Measuring Green Growth Efficiency for Chinese Manufacturing Industries

Abstract

:1. Introduction

2. Literature Review

2.1. Environmental Impacts of Chinese Manufacturing Industry

2.2. Green Growth

2.3. Green Policy on Manufacturing Industry

2.4. Green Growth Efficiency of Manufacturing Industries

3. Methodology

3.1. EBM Model

3.2. Indicator Selection

3.2.1. Input Indicators

- Labor input: There is a lack of statistical data of effective working time in China. Taking the availability of data and existing literature, the labor input is presented with the average annual numbers of employees of above-scale industrial enterprises.

- Capital input: The perpetual inventory method is a common approach to estimate the capital stock. In the perpetual inventory method, the result varies greatly with different initial capital stock and the depreciation rate. In order to reduce the deviation of the estimation, we select the net annual value of fixed assets balance of above-scale industrial enterprises by industries to produce the estimate, based on the existing literature [35,39,40]. It should be noted that in the China Industrial Economic Statistical Yearbook, there is no net value of fixed assets balance by industries from 2009 to 2011, only the net value of fixed assets. According to mean imputation, this value is replaced by the average between the net values of fixed assets in the current year and the last year.

- Energy input: The energy input is expressed as total energy consumption of above-scale industrial enterprises by industries. The unit is 10,000 tons of standard coal.

3.2.2. Output Indicators

3.3. Data Sources

4. Data Analysis and Results

4.1. Calculation of Environmental Pollutant Composite Index

- (1)

- Since waste water, waste gas and solid waste have conflicting measurement units, it is necessary to convert the original data to comparable data on uniform unit. This research advocates an extreme method for non-dimension of indexes (see Equations (5)–(9)).represents the th environmental pollutants index in the th year. is dimensionless index data and its range of values is from 0 to 1.

- (2)

- Calculate the weight coefficients of , denoted by .

- (3)

- Calculate the entropy of the -term index .

- (4)

- Calculate the weight coefficients of , denoted by .

- (5)

- Calculate the environmental pollutant composite index .

4.2. Descriptive Statistics

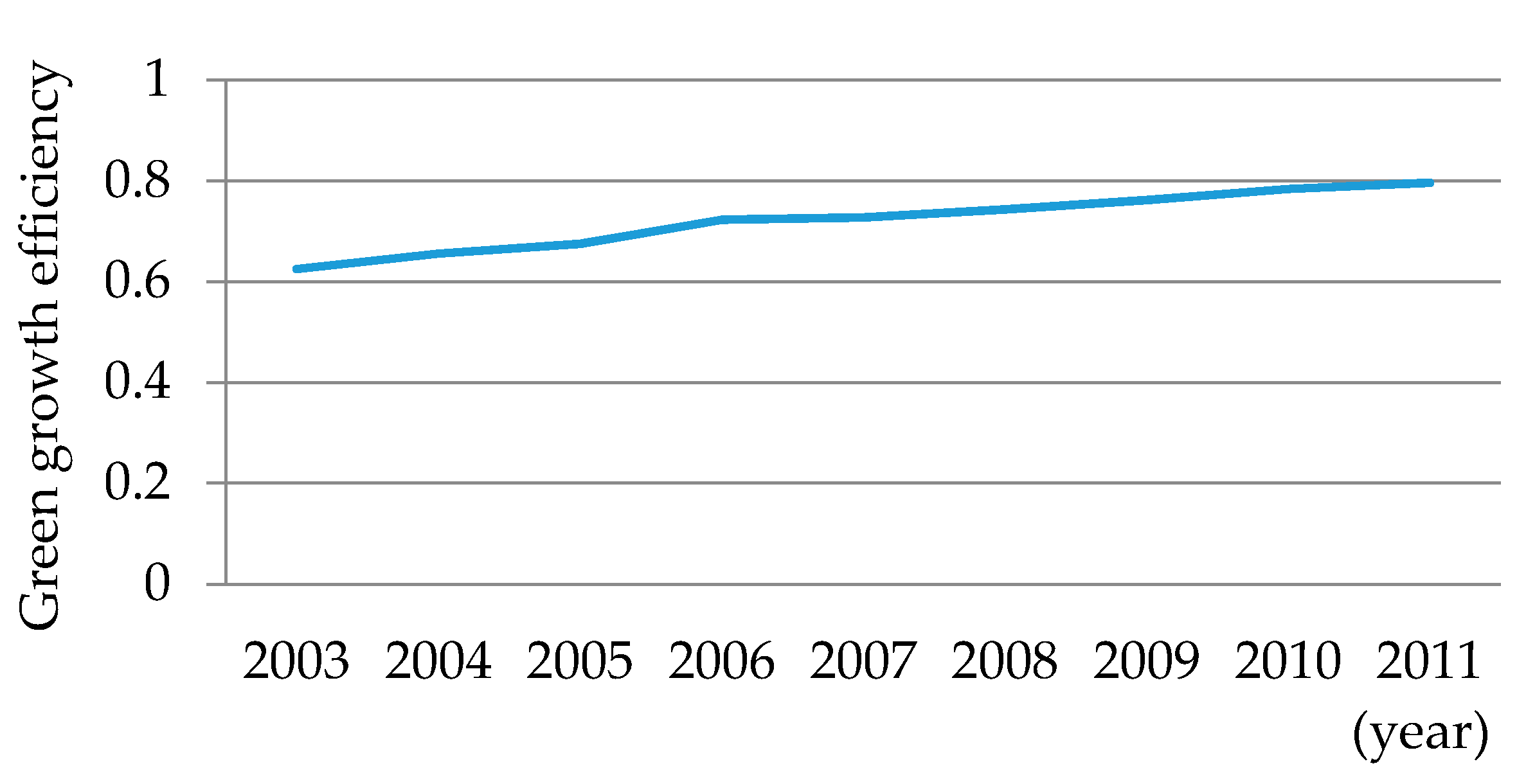

4.3. EBM Model Results

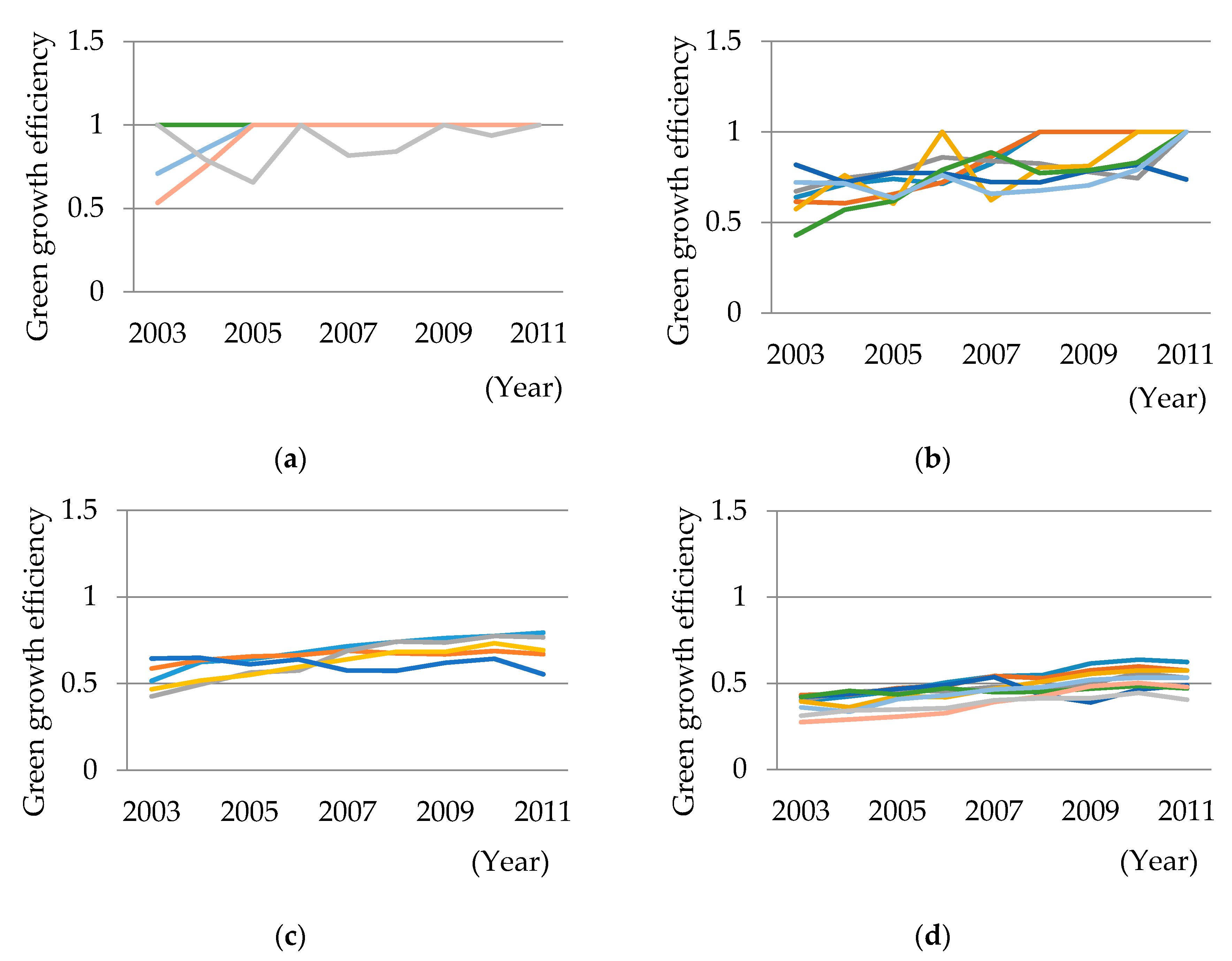

4.4. Clustering Analysis

- Green industry: The nine industries with high green growth efficiency (efficiency ≥ 0.85) are named as green industries. These industries have the characteristic of high-resource utilization and low-pollution emission.

- Light brown industry: The seven industries with medium green growth efficiency (0.7 ≤ efficiency < 0.85) is defined as light brown industries. Although the energy consumption and pollution emission of these industries are relatively low, there are still problems compared to green industries, such as the lower utilization ratio of resource and deficiency in clean production.

- Dark brown industry: The five industries with lower green growth efficiency (0.6 ≤ efficiency < 0.7) are named as dark brown industries. These industries tend to expend much on production but to create low output and cause large pollution emission. These industries are chase profits at the expense of natural resources and ecological environment, thus they become the keystone of energy-saving and emission-reduction.

- Black industry: The nine industries with very low green growth efficiency (efficiency < 0.6) are classified as black industries. High energy-consumption and high pollution emission are the characteristics of these industries.

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yu, J. Research on the Interactive Efficiency of Manufacturing and Productive Services. Ph.D. Thesis, Fudan University, Shanghai, China, 20 March 2013. [Google Scholar]

- Wang, S.; Qu, X. Research on total factor energy efficiency change of china manufacturing industry considering environmental effects: Based on DEA-malmquist index empirical study. China Popul. Resour. Environ. 2011, 8, 130–137. [Google Scholar]

- Wang, L.; Chen, Z.; Ma, D. Energy conservation and emission reduction, total factor energy productivity and industrial heterogeneity: An empirical analysis based on China’s 28 manufacturing industries. Contemp. Financ. Econ. 2013, 10, 5–15. [Google Scholar]

- The United Nations Economic and Social Commission for Asia and the Pacific. Shifting towards “Green Growth” in Asia and the Pacific. In State of the Environment in Asia and the Pacific 2005 Synthesis: Economic Growth and Sustainability; United Nations: New York, NY, USA, 2005; Volume 2. [Google Scholar]

- Organization for Economic Co-operation and Development. Towards Green Growth a Summary for Policy Makers: The OECD Meeting of the Council at Ministerial Level Paris; OCED: Paris, France, 2011. [Google Scholar]

- Lee, J.; Kim, J. South Korea’s urban green energy strategies: Policy framework and local responses under the green growth. Cities 2016, 54, 20–27. [Google Scholar] [CrossRef]

- Ramli, N.A.; Munisamy, S. Eco-efficiency in greenhouse emissions among manufacturing industries: A range adjusted measure. Econ. Model. 2015, 47, 219–227. [Google Scholar] [CrossRef]

- Zkara, Y.; Atak, M. Regional total-factor energy efficiency and electricity saving potential of manufacturing industry in Turkey. Energy 2015, 93, 495–510. [Google Scholar]

- Green Growth Knowledge Platform. Moving towards a Common Approach on Green Growth Indicators; GGKP: Paris, France, 2013. [Google Scholar]

- Egilmez, G.; Kucukvar, M.; Tatari, O. Sustainability assessment of U.S. Manufacturing sectors: An economic input output-based frontier approach. J. Clean. Prod. 2013, 53, 91–102. [Google Scholar] [CrossRef]

- Hirschnitz-Garbers, M.; Tan, A.R.; Gradmann, A.; Srebotnjak, T. Key drivers for unsustainable resource use—categories, effects and policy pointers. J. Clean. Prod. 2016, 132, 13–31. [Google Scholar] [CrossRef]

- Pahle, M.; Pachauri, S.; Steinbacher, K. Can the Green Economy deliver it all? Experiences of renewable energy policies with socio-economic objectives. Appl. Energy 2016, 179, 1331–1341. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Wang, K.; Tian, H.; Hua, S.; Zhu, C.; Gao, J.; Xue, Y.; Hao, J.; Wang, Y.; Zhou, J. A comprehensive emission inventory of multiple air pollutants from iron and steel industry in China: Temporal trends and spatial variation characteristics. Sci. Total Environ. 2016, 559, 7–14. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Lin, B. Reducing carbon dioxide emissions in China’s manufacturing industry: A dynamic vector autoregression approach. J. Clean. Prod. 2016, 131, 594–606. [Google Scholar] [CrossRef]

- Skellern, K.; Markey, R.; Thornthwaite, L. Identifying attributes of sustainable transitions for traditional regional manufacturing industry sectors—A conceptual framework. J. Clean. Prod. 2017, 140, 1782–1793. [Google Scholar] [CrossRef]

- Organization for Economic Co-operation and Development (OECD). OECD Green Growth Studies towards Green Growth; Organization for Economic Co-operation and Development (OECD): Paris, France, 2011. [Google Scholar]

- Gallagher, L.; Laflaive, X.; Zaeske, A.; Brown, C.; Lange, G.; Ahlroth, S.; Castaneda, J.; Fanaian, S.; Joyce, J.; Kamar, E.; et al. Embracing risk, uncertainty and water allocation reform when planning for green growth. Aquat. Procedia 2016, 6, 23–29. [Google Scholar] [CrossRef]

- Sonnenschein, J.; Mundaca, L. Decarbonization under green growth strategies? The case of South Korea. J. Clean. Prod. 2016, 123, 180–193. [Google Scholar] [CrossRef]

- Kim, S.E.; Kim, H.; Chae, Y. A new approach to measuring green growth: Application to the OECD and Korea. Futures 2014, 63, 37–48. [Google Scholar] [CrossRef]

- Saufi, N.A.A.; Daud, S.; Hassan, H. Green growth and corporate sustainability performance. Procedia Econ. Financ. 2016, 35, 374–378. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Zheng, S.; Yi, H.; Li, H. The impacts of provincial energy and environmental policies on air pollution control in China. Renew. Sustain. Energy Rev. 2015, 49, 386–394. [Google Scholar] [CrossRef]

- Trochu, J.; Chaabane, A.; Ouhimmou, M. Tactical planning model for procurement and manufacturing decisions under environmental regulations. IFAC-PapersOnLine 2015, 48, 362–367. [Google Scholar] [CrossRef]

- Cainelli, G.; Mazzanti, M. Environmental innovations in services: Manufacturing-services integration and policy transmissions. Res. Policy 2013, 42, 1595–1604. [Google Scholar] [CrossRef]

- Cainelli, G.; Amato, A.D.; Mazzanti, M. Adoption of waste-reducing technology in manufacturing: Regional factors and policy issues. Resour. Energy Econ. 2015, 39, 53–67. [Google Scholar] [CrossRef]

- Ellerman, A.D.; Buchner, B.; Carraro, C. Origins and development of the EU ETS. In Pricing Carbon: The European Union Emissions Trading Scheme; Cambridge University Press: London, UK, 2010; Volume 43, pp. 69–79. [Google Scholar]

- Bassi, A.M.; Yudken, J.S.; Ruth, M. Climate policy impacts on the competitiveness of energy-intensive manufacturing sectors. Energy Policy 2009, 37, 3052–3060. [Google Scholar] [CrossRef]

- Levine, M.D.; Martin, N.; Price, L.; Worrell, E. Energy Efficiency Improvement Utilising High Technology: An Assessment of Energy Use in Industry and Buildings; World Energy Council: London, UK, 1995. [Google Scholar]

- Chen, G. Research on Total Factor Energy Efficiency of Chinese Manufacture Industry and its Influence Factors Based on SFA. China Soft Sci. 2014, 1, 180–192. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Cheng, G. Basic DEA model. In Data Envelopment Analysis and MaxDEA Software; Intellectual Property Press: Beijing, China, 2014. [Google Scholar]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and undesirable outputs: A directional distance function approach. J. Environ. Manag. 1995, 51, 229–240. [Google Scholar] [CrossRef]

- Pang, R.; Li, P. Regional disparity and dynamic evolution about China’s new industrialization growth performance. Econ. Res. J. 2011, 11, 36–47. [Google Scholar]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. An epsilon-based measure of efficiency in DEA—A third pole of technical efficiency. Eur. J. Oper. Res. 2010, 207, 1554–1563. [Google Scholar] [CrossRef]

- Li, L.; Liu, B. China’s high technology industry production efficiency evaluation and recognition. Econ. Perspect. 2014, 3, 56–65. [Google Scholar]

- Tu, Z. The coordination of industrial growth with environment and resource. Econ. Res. J. 2008, 2, 93–105. [Google Scholar]

- Li, B.; Peng, X.; Ouyang, M. Environmental Regulation, Green Total Factor Productivity and the Transformation of China’s Industrial Development Mode—Analysis Based on Data of China’s 36 Industries. China Ind. Econ. 2013, 4, 56–68. [Google Scholar]

- Han, J.; Lan, Q. Research on the measurement and influencing factors of the green degrees of Chinese industry. China Popul. Resour. Environ. 2012, 2, 101–107. [Google Scholar]

- Li, H.; Guo, H.; Ren, J.; Li, S.; Wang, J. Evaluation on Eco-friendly Land Use in Huanren Mountainous Area with Entropy-based Method. China Popul. Resour. Environ. 2010, S2, 111–114. [Google Scholar]

- Guo, L.; Wu, C.; Yu, J. A study on simulating energy security system of China. Sci. Res. Manag. 2015, 1, 112–120. [Google Scholar]

- Hua, L.; Chan, Y.C.; Wu, Y.P.; Wu, B.Y. The determination of hexavalent chromium (Cr6+) in electronic and electrical components and products to comply with RoHS regulations. J. Hazard. Mater. 2009, 163, 1360–1368. [Google Scholar] [CrossRef] [PubMed]

- Kate, B. Another successful startup in China for DuPont IsoTherming Hydroprocessing Technology at PetroChina. Focus Catal. 2013, 2013, 6. [Google Scholar]

- Yang, H.; Liu, X.; Huang, D.; Lan, Y.; Wang, S. Natural gas exploration and development in Changqing Oilfield and its prospect in the 13th Five-Year Plan. Nat. Gas Ind. B 2016, 3, 291–304. [Google Scholar] [CrossRef]

- Luukkanen, J. Green paper with green electricity? Greening strategies of Nordic pulp and paper industry. Energy Policy 2003, 31, 641–655. [Google Scholar] [CrossRef]

- Wang, C.; Nie, P.; Peng, D.; Li, Z. Green insurance subsidy for promoting clean production innovation. J. Clean. Prod. 2017, 148, 111–117. [Google Scholar] [CrossRef]

- Lindman, S.; Derholm, S.P. Wind energy and green economy in Europe: Measuring policy-induced innovation using patent data. Appl. Energy 2016, 179, 1351–1359. [Google Scholar] [CrossRef]

- Costantini, V.; Crespi, F.; Palma, A. Characterizing the policy mix and its impact on eco-innovation: A patent analysis of energy-efficient technologies. Res. Policy 2017, 46, 799–819. [Google Scholar] [CrossRef]

- Wang, J.; Gao, J.; Cheng, Y.; Kang, Y.; Li, X. Ecologicalization motivations of resources enterprises in the Pan-Qaidam pilot economic zone of Qinghai Province, West China. J. Clean. Prod. 2017, 152, 330–338. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Madan Shankar, K. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

| Name of Manufacturing Industry | Environmental Pollutant Composite Index | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | Avg. | |

| Farm Byproducts Processing | 0.1214 | 0.1169 | 0.1151 | 0.0896 | 0.1187 | 0.1245 | 0.1212 | 0.1179 | 0.11 | 0.1150 |

| Food Production | 0.0446 | 0.0404 | 0.0407 | 0.0361 | 0.0355 | 0.039 | 0.0476 | 0.048 | 0.0402 | 0.0413 |

| Beverage Production | 0.0468 | 0.0428 | 0.0448 | 0.0564 | 0.0548 | 0.0552 | 0.0584 | 0.0625 | 0.0552 | 0.0530 |

| Tobacco Processing | 0.0066 | 0.0052 | 0.005 | 0.0038 | 0.0036 | 0.0035 | 0.0034 | 0.0027 | 0.0022 | 0.0040 |

| Textile Industry | 0.1424 | 0.1502 | 0.1422 | 0.1495 | 0.1491 | 0.1494 | 0.1597 | 0.1607 | 0.1539 | 0.1508 |

| Garments, Shoes and Hats Production | 0.0057 | 0.0098 | 0.0083 | 0.0099 | 0.0088 | 0.0097 | 0.0091 | 0.0073 | 0.0126 | 0.0090 |

| Leather, Furs, Down and Related Products | 0.0114 | 0.015 | 0.0148 | 0.0141 | 0.0145 | 0.0163 | 0.0159 | 0.017 | 0.0157 | 0.0150 |

| Timber Processing, Bamboo, Cane, Palm Fiber and Straw Products | 0.0124 | 0.013 | 0.0123 | 0.0089 | 0.0127 | 0.0083 | 0.01 | 0.009 | 0.0116 | 0.0109 |

| Furniture Manufacturing | 0.0011 | 0.001 | 0.0029 | 0.002 | 0.0021 | 0.0015 | 0.0009 | 0.001 | 0.0005 | 0.0014 |

| Papermaking and Paper Products | 0.2983 | 0.2859 | 0.2876 | 0.2786 | 0.288 | 0.2676 | 0.2731 | 0.2774 | 0.28 | 0.2818 |

| Printing and Record Medium Reproduction | 0.0023 | 0.001 | 0.0013 | 0.0006 | 0.0009 | 0.0009 | 0.0009 | 0.0006 | 0.0008 | 0.0010 |

| Cultural, Educational and Sports Goods | 0.0002 | 0.0006 | 0.0006 | 0.0003 | 0.0001 | 0.0003 | 0.0002 | 0.0001 | 0.001 | 0.0004 |

| Petroleum Processing, Coking and Nuclear Fuel Processing | 0.1458 | 0.1588 | 0.1332 | 0.1175 | 0.1229 | 0.1432 | 0.1295 | 0.1332 | 0.1298 | 0.1349 |

| Raw Chemical Materials and Chemical Products | 0.542 | 0.5266 | 0.4799 | 0.4434 | 0.4672 | 0.3944 | 0.4055 | 0.4096 | 0.492 | 0.4623 |

| Medical and Pharmaceutical Products | 0.0477 | 0.0447 | 0.0369 | 0.0339 | 0.0324 | 0.0356 | 0.0386 | 0.0391 | 0.0379 | 0.0385 |

| Chemical Fiber | 0.0682 | 0.0607 | 0.0552 | 0.0514 | 0.0442 | 0.0397 | 0.0406 | 0.0371 | 0.0311 | 0.0476 |

| Rubber Products | 0.0108 | 0.0101 | 0.0088 | 0.0079 | 0.0077 | 0.0072 | 0.008 | 0.0078 | 0.0171 | 0.0095 |

| Plastic Products | 0.0035 | 0.0048 | 0.0055 | 0.005 | 0.0068 | 0.0068 | 0.0048 | 0.0052 | 0.3459 | 0.0431 |

| Nonmetal Mineral Products | 0.4505 | 0.4677 | 0.4003 | 0.4011 | 0.3543 | 0.3007 | 0.3479 | 0.3324 | 0.8494 | 0.4338 |

| Smelting and Pressing of Ferrous Metals | 0.7139 | 0.8939 | 0.8721 | 0.866 | 0.8499 | 0.853 | 0.8444 | 0.8379 | 0.187 | 0.7687 |

| Smelting and Pressing of Nonferrous Metals | 0.525 | 0.2075 | 0.1875 | 0.1794 | 0.1796 | 0.1771 | 0.1697 | 0.1833 | 0.0399 | 0.2054 |

| Metal Products | 0.1135 | 0.0169 | 0.0207 | 0.0236 | 0.0329 | 0.0266 | 0.0304 | 0.0269 | 0.0117 | 0.0337 |

| Ordinary Machinery Manufacturing | 0.0199 | 0.0234 | 0.0259 | 0.0158 | 0.0143 | 0.02 | 0.0197 | 0.0201 | 0.011 | 0.0189 |

| For Special Purposes Equipment Manufacturing | 0.0208 | 0.0169 | 0.0145 | 0.0116 | 0.0089 | 0.0091 | 0.0225 | 0.0129 | 0.0192 | 0.0152 |

| Transport Equipment Manufacturing | 0.0243 | 0.0528 | 0.0337 | 0.0374 | 0.0333 | 0.0357 | 0.0342 | 0.0329 | 0.014 | 0.0331 |

| Electric Equipment and Machinery | 0.0474 | 0.0113 | 0.0095 | 0.0079 | 0.0082 | 0.0094 | 0.0093 | 0.01 | 0.0087 | 0.0135 |

| Telecommunication Equipment, Computer and Other Electronic Equipment | 0.0139 | 0.0188 | 0.0232 | 0.0259 | 0.0272 | 0.0302 | 0.0327 | 0.0409 | 0.0391 | 0.0280 |

| Instruments, Meters, Cultural and Office Machinery | 0.0167 | 0.0145 | 0.0086 | 0.0074 | 0.0069 | 0.0054 | 0.0048 | 0.0041 | 0.0009 | 0.0077 |

| Handicraft Articles and Other Manufacture | 0.0123 | 0.0024 | 0.003 | 0.0022 | 0.0022 | 0.0018 | 0.0019 | 0.0015 | 0.0041 | 0.0035 |

| Reclaiming and Processing of Abandoned Resource and Waste Material | 0.0016 | 0.0001 | 0.0001 | 0.0037 | 0.0003 | 0.0006 | 0.0007 | 0.0008 | 0.0045 | 0.0014 |

| Indicator | Avg. | S.D. | Min. | Max. | ||

|---|---|---|---|---|---|---|

| Input indicator | Annual average number of employees | 226.44 | 173.29 | 1.36 | 819.48 | |

| Annual net value of fixed assets balance | 2816.77 | 3005.19 | 4.11 | 17,594.80 | ||

| Total energy consumption | 5099.94 | 10,018.52 | 30.35 | 58,896.58 | ||

| Output indicator | Industrial gross output | 12,639.79 | 13,548.46 | 49.94 | 64,066.98 | |

| Environmental pollutant composite index | Waste gas emission | 22,019.22 | 22,019.22 | 8.00 | 173,215.00 | |

| Wastewater emission | 91,499.34 | 91,499.34 | 235.00 | 424,597.38 | ||

| Solid waste emission | 5924.87 | 5924.87 | 2.00 | 42,344.20 | ||

| Name of Manufacturing Industry | Green Growth Efficiency | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | Avg. | |

| Electric Equipment and Machinery | 0.709 | 0.856 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.952 |

| Garments, Shoes and Hats Production | 0.818 | 0.722 | 0.773 | 0.772 | 0.723 | 0.721 | 0.784 | 0.817 | 0.737 | 0.763 |

| Textile Industry | 0.402 | 0.450 | 0.461 | 0.453 | 0.480 | 0.474 | 0.499 | 0.559 | 0.532 | 0.479 |

| Nonmetal Mineral Products | 0.274 | 0.290 | 0.306 | 0.327 | 0.392 | 0.425 | 0.483 | 0.502 | 0.479 | 0.386 |

| Reclaiming and Processing of Abandoned Resource and Waste Material | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Handicraft Articles and Other Manufacture | 0.721 | 0.715 | 0.635 | 0.760 | 0.657 | 0.675 | 0.704 | 0.791 | 1.000 | 0.740 |

| Smelting and Pressing of Ferrous Metals | 0.533 | 0.750 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.920 |

| Chemical Fiber | 0.421 | 0.437 | 0.468 | 0.491 | 0.536 | 0.431 | 0.389 | 0.464 | 0.489 | 0.458 |

| Raw Chemical Materials and Chemical Products | 0.426 | 0.495 | 0.563 | 0.575 | 0.689 | 0.742 | 0.737 | 0.774 | 0.767 | 0.641 |

| Furniture Manufacturing | 1.000 | 0.792 | 0.655 | 1.000 | 0.816 | 0.840 | 1.000 | 0.936 | 1.000 | 0.893 |

| Transport Equipment Manufacturing | 0.614 | 0.605 | 0.656 | 0.721 | 0.862 | 1.000 | 1.000 | 1.000 | 1.000 | 0.829 |

| Metal Products | 0.587 | 0.635 | 0.656 | 0.663 | 0.689 | 0.674 | 0.668 | 0.687 | 0.669 | 0.659 |

| Timber Processing, Bamboo, Cane, Palm Fiber and Straw Products | 0.395 | 0.424 | 0.455 | 0.505 | 0.541 | 0.547 | 0.615 | 0.637 | 0.623 | 0.527 |

| Farm Byproducts Processing | 0.639 | 0.710 | 0.740 | 0.713 | 0.824 | 1.000 | 1.000 | 1.000 | 1.000 | 0.847 |

| Leather, Furs, Down and Related Products | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Petroleum Processing, Coking and Nuclear Fuel Processing | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Food Production | 0.432 | 0.434 | 0.473 | 0.486 | 0.542 | 0.529 | 0.576 | 0.598 | 0.575 | 0.516 |

| Plastic Products | 0.644 | 0.648 | 0.611 | 0.639 | 0.575 | 0.574 | 0.620 | 0.643 | 0.554 | 0.612 |

| Telecommunication Equipment, Computer and Other Electronic Equipment | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Ordinary Machinery Manufacturing | 0.515 | 0.624 | 0.640 | 0.676 | 0.715 | 0.741 | 0.763 | 0.774 | 0.794 | 0.694 |

| Cultural, Educational and Sports Goods | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Rubber Products | 0.421 | 0.456 | 0.435 | 0.472 | 0.448 | 0.450 | 0.469 | 0.485 | 0.471 | 0.456 |

| Tobacco Processing | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Medical and Pharmaceutical Products | 0.395 | 0.361 | 0.425 | 0.419 | 0.469 | 0.510 | 0.555 | 0.575 | 0.574 | 0.476 |

| Instruments, Meters, Cultural and Office Machinery | 0.672 | 0.745 | 0.776 | 0.859 | 0.839 | 0.825 | 0.778 | 0.744 | 1.000 | 0.804 |

| Beverage Production | 0.360 | 0.335 | 0.408 | 0.430 | 0.465 | 0.477 | 0.520 | 0.532 | 0.532 | 0.451 |

| Printing and Record Medium Reproduction | 0.573 | 0.760 | 0.603 | 1.000 | 0.622 | 0.802 | 0.810 | 1.000 | 1.000 | 0.797 |

| Smelting and Pressing of Nonferrous Metals | 0.428 | 0.570 | 0.618 | 0.789 | 0.886 | 0.772 | 0.787 | 0.830 | 1.000 | 0.742 |

| Papermaking and Paper Products | 0.312 | 0.342 | 0.347 | 0.355 | 0.402 | 0.413 | 0.413 | 0.444 | 0.405 | 0.381 |

| For Special Purposes Equipment Manufacturing | 0.467 | 0.517 | 0.550 | 0.596 | 0.640 | 0.683 | 0.683 | 0.733 | 0.692 | 0.618 |

| Avg. | 0.625 | 0.656 | 0.675 | 0.723 | 0.727 | 0.743 | 0.762 | 0.784 | 0.796 | 0.721 |

| (I) Group | (J) Group | Mean Difference (I–J) | Std. Error | Siq | 99% Confidence | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1 | 2 | 0.18507 * | 0.03234 | 0.000 | 0.0740 | 0.2961 |

| 3 | 0.32931 * | 0.03234 | 0.000 | 0.2183 | 0.4404 | |

| 4 | 0.51486 * | 0.03234 | 0.000 | 0.4038 | 0.6259 | |

| 2 | 1 | −0.18507 * | 0.03234 | 0.000 | −0.2961 | −0.0740 |

| 3 | 0.14424 * | 0.03234 | 0.001 | 0.0332 | 0.2553 | |

| 4 | 0.32979 * | 0.03234 | 0.000 | 0.2187 | 0.4408 | |

| 3 | 1 | −0.32931 * | 0.03234 | 0.000 | −0.4404 | −0.2183 |

| 2 | −0.14424 * | 0.03234 | 0.001 | −0.2553 | −0.0332 | |

| 4 | 0.18555 * | 0.03234 | 0.000 | 0.0745 | 0.2966 | |

| 4 | 1 | −0.51486 * | 0.03234 | 0.000 | −0.6259 | −0.4038 |

| 2 | −0.32979 * | 0.03234 | 0.000 | −0.4408 | −0.2187 | |

| 3 | −0.18555 * | 0.03234 | 0.000 | −0.2966 | −0.0745 | |

| Type | Industry | Interval |

|---|---|---|

| Green | Cultural, Educational and Sports Goods | [0.893, 1] |

| Tobacco Processing | ||

| Reclaiming and Processing of Abandoned Resource and Waste Material | ||

| Petroleum Processing, Coking and Nuclear Fuel Processing | ||

| Telecommunication Equipment, Computer and Other Electronic Equipment | ||

| Leather, Furs, Down and Related Products | ||

| Electric Equipment and Machinery | ||

| Smelting and Pressing of Ferrous Metals | ||

| Furniture Manufacturing | ||

| Light brown | Transport Equipment Manufacturing | [0.74, 0.847] |

| Farm Byproducts Processing | ||

| Smelting and Pressing of Nonferrous Metals | ||

| Handicraft Articles and Other Manufacture | ||

| Instruments, Meters, Cultural and Office Machinery | ||

| Garments, Shoes and Hats Production | ||

| Printing and Record Medium Reproduction | ||

| Dark brown | Raw Chemical Materials and Chemical Products | [0.612, 0.694] |

| For Special Purposes Equipment Manufacturing | ||

| Metal Products | ||

| Ordinary Machinery Manufacturing | ||

| Plastic Products | ||

| Black | Nonmetal Mineral Products | [0.381, 0.527] |

| Papermaking and Paper Products | ||

| Textile Industry | ||

| Rubber Products | ||

| Chemical Fiber | ||

| Timber Processing, Bamboo, Cane, Palm Fiber and Straw Products | ||

| Food Production | ||

| Medical and Pharmaceutical Products | ||

| Beverage Production |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Y.; Yu, Y.; Appolloni, A.; Li, M.; Liu, Y. Measuring Green Growth Efficiency for Chinese Manufacturing Industries. Sustainability 2017, 9, 637. https://doi.org/10.3390/su9040637

Qu Y, Yu Y, Appolloni A, Li M, Liu Y. Measuring Green Growth Efficiency for Chinese Manufacturing Industries. Sustainability. 2017; 9(4):637. https://doi.org/10.3390/su9040637

Chicago/Turabian StyleQu, Ying, Ying Yu, Andrea Appolloni, Mengru Li, and Yue Liu. 2017. "Measuring Green Growth Efficiency for Chinese Manufacturing Industries" Sustainability 9, no. 4: 637. https://doi.org/10.3390/su9040637