Green Shipping Practices of Shipping Firms

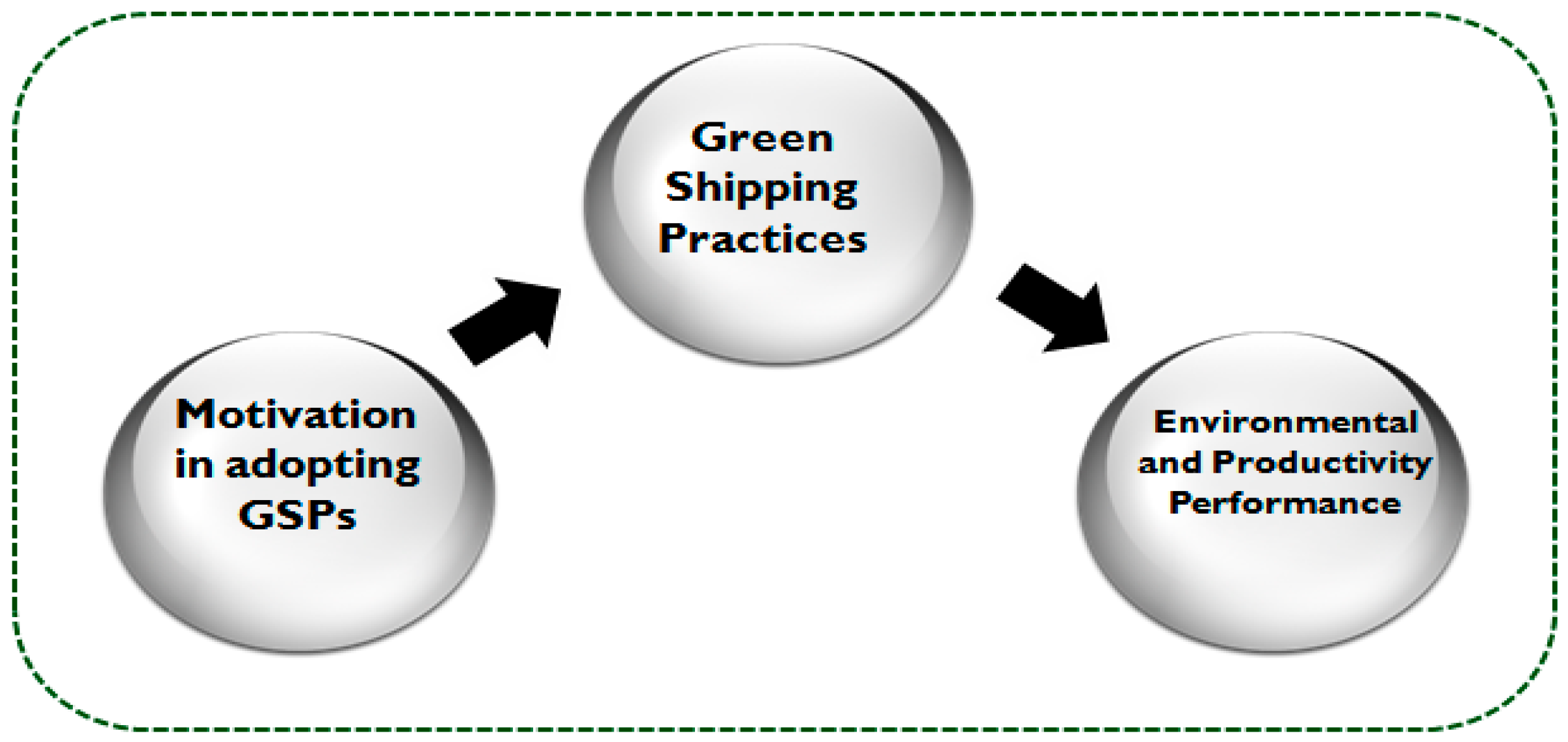

Abstract

:1. Introduction

2. Theoretical Foundation and Construct Development

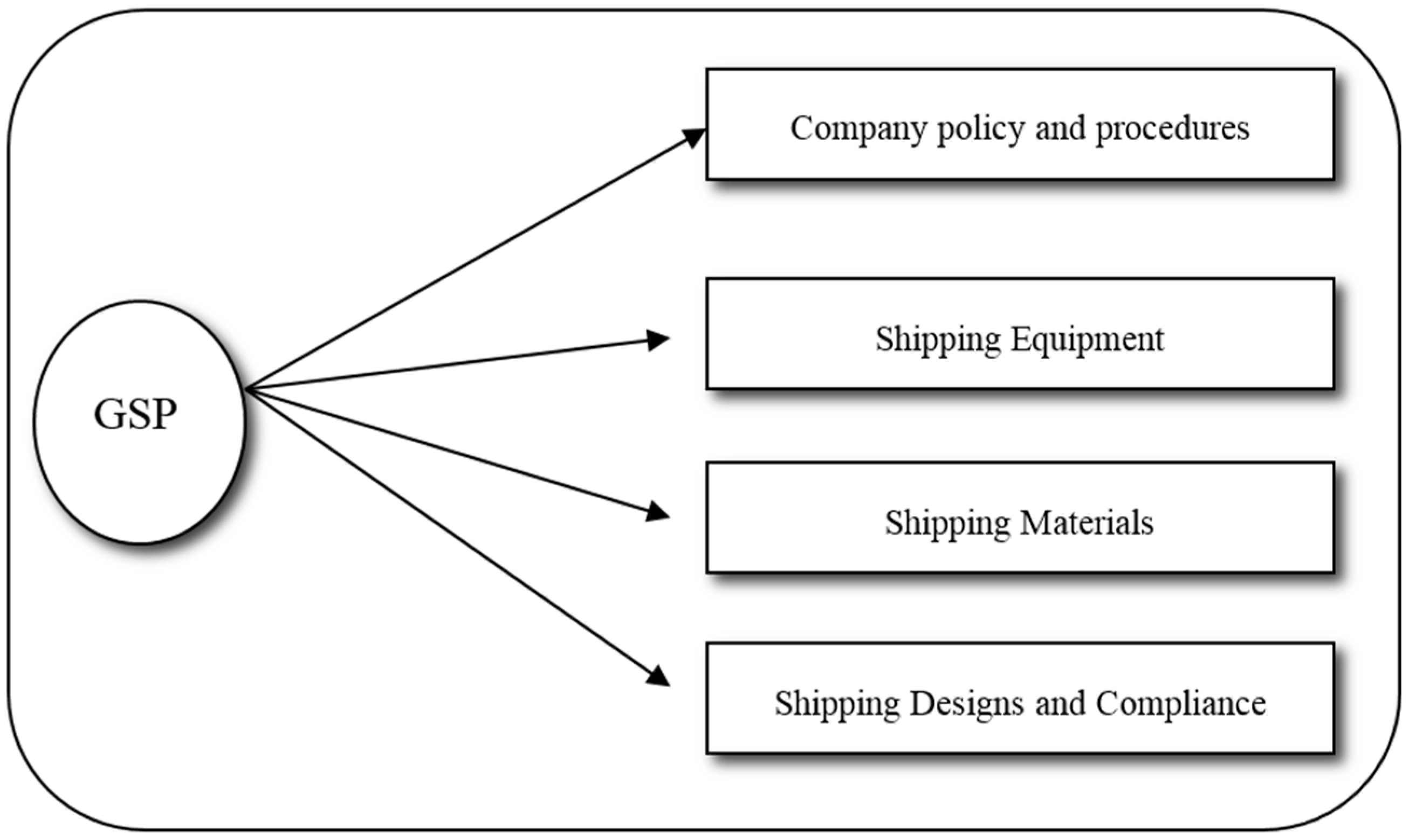

2.1. Conceptualizing Green Shipping Practices

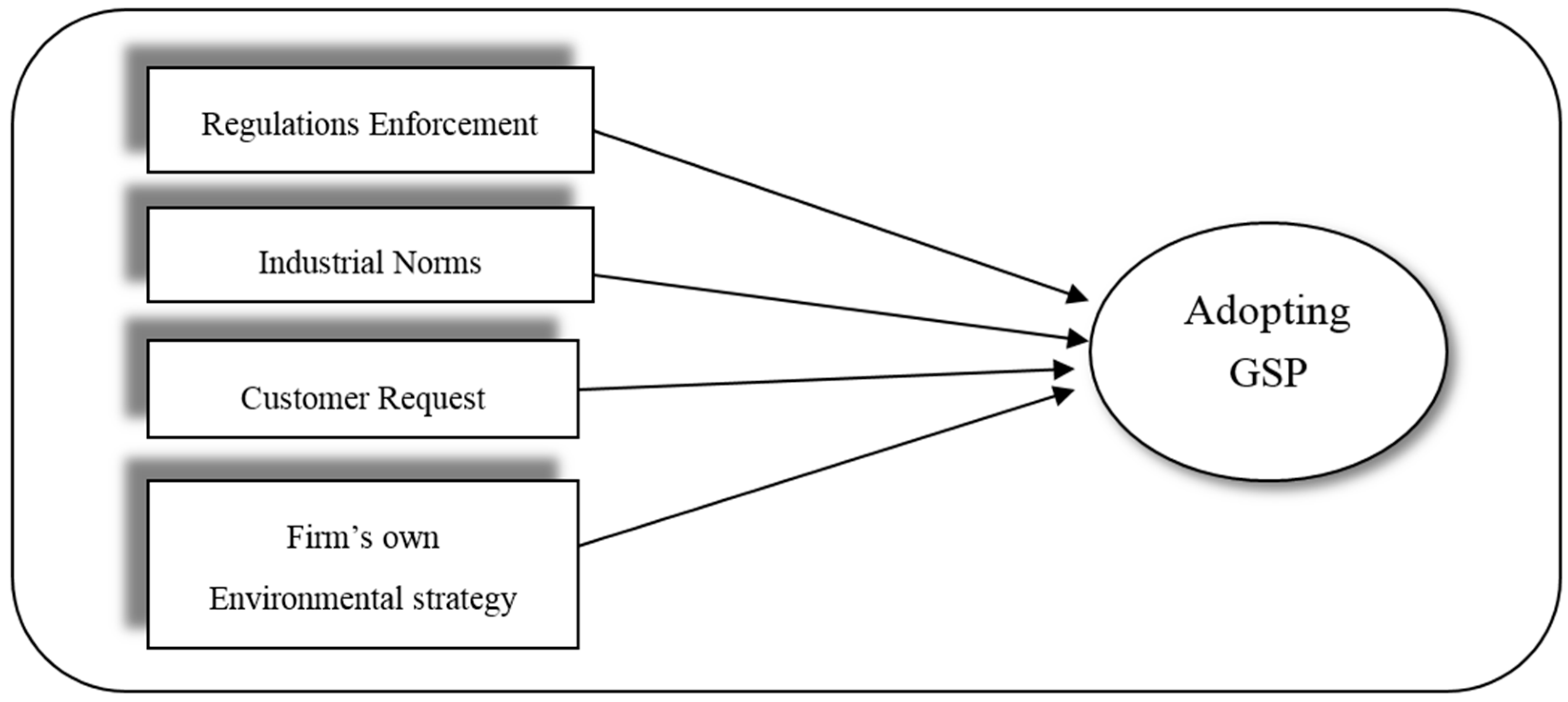

2.2. Drivers Influencing the Adoption of GSP

2.2.1. Government Regulation

2.2.2. Industrial Institutionalized Norms

2.2.3. Customer’s Environmental Demand

2.2.4. Firm’s Own Environmental Strategy

2.3. Productivity and Environmental Performance

3. Research Design and Data Collection

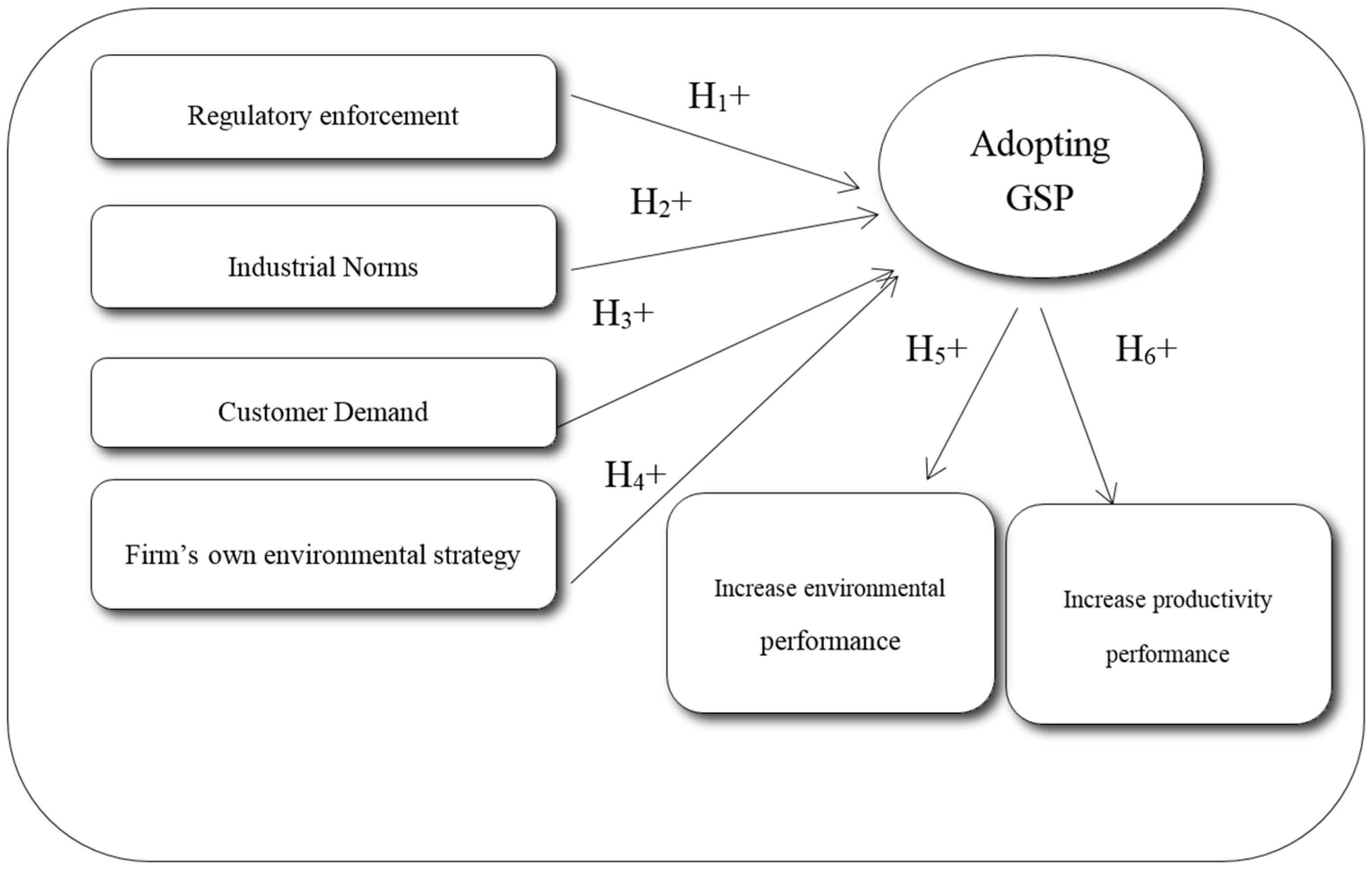

3.1. Research Hypothesis

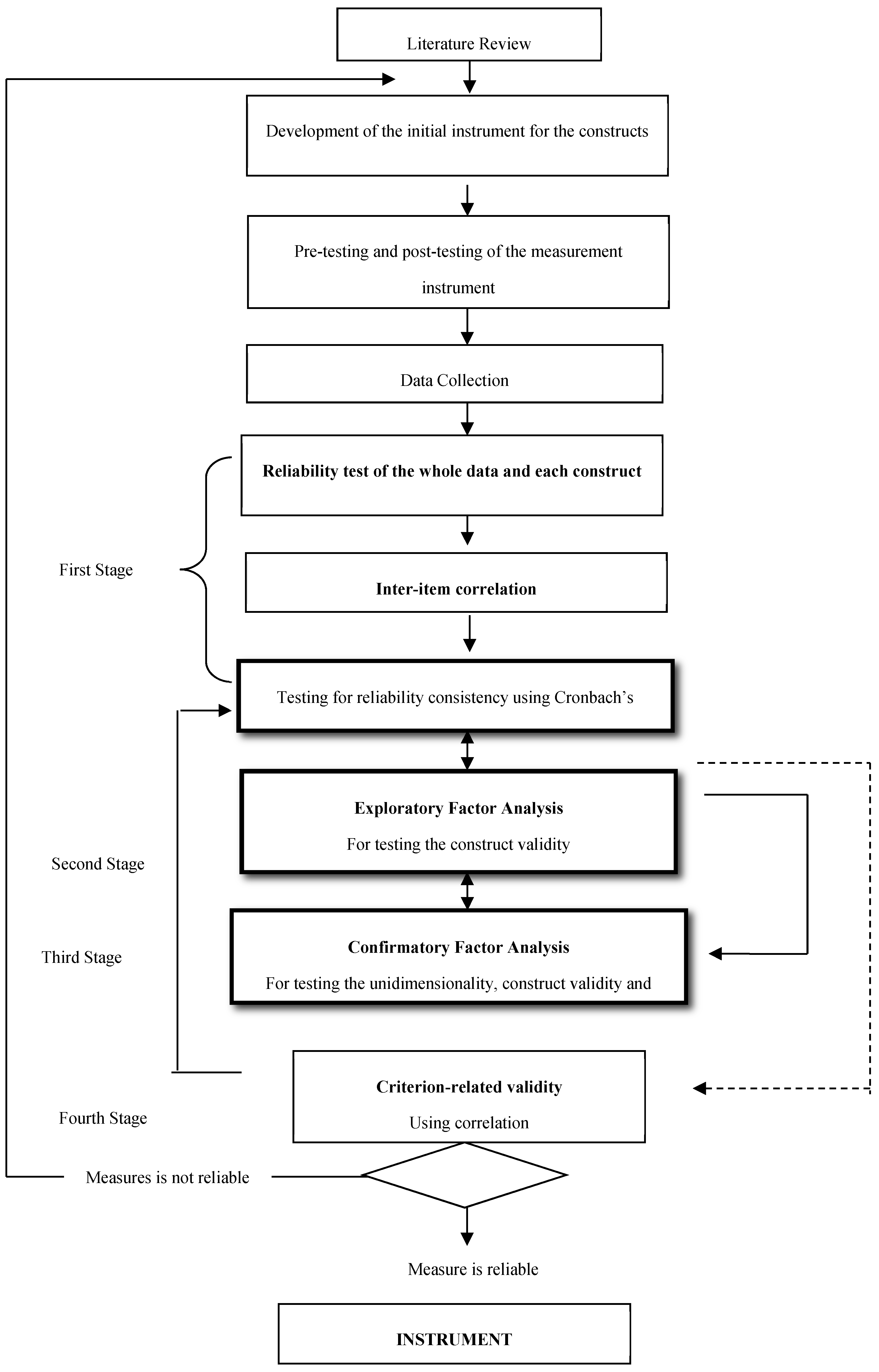

3.2. Instrument Development

3.3. Data Collection

3.3.1. The Sample

3.3.2. Non-Response Bias

4. Measurement Assessment and Result

4.1. Measurement Development and Assessment

4.1.1. Reliability Test and Inter-Item Correlation—First Stage

4.1.2. Exploratory Factor Analysis—Second Stage

4.1.3. Confirmatory Factor Analysis—Third stage

Unidimensionality

Construct Validity

4.1.4. Criterion-Related Validity—Fourth Stage

4.2. Results

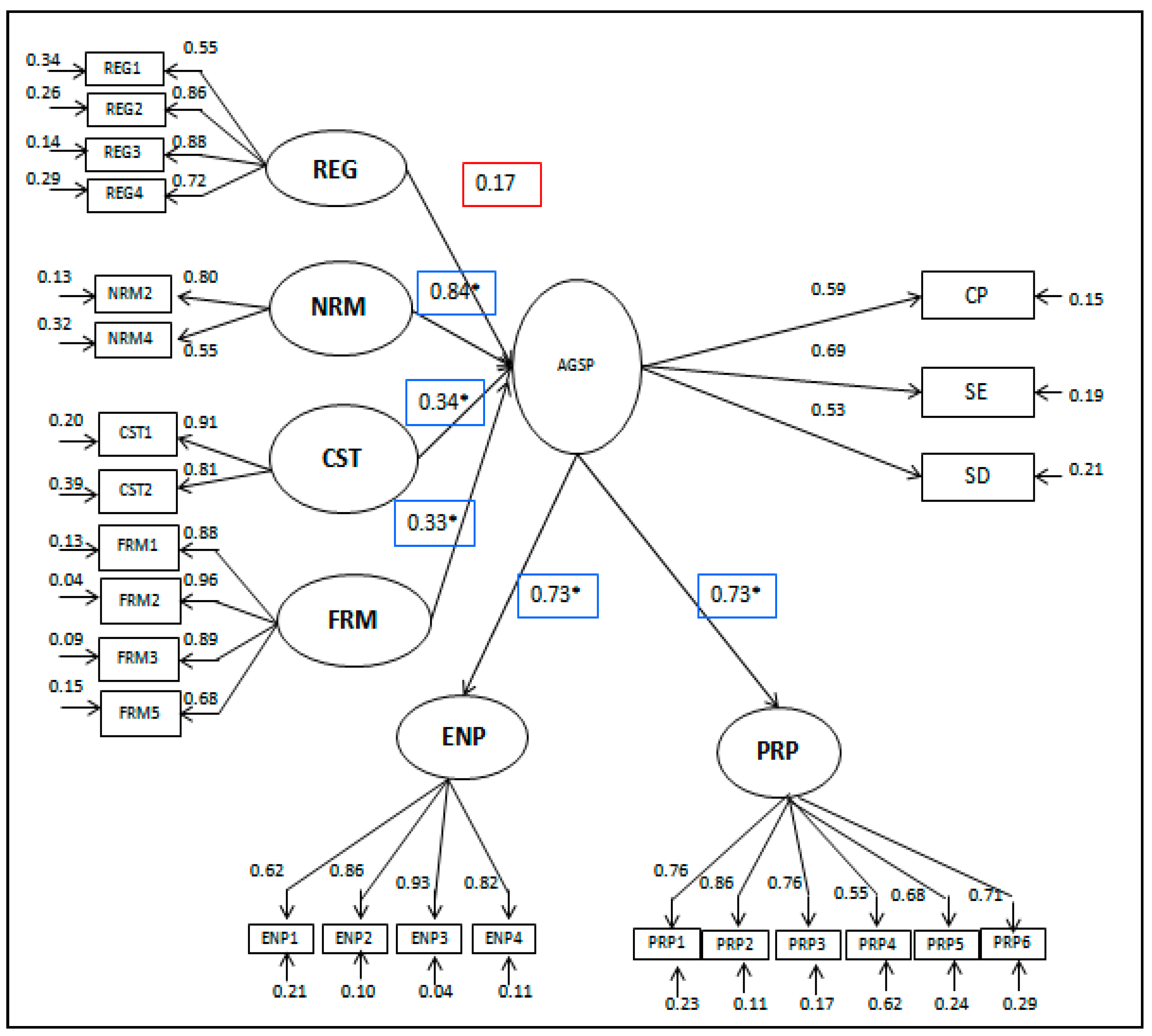

4.2.1. Structural Equation Model Results

4.2.2. Hierarchical Regression Results

4.2.3. Discussion and Implications of Results

5. Conclusions

Author Contributions

Conflicts of Interest

Appendix A

| Indicator (Cronbach’s Alpha; Eigen Value) | Principal Component Factor Loading | Measurement Model | ||||

|---|---|---|---|---|---|---|

| Standard Coefficient | R2 (0.30>) | t-Value | ||||

| Green Shipping Practices Measurement Model | ||||||

| Model fit | ||||||

| χ2 (<2) | 0.939 | |||||

| AGFI (>0.80) | 0.833 | |||||

| CFI (>0.90) | 1.000 | |||||

| TLI (>0.90) | 1.019 | |||||

| RMSEA (<0.1) | 0.000 | |||||

| Company policy and procedure (α = 0.75; eigen value = 1.76 ) | ||||||

| CP1 Our senior managers are committed to GSP | 0.741 | 0.709 | 0.503 | |||

| CP2 Our mid-level managers support GSP | 0.858 | 0.817 | 0.667 | 6.313 *** | ||

| CP3 Our company has a cross-functional cooperation for green practices | 0.731 | 0.818 | 0.668 | 6.166 *** | ||

| CP4 Our company has environmental compliance and auditing programs | 0.549 | 0.680 | 0.463 | 5.359 *** | ||

| CP7 Our company offers an End to End EDI solutions. | 0.522 | 0.338 | 0.114 | 2.672 ** | ||

| CP5 Our company has ISO 14001 certification b | ||||||

| CP6 Our company has a strong environmental policy b | ||||||

| Shipping equipment (α = 0.84; eigen value = 5.56) | ||||||

| SE2 In our company there is a cooperation with equipment suppliers about environmental objectives | 0.776 | 0.672 | 0.452 | |||

| SE3 Our company performs an environmental auditing of suppliers’ internal management | 0.820 | 0.706 | 0.498 | 5.377 *** | ||

| SE4 Our suppliers have ISO 14001 certification | 0.755 | 0.712 | 0.507 | 5.276 *** | ||

| SE5 Our company’s refrigerated containers no longer use chlorofluorocarbon (CFC). Instead we are now using more environmentally friendly types of refrigerants | 0.469 | 0.437 | 0.191 | 3.273 ** | ||

| SE6 Our company works with our customers on eco-design in cargo handling and shipments | 0.741 | 0.848 | 0.718 | 5.702 *** | ||

| SE7 Our company involves our customers in cleaner delivery for example we enforce programs for recycling, vehicle idling, packing waste collection and using green packing materials | 0.625 | 0.769 | 0.591 | 5.503 *** | ||

| SE1 Our company reuses shipping equipment b | ||||||

| Shipping Materials a | ||||||

| SM1 Our company sells our excess equipment and facilities a | ||||||

| SM2 Our company sells the used shipping materials such as packaging and cartons and collection of used oil a | ||||||

| Shipping design and compliance (α = 0.71; eigen value = 1.217 ) | ||||||

| SD1 The design of our shipping activities and equipment helps our company reduce consumption of materials and energy | 0.673 | 0.665 | 0.442 | |||

| SD2 The design of our shipping activities is for reuse, recycling and recovery of materials | 0.740 | 0.603 | 0.364 | 3.925 *** | ||

| SD3 The design of our equipment avoid or reduce the use of polluting energy | 0.817 | 0.755 | 0.570 | 4.478 *** | ||

| Reasons for adopting green shipping practices measurement model | ||||||

| χ2 | 1.162 | |||||

| AGFI | 0.835 | |||||

| CFI | 0.983 | |||||

| TLI | 0.972 | |||||

| RMSEA | 0.046 | |||||

| Strong enforcement of environmental regulations (α = 0.84; eigen value = 2.40) | ||||||

| REG1 Mandated by the International Law | 0.710 | 0.573 | 0.328 | |||

| REG2 Our service products are sold to countries with specific environmental laws | 0.863 | 0.835 | 0.698 | 4.961 *** | ||

| REG3 Environmental regulations governing our service product are very strict | 0.880 | 0.892 | 0.795 | 5.096 *** | ||

| REG4 Our shipping services are controlled by regulations that limit the emission of air pollutants | 0.745 | 0.727 | 0.529 | 4.513 *** | ||

| REG5 We comply with regulations that limit the disposal waste b | ||||||

| REG6 Our products comply with environmental regulations of many countries b | ||||||

| Industrial Norms (α = 0.60; eigen value = 0.851) | ||||||

| NRM2 Our operation is based on shipping and environmental code of practice | 0.657 | 0.837 | 0.701 | |||

| NRM4 Because we like to increase the corporate social responsibility of the company | 0.885 | 0.525 | 0.275 | 3.080 ** | ||

| NRM1 We are recommended to practice GSP by industrial association b | ||||||

| NRM3 Because other shipping companies are adopting it a | ||||||

| Strong customer demand (α = 0.84; eigen value = 1.58 ) | ||||||

| CST1 Our customers require us to have ISO 14001 certification | 0.933 | 0.643 | 0.413 | |||

| CST2 Our customer carry out environmental audits of our firm | 0.832 | 1.152 | 1.327 | 3.199 ** | ||

| Firm’s own environmental strategy (α = 0.91; eigen value = 4.59 ) | ||||||

| FRM1 We like to gain a loyalty from the customers | 0.850 | 0.889 | 0.791 | |||

| FRM2 We like to attract potential customers | 0.937 | 0.962 | 0.925 | 13.329 *** | ||

| FRM3 We like to gain competitive advantage over competitors | 0.937 | 0.888 | 0.789 | 11.099 *** | ||

| FRM5 We like to improve firm’s own image | 0.720 | 0.687 | 0.472 | 7.009 *** | ||

| FRM4 We like to strengthen international trade partnerships b | ||||||

| Result in adopting green shipping practices measurement model | ||||||

| χ2 | 2.171 | |||||

| AGFI | 0.770 | |||||

| CFI | 0.917 | |||||

| TLI | 0.866 | |||||

| RMSEA | 0.125 | |||||

| Environmental performance (α = 0.90; eigen value = 5.75 ) | ||||||

| ENP1We reduced our carbon emission | 0.781 | 0.651 | 0.424 | |||

| ENP2 We reduced our waste water | 0.881 | 0.886 | 0.785 | 6.345 *** | ||

| ENP3 We reduced our solid waste | 0.888 | 0.955 | 0.911 | 6.449 *** | ||

| ENP4 We reduced consumption of hazardous materials | 0.810 | 0.848 | 0.719 | 6.091 *** | ||

| ENP5 We reduced frequency of environmental accidents b | ||||||

| Productivity performance (α = 0.88; eigen value = 1.42) | ||||||

| PRP1 We significantly improved our product quality | 0.673 | 0.797 | 0.635 | |||

| PRP2 We improved our position in marketplace | 0.818 | 0.906 | 0.821 | 8.458 *** | ||

| PRP3 We reduced our waste operation | 0.677 | 0.789 | 0.622 | 7.229 *** | ||

| PRP4 We significantly reduced overall costs | 0.839 | 0.602 | 0.363 | 5.190 *** | ||

| PRP5 It helped enhance the reputation of our company | 0.732 | 0.724 | 0.524 | 6.412 *** | ||

| PRP6 It improved our operation in international market | 0.671 | 0.737 | 0.543 | 6.636 *** | ||

| Green shipping practices measurement model (second order CFA) | ||||||

| CP Company policy and procedure | 0.820 | 0.673 | ||||

| SE Shipping equipment | 0.754 | 0.568 | ||||

| SD Shipping design and compliance | 0.819 | 0.671 | ||||

References

- Lam, J.S.L.; Lai, K. Developing Environmental Sustainability by ANP-QFD Approach: The Case of Shipping Operations. J. Clean. Prod. 2015, 105, 275–284. [Google Scholar] [CrossRef]

- Venus Lun, Y.H.; Lai, K.; Wong, C.W.Y.; Cheng, T.C.E. Environmental Governance Mechanisms in Shipping Firms and their Environmental Performance. Transp. Res. Part E 2015, 78, 82–92. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Lai, K.; Venus Lun, Y.H.; Wong, C.W.Y. Green Shipping Management. Transp. Res. Part E 2013, 55, 1–2. [Google Scholar] [CrossRef]

- Lai, K.; Lun, V.Y.H.; Wong, C.W.Y.; Cheng, T.C.E. Green Shipping Practices in the Shipping Industry: Conceptualization, Adoption, and Implications. Resour. Conserv. Recycl. 2011, 55, 631–638. [Google Scholar] [CrossRef]

- Kim, H.; Chang, Y.; Kim, K.; Kim, H. An Epsilon-Optimal Algorithm Considering Greenhouse Gas Emissions for the Management of a Ship’s Bunker Fuel. Transp. Res. Part D 2012, 17, 97–103. [Google Scholar] [CrossRef]

- Corbett, J.J.; Wang, H.; Winebrake, J.J. The Effectiveness and Costs of Speed Reductions on Emissions from International Shipping. Transp. Res. Part D 2009, 14, 593–598. [Google Scholar] [CrossRef]

- Cariou, P. Is Slow Steaming a Sustainable Means of Reducing CO2 Emissions from Container Shipping? Transp. Res. Part D 2011, 16, 260–264. [Google Scholar] [CrossRef]

- Psaraftis, H.N.; Kontovas, C.A. Balancing the Economic and Environmental Performance of Maritime Transportation. Transp. Res. Part D 2010, 15, 458–462. [Google Scholar] [CrossRef]

- Lindstad, H.; Sandaas, I.; Strømman, A.H. Assessment of Cost as a Function of Abatement Options in Maritime Emission Control Areas. Transp. Res. Part D 2015, 38, 41–48. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Lee, H.; Aluko, O. Multi-Objective Decision Support to Enhance Environmental Sustainability in Maritime Shipping: A Review and Future Directions. Transp. Res. Part E 2015, 78, 3–18. [Google Scholar] [CrossRef]

- Mander, S. Slow Steaming and a New Dawn for Wind Propulsion: A Multi-Level Analysis of Two Low Carbon Shipping Transitions. Mar. Policy 2017, 75, 210–216. [Google Scholar] [CrossRef]

- Ren, J.; Lützen, M. Selection of Sustainable Alternative Energy Source for Shipping: Multi-Criteria Decision Making Under Incomplete Information. Renew. Sustain. Energy Rev. 2017, 74, 1003–1019. [Google Scholar] [CrossRef]

- Lister, J.; Poulsen, R.T.; Ponte, S. Orchestrating Transnational Environmental Governance in Maritime Shipping. Glob. Environ. Chang. 2015, 34, 185–195. [Google Scholar] [CrossRef]

- Van Leeuwen, J. The Regionalization of Maritime Governance: Towards a Polycentric Governance System for Sustainable Shipping in the European Union. Ocean Coast. Manag. 2015, 117, 23–31. [Google Scholar] [CrossRef]

- Sihn, W.; Pascher, H.; Ott, K.; Stein, S.; Schumacher, A.; Mascolo, G. A Green and Economic Future of Inland Waterway Shipping. Procedia CIRP 2015, 29, 317–322. [Google Scholar] [CrossRef]

- Boscarato, I.; Hickey, N.; Kašpar, J.; Prati, M.V.; Mariani, A. Green Shipping: Marine Engine Pollution Abatement using a Combined Catalyst/Seawater Scrubber System. 1. Effect of Catalyst. J. Catal. 2015, 328, 248–257. [Google Scholar] [CrossRef]

- Bell, M.G.H.; Meng, Q. Special Issue in Transportation Research Part B—Shipping, Port and Maritime Logistics. Transp. Res. Part B 2016, 93, 697–699. [Google Scholar] [CrossRef]

- Schøyen, H.; Bråthen, S. Measuring and Improving Operational Energy Efficiency in Short Sea Container Shipping. Res. Transp. Bus. Manag. 2015, 17, 26–35. [Google Scholar] [CrossRef]

- Howell, K.E.; Bhattacharya, S. Functional and Territorial Jurisdictions: Regulating a Globalized Shipping Industry. J. Transp. Geogr. 2016, 55, 92–100. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Sroufe, R.P.; Calantone, R. Assessing the Impact of Environmental Management Systems on Corporate and Environmental Performance. J. Oper. Manag. 2003, 21, 329–351. [Google Scholar] [CrossRef]

- Krozer, J.; Mass, K.; Kothuis, B. Demonstration of Environmentally Sound and Cost-Effective Shipping. J. Clean. Prod. 2003, 11, 767–777. [Google Scholar] [CrossRef]

- Nakata, T.; Lamont, A. Analysis of the Impacts of Carbon Taxes on Energy Systems in Japan. Energy Policy 2001, 29, 159–166. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Sakakibara, S. The Impact of Quality Management Practices on Performance and Competitive Advantage. Decis. Sci. 1995, 26, 659–691. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between Operational Practices and Performance among Early Adopters of Green Supply Chain Management Practices in Chinese Manufacturing Enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Bansal, P.; Roth, K. Why Companies Go Green: A Model of Ecological Responsiveness. Acad. Manag. J. 2000, 43, 717–736. [Google Scholar] [CrossRef]

- Björklund, M. Influence from the Business Environment on Environmental purchasing—Drivers and Hinders of Purchasing Green Transportation Services. J. Purch. Supply Manag. 2011, 17, 11–22. [Google Scholar] [CrossRef]

- Walton, S.V.; Handfield, R.B.; Melnyk, S.A. The Green Supply Chain: Integrating Suppliers into Environmental Management Processes. J. Supply Chain Manag. 1998, 34, 2–11. [Google Scholar] [CrossRef]

- Fryxell, G.E.; Szeto, A. The Influence of Motivations for Seeking ISO 14001 Certification: An Empirical Study of ISO 14001 Certified Facilities in Hong Kong. J. Environ. Manag. 2002, 65, 223–238. [Google Scholar] [CrossRef]

- Suchman, M.C. Managing Legitimacy: Strategic and Institutional Approaches. Acad. Manag. Rev. 1995, 20, 571–610. [Google Scholar]

- Carter, C.R.; Carter, J.R. Interorganizational Determinants of Environmental Purchasing: Initial Evidence from the Consumer Products Industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, J.; Fan, Z.; Yuan, Z.; Ge, J. Eco-Efficiency Analysis of Industrial System in China: A Data Envelopment Analysis Approach. Ecol. Econ. 2008, 68, 306–316. [Google Scholar] [CrossRef]

- Berry, M.A.; Rondinelli, D.A. Proactive Corporate Environmental Management: A New Industrial Revolution. Acad. Manag. Executive 1998, 12, 38–50. [Google Scholar] [CrossRef]

- Quazi, H.A.; Khoo, Y.; Tan, C.; Wong, P. Motivation for ISO 14000 Certification: Development of a Predictive Model. Omega 2001, 29, 525–542. [Google Scholar] [CrossRef]

- Chavan, M. An Appraisal of Environment Management Systems: A Competitive Advantage for Small Businesses. Manag. Environ. Qual. Int. J. 2005, 16, 444–463. [Google Scholar] [CrossRef]

- Montabon, F.; Sroufe, R.; Narasimhan, R. An Examination of Corporate Reporting, Environmental Management Practices and Firm Performance. J. Oper. Manag. 2007, 25, 998–1014. [Google Scholar] [CrossRef]

- Yuen, K.F.; Lim, J.M. Barriers to the Implementation of Strategic Corporate Social Responsibility in Shipping. Asian J. Shipp. Logist. 2016, 32, 49–57. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do Green Supply Chains Lead to Competitiveness and Economic Performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Klassen, R.D.; McLaughlin, C.P. The Impact of Environmental Management on Firm Performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Yang, C.; Lu, C.; Haider, J.J.; Marlow, P.B. The Effect of Green Supply Chain Management on Green Performance and Firm Competitiveness in the Context of Container Shipping in Taiwan. Transp. Res. Part E 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Lai, K.; Wong, C.W.Y. Green Logistics Management and Performance: Some Empirical Evidence from Chinese Manufacturing Exporters. Omega 2012, 40, 267–282. [Google Scholar] [CrossRef]

- Russo, M.V.; Fouts, P.A. A Resource-Based Perspective on Corporate Environmental Performance and Profitability. Acad. Manag. J. 1997, 40, 534–559. [Google Scholar] [CrossRef]

- Claver, E.; Lopez, M.D.; Molina, J.F.; Tarí, J.J. Environmental Management and Firm Performance: A Case Study. J. Environ. Manag. 2007, 84, 606–619. [Google Scholar] [CrossRef] [PubMed]

- De Burgos Jimenez, J.; Céspedes Lorente, J.J. Environmental Performance as an Operations Objective. Int. J. Oper. Prod. Manag. 2001, 21, 1553–1572. [Google Scholar] [CrossRef]

- Guimaraes, T.; Liska, K. Exploring the Business Benefits of Environmental Stewardship. Bus. Strategy Environ. 1995, 4, 9–22. [Google Scholar] [CrossRef]

- Shrivastava, P. Environmental Technologies and Competitive Advantage. Strateg. Manag. J. 1995, 16, 183–200. [Google Scholar] [CrossRef]

- Geffen, C.A.; Rothenberg, S. Suppliers and Environmental Innovation: The Automotive Paint Process. Int. J. Oper. Prod. Manag. 2000, 20, 166–186. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a Theory of Supply Chain Management: The Constructs and Measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Sakakibara, S. A Framework for Quality Management Research and an Associated Measurement Instrument. J. Oper. Manag. 1994, 11, 339–366. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory; McGraw Hill: New York, NY, USA, 1967. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis 6th Edition. Pearson Prentice Hall.New Jersey.humans: Critique and reformulation. J. Abnorm. Psychol. 2006, 87, 49–74. [Google Scholar]

- Garver, M.S.; Mentzer, J.T. Logistics Research Methods: Employing Structural Equation Modeling to Test for Construct Validity. J. Bus. Logist. 1999, 20, 33–57. [Google Scholar]

- Churchill, G.A.; Iacobucci, D. Marketing Research: Methodological Foundations; Dryden Press: New York, NY, USA, 2006. [Google Scholar]

- Jöreskog, K.G. A General Approach to Confirmatory Maximum Likelihood Factor Analysis. ETS Res. Rep. Ser. 1967, 1967, 183–202. [Google Scholar] [CrossRef]

- Campbell, D.T.; Fiske, D.W. Convergent and Discriminant Validation by the Multitrait-Multimethod Matrix. Psychol. Bull. 1959, 56, 81. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Marlow, P.B.; Lu, C. Assessing Resources, Logistics Service Capabilities, Innovation Capabilities and the Performance of Container Shipping Services in Taiwan. Int. J. Prod. Econ. 2009, 122, 4–20. [Google Scholar] [CrossRef]

- Carr, A.S.; Pearson, J.N. Strategically Managed Buyer—Supplier Relationships and Performance Outcomes. J. Oper. Manag. 1999, 17, 497–519. [Google Scholar] [CrossRef]

- Dunn, S.C.; Seaker, R.F.; Waller, M.A. Latent Variables in Business Logistics Research: Scale Development and Validation. J. Bus. Logist. 1994, 15, 145. [Google Scholar]

- Nahm, A.Y.; Vonderembse, M.A.; Koufteros, X.A. The Impact of Organizational Structure on Time-Based Manufacturing and Plant Performance. J. Oper. Manag. 2003, 21, 281–306. [Google Scholar] [CrossRef]

- Shah, R.; Goldstein, S.M. Use of Structural Equation Modeling in Operations Management Research: Looking Back and Forward. J. Oper. Manag. 2006, 24, 148–169. [Google Scholar] [CrossRef]

- Marsh, H.W. Pairwise Deletion for Missing Data in Structural Equation Models: Nonpositive Definite Matrices, Parameter Estimates, Goodness of Fit, and Adjusted Sample Sizes. Struct. Equ. Model. Multidiscip. J. 1998, 5, 22–36. [Google Scholar] [CrossRef]

- Bollen, K. Structural Equations with Latent Variables; JohnWiley & Sons: New York, NY, USA, 1989; Volume 29. [Google Scholar]

- Li, Y.; Liu, Y.; Liu, H. Co-Opetition, Distributor’s Entrepreneurial Orientation and Manufacturer’s Knowledge Acquisition: Evidence from China. J. Oper. Manag. 2011, 29, 128–142. [Google Scholar] [CrossRef]

- Dröge, C.; Claycomb, C.; Germain, R. Does Knowledge Mediate the Effect of Context on Performance? Some Initial Evidence. Decis. Sci. 2003, 34, 541–568. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, J.; Yuan, Z.; Ge, J.; Liu, B.; Bu, M. Why do Firms Engage in Environmental Management? An Empirical Study in China. J. Clean. Prod. 2008, 16, 1036–1045. [Google Scholar] [CrossRef]

- Porter, M.E.; Van der Linde, C. Green and Competitive: Ending the Stalemate. Harv. Bus. Rev. 1995, 73, 120–134. [Google Scholar]

- Lun, Y.H.V.; Lai, K.; Wong, C.W.Y.; Cheng, T.C.E. Greening and Performance Relativity: An Application in the Shipping Industry. Comput. Oper. Res. 2015, 54, 295–301. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Ponte, S.; Lister, J. Buyer-Driven Greening? Cargo-Owners and Environmental Upgrading in Maritime Shipping. Geoforum 2016, 68, 57–68. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Johnson, H. The Logic of Business vs. the Logic of Energy Management Practice: Understanding the Choices and Effects of Energy Consumption Monitoring Systems in Shipping Companies. J. Clean. Prod. 2016, 112 Pt 5, 3785–3797. [Google Scholar] [CrossRef]

- Kitada, M.; Ölçer, A. Managing People and Technology: The Challenges in CSR and Energy Efficient Shipping. Res. Transp. Bus. Manag. 2015, 17, 36–40. [Google Scholar] [CrossRef]

| Description | Correlation | Chi-Square Statistic | Difference | ||

|---|---|---|---|---|---|

| Constrained Model | Unconstrained Model | Constrained Model (d.f.) | Unconstrained Model (d.f.) | ||

| CP with | |||||

| SE | 0.884 | 0.620 | 90.59 (44) | 46.17 (43) | 44.42 * |

| SD | 0.905 | 0.667 | 53.27 (20) | 12.64 (19) | 40.63 * |

| REG | 0.792 | 0.442 | 53.28 (27) | 25.70 (26) | 27.58 * |

| NRM | 0.942 | 0.765 | 51.03 (14) | 10.89 (13) | 40.14 * |

| CST | 0.765 | 0.428 | 50.94 (14) | 25.59 (13) | 25.35 * |

| FRM | 0.786 | 0.317 | 81.95 (27) | 36.26 (26) | 45.69 * |

| SE with | |||||

| SD | 0.880 | 0.606 | 76.14 (27) | 33.28 (26) | 42.86 * |

| REG | 0.828 | 0.592 | 67.46 (35) | 41.39 (34) | 26.07 * |

| NRM | 0.897 | 0.622 | 58.58 (20) | 23.64 (19) | 34.94 * |

| CST | 0.800 | 0.681 | 41.66 (20) | 35.44 (19) | 6.22 ** |

| FRM | 0.794 | 0.507 | 83.55 (35) | 59.48 (34) | 24.07 * |

| SD with | |||||

| REG | 0.798 | 0.365 | 48.10 (14) | 10.16 (13) | 37.94 * |

| NRM | 0.980 | 0.898 | 45.64 (5) | 8.26 (4) | 37.38 * |

| CST | 0.714 | 0.205 | 35.21 (5) | 1.56 (4) | 33.65 * |

| FRM | 0.805 | 0.352 | 59.77 (14) | 18.38 (13) | 41.39 * |

| REG with | |||||

| NRM | 0.840 | 0.592 | 29.99 (9) | 3.56 (8) | 26.41 * |

| CST | 0.701 | 0.333 | 22.20 (9) | 3.70 (8) | 18.50 * |

| FRM | 0.687 | 0.202 | 50.15 (20) | 17.46 (19) | 32.69 * |

| NRM with | |||||

| CST | 0.628 | 0.120 | 29.40 (2) | 0.10 (1) | 29.30 |

| FRM | 1.128 a | 0.693 a | 369.3 (9) a | 22.90 (8) a | 346.399 a |

| CST with | |||||

| FRM | 0.725 | 0.407 | 29.20 (9) | 9.10 (8) | 20.10 * |

| ENP with | |||||

| PRP | 0.885 | 0.678 | 113.30 (35) | 73.80 (34) | 39.50 * |

| Factors | Environmental Performance Measure |

| (REG) Regulations | 0.403 ** |

| (NRM) Industrial Norms | 0.738 ** |

| (CST) Customer’s environmental demand | 0.346 * |

| (FRM) Firm’s own environmental strategy | 0.526 *** |

| (CP) Company Policy and Procedure | 0.496 *** |

| (SE) Shipping Equipment | 0.628 *** |

| (SD) Shipping Design and compliance | 0.649 *** |

| Factors | Productivity Performance Measure |

| (REG) Regulations | 0.399 ** |

| (NRM) Industrial Norms | 0.653 * |

| (CST) Customer’s environmental demand | 0.547 *** |

| (FRM) Firm’s own environmental strategy | 0.504 *** |

| (CP) Company Policy and Procedure | 0.332 * |

| (SE) Shipping Equipment | 0.645 *** |

| (SD) Shipping Design and compliance | 0.500 ** |

| Hypothesis | Path from | To | Regression Weight | Standard Error | t-Value | p-Value | |

|---|---|---|---|---|---|---|---|

| 1 | REG | AGSP | 0.17 | 0.042 | 1.422 | 0.155 | Not Supported |

| 2 | NRM | AGSP | 0.84 | 0.143 | 3.575 | *** | Supported |

| 3 | CST | AGSP | 0.34 | 0.042 | 2.787 | 0.005 ** | Supported |

| 4 | FRM | AGSP | 0.33 | 0.048 | 2.944 | 0.003 ** | Supported |

| 5 | AGSP | ENP | 0.73 | 0.230 | 5.230 | *** | Supported |

| 6 | AGSP | PRP | 0.73 | 0.280 | 4.841 | *** | Supported |

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

|---|---|---|---|---|---|---|

| Control | ||||||

| Firm’s size | 0.297 | 0.307 | 0.118 | 0.735 | 0.683 | 0.526 |

| Market Coverage Operation | 0.836 | 0.578 | 0.3 | 0.454 | 0.406 | |

| Independent Variable | ||||||

| Regulation (REG) | 0.000 *** | 0.12 | 0.471 | 0.409 | ||

| Industrial Norms (NRM) | 0.000 *** | 0.000 *** | 0.000 *** | |||

| Customer environmental demand (CST) | 0.001 ** | 0.012 * | ||||

| Firm’s own environmental strategy (FRM) | 0.046 * | |||||

| Regression Results | ||||||

| R2 | 0.016 | 0.016 | 0.224 | 0.47 | 0.547 | 0.574 |

| Adjusted R2 | 0.001 | −0.013 | 0.189 | 0.438 | 0.512 | 0.534 |

| F Value | 1.102 | 0.565 | 6.443 ** | 14.621 *** | 15.690 *** | 14.393 *** |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-T.; Danao, D. Green Shipping Practices of Shipping Firms. Sustainability 2017, 9, 829. https://doi.org/10.3390/su9050829

Chang Y-T, Danao D. Green Shipping Practices of Shipping Firms. Sustainability. 2017; 9(5):829. https://doi.org/10.3390/su9050829

Chicago/Turabian StyleChang, Young-Tae, and Denise Danao. 2017. "Green Shipping Practices of Shipping Firms" Sustainability 9, no. 5: 829. https://doi.org/10.3390/su9050829