Optimal Consumer Electronics Product Take-Back Time with Consideration of Consumer Value

Abstract

:1. Introduction

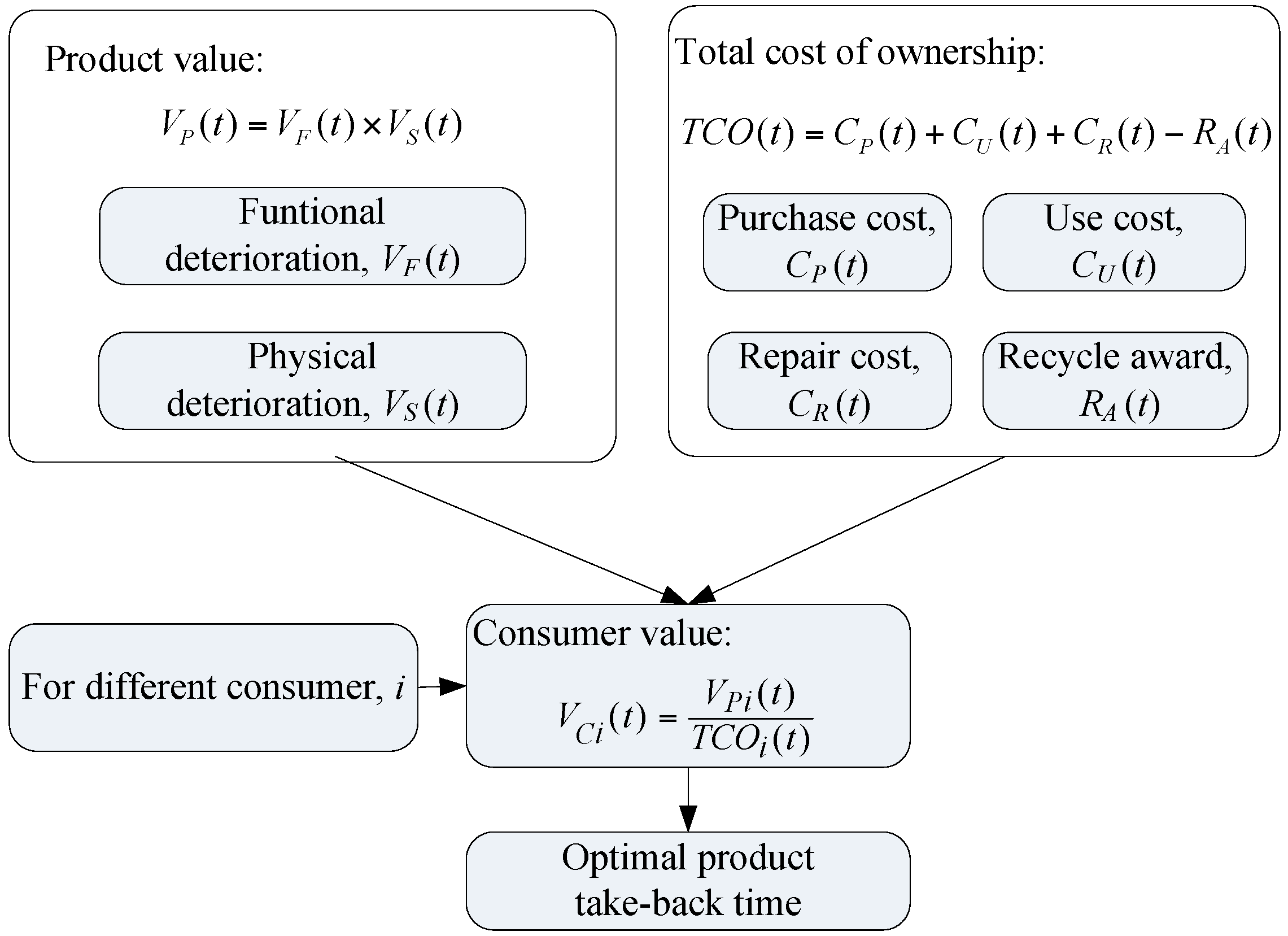

2. Model Development

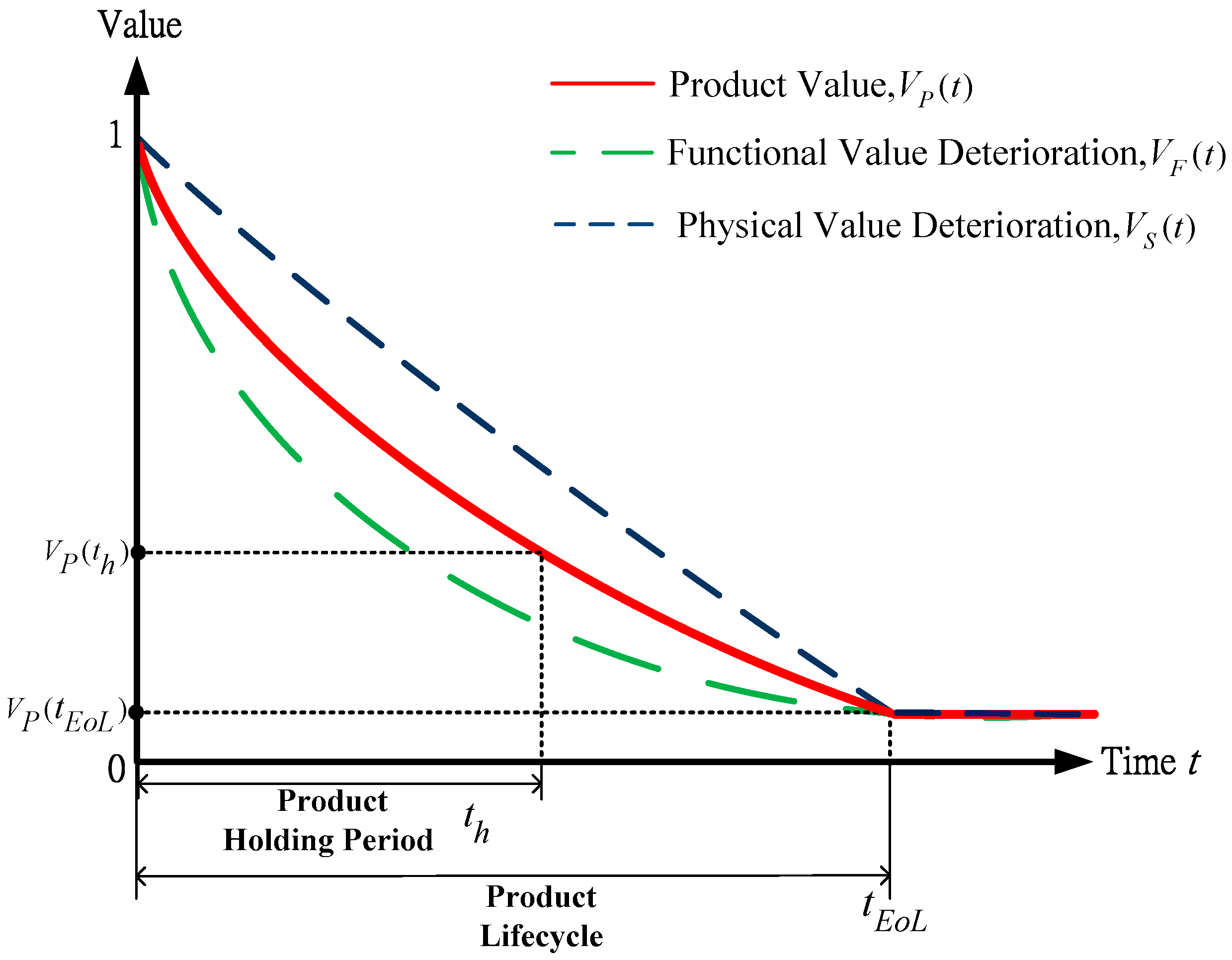

2.1. Product Value Modeling

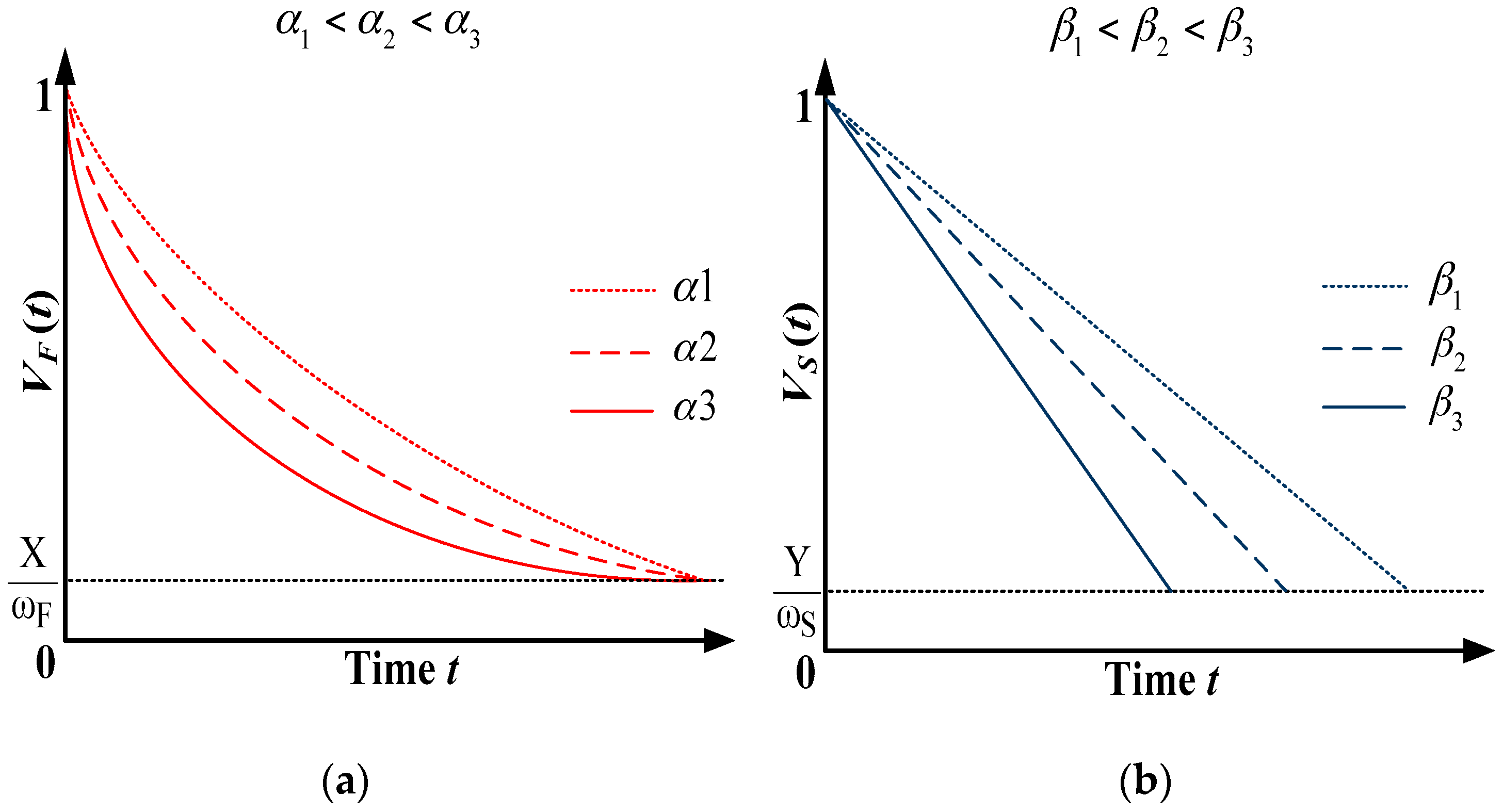

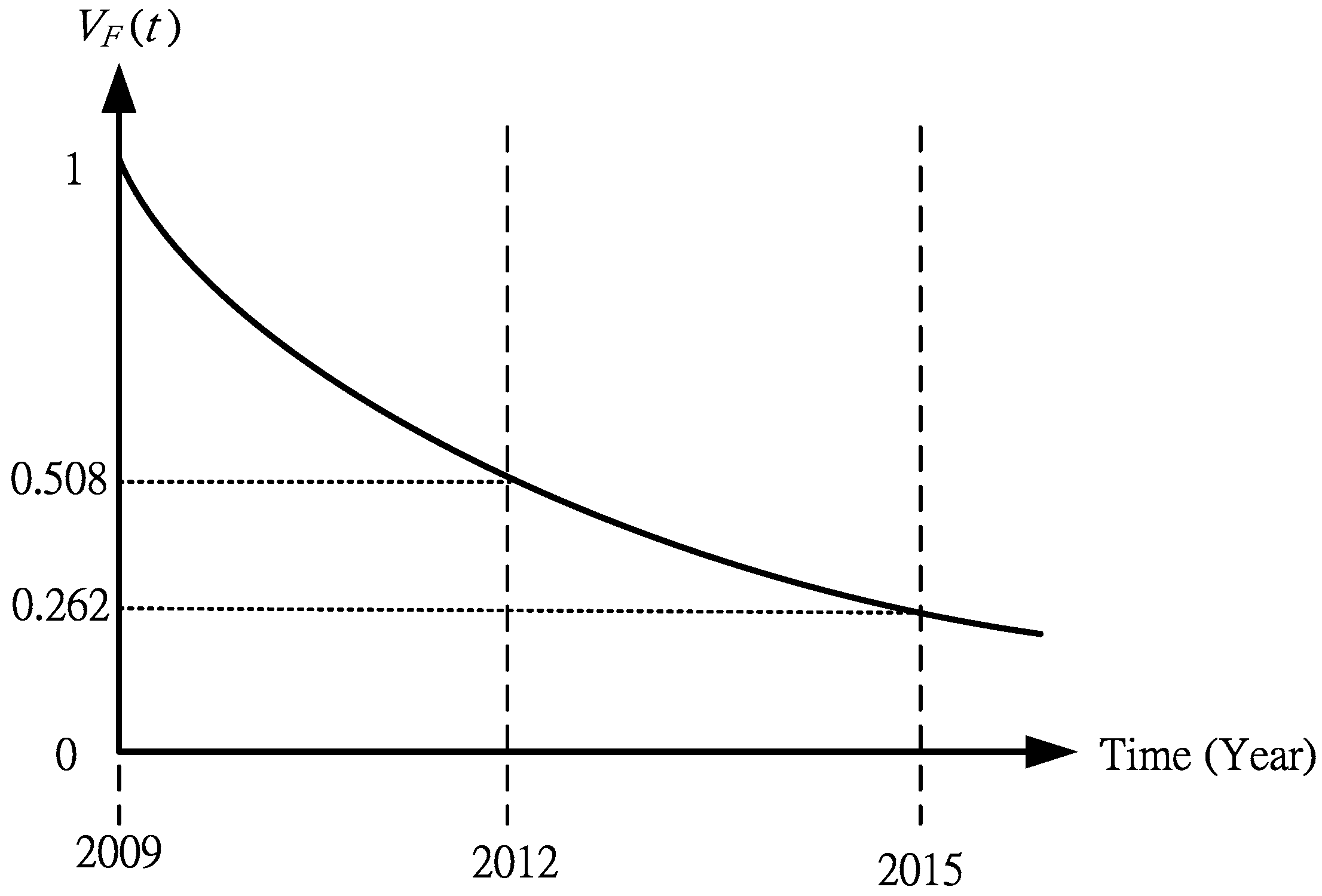

2.1.1. Functional Value and Physical Value Deterioration Model

2.1.2. Modeling the Deterioration Rate of Functional Value

- (1)

- Determine a product to be evaluated (Ep) and a product that is comparable to the reference product (Rp).

- (2)

- Identify key specifications of the product (m = 1, 2, …, M).

- (3)

- Choose the most significant attributes or functions for each key specification, then find their performance (Epm is the performance of key specification m of the evaluated product).

- (4)

- Apply the weighting factor () to express the contribution of each key specification.

- (5)

- Determine the key specifications progress vector, when the progress vector goes up, the better the performance is; and use Equation (5) to find each attribute’s performance. When the progress vector goes down, use Equation (6) for the calculation, where Rpm is the performance of key component m of the reference product.

2.2. Total Cost of Ownership Model

2.2.1. Purchase Cost Modeling

2.2.2. Use Cost Modeling

2.2.3. Repair Cost Modeling

2.2.4. Recycling Awards

2.3. Consumer Value Assessment Model

3. Numerical Illustration

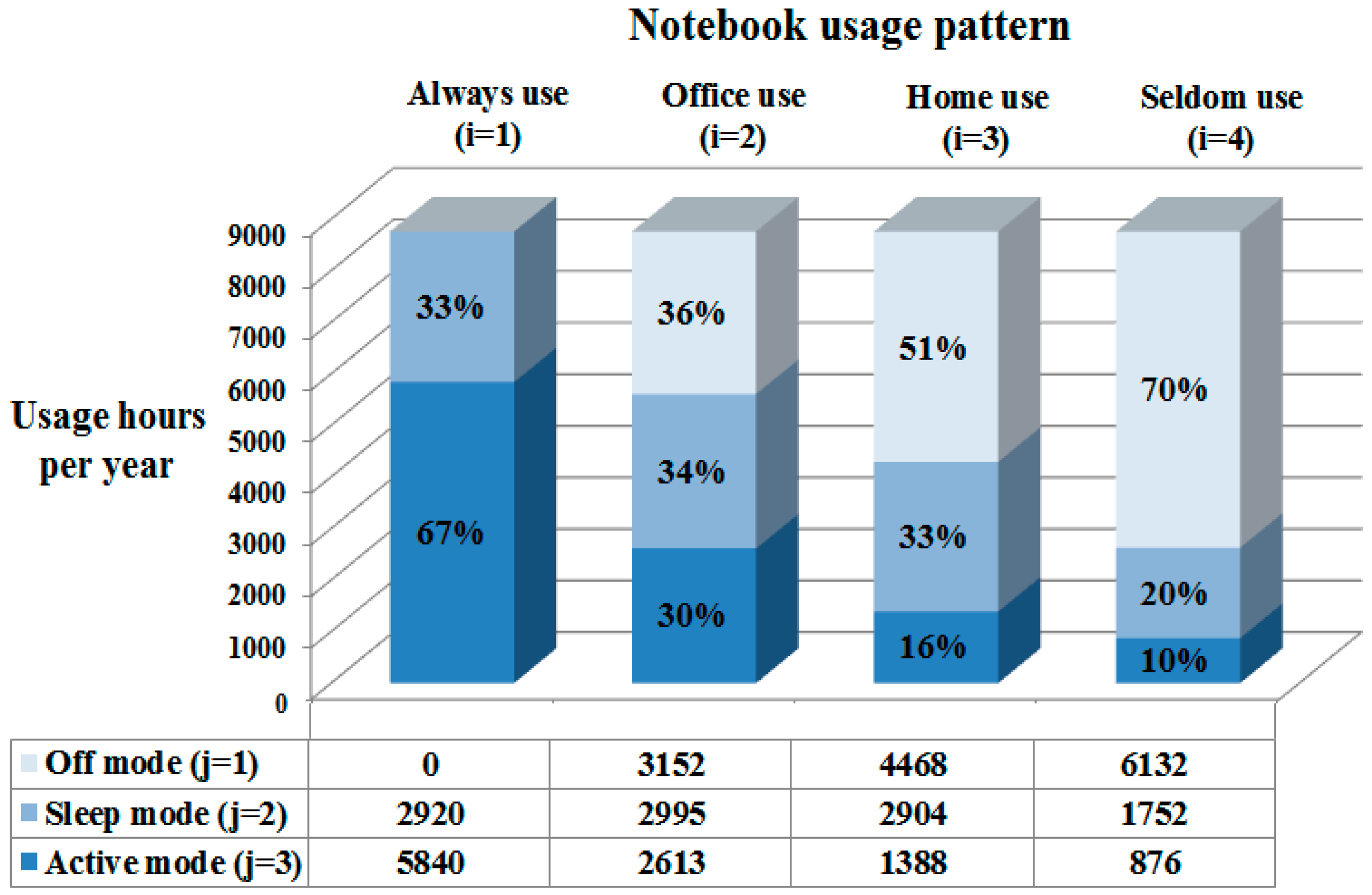

3.1. Description of Evaluated Product and Consumer Groups

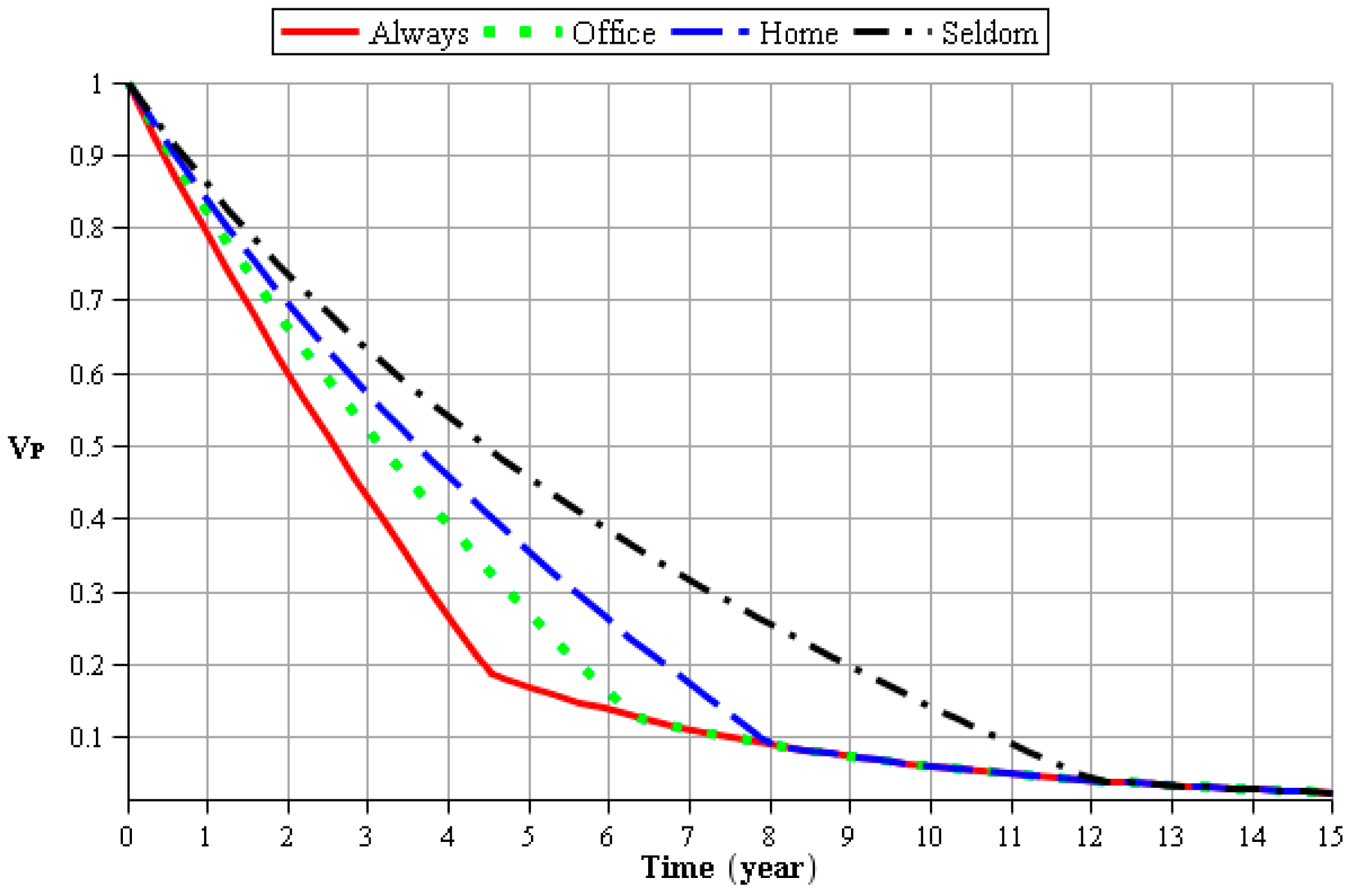

3.2. Calculation of Product Value

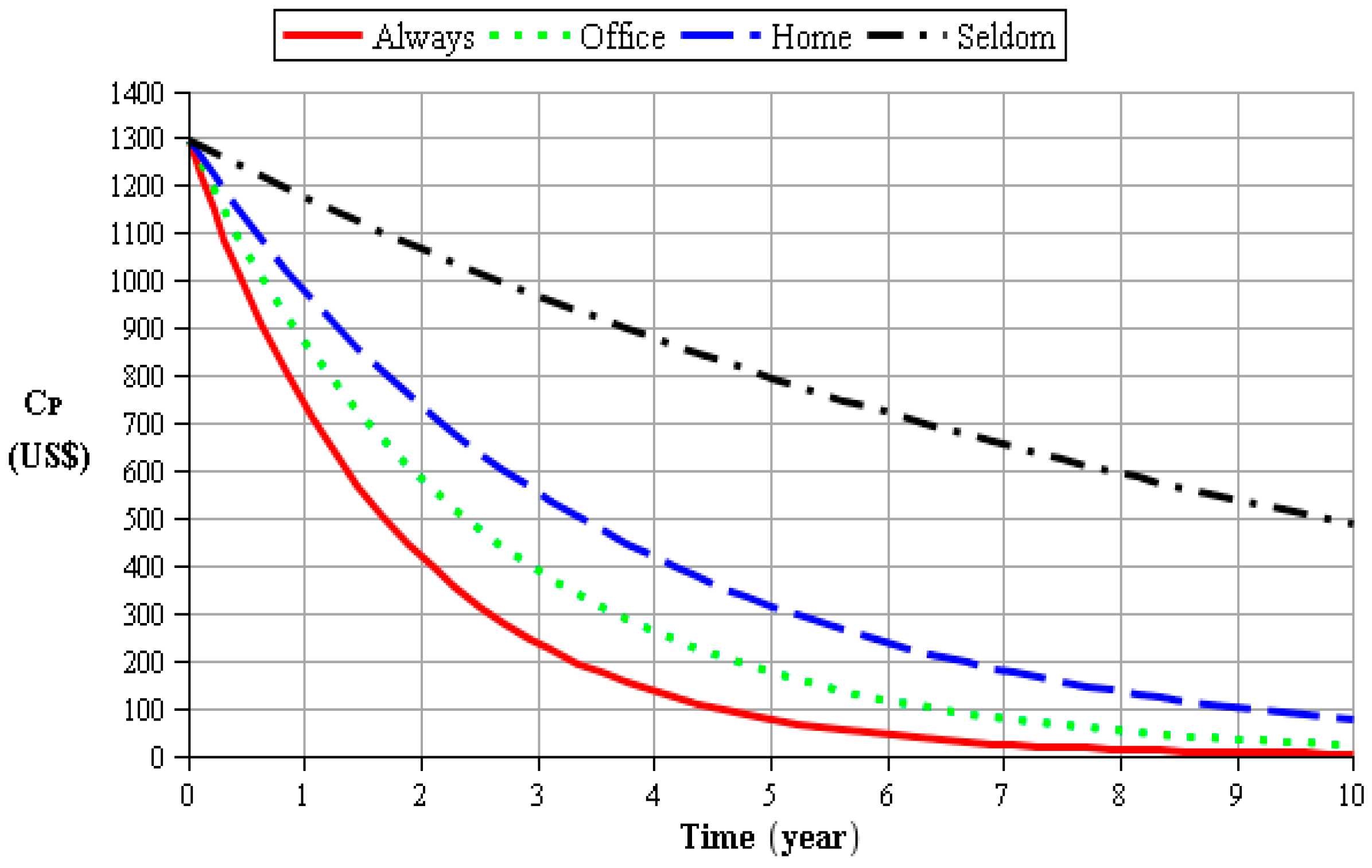

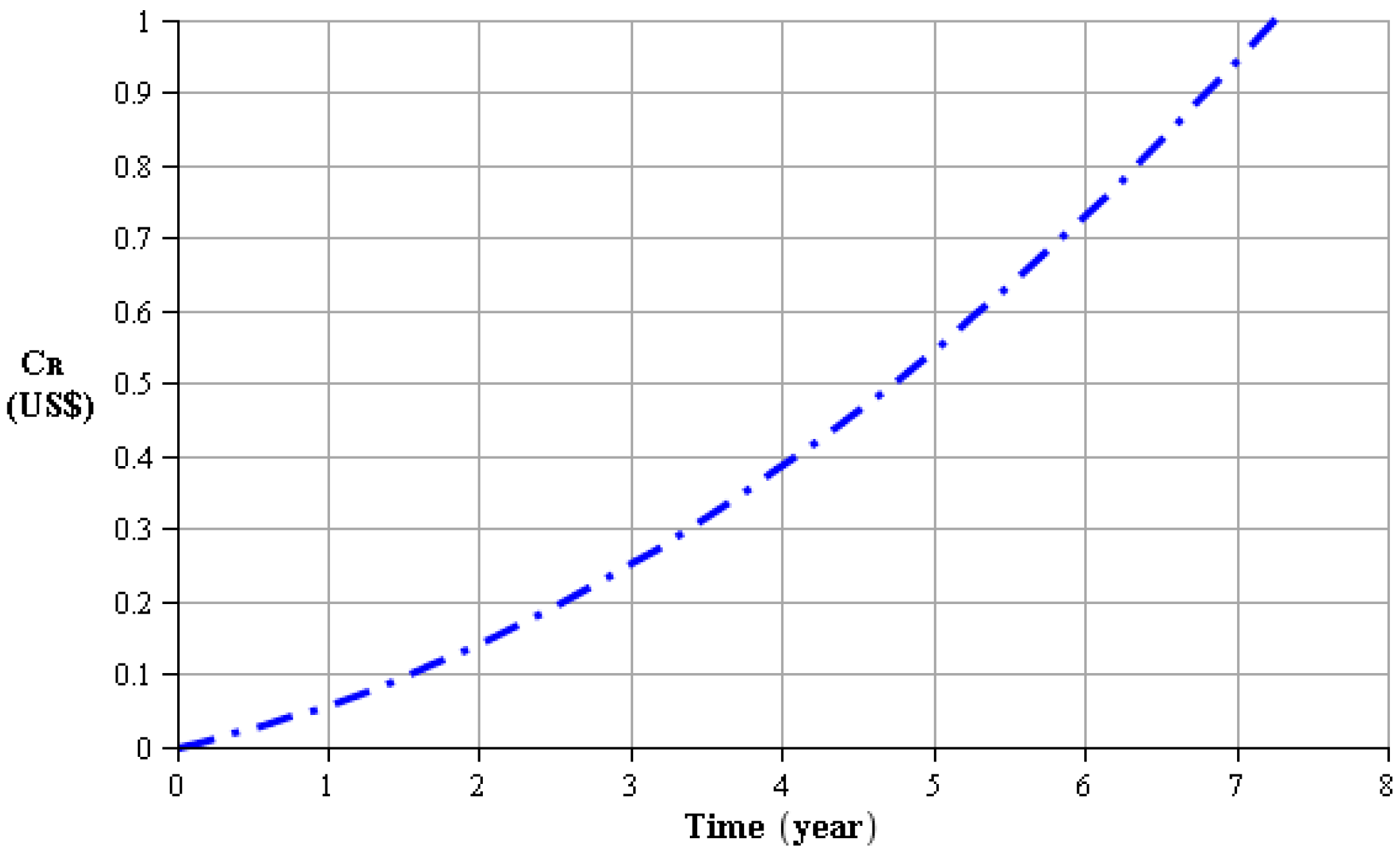

3.3. Calculation of TCO

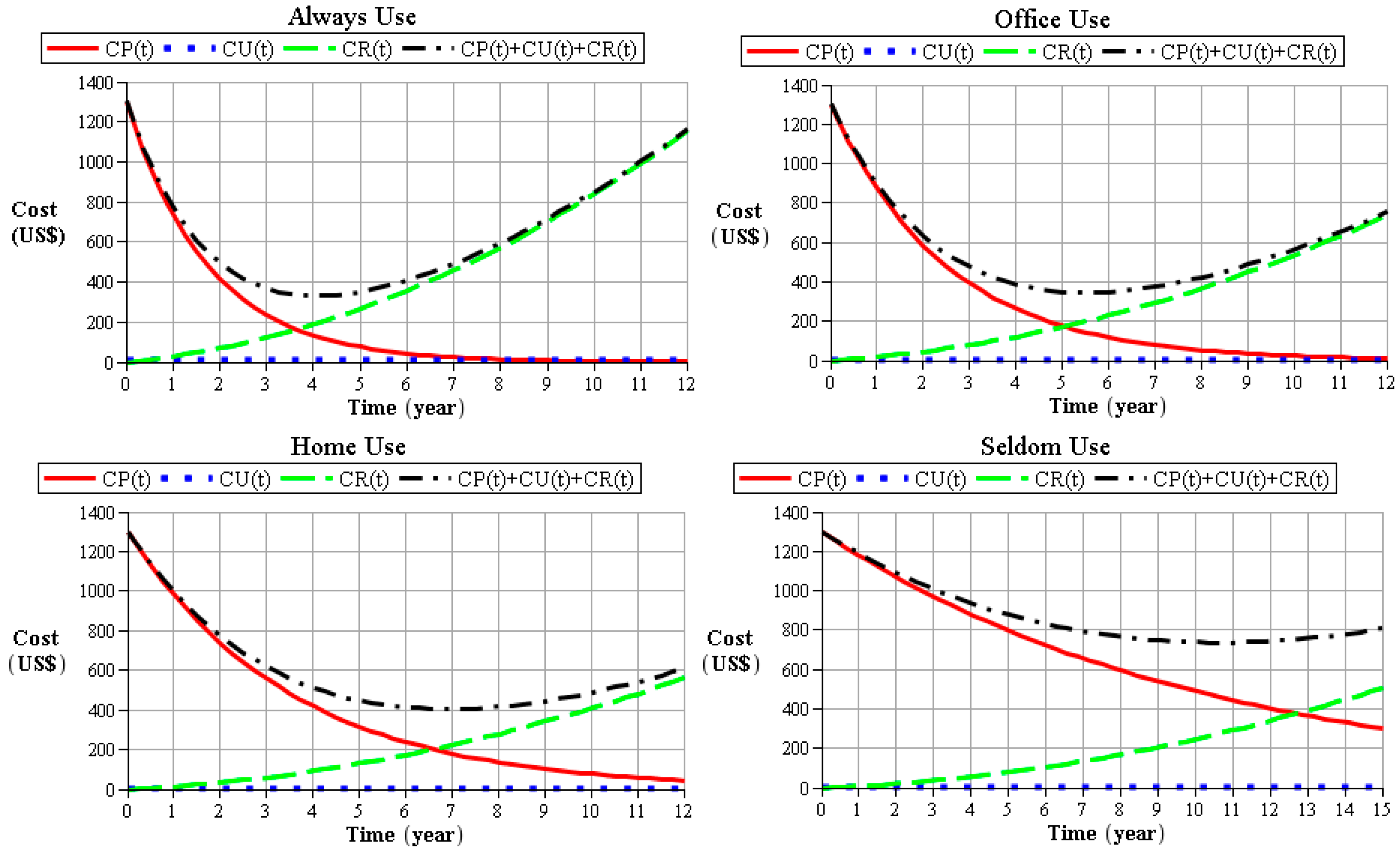

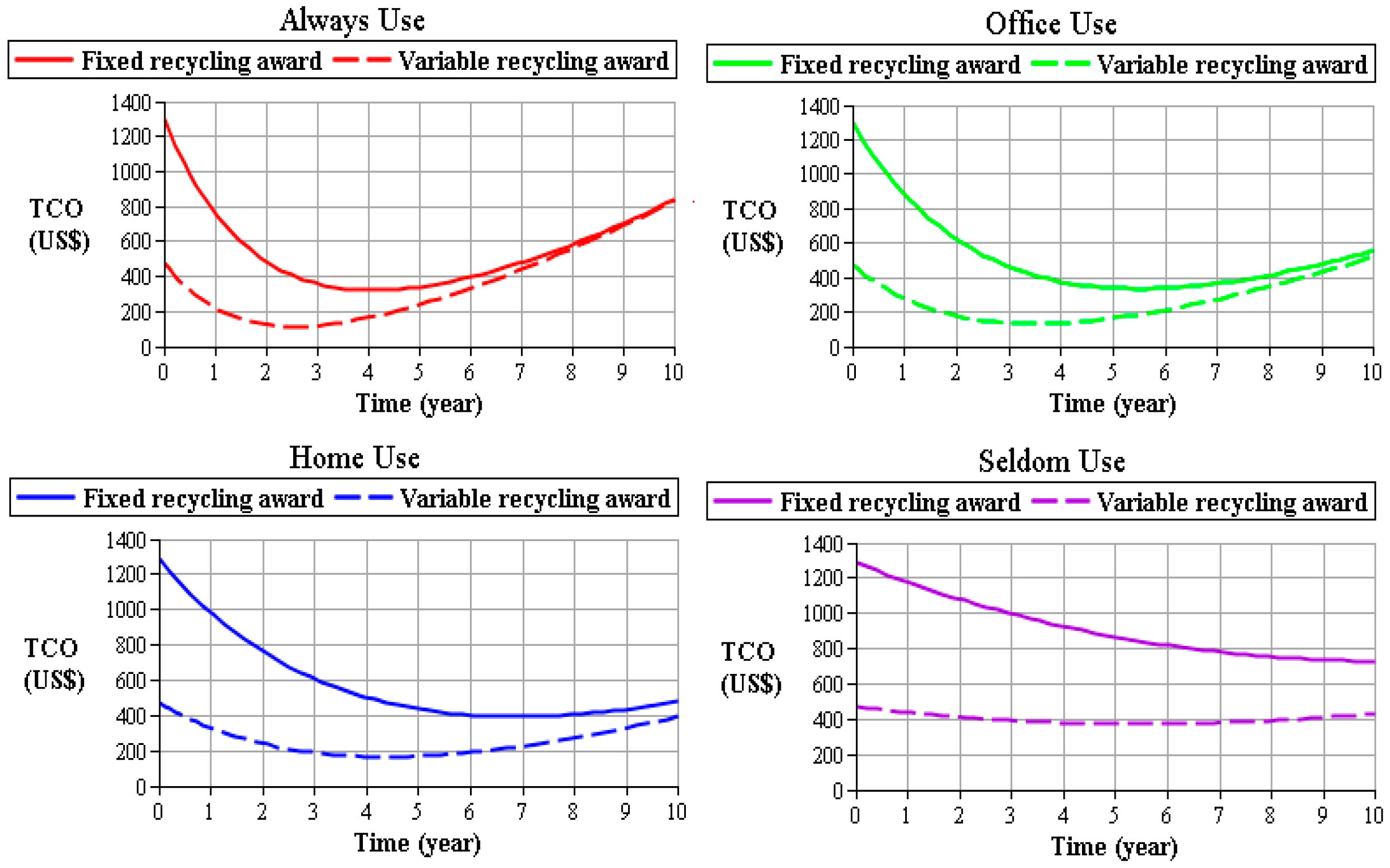

3.3.1. Purchase, Use, and Repair Cost

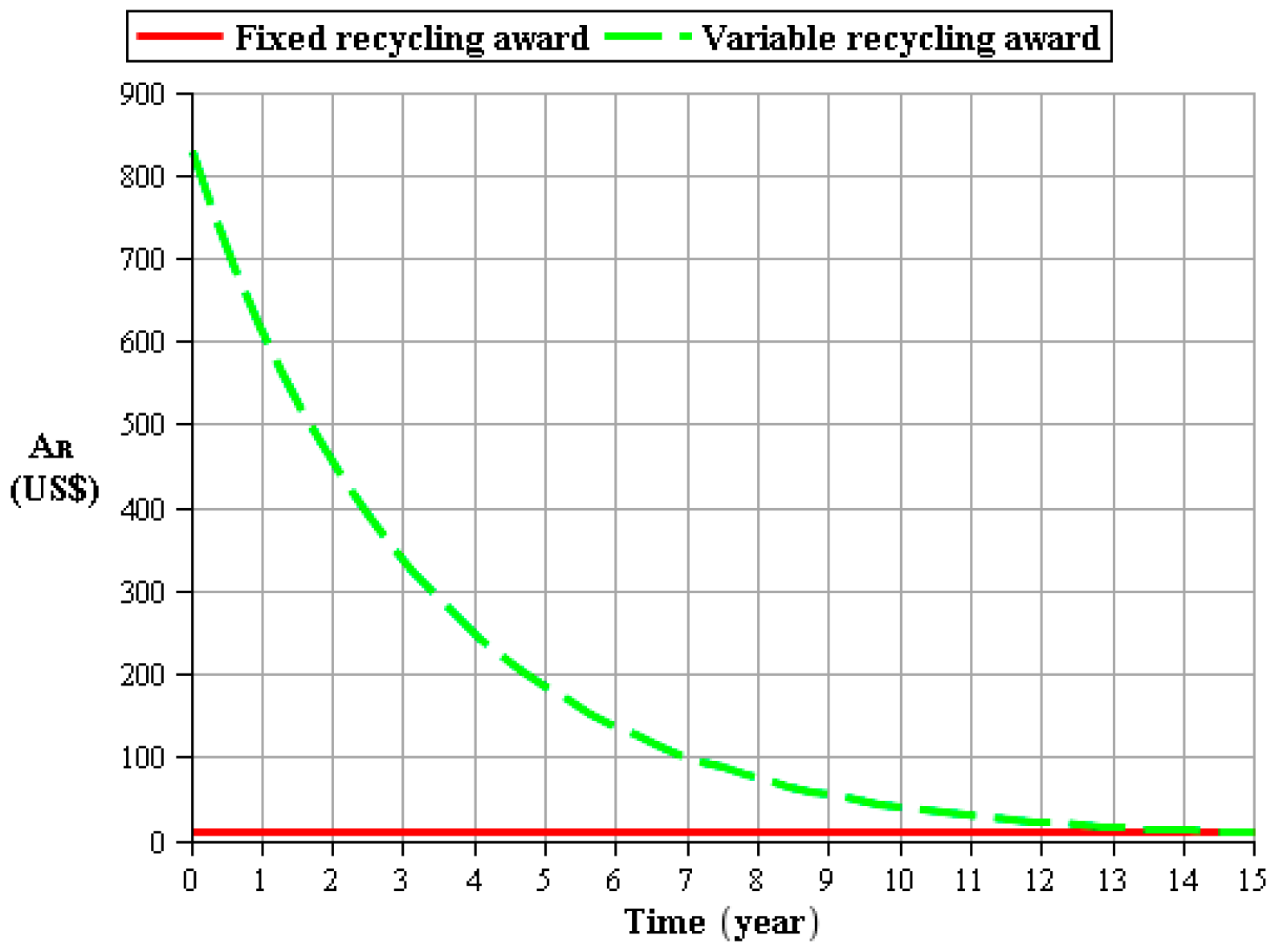

3.3.2. Recycling Award

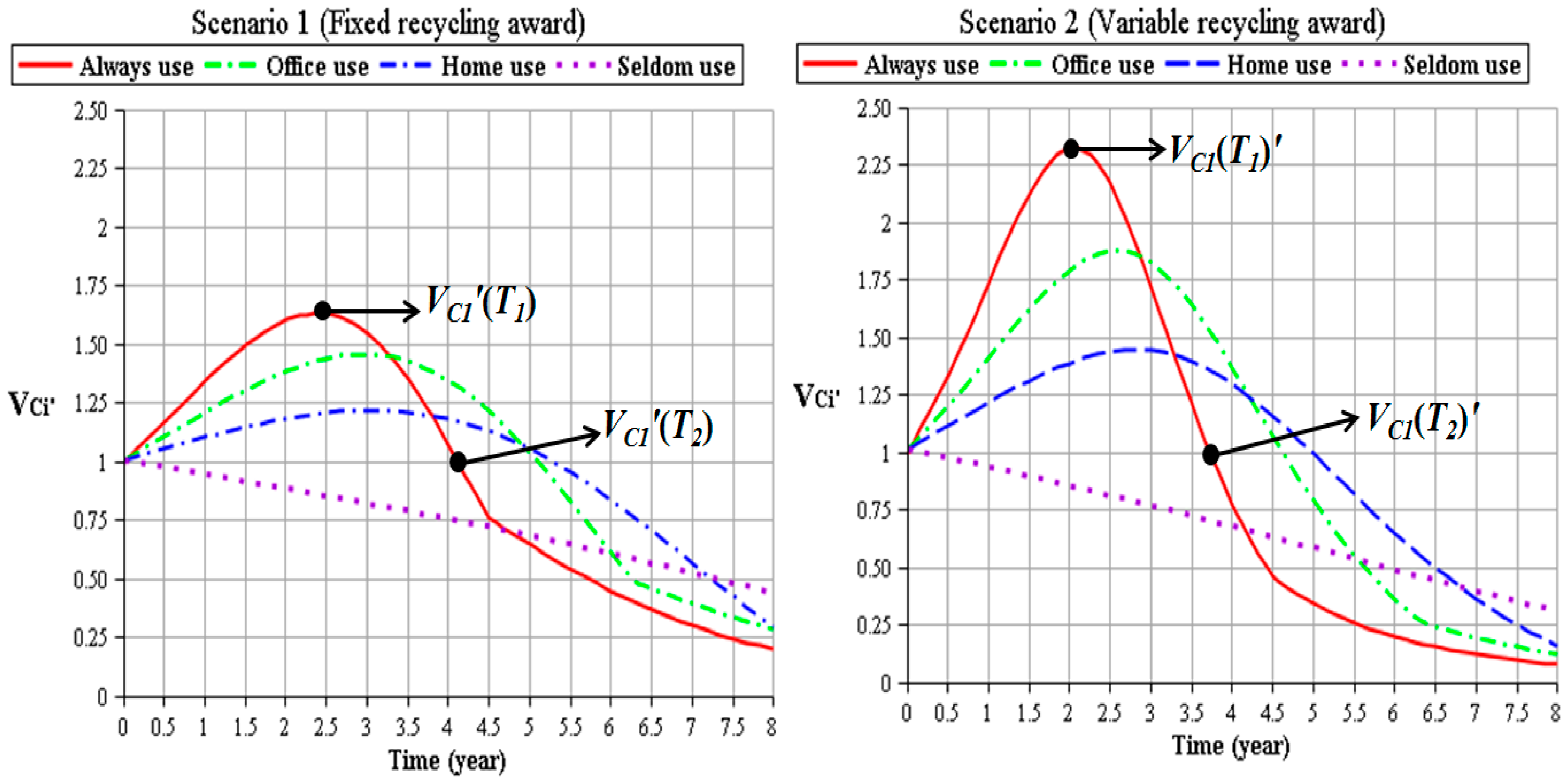

3.4. Optimal Take-Back Time of Product

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Baldé, C.P.; Wang, F.; Kuehr, R.; Huisman, J. The Global E-Waste Monitor—2014; United Nations University: Bonn, Germany, 2015. [Google Scholar]

- Greenpeace, the E-Waste Problem. Available online: http://www.greenpeace.org/international/en/campaigns/toxics/electronics/the-e-waste-problem/ (accessed on 5 February 2015).

- United Nations Environment Program (UNEP). Policy Briefs on E-Waste What, Why and How. Available online: http://www.unep.org/ietc/Portals/136/Other%20documents/PolicyBriefs/13052013_E-Waste%20Policy%20brief.pdf (accessed on 10 June 2015).

- United States Environmental Protection Agency (USEPA). Electronics Waste Management in the United States through 2009. Available online: http://www.epa.gov/wastes/conserve/materials/ecycling/docs/fullbaselinereport2011.pdf (accessed on 10 June 2015).

- Statista Website. Average Lifespan of Desktop PCs, Notebooks, Laptops and Tablets from 2012 to 2017. Available online: https://www.statista.com/statistics/267474/average-life-of-pc-and-tablets/ (accessed on 2 September 2016).

- Kwak, M.; Behdad, S.; Zhao, Y.; Kim, H.; Thurston, D. E-waste stream analysis and design implications. J. Mech. Des. 2010, 133, 1–8. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (U.S. EPA). Electronic Reuse and Recycling Infrastructure Development in Massachusetts; U.S. EPA: Boston, MS, USA, 2000.

- European Commission (EU). Integrated Product Policy (IPP) Report. Available online: http://cleanproduction.org/Steps.Products.Policy.php (accessed on 21 June 2013).

- Ramani, K.; Ramanujan, D.; Bernstein, W.Z.; Zhao, F.; Sutherland, J.; Handwerker, C.; Choi, J.K.; Kim, H.; Thurston, D. Integrated sustainable life cycle design: A review. J. Mech. Des. 2010, 132, 091004. [Google Scholar] [CrossRef]

- Ferrer, G.; Whybark, D.C. Material planning for a remanufacturing facility. Prod. Oper. Manag. 2001, 10, 112–124. [Google Scholar] [CrossRef]

- Inderfurth, K.; Langella, I.M. Planning Disassembly for Remanufacture-to-Order Systems; Environment Conscious Manufacturing: Boca Raton, FL, USA, 2008; pp. 387–411. [Google Scholar]

- Zhang, Z. Supporting end-of-life product recovery processes in closed loop supply chains. In Proceedings of the Second IEEE International Symposium on Intelligent Information Technology Application, Shanghai, China, 21–22 December 2008; pp. 804–808.

- Guide, V.D.R.; Teunter, R.H.; Wassenhove, L.N.V. Matching demand and supply to maximize profits from remanufacturing. Manuf. Serv. Oper. Manag. 2003, 5, 303–316. [Google Scholar] [CrossRef]

- Ray, S.; Boyaci, T.; Aras, N. Optimal prices and trade-in rebates for durable, remanufacturable products. Manuf. Serv. Oper. Manag. 2005, 7, 208–228. [Google Scholar] [CrossRef]

- White, C.; Masanet, E.; Rosen, C.; Beckman, S. Product recovery with some byte: An overview of management challenges and environmental consequences in reverse manufacturing for the computer industry. J. Clean. Prod. 2003, 11, 445–458. [Google Scholar] [CrossRef]

- Zhao, Y.; Pandey, V.; Kim, H.; Thurston, D. Varying lifecycle lengths within a portfolio for product take-back. J. Mech. Des. 2010, 132. [Google Scholar] [CrossRef]

- Gottinger, H.W. A computational model for solid waste management with application. Eur. J. Oper. Res. 1988, 35, 350–364. [Google Scholar] [CrossRef]

- Fleischmann, M.; Krikke, H.R.; Dekker, R.; Flapper, S.D.P. A characterization of logistics networks for product recovery. Omega 2000, 28, 653–666. [Google Scholar] [CrossRef]

- Jayaraman, V.; Luo, Y. Creating competitive advantages through new value creation: A reverse logistics perspective. Acad. Manag. 2007, 21, 56–73. [Google Scholar] [CrossRef]

- IDA, DOD Value Engineering Program. Available online: http://rtoc.ida.org/ve/ve.html (accessed on 26 June 2015).

- Kondoh, S.; Masui, K.; Hattori, M.; Mishima, N.; Matsumoto, M. Total performance analysis of product life cycle considering the deterioration and obsolescence of product value. Int. J. Prod. Dev. 2008, 6, 334–352. [Google Scholar] [CrossRef]

- Yeh, C.L. A Computation Method of Factor X Indicator by Using the Life Cycle Concept. Master’s Thesis, National Cheng Kung University, Tainan, Taiwan, 22 May 2009. [Google Scholar]

- Oikawa, S.; Ebisuji, K.; Fuse, K. Fujitsu’s Approach for Eco-efficiency Factor. Fujitsu Sci. Technol. J. 2005, 41, 236–241. [Google Scholar]

- Aoe, T. Green Product Indicators in Matsushita Electric Group; EcoDesign 2003: Tokyo, Japan, 2003. [Google Scholar]

- Toshiba Corporation. Advancing Together with Factor T. Available online: http://www.toshiba.co.jp/env/en/report/pdf/factor_t_2009_en.pdf (accessed on 10 June 2015).

- HP Corporation. Total Cost of Ownership. 2011. Available online: http://www8.hp.com/tw/zh/hp-financial-services/solutions/tco.html (accessed on 11 June 2015).

- Ellram, L. Total cost of ownership: Elements and implementation. J. Supply Chain Manag. 1993, 29, 2–11. [Google Scholar] [CrossRef]

- European Commission DG TREN. Preparatory Studies for Eco-Design Requirements of EuPs: Lot 3—Personal Computers (Desktops and Laptops) and Computer Monitors; IVF Industrial Research and Development Corporation: Molndal, Sweden, 2007. [Google Scholar]

- Thierry, M.C.; Salomon, M.; Van Nunen, J.; Van Wassenhove, L. Strategic issues in product recovery management. Calif. Manag. Rev. 1998, 37, 114–135. [Google Scholar] [CrossRef]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. OMEGA 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Mishima, K.; Mishima, N.; Nakano, M. A study on a system design approach to promote better circular use of Electrical and Electronic Equipment. EcoDesign 2011. Available online: http://link.springer.com/chapter/10.1007/978-94-007-3010-6_155#page-1 (accessed on 5 February 2017). [Google Scholar]

- Gazelle Website. Available online: https://www.gazelle.com/trade-in (accessed on 13 June 2015).

- Zeithaml, V.A. Consumer perceptions of price, quality, and value: A means-end model and synthesis of evidence. J. Mark. 1998, 52, 2–22. [Google Scholar] [CrossRef]

- Apple Website. Available online: http://www.apple.com/macbook-air/ (accessed on 13 June 2015).

- Market Intelligence & Consulting Institute (MIC). Investigation of Digital Living Expenses in Taiwan; MIC: Taipei, Taiwan, 2009. (In Chinese) [Google Scholar]

- Geekbench 3 Software—MacBook Air Benchmarks. Available online: http://www.primatelabs.com/blog/2013/06/macbook-air-benchmarks/?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+primatelabsblog+%28Primate+Labs+Blog%29 (accessed on 19 June 2015).

- PassMark Software—PC Benchmark and Test Software. Available online: http://www.cpubenchmark.net/ (accessed on 19 June 2015).

- Apple Company, Product Environmental Reports. Available online: http://images.apple.com/environment/reports/docs/MacBook-White_Environmental_Report_20091020.pdf (accessed on 21 June 2015).

- International Energy Agency. Electricity Information 2016; IEA Energy Data Center: Paris, France, 2017. [Google Scholar]

- Square Trade Company. 1 in 3 Laptops Fail over 3 Years Report. Available online: http://www.squaretrade.com/pages/laptop-reliability-1109 (accessed on 29 June 2015).

| Evaluated Product (EP) | Reference Product (RP) | Reference Product (RP) | |

|---|---|---|---|

| Introduction date | 8 June 2009 | 11 June 2012 | 9 March 2015 |

| Processor Type (Speed) | Intel Core 2 Duo SL9400 (1.86 GHz) | Intel Core i5-3427U (1.8 GHz) | Intel Core i5-5250U (1.6 GHz) |

| RAM Type (Speed) | DDR3 SDRAM 2 GB (1066 MHz) | DDR3L SDRAM 4 GB (1600 MHz) | DDR3L SDRAM 8 GB (1600 MHz) |

| Video Card | NVIDIA GeForce 9400 M | Intel HD 4000 | HD Graphics 6000 |

| Display (Resolution) | 13.3″ (1280 × 800 ) | 13.3″ (1440 × 900 ) | 13.3″ (1440 × 900 ) |

| Hard Drive | 120 GB (4200 RPM) | 256 GB SSD | 256 GB SSD |

| USB Ports | 1 (USB 2.0) | 2 (USB 3.0) | 2 (USB 3.0) |

| Battery life | 5 h | 7 h | 12 h |

| Dimensions (H × W × D) | 1.94 × 32.5 × 22.7 (cm) | 1.7 × 32.5 × 22.7 (cm) | 0.68 × 12.8 × 8.94 (cm) |

| System Weight | 1.36 kg | 1.35 kg | 1.35 kg |

| Original Price | US$1299 | US$1299 | US$1199 |

| Specifications | Performance | Unit | Epm | Rpm | Dpm | Wm |

|---|---|---|---|---|---|---|

| CPU/RAM | Geekbench Performance 1 | Score↑ | 2701 | 6757 | 0.40 | 0.34 |

| Graphic Card | PassMark G3D Rating 2 | Score↑ | 124 | 474 | 0.26 | 0.13 |

| Display | Resolution | Pixel↑ | 1,024,000 | 1,296,000 | 0.79 | 0.17 |

| Hard Drive | PassMark Disk Rating 3 | GB↑ | 181 | 3887 | 0.05 | 0.09 |

| USB Ports | Date Transfer Speed | Gbps↑ | 0.96 | 10 | 0.10 | 0.01 |

| Battery | Max. Battery Life | Hours↑ | 5 | 7 | 0.71 | 0.15 |

| Dimensions | Max. High | Cm↓ | 1.94 | 1.7 | 0.88 | 0.03 |

| Weight | Avg. Weight | Kg↓ | 1.36 | 1.35 | 0.99 | 0.09 |

| Operational Modes | Electricity Used (kW) * | Annual Power Consumption Cost (US$) | |||

|---|---|---|---|---|---|

| Always Use | Office Use | Home Use | Seldom Use | ||

| Off (kW1) | 0.00056 | 0 | 0.176 | 0.250 | 0.441 |

| Sleep (kW2) | 0.00102 | 0.327 | 0.335 | 0.325 | 0.049 |

| Active (kW3) | 0.0131 | 7.708 | 3.449 | 1.832 | 0.576 |

| Total | --------- | 8.035 | 3.961 | 2.407 | 1.068 |

| Fixed Scenario | Variable Scenario | Difference | ||

|---|---|---|---|---|

| Always Use | T1(VCi′) | 2.37 (1.63) | 2.04 (2.32) | −0.33 (+42%) |

| 4.11 | 3.72 | −0.39 | ||

| Office Use | T1(VCi′) | 2.96 (1.45) | 2.57 (1.86) | −0.39 (+28%) |

| T2 | 5.08 | 4.59 | −0.49 | |

| Home Use | T1(VCi′) | 3.04 (1.21) | 2.80 (1.42) | −0.24 (+17%) |

| T2 | 5.25 | 4.93 | −0.32 | |

| Seldom Use | T1(VCi′) | 0 (1) | 0 (1) | 0 (+0%) |

| T2 | 0 | 0 | 0 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Y.-T.; Rau, H. Optimal Consumer Electronics Product Take-Back Time with Consideration of Consumer Value. Sustainability 2017, 9, 385. https://doi.org/10.3390/su9030385

Fang Y-T, Rau H. Optimal Consumer Electronics Product Take-Back Time with Consideration of Consumer Value. Sustainability. 2017; 9(3):385. https://doi.org/10.3390/su9030385

Chicago/Turabian StyleFang, Yi-Tse, and Hsin Rau. 2017. "Optimal Consumer Electronics Product Take-Back Time with Consideration of Consumer Value" Sustainability 9, no. 3: 385. https://doi.org/10.3390/su9030385