1. Introduction

Decision-making models and methods can be used in various situations, processes, and industrial branches. This paper deals with the decision making within the production of resonant wood products. This performance can be measured by various indicators, and various criteria should be assessed. This production is not serial, and all products are produced only upon special particular demand.

Analyses of value chains should be focused on specification of so-called bottlenecks, which mention those activities that prevent an increase in business margins. At the same time, these analyses show the inefficiency caused by the over-sizing of some activities regarding a lower level of assurance, and lower performance of other business activities.

The importance of multi-criteria decision-making methods for the evaluation of alternatives should lie in a definite increase in results’ objectivity. Other priorities of this method lie mainly in the simplification of a manager’s decision making because of its quantification. It allows managers to arrange alternatives according to an extensive file of criteria, describing particular steps of a solution and its logical sequence; this methodology also requires managers to express their understanding of the importance of various criteria (which could change over time and according to various decision-making situations). All process steps of the solution are transparent, repeatable, and with evident starting assumptions, with a portrayal of how these assumptions, situations, criteria, and incidents affect reached results.

1.1. Resonant Wood

Resonant wood for the production of musical instruments in Central Europe is the subject of this study. Specifically, it looks at wood from spruce (Picea abies) and fir (Abies alba), which have suitable properties that allow emission of the maximum amount of acoustic energy without tone distortion, in connection with other parts of the musical instrument.

1.2. Identification of Resonant Wood for the Production of Musical Instruments

Resonant spruce wood can be found mainly in high and straight trees with full-boled tree trunks and highly sitting sharp crowns. Bark should be smooth and thin with bulbed and curved dandruffs. Dandruffs should be grey in their lower part and brown in their upper part. The trunk must be without knots between 2 and 6 m from the ground. It should be cylindrical, without visible defects, trunk bulges, or splits caused by growth. The optimum altitude in Slovakia for the growth of resonant wood is between 800 and 1200 m above sea level. An important factor is also exposition of the hills. The worst conditions for the growth of resonant wood are on the western and southern sides of hills. The greatest amount of resonant wood within Slovakia can be found on the northern, eastern, and northeastern sides of mountain planes. Higher acidic mountains and even strong acidic soils are the most suitable soils for consistent wood growth and adequate proportions of earlywood and latewood. Visual evaluation of resonant wood, and its potential appearance, involves evaluation of annual ring density per 1 cm of thickness, and also evaluation of the proportion between earlywood and latewood. This can be done by two possible methods:

- (1)

drilling into the wood trunk by Pressler borer and evaluation of the given borehole by a resistograph;

- (2)

non-invasive evaluation of the wood trunk by a tomograph.

Spruce wood sometimes shows a specific growth anomaly called “hazel growth”, “bear claw”, or “indented rings”. Hazel growth is an abnormality in radial growth. Such a spruce is also suitable for the production of string musical instruments. We can identify it by a simple removal of the bark and by visual identification of scratches.

One centimetre of wood thickness should contain less than four annual rings of the same width. The thickness of resonant wood should not be less than 8 cm with periodical annual rings. The proportion of latewood in annual rings should be less than 30%. Resonant boards/plates or wedges used for professional stringed instruments should contain less than 20% of latewood. The thickness proportion between earlywood and latewood in annual rings should be 2:1.

Essential quality of stringed musical instruments depends mainly on the acoustic properties of the wood used for the production of the upper resonant plate [

1]. Wood substance of coniferous trees is more homogeneous than in deciduous trees. Tracheids make up 95% of the structure of coniferous trees. Because of that, coniferous wood is more suitable for resonant wood products. Resonant wood is a material which can emit maximum amounts of acoustic energy without tone distortion, in the connection with other parts of the musical instrument. Upper resonant plates for stringed musical instruments which are cut radially are much tougher than those cut tangentially.

Resonant wood is made only from particular wood species like resonant spruce and fir. This wood is a perfect conductor of sound waves. Research confirmed that in resonant wood the sound is spread 15 times faster than in air. Because of an increasingly frequent fir defect (peeling), this wood is not suitable for the production of musical instruments.

Quality of resonant wood can vary according to various types of musical instrument. Basic requirements for resonant wood are given in technical standards or in enterprise standards. We can mention the following requirements: density of annual rings (minimally 3–4 rings per 1 cm), and a minimum or absence of knots, defects caused by biological damage, cracks, resin pockets, and angle between a tangent to the annual rings and the board surface (deviation of fibres from the radial line of the board, maximum level should be 15°). Wood species with a higher volume of annual rings (5–8 rings per 1 cm) are needed for the production of violins. In the production of piano boards, various volumes of annual rings per 1 cm are needed, depending on the placement of resonant board application (bass part of the resonant plate) and also according to type of piano—if it is a domestic piano or a concert piano. According to standards of resonant wood, there is also a defined maximum distance between annual rings for the wood used in the production of piano keys. Special application of resonant wood takes place in the production of organ wooden pipes [

2] because of its mechanical features, moisture properties, and the workability of such a homogeneous wood.

When the tree rings are smaller, with a higher density and more regularity, the resonant board will also have better properties.

Resonant wood (coniferous trees) and non-resonant wood (deciduous trees) for the production of musical instruments are cut and primarily manufactured out of the vegetation period. An important part of wood processing is also natural seasoning. During the seasoning, growth should be controlled and wood properties monitored in order to avoid risks of biotic and abiotic damage. Wood for the production of musical instruments should have an 8% moisture content.

The totality of basic requirements for the wood suitable for the production of musical instruments is given in Slovak standard STN 48 0059:2014, Wood assortments—Wood for the production of musical instruments.

1.3. Machinery for the Production of Resonant Wood from Spruce Logs

An ingredient for the production of resonant wood must be a precisely chosen slice of wood. The visual aspect of the wood surface, the cross-section, and the conicalness of the wood trunk must be evaluated.

The final product is timber of various shapes according to the demand for the production of musical string instruments. It is necessary to present a proposed cutting scheme of radial timber (

Figure 1). The shape of the slice manipulated from timber depends on the evaluation of a skilled operator who is experienced in the production of musical instruments.

Machinery for the production of resonant wood: debarking (manual operation), horizontal band saw, vertical band saw for carpentry with special shift for the cutting of radial quarters and wedges, wood splitter, cut-off saw, circular saw for formatting, planning cutter.

Technological process of the resonant timber production: (1) warehouse—log (spruce wood); (2) two halves obtained by cutting on horizontal band saw; (3) central board obtained by cutting on horizontal band saw; (4) cut-off saw (central radial boards); (4) division of two halves into quarters on carpentry band saw or on horizontal band saw; (5) radial boards from the abovementioned quarters (band saw for carpentry); (6) wedges from quarters (band saw for carpentry or wood splitter); (7) cutting off, formatting, and aligning edges; (7) warehouse with special protection.

The price of resonant wood is much higher compared to usual wood products prices. Wood for the production of musical instruments is sorted into a high-quality level according to wood assortment levels. Special attention and individual evaluation must be given to the processing of each wood log into slices. There is much manual work that must be done, and there should be no conveyors used because of the risk of mechanical damage to valuable parts of resonant wood.

2. Materials and Methods

2.1. Dynamic Monitoring of Production Processes

Complexity, extensiveness, and variability of technical, economic, and social objectives require the application of methods that allow such features that characterise the synthesis of functional parts into one unit to be managed explicitly and objectively.

Systemic model should meet the following goals:

to reflect systemic features of an object; i.e., take into account all parts, events, and processes of an object which contribute to the generation of these features,

to simplify primary complexity of an object in order for it to be technically managed,

to unify model heterogeneity of particular parts of an object and thus allow application of formalised tools,

to form a model which allows quantification and metrics of monitored parameters.

Objects must contain the following features:

interaction of the particular parts amongst themselves,

interaction of the object with an environment,

dynamics of the system and focus on the goals of the object behaviour,

adaptability of the object to environmental changes,

ability to save and to utilise experiences.

The choice of the process is managed by input assessment and by internal assumptions. Petri nets (

PN) can be defined as a suitable tool characterised as below [

3].

There are two kinds of peaks:

traditional set of peaks, which describes status parameters—this refers to elements (situations) of a system,

untraditional set of peaks, which describes transitions between various statuses of two nearby elements; respectively, it causes the change of a status in the resulting element caused by the impact in the previous element.

Transition (element from the nonstandard set of elements) differs among situations. It is an independent element like a virtual item which initiates a situation. It is also the presentation of dynamic features of a connection within the system structure. Transition is the real holder of the element’s ability to change its status.

Report of the system structure is completed by modification of incident function [

3]:

connections which describe relation from the element to the transition—“transition” incident functions,

connections in the opposite direction, i.e., coming from the element back to the transition (to that which caused the change of the given element)—“feedback” incident functions.

On the basis of the abovementioned process, Petri nets can be described as:

where:

P, T—related sets of elements and transitions,

F, B—incident transition and feedback functions,

Mo—initial system line-up.

Implementation of transition and feedback incident functions allows the division of investigations into how elements are prepared for the realisation of transitions (matrix

F) and how elements are prepared to accept incidents of transitions (matrix

B). Both matrices can be joined into one matrix

E:

Logistics systems in wood-processing manufacturing are dynamic, with permanent adaptation to turbulent market environments, and they integrate all functions of material management, starting with the assessment of materials and resource demands and ending with the selling of the final products.

2.2. Review of Multi-Criteria Decision-Making Methods

Multi-attribute utility theory (MAUT) [

4,

5] was the most commonly utilised multi-criteria decision-making (MCDM) method. MAUT is essentially an extension of multi-attribute value theory (MAVT) [

5] and is “a more rigorous methodology for how to incorporate risk preferences and uncertainty into multi criteria decision support methods” [

6]. Earlier research in MAUT compared it to then-current MCDM methods. In the last decade, various authors have come to use MAUT in order to assist decision analysis in real-world problems. Canbolat et al. [

4] applied a MAUT model to assist in selecting the location of a global manufacturing facility. MAUT was utilised due to its common use in natural resource management problems. Their approach centred around societal risk preferences, and they utilised a survey to obtain and examine desirable attributes. Gomez-Limon et al. [

7] utilised multi-criteria decision-making analysis in regards to risk aversion. MAUT is an expected utility theory that can decide the best course of action in a given problem by assigning a utility to every possible consequence and calculating the best possible utility. The major advantage of MAUT is that it takes uncertainty into account.

Analytic hierarchy process (AHP) is a method similar in popularity to MAVT/MAUT [

8]. For MAUT and AHP, “the two methods rest on different assumptions on value measurements and AHP is developed independently of other decision theories. The major characteristic of the AHP method is the use of pair-wise comparisons, which are used both to compare the alternatives with respect to the various criteria and to estimate criteria weightings” [

9].

It is one of the more popular methods of MCDM and has many advantages, as well as disadvantages. One of its advantages is its ease of use. Its use of pairwise comparisons can allow decision makers to weight coefficients and compare alternatives with relative ease. It is scalable, and can easily adjust in size to accommodate decision-making problems due to its hierarchical structure. Although it requires enough data to properly perform pairwise comparisons, it is not nearly as data-intensive as MAUT. The method has experienced problems of interdependence between criteria and alternatives. Due to the approach of pairwise comparisons, it can also be subject to inconsistencies in judgment and ranking criteria, and it does not allow individuals to grade one instrument in isolation, but in comparison with the rest, without identifying weaknesses and strengths.

Fuzzy theory has existed for several decades. Fuzzy logic itself has proven to be an effective MCDM method. Khadam and Kaluarachchi [

6] addressed the use of cost-benefit analysis as the primary method for decision analysis when addressing environmental projects.

Fuzzy set theory is an extension of classical set theory that “allows solving a lot of problems related to dealing with imprecise and uncertain data”. It has many advantages. Fuzzy logic “takes into account the insufficient information and the evolution of available knowledge” [

10]. It allows imprecise input. It allows a few rules to encompass problems with great complexity. For disadvantages, fuzzy systems can sometimes be difficult to develop. In many cases, they can require numerous simulations before being able to be used in the real world. Fuzzy set theory is established and has been used in engineering, economic, environmental, social, medical, and management applications. Many of these types of problems take advantage of the availability of imprecise input.

Simple multi-attribute rating technique (SMART) is one of the simplest forms of MAUT. It requires two assumptions, namely “utility independence and preferential independence” [

11]. This method conveniently converts importance weightings into actual numbers. Major advantages of SMART, in addition to those described in MAUT, are that it is simple to use and it actually allows for any type of weight assignment techniques (relative, absolute, etc.). It requires less effort by decision makers than MAUT. It also handles data well under each criterion. SMART’s common applications are in construction, transportation and logistics, military, manufacturing, and assembly problems. Its ease of use helps in situations where a fair amount of information is available and access to decision-makers is easy to obtain. Its simplicity appears to be what keeps this method fairly popular.

2.3. Performance Measurement and Decision Making in an Enterprise

Customers’ behaviour and their demand can be characterised by the uncertainties in the quality, quantity, and time demand of particular products. In a time of globalisation and a highly competitive environment, measuring performance has become critical to business success. Among the first and most important steps to improve and to achieve business excellence is the development and implementation of a system for performance measurement (PM). The term performance measurement is defined as the process of quantifying the efficiency and effectiveness of actions [

12]. The literature presents the following popular performance measurement frameworks, such as performance measurement matrix, balanced scorecard (BSC), performance pyramid, Sink and Tuttle framework, European Foundation for Quality Management (EFQM) excellence model, performance prism (PP), and, lastly, the Malcolm Baldrige National Quality Award (MBNQA) model, to name just a few. These performance measurement frameworks provide the following: a balanced view between an external and internal focus; results and determinants; the four perspectives of the BSC [

13]; and, finally, the multiple perspectives of the stakeholders of PP [

14]. The newly developed PM frameworks highlight the importance of non-financial/financial measures, as well as internal/external factors [

15], by providing an emphasis on the integration of the determinants (or drivers), and the result determines performance. According to Bassioni et al. [

16], a performance measurement system (PMS) refers to the measurement system implemented by an enterprise, while a PM framework is a general theoretical framework developed through research that can act as the basis for a company’s PMS.

Application of PMS can be described by three factors: decision support, work integration, and communication. The decision support factor concerns the extent to which the PMS is used for problem solving, data, causality, and relationship analysing. The second factor explains and justifies decisions, and the third factor tries to improve the effectiveness of the decision-making process. It is also necessary to allocate responsibilities and decisions, and set the goals of performance. The quantification of performance measurement is closely defined by multi-criteria decision-making methods. PMS can be characterised as a multi-criteria tool, made from a set of metrics. Our research focuses on the area of metrics, decisions, and criteria within the supply chain and the material flow of manufacturing wooden musical instruments.

3. Results and Discussion

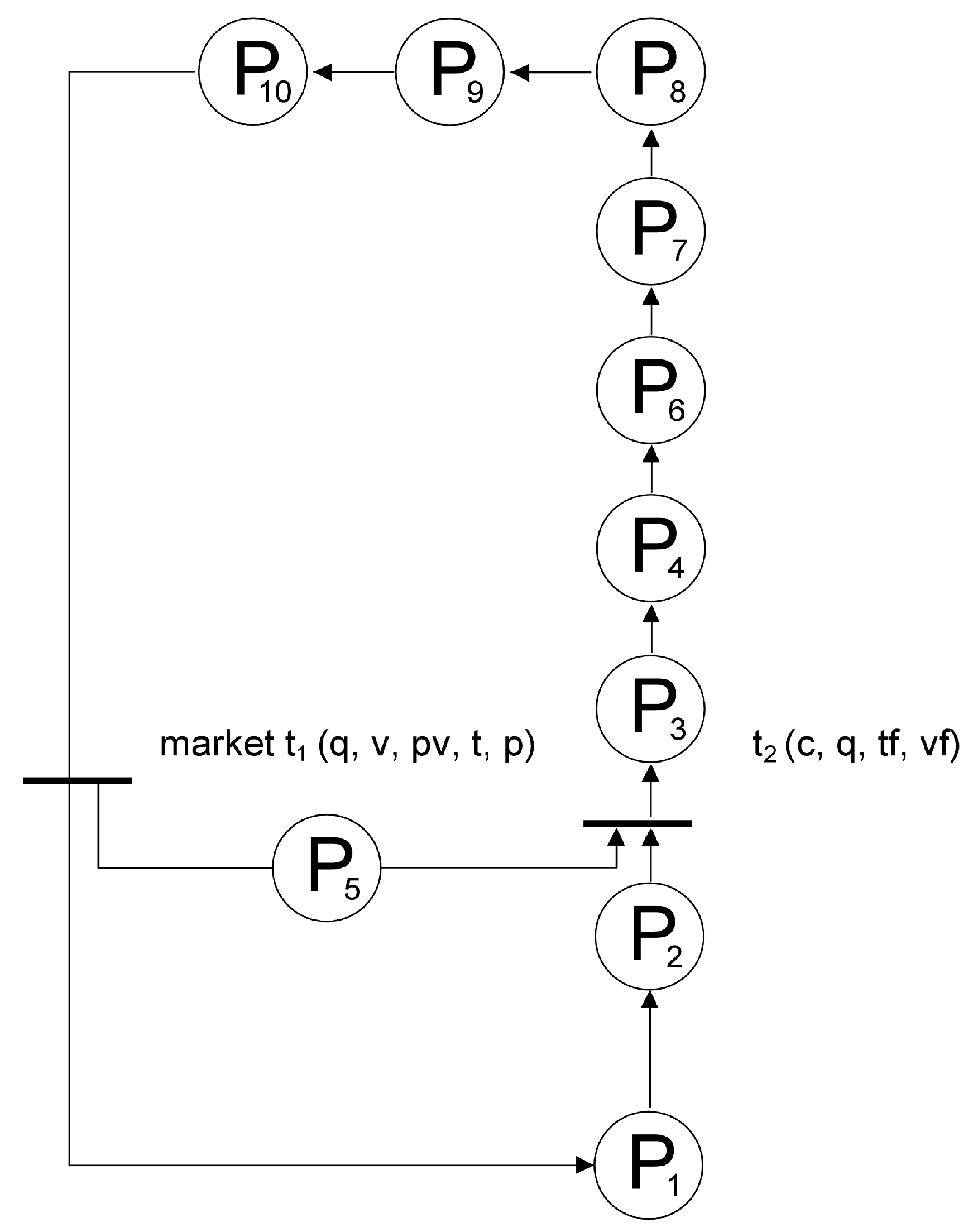

We had decided to address the supply chain element by the model of Petri nets (

Figure 2). This tool is suitable because it reflects decision-making situations, describes the whole material flow, and because of parameterization and quantification of criterions expressed by transitions and elements (situations). Some other methods, like those mentioned above, can be used in our research. There are also Critical Path Method (CPM), Program Evaluation and Review Technique (PERT), and Gantt chart, which could be suitable for the description of material flow, but these methods predominantly deal with the time optimisation of particular activities and the whole project. The decision tree identifies places where managers must make decisions. It is a visual model which has decision nodes, event (chance) nodes, end nodes, and roots. In the following, we would like to present our proposed model, which can be used not only for the purchasing and evaluation of resonant wood and for the production of final products from resonant wood, but also for other industrial branches and for various decision-making situations.

● Knot P1, place—warehouse of logs:

The first knot of the chain is warehouse of logs. We can see that there is no transition “t” before this knot. Inputs must be bought in the market from external suppliers. Of course, it is necessary to make a choice amongst suppliers as to what has a further impact on the quality of production and final product. It is necessary to assess some specific demanded parameters on inputs (wood raw or logs) in order to monitor and evaluate this process of warehousing (

Table 1).

● Knot P2, place—manipulation and debarking:

Every log which is moved to the sawing process must go through this place. Parameters of the process must be assessed in order to monitor it, to evaluate it, and to control it. Debarking must be manual because of special requirements on resonant timber (

Table 2).

● Knots P3, P5, place—supply of logs to the horizontal and vertical band saws:

Before an entry of logs into the band saw is transition “t

2”, where it is necessary to decide on the choice of logs. It is possible to take them from your own capacity after the flow through the abovementioned previous two operations or to buy debarked logs from an external supplier. This choice depends on the particular technological and economic criteria (

Table 3).

In the following, the application of multi-criteria utility analysis for decision-making about the choice of input suppliers is presented (

Table 4). The result depends on selected criteria and how suppliers meet them. Points should then be assessed (or weight of criteria calculated and assessed) for various criteria description.

The most important operation in the processing of resonant wood is cutting, which brings added value to the semi-product and the final product. As we present, it is very important to deal with the selection, evaluation, and monitoring of criteria which impact the quality of this process because there is special single-part production, rather than serial production (

Table 5). It is necessary not only to monitor the yield of the cutting and the quality of the timber, but to also focus on cost and time of the given process because these parameters significantly affect the satisfaction of a customer.

● Knots P4, P7, place—cut-off saws:

These saws cut resonant timber to exact demanded length.

● Knot P8, place—circular saw for formatting:

In this process, we can assess the following criteria: time of the process, cost of the process, and length and width of the resonant timber according to its utilisation for a particular musical instrument or its part.

● Knot P9, place—planning cutter:

In this process, there is assured surface finishing, surface planning, and alignment of all planes. Also, the following should be monitored: time of the process, cost of process, and whether the dimensions and proportions meet the demanded requirements of a customer.

● Knot P10, place—resonant timber warehouse:

The final knot and process in the logistics chain is warehouse of final products. All products are made only in response to a concrete order (according to market demand—“t

1”). Every product must meet particular qualitative parameters given by the standard and by the utilisation of this final product. All these parameters should also be monitored and controlled in the final products warehouse. In addition to those qualitative parameters that should be monitored, others should also be taken into account (

Table 6).

What can such a model and its application bring to an enterprise? Simply and generally said, this can lead to more objective decision making, alternative decision making, and decision making based on quantified parameters. As we have mentioned above, resonant wood is one of the most valuable outputs from raw wood. We can say that, very often, such a resonant wood is classified as timber for sawmills or for furniture production, resulting in less value added and less financial profit for the producer. Another important aspect is visibility of moving material and the semi-product through all stages (knots) of the material flow. Petri net and the file of tables express and describe each particular step within the material flow, and parameters which would be measured and monitored. This enables managers to detect and more easily correct eventual defects during the production.

4. Conclusions

The proposed model of a logistics chain is the combination of various methods. This model could be a suitable tool for the supply chain management. There are important quality and objectivity considerations of obtained information which should support the decision-making process. So, the question is not whether to decide or not, but how to decide and which criteria are important. An important part of the decision-making process is methodology and evaluation of information.

Manufacturing of musical instruments and production of resonant wood is a very specific, individual, and value-adding part of the wood-processing industry. Very special and professional decision making by experienced employees is necessary in the supply chain of this production.

The traditional decision-making process was accomplished only by intuition and on the basis of experiences and professional feeling for any given situation. At the same time, we can say that intuitive decision making should also lead to very good results, but this decision does not take into account feedback from the qualitative part of decisions. When problems occur, it is very hard to choose a particular place in the process where it occurred and to determine what did occur. Intuitive decision making is more subjective; the abovementioned methods should decrease the subjectivity and could lead to better performance measurement. One of the most important assumptions for managers is to quantify results and to think of alternatives. All these abovementioned methods are helpful for parameter quantification and for alternative thinking of managers. All these assumptions are special, needed, and valuable in the process where expensive and valued input is transformed into much more expensive and valued output. Moreover, our paper is dealing with such a process: that of production of musical instruments and resonant wood products. The main purpose of this paper is to suggest a decision-making model and the application of this model to the process of evaluation, selection, and classification of resonant wood for the production of musical instruments. Each particular step in the material flow should be monitored by the abovementioned tables in order to assure maximum quality of material and its transformation into final product.