Estimates of Economic Loss of Materials Caused by Acid Deposition in China

Abstract

:1. Introduction

2. Methodology

2.1. Material Loss Calculation

- is economic losses of material caused by acid rain, unit: yuan.

- is economic losses of material i caused by acid rain, unit: yuan.

- is the unit price of maintenance or replacement of material i at a time, unit: yuan/m2, details could refer to Section 2.4.

- is exposure inventory of material i, unit: m2; The calculation method will be introduced in Section 2.2.

- is service life of material i under contaminated conditions, unit: a. “a” means annum.

- is service life of material i under non-contamination conditions, unit: a.

- is CDL of material i, unit: μm, details on CDL, and are in Section 2.3.

- is corrosion rate of material i under conditions of pollution, unit: μm/a.

- is corrosion rate of material i under conditions of non-pollution, unit: μm/a.

2.2. Survey on Material Exposure Inventory

2.3. Exposure–Response Relationship (Dose–Response Relationship) and CDL

2.4. Estimates on Material Price

2.5. Data Sources

3. Results

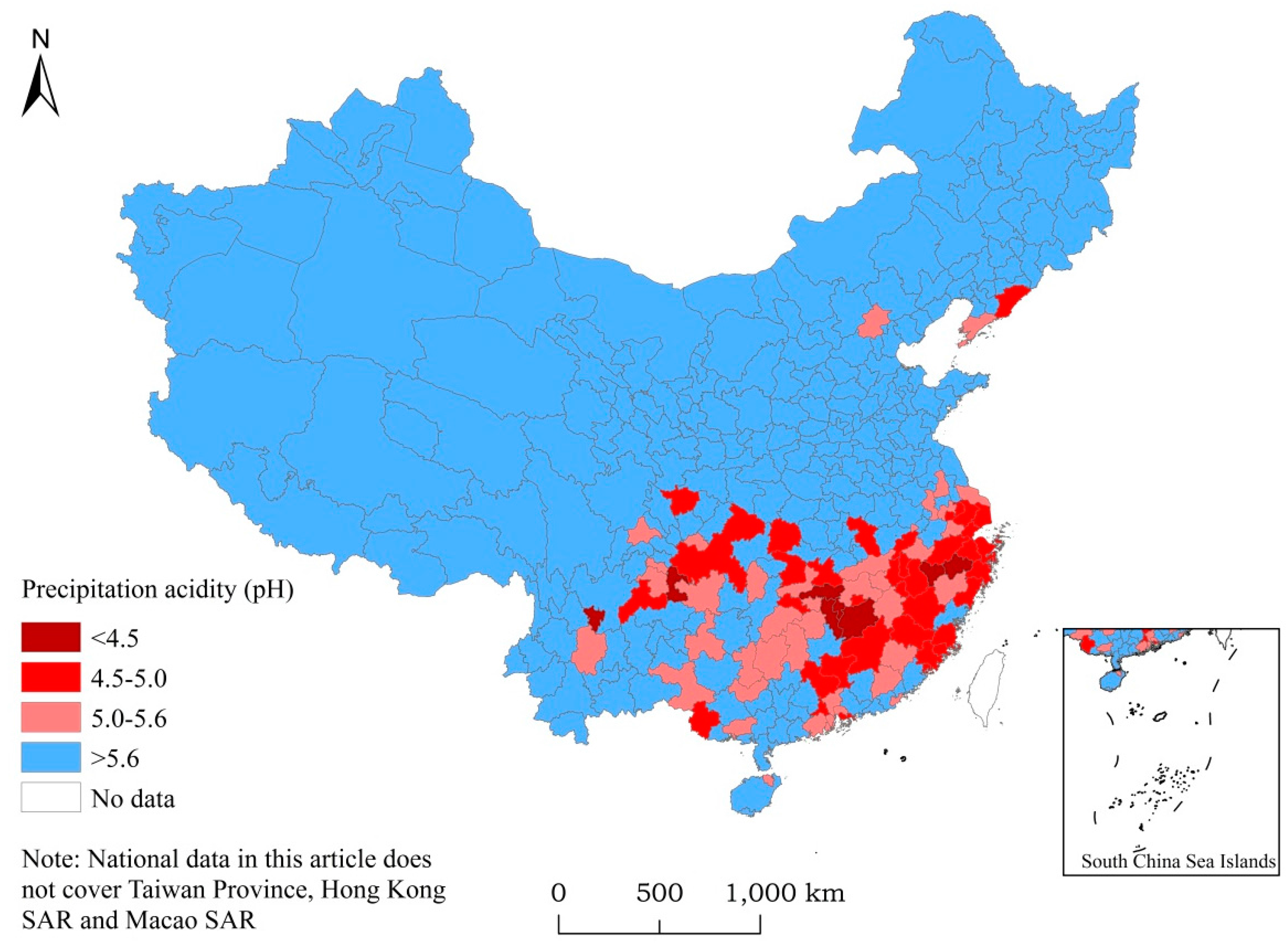

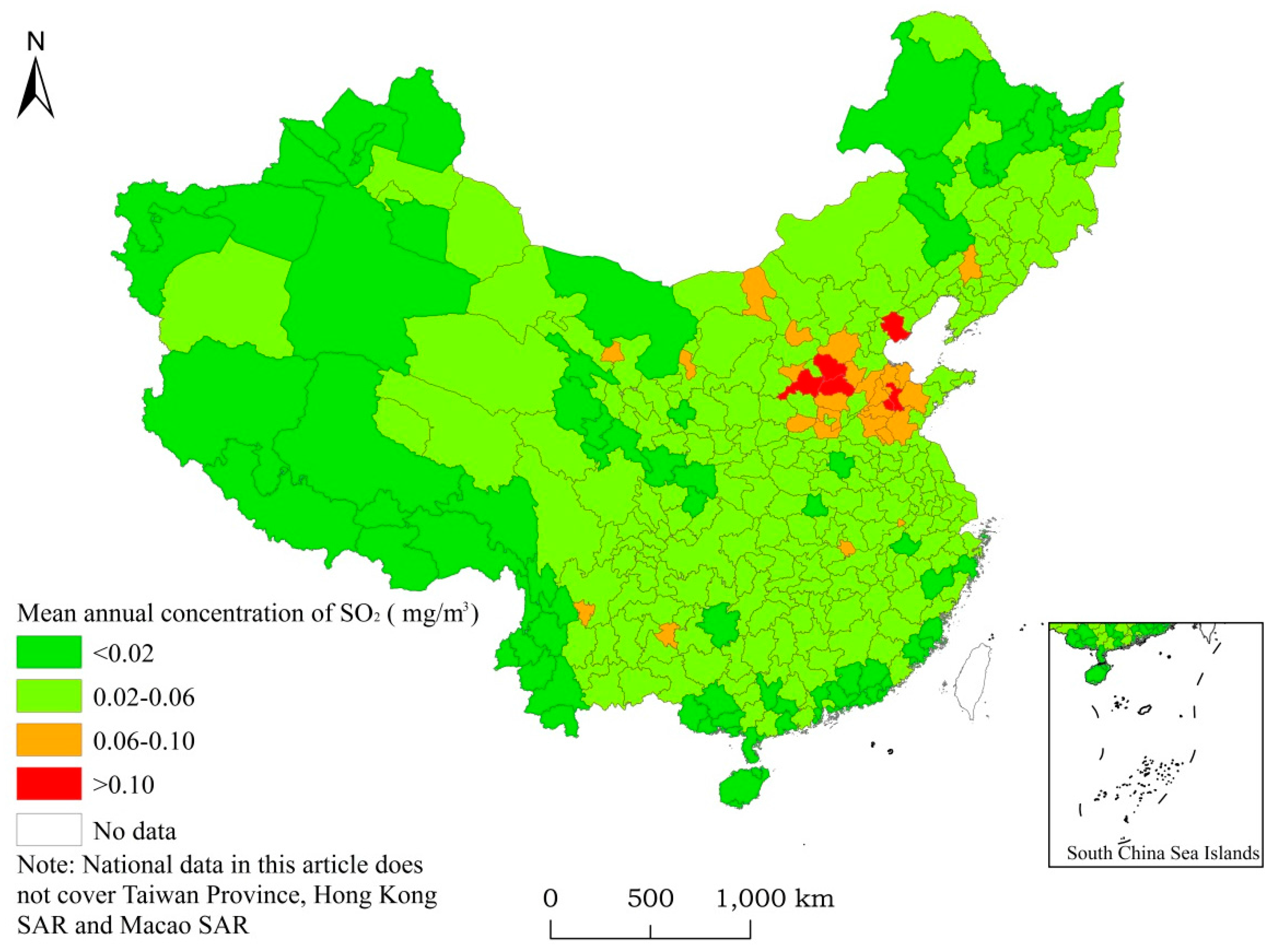

3.1. Pollution of Acid Rain and Sulfur Dioxide

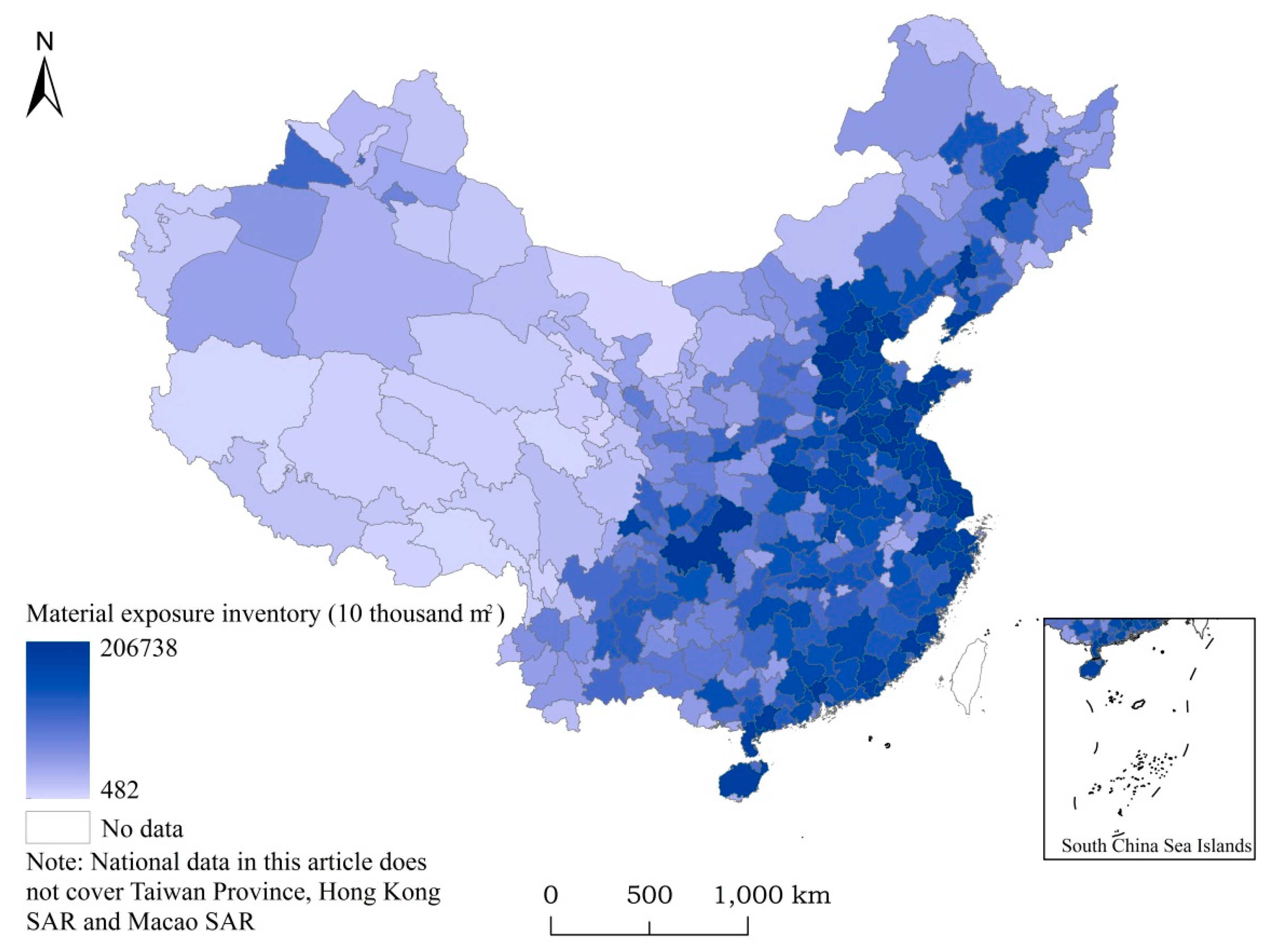

3.2. Estimations on Material Inventory

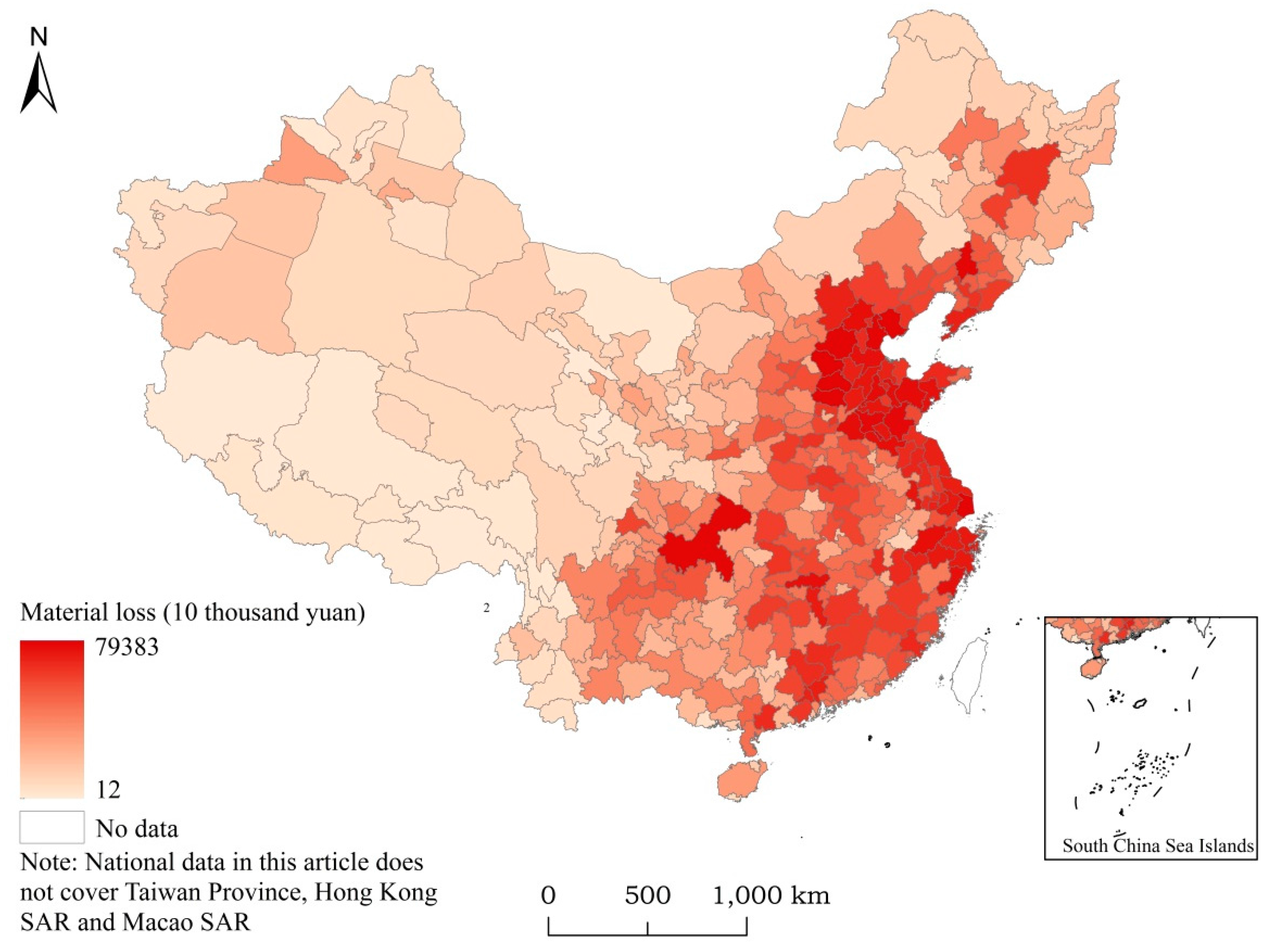

3.3. Estimates on Losses Incurred by Acid Deposition

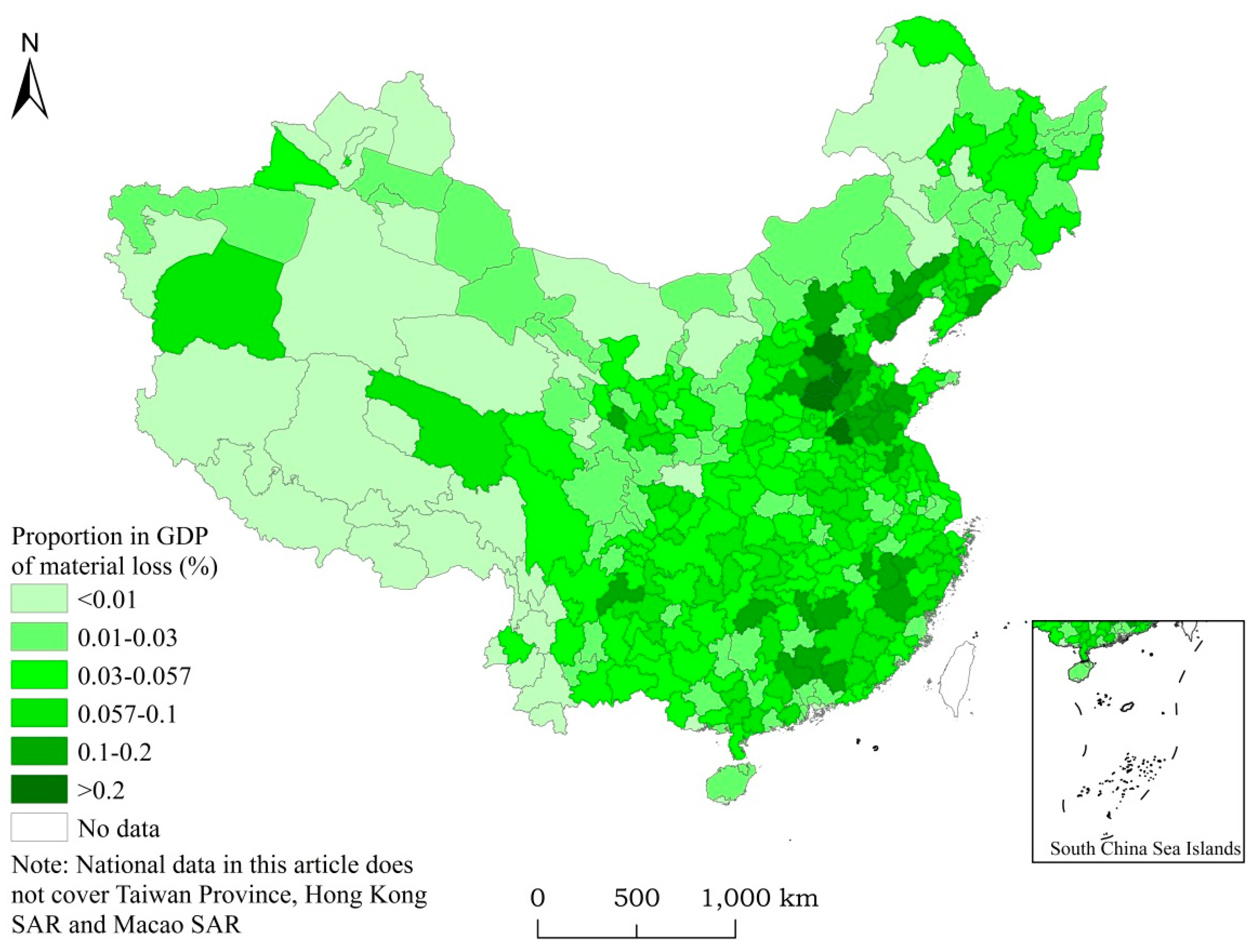

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- Smith, A.R. Air and Rain: The Beginnings of a Chemical Climatology; Longmans, Green, and Co.: London, UK, 1872. [Google Scholar]

- Zhang, X.M.; Chai, F.H.; Wang, S.L.; Sun, X.Z.; Han, M. Research progress of acid precipitation in China. Res. Environ. Sci. 2010, 23, 527–532. (In Chinese) [Google Scholar]

- Ottar, B. Organization of long range transport of air pollution monitoring in Europe. In Proceedings of the First International Symposium on Acid Precipitation and the Forest Ecosystem, Columbus, OH, USA, 12–15 May 1975; Dochinger, L.S., Seliga, T.A., Eds.; Springer: Philadelphia, PA, USA, 1976; pp. 105–117. [Google Scholar]

- Burns, D.A.; Aherne, J.; Gay, D.A.; Lehmann, C.M.B. Acid Rain and its Environmental Effects: Recent Scientific Advances. Atmos. Environ. 2016, 146, 1–4. [Google Scholar] [CrossRef]

- Vet, R.; Artz, R.S.; Carou, S.; Shaw, M.; Ro, C.U.; Aas, W.; Baker, A.; Bowersox, V.C.; Dentener, F.; Galy-Lacaux, C.; et al. A global assessment of precipitation chemistry and deposition of sulfur, nitrogen, sea salt, base cations, organic acids, acidity and pH, and phosphorus. Atmos. Environ. 2014, 93, 3–100. [Google Scholar] [CrossRef]

- Tang, X.Y.; Zhang, Y.H.; Shao, M. Atmospheric Environmental Chemistry; Higher Education Press: Beijing, China, 2006; p. 67. (In Chinese) [Google Scholar]

- Zhao, D.W.; Xiong, J.L.; Xu, Y.; Chan, W.H. Acid rain in southwestern China. Atmos. Environ. 1988, 22, 349–358. [Google Scholar]

- Li, Z.J.; Song, L.L.; Ma, J.Z.; Li, Y.G. The characteristics changes of pH and EC of atmospheric precipitation and analysis on the source of acid rain in the source area of the Yangtze River from 2010 to 2015. Atmos. Environ. 2017. [Google Scholar] [CrossRef]

- Wang, T.J.; Jin, L.S.; Li, Z.K.; Lam, K.S. A modeling study on acid rain and recommended emission control strategies in China. Atmos. Environ. 2000, 34, 4467–4477. [Google Scholar] [CrossRef]

- Luo, X.S.; Pan, Y.P.; Goulding, K.; Zhang, L.; Liu, X.J.; Zhang, F.S. Spatial and seasonal variations of atmospheric sulfur concentrations and dry deposition at 16 rural and suburban sites in China. Atmos. Environ. 2016, 146, 79–89. [Google Scholar] [CrossRef]

- Chen, F.; Chai, F.H. Control strategy of acid deposition in China. Res. Environ. Sci. 1997, 10, 27–31. (In Chinese) [Google Scholar]

- He, J.L.; Chen, H.W.; Hu, X.H.; Chen, K. On the influent factors for the formation of severe acid rain band in Jiangxi Province. China Environ. Sci. 2000, 20, 477–480. (In Chinese) [Google Scholar]

- Xie, S.Y.; Wang, R.B.; Zheng, H.H. Analysis on the acid rain from 2005 to 2011 in China. Environ. Monit. Forewarn. 2012, 4, 33–37. (In Chinese) [Google Scholar]

- Ministry of Environmental Protection, The People’s Republic of China. 2013 Report on the State of the Environment in China; Ministry of Environmental Protection: Beijing, China, 2014; p. 24.

- Fink, F.W.; Buttner, F.H.; Boyd, W.K. Technical-Economic Evaluation of Air Pollution Corrosion Costs on Metals in the U.S.; Batelle Memorial Institute: Columbus, OH, USA, 1971. [Google Scholar]

- OCED. Managing the Sulphur Problem—Control Costs and Benefits; OECD Environment Directorate: Paris, OH, USA, 1981. [Google Scholar]

- Lipfert, F.W. Effects of acidic deposition on the atmospheric deterioration of materials. Mater. Perform. 1987, 26, 12–19. [Google Scholar]

- ECOTEC. Identification and Assessment of Materials Damage to Buildings and Monuments by Air Pollution; ECOTEC Research and Consulting Ltd.: Birmingham, UK, 1990. [Google Scholar]

- Kucera, V.; Henriksen, J.; Knotkova, D.; Sjöström, Ch. Model for calculations of corrosion cost caused by air pollution and its application in three cities. In Progress in the Understanding and Prevention of Corrosion; Institute of Materials: London, UK, 1993; Volume 1, pp. 24–32. [Google Scholar]

- Cowell, D.; Apsimon, H. Estimating the cost of damage to buildings by acidifying atmospheric pollution in Europe. Atmos. Environ. 1996, 30, 2959–2968. [Google Scholar] [CrossRef]

- Rabl, A. Air pollution and buildings: An estimation of damage costs in France. Environ. Impact Assess. Rev. 1999, 19, 361–385. [Google Scholar] [CrossRef]

- Yin, Y.D. The estimation on the corrosion loss due to the acidic rain in the two provinces of southwestern China. Corros. Sci. Prot. Technol. 1991, 3, 37–43. (In Chinese) [Google Scholar]

- Yang, Z.M.; Wang, W.X.; Zhang, W.H. Study on economic estimates of acid deposition damage to materials. Shanghai Environ. Sci. 1996, 15, 14–17. (In Chinese) [Google Scholar]

- Guo, J.; Wang, W.X.; Haireti, T. Economic estimates of acid deposition damage on materials in Guangzhou. Urban Environ. Urban Ecol. 2004, 17, 15–17. (In Chinese) [Google Scholar]

- Corrosion and Protection Committee of Japan. Corrosion loss in the chemical plants of Chugoku Shikoku District of Japan. Mater. Environ. 2000, 49, 394–403. [Google Scholar]

- Zhang, X.Y.; Han, E.H.; Li, H.X. Estimation of corrosion losses by the acidic rain in China. J. Chin. Soc. Corros. Prot. 2002, 22, 316–319. (In Chinese) [Google Scholar]

- Ye, T. Study on Effects of Air Pollution on Corrosion of Materials in Chongqing; Chongqing University: Chongqing, China, 2005. (In Chinese) [Google Scholar]

- Henriksen, J.F.; Tian, K. Mapping Air Pollution Effects on Materials Including Stock at Risk in Guangzhou, China; Norwegian Institute for Air Research: Kjeller, Norway, 1999. [Google Scholar]

- Stankunas, A.R.; Unites, D.F.; McCarthy, E.F. Air-Pollution Damage to Man-Made Materials: Physical and Economic Estimates. Final Report; TRC Environmental Consultants, Inc.: East Hartford, CT, USA, 1983; pp. 2–84. [Google Scholar]

- Institute of Atmospheric Environment, Chinese Research Academy of Environmental Sciences. The study of the acid rain damage on materials in South China. The 7th Five Years Programs for Science and Technology Development of China, (75)58-05-02-05, Research Report. 1990; unpublished. (In Chinese) [Google Scholar]

- Guangzhou Environmental Monitoring Center. The study of the acid rain damage on materials in Guangzhou. The 7th Five Years Programs for Science and Technology Development of China, (75)58-05-02-05, Research Report. 1990; unpublished. (In Chinese) [Google Scholar]

- Tian, K.; He, L.W.; Krigsvoll, G. Building Materials Pollution Cost in Guangzhou; NORAD Project CHN 013, Technical Report B3; Norwegian Institute for Air Research(NILU): Kjeller, Norway, 1999. [Google Scholar]

- He, L.W. Study on Building Materials Damage Caused by Air Pollution & Its Estimation of Economic Loss in Guangzhou; Zhongshan University: Guangzhou, China, 2000. (In Chinese) [Google Scholar]

- Shanxi Environmental Information Center/Norwegian Institute for Air Pollution. Master Plan against Air Pollution in Shanxi Province; Norwegian Institute for Air Pollution: Kjeller, Norway, 2004. [Google Scholar]

- Liu, X.H.; Wang, C.; Zhu, H.M.; Gong, Y.L.; Yin, J.F. The study of the RS investigation method of urban exposure Materials inventory. In China Society for Environmental Sciences Academic Annual Conference Proceedings; China Environmental Science Press: Chongqing, China, 2008; pp. 1236–1239. (In Chinese) [Google Scholar]

- Li, X.Y. Study on Economic Loss Accounting of Chongqing’s Building Material Caused by Air Pollution; Chongqing University: Chongqing, China, 2007. (In Chinese) [Google Scholar]

- National Bureau of Rural Social and Economic Investigation Division. China City Statistical Yearbook; China Statistics Press: Beijing, China, 2014.

- Larrabee, C.P.; Coburn, S.K. The atmospheric corrosion of steels as influenced by changes in chemical composition. In Proceedings of the First International Congress on Metallic Corrosion, London, UK, 10–15 April 1961; Butterworths: London, UK, 1962. [Google Scholar]

- Chandler, K.A.; Kilculen, M.B. Atmospheric Corrosion of carbon steel. Br. Corros. J. 1974, 5, 24–28. [Google Scholar] [CrossRef]

- Ailor, W.H. Atmospheric Corrosion; John Wiley and Sons: New York, NY, USA, 1982. [Google Scholar]

- Roberge, P.R.; Klassen, R.D.; Haberecht, P.W. Atmospheric corrosivity modeling-a review. Mater. Des. 2002, 23, 321–330. [Google Scholar] [CrossRef]

- Kitase, M.; Hatakeyama, S.; Mizoguchi, T.; Maeda, Y. Regional characteristics of copper corrosion components in East Asia. Water Air Soil Pollut. 2001, 130, 1463–1468. [Google Scholar] [CrossRef]

- Maeda, Y.; Morioka, J.; Tsujino, Y.; Satoh, Y.; Zhang, X.D.; Mizoguchi, T.; Hatakeyama, S. Material damage caused by acidic air pollution in East Asia. Water Air Soil Pollut. 2001, 130, 141–150. [Google Scholar] [CrossRef]

- Hutchinson, A.J.; Johnson, J.B.; Thompson, G.E.; Wood, G.C.; Sage, P.W.; Cooke, M.J. Stone degradation due to wet deposition of pollutants. Corros. Sci. 1993, 34, 1881–1898. [Google Scholar] [CrossRef]

- Kanazu, T.; Matsumura, T.; Nishiuchi, T.; Yamamoto, T. Effect of simulated acid rain on deterioration of concrete. Water Air Soil Pollut. 2001, 130, 1481–1486. [Google Scholar] [CrossRef]

- Johnson, J.B.; Montgomery, M.; Thompson, G.E.; Wood, G.C.; Sage, P.W.; Cooke, M.J. The influence of combustion-derived pollutants on limestone deterioration: 2. The wet deposition of pollutant species. Corros. Sci. 1996, 38, 267–278. [Google Scholar] [CrossRef]

- Wallinder, I.O.; Verbiest, P.; He, W.; Leygraf, C. The influence of patina age and pollutant levels on the runoff rate of zinc from roofing materials. Corros. Sci. 1998, 40, 1977–1982. [Google Scholar]

- Verbiest, P.; Janssen, C.R.; Wallinder, I.O. Environmental Effects of Zinc runoff from Phosphated zinc Sheets used for Building Application. In Proceedings of the 14th International Corrosion Congress, Cape Town, South Africa, 26 September–1 October 1999. [Google Scholar]

- Azuma, H.; Takeichi, A.; Tachi, K. Advances in Corrosion Protection by Organic Coatings III; Electrochemical Society Inc.: Pennington, NJ, USA, 1997; p. 212. [Google Scholar]

- Tsujino, Y.; Satoh, Y.; Kuramoto, N.; Maeda, Y. Effect of acid deposition on urushi lacquer in East Asia. Water Air Soil Pollut. 2001, 130, 1487–1492. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Zheng, Y.P. The corrosion influence of metals by acid rain in southwest China. Total Corros. Control 1997, 11, 45–48. (In Chinese) [Google Scholar]

- Wang, Z.Y. The corrosion influence of painted steel by acid rain. Total Corros. Control 1997, 11, 22–24. (In Chinese) [Google Scholar]

- Wang, Z.Y.; Yu, G.C.; Zheng, Y.P. Investigation on interrelation of accelerated corrosion testing and atmospheric exposure of zinc. J. Chin. Soc. Corros. Prot. 1999, 19, 239–244. (In Chinese) [Google Scholar]

- Sun, Z.H.; Li, J.G.; Li, M.Z. Future of accelerated atmospheric corrosion testing of metal materials. J. Mater. Eng. 1995, 12, 41–42. (In Chinese) [Google Scholar]

- Wang, Z.Y.; Yu, G.C.; Han, W. Atmospheric corrosion performance of zinc at several selected test sits in China. Corros. Sci. Prot. Technol. 2003, 15, 191–195. (In Chinese) [Google Scholar]

- Yu, F.; Wang, J.N.; Cao, D.; Jiang, H.Q. Guideline for Chinese Environmental and Economic Accounting; China Environmental Science Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- ECON. An Environmental Cost Model; ECON Report No. 16/2000; ECON Centre for Economic Analysis: Oslo, Norway, 2000. [Google Scholar]

- Guo, X.M.; Yu, F.; Zhao, Y. Pollution Damage Cost Assessment: Theories and Methodologies; Environmental Science Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- National Bureau of Statistics of China. 2014 China Statistical Yearbook; China Statistics Press: Beijing, China, 2014.

| Material | Eastern Region | Central Region | Western Region | ||||

|---|---|---|---|---|---|---|---|

| Municipal District | Rural Area | Municipal District | Rural Area | Municipal District | Rural Area | ||

| 1 | Cement | 7.25 | 5.16 | 3.87 | 2.76 | 12.96 | 14.8 |

| 2 | Brick | 18.51 | 13.18 | 11.07 | 7.88 | 2.64 | 4.49 |

| 3 | Aluminum | 10.03 | 7.14 | 3.35 | 2.39 | 1.71 | 0.82 |

| 4 | Painted wood | 1.24 | 0.88 | 0.61 | 0.43 | 0.15 | 0.89 |

| 5 | Marble/granite | 9.14 | 6.51 | 0.41 | 0.29 | 1.02 | 0.75 |

| 6 | Ceramics and mosaic | 40.97 | 29.17 | 10.54 | 7.5 | 26.53 | 14.47 |

| 7 | Terrazzo | 22.51 | 16.03 | 2.62 | 1.87 | 1.68 | 0.1 |

| 8 | Coating/paint ash | 4.61 | 3.28 | 33.3 | 23.71 | 5.8 | 0.91 |

| 9 | Tile | 2.36 | 1.68 | 0.07 | 0.05 | 1.05 | 0.75 |

| 10 | Galvanized steel | 0.29 | 0.21 | 0.15 | 0.11 | 0.09 | 0.05 |

| 11 | Painted steel | 6.69 | 4.76 | 0.02 | 0.01 | 1.23 | 1.03 |

| 12 | Painted steel protective screening | 13.82 | 9.84 | 7.38 | 5.26 | 6.13 | 4.37 |

| 13 | Galvanized protective screening | 9.21 | 6.56 | 4.92 | 3.5 | 4.09 | 2.91 |

| SN | Material | Y/(μm/a) | CDL/(μm) | /(μm/a) | /(a) |

|---|---|---|---|---|---|

| 1 | Cement | If [SO2] < 15 μg/m3, then = 50 a, else = 40 a. | — | — | 50 |

| 2 | Brick | If [SO2] < 15 μg/m3, then = 70 a, else = 65 a. | — | — | 70 |

| 3 | Aluminum | Y = 0.14 + 0.98[SO2] + 0.04 × 104[H+] | 10 | 0.141 | 70.92 |

| 4 | Painted wood | Y = 5.61 + 2.84[SO2] + 0.74 × 104[H+] | 13 | 5.63 | 2.31 |

| 5 | Marble/granite | Y = 14.53 + 23.81[SO2] + 3.80 × 104[H+] | 160 | 14.63 | 10.94 |

| 6 | Ceramics and mosaic | If [SO2] < 15 μg/m3, then = 70 a, else = 65 a. | — | — | 70 |

| 7 | Terrazzo | If [SO2] < 15 μg/m3, then = 50 a, else = 40 a. | — | — | 50 |

| 8 | Coating/paint ash | Y = 5.61 + 2.84[SO2] + 0.74 × 104[H+] | 13 | 5.63 | 2.31 |

| 9 | Tile | If [SO2] < 15 μg/m3, then = 45 a, else = 40 a. | — | — | 45 |

| 10 | Galvanized steel | Y = 0.43 + 4.47[SO2] + 0.95 × 104[H+] | 7.3 | 0.45 | 16.22 |

| 11 | Painted steel | Y = 5.61 + 2.84[SO2] + 0.74 × 104[H+] | 13 | 5.63 | 2.31 |

| 12 | Painted steel protective screening | Y = 5.61 + 2.84[SO2] + 0.74 × 104[H+] | 13 | 5.63 | 2.31 |

| 13 | Galvanized protective screening | Y = 0.43 + 4.47[SO2] + 0.95 × 104[H+] | 7.3 | 0.45 | 16.22 |

| SN | Material | Price (Yuan/m2) | SN | Material | Price (Yuan/m2) |

|---|---|---|---|---|---|

| 1 | Cement | 29 | 8 | Coating/paint ash | 20 |

| 2 | Brick | 86 | 9 | Tile | 11 |

| 3 | Aluminum | 266 | 10 | Galvanized steel | 21 |

| 4 | Painted wood | 27 | 11 | Painted steel | 21 |

| 5 | Marble/granite | 266 | 12 | Painted steel protective screening | 21 |

| 6 | Ceramics and mosaic | 64 | 13 | Galvanized protective screening | 21 |

| 7 | Terrazzo | 35 |

| SN | Material | Material Exposure Inventory (10 Thousand m2) |

|---|---|---|

| 1 | Cement | 987,851 |

| 2 | Brick | 1,311,989 |

| 3 | Aluminum | 579,280 |

| 4 | Painted wood | 97,902 |

| 5 | Marble/granite | 427,495 |

| 6 | Ceramics and mosaic | 2,792,800 |

| 7 | Terrazzo | 1,054,133 |

| 8 | Coating/paint ash | 1,467,289 |

| 9 | Tile | 133,590 |

| 10 | Galvanized steel | 20,041 |

| 11 | Painted steel | 321,396 |

| 12 | Painted steel protective screening | 1,028,162 |

| 13 | Galvanized protective screening | 685,108 |

| Total | 10,907,037 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, Q.; Zhang, F.; Xie, G. Estimates of Economic Loss of Materials Caused by Acid Deposition in China. Sustainability 2017, 9, 488. https://doi.org/10.3390/su9040488

Zhang Y, Li Q, Zhang F, Xie G. Estimates of Economic Loss of Materials Caused by Acid Deposition in China. Sustainability. 2017; 9(4):488. https://doi.org/10.3390/su9040488

Chicago/Turabian StyleZhang, Yinjun, Qian Li, Fengying Zhang, and Gaodi Xie. 2017. "Estimates of Economic Loss of Materials Caused by Acid Deposition in China" Sustainability 9, no. 4: 488. https://doi.org/10.3390/su9040488