Resilience and Livelihoods in Supply Chains (RELISC): An Analytical Framework for the Development and Resilience of the UK Wood Fuel Sector

Abstract

:1. Introduction

- Policy/regulatory/institutional contexts

- Level and nature of capital investment

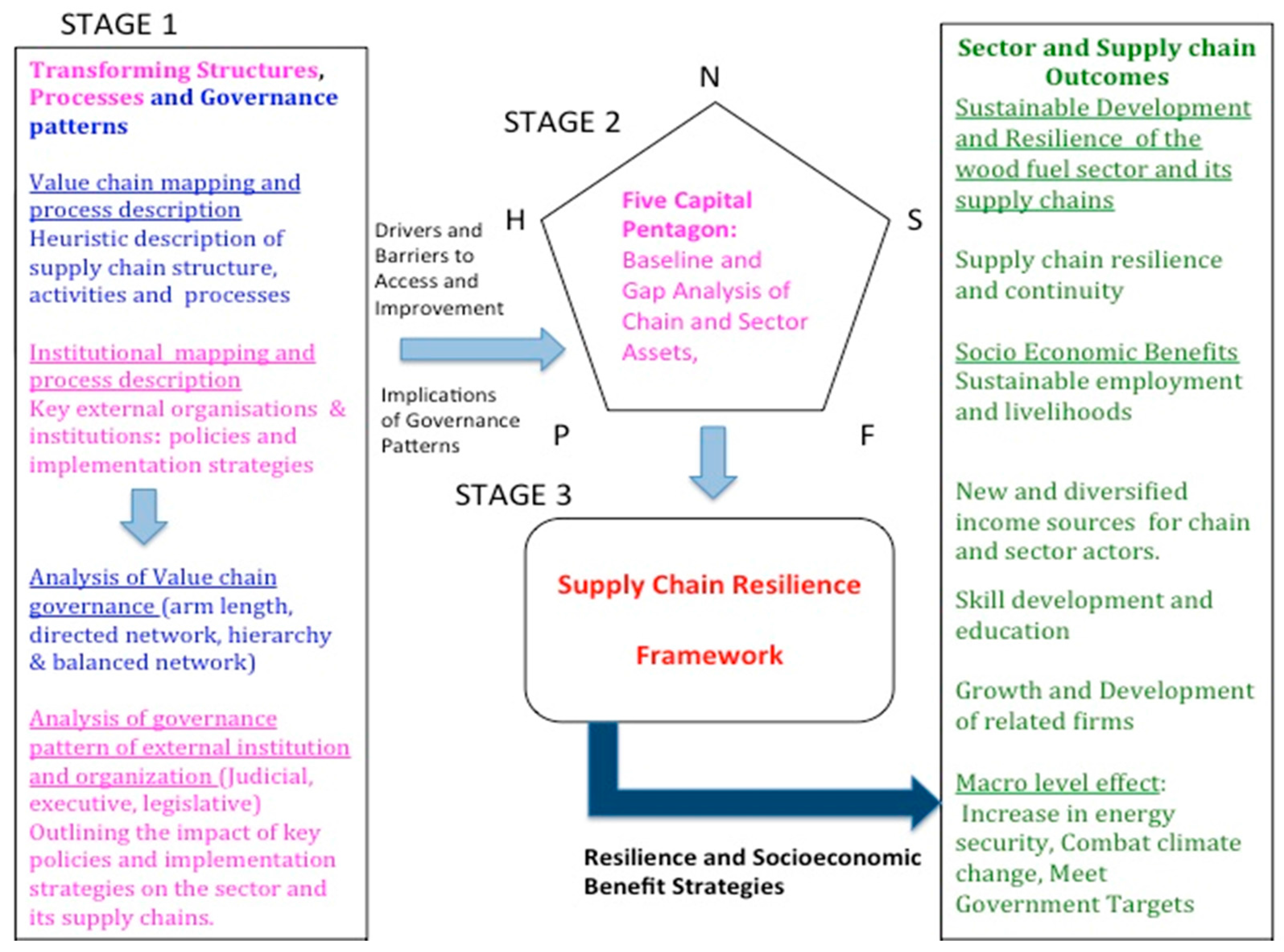

2. The RELISC Framework

3. Application of the RELISC Framework

3.1. Choice of Case Study

3.2. Data Collection

3.3. Data Analysis

- Visible Capacity: Improvement, availability and visibility of capacity and reserve capacity;

- Flexible Adaptability: Ability to quickly change in processes, sources and thinking;

- Collaboration in Dispersion: Decentralisation of capital and markets + cooperating within the network and risk sharing;

- Anticipate and Recover: Ability to discern potential events and situations + ability and plans to return to normal or better; and

- Securing Market position: Identifying, defending and improving firm or sector market share, cooperation and lobbying with governments and the public. Identifying and involving end users and meeting their needs.

4. Results of Applying the RELISC Framework

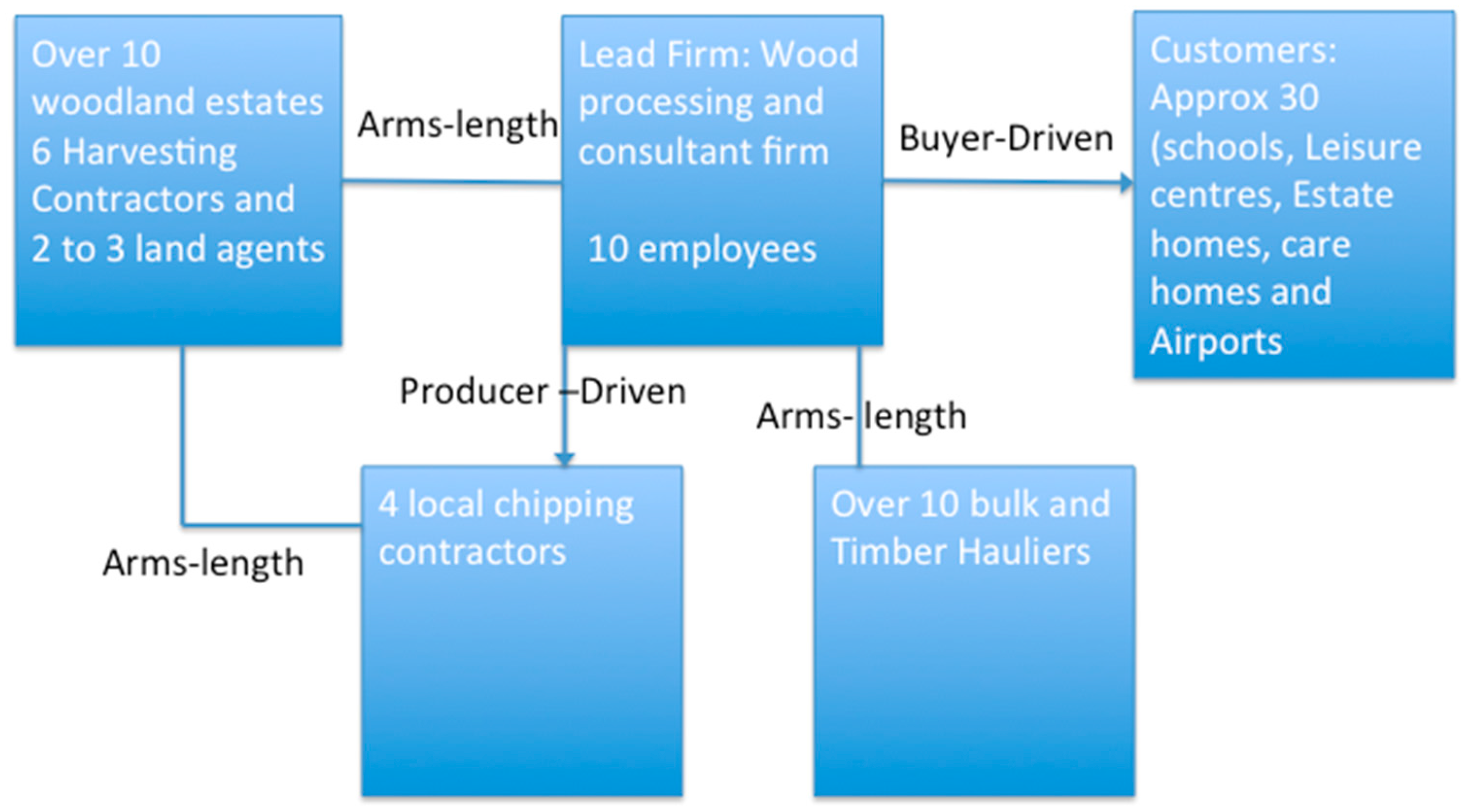

4.1. Value Chain Mapping and Internal Governance Patterns

4.2. Implications of External and Internal Governance and Five Capital Gap Assessment

4.3. Sector-Wide Vulnerability Factors

4.4. Enhancing Supply Chain Resilience and Socioeconomic Benefits

5. Discussion

- (a)

- Improve visibility and increase capacity, especially for effective public campaigns and skills, respectively.

- (b)

- Change attitude towards the felling of trees. For instance, an adaptation in terms of some institutional laws and their applications to the wood fuel sector.

- (c)

- Collaborate in spite of the different interests and varying levels of commitments of different actors.

- (d)

- Improve end-user confidence given the uncertainty and emerging nature of the sector.

- (e)

- Secure market position using good communication and lobbying strategies given the importance of the wood fuel sector in providing renewable heat.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Interview Number | Role of Actor | Organisation in Wood Chip Supply Chain |

|---|---|---|

| 1 | Lead firm manager and owner | Lead firm (wood fuel processing and consultancy) |

| 2 | Field and logistics manager | Lead firm (wood fuel processing and consultancy) |

| 3 | Forestry and operations manager | Lead firm (wood fuel processing and consultancy |

| 4 | Business development manager | Lead firm (wood fuel processing and consultancy) |

| 5 | Chipping contractor | Wood Chipping firm |

| 6 | Chipping contractor | Wood Chipping firm |

| 7 | Chipping contractor | Wood Chipping Firm |

| 8 | Harvesting contractor | Harvesting partnership |

| 9 | Harvesting contractor | Harvesting partnership |

| 10 | Owner/Manager | Transport and Haulage firm |

| 11 | Driver | Transport and Haulage firm |

| Interview number | Role of Actor | External Organisations |

| 12 | Woodland programme officer | Forestry Commission |

| 13 | Woodland programme officer | Forestry Commission |

| 14 | Regional woodland advisor | Forestry Commission (SE) |

| 15 | Regional woodland advisor | Forestry Commission (SW) |

| 16 | Regional woodland advisors | Forestry Commission (E) |

| 17 | Coordinating Officer | Woodland cooperative |

| 18 | Woodland Owner | Woodland cooperative |

| 19 | Woodland Owner | Woodland cooperative |

| 20 | Woodland Owner | Woodland cooperative |

| 21 | Local authority representative | Woodland cooperative |

| 22 | End-user and producer of woodfuel | Woodland cooperative |

| 23 | End-user and producer of wood fuel | Woodland cooperative |

| 24 | Wood Fuel Training providers | LANTRA |

| 25 | Wood Fuel Training providers | IGNITE |

| 26 | Wood Fuel Training providers | HETAS |

| 27 | Bioenergy policy Advisor (RHI) | DECC (Department for Energy and Climate change |

| 28 | Bioenergy policy Advisor | DECC (Department for Energy and Climate change |

References

- Department of Energy and Climate Change. Bioenergy Strategy; Crown Copyright 2012; Department of Energy & Climate Change: London, UK, 2012.

- Department of Energy and Climate Change. Renewable Energy. In Digest of United Kingdom Energy Statistics (DUKES); Crown Copyright 2016; Department of Energy & Climate Change: London, UK, 2016. [Google Scholar]

- Department of Energy and Climate Change. Energy Consumption in the UK, Overall Data Tables. Available online: https://www.gov.uk/government/statistics/energy-consumption-in-the-uk (accessed on 15 December 2016).

- Domac, J.; Richards, K.; Opalic, T. 12 Years of People First! Socioeconomic Aspects of Bioenergy Systems/Socioeconomic Drivers in Implementing Bioenergy Projects; Copyright 2012; IEA Bioenergy Task 29; North-West Croatia Regional Agency: Zagreb, Croatia, 2012. [Google Scholar]

- Domac, J.; Richards, K.; Risovic, S. Socioeconomic drivers in implementing bioenergy projects. Biomass Bioenergy 2005, 28, 97–106. [Google Scholar] [CrossRef]

- Madlener, R.; Koller, M. Economic and CO2 Mitigation Impacts of Promoting Biomass Heating Systems: An Input–Output Study for Vorarlberg, Austria. Available online: http://www.cepe.ethz.ch/content/dam/ethz/special-interest/mtec/cepe/cepe-dam/documents/research/cepe-wp/CEPE_WP50.pdf (accessed on 25 November 2015).

- Adams, P.W.; Hammond, G.P.; McManus, M.C.; Mezzullo, W.G. Barriers to and drivers for UK bioenergy development. Renew. Sustain. Energy Rev. 2011, 15, 1217–1227. [Google Scholar] [CrossRef]

- Madlener, R.; Hayley, M. Modelling Socioeconomic Aspects of Bioenergy Systems. A Paper Prepared for IEA Bioenergy Task 29 Workshop in Brighton/UK, 2000. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.490.7179&rep=rep1&type=pdf (accessed on 14 June 2014).

- Wicke, B. The Socio-Economic Impacts of Large-Scale Land Use Change and Export Oriented Bio-Energy Production in Argentina; Quantifying the Direct, Indirect and Induced Impacts of Agricultural Intensification and Bio-Energy Production with Input-Output Analysis. Master’s Thesis, Department of Science, Technology and Society, Copernicus Institute, Utrecht, The Netherlands, 2006. [Google Scholar]

- Krajnc, J.; Domac, J. How to model different socio-economic and environmental aspects of biomass utilisation: Case study in selected regions in Slovenia and Croatia. Energy Policy 2007, 35, 6010–6020. [Google Scholar] [CrossRef]

- Kulišic, B.; Loizou, E.; Rozakis, S.; Šegon, A. Impacts of biodiesel production on Croatian economy. Energy Policy 2007, 35, 5965–6558. [Google Scholar] [CrossRef]

- Tromberg, E.; Folsand, T.; Bolkes, J.; Birger, S. Impacts of policy means for increased use of forest-based bioenergy in Norway—A spatial partial equilibrium analysis. Energy Policy 2007, 35, 5980–5990. [Google Scholar] [CrossRef]

- Zhang, S.; Gilless, J.K.; William, S. Modeling price-driven interactions between wood bioenergy and global wood product markets. Biomass Bioenergy 2014, 60, 68–78. [Google Scholar] [CrossRef]

- Sinclair, P.; Cohen, B.; Hansen, Y.; Basson, L.; Clift, R. Stakeholder engagement within the sustainability assessment of bioenergy: Case studies in heat, power and perennial and annual crops from the UK. Biomass Bioenergy 2015, 73, 11–22. [Google Scholar] [CrossRef]

- Panoutsou, C. Socio-economic impacts of energy crops for heat generation in Northern Greece. Energy Policy 2007, 35, 6046–6059. [Google Scholar] [CrossRef]

- Lanz, V.A.; Chang, W.; Pharo, C. Benefit-cost analysis of hybrid willow crop production on agricultural land in Eastern Canada: Assessing opportunities for on-farm and off-farm bioenergy use. Biomass Bioenergy 2014, 63, 257–267. [Google Scholar] [CrossRef]

- Vis, M. An Introduction to Socioeconomic Impact Analysis Global Assessment of Biomass and Bioproduct Impacts on Socio-Economics and Sustainability. Available online: http://www.globalbiopact.eu/images/stories/publications/Global-Bio-Pact_Task%203.2%20-Report.pdf (accessed on 10 November 2013).

- Buchholz, T.S.; Volk, T.A.; Luzadis, V.A. A participatory systems approach to modeling social, economic, and ecological components of bioenergy. Energy Policy 2007, 35, 6084–6094. [Google Scholar] [CrossRef]

- Van Eijck, J.; Vis, M.; Faaij, A. Socio-Economic Indicators Identified by Case Studies. Evaluation of Measurable Socio-Economic Units and Suggestions for Future Work. Available online: http://www.globalbiopact.eu/images/stories/publications/d3.5-final.pdf (accessed on 25 November 2015).

- Lloyd, C.; Dey, P. Supply chain integration in the UK bioenergy industry: Findings from a pilot study. J. Clean. Prod. 2014, 79, 41–52. [Google Scholar] [CrossRef]

- Mafakheri, F.; Genus, A. A neo-institutional perspective of supply chains and energy security: Bioenergy in the UK. Appl. Energy 2014, 123, 307–315. [Google Scholar]

- Dale, V.; Efroymson, R.; Kline, K.; Langholtz, M.; Leiby, P.; Gbadebo, O.; Davis, M.; Downing, M.; Hilliard, M. Indicators for assessing socioeconomic sustainability of bioenergy systems: A short list of practical measures. Ecol. Indic. 2014, 26, 87–102. [Google Scholar] [CrossRef]

- McCormick, K. Sustainable bioenergy systems: Experiences from Sweden. In Proceedings of the Asia Pacific Roundtable on Sustainable Consumption and Production, Melbourne, Australia, 10–12 October 2005. [Google Scholar]

- Cruz, J.B.; Tan, R.R.; Culaba, A.B.; Ballacillo, J.-A. A dynamic input–output model for nascent bioenergy supply chains. Appl. Energy 2009, 86, S86–S94. [Google Scholar] [CrossRef]

- Gnos, C.; Rochon, L. The keynes multiplier. In Equality and Class, the Economy of Class; 2 Park Square, Milton Park: Abingdon, UK, 2011. [Google Scholar]

- Kalinsky, R.; Morris, M. A Handbook for Value Chain Research. 2001. Available online: https://www.ids.ac.uk/ids/global/pdfs/ValuechainHBRKMMNov2001.pdf (accessed on 20 November 2015).

- Department for International Development (DFID). Eliminating World Poverty: A Challenge for the 21st Century; White Paper on International Development; HMSO: London, UK, 1997. Available online: www.dfid.gov.uk/Pubs/files/whitepaper1997.pdf (accessed on 6 December 2015).

- Department for International Development (DFID). Sustainable Livelihoods Guidance Sheets; Department of International Development: London, UK, 2002. Available online: http://www.eldis.org/vfile/upload/1/document/0901/section2.pdf (accessed on 6 December 2015).

- Humphrey, J.; Schmitz, H. Governance in Global Value Chains; IDS Bulletin: Brighton, UK, 2001; Volume 32. [Google Scholar]

- Morse, S.; McNamara, N.; Acholo, M. Sustainable Livelihood Approach: A Critical Analysis of Theory and Practice. Reading Geographical Paper. Available online: https://www.reading.ac.uk/web/files/geographyandenvironmentalscience/GP189.pdf (accessed on 21 August 2014).

- Kollmier, M.; St. Gamper, J. The Sustainable Livelihoods Approach, Input Paper for the Integrated Training Course of NCCR North-South Aeschiried, Switzerland (9–20 September 2002), Compiled by M. Kollmair and St. Gamper, J., Development Study Group, University of Zurich (IP6). Available online: http://www.nccrpakistan.org/publications_pdf/General/SLA_Gamper_Kollmair.pdf (accessed on 20 August 2014).

- Sneddon, C.S. Sustainability in Ecological Economics, Ecology and Livelihoods: A Review. Prog. Hum. Geogr. 2000, 24, 521–549. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Porter, M. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Cranfield University and the Department for Transport. Creating Resilient Supply Chains: A Practical Guide; Report Produced by the Centre for Logistics and Supply Chain Management, Cranfield School of Management, Research Funded by the Department for Transport; Cranfield University: Cranfield, UK, 2003. [Google Scholar]

- Christopher, M.; Helen, P. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–13. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Parast, M. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int. J. Prod. Econ. 2016, 171, 116–133. [Google Scholar] [CrossRef]

- National Forestry Inventory Report, Preliminary Estimates of Broadleaved Species and All Species in British Woodlands. 2011. Available online: http://www.forestry.gov.uk/forestry/INFD-935MSY (accessed on 28 May 2014).

- Forestry Commission, South East & London Wood Market Update July 2013. Available online: http://www.forestry.gov.uk/pdf/1302_FCE_SEL_Market_update.pdf/$FILE/13-07-02_FCE_SEL_Market_update.pdf (accessed on 7 June 2014).

- Woodcock, M. Opportunities for wood for the South East of England, April, 2012. Forestry Commission. Forestry Commission South East England. Available online: http://www.forestry.gov.uk/pf/1301_FCE_SEL_Market_update.pdf/$FILE/13-07-02FCE_SEL_Market_update.pdf (accessed on 7 June 2014).

- Woodcock, M. Is There Enough Wood? 2013. Available online: http://www.surreyhillswoodland.co.uk/content/uploads/2013/10/1-matthew-woodcock-opt.pdf (accessed on 25 May 2014).

- DECC. Renewable Heat Incentive. Available online: https://www.gov.uk/government/policies/increasing-the-use-of-low-carbon-technologies/supporting-pages/renewable-heat-incentive-rhi (accessed on 14 July 2014).

- Forestry Commission. Red Band Needle Blight of Conifers in Britain. Available online: http://www.forestry.gov.uk/pdf/FCRN002.pdf/$FILE/FCRN002.pdf (accessed on 20 June 2014).

- Lantra. A Summary of UK Skills Assessment. Available online: http://www.lantra.co.uk/Downloads/Research/Skills-assessment/England-Skills-Assessment(2010-11).aspx (accessed on 6 July 2014).

| Internal Governance Pattern and Criteria | |

| Market based/Arm’s length | Many customers/many suppliers |

| Repeat transactions with suppliers or customers | |

| No technical assistance given to suppliers or producers | |

| Balanced Network | Supplier has various customers |

| Supplier has few customers, customers have few suppliers | |

| Intense information flow in both directions | |

| Both sides have capabilities hard to substitute | |

| Resolve problems through negotiations rather than threats or exits | |

| Directed network Buyer driven/producer driven | Customer or producer defines the products (design and technical specification |

| Main customer or supplier takes or supplies at least 50% of output | |

| Monitoring of performance by customers or suppliers | |

| Providing technical assistance to suppliers or producers | |

| Hierarchy | Vertical integration of several chain stages within the firm |

| Supply enterprise is owned by customer | |

| Limited autonomy to make local decisions, instructions from “headquarters” required. | |

| External Governance Pattern and Criteria | |

| Legislative | Setting standards and laws for participation in the supply chain or sector mostly in terms of quality, environment and performance |

| Judiciary | Monitoring the performance of supply chain actors in meeting standards and obligations |

| Executive | Providing support in supply chain operations and management to meet standards and improve performance |

| Process | Governance Pattern and Actors | Implications of Governance Patterns | Gap Analysis of Capital and Vulnerability Factors |

|---|---|---|---|

| Sourcing of sustainable resource | Arms-length Lead firm to woodland owners, harvesters and land agents. | The arms-length governance means that the lead firm has a number of woodlands (10) to source resources, However, it implies that the lead firm has little influence on ensuring compliance to sustainability standards (Interview 1, 2). | Limited availability of adaptable harvesting equipment for hard to access terrains reported by harvesters (Interview 8, 9). |

| Monitoring and issuance of felling licenses | Judicial and Executive Forestry Commission to Woodland owners, land agents and harvesters. | Only woodlands with felling licences are used by the lead firm as a result of the judicial and executive governance of felling licences. | Limited number of people (human capital) to monitor compliance as reported by woodland officers (Interview 13, 15). |

| Campaign to bring woodland into management | Executive Forestry Commission to Woodland owners, land agents and harvesters. | The Forestry Commission supports the campaign by providing financial capital in form of grants and human capital in form of woodland advisors to draw up woodland management plans. | Lack of awareness, skills and interest amongst woodland owners and general public. Risk of Job loss for woodland officers because of lack of demand for woodland management plans by woodland owners (Interviews 12, 13). A woodland programme officer states that “My job is actually at stake unless there is an improvement in the uptake of this programme” |

| Administering the forestry and sustainability standards | Legislative and Executive Forestry Commission to Woodland owners, land agents and harvesters. | Monitors and updates the Forestry standard, Promotes and provides information on best practice. | Lack of skill and different objectives and plans for the land limits small private woodland owners from implementing best practice (12, 19, 20). A woodland owner states that “I use my woodland for family recreation, I suppose I manage it to my standards, I am not sure what the forestry standard can do for me” |

| Promoting wood fuel and woodland management | Executive Conservatory bodies and Trusts. | Provides financial capital in form of grants for wood fuel establishments i.e., woodland owners and supply chain actors. | Limited use of existing human capital to monitor environmental impacts of wood fuel as reported by woodland owners (18, 19, 20). |

| Process | Governance Patterns: Supply Chain Actors and Institutions | Implications of Governance Patterns | Gap Analysis of Capital and Vulnerability Factors |

|---|---|---|---|

| Investment in building human capital | Hierarchical Lead firm to Employees | Decision to outsource and invest less on physical capital, such as trucks and vehicles in order to increase financial investment on human capital (Interview 1, 4) | The lead firm requires more suitably qualified biomass heat engineers for installation and systems design in addition to qualified and experienced plumbers and site supervisors (Interview 1, 4). “There are only about 30 good and experienced heat engineers in the UK that I can currently depend on, that is not enough” (lead firm owner (Interview 1)) Lack of suitable apprentice opportunities in UK means that it is expensive to send technical employees to Europe (Interview 1, 4). |

| Training, monitoring and building human capital | Lead firm to wood chipping contractor (producer driven) End user to woodchip contractor (buyer-driven) | Increasingly stringent requirements from end-users for wood chip quality certification drive the recruitment of skilled personnel (Interview 1) | The chipping contractor requires more trained personnel in machinery operation, including chainsaw, harvesting and forwarding and also skills to manage wood chip quality (Interview 5, 6). Narrow profit margins for chipping contractors limits funds for formal training so most training is done on the job (Interview 5, 6, 7) one chipping contractor on low profit margins states that “I fear, I may need to close shop and let the bigger players have the field!”. |

| Achieving accreditation certification and chartered status as wood fuel suppliers | Executive and judicial Training, accreditation, chartered and certification organisations: to supply chain | Provides training to improve skills as well as monitor service and product quality. Provide assurances to end-users of supplier capabilities, leading to continued custom and increased customer base. Lead firm, chipping and harvesting contractors are wood fuel quality accredited. However, only the lead firm has achieved chartered status. | Lack of collaboration between the different certification schemes and training providers means there are some overlap in training provided (Interview 25, 26) The financial cost of accreditation, time and the complex process for achieving a chartered status means that small-scale contractors and woodland owners are not able to derive benefits from such qualifications (Interview 18, 23) |

| Creating awareness and supporting the sector | Balanced Lobby groups to the supply chain | Supports and facilitates growth of the sector. | Requires skills that may not be available within small firms so their interests are not represented |

| Exchanging information and expertise and resources | Balanced Local wood fuel group to the supply chain | Collaboration and networking opportunities, | Limited funds for administrator affected the effectiveness of the group (Interview 17) |

| Supporting the development of the sector | Legislative and executive Local authority to the supply chain and wood fuel sector | Provides supportive legislation such as a default to biomass heating for new development | Lack of facilitation and awareness campaign personnel (Interview 21) |

| Process | Governance Patterns: Supply Chain Actors and Institutions | Implications of Governance Patterns | Capital Gap Analysis |

|---|---|---|---|

| Setting up wood fuel production hubs | Executive Local authority to Supply chain | Provides planning approval for infrastructure | Lack of knowledge and awareness in the Planning approval delays especially for wood fuel hubs, which is an unfamiliar concept to local authorities. (Interview 1, 21,) |

| Applying for financial grants | Executive Funding bodies to Supply chain | Supports with financial resources for physical capital. Examples of funded capital include a wheeled forwarder for harvesters, timber and wood chip storage facility for the lead firm and two Jenz chippers for the chipping contractor | Complex application process. Lack of knowledge on how to successfully apply for grants. Chipping contractor said “applications process are too complex for a simple guy like me”. Restrictions on use. Funded equipment cannot be used for non-wood fuel aspect of business.(Interview 5, 6, 7) Lack of excavation–based harvesters as well as 16 t and 12 t wheeled forwarders for harvesters in the chain (Interview 8, 9) |

| RHI applications and sustainability requirements | Legislative OFGEM (Office of Gas and Electric markets) | The RHI funds which facilitates uptake in wood fuel heating | Stringent data requirements Complex application process, sometimes requires consultants to help end-users thus adding to cost.(Interview 22, 23) Additional sustainability requirements for wood fuel suppliers including inclusion in the approved wood fuel suppliers list and the need to report on supply chain sustainability |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emmanuel-Yusuf, D.; Morse, S.; Leach, M. Resilience and Livelihoods in Supply Chains (RELISC): An Analytical Framework for the Development and Resilience of the UK Wood Fuel Sector. Sustainability 2017, 9, 660. https://doi.org/10.3390/su9040660

Emmanuel-Yusuf D, Morse S, Leach M. Resilience and Livelihoods in Supply Chains (RELISC): An Analytical Framework for the Development and Resilience of the UK Wood Fuel Sector. Sustainability. 2017; 9(4):660. https://doi.org/10.3390/su9040660

Chicago/Turabian StyleEmmanuel-Yusuf, Damiete, Stephen Morse, and Matthew Leach. 2017. "Resilience and Livelihoods in Supply Chains (RELISC): An Analytical Framework for the Development and Resilience of the UK Wood Fuel Sector" Sustainability 9, no. 4: 660. https://doi.org/10.3390/su9040660