Green Supplier Evaluation and Selection Using Cloud Model Theory and the QUALIFLEX Method

Abstract

:1. Introduction

2. Related Literature

2.1. Green Supplier Selection Methods

2.2. Applications of QUALIFLEX Method

2.3. Applications of Cloud Model Theory

3. Preliminaries

3.1. Cloud Model Theory

- (1)

- (2)

- (3)

- (4)

- (1)

- If , then is better than , i.e., ;

- (2)

- If , then is worse than , i.e., ;

- (3)

- If , then is indifferent to , i.e., .

3.2. Laplace Distribution-Based Method

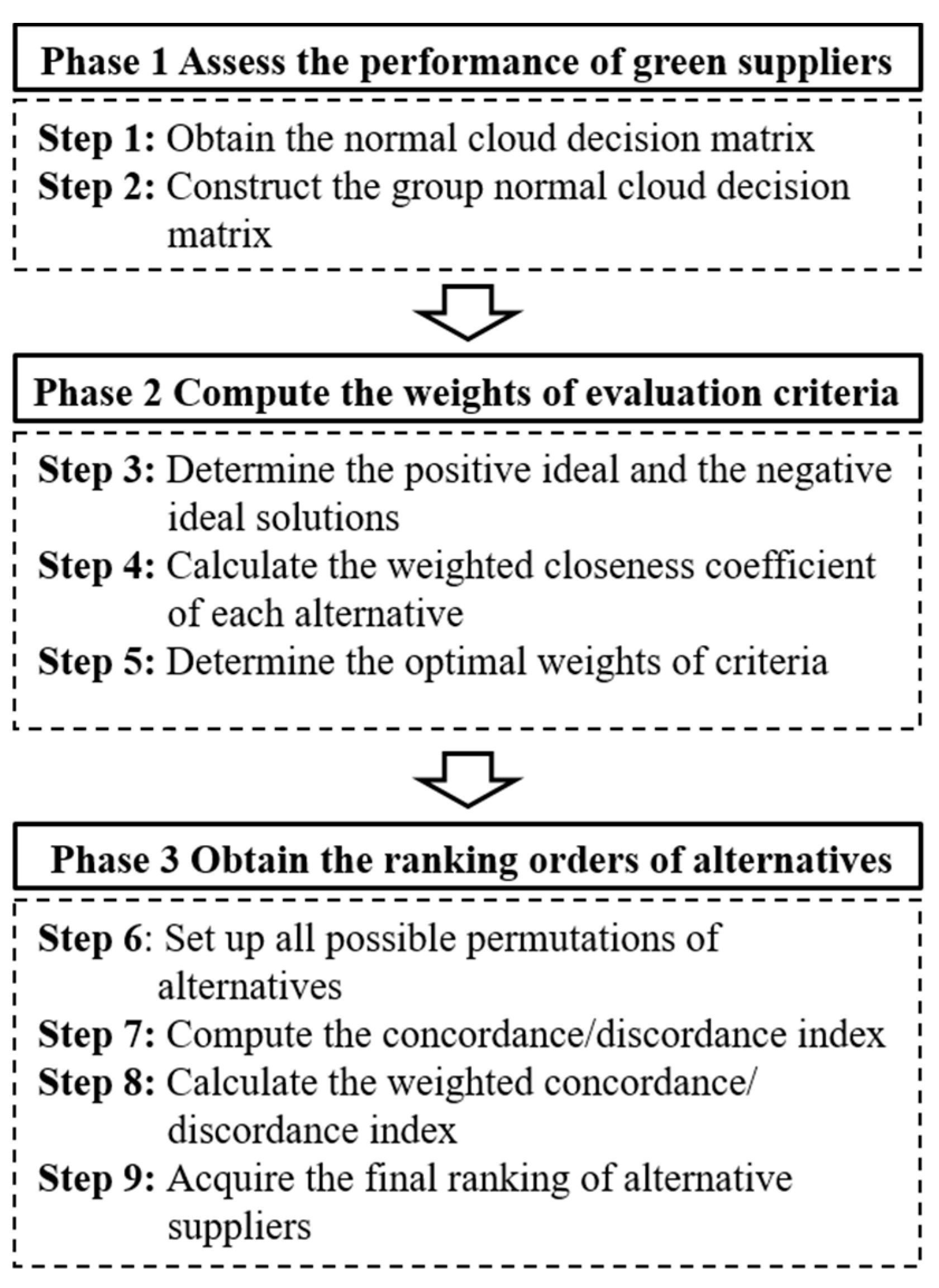

4. The Proposed Green Supplier Selection Methodology

4.1. Assess the Performance of Green Suppliers

4.2. Compute the Weights of Evaluation Criteria

4.3. Determine the Ranking Orders of Alternatives

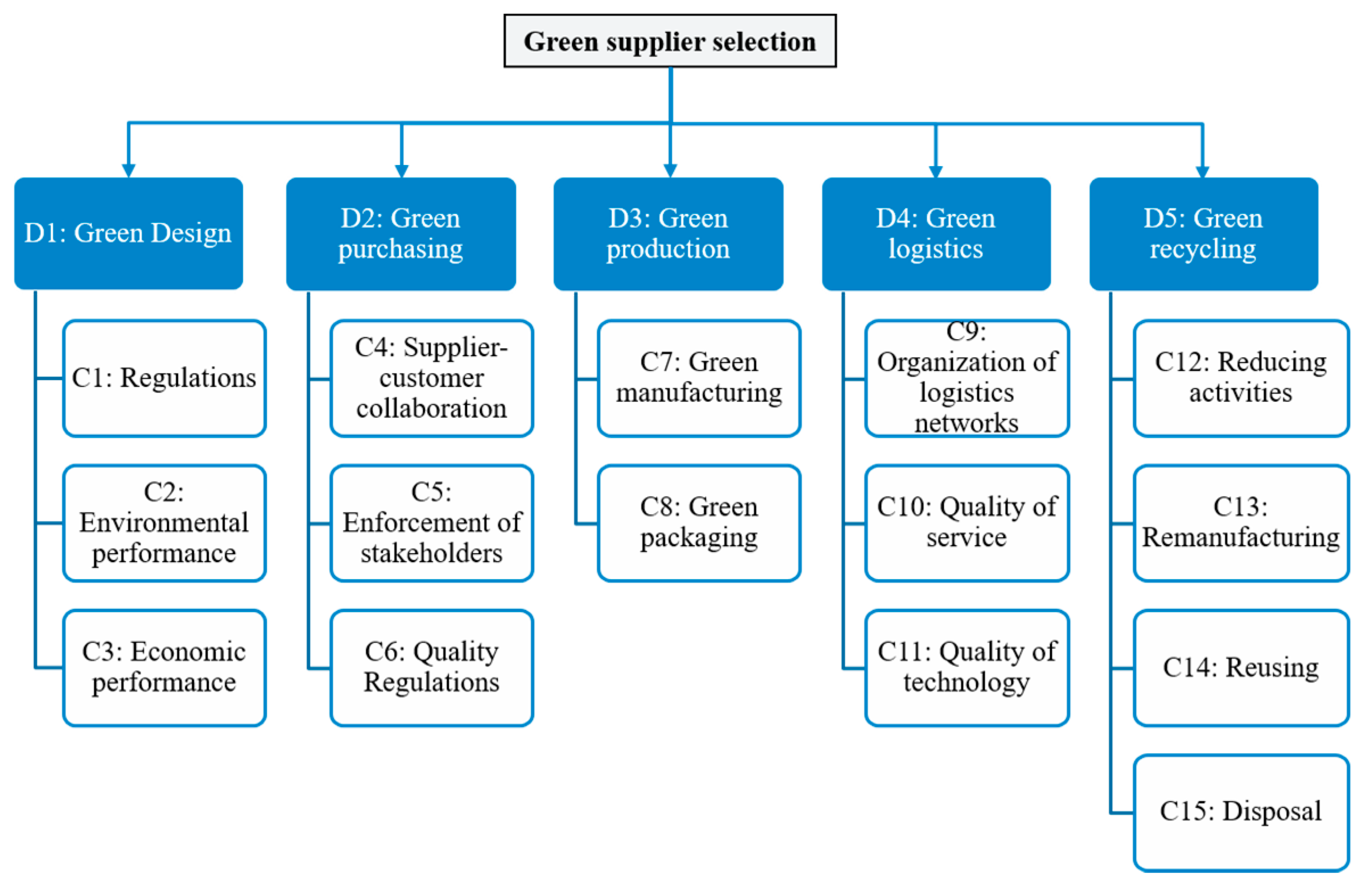

5. Illustrative Example

5.1. Background Description

5.2. Application and Results

5.3. Discussion under Incomplete Weight Information

5.4. Comparative Study

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Awasthi, A.; Kannan, G. Green supplier development program selection using NGT and VIKOR under fuzzy environment. Comput. Ind. Eng. 2016, 91, 100–108. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Green supplier development: Analytical evaluation using rough set theory. J. Clean. Prod. 2010, 18, 1200–1210. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Igarashi, M.; de Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Comput. Oper. Res. 2016. [Google Scholar] [CrossRef]

- Sarkis, J.; Dhavale, D.G. Supplier selection for sustainable operations: A triple-bottom-line approach using a Bayesian framework. Int. J. Prod. Econ. 2015, 166, 177–191. [Google Scholar] [CrossRef]

- Paelinck, J.H.P. Qualiflex: A flexible multiple-criteria method. Econ. Lett. 1978, 1, 193–197. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.Q. An extended QUALIFLEX method under probability hesitant fuzzy environment for selecting green suppliers. Int. J. Fuzzy Syst. 2017. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z.S. Hesitant fuzzy QUALIFLEX approach with a signed distance-based comparison method for multiple criteria decision analysis. Expert Syst. Appl. 2015, 42, 873–884. [Google Scholar] [CrossRef]

- Peng, J.J.; Wang, J.Q.; Yang, W.E. A multi-valued neutrosophic qualitative flexible approach based on likelihood for multi-criteria decision-making problems. Int. J. Syst. Sci. 2017, 48, 425–435. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy axiomatic design approach based green supplier selection: A case study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Xu, Z.S. A method based on linguistic aggregation operators for group decision making with linguistic preference relations. Inf. Sci. 2004, 166, 19–30. [Google Scholar] [CrossRef]

- Herrera, F.; Martínez, L. A 2-tuple fuzzy linguistic representation model for computing with words. IEEE Trans. Fuzzy Syst. 2000, 8, 746–752. [Google Scholar]

- Wang, J.Q.; Peng, L.; Zhang, H.Y.; Chen, X.H. Method of multi-criteria group decision-making based on cloud aggregation operators with linguistic information. Inf. Sci. 2014, 274, 177–191. [Google Scholar] [CrossRef]

- Li, D.Y.; Liu, C.Y.; Gan, W.Y. A new cognitive model: Cloud model. Int. J. Intell. Syst. 2009, 24, 357–375. [Google Scholar] [CrossRef]

- Wang Chen, H.M.; Chou, S.Y.; Luu, Q.D.; Yu, T.H.K. A fuzzy MCDM approach for green supplier selection from the economic and environmental aspects. Math. Probl. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Tsui, C.W.; Tzeng, G.H.; Wen, U.P. A hybrid MCDM approach for improving the performance of green suppliers in the TFT-LCD industry. Int. J. Prod. Res. 2015, 53, 6436–6454. [Google Scholar] [CrossRef]

- Liou, J.J.H.; Tamošaitienė, J.; Zavadskas, E.K.; Tzeng, G.H. New hybrid COPRAS-G MADM model for improving and selecting suppliers in green supply chain management. Int. J. Prod. Res. 2015, 54, 114–134. [Google Scholar] [CrossRef]

- Kannan, D.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Hashemkhani Zolfani, S. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Bakeshlou, E.A.; Khamseh, A.A.; Asl, M.A.G.; Sadeghi, J.; Abbaszadeh, M. Evaluating a green supplier selection problem using a hybrid MODM algorithm. J. Intell. Manuf. 2017, 28, 913–927. [Google Scholar] [CrossRef]

- Zhang, X. Multicriteria Pythagorean fuzzy decision analysis: A hierarchical QUALIFLEX approach with the closeness index-based ranking methods. Inf. Sci. 2016, 330, 104–124. [Google Scholar] [CrossRef]

- Zhang, Z. Multi-criteria decision-making using interval-valued hesitant fuzzy QUALIFLEX methods based on a likelihood-based comparison approach. Neural Comput. Appl. 2016. [Google Scholar] [CrossRef]

- Xue, Y.X.; You, J.X.; Zhao, X.; Liu, H.C. An integrated linguistic MCDM approach for robot evaluation and selection with incomplete weight information. Int. J. Prod. Res. 2016, 54, 5452–5467. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.; Wang, J.Q.; Zhang, H.Y. Simplified neutrosophic linguistic multi-criteria group decision-making approach to green product development. Group Decis. Negot. 2017, 26, 597–627. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.; Wang, J.Q.; Zhang, H.Y. A likelihood-based qualitative flexible approach with hesitant fuzzy linguistic information. Cogn. Comput. 2016, 8, 670–683. [Google Scholar] [CrossRef]

- Peng, H.G.; Zhang, H.Y.; Wang, J.Q. Probability multi-valued neutrosophic sets and its application in multi-criteria group decision-making problems. Neural Comput. Appl. 2016. [Google Scholar] [CrossRef]

- Wang, J.C.; Tsao, C.Y.; Chen, T.Y. A likelihood-based QUALIFLEX method with interval type-2 fuzzy sets for multiple criteria decision analysis. Soft Comput. 2015, 19, 2225–2243. [Google Scholar] [CrossRef]

- Chen, T.Y. Interval-valued intuitionistic fuzzy QUALIFLEX method with a likelihood-based comparison approach for multiple criteria decision analysis. Inf. Sci. 2014, 261, 149–169. [Google Scholar] [CrossRef]

- Chen, T.Y. Data construction process and QUALIFLEX-based method for multiple-criteria group decision making with interval-valued intuitionistic fuzzy sets. Int. J. Inf. Technol. Decis. Mak. 2013, 12, 425–467. [Google Scholar] [CrossRef]

- Chen, T.Y.; Chang, C.H.; Rachel Lu, J.F. The extended QUALIFLEX method for multiple criteria decision analysis based on interval type-2 fuzzy sets and applications to medical decision making. Eur. J. Oper. Res. 2013, 226, 615–625. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z.; Liu, M. Hesitant trapezoidal fuzzy QUALIFLEX method and its application in the evaluation of green supply chain initiatives. Sustainability 2016, 8. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, X.; Zhu, H.; AbouRizk, S.M. Perceiving safety risk of buildings adjacent to tunneling excavation: An information fusion approach. Automat. Constr. 2017, 73, 88–101. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, K.; Zeng, B.; Yang, M.; Li, L.; Zhang, H. A cloud decision framework in pure 2-tuple linguistic setting and its application for low-speed wind farm site selection. J. Clean. Prod. 2017, 142, 2154–2165. [Google Scholar] [CrossRef]

- Wang, M.X.; Wang, J.Q. An evolving Takagi-Sugeno model based on aggregated trapezium clouds for anomaly detection in large datasets. J. Intell. Fuzzy Syst. 2017, 32, 2295–2308. [Google Scholar] [CrossRef]

- Shi, H.; Liu, H.C.; Li, P.; Xu, X.G. An integrated decision making approach for assessing healthcare waste treatment technologies from a multiple stakeholder. Waste Manag. 2017, 59, 508–517. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Xu, P.; Chen, J.; Zheng, L.; Niu, C. Hazard assessment of debris-flow along the baicha river in Heshigten Banner, Inner Mongolia, China. Int. J. Environ. Res. Public Health 2017, 14, 30. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Yan, L.; Yang, Y. Trust evaluation method for clustered wireless sensor networks based on cloud model. Wirel. Netw. 2016. [Google Scholar] [CrossRef]

- Li, L.; Fan, F.; Ma, L.; Tang, Z. Energy utilization evaluation of carbon performance in public projects by FAHP and cloud model. Sustainability 2016, 8, 630. [Google Scholar] [CrossRef]

- Zhao, H.; Li, N. Risk evaluation of a UHV power transmission construction project based on a cloud model and FCE method for sustainability. Sustainability 2015, 7, 2885–2914. [Google Scholar] [CrossRef]

- Wang, J.Q.; Peng, J.J.; Zhang, H.Y.; Liu, T.; Chen, X.H. An uncertain linguistic multi-criteria group decision-making method based on a cloud model. Group Decis. Negot. 2015, 24, 171–192. [Google Scholar] [CrossRef]

- Wang, J.Q.; Wang, P.; Wang, J.; Zhang, H.Y.; Chen, X.H. Atanassov’s interval-valued intuitionistic linguistic multicriteria group decision-making method based on the trapezium cloud model. IEEE Trans. Fuzzy Syst. 2015, 23, 542–554. [Google Scholar] [CrossRef]

- Yager, R.R. On ordered weighted averaging aggregation operators in multicriteria decisionmaking. IEEE Trans. Syst. Man Cybern. 1988, 18, 183–190. [Google Scholar] [CrossRef]

- Mohammed, E.A.; Naugler, C.T.; Far, B.H. Breast tumor classification using a new OWA operator. Expert Syst. Appl. 2016, 61, 302–313. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attributes Decision Making Methods and Applications; Springer: Berlin, Germany, 1981. [Google Scholar]

- Zhang, X.; Xu, Z.S.; Wang, H. Heterogeneous multiple criteria group decision making with incomplete weight information: A deviation modeling approach. Inf. Fusion 2015, 25, 49–62. [Google Scholar] [CrossRef]

- Liu, H.C.; You, J.X.; Li, P.; Su, Q. Failure mode and effect analysis under uncertainty: An integrated multiple criteria decision making approach. IEEE Trans. Reliab. 2016, 65, 1380–1392. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, J.Q.; Zhang, H.Y. Stochastic multicriteria decision-making approach based on SMAA-ELECTRE with extended gray numbers. Int. Trans. Oper. Res. 2017. [Google Scholar] [CrossRef]

- Yu, S.M.; Wang, J.; Wang, J.Q. An interval type-2 fuzzy likelihood-based MABAC approach and its application in selecting hotels on a tourism website. Int. J. Fuzzy Syst. 2017, 19, 47–61. [Google Scholar] [CrossRef]

| Linguistic Terms | Normal Clouds |

|---|---|

| Very Poor (VP) | (1, 0.45, 0.05) |

| Poor (P) | (2, 0.45, 0.05) |

| Medium Poor (MP) | (3, 0.45, 0.05) |

| Fair (F) | (5, 0.45, 0.05) |

| Medium Good (MG) | (6, 0.45, 0.05) |

| Good (G) | (8, 0.45, 0.05) |

| Very Good (VG) | (9, 0.45, 0.05) |

| Decision Makers | Alternatives | Criteria | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | ||

| DM1 | A1 | G | MP | VG | VP | P | G | F | P | MG | G | G | F | VG | P | G |

| A2 | F | P | VG | P | VP | VG | VG | P | P | G | F | G | F | VP | F | |

| A3 | P | MG | G | F | F | G | F | P | G | F | MP | MG | MG | F | G | |

| DM2 | A1 | G | MP | G | P | P | VG | MG | P | F | VG | F | MG | VG | MP | VG |

| A2 | MP | MP | MG | VP | MP | G | G | P | VP | G | MG | G | F | P | F | |

| A3 | F | G | G | VP | MG | VG | VG | F | F | VG | MP | F | F | F | P | |

| DM3 | A1 | G | F | G | VP | VP | VG | F | MP | F | G | P | F | VG | P | VG |

| A2 | MP | P | MG | P | F | VG | VG | VP | P | VG | F | MG | F | MP | MP | |

| A3 | MP | MG | VG | MP | G | G | VG | MP | G | P | F | F | MP | MG | F | |

| DM4 | A1 | G | MP | VG | VP | VP | G | F | MP | G | G | F | MG | G | MP | VG |

| A2 | F | P | MG | P | VP | VG | G | VP | VP | VG | MG | G | F | VP | F | |

| A3 | F | G | MG | F | F | G | VG | MP | G | G | P | MG | F | P | F | |

| DM5 | A1 | VG | MP | G | P | P | G | MP | MG | VG | MG | MG | F | G | VP | VG |

| A2 | F | P | F | VP | VP | VG | VG | P | P | G | G | F | F | VP | P | |

| A3 | P | MG | G | P | MG | VG | G | MG | G | F | F | MP | MP | G | F | |

| C1 | C2 | C3 | C4 | C5 | |

| A1 | (8.07, 0.45, 0.05) | (3.14, 0.45, 0.05) | (8.25, 0.45, 0.05) | (1.25, 0.45, 0.05) | (1.75, 0.45, 0.05) |

| A2 | (4.50, 0.45, 0.05) | (2.07, 0.45, 0.05) | (6.14, 0.45, 0.05) | (1.75, 0.45, 0.05) | (1.64, 0.45, 0.05) |

| A3 | (3.25, 0.45, 0.05) | (6.50, 0.45, 0.05) | (7.93, 0.45, 0.05) | (3.18, 0.45, 0.05) | (5.89, 0.45, 0.05) |

| A+ | (8.07, 0.45, 0.05) | (6.50, 0.45, 0.05) | (8.25, 0.45, 0.05) | (3.18, 0.45, 0.05) | (5.89, 0.45, 0.05) |

| A− | (3.25, 0.45, 0.05) | (2.07, 0.45, 0.05) | (6.14, 0.45, 0.05) | (1.25, 0.45, 0.05) | (1.64, 0.45, 0.05) |

| C6 | C7 | C8 | C9 | C10 | |

| A1 | (8.25, 0.45, 0.05) | (4.93, 0.45, 0.05) | (2.95, 0.45, 0.05) | (6.32, 0.45, 0.05) | (7.93, 0.45, 0.05) |

| A2 | (8.93, 0.45, 0.05) | (8.75, 0.45, 0.05) | (1.75, 0.45, 0.05) | (1.75, 0.45, 0.05) | (8.25, 0.45, 0.05) |

| A3 | (8.25, 0.45, 0.05) | (8.55, 0.45, 0.05) | (3.50, 0.45, 0.05) | (7.80, 0.45, 0.05) | (5.62, 0.45, 0.05) |

| A+ | (8.93, 0.45, 0.05) | (8.75, 0.45, 0.05) | (3.50, 0.45, 0.05) | (7.80, 0.45, 0.05) | (8.25, 0.45, 0.05) |

| A− | (8.25, 0.45, 0.05) | (4.93, 0.45, 0.05) | (1.75, 0.45, 0.05) | (1.75, 0.45, 0.05) | (5.62, 0.45, 0.05) |

| C11 | C12 | C13 | C14 | C15 | |

| A1 | (5.18, 0.45, 0.05) | (5.25, 0.45, 0.05) | (8.75, 0.45, 0.05) | (2.18, 0.45, 0.05) | (8.93, 0.45, 0.05) |

| A2 | (5.89, 0.45, 0.05) | (7.43, 0.45, 0.05) | (5.00, 0.45, 0.05) | (1.32, 0.45, 0.05) | (4.43, 0.45, 0.05) |

| A3 | (3.43, 0.45, 0.05) | (5.12, 0.45, 0.05) | (4.57, 0.45, 0.05) | (5.18, 0.45, 0.05) | (5.00, 0.45, 0.05) |

| A+ | (5.89, 0.45, 0.05) | (7.43, 0.45, 0.05) | (8.75, 0.45, 0.05) | (5.18, 0.45, 0.05) | (8.93, 0.45, 0.05) |

| A− | (3.43, 0.45, 0.05) | (5.12, 0.45, 0.05) | (4.57, 0.45, 0.05) | (1.32, 0.45, 0.05) | (4.43, 0.45, 0.05) |

| P1 | |||

|---|---|---|---|

| C1 | 3.570 | 4.817 | 1.247 |

| C2 | 1.068 | −3.366 | −4.434 |

| C3 | 2.115 | 0.319 | −1.796 |

| C4 | −0.498 | −1.932 | −1.434 |

| C5 | 0.111 | −4.136 | −4.247 |

| C6 | −0.681 | 0.000 | 0.681 |

| C7 | −3.817 | −3.613 | 0.204 |

| C8 | 1.204 | −0.549 | −1.753 |

| C9 | 4.570 | −1.477 | −6.047 |

| C10 | −0.319 | 2.315 | 2.634 |

| C11 | −0.702 | 1.749 | 2.451 |

| C12 | −2.179 | 0.136 | 2.315 |

| C13 | 3.749 | 4.183 | 0.434 |

| C14 | 0.864 | −3.000 | −3.864 |

| C15 | 4.502 | 3.932 | −0.570 |

| P1 | P2 | P3 | |||

| 0.820 | −0.089 | −0.820 | |||

| −0.089 | 0.820 | −0.909 | |||

| −0.909 | 0.909 | −0.089 | |||

| P4 | P5 | P6 | |||

| -0.909 | 0.089 | 0.909 | |||

| -0.820 | 0.909 | 0.089 | |||

| 0.089 | 0.820 | −0.820 |

| Alternatives | Fuzzy VIKOR | Fuzzy TOPSIS | Improved GRA | The Proposed Method |

|---|---|---|---|---|

| A1 | 2 | 2 | 2 | 2 |

| A2 | 2 | 3 | 3 | 3 |

| A3 | 1 | 1 | 1 | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.-Q.; Liu, H.-C.; Liu, L.; Huang, J. Green Supplier Evaluation and Selection Using Cloud Model Theory and the QUALIFLEX Method. Sustainability 2017, 9, 688. https://doi.org/10.3390/su9050688

Wang K-Q, Liu H-C, Liu L, Huang J. Green Supplier Evaluation and Selection Using Cloud Model Theory and the QUALIFLEX Method. Sustainability. 2017; 9(5):688. https://doi.org/10.3390/su9050688

Chicago/Turabian StyleWang, Ke-Qin, Hu-Chen Liu, Liping Liu, and Jia Huang. 2017. "Green Supplier Evaluation and Selection Using Cloud Model Theory and the QUALIFLEX Method" Sustainability 9, no. 5: 688. https://doi.org/10.3390/su9050688