1. Introduction

An important goal in pesticide application is adequate deposition on the entire canopy according to treatment specifications. Highly efficacious and efficient spray application could simultaneously increase the benefits of plant protection products (PPP), reduce the risk of environmental contamination, and produce higher quality food in a more sustainable agriculture. Spray drift continues to be a major challenge when applying agrochemicals because pesticides deposited in undesirable areas may pose risks to both the environment and bystander [

1].

Agriculture is already a major contributor to water pollution from nitrates, phosphates and pesticides [

2]. The 2009/128/EC European Directive for Sustainable Use of Pesticide [

3] represents bedrock EU legislation for all improvements pertaining to drift reduction and efficiency of pesticide application, including an overall definition and requirement for dedicated buffer zones [

4]. Each EU Member State (MS) specifies the characteristics of these zones in its National Action Plan (NAP). Among the technical information contained in the NAP, minimum buffer zone widths and their relationship to different spray application techniques must also be delineated (in terms of drift reduction or avoidance capacity). These requirements clearly indicate that drift measurement methodologies and classification schemes unique to each sprayer/technology, based on potential contamination risk, are essential tools.

According to ISO22866:2005 [

5], drift is defined as “the quantity of plant protection product that is carried out of the sprayed area (treated) by the action of air currents during the application process”. In an orchard, this includes droplets that move horizontally through the orchard canopy and beyond the orchard, as well as those above the canopy (via direct spraying into the air or upward diffusion from the sprayed canopy) that move vertically into the atmosphere. Some authors quantify that, during one spray application, 30 up to 50% of the amount of PPP spray mixture applied can be lost to the air from targeted site to non-target receptor site [

6]. In addition to the more localized movement of agrochemical residues in turbulent air masses downwind of application, they can also become concentrated in inversions or stable air masses and be transported at long distances [

7]. Thus, during and immediately after spray application non-target receptors including water [

8], plants [

9] and animals [

10,

11,

12,

13] can be exposed acutely and may therefore face the risk of adverse effects. Thus, drift may cause damage to non-target plants, contaminate water courses, result in illegal residues in food and feed commodities [

14] and cause adverse animals and humans exposure [

7,

15].

Spray drift is strongly influenced by many factors that fall into four categories [

16]: equipment and application techniques, PPP and spray characteristics, operator care and skills [

17] and environmental and meteorological conditions. In recent years, several studies have evaluated and quantified the effect of different factors involved in spray drift [

1,

17,

18,

19,

20,

21,

22]. Some countries have invested considerable effort into classifying particular sprayers and techniques as spray drift reduction solutions [

23]. Such work is complicated by the great variability of results achieved from spray drift measurements undertaken in field conditions, due to the influence of weather conditions [

21,

24,

25,

26,

27]. While the influence of environmental factors has long been studied, the relative importance of factors is not yet definitively understood, as demonstrated by the different factors named at one time or another as most important in drift process studies: droplet size distribution [

28], air temperature and humidity [

29], horizontal wind speed [

22,

30], and atmospheric stability [

20,

31,

32]. Nonetheless, since 1959, droplet size distribution and wind behavior have been consistently recognized as important drift process factors [

33], with higher wind speeds resulting in higher spray drift amounts.

Spray drift assessments are typically mandated in PPP regulatory evaluations at the level of European country and zone, in which field trial results commonly serve as the source for PPP registration purposes [

34]. Spray drift field measurement should follow the standardized protocol established by ISO22866:2005 [

5], which employs a complicated and time-consuming set of experiments [

35,

36,

37,

38,

39] that depend highly on external factors. On the other hand, field drift studies can also be conducted using a range of reference conditions, such as wind characteristics, humidity, temperature, sprayer adjustment, and so on. As expected, assessment outcomes vary with the standard reference conditions chosen for testing [

40]. Moreover, field experiments using different spray systems cannot be performed under identical and perfectly repeatable conditions [

5] due to the nature of environmental conditions. While it is reasonable to obtain information on the driftability of a specific sprayer configuration, the wide variation in test results makes them unsuitable for establishing any ranking or classification [

41]. Therefore, differences in drift reduction capability of spray technology are generally determined only through many test replicates made under similar conditions and pair-wise comparison. The fall-out drift can, in some cases, differ by as much as a factor of 10 for the same nozzle size and working pressure [

17], a difference that may be attributed to weather conditions, spray application technology, and/or different measurement procedures [

1]. Whereas it is commonly agreed that crop type and canopy growth stage is primarily related to the spray drift amount [

42]. Likewise, it is clear that spray drift amount also depends on the complex of architecture (e.g., pruning and training technique) and geometry of cultivation [

43,

44,

45].

Until now, various studies have proposed alternative drift measurement methods that target easy, repeatable, and precise procedures. Among these has been a focus on drift measurements and drift classification of field crop sprayers [

1,

46,

47,

48,

49]. Studies have also investigated a wide range of variables: droplet characteristic and drift value relationships [

50], horizontal and vertical boom movement relative importance, boom length effects on drift value [

51], fall-out drift measurement variability due to weather conditions, spray technology differences, and measurement procedure differences [

17]. Researchers have proposed the following as the main easy, repeatable, and precise methods as alternatives for drift measurement based on spray drift potential: Phase Doppler Particle Analyzer (PDPA) laser measurement [

52,

53,

54,

55,

56,

57,

58], wind tunnel measurement [

59,

60,

61,

62,

63,

64,

65], and ad hoc test bench measurement [

25,

50,

66,

67,

68,

69].

Concurrently, many authors turned to computer models and mathematical simulations to complement field tests and to consider the constant change in environmental variables and technical conditions over time and in space. Indeed, plume models [

70,

71,

72] and droplet trajectory models were developed to predict drift from boom sprayers [

73,

74,

75,

76] or from turbulent flow (orchard sprayers) [

44,

77,

78,

79,

80]. Alternative drift measurement methods and mathematical/computational models to determine pesticide droplet transport certainly simplifies test and field evaluation; however, detailed characterization of the agricultural environment, with temporal and spatial variations, is still necessary. Drift values under realistic conditions can only be obtained by means of field drift experiments [

81].

The difficulties that arise during application of the standardized test protocol [

5] for field drift measurement are magnified in the case of field evaluation trials in arboreal crops. High heterogeneity of cultures (olive trees, vineyard, fruit orchards, citrus, and others) amongst wide variation in canopy structure and dimension during crop season [

19] demand wide flexibility in spray technology and operative sprayer parameter selection during the application process (such as, nozzle type, working pressure, forward speed, and air assistance), and make it difficult to establish an objective and broadly applicable drift measurement method for these crops [

82,

83,

84,

85], as described by Llorens et al. [

86] and Ravier et al. [

38] in their work to obtain objective and reproducible results during application under the stringent requirements of ISO22866:2005. Similarly, drifting spray is a complex problem in which equipment design and application parameters, spray physical properties and formulation, and meteorological conditions interact and influence pesticide losses [

87].

Irrespective of the large list of variables affecting spray drift during spray application, it is necessary to evaluate and clarify the objectiveness, effectiveness, and repeatability of the actual ISO 22866:2005 standard [

5] to evaluate the performance of Spray Drift Reducing Technologies (SDRTs) in terms of spray drift reduction benefit achievable. The adoption of SDRTs (e.g., low drift nozzles, reduction of fan air volume, etc.) could benefits farmers to reduce the mandatory buffer zones [

3,

4] width as a function of spray drift reduction performance obtained by a given SDRT [

88]. Thus, the use of proven effective SDRTs in reducing spray drift could minimize the amplitude of no-spray buffer zone areas to be adopted, highly improving the crop profitability [

89] but at the same time satisfying the balance between farmer profit and sustainability, both for environment, animal and human health.

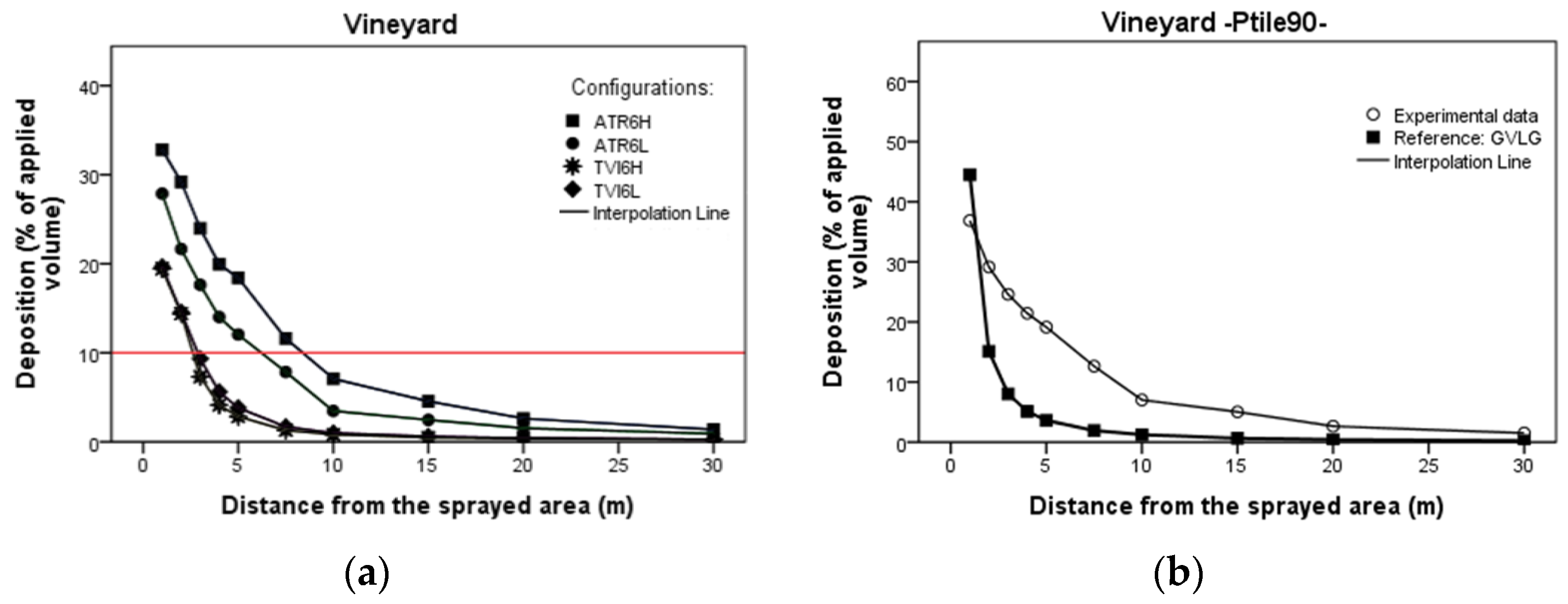

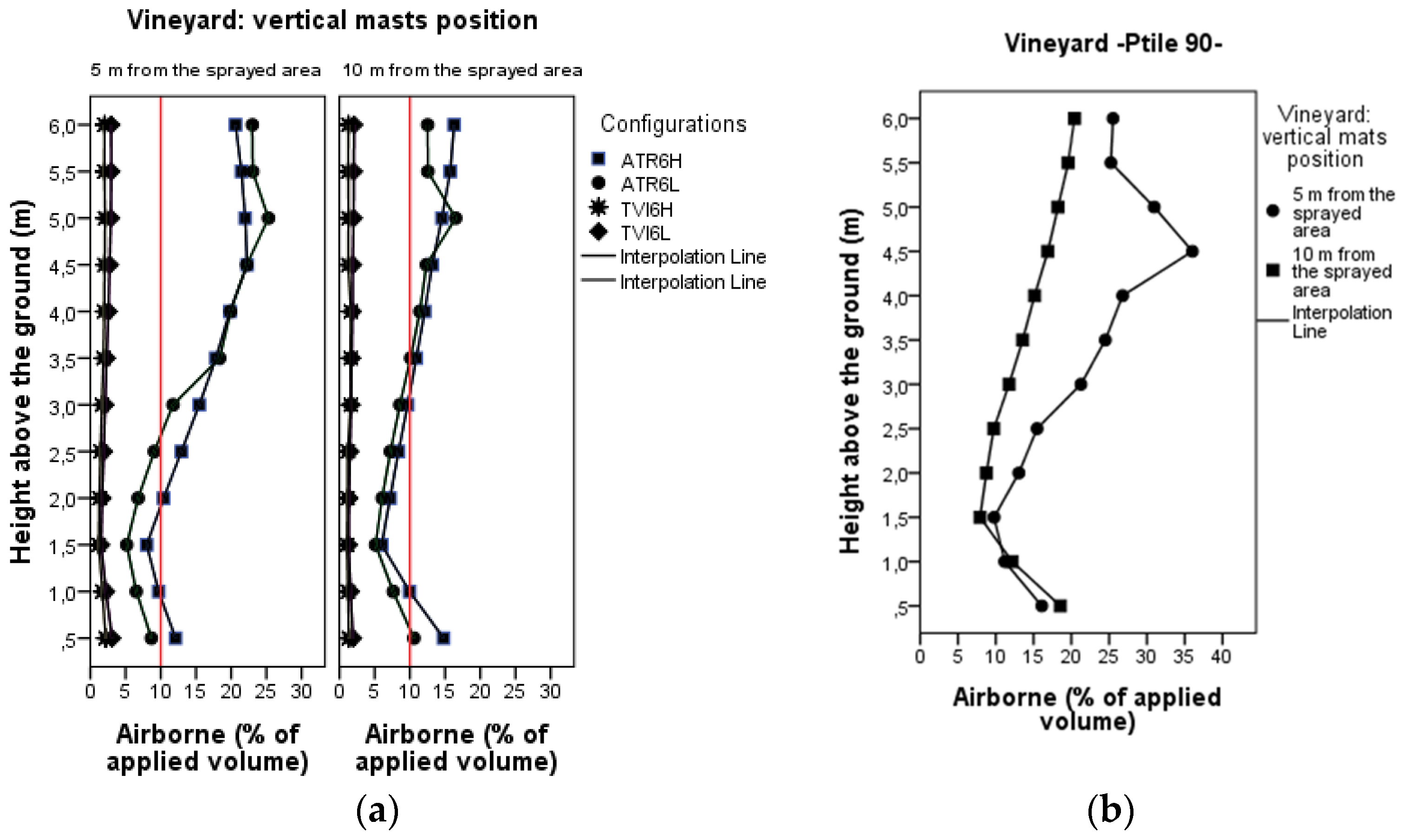

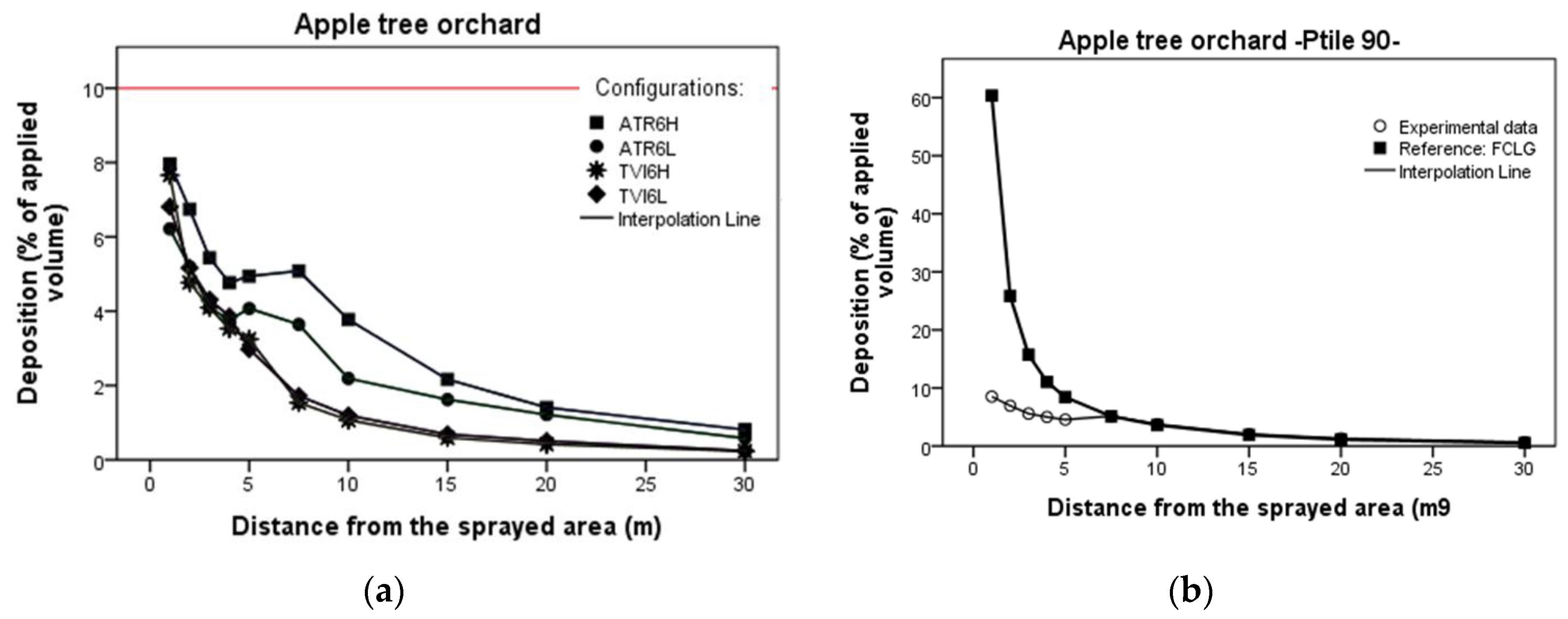

Within this context, this study aimed to evaluate and quantify the effect of different parameters involved in ground and airborne spray drift generation in vineyard and orchard spray application. The evaluation used field trials in vineyard and apple tree orchard under the standardized test methodology of ISO22866:2005. In particular, the study focused on quantifying the influence from controllable variables (sprayer setting parameters) and from external non-controllable variables (environmental conditions).

2. Materials and Methods

2.1. Tests Location and Crop Characterization

Tests were performed in two crops: (a) vineyard located in Penelles, Lleida, NE Spain (41°43′05″ N 0°57′46″ E); and (b) apple tree orchard located in La Fuliola, Lleida, NE Spain (41°43′32″ N 0°59′23″ E).

The vineyard tests were carried out in an espalier-trained vineyard (cv: Tempranillo) at growth stage BBCH 83 “Berries developing colors” [

90,

91]. Planting distances were 2.8 m between rows and 1.2 m in rows to result in a density of 2976 vines ha

−1. The average vine height was about 1.6 m, with the leaves and grape band occupying the zone above ground between 0.8 and 1.6 m.

Apple orchard tests were conducted in an espalier-trained apple tree orchard (cv: Golden Delicius) at growth stage BBCH 81 “Beginning of ripening: first appearance of cultivar-specific color” [

90,

92]. In this case, the between row and in row distances were 4 m and 1.2 m, respectively, for a density of 2083 trees ha

−1. The average apple tree height was about 3.4 m.

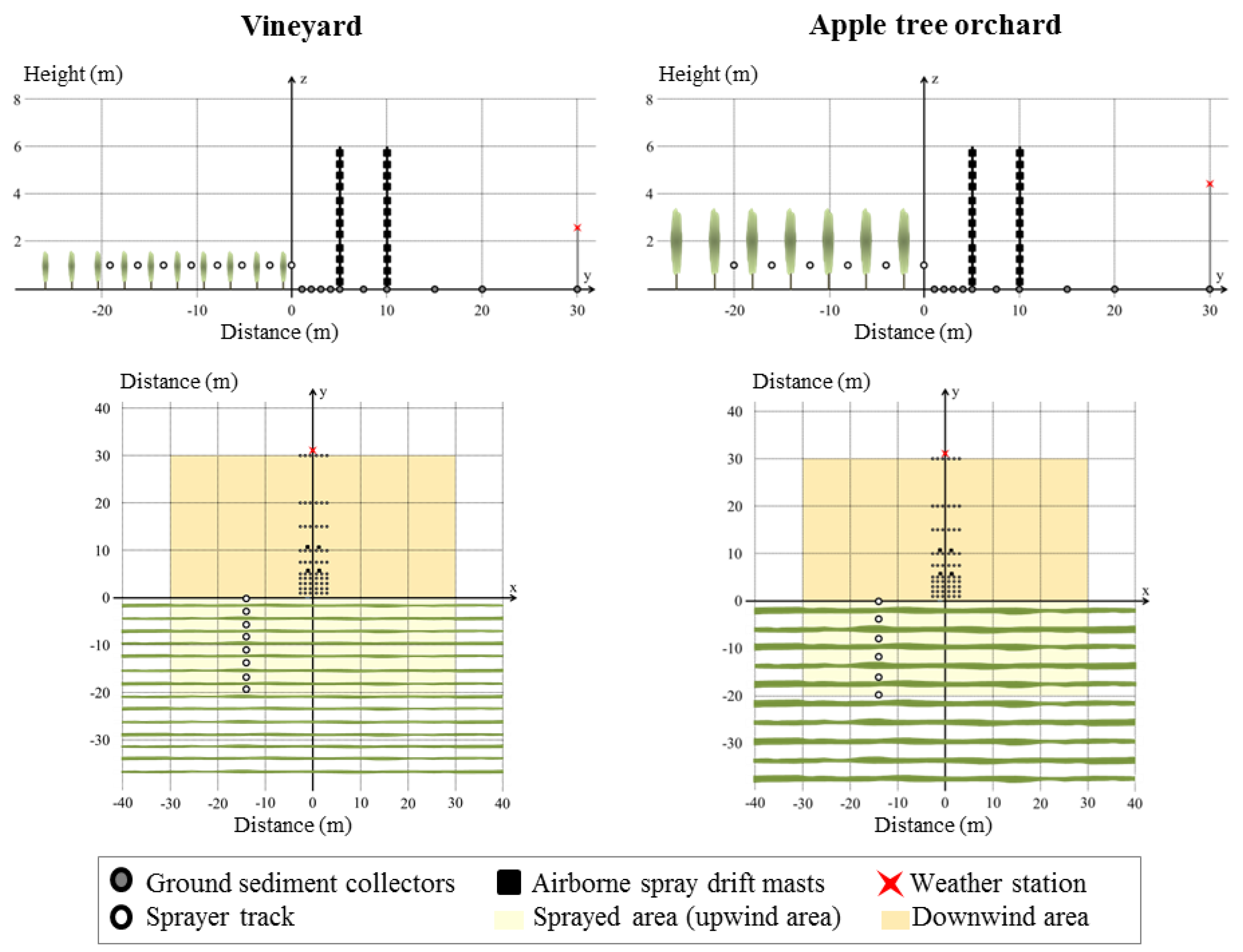

2.2. Experimental Plot Design

To assess the amount of spray drift generated during spray application in both crops, the test methodology described in ISO22866:2005 [

5] for field measurements of spray drift was followed. The methodology prescribes that the directly-sprayed area has to be a minimum of 20 m wide and located immediately upwind of the edge of the cropped area and 60 m spray track (twice the largest downwind sampling distance). Accordingly, vineyard tests were performed by spraying the eight outer downwind rows (two sides of the first seven rows starting from the edge of the upwind area and only a single side of the eighth row) equal to a surface of 1260 m

2 (60 × 21 m) and apple orchard tests were made by spraying the five outer downwind rows equaling a surface of 1200 m

2 (60 × 20 m) (

Figure 1).

Each replicate involved sampling both ground and airborne spray drift downwind to the directly sprayed area. For the ground sediment spray drift assessment, ten bare-soil sampling locations at distances of 1, 2, 3, 4, 5, 7.5, 10, 15, 20, and 30 m downwind from the directly sprayed area were identified. At each location, six discrete ground level horizontal samplers (Petri dishes, 14 cm diameter and placed at distance of 1 m from each other) were employed to yield a total collection area of 924 cm

2 at each downwind location (

Figure 1). Airborne spray drift measurements were taken at two distances (5 and 10 m) downwind from the edge of the directly sprayed area, with two continuous vertical samplers (Polyethene lines 6 m high and 2 mm in diameter) at each distance. Each continuous vertical sampler was utilized like an array of twelve sampling collectors (sampled discretely), considering each collector as a Polyethene line 0.5 m long and 2 mm in diameter (

Figure 1). Therefore, each collector was characterized by 31.4 cm

2 of collection area.

After a 60 s test, the sprayed Petri dishes were covered and each 6 m Polyethene line was cut into sections of 0.5 m, each considered as a single sample, and then collected. Each sample was stored individually in a sealed plastic bag. Finally, all samples were collected in closed dark boxes to prevent light degradation.

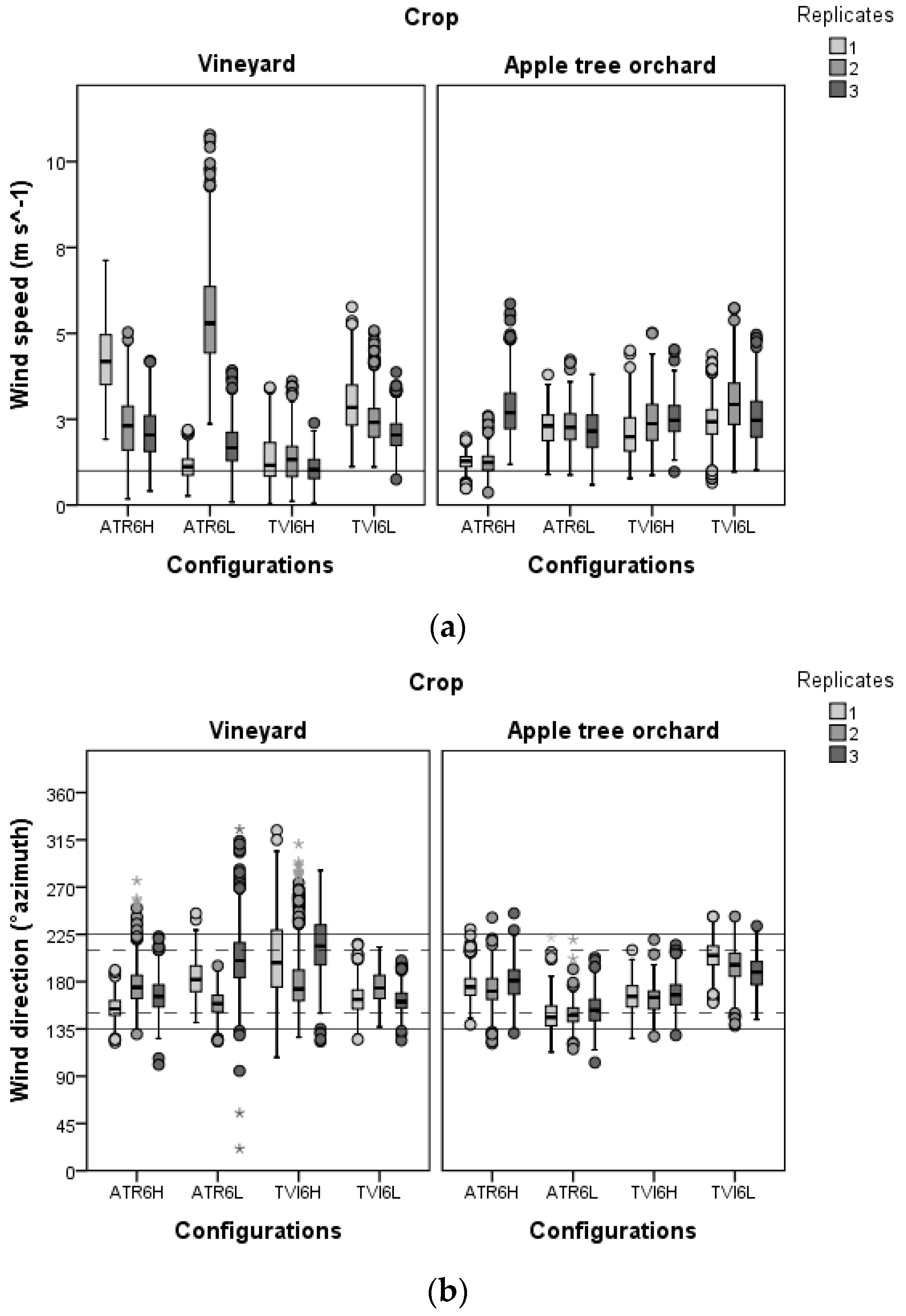

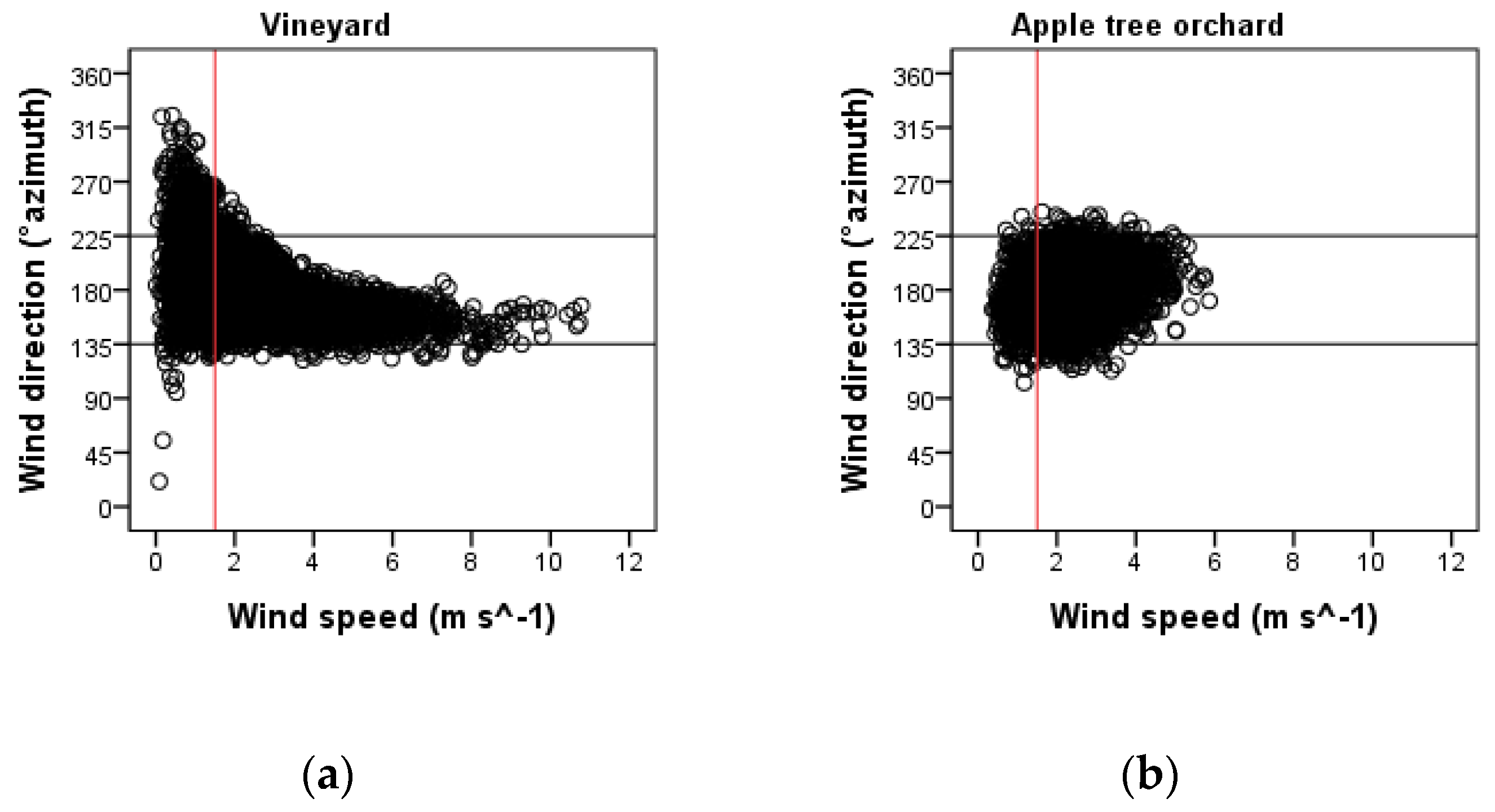

2.3. Weather Conditions during Trials

Following ISO22866:2005 [

5], a weather station was mounted close to the test area. A mast supporting sensors was placed at least 1 m above the canopy to ensure a distance more than 2 m above the ground. The mast was placed at the edge of the downwind area in the center of the drift sampling area (30 m from the sprayed area) (

Figure 1). To monitor environmental conditions during the trials, the weather station was equipped with a sonic anemometer 232 (Campbell Scientific, Logan, UT, USA) to measure wind speed and wind direction relative to the spray track, and two thermo-hygrometer HC2S3 probes (Campbell Scientific) placed at two different heights (1 m between sensors) to measure air temperature and humidity changes. All measurements were taken at a frequency of 0.1 Hz sampling rate and all data were recorded automatically by datalogger CR800 (Campbell Scientific). The environmental conditions were monitored for the entire duration of each test replicate: it derived that in vineyard trials the environmental parameters were measured for 5′24″ plus 60″ after the end of spray distribution and in apple orchard trials were measured for 3′36″ plus 60″ after the end of spray distribution.

To check that environmental conditions during the field trials met ISO22866:2005 [

5] requirements, the following were calculated for each replicate: (a) number of wind measurements less than 1 m s

−1 (outliers) must not exceed 10%; (b) mean wind direction must be 90° ± 30° to the spray track; (c) frequency of wind direction > 45° to the spray track (not centered) must not exceed 30%; and (d) mean temperature must be between 5 °C and 35 °C.

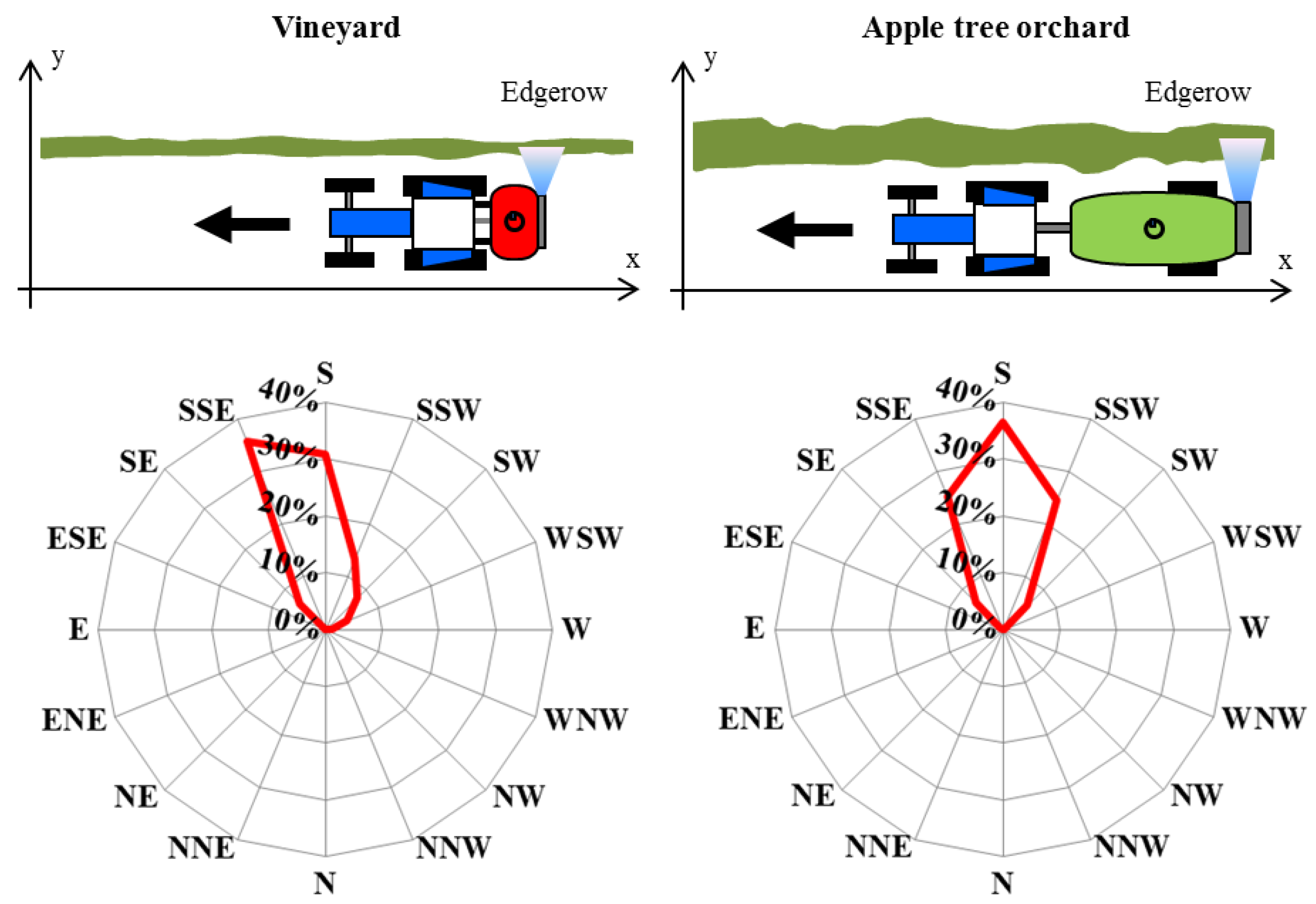

2.4. Characteristics and Configurations of Airblast Sprayers

Two different airblast sprayers were tested. The one in vineyard was a mounted sprayer Dragone k2 500 (Dragone S.n.c., Castagnole Asti, AT, Italy) with a 200 L polyethylene tank, an axial fan (600 mm of diameter) with a two-speed gearbox that generated two airflow rates 11,000 m3 h−1 or 20,000 m3 h−1 (PTO revolution speed 540 rev min−1 equal to 56.52 rad s−1), a tower-shaped air conveyor, and six nozzles on each side of the sprayer. In apple orchard, the sprayer tested was a trailed sprayer Fede Qi 90 Futur 2000 (Pulverizadores Fede S.L., Cheste, Valencia, Spain) equipped with a 2000 L polyethylene tank, an axial fan (900 mm of diameter) with a two-speed gearbox that produced airflow rates of either 29,000 m3 h−1 or 46,000 m3 h−1 (PTO revolution speed 540 rev min−1 equal to 56.52 rad s−1), and 13 nozzles for each side of the sprayer positioned in two lines (six in the first line and seven in the second one).

The vineyard sprayer was tested in four configurations resulting from combinations of two different fan airflow rates (11,000 m

3 h

−1 and 20,000 m

3 h

−1) and two different nozzle types, one conventional hollow cone (Albuz

® ATR 80 orange) and one air induction hollow cone (Albuz

® TVI 8002 yellow) (CoorsTek, Evereux, France) (

Table 1). All tests were performed operating at 1.67 m s

−1 (6 km h

−1) forward speed, adopting a working pressure of 1.0 MPa, producing nominal nozzle flow rates of 1.39 L min

−1 and 1.46 L min

−1, respectively. During testing, all nozzles were activated (6 + 6 nozzles) and the applied volume rates resulted as 596 L ha

−1 for ATR nozzles and 626 L ha

−1 for TVI nozzles.

The orchard sprayer was tested in four configurations resulting from combinations of two different fan airflow rates (29,000 m

3 h

−1 and 46,000 m

3 h

−1) and two different nozzle types, one conventional (Albuz

® ATR 80 red) and one air induction (Albuz

® TVI 80025 lilac) (

Table 1). All orchard tests were conducted operating at a single forward speed (1.67 m s

−1 equal to 6 km h

−1), but used a higher (compared to the vineyard) working pressure (1.5 MPa), with nominal nozzle flow rates of 2.33 L min

−1 (ATR) and 2.24 L min

−1 (TVI). During the tests, the eight nozzles in the central positions of the two lines (8 + 8 nozzles) were activated. These configurations resulted in volume rates of 932 L ha

−1 when employing ATR nozzles and 896 L ha

−1 using TVI nozzles.

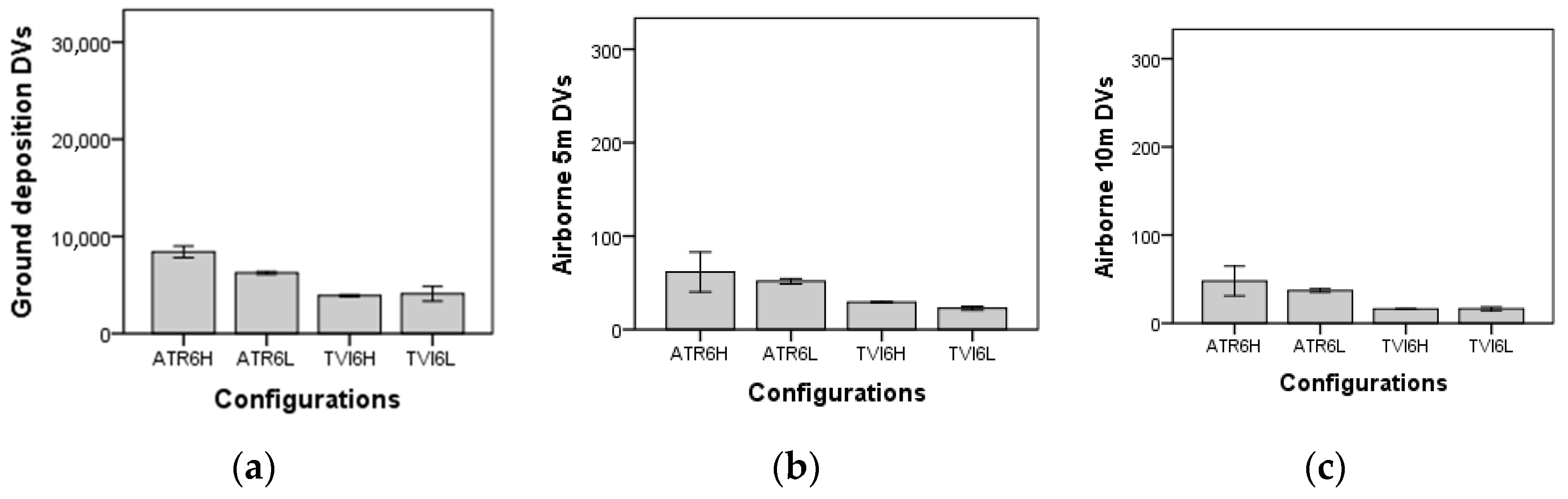

Three test replicates were conducted for each configuration; the results are summarized in

Table 1.

2.5. Characterization of Nozzle Droplet Size Spectra

The droplet size spectrum for each nozzle type used during field trials was determined. Laboratory measurements of droplet sizes were performed using a Malvern Spraytec laser diffraction system STP5342 (Malvern Instruments Ltd., Worcestershire, UK). All tests were made with the nozzle positioned orthogonally, at 30 cm height with respect to the laser beam emitted by the instrument; measurements were taken at five different positions within the spray cone. At each measuring point droplet size data were acquired for 60 s. For each nozzle type, three nozzles were randomly chosen from a 100-nozzle batch; each was then measured three times. The pressures adopted were identical to those utilized in the field trials: 1.0 MPa for ATR 80 orange and TVI 8002 yellow coupled with Dragone k2 500 in vineyard, and 1.5 MPa for ATR80 and TVI 80025 lilac coupled with Fede Qi 90 Futur 2000 in apple tree orchard. The 10th percentile (D[v,0.1]), 50th percentile or Volume Median Diameter (D[v,0.5]), and 90th-percentile (D[v,0.9]) values were determined for each nozzle.

Table 2 shows the main characteristics of the trial nozzles.

2.6. Spray Liquid and Tracer Concentration

E-102 Tartrazine yellow dye tracer −85% (w/w)-(Fiorio Colori S.r.l., Milano, Italy) was added to the sprayer’s tank at a concentration of about 10 g L

−1 [

93]. The tracer concentration was quantified on artificial collectors by using a spectrophotometer FLUOstar Omega (BMG LABTECH GmbH, Otenberg, Germany) set at a wavelength of 427 nm, corresponding to peak absorption of the Tartrazine dye.

Prior to each test, a blank sample was processed with a Petri dish placed in the middle of the sprayed area that was collected 30 s before spraying started. Three samples of the sprayed liquid were also collected from the spray tank (sampled directly from a nozzle) before and after the spraying process to determine the precise tracer concentration at the nozzle outlet at each test.

2.7. Spray Drift Assessment

The deposit on each artificial collector (

Di), expressed in µL cm

−2, was calculated according to ISO 22401:2015 [

94], as follows:

where

Di is the spray deposit on a single deposit collector, expressed in µL cm

−2;

psmpl is the absorbance value of the sample (adim.);

pblk is the absorbance of the blanks (adim.);

Vdil is the volume of the dilution liquid (deionized water) used to dissolve the tracer deposit from the collector in µL;

pspray is the absorbance value of the spray mix concentration applied during the tests and sampled at the nozzle outlet (adim.); and

Acol is the projected area of the collector detecting the spray drift (Petri dish and Polyethene line) in cm

2.

For drift ground sediment, once the tracer amount on each collector was measured, the mean of values derived from the six samples placed at each downwind distance was calculated. The amount (µL cm

−2) obtained from each replicate was then transformed using a proportion to express ground sediments as percentage of application rate (%) following ISO22866:2005 protocol [

5].

For airborne drift, the mean tracer amount derived from the two samples placed at each sampling height above the ground was calculated separately for each of the two sampled downwind distances (5 and 10 m from the sprayed area). In this case, the amount (µL cm−2) obtained from each replicate was transformed to express airborne spray drift as percentage of application rate (%).

2.8. Drift Value Calculation

For each replicate, the numerical integral of spray drift curves obtained was calculated to achieve its corresponding Drift Value (DV). The DVs for ground spray drift curves were obtained following the methodology proposed by Grella et al. [

95]; the DVs for airborne spray drift curves were calculated adapting the same methodology. The methodology allowed calculation of an approximation of definite integral using the mid-ordinate rule.

The calculation performed was: division of the interval [

a,

b], into

n equal intervals of width

where

h is equal to 0.5 m; for the calculation of DV for ground and airborne drift curves

a correspond, respectively, to 0.75 m distance from the sprayed area and to 0 m height above the ground, in both vineyard and apple tree orchard crops; for the calculation of DV for ground and airborne drift curves,

b correspond, respectively, to 30.25 m distance from the sprayed area and to 6 m height above the ground, in both vineyard and apple tree orchard crops.

The intervals’ midpoint was performed as follows:

where

x1,

x2,

x3, …,

xn are the midpoint values of the equal intervals of

h width, included into [

a,

b] interval.

The calculation of the sum of the rectangles’ areas followed

where

Sn is the sum of rectangles’ areas;

h is the rectangles’ base; and

f(

x1)

f(

x2)

f(

x3) …

f(

xn) are the rectangles’ heights.

The decision to use h equal to 0.5 m arise from the definition of integral:

To obtain a good approximation, an h equal to 0.5 m was used, where the higher the number (n) of intervals to divide the interval [a,b], the better the approximation.

2.9. Statistical Analysis

All statistical analyses were performed using IBM SPSS Statistics (Statistical Package for the Social Sciences) for Windows [

96]. A

p-value < 0.05 was considered to be statistically significant. For each sprayer, the statistical differences among Drift Values (DVs) for each tested configuration was evaluated using two-way Analysis of Variance (ANOVA) considering the nozzle type and fan airflow rate as sources of variation. Residuals analyses were also performed.

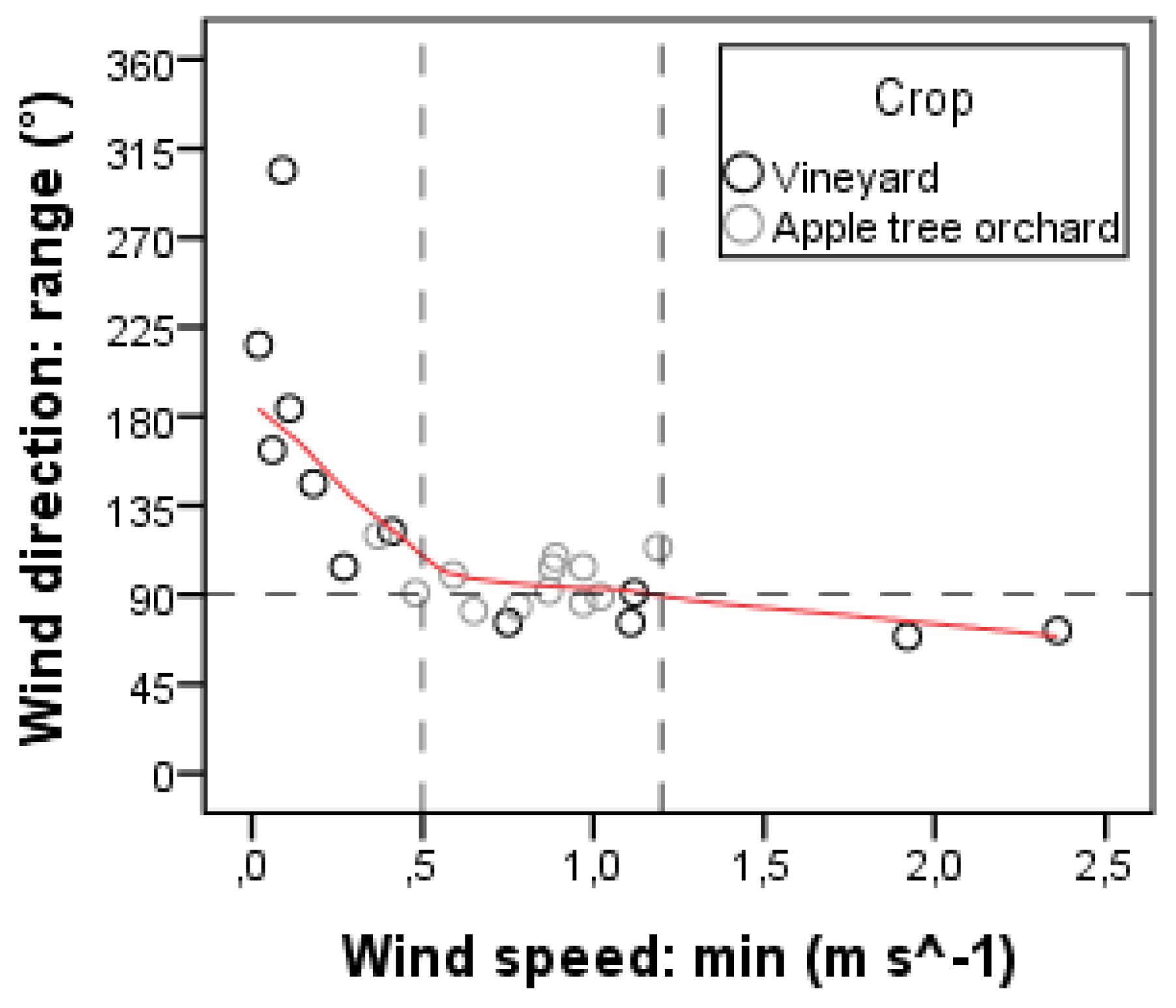

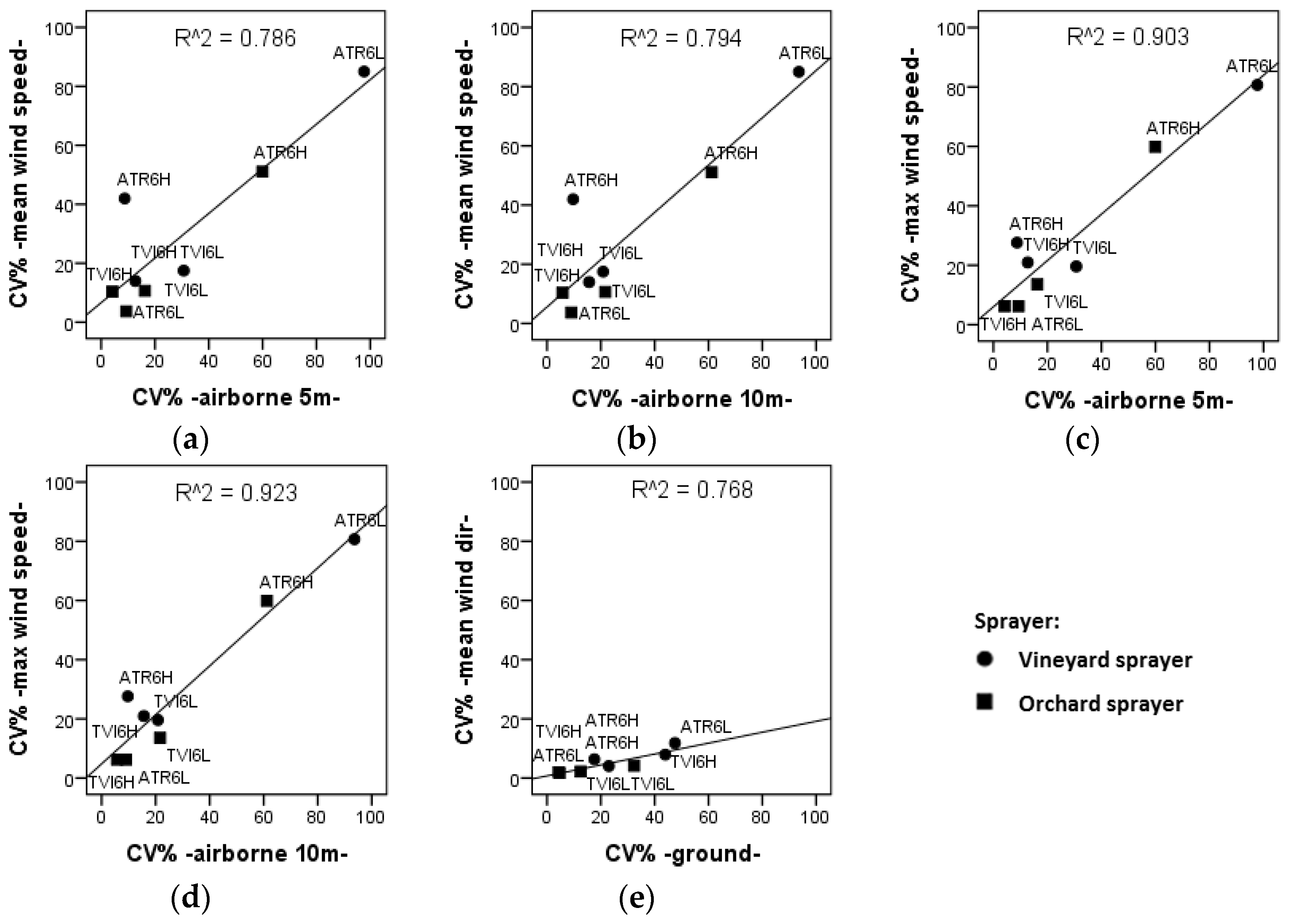

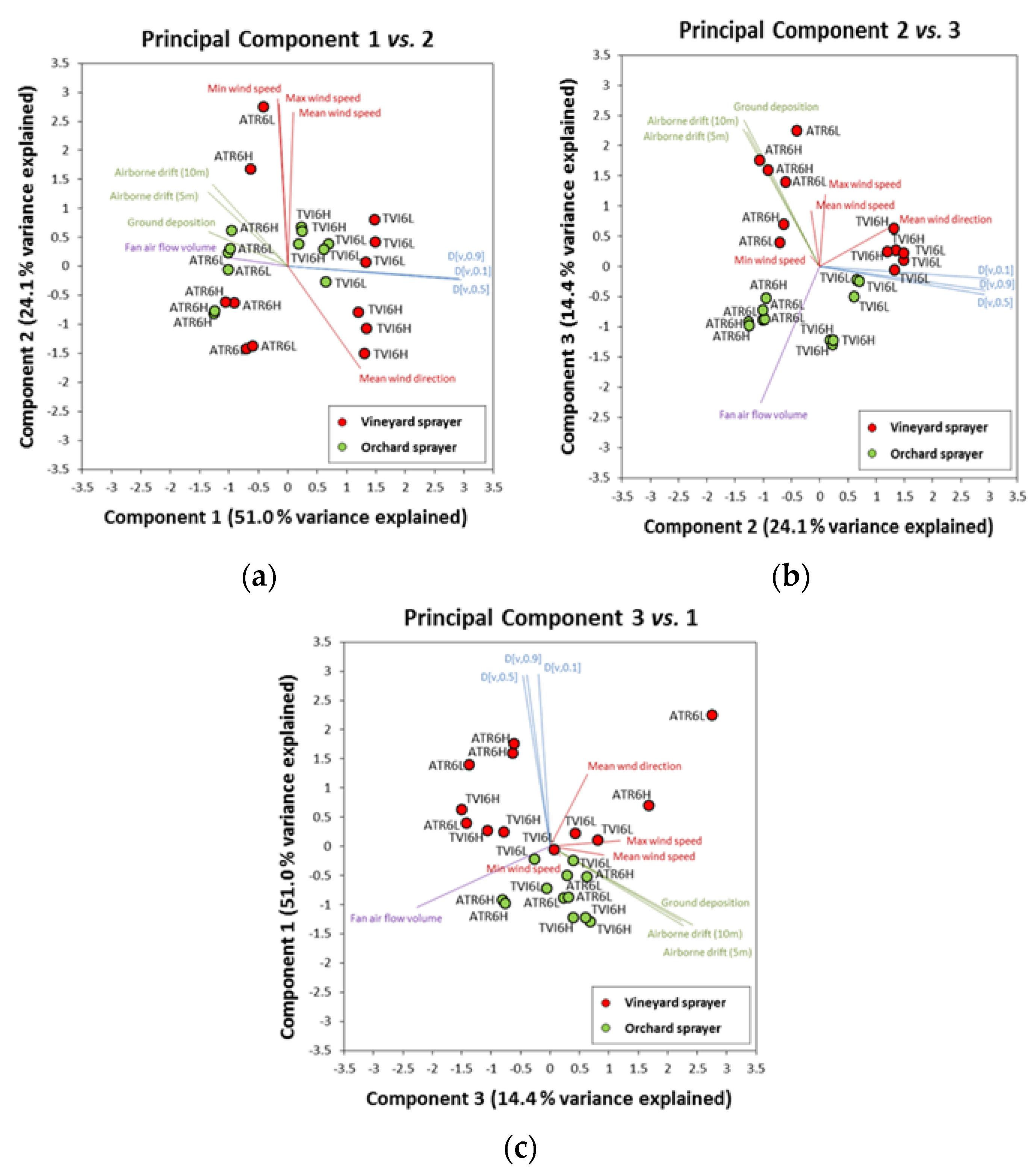

The correlations between wind speed parameters (minimum, maximum, mean, and outliers) and wind direction parameters (mean, range, and center directions) were evaluated. The relationship between wind characteristics and the DVs of ground and airborne spray drift (airborne measured at 5 and 10 m from the sprayed area) were analyzed to assess the influence of wind characteristics on the DV obtained in each test. To assess the influence of wind characteristics within each tested configuration when wind variation was detected by DV variation, the relationship between the CV% of wind characteristics and the CV% of DVs were analyzed.

Moreover, a Principal Component Analysis (PCA) on standardized values (Z scores) was carried out to evaluate and quantify the effect of different variables (sprayer settings parameters, main wind characteristics, and the DVs of spray drift deposition) during the spray drift process in vineyard and apple tree orchard.

4. Conclusions

ISO22866:2005 [

5] standard protocol is effective for determining realistic drift values, both ground and airborne, under actual conditions, by means of field drift experiments. However, when the test objective is to make a comparative assessment of drift risk from different sprayer settings, application of ISO standard protocol is problematic. In fact, when the evaluation of contamination risk to surface water (ground deposition onto horizontal surface) was performed, small variations in mean wind direction were shown to strongly influence drift value (DV) variability. At the same time, when the risk assessment was undertaken for bystander exposure (airborne profile), wind direction failed to affect the results; airborne DV variability was instead strongly influenced by high wind speed (maximum wind speed parameter). Furthermore, high wind speed always affected total spray drift amounts (DVs), be they ground or airborne profiles.

The experimental results from the application of ISO22866:2005, both in vineyard and in apple tree orchard, made evident that reduced spray drift can be achieved by the air induction nozzle configuration; the choose of nozzles types is resulted the variable most relevant in the spray drift process generation explaining 51% of spray drift variability. On the contrary, the effect of reduced fan airflow rates do not shows effect in terms of drift reduction. The wind characteristics (speed and direction), at the time of field trials, concealed the influence of adopted fan airflow rates on final spray drift assessment results. In fact, the wind characteristics explain about 24% of spray drift variability.

In addition, some evidence suggests crop canopy structure also played a role in DV generation, which requires an ad hoc experiment to tease out the effects of crop type, training system, and growth stage from the influence of canopy in the spray drift process.

This finding shows the difficulties in apply ISO standard, meeting its atmospheric conditions requirements, and to quantify the influence of each parameter involved in spray drift process during field spray application. The proved influence of wind characteristics confirmed the unfitness of the ISO22866 protocol for comparative evaluations of drift risk from different sprayer settings or Spray Drift Reducing Technologies (SDRT) to be tested, because it is not possible to directly replicate a given measurement.