Improving the Diagnosis Accuracy of Hydrothermal Aging Degree of V2O5/WO3–TiO2 Catalyst in SCR Control System Using an GS–PSO–SVM Algorithm

Abstract

:1. Introduction

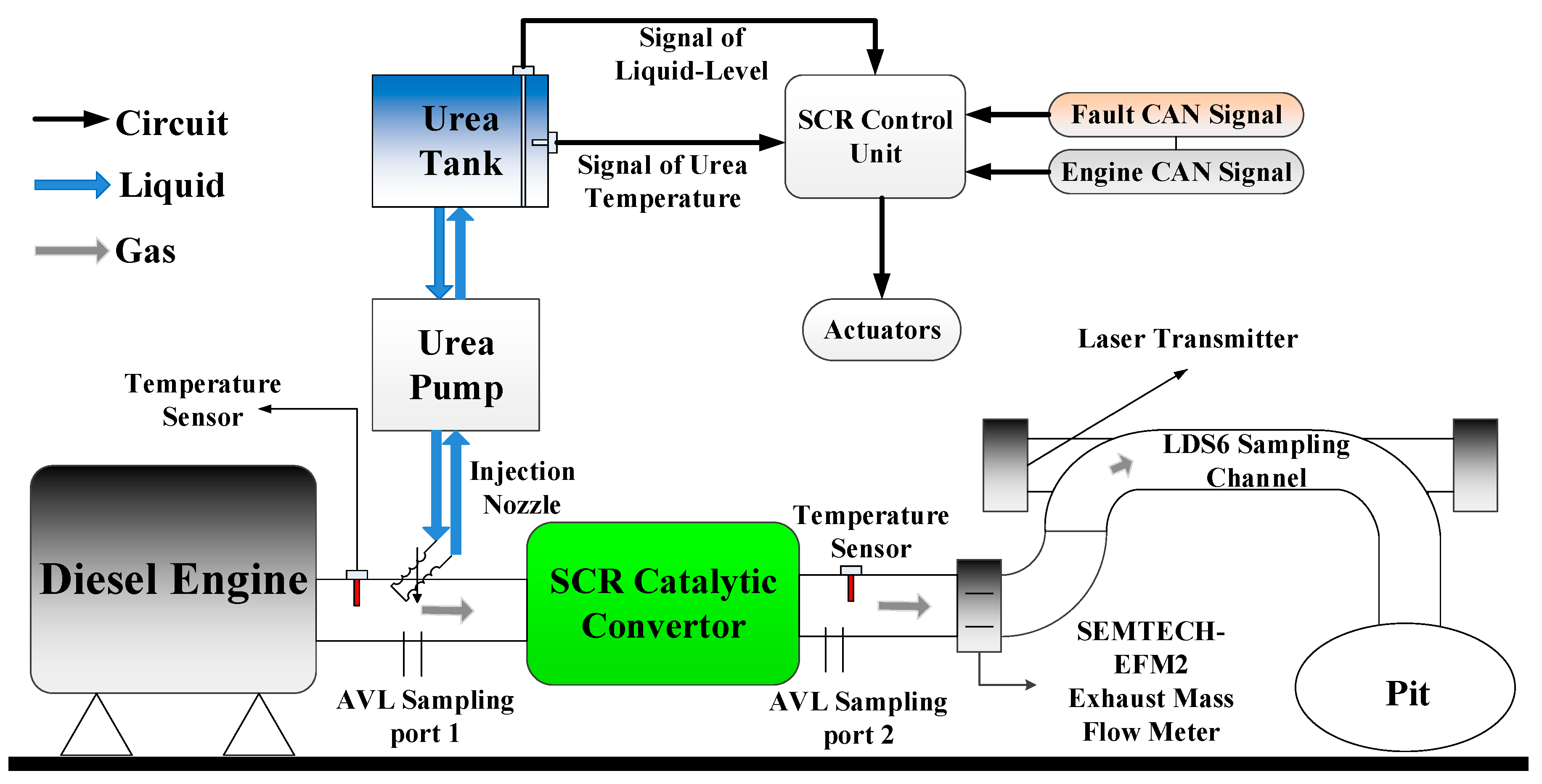

2. Experimental Setup and Data Processing

3. Modeling

3.1. SCR Modeling

3.1.1. SCR Operation Principles

3.1.2. SCR Modeling

- The components of exhaust gasses are regarded as homogeneous and incompressible ideal gas.

- The effect of variations in the water and oxygen concentration of the exhaust gas is negligible.

- The catalyst convertor can be divided into limited cells along the flow axis.

- All variables are homogeneous in each cell and only vary in the axis of catalyst convertor.

- The dynamic of adsorption/desorption reaction rate is much slower than other reactions.

- Only adsorbed NH3 will be involved in NOx removal reaction.

- Adsorption reaction

- Desorption reaction

- SCR reaction

- NH3 oxidation reaction

3.2. SVM Modeling and Optimization Method

4. Results and Discussion

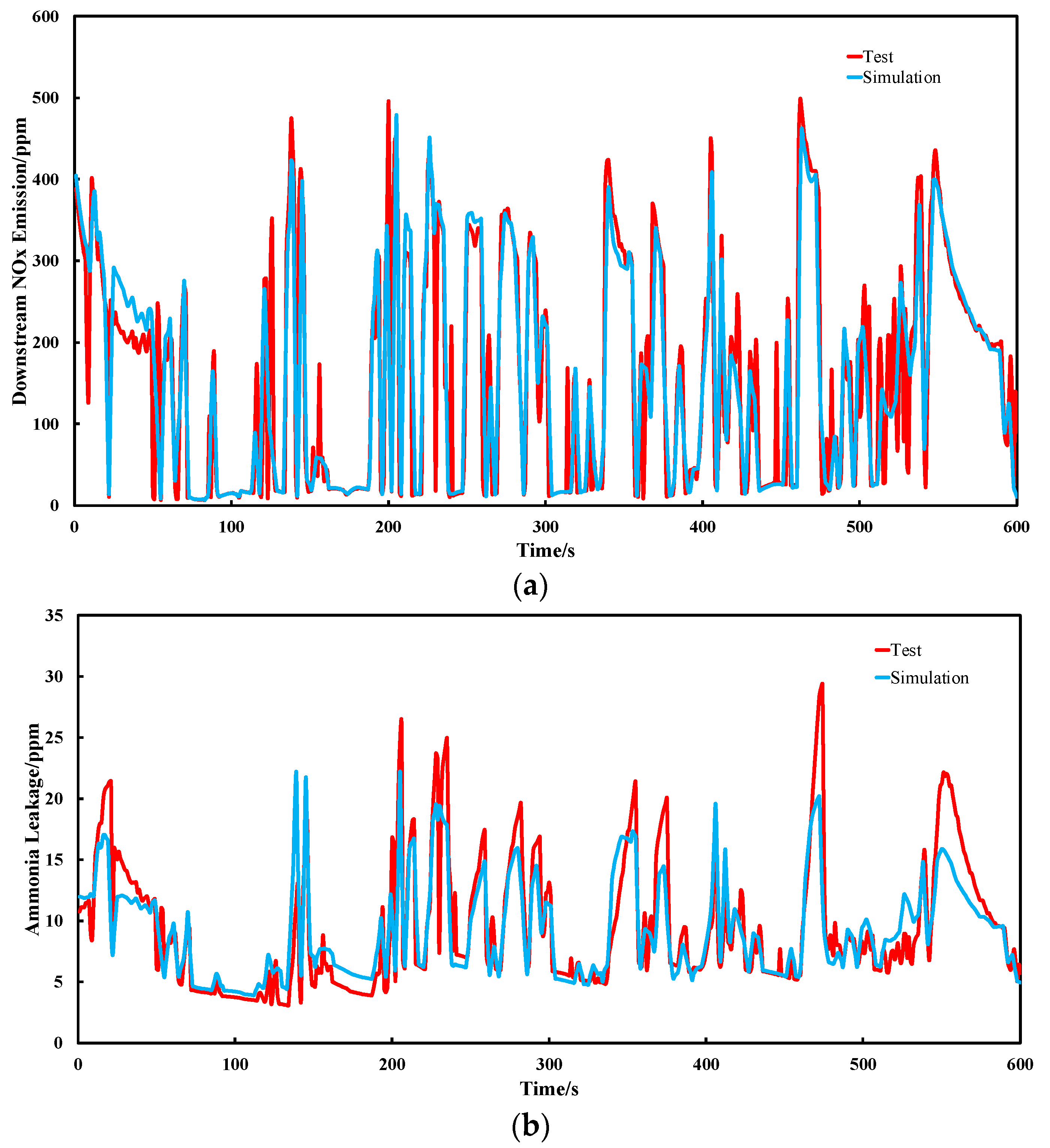

4.1. SCR Model Validation

4.2. Simulation Study

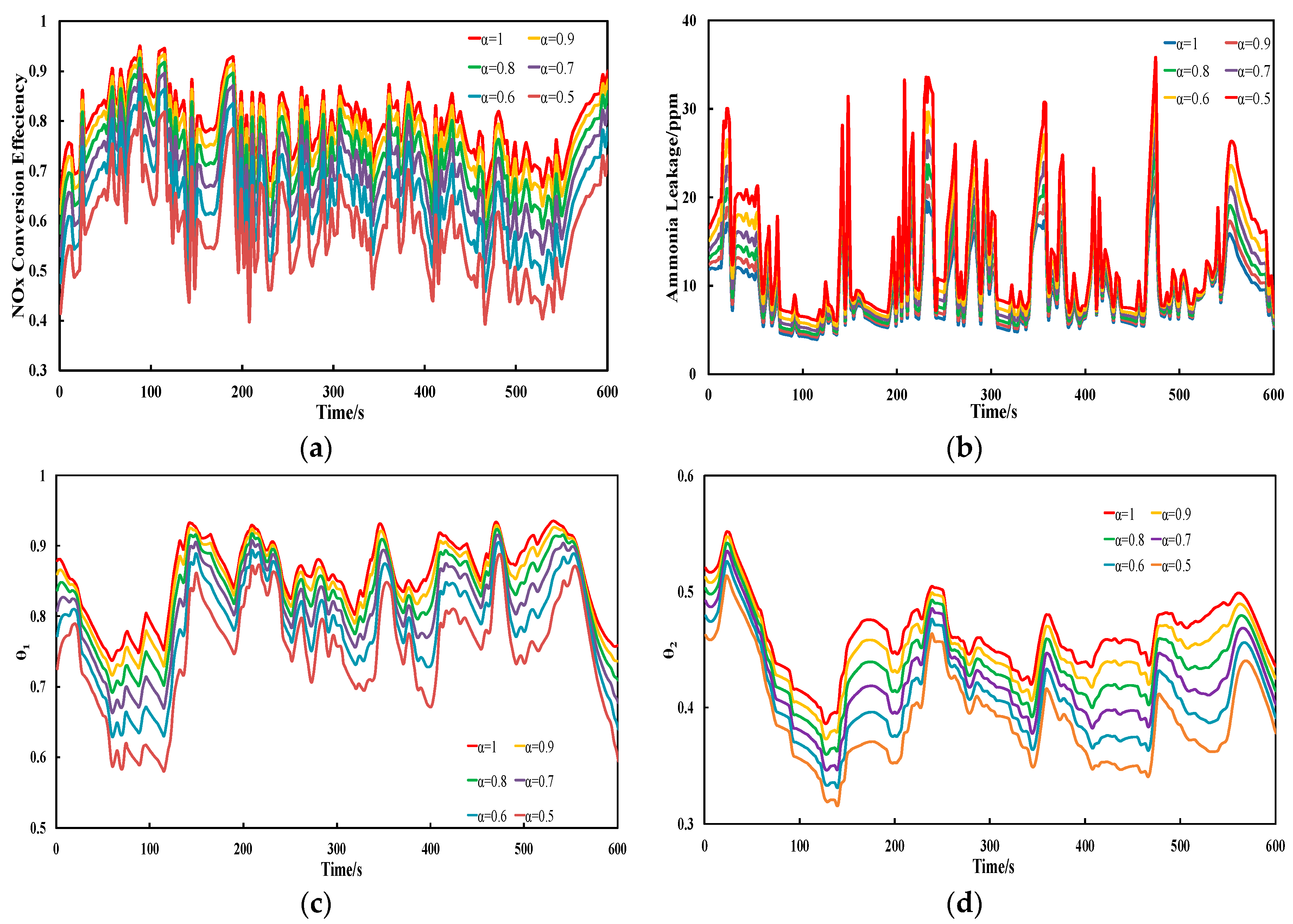

4.2.1. Effect of Aging on SCR Performance

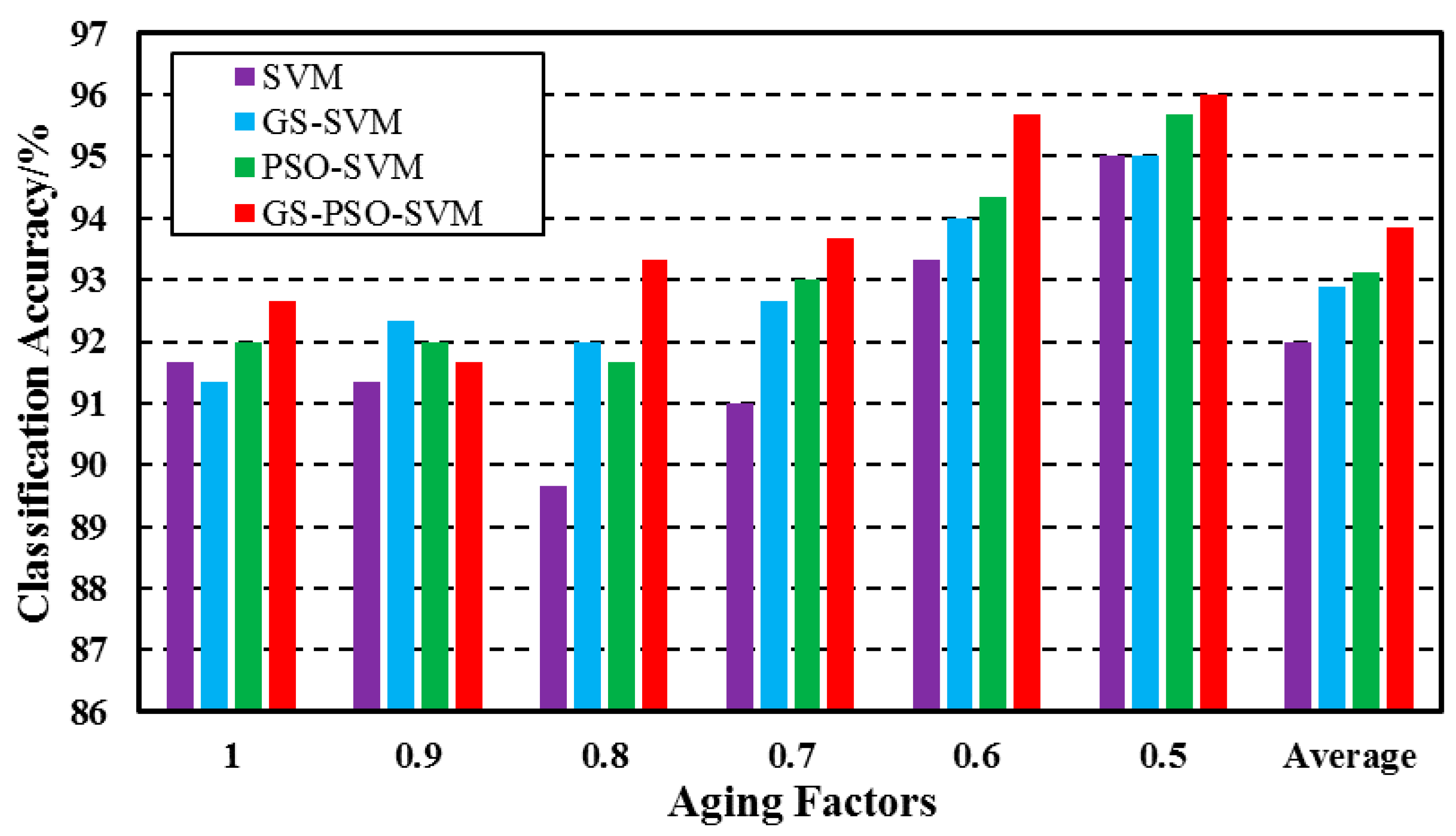

4.2.2. Diagnosis of Aging of the Catalyst

5. Conclusions

- The SCR model has been built for the investigation, in a simulation, of the effect of an aging catalyst on SCR performance. It was validated under a NH3 based closed-loop control strategy by transient test data and the results show that this SCR model can roughly predict NOx emission and NH3 leakage at the outlet of a catalyst convertor.

- Considering that the activity of the SCR reaction is the main factor affecting NOx conversion efficiency, the SCR reaction rate () was selected as the major parameter affected by the hydrothermal aging and the aging factor (α) was defined simultaneously.

- The aging effect on the performance of a NH3 closed-loop SCR control system was studied by changing the aging factor (α). The result indicates that the aging of the SCR catalyst has significant negative impact on the performance of the SCR control system.

- To highlight the advantages of GS–PSO–SVM, this system was compared with PSO–SVM, GS–SVM and SVM. The results show that the diagnosis accuracy of GS–PSO–SVM, PSO–SVM, GS–SVM and SVM are 93.8%, 93.1%, 92.9% and 92.0% respectively. It indicates that GS–PSO–SVM exhibits better performance in the diagnosis of catalytic aging than PSO–SVM, GS–SVM or SVM.

Acknowledgments

Author Contributions

Conflicts of Interest

Definitions/Abbreviations

| NOx | Nitrogen oxide and dioxide |

| NH3 | Ammonia |

| Exhaust Gas specific constant | |

| R | Universal gas constant |

| T | Temperature in catalyst convertor |

| Exhaust mass flow | |

| Ambient pressure | |

| Number of SCR cell in the model | |

| ε | Ratio of gas to total convertor volume |

| Converter volume | |

| Concentration of active atoms with respect to converter volume | |

| Area of 1 mol of active surface atoms | |

| Sticking probability | |

| NH3 molar mass | |

| Pre-exponential factor of desorption | |

| Pre-exponential factor of SCR | |

| Pre-exponential factor of NH3 oxidation | |

| Activation energy of desorption | |

| Activation energy of SCR | |

| Activation energy of NH3 oxidation | |

| θ | Ammonia surface coverage |

| θ1 | Ammonia surface coverage in first cell of catalyst convertor |

| θ2 | Ammonia surface coverage in second cell of catalyst convertor |

| NOx concentration | |

| NH3 concentration | |

| Reaction rate of adsorption | |

| Reaction rate of desorption | |

| Reaction rate of SCR | |

| Reaction rate of NH3 oxidation | |

| NOx molar flow at inlet of catalyst convertor | |

| NH3 molar flow at inlet of catalyst convertor |

References

- Johnson, T.V. Review of Vehicular Emissions Trends. SAE Int. J. Engines 2015, 8, 1152–1167. [Google Scholar] [CrossRef]

- Prabhu, S.S.; Nayak, N.S.; Kapilan, N.; Hindasageri, V. An experimental and numerical study on effects of exhaust gas temperature and flow rate on deposit formation in Urea-Selective Catalytic Reduction (SCR) system of modern automobiles. Appl. Thermal Eng. 2017, 111, 1211–1231. [Google Scholar] [CrossRef]

- Åberg, A.; Widd, A.; Abildskov, J.; Huusom, J.K. Parameter estimation and analysis of an automotive heavy-duty SCR catalyst model. Chem. Eng. Sci. 2017, 161, 167–177. [Google Scholar] [CrossRef]

- Zhan, S.; Zhang, H.; Zhang, Y.; Shi, Q.; Li, Y.; Li, X. Efficient NH3-SCR removal of NOx with highly ordered mesoporous WO3(χ)-CeO2 at low temperatures. Appl. Catal. B Environ. 2017, 203, 199–209. [Google Scholar] [CrossRef]

- Gieshoff, J.; Schäfer-Sindlinger, A.; Spurk, P.C.; van den Tillaart, J.A.A.; Garr, G. Improved SCR Systems for Heavy Duty Applications. Available online: http://papers.sae.org/2000-01-0189/ (accessed on 10 April 2017).

- Adams, T.R. Development of an Open Loop Fuzzy Logic Urea Dosage Controller for use With an SCR Equipped HDD Engine; West Virginia University: Morgantown, WV, USA, 2008. [Google Scholar]

- Zhao, J.; Chen, Z.; Hu, Y.; Chen, H. Urea-SCR process control for diesel engine using feedforward-feedback nonlinear method. IFAC 2015, 48, 367–372. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, Y.; Zhang, Y.; Shuai, S.; Wang, J. Development of Closed-Loop Control Strategy for Urea-SCR Based on NOx Sensors. Available online: http://papers.sae.org/2011-01-1324/ (accessed on 10 April 2017).

- Willems, F.; Cloudt, R. Experimental demonstration of a new model-based SCR control strategy for cleaner heavy-duty diesel engines. IEEE Trans. Control Syst. Technol. 2011, 19, 1305–1313. [Google Scholar] [CrossRef]

- Willems, F.; Cloudt, R.; van den Eijnden, E.; van Genderen, M.; Verbeek, R.; de Jager, B.; Boomsma, W.; van den Heuvel, I. Is Closed-Loop SCR Control Required to Meet Future Emission Targets? Available online: http://papers.sae.org/2007-01-1574/ (accessed on 10 April 2017).

- Devarakonda, M.; Parker, G.; Johnson, J.H.; Strots, V. Model-based control system design in a Urea-SCR aftertreatment system based on NH3 sensor feedback. Int. J. Autom. Technol. 2009, 10, 653–662. [Google Scholar] [CrossRef]

- Herman, A.; Wu, M.; Cabush, D.; Shost, M. Model Based Control of SCR Dosing and OBD Strategies with Feedback from NH3 Sensors. Available online: http://papers.sae.org/2009-01-0911/ (accessed on 4 April 2017).

- Bonfils, A.; Creff, Y.; Lepreux, O.; Petit, N. Closed-loop control of a SCR system using a NOx sensor cross-sensitive to NH3. J. Process Control 2014, 24, 368–378. [Google Scholar] [CrossRef]

- Feng, T.; Lu, L. The characteristics of ammonia storage and the development of model-based control for diesel engine urea-SCR system. J. Ind. Eng. Chem. 2015, 28, 97–109. [Google Scholar] [CrossRef]

- Opitz, B.; Bendrich, M.; Drochner, A.; Vogel, H.; Hayes, R.E.; Forbes, J.F.; Votsmeier, M. Simulation study of SCR catalysts with individually adjusted ammonia dosing strategies. Chem. Eng. J. 2015, 264, 936–944. [Google Scholar] [CrossRef]

- Pang, L.; Fan, C.; Shao, L.; Yi, J.; Cai, X.; Wang, J.; Kang, M.; Li, T. Effect of V2O5/WO3-TiO2 catalyst preparation method on NOx removal from diesel exhaust. Chin. J. Catal. 2014, 35, 2020–2028. [Google Scholar] [CrossRef]

- Marberger, A.; Elsener, M.; Ferri, D.; Kröcher, O. VOx Surface Coverage Optimization of V2O5/WO3-TiO2 SCR Catalysts by Variation of the V Loading and by Aging. Catalysts 2015, 5, 1704–1720. [Google Scholar] [CrossRef]

- Li, Z.; Li, J.; Liu, S.; Ren, X.; Ma, J.; Su, W.; Peng, Y. Ultra hydrothermal stability of CeO2-WO3/TiO2 for NH3-SCR of NO compared to traditional V2O5/WO3-TiO2 catalyst. Catal. Today 2015, 258, 11–16. [Google Scholar] [CrossRef]

- Seo, C.-K.; Choi, B. Physicochemical characteristics according to aging of Fe-zeolite and V2O5-WO3-TiO2 SCR for diesel engines. J. Ind. Eng. Chem. 2015, 25, 239–249. [Google Scholar] [CrossRef]

- Liu, X.; Wu, X.; Xu, T.; Weng, D.; Si, Z.; Ran, R. Effects of silica additive on the NH3-SCR activity and thermal stability of a V2O5-WO3/TiO2 catalyst. Chin. J. Catal. 2016, 37, 1340–1346. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J. Observer-based estimation of aging condition for selective catalytic reduction systems in vehicle applications. J. Dyn. Syst. Meas. Control 2017, 139, 21002. [Google Scholar] [CrossRef]

- Zhu, K.; Song, X.; Xue, D. A roller bearing fault diagnosis method based on hierarchical entropy and support vector machine with particle swarm optimization algorithm. Measurement 2014, 47, 669–675. [Google Scholar] [CrossRef]

- Gao, X.; Hou, J. An improved SVM integrated GS-PCA fault diagnosis approach of Tennessee Eastman process. Neurocomputing 2016, 174, 906–911. [Google Scholar] [CrossRef]

- An, R.; Yang, C.; Zhou, Z.; Wang, L.; Pan, Y. Comparison of different optimization methods with support vector machine for blast furnace multi-fault classification. IFAC 2015, 48–21, 1204–1209. [Google Scholar]

- Rajeswari, C.; Sathiyabhama, B.; Devendiran, S.; Manivannan, K. Bearing fault diagnosis using wavelet packet transform, hybrid PSO and support vector machine. Procedia Eng. 2014, 97, 1772–1783. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J. Ammonia coverage ratio and input simultaneous estimation in ground vehicle selective catalytic reduction (SCR) systems. J. Frankl. Inst. 2015, 352, 708–723. [Google Scholar] [CrossRef]

- Ruggeri, M.P.; Nova, I.; Tronconi, E. Experimental and modeling study of the impact of interphase and interphase diffusional limitations on the DeNOx efficiency of a V-based extruded catalyst for NH3–SCR of Diesel exhausts. Chem. Eng. J. 2012, 207–208, 57–65. [Google Scholar] [CrossRef]

- Hsieh, M.-F.; Wang, J. Development and experimental studies of a control-oriented SCR model for a two-catalyst urea-SCR system. Control Eng. Pract. 2011, 19, 409–422. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J. Removal of NOx sensor ammonia cross sensitivity from contaminated measurements in Diesel-engine selective catalytic reduction systems. Fuel. 2015, 150, 448–456. [Google Scholar] [CrossRef]

- Devarakonda, M.; Parker, G.; Johnson, J.H.; Strots, V.; Santhanam, S. Adequacy of Reduced Order Models for Model-Based Control in a Urea-SCR Aftertreatment System. Available online: http://papers.sae.org/2008-01-0617/ (accessed on 4 April 2017).

- Schar, C.M.; Onder, C.H.; Geering, H.P. Control of an SCR catalytic converter system for a mobile heavy-duty application. IEEE Trans. Control Syst. Technol. 2006, 14, 641–653. [Google Scholar] [CrossRef]

- Stadlbauer, S.; Waschl, H.; Re, L.D. Adaptive SCR Model for MPC Control Including Aging Effects. Available online: http://papers.sae.org/2015-01-1045/ (accessed on 4 April 2017).

- Dibike, Y.B.; Velickov, S.; Solomatine, D.; Abbott, M.B. Model induction with support vector machines: introduction and applications. J. Comput. Civ. Eng. 2001, 15, 208–216. [Google Scholar] [CrossRef]

- Liu, B.; Hu, J.; Yan, F.; Turkson, R.F.; Lin, F. A novel optimal support vector machine ensemble model for NOx emissions prediction of a diesel engine. Measurement 2016, 92, 183–192. [Google Scholar] [CrossRef]

- Stoppato, A.; Cavazzini, G.; Ardizzon, G.; Rossetti, A. A PSO (particle swarm optimization)-based model for the optimal management of a small PV(Photovoltaic)-pump hydro energy storage in a rural dry area. Energy 2014, 76, 168–174. [Google Scholar] [CrossRef]

- Delgarm, N.; Sajadi, B.; Kowsary, F.; Delgarm, S. Multi-objective optimization of the building energy performance: A simulation-based approach by means of particle swarm optimization (PSO). Appl. Energy 2016, 170, 293–303. [Google Scholar] [CrossRef]

| Features | Parameters |

|---|---|

| Engine model | Inline 6-cylinder, YC6J-42 |

| Displacement | 6.6 L |

| Rated power | 132 kW |

| Maximum torque | 660 Nm (1200–1700 rpm) |

| Idle speed | 650 ± 50 rpm |

| Equipment | Application | |

|---|---|---|

| AVL PUMA OPEN test bench | AC electrical dynamometer | Measuring engine speed and torque |

| dynamometer control system | Controlling speed or torque of dynamometer to change the engine load | |

| throttle actuator | Regulating the operating condition of engine | |

| thermal measurement system | Monitoring thermodynamic parameters such as cooling water temperature, intake and exhaust pressure and etc. | |

| SEMTECH-EFM2 | Measuring exhaust mass flow | |

| AVL DiGas 4000 light (Port 1) | Measuring NOx concentration at upstream pipe | |

| AVL DiGas 4000 light (Port 2) | Measuring NOx concentration at downstream pipe | |

| LDS6 | Measuring NH3 Leakage | |

| Temperature sensor (Upstream) | Measuring upstream temperature | |

| Temperature sensor (Downstream) | Measuring downstream temperature | |

| Aging Factor | Mean NOx Conversion Efficiency | Mean NH3 Leakage/ppm | Peak NH3 Leakage/ppm | Variance of NH3 Leakage |

|---|---|---|---|---|

| 1 | 79.7% | 9.28 | 22.24 | 15.31 |

| 0.9 | 77.0% | 9.86 | 23.81 | 18.46 |

| 0.8 | 73.7% | 10.56 | 25.64 | 22.62 |

| 0.7 | 69.6% | 11.39 | 27.97 | 28.22 |

| 0.6 | 64.7% | 12.41 | 31.57 | 35.83 |

| 0.5 | 58.4% | 13.67 | 35.65 | 46.31 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Zeng, J.; Wei, L.; Yan, F. Improving the Diagnosis Accuracy of Hydrothermal Aging Degree of V2O5/WO3–TiO2 Catalyst in SCR Control System Using an GS–PSO–SVM Algorithm. Sustainability 2017, 9, 611. https://doi.org/10.3390/su9040611

Hu J, Zeng J, Wei L, Yan F. Improving the Diagnosis Accuracy of Hydrothermal Aging Degree of V2O5/WO3–TiO2 Catalyst in SCR Control System Using an GS–PSO–SVM Algorithm. Sustainability. 2017; 9(4):611. https://doi.org/10.3390/su9040611

Chicago/Turabian StyleHu, Jie, Jiawei Zeng, Li Wei, and Fuwu Yan. 2017. "Improving the Diagnosis Accuracy of Hydrothermal Aging Degree of V2O5/WO3–TiO2 Catalyst in SCR Control System Using an GS–PSO–SVM Algorithm" Sustainability 9, no. 4: 611. https://doi.org/10.3390/su9040611