Building Criteria for Evaluating Green Project Management: An Integrated Approach of DEMATEL and ANP

Abstract

:1. Introduction

2. Literature Review

2.1. Green Project Management

2.2. Green Project Management Evaluation

3. Method

3.1. Data Collection

3.2. Integrated Approach of DEMATEL and ANP

4. Empirical Results

4.1. Results of the DEMATEL Model

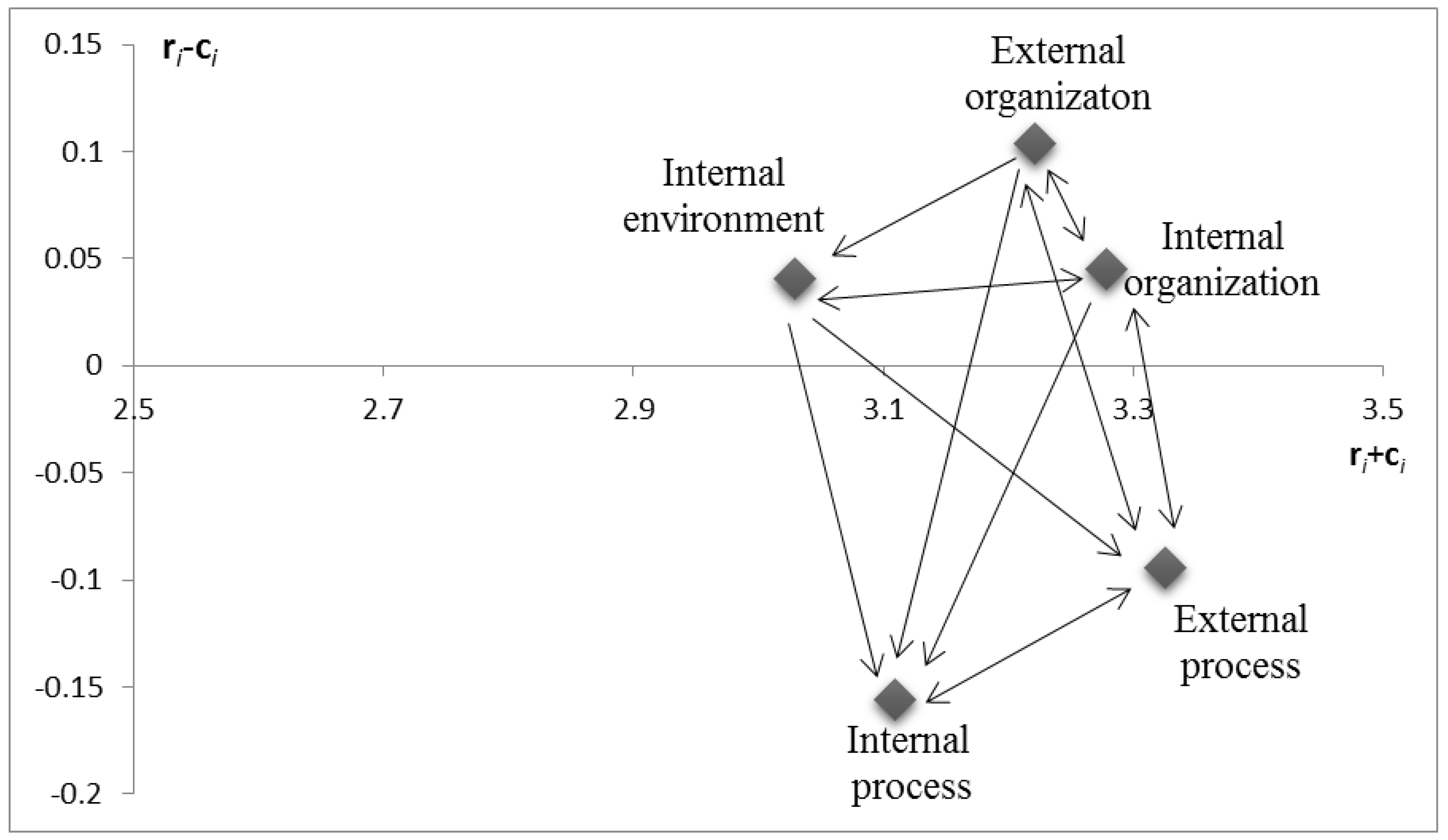

4.1.1. Interrelationships among Dimensions of a Green Project Management

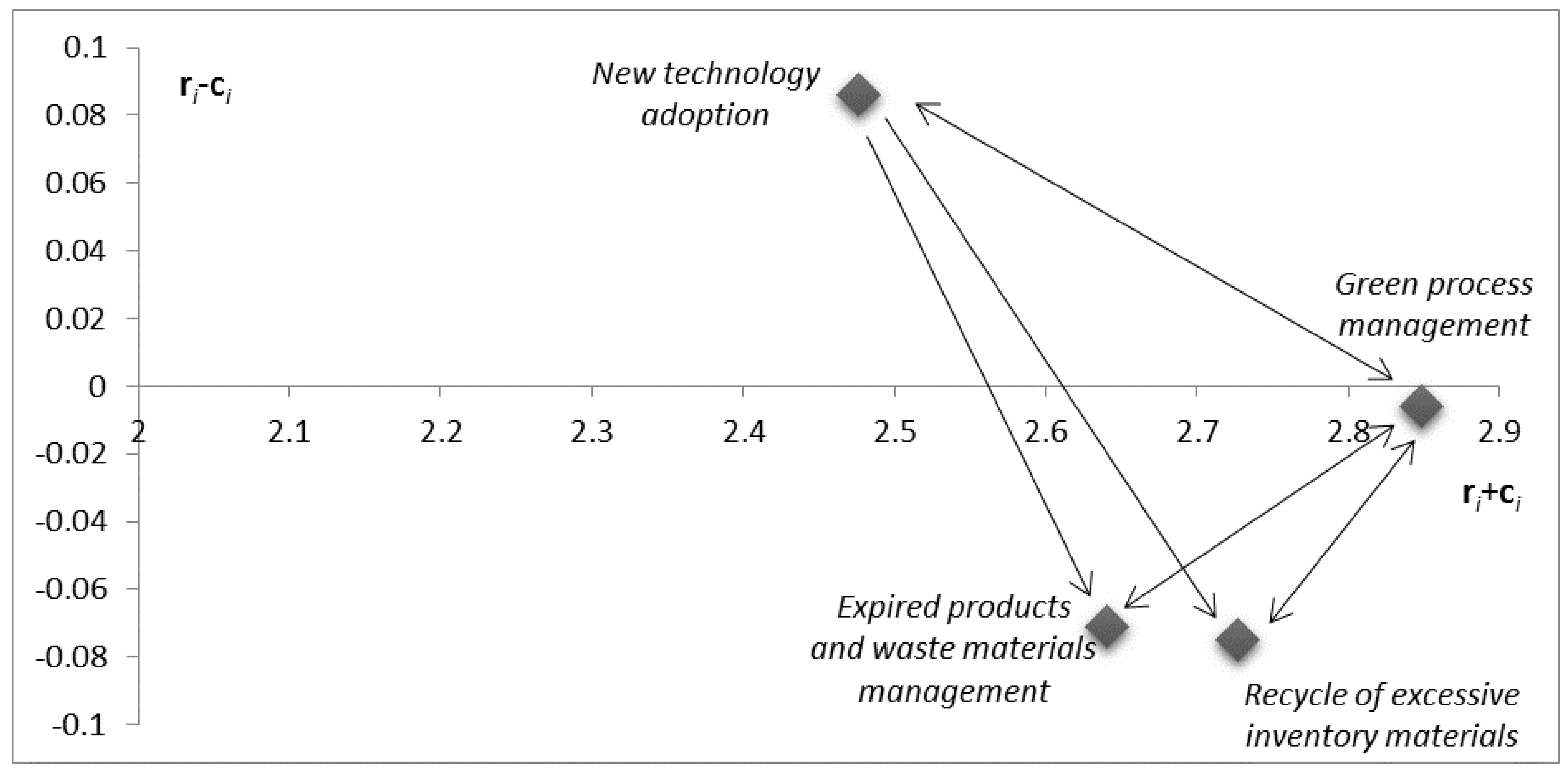

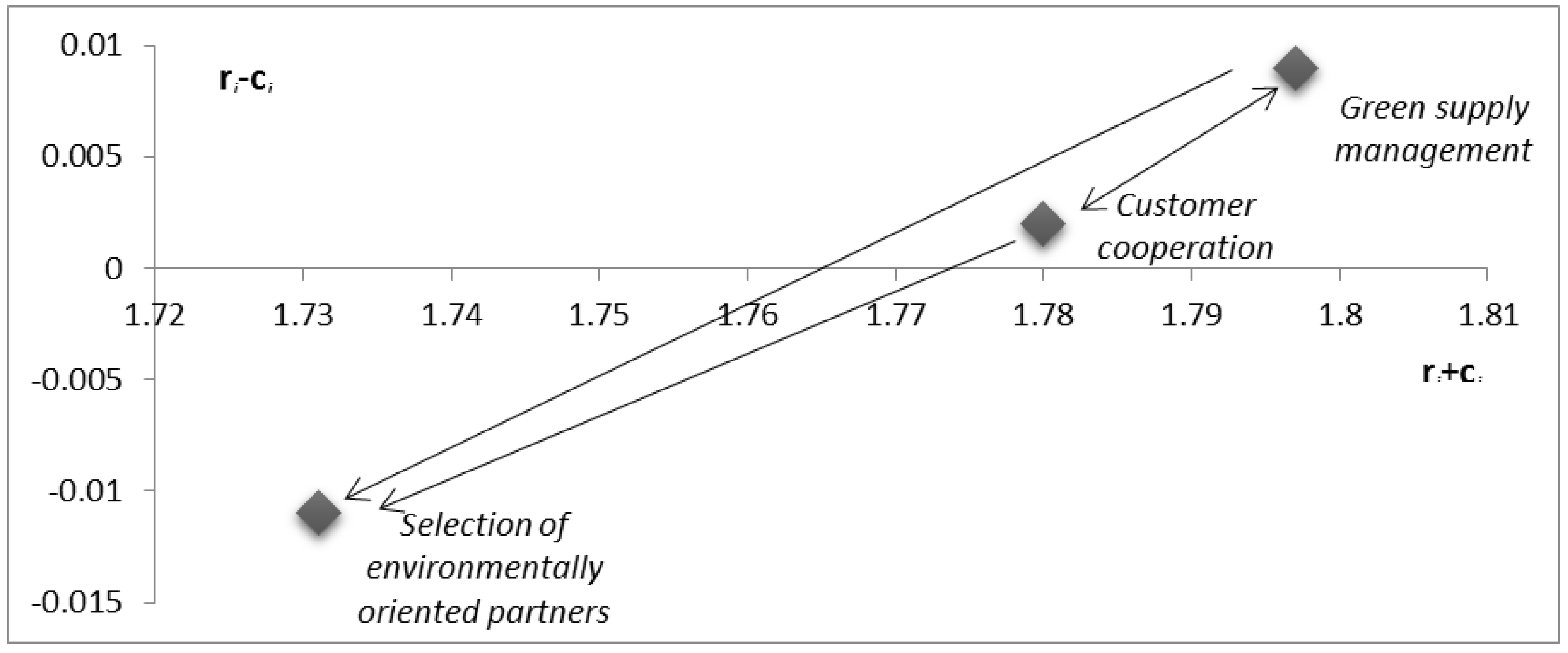

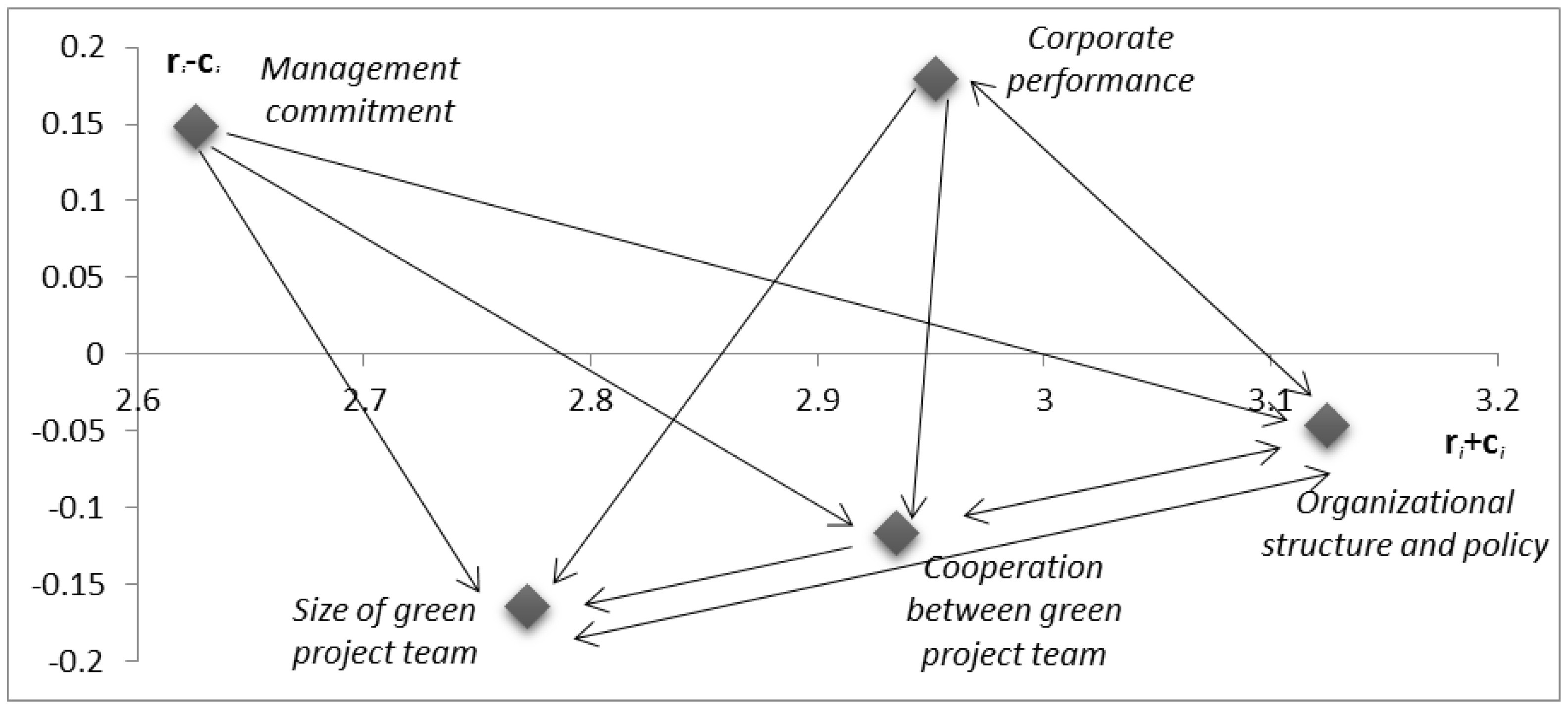

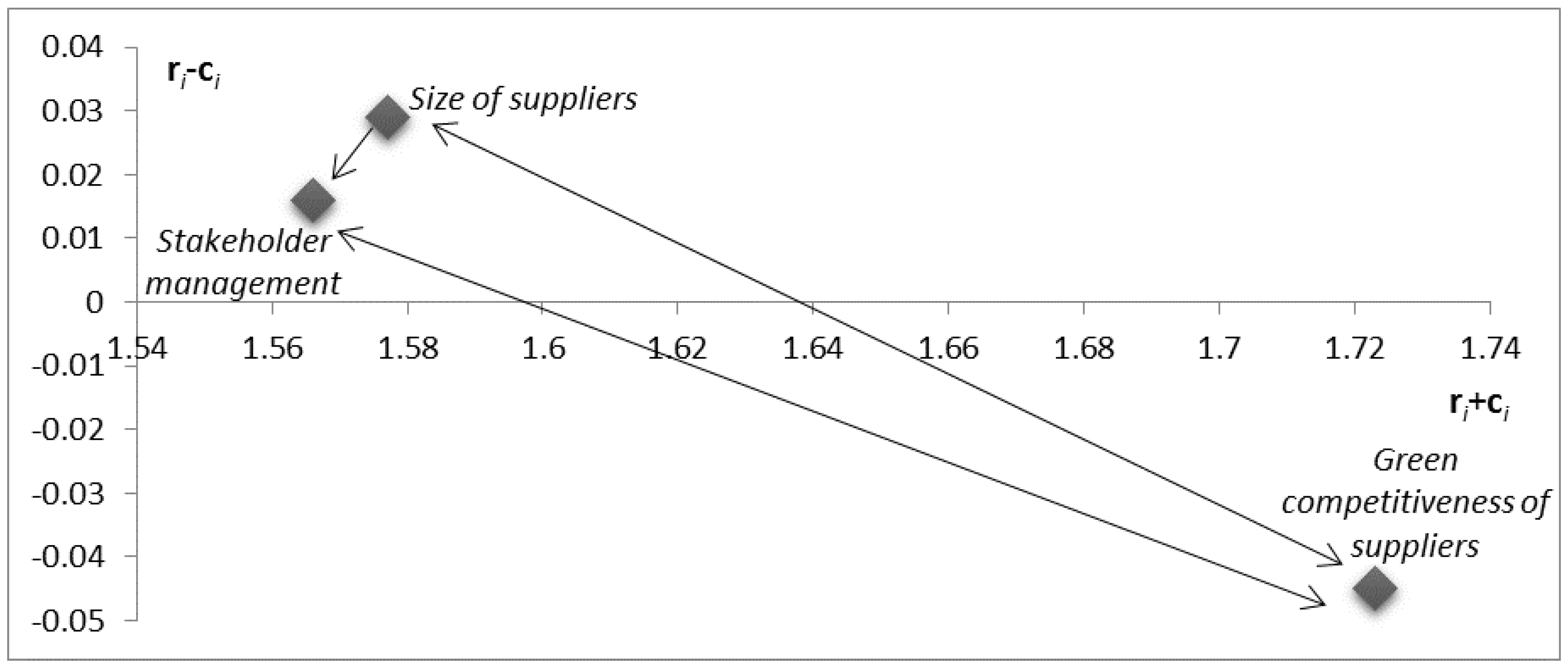

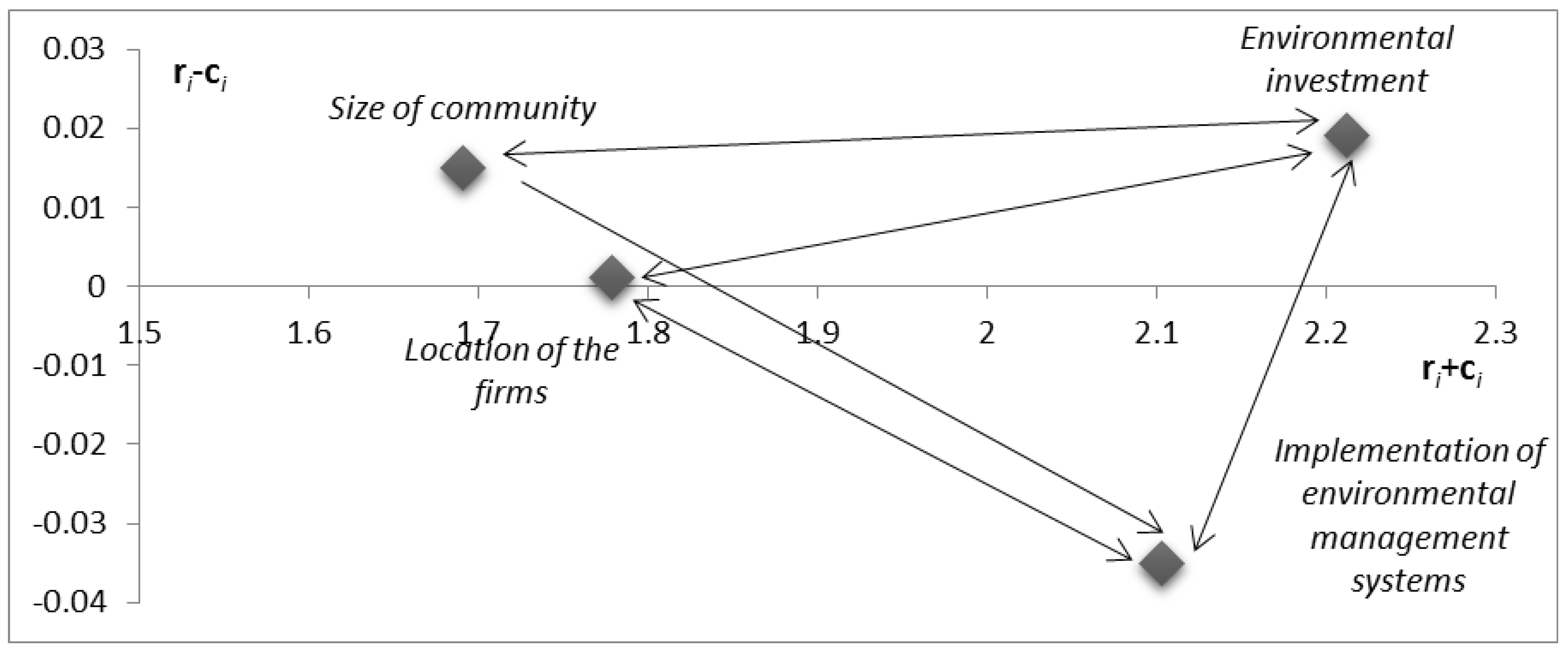

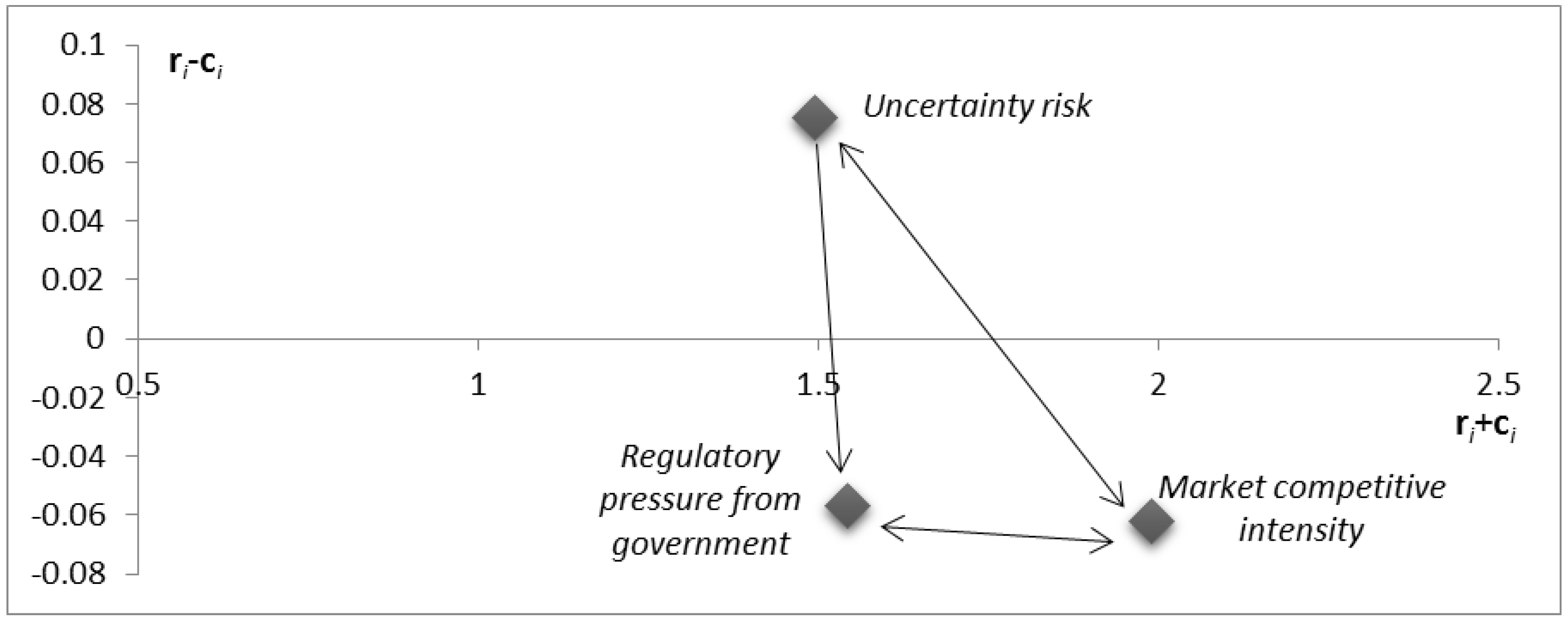

4.1.2. Interrelationships among Criteria of Dimensions in a Green Project Management

4.2. Results of the ANP Model

4.2.1. Comparisons of Six Dimensions in a Green Project Management

4.2.2. Comparisons of Criteria in a Green Project Management

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Example of DEMATEL Questionnaire

| Internal Process | External Process | Internal Organization | External Organization | Internal Environment | External Environment | |

| Internal process | 0 | |||||

| External process | 0 | |||||

| Internal organization | 0 | |||||

| External organization | 0 | |||||

| Internal environment | 0 | |||||

| External environment | 0 |

Appendix B. Example of ANP Questionnaire

| 9: 8: 7: 6: 5: 4: 3: 2: 1: 2: 3: 4: 5: 6: 7: 8: 9 | ||

| Internal process | External process | |

| Internal process | Internal organization | |

| Internal process | External organization | |

| Internal process | Internal environment | |

| Internal process | External environment | |

| External process | Internal organization | |

| External process | External organization | |

| External process | Internal environment | |

| External process | External environment | |

| Internal organization | External organization | |

| Internal organization | Internal environment | |

| Internal organization | External environment | |

| External organization | Internal environment | |

| External organization | External environment | |

| Internal environment | External environment |

References

- Albino, V.; Balice, A.; Dangelico, R.M. Environmental strategies and green product development: An overview on sustainability-driven companies. Bus. Strat. Environ. 2009, 18, 83–96. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Eth. 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Chan, R.Y.K.; He, H.; Chan, H.K.; Wang, W.Y.C. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Chung, Y.; Tsai, C. The effect of green design activities on new product strategies and performance: An empirical study among high-tech companies. Int. J. Manag. 2007, 24, 276–288. [Google Scholar]

- Maxwell, D.; Sheate, W.; van der Vorst, R. Functional and system aspects of the sustainable product and service development approach for industry. J. Clean. Prod. 2006, 14, 1466–1479. [Google Scholar] [CrossRef]

- Chrismann, P. Effect of best practices’ of environmental management on cost advantage: The role of complementary assets. Acad. Manag. J. 2000, 43, 663–680. [Google Scholar] [CrossRef]

- Orsato, R.J. Competitive environmental strategies: When does it pay to be green? Calif. Manag. Rev. 2006, 48, 127–143. [Google Scholar] [CrossRef]

- Pujari, D. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 2006, 26, 76–85. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Kjaerheim, G. Cleaner production and sustainability. J. Clean. Prod. 2005, 13, 329–339. [Google Scholar] [CrossRef]

- Florida, R.; Davison, D. Gaining from green management: environmental management systems inside and outside the factory. Calif. Manag. Rev. 2001, 43, 64–81. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R.; Tiwari, M.K. Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Comput. Ind. Eng. 2005, 48, 327–356. [Google Scholar] [CrossRef]

- Thoumy, M.; Vachon, S. Environmental projects and financial performance: Exploring the impact of project characteristics. Int. J. Prod. Econ. 2012, 140, 28–34. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Green project partnership in the supply chain: The case of the package printing industry. J. Clean. Prod. 2006, 14, 661–671. [Google Scholar] [CrossRef]

- Baines, T.; Brown, S.; Benedettini, O.; Ball, P. Examining green production and its role within the competitive strategy of manufacturers. J. Ind. Eng. Manag. 2012, 5, 53–87. [Google Scholar] [CrossRef]

- Geraldi, J.; Maylor, H.; Williams, T. Now, let’s make it really complex (complicated). Int. J. Oper. Prod. Manag. 2011, 20, 966–990. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. An exploratory investigation of the effects of supply chain complexity on delivery performance. IEEE Trans. Eng. Manag. 2002, 49, 218–230. [Google Scholar] [CrossRef]

- Rehman, M.A.; Seth, D.; Shrivastava, R.L. Impact of green manufacturing practices on organizational performance in Indian context: An empirical study. J. Clean. Prod. 2016, 137, 427–448. [Google Scholar] [CrossRef]

- Salem, A.H.; Deif, A.M. Developing greenometer for green manufacturing assessment. J. Clean. Prod. 2016, 154, 413–423. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lai, K.; Shangc, K.; Lud, C.; Leunge, T.K.P. Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance. Int. J. Prod. Econ. 2012, 140, 283–294. [Google Scholar] [CrossRef]

- Jonrinaldi, J.; Zhang, D.Z. An integrated production, inventory and transportation decision in a whole green manufacturing supply chain. Int. J. Ind. Syst. Eng. 2017, 25, 520–544. [Google Scholar]

- Fu, X.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs at a telecommunication systems providers. Int. J. Prod. Econ. 2012, 140, 357–367. [Google Scholar] [CrossRef]

- Klassen, R.D.; Whybark, D.C. Environmental management in operations: The selection of environmental technologies. Decis. Sci. 1999, 30, 601–631. [Google Scholar] [CrossRef]

- Chen, C. Design for the environment: A quality-based model for green production development. Manag. Sci. 2001, 47, 250–263. [Google Scholar] [CrossRef]

- Pil, F.K.; Rothenberg, S. Environmental performance as a driver of superior quality. Prod. Oper. Manag. 2003, 12, 404–415. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.Y.; Hsu, C.F.; Hung, H.C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Gavronski, I.; Klassen, R.D.; Vachon, S.; Nascimeto, L.F.M.D. A resource-based view of green supply management. Transp. Res. Part E 2011, 47, 872–885. [Google Scholar] [CrossRef]

- Sarkis, J. Evaluating environmentally conscious business practices. Eur. J. Oper. Res. 1998, 107, 159–174. [Google Scholar] [CrossRef]

- Hoeck, R.I.V. From inverse logistics to green supply chains. Logist. Solut. 2000, 2, 28–33. [Google Scholar]

- Kolk, A.; Pinkse, J. Business responses to climate change: Identifying emergent strategies. Calif. Manag. Rev. 2005, 47, 6–20. [Google Scholar] [CrossRef]

- Humphreys, P.; Mclvor, R.; Chan, F.T.S. Integrating environmental criteria into the supplier selection process. J. Mater. Process. Technol. 2003, 138, 349–356. [Google Scholar] [CrossRef]

- Shar, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar]

- Zhao, X.; Hwang, B.G.; Gao, Y. A fuzzy synthetic evaluation approach for risk assessment: A case of Singapore’s green projects. J. Clean. Prod. 2015, 115, 203–213. [Google Scholar] [CrossRef]

- Rostamzadeth, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Chiang, C.H.; Li, C.W. Evaluating intertwined effects in e-learning programs: A novel hybrid MCDM model based on factor analysis and MEMATEL. Expert Syst. Appl. 2007, 32, 1028–1044. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraaw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Yang, J.L.; Tzeng, G.H. An integrated MCDM technique combined with DEMATEL for a novel cluster-weighted with ANP method. Expert Syst. Appl. 2011, 38, 1417–1424. [Google Scholar] [CrossRef]

- Yang, Y.P.O.; Shieh, H.M.; Leu, J.D.; Tzeng, G.H. A novel hybrid MCDM model combined with DEMATEL and ANP with applications. Int. J. Oper. Res. 2008, 5, 160–168. [Google Scholar]

- Baviera-Puig, A.; Gómez-Navarro, T.; García-Melón, M.; García-Martínez, G. Assessing the Communication Quality of CSR Reports. A Case Study on Four Spanish Food Companies. Sustainability 2015, 7, 11010–11031. [Google Scholar] [CrossRef]

- Caballero-Luque, A.; Aragones-Beltran, P.; Garcia-Melon, M. Analysis of the Alignment of Company Goals to Web Content Using ANP. Int. J. Inf. Technol. Decis. Mak. 2010, 9, 419–436. [Google Scholar] [CrossRef]

- Pan, J.N.; Nguyen, H.T.N. Achieving Customer Satisfaction through Product-Service Systems. Eur. J. Oper. Res. 2015, 247, 179–190. [Google Scholar] [CrossRef]

| Process Construct |

| Internal process |

|

| External process |

|

| Organization Construct |

| Internal organization |

|

| External organization |

|

| Environment Construct |

| Internal environment |

|

| External environment |

|

| Dimensions | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| 1. Internal process | 0.258 | 0.277 | 0.253 | 0.245 | 0.235 | 0.209 |

| 2. External process | 0.286 | 0.295 | 0.281 | 0.274 | 0.256 | 0.224 |

| 3. Internal organization | 0.288 | 0.310 | 0.288 | 0.283 | 0.264 | 0.230 |

| 4. External organization | 0.288 | 0.313 | 0.291 | 0.270 | 0.269 | 0.231 |

| 5. Internal environment | 0.269 | 0.285 | 0.265 | 0.256 | 0.243 | 0.217 |

| 6. External environment | 0.243 | 0.230 | 0.239 | 0.231 | 0.228 | 0.187 |

| Dimension | ri + ci | ri − ci |

|---|---|---|

| 1. Internal process | 3.110 | −0.156 |

| 2. External process | 3.326 | −0.094 |

| 3. Internal organization | 3.279 | 0.045 |

| 4. External organization | 3.222 | 0.104 |

| 5. Internal environment | 3.029 | 0.041 |

| 6. External environment | 2.655 | 0.061 |

| Dimensions | Criteria | ri + ci | ri − ci |

|---|---|---|---|

| Internal process | Recycle of excessive inventory materials | 2.727 | −0.075 |

| Expired products and waste materials management | 2.641 | −0.071 | |

| Green process management | 2.848 | −0.006 | |

| Uncertainty of technology | 2.232 | 0.066 | |

| New technology adoption | 2.476 | 0.086 | |

| External process | Selection of environmentally oriented partners | 1.731 | −0.011 |

| Green supply management | 1.797 | 0.009 | |

| Customer cooperation | 1.780 | 0.002 | |

| Internal organization | Cooperation between green project team | 2.935 | −0.117 |

| Size of green project team | 2.772 | −0.164 | |

| Organizational structure and policy | 3.125 | −0.047 | |

| Management commitment | 2.626 | 0.148 | |

| Corporate performance | 2.952 | 0.180 | |

| External organization | Stakeholder management | 1.566 | 0.016 |

| Size of suppliers | 1.577 | 0.029 | |

| Green competitiveness of suppliers | 1.723 | −0.045 | |

| Internal environment | Environmental investment | 2.213 | 0.019 |

| Location of the firms | 1.779 | 0.001 | |

| Size of community | 1.691 | 0.015 | |

| Implementation of environmental management systems | 2.103 | −0.035 | |

| External environment | Market competitive intensity | 1.990 | −0.062 |

| Regulatory pressure from government | 1.543 | −0.057 | |

| Climate change | 0.942 | 0.044 | |

| Uncertainty risk | 1.497 | 0.075 |

| Dimension | Weight | Rank |

|---|---|---|

| External Process | 0.187 | 1 |

| Internal Process | 0.175 | 2 |

| External organization | 0.171 | 3 |

| Internal organization | 0.166 | 4 |

| Internal environment | 0.159 | 5 |

| External environment | 0.141 | 6 |

| Dimensions | Criteria | Weight | Rank |

|---|---|---|---|

| Internal process | Recycle of excessive inventory materials | 0.035 | 11 |

| Expired products and waste materials management | 0.034 | 14 | |

| Green process management | 0.036 | 10 | |

| Uncertainty of technology | 0.027 | 23 | |

| New technology adoption | 0.030 | 20 | |

| External process | Selection of environmentally oriented partners | 0.080 | 3 |

| Green supply management | 0.082 | 1 | |

| Customer cooperation | 0.081 | 2 | |

| Internal organization | Cooperation between green project team | 0.034 | 15 |

| Size of green project team | 0.033 | 16 | |

| Organizational structure and policy | 0.035 | 12 | |

| Management commitment | 0.028 | 22 | |

| Corporate performance | 0.031 | 18 | |

| External organization | Stakeholder management | 0.049 | 5 |

| Size of suppliers | 0.049 | 6 | |

| Green competitiveness of suppliers | 0.057 | 4 | |

| Internal environment | Environmental investment | 0.042 | 8 |

| Location of the firms | 0.033 | 17 | |

| Size of community | 0.031 | 19 | |

| Implementation of environmental management systems | 0.042 | 9 | |

| External environment | Market competitive intensity | 0.045 | 7 |

| Regulatory pressure from government | 0.035 | 13 | |

| Climate change | 0.019 | 24 | |

| Uncertainty risk | 0.030 | 21 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chou, Y.-C.; Yang, C.-H.; Lu, C.-H.; Dang, V.T.; Yang, P.-A. Building Criteria for Evaluating Green Project Management: An Integrated Approach of DEMATEL and ANP. Sustainability 2017, 9, 740. https://doi.org/10.3390/su9050740

Chou Y-C, Yang C-H, Lu C-H, Dang VT, Yang P-A. Building Criteria for Evaluating Green Project Management: An Integrated Approach of DEMATEL and ANP. Sustainability. 2017; 9(5):740. https://doi.org/10.3390/su9050740

Chicago/Turabian StyleChou, Ying-Chyi, Chia-Han Yang, Ching-Hua Lu, Van Thac Dang, and Pei-An Yang. 2017. "Building Criteria for Evaluating Green Project Management: An Integrated Approach of DEMATEL and ANP" Sustainability 9, no. 5: 740. https://doi.org/10.3390/su9050740