang, Malaysia, 11–13 December 2012; pp. 515–522.

- Thannimalay, L.; Yusoff, S.; Zawawi, N.Z. Life Cycle Assessment of Sodium Hydroxide. Aust. J. Basic Appl. Sci. 2013, 7, 421–431. [Google Scholar]

- Sharaai, A.H.; Mahmood, N.Z.; Sulaiman, A.H. Potential of the Application of Life Cycle Assessment (LCA) in the Water Treatment Process in Malaysia; LCA: Malaysia, 2009; Available online: http://www.lcamalaysia.com/i_news/Potential_of_the_application_of_LCA_in_WTP_in_msia.pdf (accessed on 17 June 2014).

- Sharaai, A.H.; Mahmood, N.Z.; Sulaiman, A.H. Life Cycle Assessment (LCA) in Potable Water Production: An Analysis of Green House Gases Emission from Chemicals and Electricity Usage in Water Treatment in Malaysia. Asian J. Water Environ. Pollut. 2009, 6, 27–34. [Google Scholar]

- Shafie, S.M.; Mahlia, T.M.I.; Masjuki, H.H.; Rismanchi, B. Life Cycle Assessment (LCA) of Electricity Generation from Rice Husk in Malaysia. Energy Procedia 2012, 14, 499–504. [Google Scholar] [CrossRef]

- SIRIM. Cradle-to-Gate Life Cycle Inventory Analysis for Bio-Mate Composting System; Environmental Technology Research Centre: Shah Alam, Malaysia, 2011. [Google Scholar]

- Sumiani, Y.; Onn, C.C.; Din, M.A.M.; Jaafar, W. Environmental Planning Strategies for Optimum Solid Waste Landfill Siting. Sains Malays. 2009, 38, 457–462. [Google Scholar]

- Hassan, M.; Awang, M.; Lee Chong, T.; Zakaria, Z.; Bee Lay, L.; Yusoff, N.; Sino, H. The Application of an Life Cycle Inventory (LCI) Model for Solid Waste Disposal Systems in Malaysia. Int. J. Life Cycle Assess. 1999, 4, 188–190. [Google Scholar] [CrossRef]

- Fujita, Y.; Matsumoto, H.; Ho, C.S. Life Cycle Assessment Using Input-Output Analysis of CO2 Emissions from Housing in Malaysia. In Proceedings of the International Conference on Sustainable Energy Technologies, Seoul, Korea, 24–27 August 2008.

- Omar, W.M.S.W.; Doh, J.-H.; Panuwatwanich, K.; Miller, D. Assessment of the Embodied Carbon in Precast Concrete Wall Panels Using a Hybrid Life Cycle Assessment Approach in Malaysia. Sustain. Cities Soc. 2014, 10, 101–111. [Google Scholar] [CrossRef]

- Wen, T.J.; Siong, H.C.; Noor, Z.Z. Assessment of Embodied Energy and Global Warming Potential of Building Construction Using Life Cycle Analysis Approach: Case Studies of Residential Buildings in Iskandar Malaysia. Energy Build. 2014, 93, 295–302. [Google Scholar] [CrossRef]

- Bin Marsono, A.K.; Balasbaneh, A.T. Combinations of Building Construction Material for Residential Building for the Global Warming Mitigation for Malaysia. Constr. Build. Mater. 2015, 85, 100–108. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14044 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Abd Rashid, A.F.; Yusoff, S. Sustainability in the Building Industry: A Review on the Implementation of Life Cycle Assessment. In Proccedings of the 2nd International Conference on Climate Change & Social Issues, Kuala Lumpur, Malaysia, 28–29 November 2012; Wijesuriya, K., Ed.; International Center for Research and Development (ICRD): Kuala Lumpur, Malaysia, 2012. [Google Scholar]

- Kadir, M.R.A.; Lee, W.P.; Jaafar, M.S.; Sapuan, S.M.; Ali, A.A.A. Construction Performance Comparison between Conventional and Industrialised Building Systems in Malaysia. Struct. Surv. 2006, 24, 412–424. [Google Scholar] [CrossRef]

- Iyer-Raniga, U.; Wong, J.P.C. Evaluation of Whole Life Cycle Assessment for Heritage Buildings in Australia. Build. Environ. 2012, 47, 138–149. [Google Scholar] [CrossRef]

- PRé. SimaPro. Available online: http://www.pre-sustainability.com/simapro (accessed on 1 February 2015).

- Herrmann, I.T.; Moltesen, A. Does It Matter Which Life Cycle Assessment (LCA) Tool You Choose?—A Comparative Assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- MY-LCID. Malaysia Life Cycle Inventory Database. Available online: http://mylcid.sirim.my/sirimlca/ (accessed on 22 March 2013).

- Horváth, S.E.; Szalay, Z. Decision-Making Case Study for Retrofit of High-Rise Concrete Buildings Based on Life Cycle Assessment Scenarios. In International Symposium on Life Cycle Assessment and Construction—Civil Engineering and Buildings; Ventura, A., De la Roche, C., Eds.; RILEM Publications SARL: Nantes, France, 2012; pp. 116–124. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.J.; Doka, G.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; Spielmann, M. Overview and Methodology. Ecoinvent Rep. 2007, Report No. 1. Available online: http://www.ecoinvent.org/files/200712_frischknecht_jungbluth_overview_methodology_ecoinvent2.pdf (accessed on 12 February 2015).

- Rossi, B.; Marique, A.-F.; Glaumann, M.; Reiter, S. Life-Cycle Assessment of Residential Buildings in Three Different European Locations, Basic Tool. Build. Environ. 2012, 51, 395–401. [Google Scholar] [CrossRef]

- Buchan, R.D.; Fleming, F.E.; Grant, F.E. Estimating for Builders & Surveyors, 2nd ed.; Elsevier: Oxford, UK, 2003. [Google Scholar]

- Arham, A. A Methodological Analysis of Demolition Works in Malaysia; Faculty of Civil Engineering, Universiti Teknologi Malaysia: Skudai, Malaysia, 2008. [Google Scholar]

- Wittstock, B.; Gantner, J.; Saunders, T.; Anderson, J.; Lenz, K.; Carter, C.; Gyetvai, Z.; Kreißig, J.; Braune, A.; Lasvaux, S.; et al. EeBGuide Guidance Document Part B: BUILDINGS; Fraunhofer Verlag: Stuttgart, Germany, 2012. [Google Scholar]

- Abdullah, A. Anggaran Kos Kerja Bangunan; Pearson/Prentice Hall: Petaling Jaya, Malaysia, 2005. [Google Scholar]

- OpenStudio. Available online: https://www.openstudio.net/ (accessed on 13 May 2014).

- Kubota, T.; Jeong, S.; Toe, D.H.C.; Ossen, D.R. Energy Consumption and Air-Conditioning Usage in Residential Buildings of Malaysia. J. Int. Dev. Coorper. 2011, 17, 61–69. [Google Scholar]

- Ortiz-Rodríguez, O.; Castells, F.; Sonnemann, G. Life Cycle Assessment of Two Dwellings: One in Spain, a Developed Country, and One in Colombia, a Country under Development. Sci. Total Environ. 2010, 408, 2435–2443. [Google Scholar] [CrossRef] [PubMed]

- Ochsendorf, J.; Norford, L.K.; Brown, D.; Durchlag, H.; Hsu, S.L.; Love, A.; Santero, N.; Swei, O.; Webb, A.; Wildnauer, M. Methods, Impacts, and Opportunities in the Concrete Building Life Cycle. 2011. Available online: http://www.greenconcrete.info/downloads/MITBuildingsLCAreport.pdf (accessed on 8 June 2015).

- Blengini, G.A.; Di Carlo, T. The Changing Role of Life Cycle Phases, Subsystems and Materials in the LCA of Low Energy Buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F. Life-Cycle Assessment of a House with Alternative Exterior Walls: Comparison of Three Impact Assessment Methods. Energy Build. 2012, 47, 572–583. [Google Scholar] [CrossRef]

- Khasreen, M.; Banfill, P.F.; Menzies, G. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef] [Green Version]

- Kashef-Haghighi, S.; Shao, Y.; Ghoshal, S. Mathematical Modeling of CO2 Uptake by Concrete during Accelerated Carbonation Curing. Cem. Concr. Res. 2015, 67, 1–10. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Feng, Y.; Mao, C. Uncertainty Analysis for Measuring Greenhouse Gas Emissions in the Building Construction Phase: A Case Study in China. J. Clean. Prod. 2016, 129, 183–195. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental Impacts of the UK Residential Sector: Life Cycle Assessment of Houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Utama, A.; Gheewala, S.H. Life Cycle Energy of Single Landed Houses in Indonesia. Energy Build. 2008, 40, 1911–1916. [Google Scholar] [CrossRef]

- Ortiz, O.; Bonnet, C.; Bruno, J.C.; Castells, F. Sustainability Based on LCM of Residential Dwellings: A Case Study in Catalonia, Spain. Build. Environ. 2009, 44, 584–594. [Google Scholar] [CrossRef]

| Item | Materials | Quantity | Quantity/m2 GFA | Unit |

|---|---|---|---|---|

| A | Substructure | |||

| Excavation | 86.02 | 0.35 | m3 | |

| Hardcore | 15.44 | 0.06 | m3 | |

| Concrete grade 7 blinding | 21.74 | 0.09 | m3 | |

| Concrete grade 25 | 184.03 | 0.75 | m3 | |

| Steel reinforcement | 2561.62 | 10.41 | kg | |

| Timber formwork | 4.13 | 0.02 | m3 | |

| B | Frame | |||

| Concrete grade 25 | 23.20 | 0.09 | m3 | |

| Steel reinforcement | 3883.00 | 15.78 | kg | |

| Timber formwork | 7.69 | 0.03 | m3 | |

| C | Upper Floor | |||

| Concrete grade 25 | 28.73 | 0.12 | m3 | |

| Steel reinforcement | 1709.62 | 6.95 | kg | |

| Timber formwork | 3.35 | 0.01 | m3 | |

| D | Stairs | |||

| Concrete grade 25 | 2.78 | 0.01 | m3 | |

| Steel reinforcement | 243.00 | 0.99 | kg | |

| Timber formwork | 1.07 | 0.00 | m3 | |

| E | Brickwall | |||

| Clay brick | ||||

| Half brick thick | 381.00 | 1.55 | m2 | |

| One brick thick | 37.14 | 0.15 | m2 | |

| F | Roof and covering | |||

| Fascia board | 0.31 | 0.00 | m3 | |

| Painting for roof trusses | 21.61 | 0.09 | m2 | |

| Timber roof trusses | 10.65 | 0.04 | m3 | |

| Clay roof coverings | 213.84 | 0.87 | m2 | |

| G | Finishes | |||

| Cement screed | 9.47 | 0.04 | m3 | |

| Ceramic tiles | 357.59 | 1.45 | m2 | |

| Timber strip | 116.09 | 0.47 | m2 | |

| Plasterwork | 18.57 | 0.08 | m3 | |

| Painting to wall | 1229.50 | 5.00 | m2 |

| Elements | Amount (kWh) |

|---|---|

| Air conditioning | 341,236.50 |

| Illumination | 119,142.50 |

| Electrical Equipment | 265,266.00 |

| Total | 725,645.00 |

| Total/GFA (kWh/m2) | 2949.78 |

| Elements | Expected Lifespan | Number of Replacements in 50 years |

|---|---|---|

| Painting | 10 years | 4 times |

| Roof covering | 25 years | 1 times |

| Window | 30 years | 1 times |

| Impact Category | Unit | Door | Finishes | Frame | Roof & Covering | Stair | Upper Floor | Wall | Substructure | Window |

|---|---|---|---|---|---|---|---|---|---|---|

| Acidification | kg SO2 eq | 8.86 × 10−2 | 4.38 × 10−1 | 2.20 × 10−1 | 7.34 × 10−2 | 2.35 × 10−2 | 2.22 × 10−1 | 3.48 × 10−1 | 1.54 | 1.61 × 10−1 |

| Eutrophication | kg PO4-eq | 3.48 × 10−2 | 9.59 × 10−2 | 5.25 × 10−2 | 1.78 × 10−2 | 4.57 × 10−3 | 2.94 × 10−2 | 7.76 × 10−2 | 2.22 × 10−1 | 6.88 × 10−2 |

| Global warming (GWP100) | kg CO2 eq | 2.11 × 101 | 1.22 × 102 | 5.39 × 101 | 2.15 × 101 | 5.68 | 5.27 × 101 | 1.14 × 102 | 3.65 × 102 | 4.21 × 101 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 1.76 × 10−6 | 5.20 × 10−6 | 1.12 × 10−6 | 1.28 × 10−6 | 8.92 × 10−8 | 4.37 × 10−7 | 6.28 × 10−6 | 3.66 × 10−6 | 3.79 × 10−6 |

| Impact Category | Unit | Aluminium Window | Clay Roof Tiles | Painting |

|---|---|---|---|---|

| Acidification | kg SO2 eq | 1.61 × 10−1 | 3.54 × 10−2 | 2.13 × 10−1 |

| Eutrophication | kg PO4-eq | 6.88 × 10−2 | 5.20 × 10−3 | 7.52 × 10−2 |

| Global warming (GWP100) | kg CO2 eq | 4.21 × 101 | 1.46 × 101 | 3.53 × 101 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 3.79 × 10−6 | 8.13 × 10−7 | 4.81 × 10−6 |

| Impact Category | Unit | Hardcore (Crushed Stone) | Concrete | Steel Reinforcement |

|---|---|---|---|---|

| Acidification | kg SO2 eq | 2.44 × 10−3 | 1.44 | 2.62 × 10−2 |

| Eutrophication | kg PO4 eq | 8.61 × 10−4 | 1.93 × 10−1 | 1.81 × 10−2 |

| Global warming (GWP100) | kg CO2 eq | 4.32 × 10−1 | 3.40 × 102 | 7.28 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 4.09 × 10−8 | 2.96 × 10−6 | 4.84 × 10−7 |

| Impact Category | Unit | Total | Cement | Transportation of Concrete | Remaining Process | |||

|---|---|---|---|---|---|---|---|---|

| Acidification | kg SO2 eq | 1.44 | 1.13 | (78%) | 1.74 × 10−1 | (12%) | 1.66 × 10−1 | (12%) |

| Eutrophication | kg PO4 eq | 1.93 × 10−1 | 1.11 × 10−1 | (58%) | 4.48 × 10−2 | (23%) | 5.62 × 10−2 | (29%) |

| Global warming potential (GWP100) | kg CO2 eq | 3.40 × 102 | 2.82 × 102 | (83%) | 3.40 × 101 | (10%) | 3.20 × 101 | (9%) |

| Impact Category | Unit | Percentage |

|---|---|---|

| Acidification | kg SO2 eq | 3.06% |

| Eutrophication | kg PO4 eq | 5.51% |

| Global warming (GWP100) | kg CO2 eq | 2.54% |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 8.78% |

| Impact Category | Unit | Semi-Detached (This Study) | Semi-Detached in Spain [48] | Semi-Detached in UK [46] |

|---|---|---|---|---|

| Global Warming Potential (GWP) | kg CO2 eq | 3.72 × 103 | 2.43 × 103 | 4.16 × 103 |

| Acidification | kg SO2 eq | 1.51 × 101 | 1.85 × 101 | - |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 3.77 × 10−5 | 1.17 × 10−4 | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abd Rashid, A.F.; Idris, J.; Yusoff, S. Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment. Sustainability 2017, 9, 329. https://doi.org/10.3390/su9030329

Abd Rashid AF, Idris J, Yusoff S. Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment. Sustainability. 2017; 9(3):329. https://doi.org/10.3390/su9030329

Chicago/Turabian StyleAbd Rashid, Ahmad Faiz, Juferi Idris, and Sumiani Yusoff. 2017. "Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment" Sustainability 9, no. 3: 329. https://doi.org/10.3390/su9030329